Controller Design for Air Conditioner of a Vehicle with Three Control Inputs Using Model Predictive Control

Abstract

1. Introduction

- Objective 1. In addition to controlling the compressor clutch only, determine the improvement in A/C system energy use and air-to-cabin reference temperature tracking that can be achieved by switching from PID (benchmark) to MPC.

- Objective 2. Identify what further improvement, if any, can be achieved by including the condenser fan rotational speed and AGS position in the MPC formulation.

2. Materials and Methods

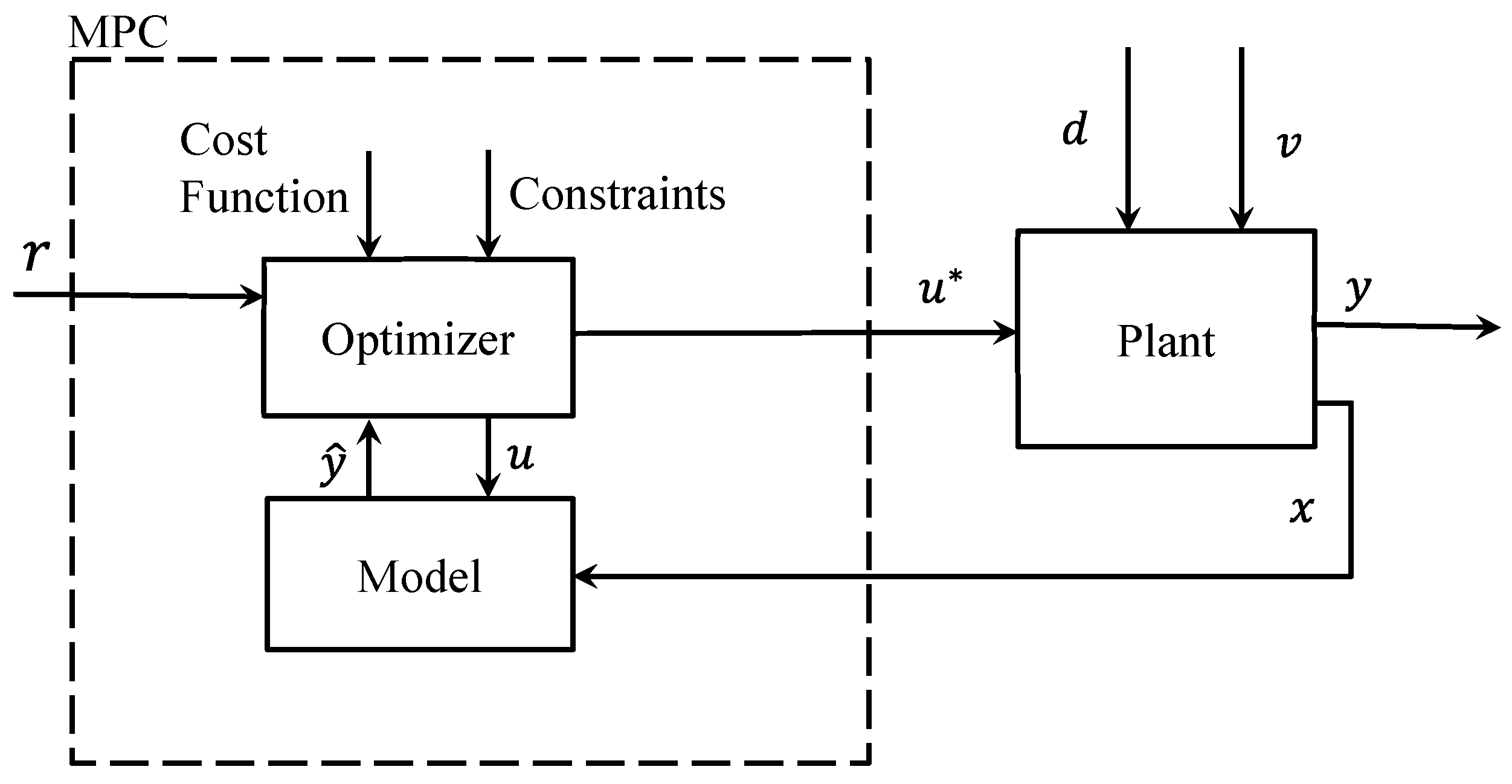

2.1. MPC Design

2.1.1. Type Selection

- Time-varying dynamics: The system’s dynamics in [28] change over time due to various factors such as varying operating conditions or system wear and tear.

- Uncertain models: Some of the model parameters [28] are not precisely known as they are embedded in the model developed by the industrial partner where the exact values of the parameters are unknown and approximate values were used to build the semi-analytical model, and there is uncertainty about the model’s accuracy.

- Nonlinear systems: The system in [28] is highly nonlinear and for controlling systems with nonlinear behavior, where a linear model may not be sufficient, and an adaptive model helps to approximate the nonlinear dynamics better.

- Disturbance rejection: As mentioned in item 2, some of the system parameters are not entirely known throughout the simulation as they are provided by the software-in-the-loop and depend on the driving cycle that the tests are being run over. When dealing with systems subject to disturbances that are not entirely predictable or change over time, adaptive MPC is the plausible choice.

- Parameter variations: Some of the system parameters in [28] change over time, and their values are embedded in the software-in-the-loop provided by the industrial partner. In cases where there are abrupt changes or slow variations in system parameters, adaptive MPC can be useful.

2.1.2. Design Parameters

- Sample time: The choice of the sample time determines the controller’s operational frequency, impacting its ability to respond to disturbances and setpoint changes. Balancing between rapid disturbance rejection and computational load, it is advisable to accommodate 10 to 20 samples within the open-loop system’s rise time [30]. This ensures a responsive controller without overwhelming computational demands. Further details about this parameter in this study are provided in Section 3.4.2.

- Prediction horizon: The prediction horizon influences the extent to which the controller anticipates future plant behavior. A cautious prediction horizon encompasses a timeframe that captures significant system dynamics, preventing untimely responses to disturbances. To account for open-loop transient responses, selecting 10 to 20 samples is recommended [30]. Further details about this parameter in this study are provided in Section 3.4.2.

- Control horizon: Conversely, the control horizon determines the number of future control inputs that shape the predicted plant output. A smaller control horizon minimizes computational efforts but may compromise maneuverability. An optimal balance can be struck by setting the control horizon to 10–20% of the prediction horizon, ensuring a minimum of 2–3 steps to account for effective control [30]. Further details about this parameter in this study are provided in Section 3.4.2.

- Constraints: Constraints on inputs, input rate changes, and outputs can be imposed within the MPC framework. These constraints may be either hard or soft. The distinction lies in the feasibility of violation: hard constraints remain inviolable, while soft constraints can be breached within limits. Balancing the conflicting interests of inputs and outputs, it is advised to adopt soft constraints for outputs, eschewing simultaneous hard constraints on inputs and their rate of change. This minimizes the risk of infeasibility and ensures more adaptable control [30]. Further details about this parameter in this study are provided in Section 3.3 and Section 3.4.3.

- Weights: Weight assignment is a critical aspect of optimizing control performance. Weights gauge the significance of objectives in MPC. These objectives involve tracking setpoints and achieving smooth control maneuvers. Achieving a harmonious performance balance necessitates cautiously weighing input rates and outputs relative to each other. Additionally, adjusting weights within these categories fine-tunes performance to the specific control objectives [30]. Further details about this parameter in this study are provided in Section 3.3 and Section 3.4.4.

2.2. Discrete State-Space General Form

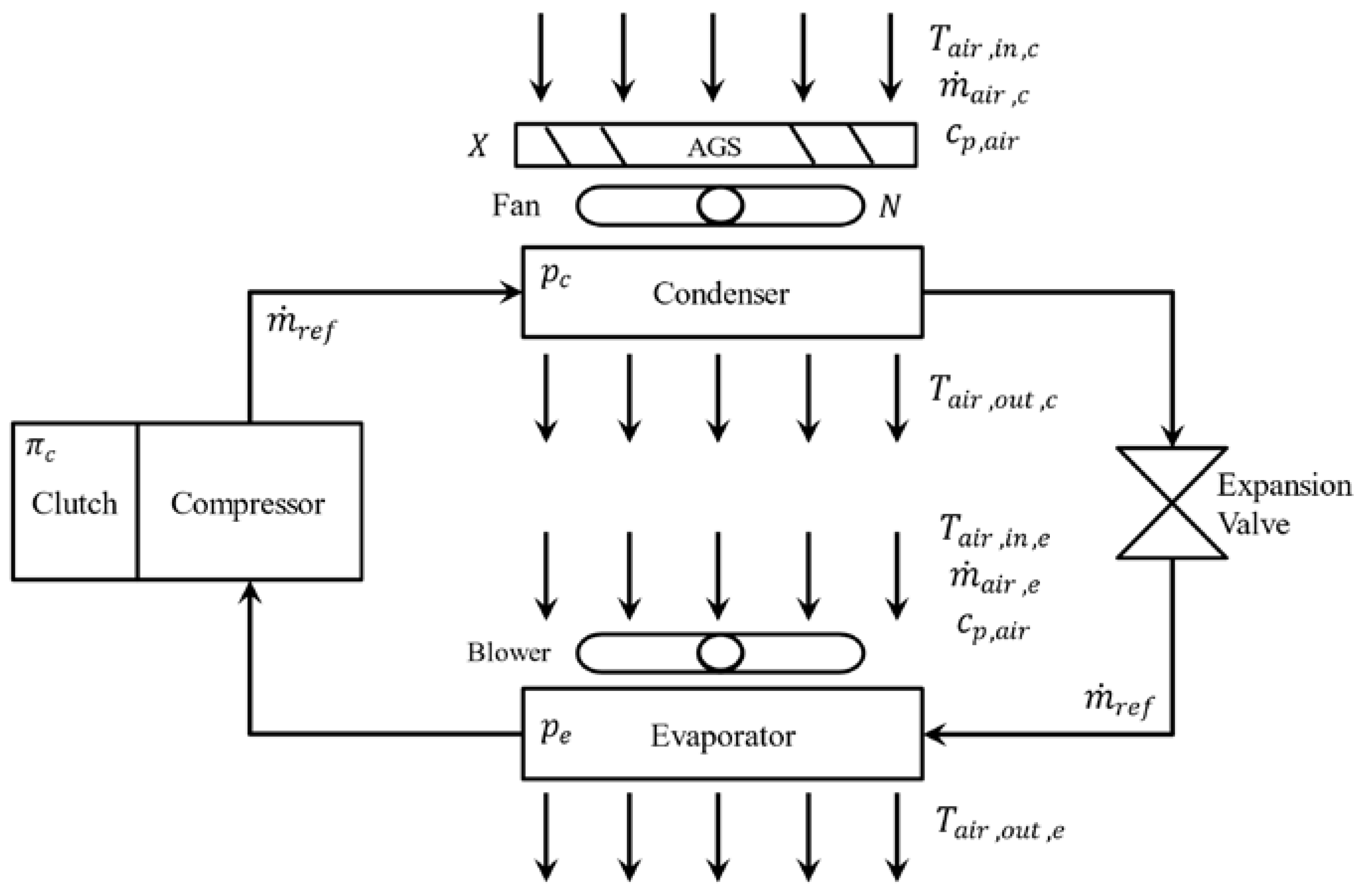

2.3. Introduction of A/C System

3. Problem Definition

3.1. Introduction

3.2. System Equations

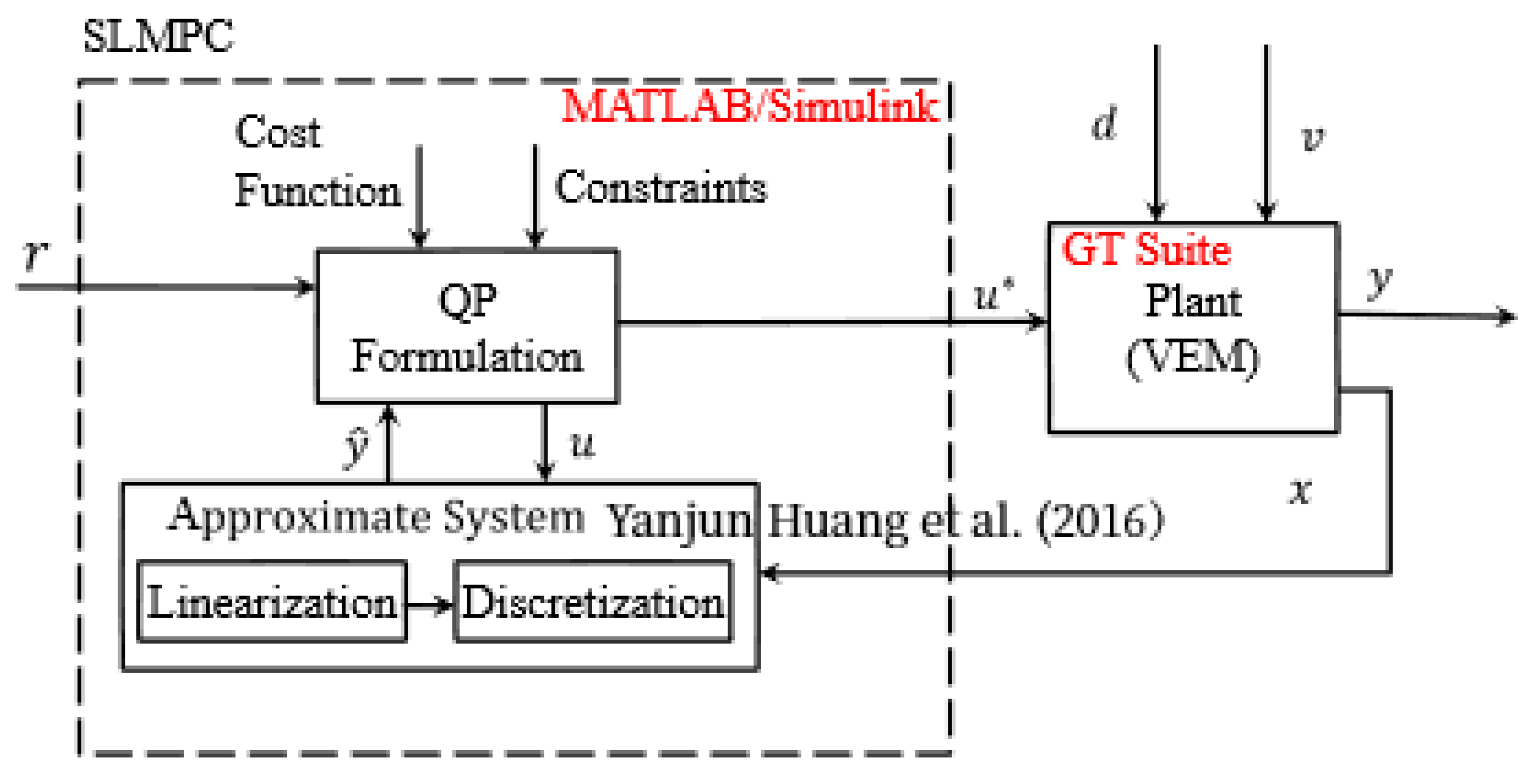

3.3. Quadratic Programming Formulation

3.4. Implementation

3.4.1. States, Inputs, and Outputs

3.4.2. Sampling Time, Prediction Horizon, and Control Horizon

3.4.3. Constraints

3.4.4. Weights

3.4.5. Scenarios

3.4.6. Summary

4. Results and Discussion

4.1. MPC Tuning Process

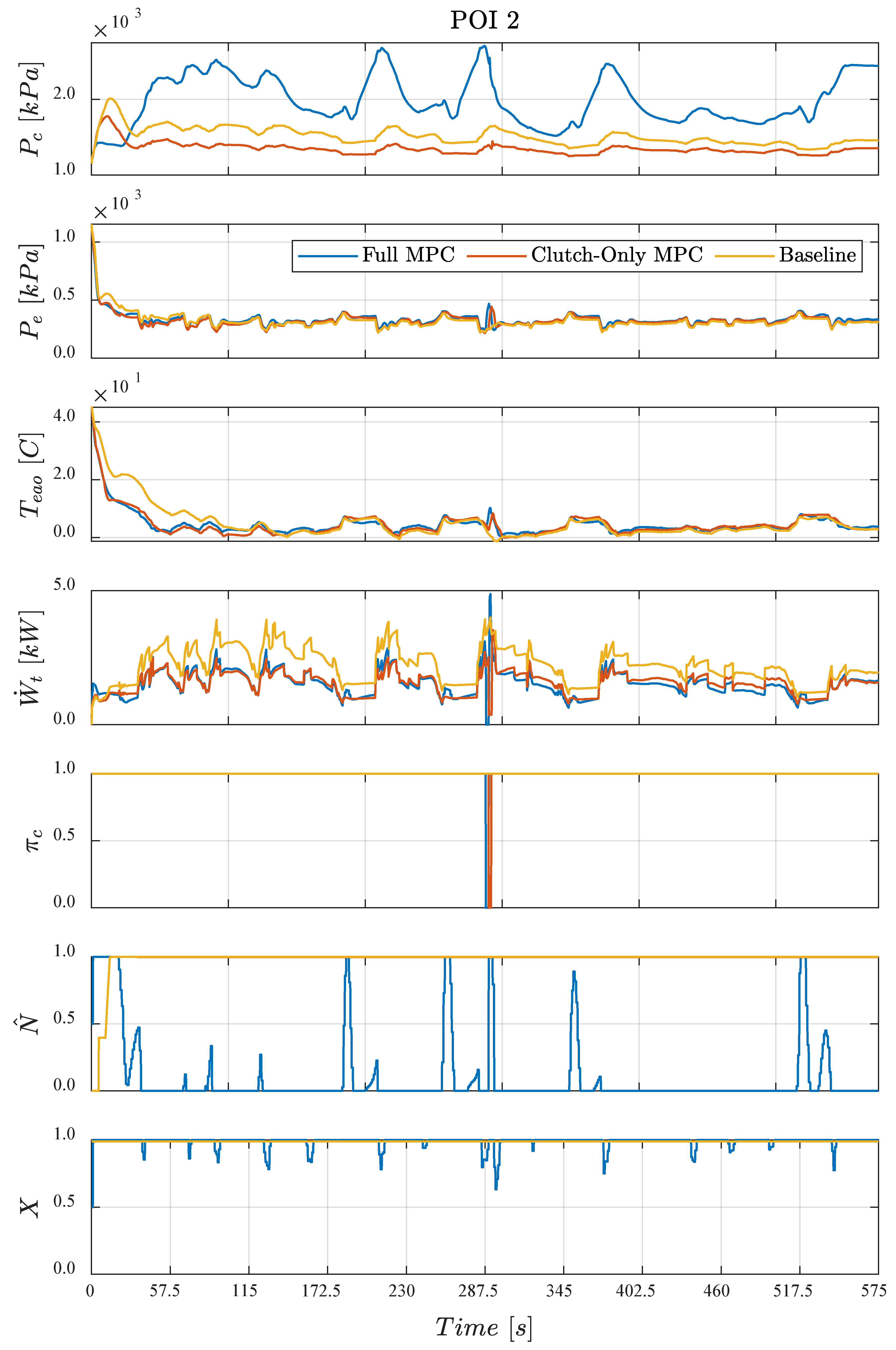

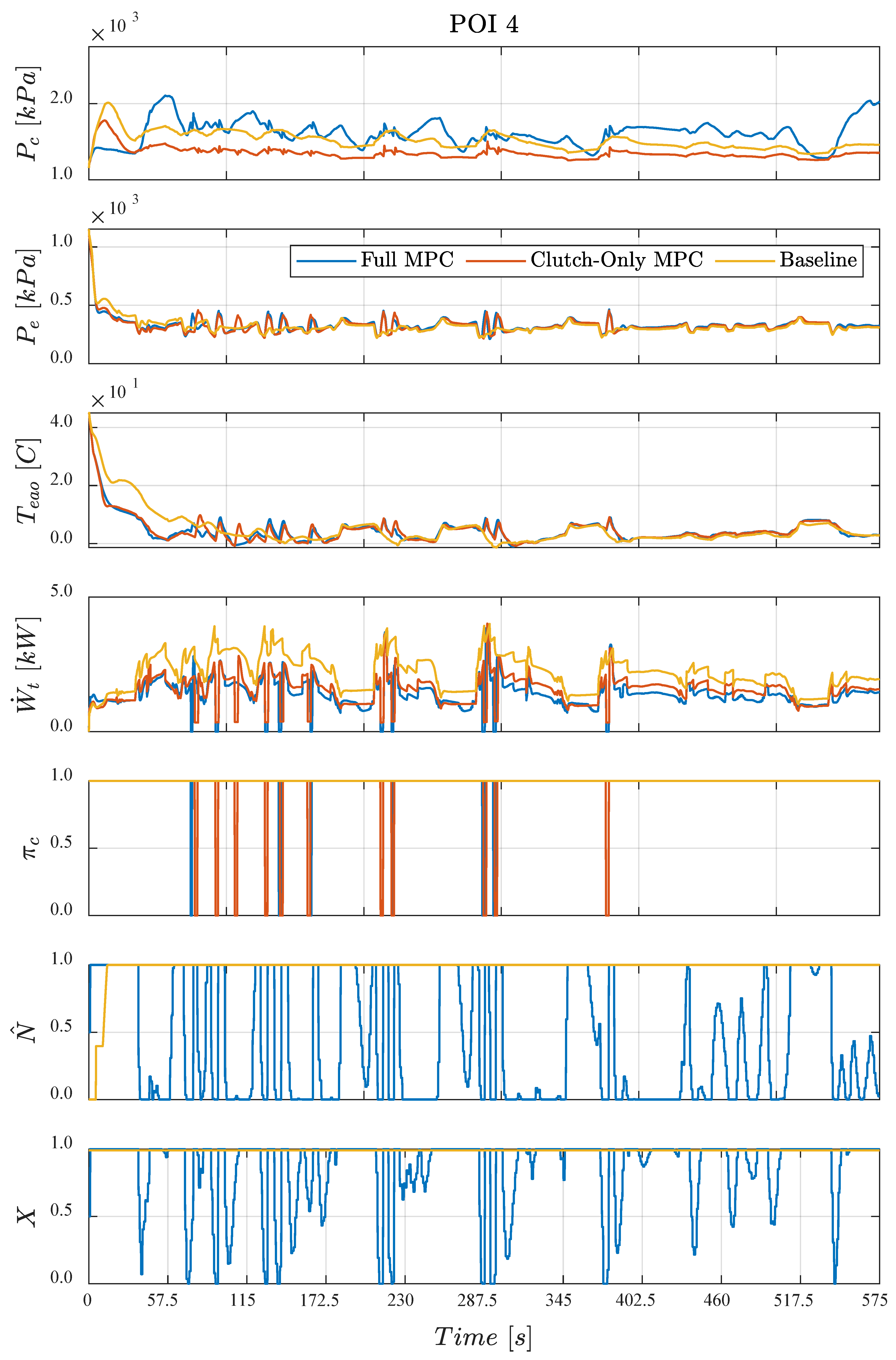

4.2. Points of Interest

- First, the upper bound of energy consumption is 1000 kJ, 21% lower than that for the baseline control scheme for the plant. Hence, all assessed MPC configurations significantly reduce A/C system energy consumption.

- Second, in a similar way, the largest air temperature error is 4.6 , 27% less than that for the baseline controls. This suggests that the model being re-linearized at every operating point is key to good control performance, as the baseline controls do not include this.

- Third, clutch actuation frequency ranges from 0 (same as baseline) to ~16 actuations per minute over the SC03 cycle, with higher clutch actuations, in general, being traded for lower energy consumption. This suggests there is no single optimal value of the QP weights but rather a trading relationship the control designer must choose within.

- Finally, the difference between the total energy consumption using clutch-only MPC and full MPC is apparent, with clutch-only MPC yielding higher energy consumption. The impact of the inclusion of two extra actuators into the MPC framework is easier to establish by examining the same data in each of the three two-dimensional views in Figure 4b–d.

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Successive Linearization Based MPC

Appendix A.1. Continuous Nonlinear System Linearization

Appendix A.2. Continuous Linearized System Discretization

Appendix A.3. Quadratic Programming Problem Derivation

Appendix B. Relaxation of MPC Formulation

Appendix B.1. Notation

Appendix B.2. Control Problem

Appendix B.3. Relaxations

References

- Høgh, G.; Nielsen, R. Model Based Nonlinear Control of Refrigeration Systems. Master’s Thesis, Aalborg University, Aalborg Municipality, Denmark, 2008. [Google Scholar]

- Koo, B.; Yoo, Y.; Won, S. Super-Twisting Algorithm-Based Sliding Mode Controller for a Refrigeration System. In Proceedings of the 2012 12th International Conference on Control, Automation and Systems, Jeju, Republic of Korea, 17–21 October 2012; pp. 34–38. [Google Scholar]

- Liu, J.; Zhou, H.; Zhou, X.; Cao, Y.; Zhao, H. Automative Air Conditioning System Control—A Survey. In Proceedings of the 2011 International Conference on Electronic & Mechanical Engineering and Information Technology, Harbin, China, 12–14 August 2011; pp. 3408–3412. [Google Scholar]

- Cvok, I.; Škugor, B.; Deur, J. Control Trajectory Optimisation and Optimal Control of an Electric Vehicle HVAC System for Favourable Efficiency and Thermal Comfort. Optim. Eng. 2021, 22, 83–102. [Google Scholar] [CrossRef]

- Kim, N.; Park, Y.; Son, J.E.; Shin, S.; Min, B.; Park, H.; Kang, S.; Hur, H.; Ha, M.Y.; Lee, M.C. Robust Sliding Mode Control of a Vapor Compression Cycle. Int. J. Control Autom. Syst. 2018, 16, 62–78. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, Z.; Liu, J.; Li, K.; Zhang, Y.; Wu, C.; Wang, P.; Wang, X. A Self-Learning Intelligent Passenger Vehicle Comfort Cooling System Control Strategy. Appl. Therm. Eng. 2020, 166, 114646. [Google Scholar] [CrossRef]

- Huang, Y.; Khajepour, A.; Ding, H.; Bagheri, F.; Bahrami, M. An Energy-Saving Set-Point Optimizer with a Sliding Mode Controller for Automotive Air-Conditioning/Refrigeration Systems. Appl. Energy 2017, 188, 576–585. [Google Scholar] [CrossRef]

- Liberati, F.; Giorgio, A.D.; Giuseppi, A.; Pietrabissa, A.; Habib, E.; Martirano, L. Joint Model Predictive Control of Electric and Heating Resources in a Smart Building. IEEE Trans. Ind. Applicat. 2019, 55, 7015–7027. [Google Scholar] [CrossRef]

- Borreggine, S.; Monopoli, V.G.; Rizzello, G.; Naso, D.; Cupertino, F.; Consoletti, R. A Review on Model Predictive Control and Its Applications in Power Electronics. In Proceedings of the 2019 AEIT International Conference of Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Torino, Italy, 2–4 July 2019; pp. 1–6. [Google Scholar]

- Huang, Y.; Wang, H.; Khajepour, A.; He, H.; Ji, J. Model Predictive Control Power Management Strategies for HEVs: A Review. J. Power Sources 2017, 341, 91–106. [Google Scholar] [CrossRef]

- Wang, H.; Kolmanovsky, I.; Amini, M.R.; Sun, J. Model Predictive Climate Control of Connected and Automated Vehicles for Improved Energy Efficiency. In Proceedings of the 2018 Annual American Control Conference (ACC), Milwaukee, WI, USA, 27–29 June 2018; pp. 828–833. [Google Scholar]

- Pereira, D.F.; Lopes, F.D.C.; Watanabe, E.H. Nonlinear Model Predictive Control for the Energy Management of Fuel Cell Hybrid Electric Vehicles in Real Time. IEEE Trans. Ind. Electron. 2021, 68, 3213–3223. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, Z.; Li, K.; Liu, J.; Zhang, Y.; Dan, D.; Wu, C.; Wang, P.; Wang, X. An Improved Intelligent Model Predictive Controller for Cooling System of Electric Vehicle. Appl. Therm. Eng. 2021, 182, 116084. [Google Scholar] [CrossRef]

- Glos, J.; Otava, L.; Vaclavek, P. Non-Linear Model Predictive Control of Cabin Temperature and Air Quality in Fully Electric Vehicles. IEEE Trans. Veh. Technol. 2021, 70, 1216–1229. [Google Scholar] [CrossRef]

- Kibalama, D.; Liu, Y.; Stockar, S.; Canova, M. Model Predictive Control for Automotive Climate Control Systems via Value Function Approximation. IEEE Control Syst. Lett. 2022, 6, 1820–1825. [Google Scholar] [CrossRef]

- Göltz, S.; Sawodny, O. Design and Comparison of Model-Based Controllers for an Automotive Air Conditioning System in an Electric Vehicle. Control Eng. Pract. 2023, 130, 105376. [Google Scholar] [CrossRef]

- El-Sharkawy, A.E.; Kamrad, J.C.; Lounsberry, T.H.; Baker, G.L.; Rahman, S.S. Evaluation of Impact of Active Grille Shutter on Vehicle Thermal Management. SAE Int. J. Mater. Manuf. 2011, 4, 1244–1254. [Google Scholar] [CrossRef]

- Shigarkanthi, V.; Damodaran, V.; Soundararaju, D.; Kanniah, K. Application of Design of Experiments and Physics Based Approach in the Development of Aero Shutter Control Algorithm. SAE Tech. Paper 2011. [Google Scholar] [CrossRef]

- Chen, Y.; Kwak, K.H.; Kim, J.; Kim, Y.; Jung, D. Energy-efficient Cabin Climate Control of Electric Vehicles Using Linear Time-varying Model Predictive Control. Optim. Control Appl. Methods 2023, 44, 773–797. [Google Scholar] [CrossRef]

- Coppola, A.; Lui, D.G.; Petrillo, A.; Santini, S. Eco-Driving Control Architecture for Platoons of Uncertain Heterogeneous Nonlinear Connected Autonomous Electric Vehicles. IEEE Trans. Intell. Transport. Syst. 2022, 23, 24220–24234. [Google Scholar] [CrossRef]

- He, H.; Jia, H.; Sun, C.; Sun, F. Stochastic Model Predictive Control of Air Conditioning System for Electric Vehicles: Sensitivity Study, Comparison, and Improvement. IEEE Trans. Ind. Inf. 2018, 14, 4179–4189. [Google Scholar] [CrossRef]

- Huang, Y.; Khajepour, A.; Bagheri, F.; Bahrami, M. Optimal Energy-Efficient Predictive Controllers in Automotive Air-Conditioning/Refrigeration Systems. Appl. Energy 2016, 184, 605–618. [Google Scholar] [CrossRef]

- Parent, T. Developing a Compressor, Fan, and Active Grille Shutter Control Strategy for Air Conditioner Duty Cycles to Improve Overall Vehicle Power Consumption. Master’s Thesis, University of Windsor, Windsor, ON, Canada, 2023. [Google Scholar]

- Parent, T. Developing a Compressor, Fan, and Active Grille Shutter Control Strategy for Air Conditioner Duty Cycles to Improve the Overall Vehicle Power Consumption. Master’s Thesis, Politecnico di Torino, Torino, Italy, 2023. [Google Scholar]

- Zhang, Q.Z. Modeling, Energy Optimization and Control of Vapor Compression Refrigeration Systems For Automotive Applications. Ph.D. Thesis, Ohio State University, Columbus, OH, USA, 2014. [Google Scholar]

- Dhar, A.; Bhasin, S. Indirect Adaptive MPC for Discrete-Time LTI Systems with Parametric Uncertainties. IEEE Trans. Automat. Contr. 2021, 66, 5498–5505. [Google Scholar] [CrossRef]

- Hu, D.; Li, G.; Deng, F. Gain-Scheduled Model Predictive Control for a Commercial Vehicle Air Brake System. Processes 2021, 9, 899. [Google Scholar] [CrossRef]

- Parent, T.; Defoe, J.J.; Rahimi, A. Nonlinear Modeling of an Automotive Air Conditioning System Considering Active Grille Shutters. Modelling 2023, 4, 70–86. [Google Scholar] [CrossRef]

- Zhakatayev, A.; Rakhim, B.; Adiyatov, O.; Baimyshev, A.; Varol, H.A. Successive Linearization Based Model Predictive Control of Variable Stiffness Actuated Robots. In Proceedings of the 2017 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Munich, Germany, 3–7 July 2017; pp. 1774–1779. [Google Scholar]

- Alhajeri, M.; Soroush, M. Tuning Guidelines for Model-Predictive Control. Ind. Eng. Chem. Res. 2020, 59, 4177–4191. [Google Scholar] [CrossRef]

- Gajić, Z. Linear Dynamic Systems and Signals; Pearson Education: Upper Saddle River, NJ, USA, 2003; ISBN 978-0-201-61854-9. [Google Scholar]

- Rawlings, J.B.; Mayne, D.Q. Model Predictive Control: Theory and Design; Nob Hill Pub: Madison, WI, USA, 2009; ISBN 978-0-9759377-0-9. [Google Scholar]

- EPA SC03 Supplemental Federal Test Procedure (SFTP) with Air Conditioning. Available online: https://www.epa.gov/emission-standards-reference-guide/epa-sc03-supplemental-federal-test-procedure-sftp-air (accessed on 1 February 2021).

- Dhar, A.; Bhasin, S. Adaptive MPC for Uncertain Discrete-Time LTI MIMO Systems with Incremental Input Constraints. IFAC-PapersOnLine 2018, 51, 329–334. [Google Scholar] [CrossRef]

- De Prada, C.; Grossmann, I.; Sarabia, D.; Cristea, S. A Strategy for Predictive Control of a Mixed Continuous Batch Process. J. Process Control 2009, 19, 123–137. [Google Scholar] [CrossRef]

- Karer, G.; Mušič, G.; Škrjanc, I.; Zupančič, B. Model Predictive Control of Nonlinear Hybrid Systems with Discrete Inputs Employing a Hybrid Fuzzy Model. Nonlinear Anal. Hybrid Syst. 2008, 2, 491–509. [Google Scholar] [CrossRef]

- Rawlings, J.B.; Risbeck, M.J. Model Predictive Control with Discrete Actuators: Theory and Application. Automatica 2017, 78, 258–265. [Google Scholar] [CrossRef]

- Takács, G.; Rohal’-Ilkiv, B. Stability and Feasibility of MPC. In Model Predictive Vibration Control; Springer: London, UK, 2012; pp. 253–285. ISBN 978-1-4471-2332-3. [Google Scholar]

- Vazquez, S.; Marino, D.; Zafra, E.; Peña, M.D.V.; Rodríguez-Andina, J.J.; Franquelo, L.G.; Manic, M. An Artificial Intelligence Approach for Real-Time Tuning of Weighting Factors in FCS-MPC for Power Converters. IEEE Trans. Ind. Electron. 2022, 69, 11987–11998. [Google Scholar] [CrossRef]

- Yamashita, A.S.; Martins, W.T.; Pinto, T.V.B.; Raffo, G.V.; Euzébio, T.A.M. Multiobjective Tuning Technique for MPC in Grinding Circuits. IEEE Access 2023, 11, 43041–43054. [Google Scholar] [CrossRef]

- Huntington, D.E.; Lyrintzis, C.S. Improvements to and Limitations of Latin Hypercube Sampling. Probabilistic Eng. Mech. 1998, 13, 245–253. [Google Scholar] [CrossRef]

- Mogro, A.E.; Huertas, J.I. Assessment of the Effect of Using Air Conditioning on the Vehicle’s Real Fuel Consumption. Int. J. Interact. Des. Manuf. 2021, 15, 271–285. [Google Scholar] [CrossRef]

- Axehill, D.; Vandenberghe, L.; Hansson, A. Convex Relaxations for Mixed Integer Predictive Control. Automatica 2010, 46, 1540–1545. [Google Scholar] [CrossRef]

- Yang, L.; Katnik, A.; Ozay, N. Quickly Finding Recursively Feasible Solutions for MPC with Discrete Variables. In Proceedings of the 2019 IEEE Conference on Control Technology and Applications (CCTA), Hong Kong, China, 19–21 August 2019; pp. 374–381. [Google Scholar]

| Model | [C] | [kJ] | |

|---|---|---|---|

| Baseline GT-Suite | 6.27 | 0 |

| Model | Full Control | Clutch-Only Control | ||||

|---|---|---|---|---|---|---|

| [C] | [kJ] | [C] | [kJ] | |||

| Baseline GT-Suite | 6.27 | 1262.8 | 0 | 6.27 | 1262.8 | 0 |

| POI 1 | 4.10 | 998.6 | 0 | – | – | – |

| POI 2 | 4.10 | 872.1 | 0.20 | 4.38 | 894.7 | 0.20 |

| POI 3 | 4.35 | 827.6 | 1.01 | 4.40 | 891.7 | 1.01 |

| POI 4 | 4.46 | 797.3 | 2.03 | 4.41 | 882.9 | 2.03 |

| POI 5 | 4.22 | 797.0 | 10.7 | 4.25 | 864.9 | 10.7 |

| POI 6 | 4.44 | 788.2 | 16.2 | 4.46 | 850.4 | 16.2 |

| Model | Full Control | Clutch-Only Control | ||||

|---|---|---|---|---|---|---|

| POI 1 | 1.0 | 35.3 | 956.4 | – | – | – |

| POI 2 | 3.8 | 28.7 | 371.5 | 0.5 | 18.1 | 53.4 |

| POI 3 | 7.2 | 35.6 | 837.1 | 0.8 | 20.0 | 223.5 |

| POI 4 | 5.8 | 4.7 | 624.4 | 6.6 | 36.4 | 929.3 |

| POI 5 | 22.4 | 3.1 | 551.4 | 16.4 | 35.4 | 563.3 |

| POI 6 | 32.0 | 15.6 | 37.7 | 49.5 | 12.4 | 51.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parent, T.; Defoe, J.J.; Rahimi, A. Controller Design for Air Conditioner of a Vehicle with Three Control Inputs Using Model Predictive Control. Modelling 2024, 5, 117-152. https://doi.org/10.3390/modelling5010008

Parent T, Defoe JJ, Rahimi A. Controller Design for Air Conditioner of a Vehicle with Three Control Inputs Using Model Predictive Control. Modelling. 2024; 5(1):117-152. https://doi.org/10.3390/modelling5010008

Chicago/Turabian StyleParent, Trevor, Jeffrey J. Defoe, and Afshin Rahimi. 2024. "Controller Design for Air Conditioner of a Vehicle with Three Control Inputs Using Model Predictive Control" Modelling 5, no. 1: 117-152. https://doi.org/10.3390/modelling5010008

APA StyleParent, T., Defoe, J. J., & Rahimi, A. (2024). Controller Design for Air Conditioner of a Vehicle with Three Control Inputs Using Model Predictive Control. Modelling, 5(1), 117-152. https://doi.org/10.3390/modelling5010008