Experimental Study on the Growth Pattern and Flexural Strength Characteristics of Rafted Ice

Abstract

1. Introduction

2. Experimental Methods

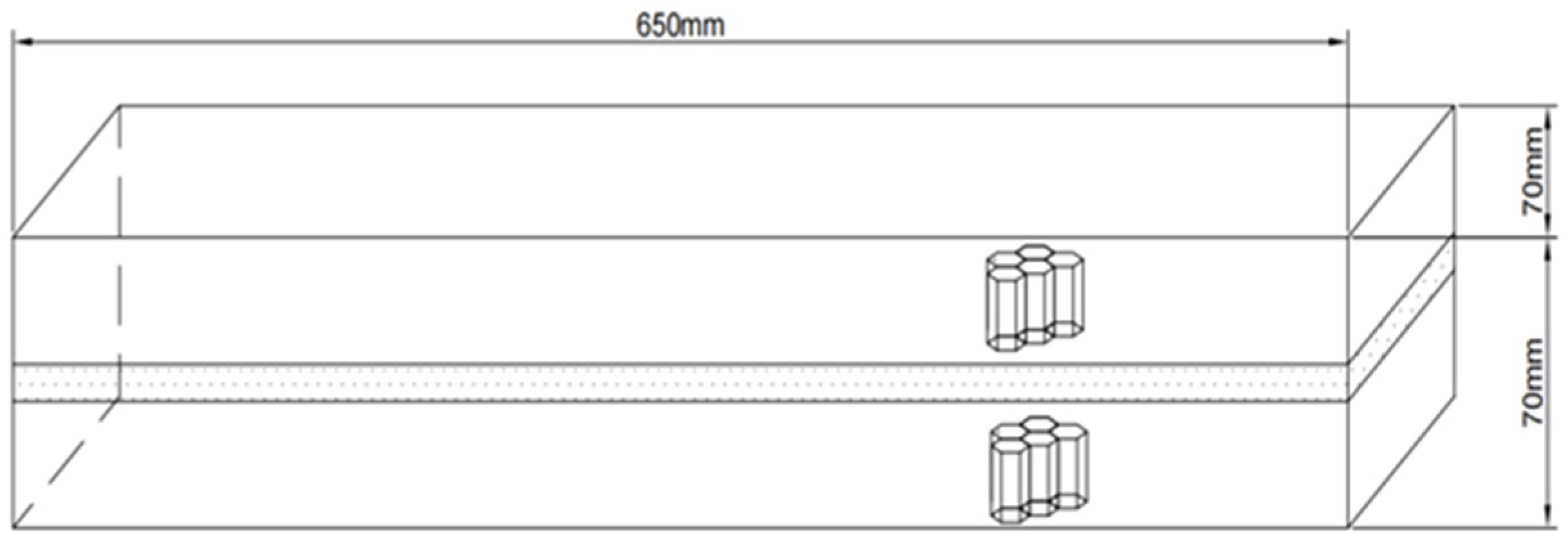

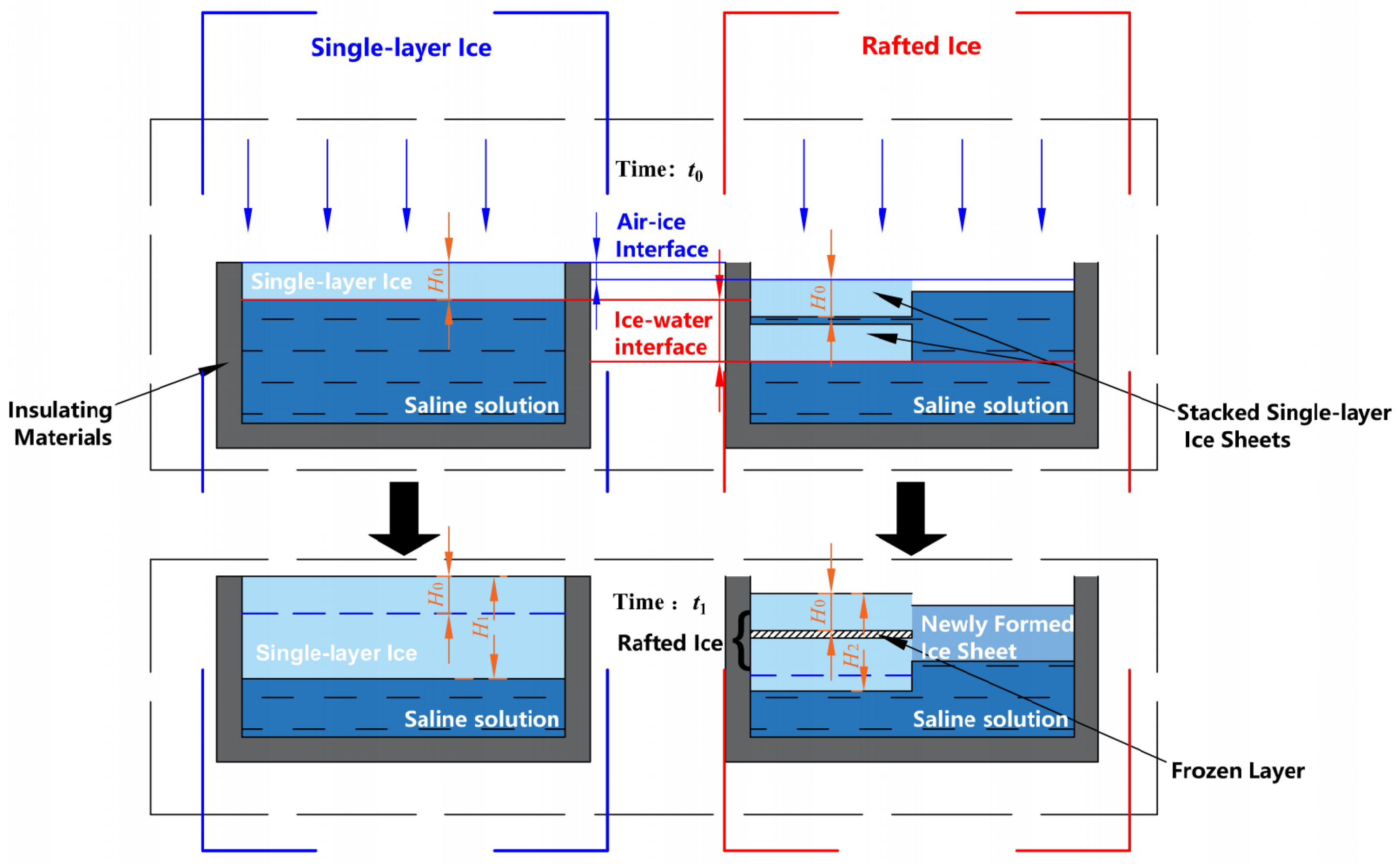

2.1. Specimen Preparation

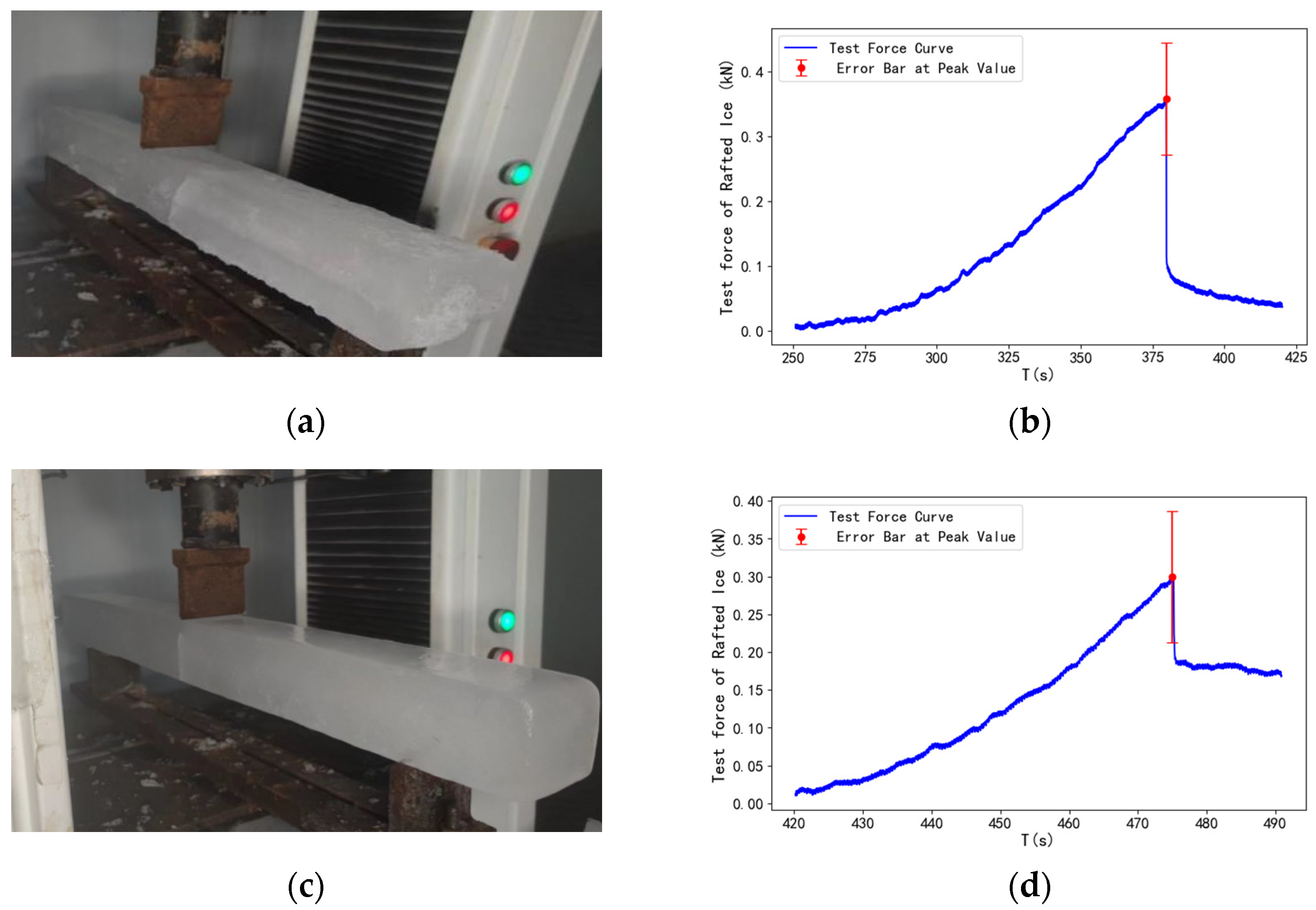

2.2. Rafted Ice Flexural Strength Test Method

3. Analysis of Rafted Ice Growth Phenomena

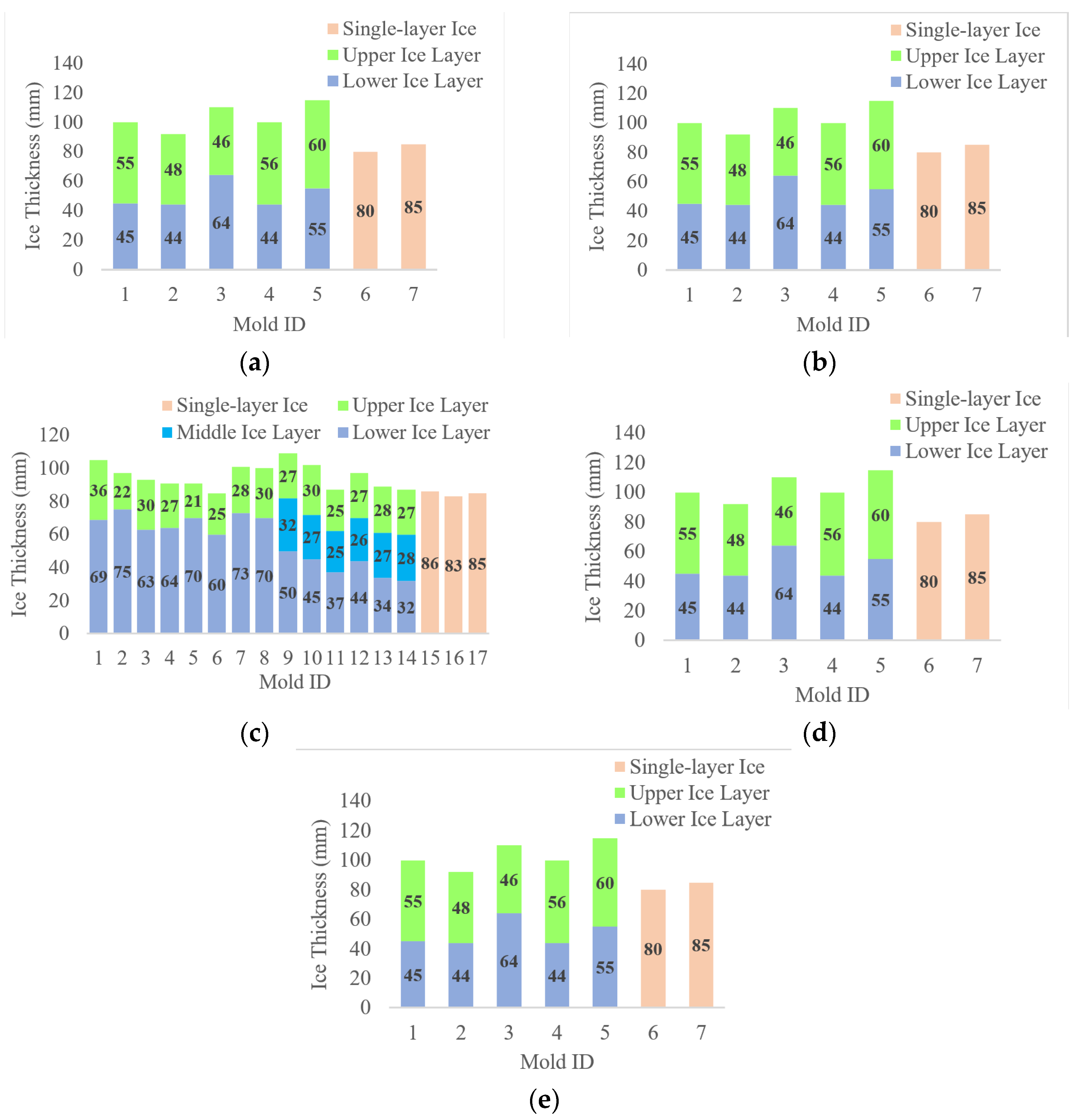

3.1. Growth Pattern of Rafted Ice Thickness

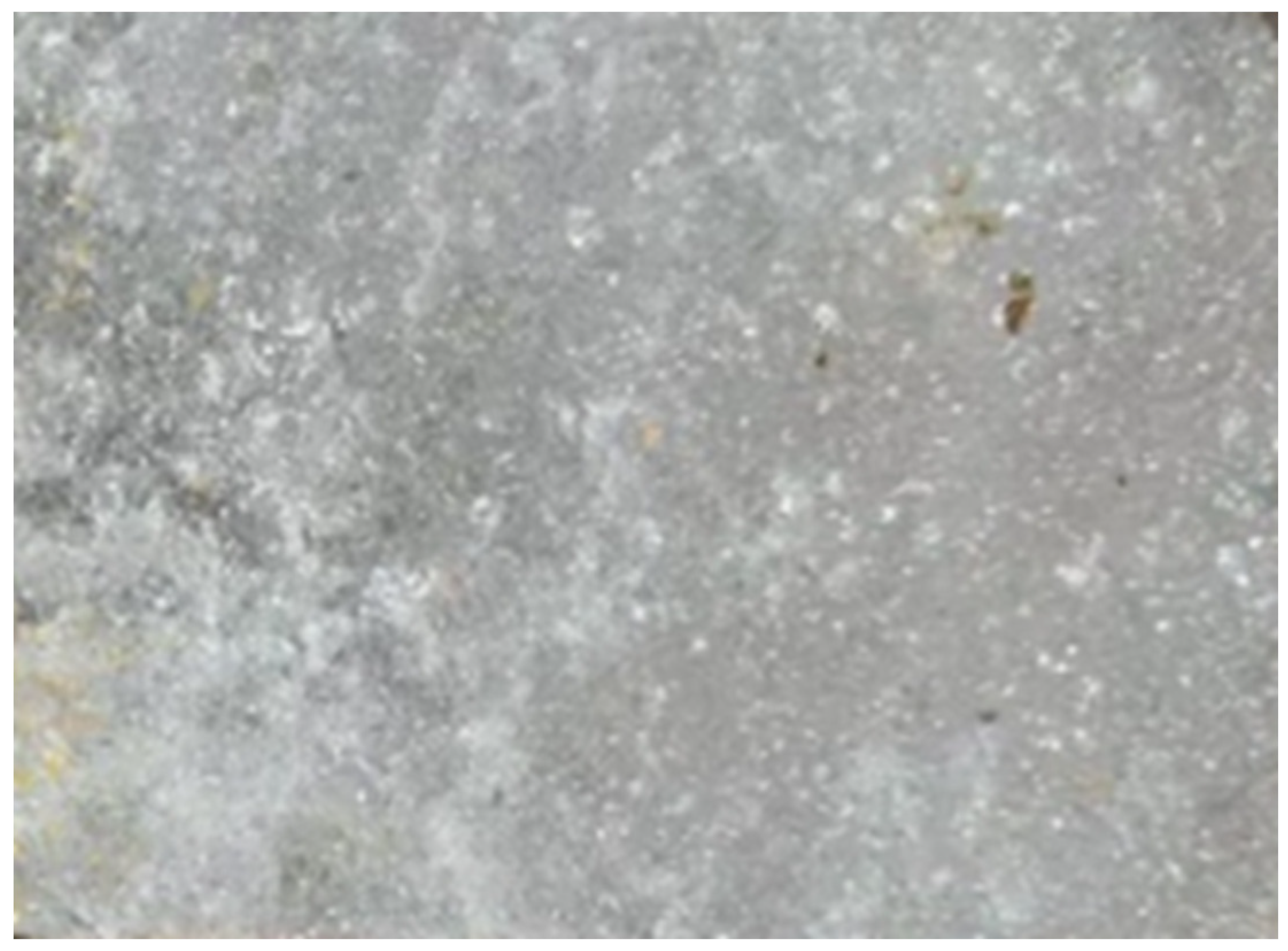

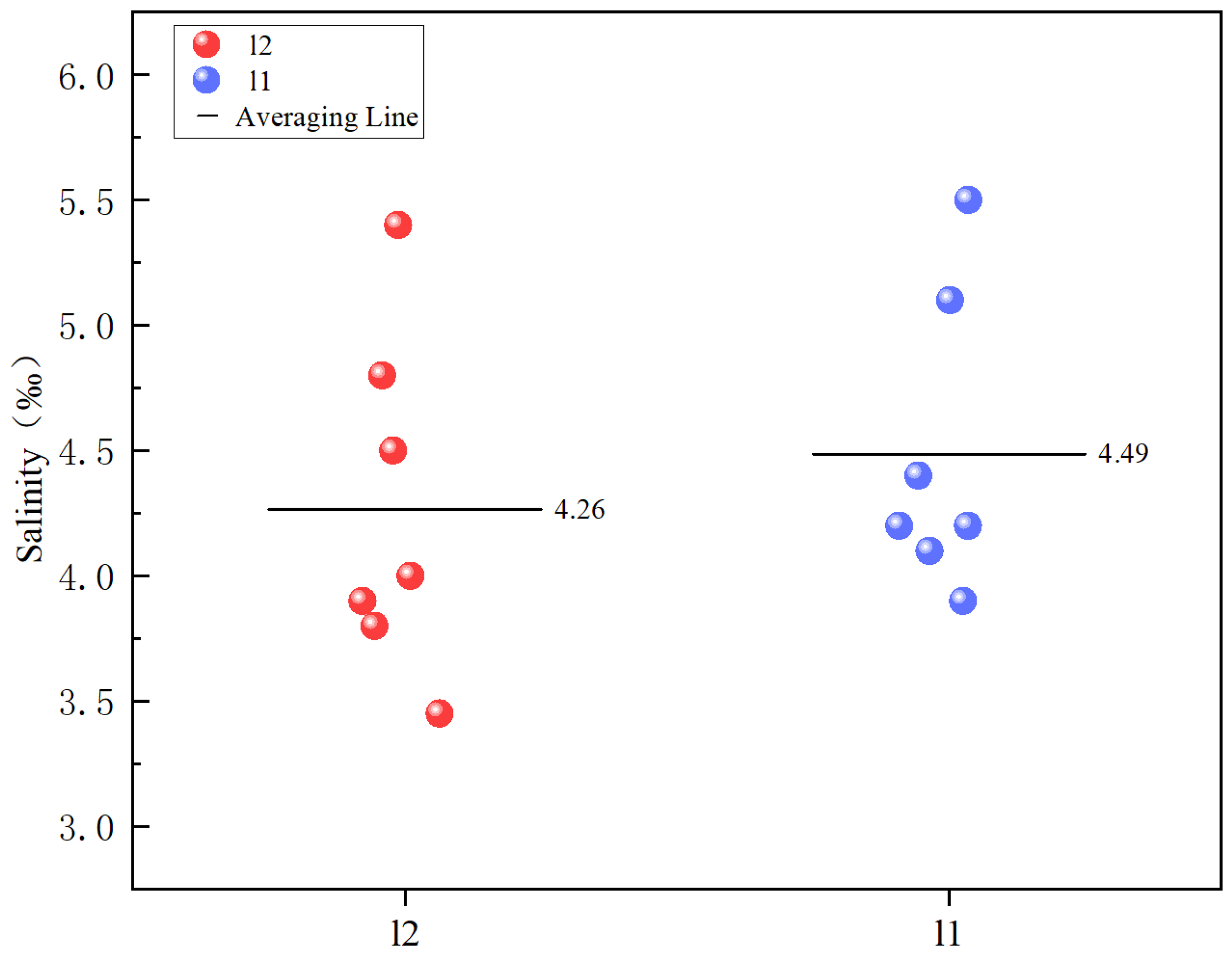

3.2. Density Characteristics of Rafted Ice

4. Analysis of Rafted Ice Flexural Strength Characteristics

4.1. Analysis of Failure Characteristics

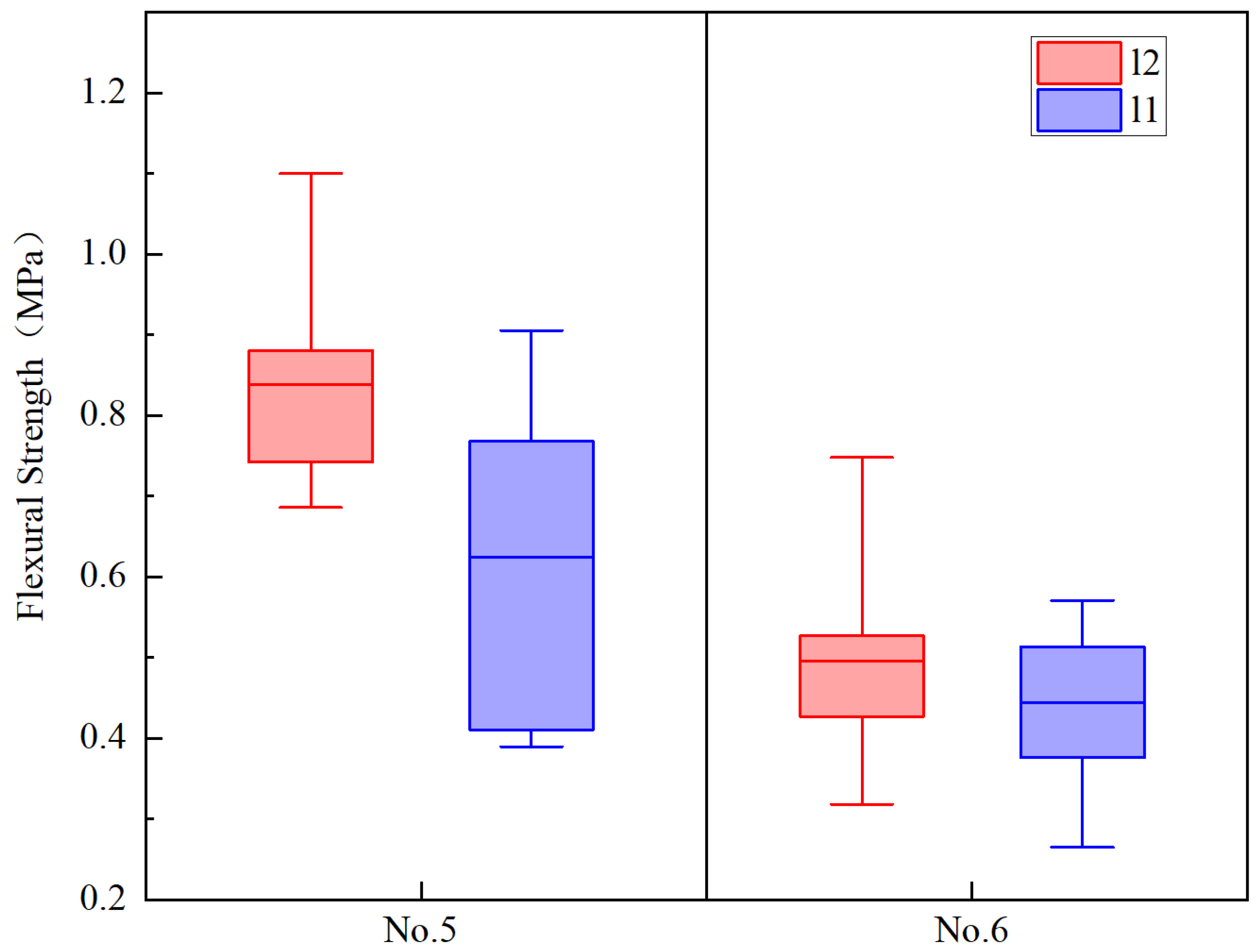

4.2. Analysis of Flexural Strength

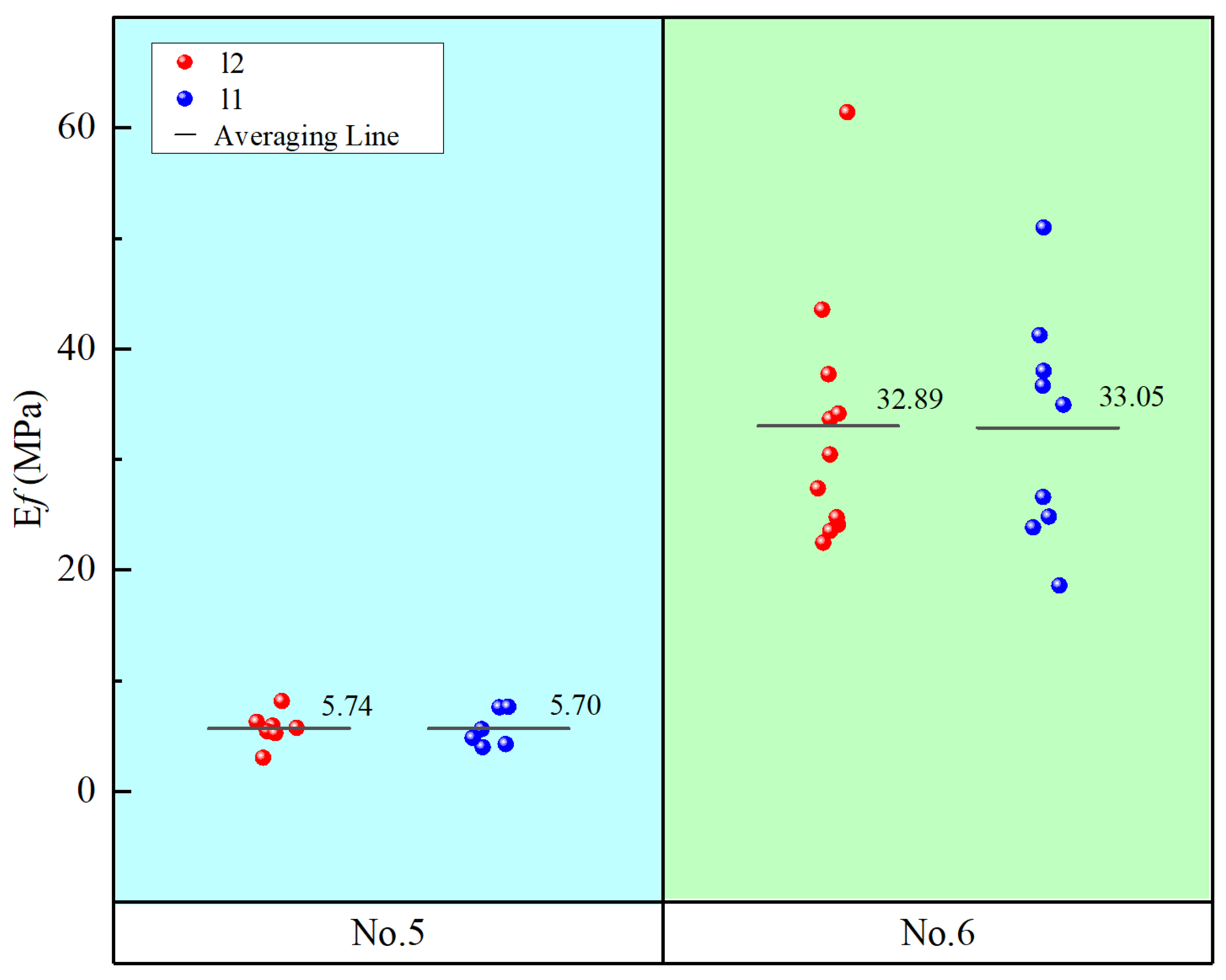

4.3. Elastic Modulus of Rafted Ice

5. Conclusions

- During the growth process, the thickness of rafted ice exhibits a negative correlation with ambient temperature and initial single-layer ice thickness. Due to the higher porosity of the frozen layer, its average density is significantly reduced by approximately 8% compared to single-layer ice.

- Three-point bending tests demonstrate that, under the combined effect of enhanced tensile strength in the lower ice layer and energy absorption by the porosity of the frozen layer, the flexural strength of rafted ice ranges from 1.12 to 1.34 times that of single-layer ice.

- The effective elastic modulus of rafted ice is similar to that of single-layer ice, indicating that the layered structure does not significantly affect its overall stiffness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Zhang, D.; Yue, Q.; Yu, S. Study on the dynamic ice load of offshore wind turbines with installed ice-breaking cones in cold regions. Energies 2022, 15, 3357. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y. Design criteria of Bohai Sea ice-control engineering. Ocean Eng. 2000, 18, 61–65. [Google Scholar]

- Bailey, E.; Sammonds, P.R.; Feltham, D.L. The consolidation and bond strength of rafted sea ice. Cold Regions Sci. Technol. 2012, 83, 37–48. [Google Scholar] [CrossRef]

- Li, Z.; Ding, D.; Sui, J. Theoretical analysis on the rafted ice thickness in Liaodong Bay. J. Mar. Environ. Sci. 1997, 16, 21–25. [Google Scholar]

- Kovacs, A. On the Structure of Pressured Sea Ice; Report prepared for the U.S. Coast Guard by U.S.; Army Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1970. [Google Scholar]

- Li, W.; Guo, Y.; Li, S.; Gao, Y.; Qu, Y. Inversion Method Based on Temporal Convolutional Networks for Random Ice Load on Conical Offshore Platforms. J. Mar. Sci. Eng. 2025, 13, 1000. [Google Scholar] [CrossRef]

- Kovacs, A.; Mellor, M. Sea ice morphology and ice as a geologic agent in the southern Beaufort Sea. In Coast and Shelf of the Beaufort Sea; The Arctic Institute of North America: Calgary, AB, Canada, 1974; pp. 113–161. [Google Scholar]

- Parmerter, R.E.; Reid, R. A model of simple rafting in sea ice. J. Geophys. Res. 1975, 80, 1948–1952. [Google Scholar] [CrossRef]

- Hopkins, M.A.; Tuhkuri, J.; Lensu, M. Rafting and ridging of thin ice sheets. J. Geophys. Res. Oceans 1999, 104, 13605–13613. [Google Scholar] [CrossRef]

- Weeks, W.F.; Anderson, D.L. Sea ice thrust structures. J. Glaciol. 1958, 3, 173–175. [Google Scholar] [CrossRef]

- Worby, A.P.; Jeffries, M.O.; Weeks, W.F.; Morris, K.; Jaña, R. The thickness distribution of sea ice and snow cover during late winter in the Bellingshausen and Amundsen Seas, Antarctica. J. Geophys. Res. Oceans 1996, 101, 28441–28455. [Google Scholar] [CrossRef]

- Melling, H.; Topham, D.R.; Riedel, D. Topography of the upper and lower surfaces of 10 hectares of deformed sea ice. Cold Regions Sci. Technol. 1993, 21, 349–369. [Google Scholar] [CrossRef]

- Toyota, T.; Takatsuji, S.; Tateyama, K.; Naoki, K.; Ohshima, K.I. Properties of sea ice and overlying snow in the southern Sea of Okhotsk. J. Oceanogr. 2007, 63, 393–411. [Google Scholar] [CrossRef]

- Wang, A.; Poplin, J.P.; Heuer, C.E. Hydrocarbon production concepts for dynamic annual sea ice regions. Hydrotech. Constr. 1994, 28, 472–492. [Google Scholar] [CrossRef]

- HY/T 047–2016; The Specification for Engineering Sea Ice Techniques. State Oceanic Administration: Beijing, China, 2016.

- Q/HSn 3000–2002; Regulations for Offshore Ice Condition and Application in China Sea. Company Standard of China National Offshore Oil Corporation, China National Offshore Oil Corporation: Beijing, China, 2002. (In Chinese)

- Buil, P.; Kellner, L.; Ehlers, S.; Von Bock und Polach, R.U.F. Analyzing flexural strength data of ice: How useful is explainable machine learning? In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Hamburg, Germany, 5–10 June 2022; p. 85918. [Google Scholar]

- Wang, Q.; Liu, Y.; Lu, P.; Li, Z. The mechanical properties of gas-enriched sea ice. Cold Reg. Sci. Technol. 2025, 239, 104576. [Google Scholar] [CrossRef]

- Meng, D.; Chen, X.; Wei, Z.; Ji, S. Prediction of flexural and uniaxial compressive strengths of sea ice with optimized recurrent neural network. Ocean Eng. 2023, 288, 115921. [Google Scholar] [CrossRef]

- Xiu, Y.; Li, Z.; Wang, Q.; Han, H.; Zong, Z.; Zu, Y.; Zhang, Y. Experimental study on flexural strength and effective elastic modulus of granular ice in the Bohai Sea, China. Front. Energy Res. 2022, 10, 970051. [Google Scholar] [CrossRef]

- Hornnes, V.; Salganik, E.; Høyland, K.V. Relationship of physical and mechanical properties of sea ice during the freeze-up season in Nansen Basin. Cold Regions Sci. Technol. 2025, 229, 104353. [Google Scholar] [CrossRef]

- Tian, Y.; Zhao, W.; Yu, C.; Gang, X.; Lu, P.; Yue, Q. Investigations on flexural strength of a columnar saline model ice under circular plate central loading. Water 2023, 15, 3371. [Google Scholar] [CrossRef]

- Poplin, J.P.; Wang, A.T. Mechanical properties of rafted annual sea ice. Cold Regions Sci. Technol. 1994, 23, 41–67. [Google Scholar] [CrossRef]

- Shafrova, S.; Høyland, K.V. The freeze-bond strength in first-year ice ridges: Small-scale field and laboratory experiments. Cold Regions Sci. Technol. 2008, 54, 54–71. [Google Scholar] [CrossRef]

- Chen, X.; Wang, A.; Ji, S. Comparative study of the brittle-ductile transition between level ice and rafted ice based on uniaxial compression experiments. Int. J. Mater. Struct. Integr. 2021, 14, 255–272. [Google Scholar] [CrossRef]

- ISO-19906; Petroleum and Natural Gas Industries—Arctic Offshore Structures. International Organization for Standardization: Geneva, Switzerland, 2019.

- Li, W.; Yin, H.; Fu, D.; Sun, S. Key Issues and Suggestions for Ice-Resistant Design of Offshore Platform Structures in China. China Offshore Oil Gas 2024, 36, 199–211. [Google Scholar]

- Meng, D.; Chen, X.; Ji, S. Experimental study on the flexural strength and failure process of sea ice. Mar. Sci. Bull. 2021, 40, 12. [Google Scholar]

- Chen, X.; Høyland, K.; Wang, A.; Ji, S. Determination of heat transfer coefficient on water-ice interface under free-convection condition. Acta Oceanol. Sin. 2018, 40, 140–148. [Google Scholar]

- Chen, X.; Høyland, K.V.; Ji, S. Laboratory tests to investigate the initial phase of ice-ridge consolidation. Cold Regions Sci. Technol. 2020, 176, 103093. [Google Scholar] [CrossRef]

- Timco, G.W.; Weeks, W.F. A review of the engineering properties of sea ice. Cold Regions Sci. Technol. 2010, 60, 107–129. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, J.; Yao, Y.; Li, S.; Li, X.; Li, T. Physical and optical properties of the first-year ice in the Amundsen Gulf of the Arctic. Haiyang Xuebao 2021, 43, 138–151. [Google Scholar]

- Ji, S.; Wang, A.; Su, J.; Yue, Q. Experimental studies and characteristics analysis of sea ice flexural strength around the Bohai Sea. Adv. Water Sci. 2011, 22, 266–272. [Google Scholar]

| Preparation Location | Specimen No. | Ambient Temperature T (°C) | Single-Layer Freezing Time t0 (h) | Rafted Ice Consolidation Time t1 (h) |

|---|---|---|---|---|

| Outdoor | No. 1 | −10~−2 | 40 | 32 |

| −10~−2 | ||||

| −14~−8 | ||||

| −13~0 | ||||

| No. 2 | −13~0 | 38 | 26 | |

| −10~−3 | ||||

| −14~−1 | ||||

| −9~3 | ||||

| Indoor | No. 3 | −10~−3 | 9 | 36 |

| No. 4 | 8 | 38 | ||

| No. 5 | 12 | 36 | ||

| No. 6 | 9 | 24 |

| Specimen No. | Ice Type | Mean Density (kg·m−3) | Density Standard Deviation (kg·m−3) |

|---|---|---|---|

| No. 1 | l2 | 900.75 | 40.44 |

| l1 | 925.72 | 71.9 | |

| No. 2 | l2 | 830.44 | 52.7 |

| l1 | 954.18 | 61.5 | |

| No. 3 | l2 | 867.76 | 43.45 |

| l1 | 922.57 | 41.52 | |

| No. 4 | l2 | 863 | 27.37 |

| l1 | 917.18 | 24.82 | |

| No. 5 | l2 | 857.20 | 40.05 |

| l1 | 885.50 | 28.07 | |

| No. 6 | l2 | 879.63 | 24.60 |

| l1 | 946.90 | 48.25 |

| Test Specimen No. | Total Tests (Groups) | Ice Type | Mean Flexural Strength (MPa) | Flexural Strength Standard Deviation (MPa) | Flexural Strength 95% CI (MPa) |

|---|---|---|---|---|---|

| No. 5 | 7 | l2 | 0.84 | 0.13 | 0.73~0.95 |

| 6 | l1 | 0.65 | 0.20 | 0.47~0.83 | |

| No. 6 | 13 | l2 | 0.49 | 0.12 | 0.42~0.56 |

| 12 | l1 | 0.44 | 0.10 | 0.38~0.50 |

| Specimen No. | Ice Type | Mean Effective Elastic Modulus (MPa) | Effective Elastic Modulus Standard Deviation (MPa) | Effective Elastic Modulus 95% CI (MPa) |

|---|---|---|---|---|

| No. 1 | l2 | 5.74 | 1.51 | 4.34~7.14 |

| l1 | 5.70 | 1.62 | 4~7.4 | |

| No. 2 | l2 | 32.89 | 11.52 | 25.93~39.85 |

| l1 | 33.05 | 10.20 | 26.57~39.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Li, W.; Wu, K.; Ma, S.; Wang, G.; Li, Y.; Zhang, D. Experimental Study on the Growth Pattern and Flexural Strength Characteristics of Rafted Ice. Oceans 2025, 6, 62. https://doi.org/10.3390/oceans6040062

Xu Y, Li W, Wu K, Ma S, Wang G, Li Y, Zhang D. Experimental Study on the Growth Pattern and Flexural Strength Characteristics of Rafted Ice. Oceans. 2025; 6(4):62. https://doi.org/10.3390/oceans6040062

Chicago/Turabian StyleXu, Ying, Wei Li, Kuankuan Wu, Sichong Ma, Guojun Wang, Yuepeng Li, and Dayong Zhang. 2025. "Experimental Study on the Growth Pattern and Flexural Strength Characteristics of Rafted Ice" Oceans 6, no. 4: 62. https://doi.org/10.3390/oceans6040062

APA StyleXu, Y., Li, W., Wu, K., Ma, S., Wang, G., Li, Y., & Zhang, D. (2025). Experimental Study on the Growth Pattern and Flexural Strength Characteristics of Rafted Ice. Oceans, 6(4), 62. https://doi.org/10.3390/oceans6040062