1. Introduction

In the last few years, new digital technologies have paved the way for novel diagnostic and operative tools that have significantly modified the clinical approach used for patients in need of surgery. Digital radiography, based on computed tomography (CT) and cone beam CT (CBCT) has allowed for the preoperative evaluation of bone volume, quantity, and quality, as well as for the identification of important anatomical structures (i.e., blood vessels, nerves, sinuses, and foramina) that could influence the placement of dental implants [

1,

2,

3,

4]. Furthermore, computer-aided design/computer-aided manufacturing (CAD/CAM) technologies and three-dimensional (3D) production processes (i.e., stereolithography, 3D printing, etc.) permitted researchers to widen the treatment options in implant dentistry, introducing novel operative concepts to dental implant surgery [

3,

4,

5,

6,

7,

8].

This innovative scenario opened the way to prosthetically guided implant surgery [

2,

4,

5,

6,

7,

8,

9]. Computer-guided surgery allowed researchers to simplify and significantly improve clinical procedures, in comparison with traditional implant surgery, and offers different advantages, such as better accuracy in terms of fixture positioning, improved patient comfort, and the pre-surgical fabrication of temporary prostheses [

5,

6,

7,

9].

CT and 3D planning software offer accurate data and anatomic information that are crucial to designing implant-supported prostheses; furthermore, such digital datasets can be merged with CAD/CAM workflows, using stereolithography or rapid prototyping to fabricate surgical templates that guide the precise placement of fixtures, created according to prosthetically guided digital plans [

1,

2,

3,

4,

6,

7,

9].

According to a recent consensus conference, computer-guided surgery can be considered a viable treatment option that significantly reduces the risk of injuring important anatomical structures (i.e., nerves, bones, sinus cavities, adjacent teeth, etc.) [

6,

7,

9]. However, the precision of this technique is still controversial and, currently, clinical evidence is scant [

5,

6,

10,

11,

12].

The accuracy of computer-guided implant surgery regards the matching between the digital placement of implants, as planned in the software, and the actual position of fixtures in the oral cavity [

1,

2,

3,

4,

5,

6,

7,

10,

11,

13]. In particular, it is influenced by the sum of all intrinsic errors and deviations, from digital imaging over the conversion of datasets in the surgical guide to the implant’s wrong placement and/or stabilization in the oral cavity [

7,

9,

14,

15]. Cumulative inaccuracy can be due to errors during image acquisition, data processing, surgical template production, implant positioning and stabilization, drilling, and the wrong use of surgical tools [

5,

7,

9,

16,

17,

18,

19,

20,

21].

Several investigations and systematic reviews evaluated the operative variables affecting the accuracy of computer-guided implant surgery and the clinical survival rates and complications, as well as the technical advantages and drawbacks of such an approach [

7,

11,

14,

15,

16,

17,

18,

19,

20,

21]. Nonetheless, currently, only scarce and incomplete data are available, and no univocal consensus exists about the clinical applications of guided surgery and the technical limitations of this technique [

10,

11,

20]. Indeed, the tolerances between the internal diameter of the sleeves and the circumference of the drills, as well as the length of the sleeves, significantly affect the accuracy of the system; moreover, the room that is necessary to stabilize the surgical template and manage the surgical instruments correctly may limit the indications of computer-guided implant surgery in posterior regions and/or in the case of reduced mouth opening, making the clinical steps less user-friendly and increasing the patient’s discomfort [

5,

6,

10,

11,

20].

The present paper aimed to present a novel approach to guided implant surgery, describing the technical characteristics of an innovative guided surgical kit made up of modified sleeves with increased length and modular surgical drills with reduced height.

2. Description of the Guided Implant System: Technical Characteristics and Innovations

The proposed guided surgical kit (Due Drill CE-approved, Sweden & Martina, Due Carrare, PD, Italy) is based on a novel patented system of sleeves and modular burs, with increased length of the metal sleeves and reduced height of the drills.

The surgical sleeves are the actual guiding tools during implant placement and need to be furnished with proper lengths and minimal engineering tolerance, to guide drills and implant mounters with the utmost precision. This innovative system uses metal sleeves with a height of 8 mm (thus, longer than conventional ones) and a minimal tolerance between their internal diameter and those of guided drills; the sleeves are solidarized within the surgical template by friction. Such mechanical features guarantee a fluent and tight contact between the neck of the drills and the internal portion of the sleeve and compensate for any possible lateral bending movement of the drills, improving the stability of both the surgical template and the working tips. The proposed 8-millimeter sleeves will avoid any bending moment of the drills passing through a longer path, guiding the surgical tips much more precisely than conventional sleeves, allowing them to slide into a very precise tunnel and achieving an improved accuracy of implant placement. Due to the increased height of the sleeves, the overall distance between the edge of the sleeve and the planned position of the implant neck is 11 mm.

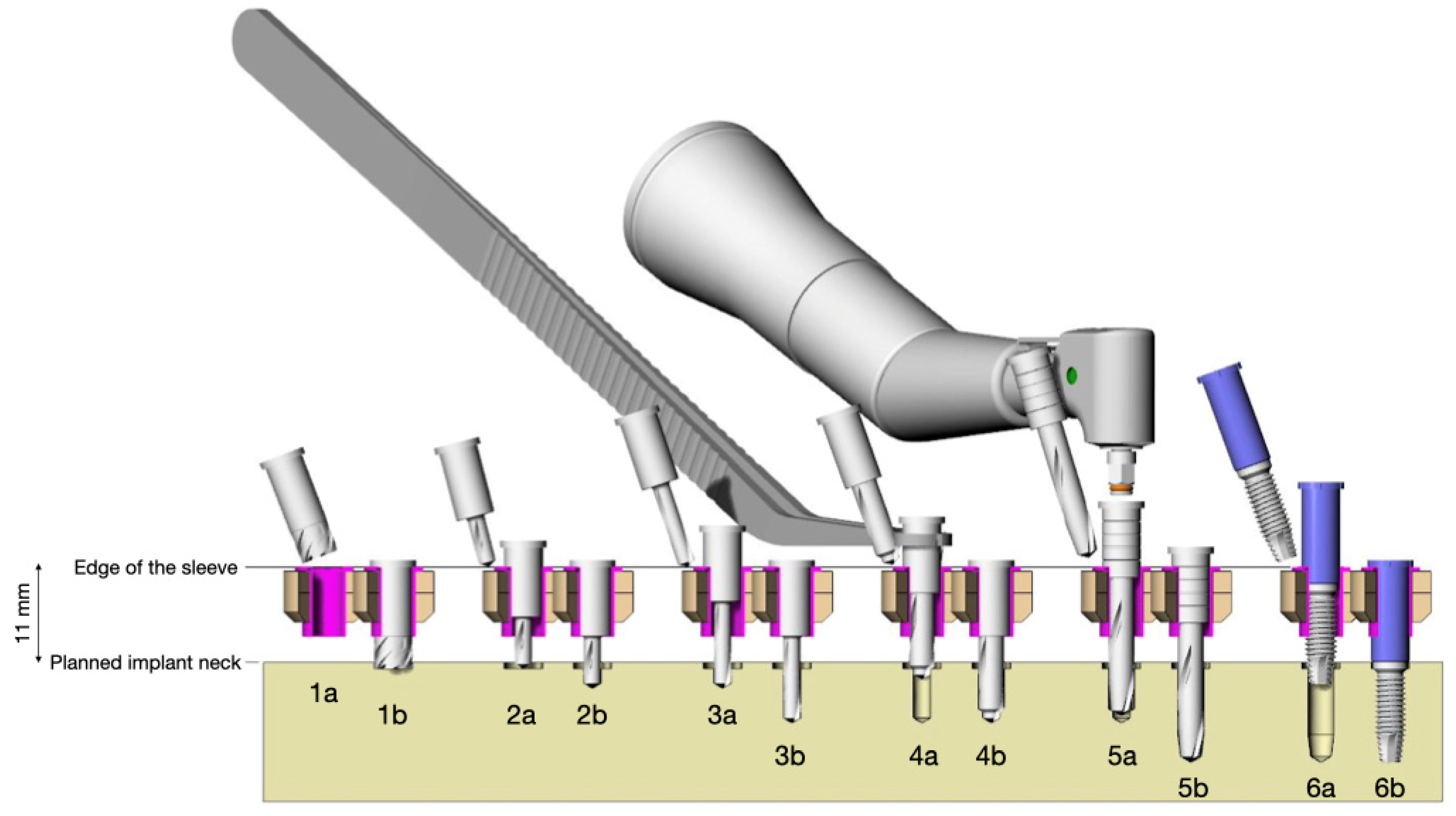

The novel surgical kit is made up of modular drills, composed of two separate components that can be arranged intraorally with reduced encumbrance (

Figure 1); indeed, the working tips can be inserted directly into the sleeves and coupled via their shank to a hexagonal driver, through a smart easy-insert. The system presents optimized ergonomics since such a hexagonal driver is unique and clinicians have no need to remove and replace it from the implant handpiece. The working drills are transferred from the surgical kit to the oral cavity, back and forth, by means of dedicated tweezers; then, the surgical drills are placed firmly and stabilized into the sleeves before the implant handpiece is powered. These features reduce the encumbrance of the innovative drills by up to 25–40% compared to conventional guided implant drills, resulting in a reduction in the vertical space necessary to approach surgical sleeves by about 18 mm (

Figure 2).

The step-shaped tip of the drills can guide the subsequent working tips precisely, avoiding possible micromovements and imprecisions, due to human errors and/or poor bone quality, and improving the stability of both surgical templates and drills. Moreover, the straight access to the sleeves would minimize any lateral bending of the surgical template.

The modular guided implant drills present the shape of a cylindrical socket that can be joined to mechanical pulling and drilling tools, with a smart insertion system. Furthermore, similarly to conventional guided drills, the proposed instruments are provided with an easy-grip surface to catch the implant and a vertical stop to couple the diameter of the sleeve exactly, so as to maintain the planned corono-apical position of the fixture; the vertical position of the implant can easily be checked on sight, due to the presence of horizontal depth-reference notches of the necks of the drills (

Figure 3).

The patented modular drills allow clinicians to use prosthetically guided implant surgery in all clinical situations; their reduced height makes this system particularly useful in posterior areas with limited inter-arch space. Moreover, the modularity of the guided drills allows clinicians to exert a passive action within the sleeves, avoiding any risk of deviation or seizing.

The implant mounters have been designed according to the same project criterion and standard as the surgical drills.

3. Clinical Case Presentation

A 54-year-old female patient with a missing mandibular molar was treated using the proposed, innovative guided surgical kit.

The anatomical information, obtained from precision polyether impressions and gypsum models, was merged with 3D CBCT scanned data, in accordance with residual dentition. The proper position of the fixture was digitally planned and a surgical template was fabricated, by means of stereolithography-assisted rapid prototyping (SLA-RP). Then, a metal sleeve with a length of 8 mm was fixed into the surgical template, according to the planned implant position, to guide the implant drills. Data merging, fixture position, angle determination, and data transmission were performed using dedicated software (Dental Vox, Erascientific Service, San Giovanni, Marignano, Italy) (

Figure 4).

At the time of the intervention, the site to be treated had been healed for 3 months after the extraction; the bone volume was evaluated preoperatively to achieve satisfactory implant primary stability. The surgical procedures were performed under local anesthesia.

The implant was positioned by an expert implant surgeon (F.F.) using a guided-surgery approach, after the careful stabilization of the surgical templates onto the residual dentition. In order to overcome the operative limitations due to limited mouth opening and/or reduced intermaxillary room in the posterior areas, the requisite working tips were inserted directly into the sleeve; then, these tips were coupled easily to the shank through a hexagonal driver with a smart easy insert, resulting in a significant reduction in the room necessary to access the posterior intraoral areas and with no necessity to climb over the surgical template (

Figure 5,

Figure 6,

Figure 7 and

Figure 8). The step-shaped tips of the drills allowed the clinicians to guide the subsequent surgical steps easily and precisely. The guide hole has to be made so that the surgical drills can be used progressively, in terms of both length and in diameter (

Figure 9,

Figure 10,

Figure 11 and

Figure 12).

Moreover, the innovative metal sleeves used in the present research were characterized by a length of 8 mm, guaranteeing the improved stability of both the drills and the surgical template and also the major precision of fixture placement, thanks to the limited engineering clearance of the system (

Figure 13 and

Figure 14).

After implant site preparation, the fixture was positioned in the digitally planned position and protected with a cover screw (

Figure 15). The implant position was verified using standardized periodical radiographs with a paralleling technique.

One week after implant placement, a follow-up visit was scheduled to check implant stability and assess the healing process.

The patient was provided with a screw-retained temporary single crown to condition the peri-implant tissues properly for a period of 4 weeks until optimal healing of the implant site was achieved (

Figure 16). Subsequently, precision impressions with elastomeric materials (Permadyne Penta H, Impregum Penta Soft, 3M ESPE, Seefeld, Germany) and a pick-up technique were made to fabricate the final restoration. The patient was provided with an implant-supported monolithic zirconia (Zirconia Katana STML, Kuraray Noritake Dental Inc., Tokyo, Japan) single crown, which was cemented onto the implant (

Figure 17). Standardized periapical radiographs were taken to verify the correct coupling of the implant–prosthetic components (

Figure 18).

4. Discussion

With the development of computer technologies and 3D-imaging techniques, guided implant surgery has permitted clinicians to improve the reliability of conventional pre-surgical planning, avoiding the limitations of 2D radiographs and study casts [

1,

2,

3,

4,

6,

7,

9,

10,

11,

20]. The proper evaluation of 3D digital datasets that can be obtained with CBCT, planning software, and intraoral scanners allows surgeons to simulate surgical interventions precisely, enabling the planning before implant surgery of the angulation and position according to bone volume and quality, the location of anatomical structures (i.e., nerves, blood vessels, foramina, sinuses, etc.) and the prosthetic necessities of each case [

6,

10,

11]. Moreover, the pre-surgical planning of fixture position permits clinicians to produce surgical templates that guide the operator during implant placement, mainly via a flapless approach, shortening the duration of surgery and thereby limiting the possible complication rates and patients’ discomfort [

6,

7,

10,

14,

15,

16,

17,

18,

19,

20,

21].

Notwithstanding these advantages, guided implant surgery may suffer the technical drawbacks related to cumbersome surgical kits [

5,

6,

10,

12]. In fact, in order to drive the surgical instruments properly within the surgical guide, guided implant drills are usually much longer than conventional implant drills since they have to work through the thickness of surgical templates; this could result in a distance between the shank and the tip of the guided drills of about 40 mm.

The space required to climb over the surgical template and fit the guided drills inside the sleeves could represent a limiting operative variable for surgeons because of the presence of anatomical structures (i.e., antagonist teeth, coronoid process, mandibular ramus), particularly in cases of reduced mouth-opening capacity [

5,

6,

10,

12].

In order to avoid such drawbacks, sometimes it is necessary to open windows laterally to the sleeves to compensate for the thickness of surgical guides and thereby introduce the implant drills from the buccal or lingual surfaces; nonetheless, this operative trick could negatively affect the stability of the surgical templates, causing bending moments in the working tips and significant imprecision in implant placement, as well as reducing the strength of the surgical guides, leading to possible fractures [

5,

9,

12].

Differently from the guided surgical kits currently available on the market, the novel system presented in this paper uses longer metal sleeves with a height of 8 mm, and minimal tolerances between their internal diameter and those of the guided drills. Such properties offer the utmost precision during surgery since they allow for fluent and tight friction between the inner surface of the sleeve and the neck of the drills and compensate for the possible bending moments of the drills, increasing the stability and precision of implant site preparation.

The proposed 8-millimeter length of the guided sleeves leads to an offset distance of 11 mm between the stop of the sleeve itself and the planned position of the implant neck. This dimension was derived from a series of mechanical tests with shorter and longer sleeves; 8 mm was proved to offer the best compromise between the mechanical precision of guidance and inter-arch encumbrance.

Furthermore, a length shorter than 8 mm would limit the possibility of properly supporting and blocking the sleeve with resin within the surgical template, risking possible intraoperative catastrophic fractures of the template, particularly when significant vertical misleveling between the occlusal plane and the planned implant level is present.

As reported in several studies, the length of the guided sleeve significantly influences the accuracy of the implant position [

5,

12]. Most of the guided surgical kits available on the market today show a significant lack of fitting between the circumference of the drills and the internal diameter of the sleeves, which in turn, present a standard length of 4 mm; this is often not sufficient to withstand the possible lateral bending movements of longer surgical drills [

5,

12]. As bone quality may vary between patients and there is not always a proper diagnostic visualization of its density during pre-surgical planning [

5,

6,

11,

12,

13], the preparation of guided pilot holes could easily not be enough to stabilize conventional, longer guided drills. All these variables could significantly reduce the precision of fixture placement, causing a crucial mismatch between the digital pre-surgical planning and the real surgical intervention; this results in a subsequent inconsistent positioning of implants that could create crucial drawbacks in the position and biomechanics of implant-supported prostheses.

However, it is worth noting that in the last few years, surgical templates without metallic sleeves and dedicated kits have been provided as well. This concept allows for satisfactory accuracy and also allows the clinician to work in reduced vertical spaces, as reported in randomized clinical trials (RCTs) and systematic reviews [

2,

4,

22]. Surgical templates without metallic sleeves showed good levels of accuracy in partially edentulous patients [

4], particularly in terms of the vertical plane and angle [

2]. However, in a recent RCT, although good precision was reported in all the measured outcomes, the posterior implants were less accurate because of the use of open-sleeve templates [

22].

The innovative surgical instruments presented in this paper are modular drills made up of two separate components that can be assembled intraorally, reducing encumbrance. In particular, the working tip can be inserted directly into the sleeve and then coupled to the shank by means of a smart easy insert. In comparison with conventional surgical kits, this assembly system could reduce the encumbrance of guided implant drills by up to 25–40% (about 10–18 mm) [

5,

6,

12,

21], resulting in a significant reduction in the space necessary to access posterior intraoral regions.

It was reported that the longer a drill is, the higher the linear and angular mismatch at the implant apex will be, due to a pantographic effect that is related to the distance between the tang and the working tip of the drill [

5,

10]. Similarly, the proposed 8-millimeter sleeves will block possible rotational movements of the drills through a longer path, guiding the working tip much more precisely than conventional sleeves, allowing it to slide into a very precise tunnel, and resulting in improved accuracy of implant placement.

Furthermore, the step-shaped tip of the drills described herein could drive the subsequent working tips precisely, limiting undesired micromovements and imprecisions due to operative errors and/or poor bone quality and improving the stability of drills and surgical templates.

Avoiding the necessity of climbing over the surgical template would even limit the risk of implant surface contamination, due to the contact between the fixture and the sleeve during implant placement [

5,

12]. Moreover, straight access to the sleeves would minimize the lateral bending of the surgical template, allowing the clinician to maintain a proper implant axis during drilling and fixture placement [

5,

6,

12].

The proposed modular guided implant drills have the shape of a cylindrical socket that can be joined to mechanical pulling and drilling tools with a smart insertion system; in addition, they are provided with an easy grip to catch the fixture and a vertical stop to couple the diameter of the sleeve exactly, so as to maintain the planned corono-apical position of the implant; the vertical position of the fixture can be checked easily on sight due to the presence of reference horizontal depth notches on the necks of the drills.

The described guided surgical kit would allow the clinician to position every type of fixture and can be adapted to almost all conventional guided implant kits. In addition, the utmost precision of planning and intervention permits the clinician to fabricate pre-surgical screw-retained temporary prostheses, ready to be placed soon after surgery, reducing chairside time and improving patients’ comfort.