Application of Continuous Stability Control to a Lightweight Solar-Electric Vehicle Using SMC and MPC

Abstract

1. Introduction

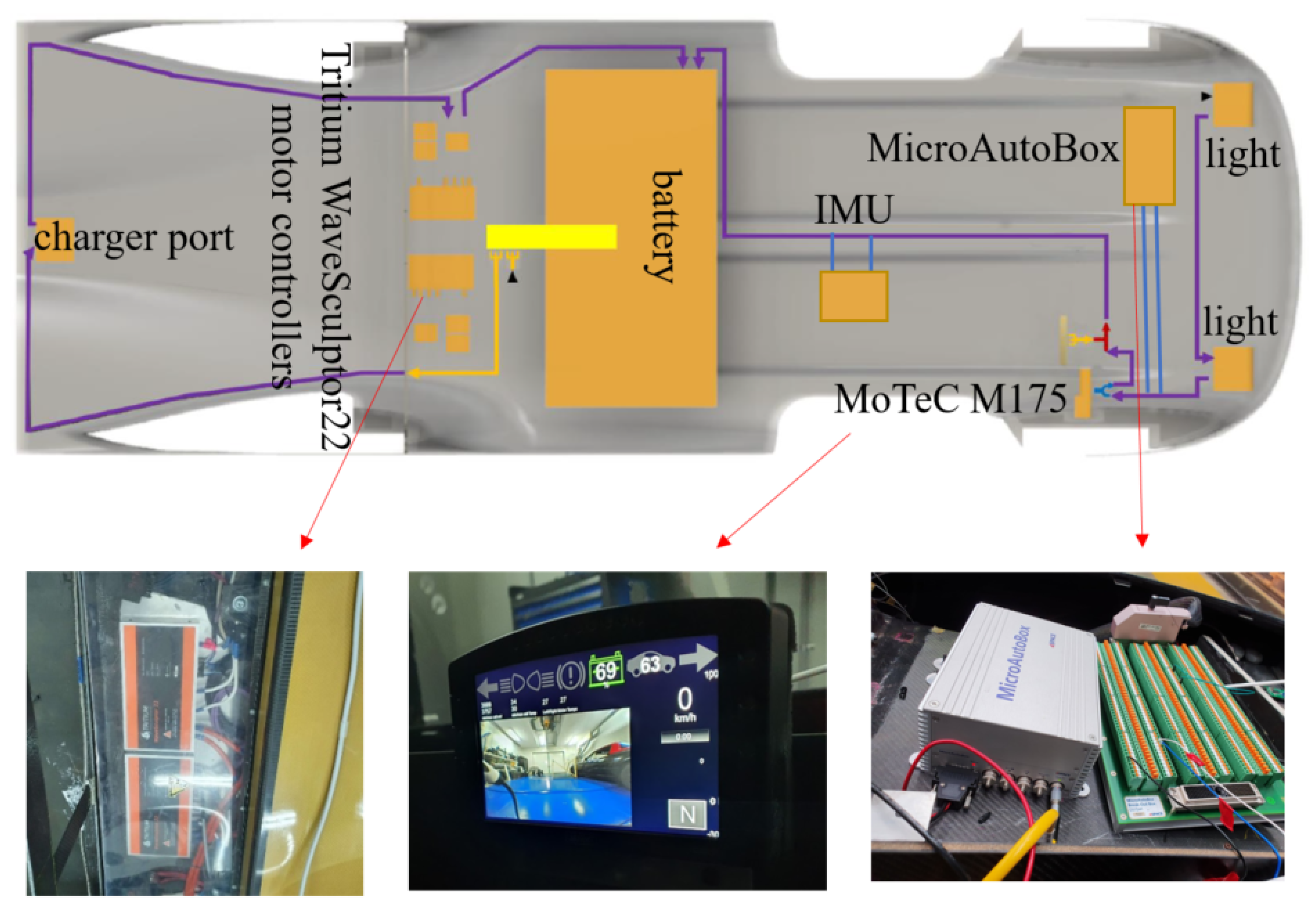

2. Vehicle Specification: ATN Solar Car

2.1. Vehicle Parameter Identification

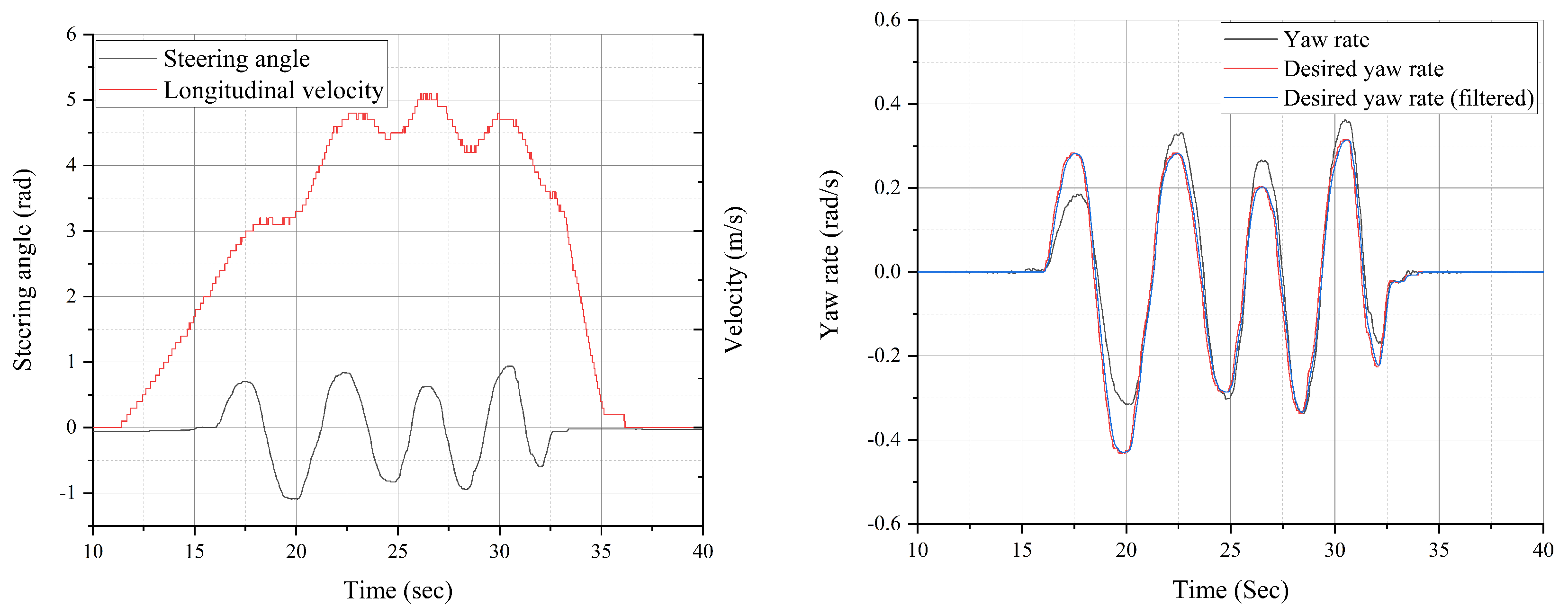

Cornering Stiffness

3. Control Design

3.1. Reference Model

3.2. System Model

3.3. Sliding-Mode Control Strategy Design

3.4. Model Predictive Control Strategy Design

3.5. Torque Allocation

4. Vehicle Side-Slip Estimation

Lateral Acceleration Compensation

5. Data Acquisition and Control Unit Integration

6. Results

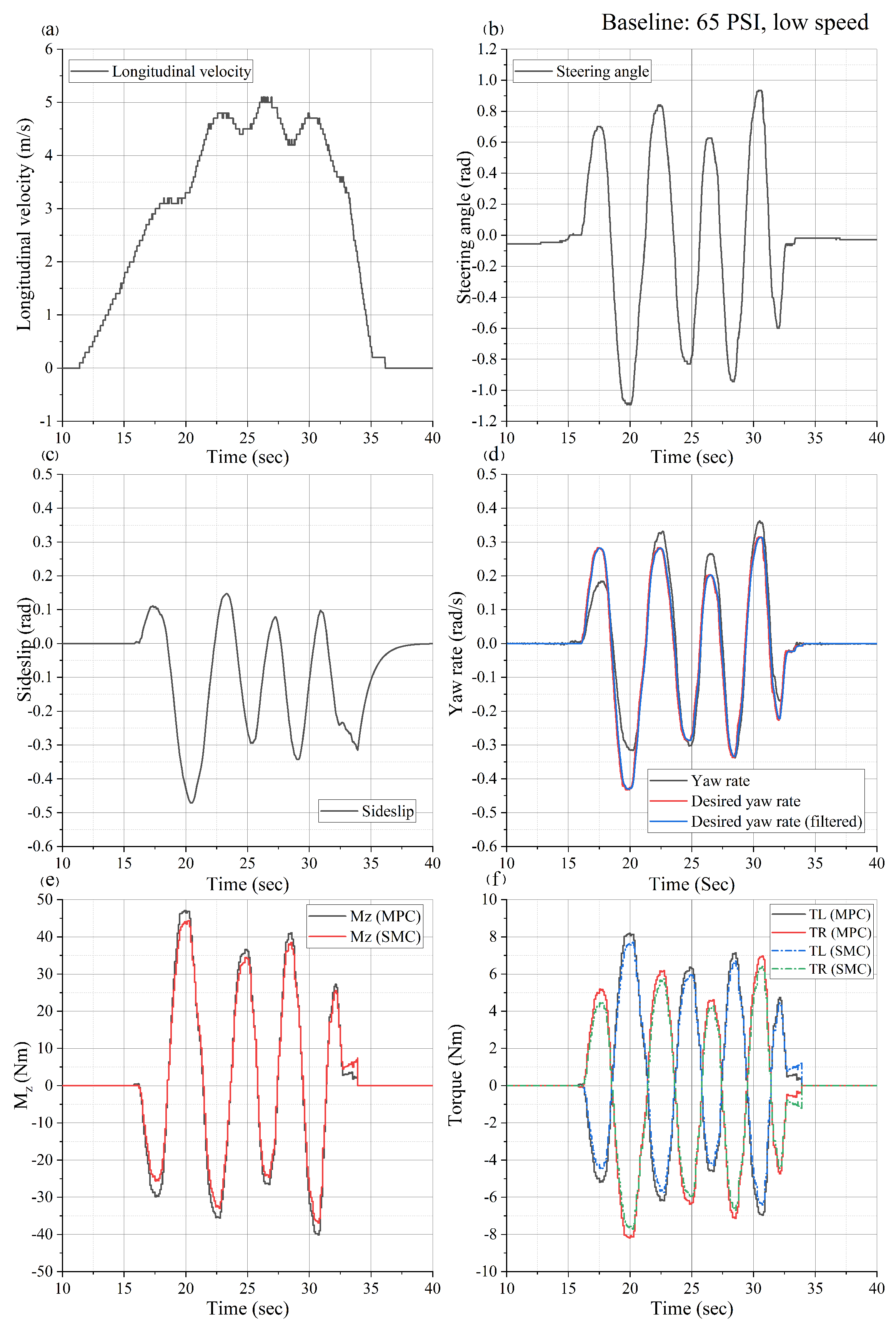

6.1. Baseline Slalom Maneuver with Low Velocity < 5 m/s

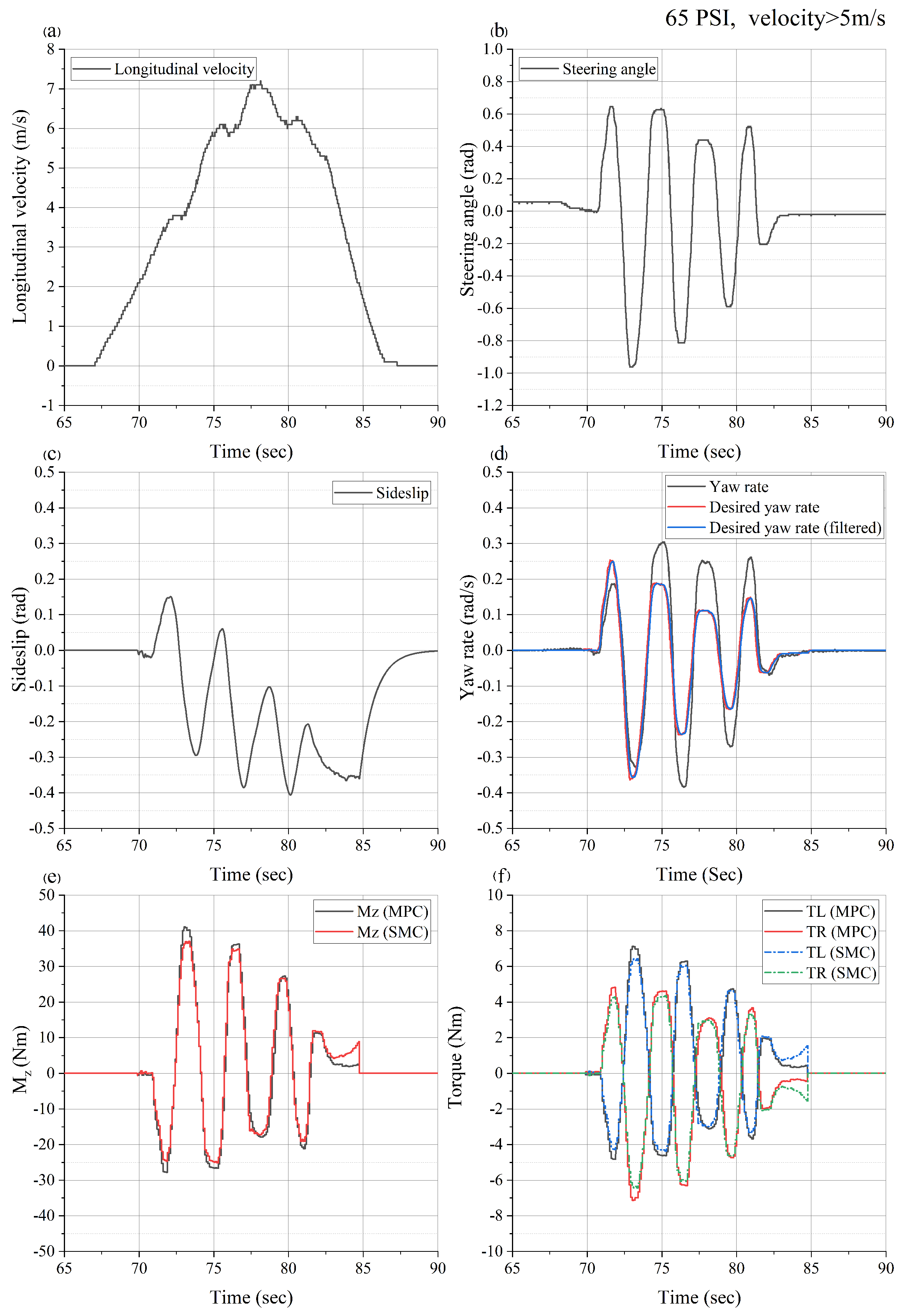

6.2. Slalom Maneuver with Velocity > 5 m/s

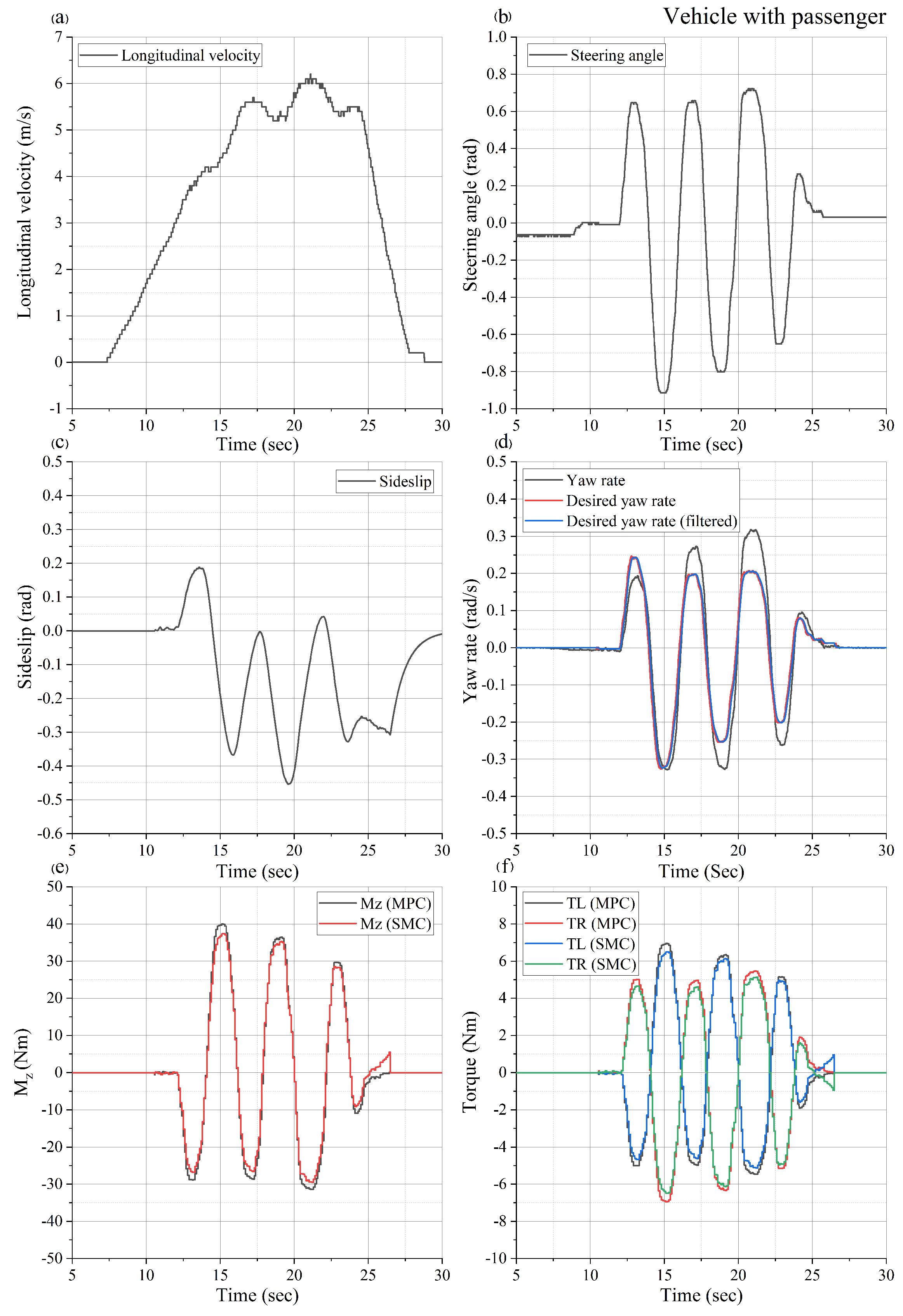

6.3. Slalom Maneuver with Passenger

6.4. Simulation Model Comparison

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ATN | Australian Technology Network |

| DOF | Degree of freedom |

| SMC | Slide mode control |

| MPC | Model predictive control |

| IMU | inertia measurement unit |

References

- Bridgestone World Solar Challenge. 2022. Available online: https://www.worldsolarchallenge.org/ (accessed on 27 May 2022).

- Minak, G.; Brugo, T.M.; Fragassa, C.; Pavlovic, A.; de Camargo, F.V.; Zavatta, N. Structural design and manufacturing of a cruiser class solar vehicle. J. Vis. Exp. 2019, 143, e58525. [Google Scholar]

- Pavlovic, A.; Sintoni, D.; Fragassa, C.; Minak, G. Multi-objective design optimization of the reinforced composite roof in a solar vehicle. Appl. Sci. 2020, 10, 2665. [Google Scholar] [CrossRef]

- Paterson, S.; Vijayaratnam, P.; Perera, C.; Doig, G. Design and development of the Sunswift eVe solar vehicle: A record-breaking electric car. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2016, 230, 1972–1986. [Google Scholar] [CrossRef]

- Lenzo, B.; Zanchetta, M.; Sorniotti, A.; Gruber, P.; De Nijs, W. Yaw rate and sideslip angle control through single input single output direct yaw moment control. IEEE Trans. Control Syst. Technol. 2021, 29, 124–139. [Google Scholar] [CrossRef]

- Choi, M.; Choi, S.B. Model predictive control for vehicle yaw stability with practical concerns. IEEE Trans. Veh. Technol. 2014, 63, 3539–3548. [Google Scholar] [CrossRef]

- Lutz, A.; Schick, B.; Holzmann, H.; Kochem, M.; Meyer-Tuve, H.; Lange, O.; Mao, Y.; Tosolin, G. Simulation methods supporting homologation of Electronic Stability Control in vehicle variants. Veh. Syst. Dyn. 2017, 55, 1432–1497. [Google Scholar] [CrossRef]

- Li, L.; Lu, Y.; Wang, R.; Chen, J. A three-dimensional dynamics control framework of vehicle lateral stability and rollover prevention via active braking with MPC. IEEE Trans. Ind. Electron. 2016, 64, 3389–3401. [Google Scholar] [CrossRef]

- Jalali, M.; Hashemi, E.; Khajepour, A.; Chen, S.k.; Litkouhi, B. A combined-slip predictive control of vehicle stability with experimental verification. Veh. Syst. Dyn. 2018, 56, 319–340. [Google Scholar] [CrossRef]

- Termous, H.; Shraïm, H.; Talj, R.; Francis, C.; Charara, A. Coordinated control strategies for active steering, differential braking and active suspension for vehicle stability, handling and safety improvement. Veh. Syst. Dyn. 2019, 57, 1494–1529. [Google Scholar] [CrossRef]

- Wang, F.; Chen, H.; Guo, K.; Cao, D. A novel integrated approach for path following and directional stability control of road vehicles after a tire blow-out. Mech. Syst. Signal Process. 2017, 93, 431–444. [Google Scholar] [CrossRef]

- Kumbhar, B.K.; Patil, S.R.; Sawant, S.M. A Comparative study on automotive brake testing standards. J. Inst. Eng. Ser. C 2017, 98, 527–531. [Google Scholar] [CrossRef]

- Thiyagarajan, V.; Kalaichelvan, K.; Vijay, R.; Lenin Singaravelu, D. Influence of thermal conductivity and thermal stability on the fade and recovery characteristics of non-asbestos semi-metallic disc brake pad. J. Braz. Soc. Mech. Sci. Eng. 2016, 38, 1207–1219. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, H.; Huang, Y.; Wang, P.; Guo, K. Human-centered torque vectoring control for distributed drive electric vehicle considering driving characteristics. IEEE Trans. Veh. Technol. 2021, 70, 7386–7399. [Google Scholar] [CrossRef]

- Li, X.; Xu, N.; Guo, K.; Huang, Y. An adaptive SMC controller for EVs with four IWMs handling and stability enhancement based on a stability index. Veh. Syst. Dyn. 2021, 59, 1509–1532. [Google Scholar] [CrossRef]

- Jin, X.; Yin, G.; Zeng, X.; Chen, J. Robust gain-scheduled output feedback yaw stability control for in-wheel-motor-driven electric vehicles with external yaw-moment. J. Frankl. Inst. 2018, 355, 9271–9297. [Google Scholar] [CrossRef]

- Ataei, M.; Khajepour, A.; Jeon, S. Model predictive control for integrated lateral stability, traction/braking control, and rollover prevention of electric vehicles. Veh. Syst. Dyn. 2020, 58, 49–73. [Google Scholar] [CrossRef]

- Ren, B.; Chen, H.; Zhao, H.; Yuan, L. MPC-based yaw stability control in in-wheel-motored EV via active front steering and motor torque distribution. Mechatronics 2016, 38, 103–114. [Google Scholar] [CrossRef]

- Kırlı, A.; Chen, Y.; Okwudire, C.E.; Ulsoy, A.G. Torque-vectoring-based backup steering strategy for steer-by-wire autonomous vehicles with vehicle stability control. IEEE Trans. Veh. Technol. 2019, 68, 7319–7328. [Google Scholar] [CrossRef]

- Fu, C.; Hoseinnezhad, R.; Li, K.; Hu, M. A novel adaptive sliding mode control approach for electric vehicle direct yaw-moment control. Adv. Mech. Eng. 2018, 10, 1687814018803179. [Google Scholar] [CrossRef]

- Kohlhuber, F.; Lienkamp, M.; Pfeffer, P.E. Load problem of lightweight electric vehicles and solution by online model adaptation. In Proceedings of the 5th International Munich Chassis Symposium, Munich, Germany, 29 July 2014; pp. 281–302. [Google Scholar] [CrossRef]

- Lidfors Lindqvist, A.; Zhou, S.; Walker, P.D. Direct yaw moment control of an ultra-lightweight solar-electric passenger vehicle with variation in loading conditions. Veh. Syst. Dyn. 2020, 60, 1393–1415. [Google Scholar] [CrossRef]

- Uli, R. Non-Lagging Effect of Motorcycle Tyres: An Experimental Study with the Flat Plank Tyre Tester; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2006. [Google Scholar]

- Regolin, E.; Savitski, D.; Ivanov, V.; Augsburg, K.; Ferrara, A. Lateral vehicle dynamics control via sliding modes generation. Sliding Mode Control Veh. Dyn. 2017, 121–158. [Google Scholar] [CrossRef]

- Jang, Y.; Lee, M.; Suh, I.S.; Nam, K. Lateral handling improvement with dynamic curvature control for an independent rear wheel drive EV. Int. J. Automot. Technol. 2017, 18, 505–510. [Google Scholar] [CrossRef]

- Ding, S.; Liu, L.; Zheng, W. Sliding mode direct yaw-moment control design for in-Wheel electric vehicles. IEEE Trans. Ind. Electron. 2017, 64, 6752–6762. [Google Scholar] [CrossRef]

- Ji, X.; He, X.; Lv, C.; Liu, Y.; Wu, J. A vehicle stability control strategy with adaptive neural network sliding mode theory based on system uncertainty approximation. Veh. Syst. Dyn. 2018, 56, 923–946. [Google Scholar] [CrossRef]

- Truong, D.V.T.; Meywerk, M.; Tomaske, W. Torque vectoring for rear axle using Adaptive Sliding Mode Control. In Proceedings of the 2013 International Conference on Control, Automation and Information Sciences (ICCAIS), Nha Trang, Vietnam, 25–28 November 2013; pp. 328–333. [Google Scholar] [CrossRef]

- Cao, Y.; Zhai, L.; Sun, T.; Gu, H. Straight running stability control based on optimal torque distribution for a four in-wheel motor drive electric vehicle. Energy Procedia 2017, 105, 2825–2830. [Google Scholar] [CrossRef]

- Ding, S.; Sun, J. Direct yaw-moment control for 4WID electric vehicle via finite-time control technique. Nonlinear Dyn. 2017, 88, 239–254. [Google Scholar] [CrossRef]

- Ahmed, A.A. Simulation of Stability Control for In-Whee-Motored Vehicle Using Fuzzy PID Controller. In Proceedings of the Automotive and Vehicle Technologies Conference Proceedings, Istanbul, Turkey, 23–24 November 2015. [Google Scholar]

- Schramm, D.; Hiller, M.; Bardini, R. Single Track Models. In Vehicle Dynamics: Modeling and Simulation; Springer: Berlin/Heidelberg, Germany, 2018; pp. 225–257. [Google Scholar] [CrossRef]

- Abe, M. Vehicle Handling Dynamics: Theory and Application; Elsevier Science & Technology: Oxford, UK, 2015. [Google Scholar]

- Singh, K.B. Vehicle sideslip angle estimation based on tire model adaptation. Electronics 2019, 8, 199. [Google Scholar] [CrossRef]

- Selmanaj, D.; Corno, M.; Panzani, G.; Savaresi, S.M. Vehicle sideslip estimation: A kinematic based approach. Control Eng. Pract. 2017, 67, 1–12. [Google Scholar] [CrossRef]

- Piyabongkarn, D.; Rajamani, R.; Grogg, J.A.; Lew, J.Y. Development and experimental evaluation of a slip angle estimator for vehicle stability control. IEEE Trans. Control Syst. Technol. 2009, 17, 78–88. [Google Scholar] [CrossRef]

- Okajima, H.; Yonaha, S.; Matsunaga, N.; Kawaji, S. Direct Yaw-moment Control method for electric vehicles to follow the desired path by driver. In Proceedings of the SICE Annual Conference 2010, Taipei, Taiwan, 18–21 August 2010; pp. 642–647. [Google Scholar]

- Taheri, S.; Singh, K.B. Integrated state and parameter estimation for vehicle dynamics control. Int. J. Veh. Perform. 2019, 5, 329–376. [Google Scholar] [CrossRef]

- Cho, K.; Son, H.; Choi, S.B.; Kang, S. Lateral acceleration compensation of a vehicle based on roll angle estimation. In Proceedings of the 2010 IEEE International Conference on Control Applications, Yokohama, Japan, 8–10 September 2010; IEEE: Piscataway, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Ding, E.; Massel, T. Estimation of vehicle roll angle. IFAC Proc. Vol. 2005, 38, 122–127. [Google Scholar] [CrossRef]

| Location | Front | Rear | ||

|---|---|---|---|---|

| Right | Left | Right | Left | |

| Weight (N) | 1098 | 1001 | 1177 | 961 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lidfors Lindqvist, A.; Zhou, S.; Halkon, B.; Aguilera, R.P.; Walker, P.D. Application of Continuous Stability Control to a Lightweight Solar-Electric Vehicle Using SMC and MPC. Vehicles 2024, 6, 874-894. https://doi.org/10.3390/vehicles6020042

Lidfors Lindqvist A, Zhou S, Halkon B, Aguilera RP, Walker PD. Application of Continuous Stability Control to a Lightweight Solar-Electric Vehicle Using SMC and MPC. Vehicles. 2024; 6(2):874-894. https://doi.org/10.3390/vehicles6020042

Chicago/Turabian StyleLidfors Lindqvist, Anna, Shilei Zhou, Benjamin Halkon, Ricardo P. Aguilera, and Paul D. Walker. 2024. "Application of Continuous Stability Control to a Lightweight Solar-Electric Vehicle Using SMC and MPC" Vehicles 6, no. 2: 874-894. https://doi.org/10.3390/vehicles6020042

APA StyleLidfors Lindqvist, A., Zhou, S., Halkon, B., Aguilera, R. P., & Walker, P. D. (2024). Application of Continuous Stability Control to a Lightweight Solar-Electric Vehicle Using SMC and MPC. Vehicles, 6(2), 874-894. https://doi.org/10.3390/vehicles6020042