Impact of Different Milk Types and Storage Period on the Quality Characteristics of Malatya Cheese

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cheese Making

2.3. Compositional Analysis

2.4. Proteolytic Ripening Parameters of Cheeses

2.5. Determination of Volatile Compounds

2.6. Statistical Analyses

3. Results and Discussion

3.1. Composition

3.2. Ripening Parameters

3.3. Volatile Compounds

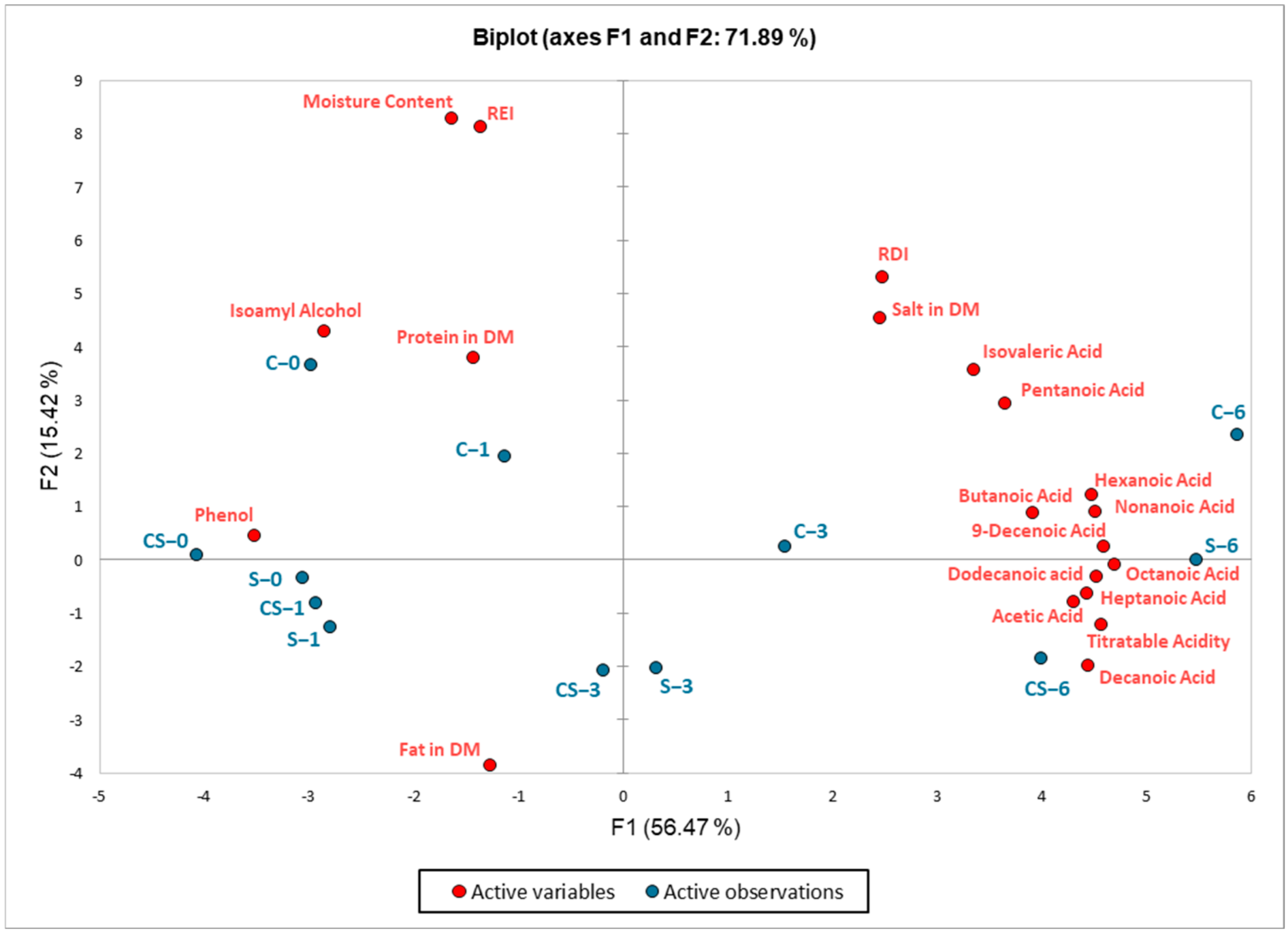

3.4. Principle Component Analysis (PCA)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hayaloglu, A.A.; Ozer, B.H.; Fox, P.F. Cheeses of Turkey: 2. Varieties ripened under brine. Dairy Sci. Technol. 2008, 88, 225–244. [Google Scholar] [CrossRef]

- Dagdelen, S.; Bilenler, T.; Durmaz, G.; Gokbulut, I.; Hayaloglu, A.A.; Karabulut, I. Volatile composition, antioxidant and antimicrobial activities of herbal plants used in the manufacture of van herby (OTLU) cheese. J. Food Process. Preserv. 2014, 38, 1716–1725. [Google Scholar] [CrossRef]

- Güler, Z.; Türkmen, D.; Dursun, A. Different scalding duration in hot whey influencing chemical, biochemical, physical, microstructural, textural and sensorial characteristics of brine-type cheese. LWT—Food Sci. Technol. 2021, 145, 111312. [Google Scholar] [CrossRef]

- Yasar, D.; Erim Kose, Y.; Kose, S. Kinetic modeling of macroelement concentration of Malatya cheese produced by traditional method. J. Food Process. Preserv. 2021, 45, e16021. [Google Scholar] [CrossRef]

- Kose, S.; Ceylan, M.M.; Altun, I.; Erim Kose, Y. Determination of some basic properties of traditional Malatya cheese. Food Sci. Technol. 2022, 42, e03921. [Google Scholar] [CrossRef]

- Hayaloglu, A.A.; Deegan, K.C.; McSweeney, P.L.H. Effect of milk pasteurization and curd scalding temperature on proteolysis in Malatya, a Halloumi-type cheese. Dairy Sci. Technol. 2010, 90, 99–109. [Google Scholar] [CrossRef]

- Hayaloglu, A.A.; Karatekin, B.; Gurkan, H. Thermal stability of chymosin or microbial coagulant in the manufacture of Malatya, a Halloumi type cheese: Proteolysis, microstructure and functional properties. Int. Dairy J. 2014, 38, 136–144. [Google Scholar] [CrossRef]

- Hayaloglu, A.A.; Karabulut, I. Characterization and comparison of free fatty acid profiles of eleven varieties of turkish cheeses. Int. J. Food Prop. 2013, 16, 1407–1416. [Google Scholar] [CrossRef]

- Hayaloglu, A.A.; Karabulut, I. Primary and secondary proteolysis in eleven Turkish cheese varieties. Int. J. Food Prop. 2013, 16, 1663–1675. [Google Scholar] [CrossRef]

- Hayaloglu, A.A.; Karabulut, I. SPME/GC-MS characterization and comparison of volatiles of eleven varieties of Turkish cheeses. Int. J. Food Prop. 2013, 16, 1630–1653. [Google Scholar] [CrossRef]

- AOAC. Loss on Drying (Moisture) in Cheese; AOAC International: Gaithersburg, MD, USA, 2012. [Google Scholar]

- AOAC. Fat Content of Raw and Pasteurized Whole Milk, Gerber Method by Weight; AOAC International: Gaithersburg, MD, USA, 2012. [Google Scholar]

- Funke-Gerber Laboratory Catalogue for Milk Analysis. Available online: https://egelaborsis.com/wp-content/uploads/2020/02/FUNKE-GERBER-CATALOG.pdf (accessed on 25 June 2025).

- AOAC International. Determination of Nitrogen (Total) in Cheese, Kjeldahl Method, Official Method 2001.14. In Official Methods of Analysis of AOAC International; Latimer, G.W., Jr., Ed.; AOAC International: Gaithersburg, MD, USA, 2012. [Google Scholar]

- AOAC. Ash of Cheese; AOAC International: Gaithersburg, MD, USA, 2012. [Google Scholar]

- ISO 5943:2006 (IDF 88:2006); ISO-IDF Cheese and Processed Cheese Products—Determination of Chloride Content—Potentiometric Titration Method. ISO International Organization for Standardization: Geneva, Switzerland, 2006.

- AOAC. Acidity of Milk, Titrimetric Method; AOAC International: Gaithersburg, MD, USA, 2012. [Google Scholar]

- Bütikofer, U.; Rüegg, M.; Ardö, Y. Determination of Nitrogen Fractions in Cheese: Evaluation of a Collaborative Study. LWT—Food Sci. Technol. 1993, 26, 271–275. [Google Scholar] [CrossRef]

- Pereira, C.I.; Gomes, E.O.; Gomes, A.M.P.; Malcata, F.X. Proteolysis in model Portuguese cheeses: Effects of rennet and starter culture. Food Chem. 2008, 108, 862–868. [Google Scholar] [CrossRef] [PubMed]

- Salum, P.; Erbay, Z.; Kelebek, H.; Selli, S. Optimization of Headspace Solid-Phase Microextraction with Different Fibers for the Analysis of Volatile Compounds of White-Brined Cheese by Using Response Surface Methodology. Food Anal. Methods 2017, 10, 1956–1964. [Google Scholar] [CrossRef]

- Ertekin, M.; Uğurlu, Ö.; Salum, P.; Erbay, Z. Effects of milk types used in Antep cheese production on some cheese organoleptic quality parameters and brine composition during 5-month ripening. J. Food Sci. 2023, 88, 1445–1465. [Google Scholar] [CrossRef]

- Akın, N.; Aydemir, S.; Koçak, C.; Yıldız, M.A. Changes of free fatty acid contents and sensory properties of white pickled cheese during ripening. Food Chem. 2003, 80, 77–83. [Google Scholar] [CrossRef]

- Polychroniadou, A.; Michaelidou, A.; Paschaloudis, N. Effect of time, temperature and extraction method on the trichloroacetic acid-soluble nitrogen of cheese. Int. Dairy J. 1999, 9, 559–568. [Google Scholar] [CrossRef]

- Michaelidou, A.; Alichanidis, E.; Polychroniadou, A.; Zerfiridis, G. Migration of water-soluble nitrogenous compounds of Feta cheese from the cheese blocks into the brine. Int. Dairy J. 2005, 15, 663–668. [Google Scholar] [CrossRef]

- Barac, M.; Pesic, M.; Zilic, S.; Smiljanic, M.; Sredovic Ignjatovic, I.; Vucic, T.; Kostic, A.; Milincic, D. The Influence of Milk Type on the Proteolysis and Antioxidant Capacity of White-Brined Cheese Manufactured from High-Heat-Treated Milk Pretreated with Chymosin. Foods 2019, 8, 128. [Google Scholar] [CrossRef]

- Niro, S.; Succi, M.; Tremonte, P.; Sorrentino, E.; Coppola, R.; Panfili, G.; Fratianni, A. Evolution of free amino acids during ripening of Caciocavallo cheeses made with different milks. J. Dairy Sci. 2017, 100, 9521–9531. [Google Scholar] [CrossRef]

- Tagliazucchi, D.; Martini, S.; Shamsia, S.; Helal, A.; Conte, A. Biological activities and peptidomic profile of in vitro-digested cow, camel, goat and sheep milk. Int. Dairy J. 2018, 81, 19–27. [Google Scholar] [CrossRef]

- Pappa, E.C.; Kandarakis, I.; Anifantakis, E.M.; Zerfiridis, G.K. Influence of types of milk and culture on the manufacturing practices, composition and sensory characteristics of Teleme cheese during ripening. Food Control 2006, 17, 570–581. [Google Scholar] [CrossRef]

- Öner, Z.; Saridağ, A.M. Proteolysis in the beyaz (White) cheese produced from various milk. Tarim Bilim. Derg. 2018, 24, 269–277. [Google Scholar] [CrossRef]

- Collins, Y.F.; McSweeney, P.L.H.; Wilkinson, M.G. Lipolysis and free fatty acid catabolism in cheese: A review of current knowledge. Int. Dairy J. 2003, 13, 841–866. [Google Scholar] [CrossRef]

- Yvon, M.; Rijnen, L. Cheese flavour formation by amino acid catabolism. Int. Dairy J. 2001, 11, 185–201. [Google Scholar] [CrossRef]

- Curioni, P.M.G.; Bosset, J.O. Key odorants in various cheese types as determined by gas chromatography-olfactometry. Int. Dairy J. 2002, 12, 959–984. [Google Scholar] [CrossRef]

| Cow Milk (%) | Sheep Milk (%) | p-Value | |

|---|---|---|---|

| Dry Matter (%) | 10.12 ± 0.01 | 15.38 ± 0.08 | 0.000 |

| Protein (%) | 3.55 ± 0.17 | 5.25 ± 0.24 | 0.015 |

| Fat (%) | 2.25 ± 0.07 | 4.85 ± 0.07 | 0.001 |

| Ash (%) | 0.81 ± 0.04 | 1.05 ± 0.14 | 0.147 |

| Titratable acidity (%) | 0.200 ± 0.004 | 0.188 ± 0.003 | 0.073 |

| Day | Moisture (%) | Protein (%) | Fat (%) | Ash (%) | Salt (%) | pH | |

|---|---|---|---|---|---|---|---|

| CC | 0 | 52.29 ± 0.29 b,B | 18.35 ± 0.21 a,B | 14.53 ± 0.42 a,A | 14.13 ± 0.08 a,C | 12.52 ± 0.15 a,B | 6.62 ± 0.02 c,B |

| 30 | 51.53 ± 0.22 ab,A | 18.16 ± 0.21 a,B | 14.37 ± 0.32 a,A | 15.54 ± 0.22 b,B | 14.16 ± 0.25 b,B | 6.58 ± 0.04 c,A | |

| 90 | 51.37 ± 0.41 a,B | 17.98 ± 0.43 a,AB | 14.67 ± 0.29 a,A | 15.59 ± 0.03 b,C | 14.27 ± 0.35 b,B | 6.45 ± 0.02 b,A | |

| 180 | 51.09 ± 0.05 a,A | 18.10 ± 0.24 a,AB | 14.50 ± 0.50 a,A | 15.79 ± 0.13 b,C | 14.42 ± 0.17 b,B | 6.37 ± 0.02 a,A | |

| CCS | 0 | 50.53 ± 0.04 a,A | 19.06 ± 0.24 a,C | 17.67 ± 0.29 a,B | 11.79 ± 0.22 a,A | 10.04 ± 0.00 a,A | 6.62 ± 0.02 c,B |

| 30 | 49.89 ± 0.17 a,A | 18.96 ± 0.25 a,C | 17.50 ± 0.50 a,B | 13.28 ± 0.08 b,A | 11.98 ± 0.06 b,A | 6.60 ± 0.06 bc,A | |

| 90 | 49.40 ± 0.34 a,A | 19.06 ± 0.44 a,B | 17.33 ± 0.58 a,B | 14.03 ± 0.16 c,B | 12.58 ± 0.17 c,A | 6.47 ± 0.06 ab,A | |

| 180 | 49.01 ± 1.07 a,A | 18.95 ± 0.41 a,B | 17.67 ± 0.29 a,B | 14.22 ± 0.19 c,B | 12.65 ± 0.28 c,A | 6.35 ± 0.04 a,A | |

| CS | 0 | 50.74 ± 0.32 a,A | 17.54 ± 0.20 a,A | 18.27 ± 0.25 a,B | 12.57 ± 0.09 a,B | 10.92 ± 0.83 a,A | 6.54 ± 0.01 c,A |

| 30 | 50.11 ± 0.85 a,A | 17.48 ± 0.10 a,A | 18.40 ± 0.36 a,B | 13.59 ± 0.07 b,A | 12.16 ± 0.08 ab,A | 6.52 ± 0.02 bc,A | |

| 90 | 49.82 ± 0.09 a,A | 17.53 ± 0.32 a,A | 18.47 ± 0.50 a,B | 13.54 ± 0.10 bc,A | 12.30 ± 0.39 b,A | 6.43 ± 0.03 ab,A | |

| 180 | 49.57 ± 0.90 a,A | 17.61 ± 0.12 a,A | 18.67 ± 0.29 a,B | 13.77 ± 0.06 c,A | 12.54 ± 0.13 b,A | 6.36 ± 0.05 a,A | |

| BC | 0 | 77.45 ± 0.57 w,W | 0.08 ± 0.01 w,W | - | 20.62 ± 0.05 y,W | 19.89 ± 0.16 w,W | 6.80 ± 0.03 z,X |

| 30 | 77.40 ± 0.55 w,W | 0.33 ± 0.01 x,W | - | 20.44 ± 0.15 xy,W | 19.65 ± 0.32 w,W | 6.49 ± 0.05 y,X | |

| 90 | 77.46 ± 0.13 w,W | 0.49 ± 0.03 y,W | - | 20.220.12 x,W | 19.40 ± 0.30 w,W | 6.17 ± 0.05 x,X | |

| 180 | 77.66 ± 0.14 w,W | 0.61 ± 0.01 z,W | - | 19.72 ± 0.09 w,W | 19.07 ± 0.50 w,W | 5.81 ± 0.01 w,W | |

| BCS | 0 | 77.79 ± 0.36 w,W | 0.07 ± 0.01 w,W | - | 20.84 ± 0.06 y,X | 20.13 ± 0.13 x,W | 6.49 ± 0.06 y,w |

| 30 | 77.74 ± 0.52 w,W | 0.61 ± 0.04 x,X | - | 20.45 ± 0.03 xy,W | 19.75 ± 0.19 wx,W | 6.28 ± 0.04 x,W | |

| 90 | 78.23 ± 0.54 w,W | 0.80 ± 0.01 y,X | - | 20.05 ± 0.27 wx,W | 19.38 ± 0.28 wx,W | 6.02 ± 0.06 w,W | |

| 180 | 78.34 ± 0.35 w,W | 0.82 ± 0.01 y,X | - | 19.88 ± 0.12 w,W | 19.17 ± 0.41 w,W | 5.94 ± 0.01 w,X | |

| BS | 0 | 77.26 ± 0.85 w,W | 0.07 ± 0.01 w,W | - | 20.84 ± 0.08 y,X | 20.14 ± 0.31 x,W | 6.68 ± 0.04 z,X |

| 30 | 77.91 ± 0.71 w,W | 0.73 ± 0.02 x,Y | - | 20.45 ± 0.08 x,W | 19.76 ± 0.15 wx,W | 6.42 ± 0.03 y,X | |

| 90 | 77.79 ± 0.44 w,W | 0.87 ± 0.01 y,Y | - | 20.08 ± 0.13 w,W | 19.50 ± 0.27 w,W | 6.23 ± 0.03 x,X | |

| 180 | 77.91 ± 0.21 w,W | 0.98 ± 0.02 z,Y | - | 19.86 ± 0.08 w,W | 19.29 ± 0.14 w,W | 6.01 ± 0.01 w,Y |

| Day | Titratable Acidity (%) | TN (%) | WSN (%) | TCA-SN (%) | REI (%) | RDI (%) | |

|---|---|---|---|---|---|---|---|

| CC | 0 | 0.130 ± 0.022 a,A | 2.88 ± 0.03 a,B | 0.356 ± 0.005 d,C | 0.092 ± 0.002 c,B | 12.37 | 3.21 |

| 30 | 0.188 ± 0.014 a,A | 2.87 ± 0.03 a,B | 0.241 ± 0.003 c,C | 0.064 ± 0.001 b,C | 8.40 | 2.25 | |

| 90 | 0.497 ± 0.030 b,B | 2.82 ± 0.07 a,AB | 0.170 ± 0.003 a,B | 0.047 ± 0.001 a,A | 6.03 | 1.66 | |

| 180 | 0.583 ± 0.049 c,A | 2.84 ± 0.04 a,AB | 0.215 ± 0.010 b,C | 0.090 ± 0.010 c,A | 7.58 | 3.17 | |

| CCS | 0 | 0.146 ± 0.006 a,A | 2.99 ± 0.01 a,C | 0.231 ± 0.003 c,B | 0.061 ± 0.005 b,A | 7.73 | 2.06 |

| 30 | 0.209 ± 0.006 a,A | 2.97 ± 0.04 a,C | 0.180 ± 0.004 b,B | 0.055 ± 0.001 ab,B | 6.07 | 1.84 | |

| 90 | 0.355 ± 0.036 b,A | 2.99 ± 0.07 a,B | 0.147 ± 0.010 a,A | 0.044 ± 0.003 a,A | 4.94 | 1.46 | |

| 180 | 0.462 ± 0.047 c,A | 2.97 ± 0.06 a,B | 0.141 ± 0.008 a,A | 0.083 ± 0.006 c,A | 4.76 | 2.80 | |

| CS | 0 | 0.165 ± 0.006 a,A | 2.75 ± 0.03 a,A | 0.204 ± 0.007 c,A | 0.066 ± 0.006 b,A | 7.42 | 2.39 |

| 30 | 0.199 ± 0.006 a,A | 2.74 ± 0.02 a,A | 0.162 ± 0.005 b,A | 0.042 ± 0.002 a,A | 5.90 | 1.54 | |

| 90 | 0.361 ± 0.039 b,A | 2.75 ± 0.05 a,A | 0.139 ± 0.006 a,A | 0.039 ± 0.003 a,A | 5.07 | 1.42 | |

| 180 | 0.498 ± 0.025 c,A | 2.76 ± 0.02 a,A | 0.172 ± 0.005 b,B | 0.103 ± 0.014 c,A | 6.23 | 3.72 |

| Day | Isoamyl Alcohol | Acetic Acid | Butanoic Acid | Isovaleric Acid | Pentanoic Acid | Hexanoic Acid | Phenylethyl Alcohol | |

|---|---|---|---|---|---|---|---|---|

| 1231 | 1445 | 1630 | 1672 | 1731 | 1843 | 1890 | ||

| CC | 0 | 86.5 ± 1.8 c | ND | 147.2 ± 0.5 a,B | ND | ND | 337.0 ± 42.2 a,B | ND |

| 30 | 56.7 ± 0.3 b | ND | 200.6 ± 8.6 b,B | ND | ND | 867.7 ± 15.1 c,C | ND | |

| 90 | 31.6 ± 0.8 a | 42.1 ± 1.7 C | 188.4 ± 14.4 b,B | ND | ND | 676.2 ± 82.6 b,B | ND | |

| 180 | ND | 39.7 ± 0.5 B | 235.8 ± 4.3 c,A | 91.2 ± 2.1 | 6.55 ± 0.19 | 1390.2 ± 3.1 d,A | ND | |

| CCS | 0 | 112.8 ± 1.0 | ND | 116.2 ± 2.9 a,A | ND | ND | 223.5 ± 27.5 a,A | ND |

| 30 | 71.8 ± 1.3 | ND | 106.9 ± 6.3 a,A | ND | ND | 272.6 ± 10.9 a,B | ND | |

| 90 | ND | 26.8 ± 2.3 B | 207.2 ± 29.8 b,B | ND | ND | 420.0 ± 55.7 b,A. | ND | |

| 180 | ND | 28.6 ± 0.6 A | 294.2 ± 28.1 c,A | ND | ND | 1461.7 ± 207.8 c,A | ND | |

| CS | 0 | ND | ND | 104.1 ± 11.6 a,A | ND | ND | 147.2 ± 10.6 a,A | ND |

| 30 | ND | ND | 86.9 ± 3.76 a,A | ND | ND | 198.9 ± 10.4 a,A | ND | |

| 90 | ND | 13.3 ± 0.6 A | 107.0 ± 2.7 a,A | ND | ND | 414.3 ± 15.3 b,A | ND | |

| 180 | ND | 36.9 ± 4.7 AB | 228.6 ± 25.5 b,A | 36.6 ± 2.4 | 5.73 ± 0.03 | 1705.4 ± 189.6 c,A | ND | |

| BC | 0 | 13.8 ± 0.6 w | 1.48 ± 0.00 w | 2.57 ± 0.04 w | ND | ND | 4.87 ± 0.62 w,X | 3.66 ± 0.58 w |

| 30 | 13.3 ± 0.7 w | 1.76 ± 0.14 w | 6.27 ± 0.47 x | ND | ND | 30.0 ± 0.9 x,Y | 3.72 ± 0.51 w | |

| 90 | 27.0 ± 0.1 x | 2.92 ± 0.01 x,W | 17.2 ± 0.1 y,X | ND | ND | 117.1 ± 4.4 y,X | 4.14 ± 0.06 w | |

| 180 | 25.9 ± 0.2 x | 4.46 ± 0.34 y,X | 38.9 ± 0.3 z,Y | 14.5 ± 0.2 X | ND | 268.9 ± 12.8 z,W | 6.66 ± 0.12 x | |

| BCS | 0 | 12.0 ± 0.8 w | 1.44 ± 0.04 w | 3.01 ± 0.06 w | ND | ND | 4.87 ± 0.46 w,X | 2.05 ± 0.02 w |

| 30 | 18.3 ± 1.2 x | 1.67 ± 0.12 w | 6.06 ± 0.10 x | ND | ND | 27.6 ± 0.1 x,X | 2.03 ± 0.04 w | |

| 90 | 33.3 ± 2.0 y | 2.54 ± 0.16 x,W | 18.7 ± 0.6 y,X | 6.52 ± 0.05 | ND | 113.2 ± 8.0 y,X | 2.57 ± 0.12 x | |

| 180 | 33.5 ± 0.2 y | 5.69 ± 0.39 y,Y | 35.8 ± 0.9 z,X | 25.6 ± 1.1 Y | ND | 249.1 ± 11.2 z,W | 3.35 ± 0.15 y | |

| BS | 0 | ND | ND | ND | ND | ND | 0.65 ± 0.01 w,W | ND |

| 30 | ND | ND | ND | ND | ND | 5.65 ± 0.16 w,W | ND | |

| 90 | ND | 3.41 ± 0.49 W | 10.4 ± 1.1 W | ND | ND | 88.1 ± 9.6 x,W | ND | |

| 180 | ND | 3.00 ± 0.01 W | 23.4 ± 0.1 W | 7.20 ± 0.62 W | ND | 250.4 ± 12.7 y,W | ND |

| Day | Heptanoic Acid | Phenol | Octanoic Acid | Nonanoic Acid | Decanoic Acid | 9-Decenoic Acid | Dodecanoic Acid | |

|---|---|---|---|---|---|---|---|---|

| 1934 | 1996 | 2072 | 2161 | 2274 | 2337 | 2492 | ||

| CC | 0 | ND | 32.1 ± 4.5 bc,A | 268.5 ± 38.3 a,B | ND | 161.0 ± 4.7 a,C | ND | 15.2 ± 0.2 a |

| 30 | ND | 34.6 ± 1.8 c,A | 833.3 ± 36.6 b,B | 22.8 ± 1.4 a | 414.1 ± 15.6 b,C | ND | 51.4 ± 3.2 b | |

| 90 | 30.3 ± 4.8 | 21.3 ± 6.5 ab,A | 1195.7 ± 0.5 c,C | 24.4 ± 0.9 a | 755.0 ± 30.3 c,A | 49.9 ± 4.2 C | 71.7 ± 3.2 b,B | |

| 180 | 39.9 ± 2.5 A | 18.9 ± 2.1 a,A | 2370.9 ± 34.3 d,A | 40.4 ± 2.1 b,AB | 1333.4 ± 183.0 d,A | 110.3 ± 6.0 B | 138.1 ± 18.3 c,B | |

| CCS | 0 | ND | 49.8 ± 2.9 b,B | 137.8 ± 8.2 a,A | ND | 114.7 ± 3.9 a,A | ND | ND |

| 30 | ND | 27.8 ± 2.4 a,A | 305.0 ± 11.8 a,A | ND | 181.7 ± 2.2 a,A | ND | ND | |

| 90 | 20.9 ± 2.9 | 23.4 ± 2.8 a,A | 754.2 ± 24.8 b,A | ND | 699.0 ± 76.0 b,A | 23.3 ± 2.0 A | 46.9 ± 4.4 A | |

| 180 | 46.0 ± 4.8 A | 24.1 ± 2.1 a,A | 2434.9 ± 265.4 c,A | 35.7 ± 3.1 A | 1878.9 ± 117.9 c,AB | 73.2 ± 3.1 A | 128.1 ± 3.3 AB | |

| CS | 0 | ND | 50.2 ± 2.5 b,B | 149.6 ± 0.7 a,A | ND | 140.9 ± 0.5 a,B | ND | ND |

| 30 | ND | 48.7 ± 3.1 b,B | 259.2 ± 7.1 a,A | ND | 245.1 ± 20.9 a,B | ND | ND | |

| 90 | ND | 16.8 ± 2.6 a,A | 1007.2 ± 59.3 b,B | 22.2 ± 0.1 | 1229.5 ± 111.5 b,B | 33.9 ± 2.6 B | 100.8 ± 8.1 C | |

| 180 | 40.2 ± 2.0 A | 21.8 ± 0.4 a,A | 3048.8 ± 423.8 c,A | 43.4 ± 1.6 B | 2232.5 ± 270.2 c,B | 63.2 ± 5.0 A | 100.7 ± 6.6 A | |

| BC | 0 | ND | ND | 18.2 ± 0.5 w,X | 2.38 ± 0.10 w | 19.9 ± 0.4 w,X | 2.49 ± 0.09 w | 16.5 ± 0.62 wx |

| 30 | ND | ND | 86.8 ± 5.0 x,Y | 4.57 ± 0.21 w | 101.9 ± 14.9 x,Y | 3.87 ± 0.02 x | 13.2 ± 0.71 w | |

| 90 | 6.42 ± 0.45 | ND | 261.5 ± 3.9 y,Y | 7.16 ± 0.25 x,X | 158.7 ± 6.4 y,W | 11.6 ± 0.2 y,Y | 19.3 ± 0.10 x | |

| 180 | 9.40 ± 0.08 | ND | 454.3 ± 2.9 z,X | 7.24 ± 0.19 x,X | 187.6 ± 9.4 z,W | 13.0 ± 0.2 z,X | 35.7 ± 2.74 y | |

| BCS | 0 | ND | ND | 21.7 ± 1.2 w,Y | 2.37 ± 0.05 w | 42.3 ± 1.62 w,Y | ND | ND |

| 30 | ND | ND | 59.7 ± 5.2 x,X | 2.51 ± 0.02 w | 78.3 ± 3.7 x,X | ND | ND | |

| 90 | 4.68 ± 0.26 | ND | 245.1 ± 6.0 y,X | 4.59 ± 0.42 x,W | 232.3 ± 22.0 y,X | 8.44 ± 0.33 X | ND | |

| 180 | 6.83 ± 0.51 | ND | 397.5 ± 9.7 z,W | 5.53 ± 0.09 y,W | 340.2 ± 44.0 z,X | 9.88 ± 0.99 W | ND | |

| BS | 0 | ND | 1.65 ± 0.04 w | 4.81 ± 0.33 w,W | ND | 9.05 ± 0.24 w,W | ND | ND |

| 30 | ND | 1.98 ± 0.04 x | 20.2 ± 0.9 x,W | ND | 43.2 ± 6.8 x,W | ND | ND | |

| 90 | ND | 2.81 ± 0.09 y | 183.3 ± 8.9 y,W | 4.22 ± 0.71 W | 202.2 ± 16.0 y,WX | 5.51 ± 0.35 W | 13.5 ± 0.78 | |

| 180 | ND | 3.07 ± 0.06 z | 543.9 ± 8.7 z,Y | 7.14 ± 0.53 X | 304.1 ± 5.12 z,X | 9.85 ± 1.01 W | 16.0 ± 1.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aydoğan, E.; Ayrancı, V.K.; Salum, P.; Erbay, Z. Impact of Different Milk Types and Storage Period on the Quality Characteristics of Malatya Cheese. Dairy 2025, 6, 30. https://doi.org/10.3390/dairy6040030

Aydoğan E, Ayrancı VK, Salum P, Erbay Z. Impact of Different Milk Types and Storage Period on the Quality Characteristics of Malatya Cheese. Dairy. 2025; 6(4):30. https://doi.org/10.3390/dairy6040030

Chicago/Turabian StyleAydoğan, Erçin, Vasıf Kubilay Ayrancı, Pelin Salum, and Zafer Erbay. 2025. "Impact of Different Milk Types and Storage Period on the Quality Characteristics of Malatya Cheese" Dairy 6, no. 4: 30. https://doi.org/10.3390/dairy6040030

APA StyleAydoğan, E., Ayrancı, V. K., Salum, P., & Erbay, Z. (2025). Impact of Different Milk Types and Storage Period on the Quality Characteristics of Malatya Cheese. Dairy, 6(4), 30. https://doi.org/10.3390/dairy6040030