Abstract

Dairy proteins are potential and multipurpose ingredients used to prepare various food products. It exhibits many beneficial functionalities and bioactivities in the processing of food products. All the functionalities of different dairy proteins depend on their peculiar structural characteristics. So, the present study aimed to characterize high-protein powders with different matrices (milk protein concentrate (MPC), rennet casein (RCN), micellar casein concentrate (MCC), whey protein isolate (WPI), and native whey concentrate (NWC)) for their composition, handling, and reconstitution properties, and microstructure and compared them with whole milk powder (WMP) and skim milk powder (SMP). The bulk density of the high-protein powders was significantly (p < 0.05) lower than WMP and NFDM. Due to the low bulk density of the high-protein powders, the wettability of these powders in the water was very high. Microstructural analysis of powders by scanning electron microscopy reveals that the high-protein powder had tetrahedron-to-polyhedron-shaped particles depending on the protein level. The idea regarding the powder’s morphology might be helpful for further improvement in the production processes to modify the functional properties of high-protein milk powders.

1. Introduction

Dairy proteins are crucial in diverse food products due to their various functionalities and bioactivities. The dairy protein global market size was valued at USD 11 billion (in 2021) which reached USD 14 billion (in 2022) and is projected to grow at a compound annual growth rate (CAGR) of 5.95% to reach USD 19 billion by 2028 [1]. Consumers seek health and wellness, driving the high-protein dairy market [2]. Milk proteins are particularly significant in providing functional properties and forming the structural network of almost all dairy and food products. Milk proteins are essential for numerous food applications with water-binding, viscosity, gelation, emulsifying, and foaming properties. Moreover, processing techniques, such as heat treatment, concentration (evaporation and membrane processing), and drying can impact the functionality of milk proteins in food products [3,4].

Technological, engineering, research, and development efforts have been made to understand the factors that impact the functional properties of milk proteins, leading to the production of milk protein products specifically tailored for various applications. The developmental approaches for manufacturing milk-protein-enriched ingredients can be broadly categorized into three groups: (1) ingredients with a normal ratio of milk constituents, such as skimmed milk powder (SMP) and non-fat dry milk (NFDM), which are fat-free, and whole milk powder (WMP) and full cream milk powder (FCMP), which have milk fat; (2) whey-protein-rich ingredients, such as whey protein concentrate (WPC), whey protein isolate (WPI), and native whey concentrate (NWC); and (3) casein-rich ingredients, such as rennet casein (RCN), milk protein concentrate (MPC), micellar casein concentrate (MCC), milk protein isolate (MPI), and acid casein. Other categories like fat-only (cream, anhydrous milk fat (AMF), and butter oil) and lactose-only (lactose powder and deproteinized whey powder) products are also available. Furthermore, treated and modified powders, such as calcium caseinate-, sodium caseinate-, hydrolysate-, and α-lactalbumin-rich powders are also available. Generally, high-protein dairy powders are produced by spray-drying for ease of usage, longer shelf-life, and ease of storage and transport.

Manufacturing high-protein dairy powder involves several fundamental principles: separation or fractionation, concentration, and drying. Different fractionation or crude separation methods are utilized to obtain individual milk-protein fractions, including enzymatic, acidification, chromatographic techniques, and ion exchange. Each manufacturing technique yields a product with unique constituents and functionalities. The membrane separation process is widely used for large-scale fractionation or separation of individual components due to its cost-effectiveness, efficiency, and eco-friendliness. As a result, well-defined fractions are created, which can be optimally utilized for their functional properties and health benefits in various applications. With advancements in membrane filtration technology, new products are continually being developed using either a single process or a combination of processes [5,6]. The primary protein fractions in milk (casein and serum) can be directly separated by filtration, creating highly nutritious and distinct functional protein streams: micellar casein and milk-derived whey protein [7]. The casein-rich ingredients (MPC and MCC) are preferred in low-acid ingredients, whereas whey protein-rich ingredients are preferred in high-acid beverages [2]. Because of the ingredients’ separation or fractionation and concentration, many high-protein powders have altered fat-to-protein or casein-to-total-protein or protein-to-total-solids ratio in the finished product compared to regular milk, which has an impact on microstructure and functionality.

Due to their modified constituents, these high-protein powders exhibit distinct functionalities and behaviors in the products they are incorporated into. The powders’ particle size, microstructure, reconstitution properties, and flow characteristics are closely linked to their final quality, which is determined by the raw materials, processing conditions, and drying equipment employed. The powders’ surface composition is anticipated to significantly impact their end use and functionality [8]. High-protein dairy powders are characterized by poor solubility, wettability, flowability, etc. [9,10,11,12,13]. The hydration and rehydration of these high-protein powders is a big issue [11,14,15,16,17]. Complete wetting, dispersion, solubility, and dissolution in water is necessary for exhibiting the full functional properties and characteristics.

Microstructural differences can have a significant impact on quality, functionality, handling and reconstitution properties, and cost-related issues. Investigating and comprehending such disparities can be advantageous for research and development and the development of new products using milk powders. Examining micro-level structures uncovers the interactions, aggregations, networks, and complexes formed between dairy constituents and additives, which can impact the physical and sensory attributes of the product [18]. The manufacturing process largely governs the microstructure of dairy products; however, the microstructure also determines specific properties, such as viscosity, syneresis, firmness, and mouthfeel [19]. This information can be utilized to relate the effects of the manufacturing process to the properties of the products. Optical and electron microscopic techniques can be instrumental in comprehending the spatial distribution of components in complex multiphase systems, enabling an understanding of the physical and chemical properties of the material [20].

Solid particles with distinct powder surfaces are formed from liquid-milk feed droplets during drying. A milk powder particle typically comprises amorphous lactose and other constituents with embedded fat globules, casein micelles, and serum proteins. These particles also contain vacuoles filled with enclosed air, where the surfaces of the particles do not touch. The shape of powder particles is influenced by the type of raw material, degree of heat treatment, and other compositional and processing parameters [21]. The formation of the surface of powder particles is thought to occur through three mechanisms: crust/skin formation during drying, solid/solute segregation during drying, and protein adsorption on an air/liquid interface during atomization [22].

The most commonly used technique for dried milk powders to study the microstructure is scanning electron microscopy (SEM) [18,23,24,25]. Other techniques, such as transmission electron and atomic force microscopy, have been used. However, the techniques depend on the goals to be reached [25] and what needs to be viewed. SEM works on the principle of an electron beam interacting with a sample specimen and generating signals, which can be used to generate the image [24]. The three-dimensional structure exhibited by SEM helps characterize ingredients’ physical and textural properties [26]. In addition, sputter coating with gold/palladium increases the clarity and sharpness of the microscopic images as it reduces the charging effect.

There is no clear definition of high-protein dairy powders. The type of product and processing techniques used determines the protein content and other constituents in the dairy powders, which decides their functionality and usage. Generally, WMP and FCMP have 23.0–26.0%; SMP and NFDM have 33.0–37.0%; MPC and WPC have 34–85%; rennet casein powder has 80–82%; and MCC, MPI, and WPI have 85–92% total protein in the powders. The functionality and usage of these powders have been discussed elsewhere [5,7,27,28]. There is insufficient literature comparing the microscopic features of various high-protein powders. Therefore, the goal of this study was to elucidate the microstructure of high-protein dairy powders with distinct matrices, including regular powders (such as fresh and stored WMP and SMP), high casein-rich powders (such as RCN, MPC, and MCC), and high-whey protein-rich powders (such as WPI and NWC).

2. Materials and Methods

2.1. Experimental Design

Eight high-protein dairy powders with different product matrices made commercially or in a pilot plant were selected for the experiment. The powders selected were SMP, WMP (fresh and stored), RCN, WPI, NWC, MPC, and MCC. The SMP and WMP were powders with normal milk constituents, whereas RCN, MPC, and MCC were casein-rich powders. The WPI and NWC powders were whey protein-rich powders. The powders were analyzed for gross composition, handling, and reconstitution properties. To see the differences in the powder microstructure, SEM was used.

2.2. Milk Protein Powder Samples

The MPC and MCC were manufactured at the South Dakota State University, Brookings, SD, USA, from skimmed milk using ultra- and micro-filtration, respectively, and the concentrate was spray-dried. The WPI and NWC were manufactured in the pilot plant using membrane systems and spray-dried. The low-heat SMP, RCN (30 mesh size), WMP (fresh), and WMP (stored at 23 °C under atmospheric conditions for twelve months) were commercial samples.

2.3. Gross Compositional Analysis

The gross composition of the powders was analyzed using the standard methods described by Hooi et al., 2004 [29].

2.4. Handling and Reconstitution Properties

The powders were analyzed for various handling and reconstitution properties, including bulk density ((BD); loose, and tapped 10 and 100 times), compressibility index (CI), Hausner ratio (HR), and wettability. Flowability and cohesiveness can be expressed in terms of CI and HR, respectively.

The BD of the samples was measured using the procedure described by NIRO [30]. Loose bulk density (LBD) was measured by weighing a 100 mL calibrated cylinder filled with dried powder (leveled, without compacting). The LBD was calculated as powder weight (g)/powder volume (mL). The tapped bulk density (TBD) was measured on the cylinder containing the dried milk that was gently tapped 10 times (TBD10) and 100 times (TBD100). The new volume obtained after tapping (10 or 100 times) was read on the graduated cylinder, and the TBD was calculated as TBD10 or TBD100 powder weight (g)/volume of tapped powder (mL). The CI was calculated as the percentage increase from the loose bulk density to tapped bulk density: CI% = 100 × (TBD100 − LBD)/TBD100. Finally, the Hausner ratio was calculated by dividing the tapped or compressed bulk density by the loose bulk density: HR = TBD100/LBD. All the analyses were performed in duplicate.

The samples’ wettability was measured per the procedure described by NIRO [30]. 10 g of sample was measured and suspended onto the still surface of distilled water at 20 °C, and the time taken for the last particle to go into the solution was measured.

2.5. Microstructure Using SEM

The samples were prepared and observed per standard procedures [18]. A double-sided carbon (sticky small circular) tape was attached to the SEM aluminum stub. The powder was spread on the tape. To improve the clarity of images and reduce the charging effect, gold (Au) (Kurt J Lesker Company, Jefferson Hills, PA, USA) was coated (10 nm thickness) as sputtering material in the sputtering machine (CRC-150 sputtering System, Plasma Science Inc., Marlboro, NY, USA). The samples were examined using SEM (Scanning Electron Microscope, S-3400N, Hitachi Sci. Systems Ltd., Ibaraki, Japan) at 200, 100, 50, and 30 μm levels.

2.6. Statistical Analysis

All the results obtained for the handling and reconstitution properties were subjected to statistical analysis using Proc GLM of the SAS program (Version 9.2, SAS Institute, Cary, NC, USA, 2008). The means value comparisons were made at a 0.05 significance level using Fisher’s least significance difference (LSD), and the results were considered significant at p < 0.05.

3. Results and Discussion

3.1. Gross Composition, Handling, and Reconstitution Properties

The gross composition of the eight different dairy powder samples is shown in Table 1. The WMP had the highest fat and lowest protein content among the powders. The moisture content of the commercial RCN was the highest, while all other powders were below 4.3% (w/w). Whey powders (WPI and NWC) had a protein content of above 90% (w/w), whereas caseinates (RCN, MPC, and MCC) had a protein content of approximately 80% (w/w) (Table 1). As the protein content in the powders increased, the lactose content decreased, indicating removal of lactose is necessary for the manufacture of high-protein dairy powders [6].

Table 1.

Gross composition (w/w) of the powders.

Table 2 shows the bulk density and volume of the samples. The bulk density of milk powder is a critical property with economic, commercial, and functional implications. Powder density also determines container volume, packaging material requirements, and machinery selection for handling. Commercial WMP and SMP were significantly heavier (p < 0.05) than other protein-rich milk powders. The BD of WPI and NWC was the lowest, and NWC was the most voluminous among these powder samples. There was no significant difference (p < 0.05) between MCC and MPC; however, MCC’s low BD indicated its fluffier nature. Other researchers have reported that high-protein dairy powders, especially MCC, had a low loose and tap bulk density [17].

Table 2.

Bulk density, Hausner ratio, compressibility index, flowability, and wettability of the powders.

Wettability is a powder’s capability to absorb water on its surface, become wet, and penetrate the surface of still water. Wetting involves the displacement of air or voids within a powder with water. Typically, wettability depends on powder particle size, density, porosity, surface charge, surface area, the presence of amphipathic substances, and the surface activity of the particles [21]. In the present study, the wettability of SMP and fresh WMP were 10 and 18 s (Table 2), respectively, whereas the stored WMP had high wettability of 28 s. The high wettability of SMP and WMP might be due to the coverage of the surface with hygroscopic components (such as lactose). The surface composition of powders is expected to play an essential role in the wetting process. All other protein-rich samples had a wettability of more than five minutes (300 s), indicating that slower rate of wetting or solubilizing. This also indicates that mechanical action is required for mixing and solubilizing these powders. Typically, high-protein powder comprises bulky particles that result from the fusion of casein micelles via protein–protein interactions. These fused casein micelles seem to create a skin-like layer on the powder particle’s outer surface, hindering water penetration into the particle and leading to slow wetting behavior. The wettability may be an inappropriate test for casein-based powders [9] as the casein-rich powders tend to float [9,31]. However, the microstructure of particles does not have any role in wetting and sinking except for its effect on the solubilization of the components [32]. When reconstituted in water, most of these particles remain undissolved [33]. Others have reported that the wettability of protein-rich powders was greater than 180 s [17]. They observed the development of a sticky coating or clumps on the surface of the particles during wetting, which impeded water absorption by the powder particles. Furthermore, the reduced lactose content of high-protein milk powders results in lower solubility, as the presence of lactose influences the spatial arrangement of proteins.

The resistance to the flow of the powder particles to each other is referred to as flowability, which can be assessed by calculating HR and CI. High-protein powders can be classified based on HR and CI, where powders with a higher HR are more cohesive, and those with a lower CI are more flowable or free-flowing [17]. The flowability of powder is also defined as the ability of powder to flow under environmental and processing conditions [10]. The results presented in Table 2 indicate that WMP and SMP exhibited excellent flowability, which may be attributed to the presence of lactose in the powder samples. Conversely, the high-protein powders had significantly (p < 0.05) lower flowability. They were more cohesive than the low-protein powders due to strong intermolecular interactions between the protein at a reduced lactose level, leading to enhanced cohesive forces that affect flowability. Poor flowability is an issue with high-protein dairy powders [10] and particle size influences the flowability and cohesiveness of powders [17]. Flowability depends on the type and extent of interparticle interactions (van der Waals and electrostatic interactions), resulting in increased cohesive forces and reduced flowability [10]. Agglomeration can be used to mitigate the problems associated with flowability [10] and rehydration issues [16]; however, agglomeration can also result in the reduction in powder bulk density and dispersibility when rehydrated [10,16].

For determining the powder handling powder properties, such as BD, HR, CI, and flowability are essential; however, rehydration properties, like wettability, solubility, dispersibility, are critical for functional properties. Along with these properties and the challenges associated with understanding the growing varieties of dairy powders [16], the microstructural details and surface properties are also crucial for understanding the behavior of various high-protein dairy powders.

3.2. Microstructure of Powder

3.2.1. Effect of Sputtering and Non-Sputtering Samples on the Micrograph Clarity

Table 3 lists the observations on SMP and WMP samples, either with sputter coating or without it (Figure 1). Clarity and topographical details increased when sputter coating was performed. Without sputter coating, it was difficult to see the surface as the charge on the particle surface caused wrinkles that appeared as white lines. The charging effect was evident in WMP, and we were not allowed to use SEM for WMP without sputter coating. Compared to high-protein products, operating and seeing structural details in high-fat products without sputter coating was not easy. Observing samples without sputter coating can lead to artifacts and the wrong interpretations of images (Figure 1). Overall, sputter coating of the sample improved the image quality and revealed more accurate structural details.

Table 3.

Comparison and observations of sputter coating of samples.

Figure 1.

Impact of sputter coating in scanning electron microstructure of SMP at (a) no sputter coating 100 µm, (b) no sputter coating 50 µm, (c) sputter coating 100 µm, and (d) sputter coating 50 µm.

3.2.2. SMP and WMP (Fresh and Stored)

Whole milk powder is manufactured by standardizing whole milk, pasteurizing, concentrating, and drying. To improve certain properties, such as wettability or reconstitution properties, WMP is agglomerated and/or lecithinated. SMP is manufactured by separating the whole milk and following similar steps.

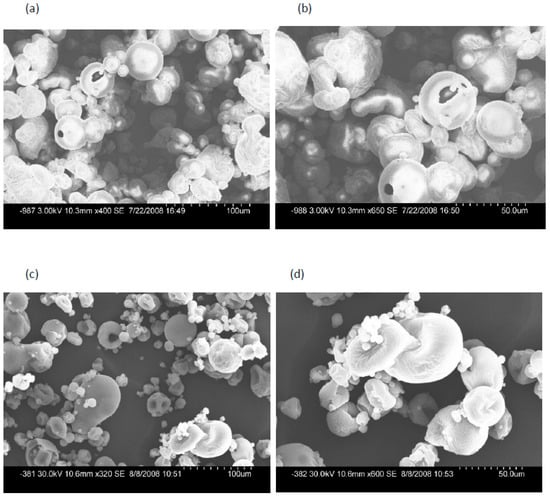

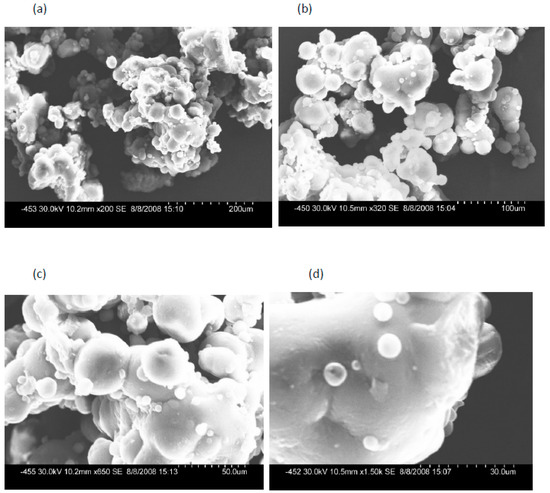

Two WMP samples were studied: one fresh (Figure 2) and the other stored at 23 °C for 12 months (Figure 3). The fresh sample consisted of spherical and fused particles, while the stored sample consisted of significantly larger particles, with many fused to form lumps. The smaller particles were attached to the larger particles, and wrinkles were visible on the surface, which appeared to be covered with a layer of fat. Even after sputter coating, the stored sample showed a charging effect. Some lactose crystals were observed in both samples, but their size increased with storage, and the larger particles fused to form even larger particles.

Figure 2.

Scanning electron microstructure of fresh WMP at (a) 200 µm, (b) 100 µm, (c) 50 µm, and (d) 30 µm.

Figure 3.

Scanning electron microstructure of stored WMP at (a) 300 µm, (b) 200 µm, (c) 100 µm, and (d) 50 µm.

The dried whole-milk particles, varying in diameter from several to tens of micrometers, displayed porous and wrinkled surfaces. Large particles contained central vacuoles that frequently housed smaller particles. The pore sizes of particles obtained from homogenized, concentrated milk differed, with most pores believed to be occupied by fat globules due to their similar dimensions. However, even spray-dried caseinate particles containing no fat were also porous. The casein contraction during spray-drying caused wrinkles on milk particle surfaces since spray-dried sodium caseinate solutions had a similar appearance [34]. In contrast, lactose-solution spray-drying produced smooth-surfaced particles. A comparison of casein micelle distribution in spray-dried and roller-dried milk powders showed individual globular entities of casein micelles in spray-dried milk but clustered and fused casein micelles in roller-dried milk [35,36]. The fat mainly covered the powder surface, even when the fat content was low [37]. It has been reported that all powders exhibited relatively high surface fat coverage, with fat globules encapsulated by proteins located preferentially beneath the surface fat [8].

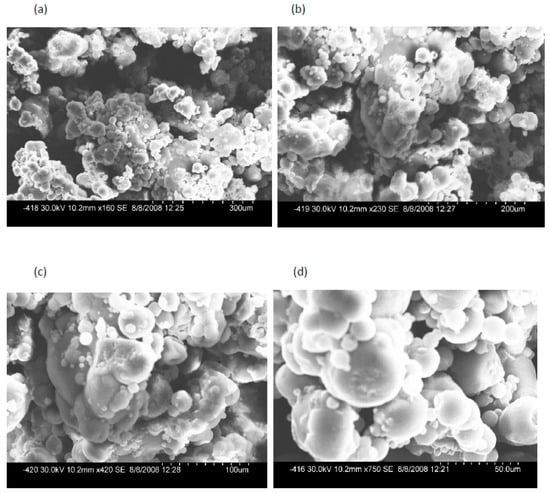

The microstructure of SMP (Figure 4) differs slightly from that of WMP, mainly due to its higher lactose content [23,38,39,40,41]. The drying temperature affects the crystallization of lactose during the drying process, which determines the powder’s microstructure. The powder surface structure becomes smoother as lactose is reduced [42]. In SMP, small prism-shaped crystals (alpha-hydrate type) are common, but in stored powder, especially high humidity or high moisture products, the crystal size increases while the number of prism-shaped particles decreases [23,42].

Figure 4.

Scanning electron microstructure of SMP at (a) 200 µm, (b) 100 µm, (c) 50 µm, and (d) 30 µm and (e) 10 µm.

Since the powders were agglomerated, the particles were stuck to each other. Our observations are similar to those made by other researchers. While observing various powder particles, Kalab [19,23] noted that there is wide variation in particle shape and that they have wrinkled surfaces and may be porous and hollow. SMP with higher lactose has more wrinkles on the surface [41]. Smaller particles may be entrapped in the big vacuole. The cause of the wrinkle surface was attributed to the contraction of casein micelles during drying [19,23,43]. The instant powder has a different structure and is defined by the processing method. The smooth or rough surface of the agglomerated powder particle is related to small or large lactose crystals, respectively, present on the surface [44]. Powder microstructure is affected by processing conditions during drying [19,23] and by the type of atomizer, which affects the size and shape of particles [44,45].

3.2.3. Casein-Rich Milk Protein Powders

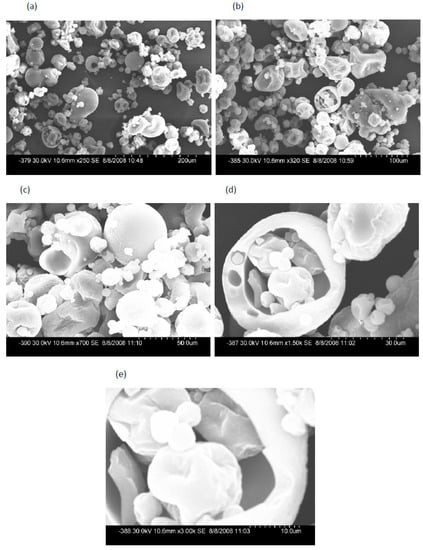

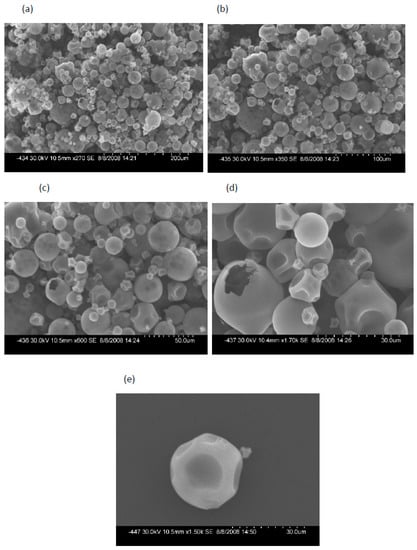

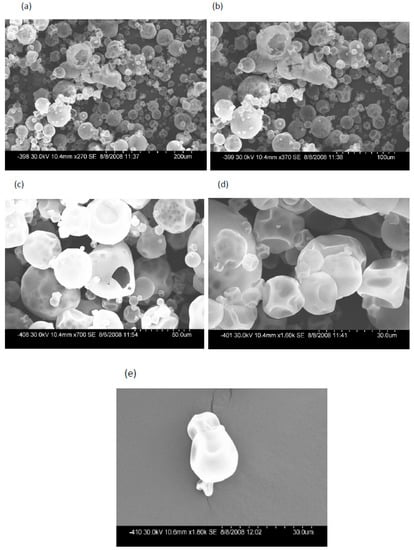

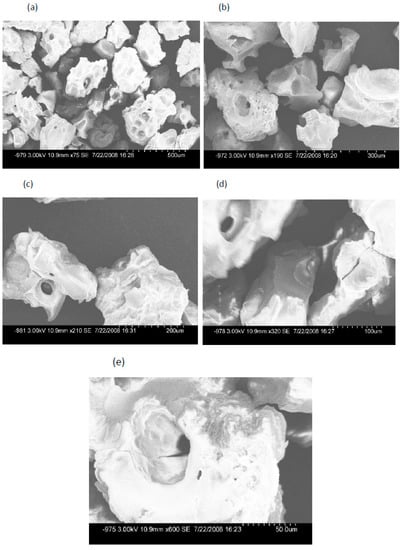

Table 3 illustrates the microstructural differences among MPC, MCC, and RCN powders; images are shown in Figure 5, Figure 6 and Figure 7, respectively. These differences are evident at various particle sizes, such as 200 microns, 100 microns, 50 microns, and 30 microns. When the samples were seen without sputter coating, there were problems in observing the topography, and the particles were misunderstood as cracked, but they were intact. The artifacts were removed once sputter coating on samples was completed. The MPC powder had bigger particles at the 200 micron level, whereas the MCC had numerous small particles. At each particle size, there were small tetrahedron particles attached, which many researchers have identified as lactose crystals, even though these powders have a very low lactose content. Another unique feature was the golf-ball-like or dimpled structure, which was more evident in MPC than in MCC. MCC had more hard, cracked shells, possibly due to the compactness of the protein structure. The reported retentate or high-protein powders were moist-looking with easily separable small particle aggregates [46]. The powder surface was smooth with shallow dimples, whereas Mistry et al. [42] observed deep dents in the particles that were attributed to harsh single-stage drying conditions.

Figure 5.

Scanning electron microstructure of MPC powder at (a) 200 µm, (b) 100 µm, (c) 50 µm, (d) 30 µm, and (e) single particle at 30 µm.

Figure 6.

Scanning electron microstructure of MCC powder at (a) 200 µm, (b) 100 µm, (c) 50 µm, (d) 30 µm, and (e) single particle at 30 µm.

Figure 7.

Scanning electron microstructure of RCN at (a) 500 µm, (b) 300 µm, (c) 200 µm, (d) 100 µm, and (e) 50 µm.

The particles of MPC powder (Figure 5) exhibited a range of shapes, from spherical to truncated tetrahedrons to polyhedrons. The particle surfaces ranged from wrinkled to smooth and were visible. A unique observation was the presence of a golf-ball-like or dimpled structure on the surface of spherical particles, with at least one small particle attached to a larger particle at a particular point. Despite some faces being collapsed, the particles remained intact, and after sputter coating, the particle surface became even more visible.

The microstructure of MCC powder was predominantly composed of small particles, with a few spherical particles scattered among them, as shown in Figure 6. The small particles resembled broken fragments of a clay pot, with some having vacuoles and others exhibiting a broken surface. Many small particles had a unique shape, ranging from truncated pyramids to tetrahedrons to polyhedrons. An interesting observation was the presence of a spherical particle with a golf-ball-like or dimpled structure. The collapsed structures with smooth surfaces in high-protein powders were all related to lactose [41]. The number of small particles with this unique shape was greater in MCC when compared to MPC. Sputter coating increased the contrast and clarity of the sample.

The RCN structure observed at a mesh size of 30 (Figure 7) appeared large and compact with noticeable larger holes. The particles had irregular and cracked surfaces that collapsed. The structure of rennet casein is not available. However, calcium caseinates have smoother surfaces, while they may have a denser or more compact structure than SMP [47]. On the other hand, sodium caseinates have irregular, cracked, collapsed, elongated, and stringy structures, which may be due to the drying conditions during manufacturing. The RCN particles were too big and highly irregular in shape, indicating that they were not spray-dried. In addition, the surface was highly wrinkled with visible holes, indicating a difference in drying technology. This difference in structure makes RCN powder unique, with different functional properties compared to MPC and MCC powders. Differences in functional properties between RCN and MPC or MCC have been reported in processed cheese products [48] and imitation mozzarella cheeses [49,50].

The microstructural differences may be attributed to the manufacturing process used for MPC, MCC, and RCN powders. The MPC and MCC are produced using membrane systems ultrafiltration and microfiltration, respectively, with MPC having similar constituents as skim milk from which it was manufactured. In contrast, MCC has altered the casein-to-total-protein ratio [6]. RCN powder is produced by precipitating milk using chymosin or rennet enzyme, removing whey, and drying. These differences affect the microstructure and various functional properties, such as solubility, viscosity, emulsification, flowability, etc. However, the composition would affect the structural properties, but microstructure may not affect the functional properties directly [40]. Surface structure was affected by the lactose and protein content of dried milk [42].

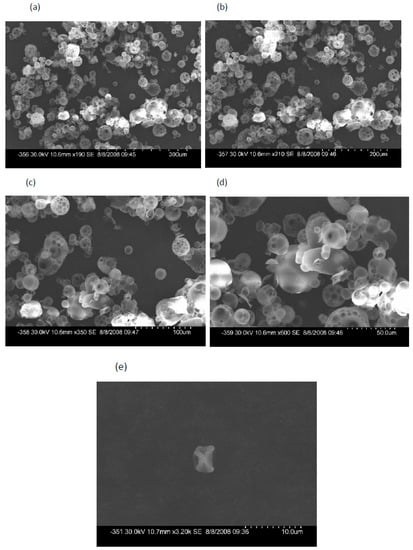

3.2.4. Whey Protein-Rich Powders

The micrograph of whey protein-rich milk powders is given in Figure 8 and Figure 9 for WPI and NWC powders, respectively. WPI is made from whey via the combination of membrane separation techniques, whereas NWC is produced directly from milk using those techniques. The WPI sample had a large number of golf ball-like structures, in which a small amount of truncated-pyramid-, tetrahedron-, and polyhedron-shaped particles were dispersed. The depth of the spherical collapse curves was greater than in the MPC or MCC powder samples. The ratio of large particles to small particles of unique shape was more than in MPC or MCC samples, and it had more depth in the collapsed points on the surface of spherical particles.

Figure 8.

Scanning electron microstructure of WPI at (a) 300 µm, (b) 200 µm, (c) 100 µm, (d) 50 µm, and (e) 10 µm.

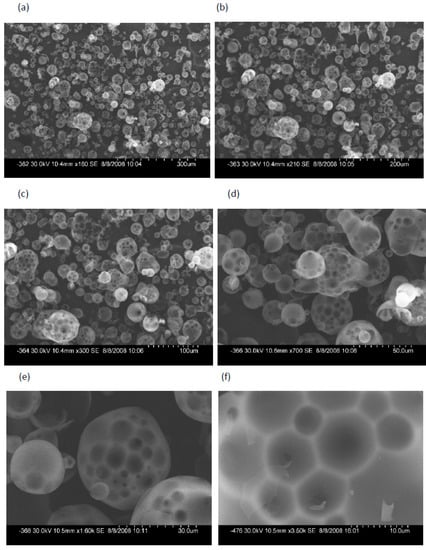

Figure 9.

Scanning electron microstructure of native WPC powder at (a) 300 µm, (b) 200 µm, (c) 100 µm, (d) 50 µm, (e) 30 µm, and (f) 10 µm.

The NWC sample exhibited a mixture of smooth and golf-ball-like surface particles, with the absence of truncated-pyramid-, tetrahedron, and polyhedron-shaped particles. Few to no truncated-pyramids-, tetrahedron-, and polyhedron-shaped particles were observed. Instead, NWC had a large number of spherical particles with a honeycomb-like structure, some of which were complete spheres, while others had vacuoles (Figure 9). The honeycomb-type structure was visible. The chemical composition of whey powder, mainly lactose, whey proteins, and minerals, results in a distinct microstructure with a non-smooth surface. A few plateaus or angular-shaped particles may be lactose crystals [47]. WPC structure differs from whey powder due to its higher protein and lower lactose content, but the composition and processing conditions also play a role in determining the microstructure. WPC has small particles fused in the dimples of larger particles, with a surface ranging from smooth to wrinkled. The presence of dense or thin shells and cracked particles can be attributed to the degree of aeration during drying [47].

The structure of WPI was similar to that of NWC but with higher porosity, as seen in Figure 8. The presence of a large number of fractured particles in WPI powder was attributed to the demineralization process used during its production. However, some samples had less fragmentation and plenty of small particles [47].

4. Conclusions

SEM is a tool for analyzing dried milk samples, and sputter coating is necessary to avoid artifacts and to understand the structure and topography of the dried milk powder samples. The requirements for high-protein dairy powders are diverse due to their use in various food applications. The particle size and microstructural characteristics are vital in determining their reconstitution properties and flowability. The study revealed that dairy powders with high-protein content have smaller particles with greater cohesiveness but lower flowability when compared to SMP and WMP, which have larger particles with higher flowability. The high-protein powders exhibited high wettability due to their low bulk density compared to SMP. The variations in microstructural characteristics of different dairy protein powders confirmed the differences in their functional behavior, such as powder solubility, wettability, bulk density, and flowability. The high-protein powders contained particles with truncated pyramids, tetrahedron, and polyhedron shapes depending on the protein level. The golf-ball-like structure was observed more frequently in whey powder than in other powders, including MPC and MCC, where the former contained more whey protein. The findings of this study can guide the development of new ingredients with specific ratios of milk constituents, particularly casein, certain whey proteins, and lactose, that can interact together to create multi-constituent bonding with enhanced functionalities. Regarding high-protein powders, even though are produced from homogenous concentrate using different processing techniques, the microstructural analysis makes us think that these powders are a mixture of specific constituents in certain ratios, particularly of casein, whey proteins, and some lactose, which is not the case in NFDM or WMP, in which the particles are bonded or fused, showing multi-constituent bonding. In the future, if micro-separation techniques for dried products become available, they can separate the individual particles leading to a better concentration of components and improved functionality.

Author Contributions

Conceptualization, P.S. and L.E.M.; analysis, P.S. and A.S.; data acquisition, P.S. original draft preparation, P.S.; review and editing, P.S., A.S. and L.E.M.; funding application, L.E.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Dairy Research Institute (Rosemont, IL, USA), grant number 21101.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We thank the Department for Electrical Engineering and Computer Sciences at South Dakota State University, Brookings, SD, for their help in performing the SEM microstructural analysis.

Conflicts of Interest

The authors declare no conflict of interest. The research was carried out at the Dairy and Food Science Department, South Dakota State University, Brookings, SD, USA, 57007, and funded by the Dairy Research Institute. The funding agency has no role in designing the experiment; collecting, and analyzing samples or data; or manuscript writing. The authors do not plan to profit from the results presented in this paper directly.

References

- Global “Dairy Protein Market” Trend 2023, Prominent Players in Various Ragions, Forecast 2028—MarketWatch. 2023. Available online: www.marketwatch.com (accessed on 28 June 2023).

- Singh, R.; Rathod, G.; Meletharayil, G.H.; Kapoor, R.; Sankarlal, V.M.; Amamcharla, J.K. Invited review: Shelf-stable dairy protein beverages—Scientific and technological aspects. J. Dairy Sci. 2022, 105, 9327–9346. [Google Scholar] [CrossRef] [PubMed]

- Kinsella, J.E. Milk proteins: Physicochemical and functional properties. CRC Crit. Rev. Food Sci. Nutr. 1984, 21, 197–262. [Google Scholar] [CrossRef] [PubMed]

- Henning, D.R.; Baer, R.J.; Hassan, A.N.; Dave, R. Major Advances in Concentrated and Dry Milk Products, Cheese, and Milk Fat-Based Spreads. J. Dairy Sci. 2006, 89, 1179–1188. [Google Scholar] [CrossRef]

- Hammam, A.R.; Martínez-Monteagudo, S.I.; Metzger, L.E. Progress in micellar casein concentrate: Production and applications. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4426–4449. [Google Scholar] [CrossRef]

- Salunke, P.; Marella, C.; Metzger, L.E. Microfiltration and Ultrafiltration process to produce Micellar Casein and Milk Protein Concentrates with 80% Crude Protein Content: Partitioning of various protein fractions and constituents. Dairy 2021, 2, 367–384. [Google Scholar] [CrossRef]

- Carter, B.G.; Cheng, N.; Kapoor, R.; Meletharayil, G.H.; Drake, M.A. Invited review: Microfiltration-derived casein and whey proteins from milk. J. Dairy Sci. 2020, 104, 2465–2479. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.H.J.; Chen, X.D.; Pearce, D. Surface characterization of four industrial spray-dried dairy powders in relation to chemical composition, structure and wetting property. Colloids Surf. B Biointerfaces 2002, 26, 197–212. [Google Scholar] [CrossRef]

- Ji, J.; Fitzpatrick, J.; Cronin, K.; Maguire, P.; Zhang, H.; Miao, S. Rehydration behaviours of high protein dairy powders: The influence of agglomeration on wettability, dispersibility and solubility. Food Hydrocoll. 2016, 58, 194–203. [Google Scholar] [CrossRef]

- Hazlett, R.; Schmidmeier, C.; O’Mahony, J.A. Approaches for improving the flowability of high-protein dairy powders post spray drying—A review. Powder Technol. 2021, 388, 26–40. [Google Scholar] [CrossRef]

- McSweeney, D.J.; O’Mahony, J.A.; McCarthy, N.A. Strategies to enhance the rehydration performance of micellar casein dominant dairy powders. Int. Dairy J. 2021, 122, 105116. [Google Scholar] [CrossRef]

- Murayama, D.; Zhu, Y.; Ikeda, S. Correlations between the solubility and surface characteristics of milk protein concentrate powder particles. J. Dairy Sci. 2021, 104, 3916–3926. [Google Scholar] [CrossRef] [PubMed]

- Paul, A.; Martin, F.; Simard, B.; Scher, J.; Gaiani, C.; le Floch-Fouere, C.; Jeantet, R.; Burgain, J. Deciphering the segregation of proteins in high-protein dairy powders after spray-drying. J. Dairy Sci. 2022, 106, 843–851. [Google Scholar] [CrossRef] [PubMed]

- Huppertz, T.; Gazi, I.; Luyten, H.; Nieuwenhuijse, H.; Alting, A.; Schokker, E. Hydration of casein micelles and caseinates: Implications for casein micelle structure. Int. Dairy J. 2017, 74, 1–11. [Google Scholar] [CrossRef]

- Nasser, S.; Jeantet, R.; De-Sa-Peixoto, P.; Ronse, G.; Nuns, N.; Pourpoint, F.; Burgain, J.; Gaiani, C.; Hedoux, A.; Delaplace, G. Microstructure evolution of micellar casein powder upon ageing: Consequences on rehydration dynamics. J. Food Eng. 2017, 206, 57–66. [Google Scholar] [CrossRef]

- Wu, S.; Cronin, K.; Fitzpatrick, J.; Miao, S. Updating insights into the rehydration of dairy-based powder and the achievement of functionality. Crit. Rev. Food Sci. Nutr. 2022, 62, 6664–6681. [Google Scholar] [CrossRef] [PubMed]

- Dec, B.; Kiełczewska, K.; Smoczy’nski, M.; Baranowska, M.; Kowalik, J. Properties and Fractal Analysis of High-Protein Milk Powders. Appl. Sci. 2023, 13, 3573. [Google Scholar] [CrossRef]

- Kalab, M. Electron Microscopy of milk products: A review of technique. In Scanning Electron Microscopy; Part III; SCM Inc., AMT O’Hare: Chicago, IL, USA, 1981; pp. 453–472. [Google Scholar]

- Kalab, M. Microstructure of dairy foods: 1. Milk products based on protein. J. Dairy Sci. 1979, 62, 1352–1364. [Google Scholar] [CrossRef]

- Gejl-Hansen, F.; Flink, J.M. Application of microscopic techniques to the description of structure of dehydrated food systems. J. Food Sci. 1976, 41, 483–489. [Google Scholar] [CrossRef]

- Sharma, A.; Jana, A.H.; Chavan, R.S. Functionality of milk powders and milk-based powders for end use applications—A review. Compr. Rev. Food Sci. Food Saf. 2012, 11, 518–528. [Google Scholar] [CrossRef]

- Kim, E.H.J.; Chen, X.D.; Pearce, D. On the mechanisms of surface formation and the surface compositions of industrial milk powders. Dry. Technol. 2003, 21, 265–278. [Google Scholar] [CrossRef]

- Kalab, M. Scanning Electron Microscopy of dairy products: An overview. In Scanning Electron Microscopy; Part III; SCM Inc., AMT O’Hare: Chicago, IL, USA, 1979; pp. 261–272. [Google Scholar]

- Lewis, D.F. Overview of Microscopical approaches. In Structure of Dairy Products; Tamime, A., Ed.; Blackwell Publishing: Oxford, UK, 2007; pp. 1–16. [Google Scholar]

- Schmidt, D.G. Electron Microscopy of Milk and Milk Products: Problems and Possibilities. Food Struct. 1982, 1, 6. [Google Scholar]

- Lee, C.-H.; Rha, C.K. Application of scanning electron microscopy for the development of materials for food. In Scanning Electron Microscopy; Part III; SCM Inc., AMT O’Hare: Chicago, IL, USA, 1979; pp. 465–471. [Google Scholar]

- Shah, K.; Salunke, P.; Metzger, L.E. Effect of storage of skim milk powder, nonfat dry milk, and milk protein concentrate on functional properties. Dairy 2022, 3, 565–576. [Google Scholar] [CrossRef]

- Shah, K.; Salunke, P.; Metzger, L.E. High Protein Powders Fortification of Nonfat Yoghurt: Impact of Protein Source, Protein to Total Solids Ratio, Storage, and Seasonality on the Functionality of Nonfat Yoghurt Made Using Glucono-δ-Lactone (GDL). J. Food Process. Technol. 2022, 13, 1000946. [Google Scholar]

- Hooi, R.; Barbano, D.M.; Bradley, R.L.; Budde, D.; Bulthaus, M.; Chettiar, M.; Lynch, J.; Reddy, R. Chapter 15 Chemical and Physical Methods. In Standard Methods for the Examination of Dairy Products, 17th ed.; Wehr, H.M., Frank, J.F., Eds.; American Public Health Association: Washington, DC, USA, 2004; pp. 480–510. [Google Scholar]

- Niro A/S. Analytical Methods. 2008. Available online: www.niro.com (accessed on 8 January 2018).

- Silva, J.V.C.; O’Mahony, J.A. Flowability and wetting behaviour of milk protein ingredients as influenced by powder composition. Part. Size Microstruct. 2017, 70, 277–286. [Google Scholar] [CrossRef]

- van Kreveld, A. Studies on the wetting of milk powder. Neth. Milk Dairy J. 1974, 28, 23–45. [Google Scholar]

- Singh, H. Interactions of milk proteins during the manufacture of milk powders. Le Lait 2007, 87, 413–423. [Google Scholar] [CrossRef]

- Buma, T.J.; Henstra, S. Particle structure of spray-dried caseinate and spray-dried lactose as observed by scanning electron microscope. Neth. Milk Dairy J. 1971, 25, 278. [Google Scholar]

- Muller, H.R. Elekttonenmikroskopische Untersuchungen an Milch und Milchprodukten. 1. Strukturaufldii.rung in Milchpulvern. Milchwissenschaft 1964, 19, 345. [Google Scholar]

- Kalab, M.; Emmons, D.B. Milk gel structure. III. Microstructure of skim milk powder and gels as related to the drying procedure. Milchwissenschaft 1974, 29, 585. [Google Scholar]

- Vega, C.; Roos, Y.H. Spray-Dried Dairy and Dairy-Like Emulsions—Compositional Considerations. J. Dairy Sci. 2006, 89, 383–401. [Google Scholar] [CrossRef]

- Kalab, M. Food structure and milk products. In Encyclopedia of Food Science and Technology; Hui, Y.H., Ed.; John Eiley & Sons, Inc.: Hoboken, NJ, USA, 1992; Volume 2, pp. 1170–1196. [Google Scholar]

- Roos, Y.H. Importance of glass transition and water activity to spray drying and stability of dairy powders. Lait 2002, 82, 475–484. [Google Scholar] [CrossRef]

- Mistry, V.V.; Hassan, H.N. Delactosed, high milk protein powder. 2. Physical and Functional properties. J. Dairy Sci. 1991, 74, 3716–3723. [Google Scholar] [CrossRef]

- Mistry, V.V. Manufacture and application of high milk protein powder. Lait 2002, 82, 515–522. [Google Scholar] [CrossRef]

- Mistry, V.V.; Hassan, H.N.; Robinson, D.J. Effect of lactose and protein on the microstructure of dried milk. Food Struct. 1992, 11, 73–82. [Google Scholar]

- Hardy, J.; Scher, J.; Banon, S. Water activity and hydration of dairy powders. Lait 2002, 82, 441–452. [Google Scholar] [CrossRef][Green Version]

- Verdurmen, R.E.M.; Straatsma, H.; Verschuren, V.; van Haren, J.J.; Smit, E.; Bargeman, G.; de Jong, P. Modeling spray drying processes for dairy products. Lait 2002, 82, 453–463. [Google Scholar] [CrossRef]

- Pisecky, I.J. Handbook of Milk Powder Manufacture; Westergaard, V., Refstrup, E., Eds.; GEA Process Engineering A/S (GEA Niro): Copenhagen, Denmark, 2010. [Google Scholar]

- Kalab, M.; Caric, M.; Zaher, M.; Harwalker, V.R. Composition and some properties of spray dried retantates obtained by the ultrafiltration of milk. Food Microstruct. 1989, 8, 225–233. [Google Scholar]

- Tamime, A.Y.; Robinson, R.K.; Michel, M. Microstructure of concentrated and dried milk products. In Structure of Dairy Products; Tamime, A., Ed.; Blackwell Publishing: Oxford, UK, 2007; pp. 104–133. [Google Scholar]

- Salunke, P.; Metzger, L.E. Impact of transglutaminase treatment given to the skim milk before or after microfiltration on the functionality of micellar casein concentrate used in process cheese product and comparison with rennet casein. Int. Dairy J. 2022, 128, 105317. [Google Scholar] [CrossRef]

- Salunke, P.; Marella, C.; Amamcharla, J.K.; Muthukumarappan, K.; Metzger, L.E. Use of Micellar Casein Concentrate and Milk Protein Concentrate Treated with Transglutaminase in Imitation cheese products—Melt and Stretch properties. J. Dairy Sci. 2022, 105, 7904–7916. [Google Scholar] [CrossRef]

- Salunke, P.; Marella, C.; Amamcharla, J.K.; Muthukumarappan, K.; Metzger, L.E. Use of Micellar Casein Concentrate and Milk Protein Concentrate Treated with Transglutaminase in Imitation cheese products—Unmelted texture. J. Dairy Sci. 2022, 105, 7891–7903. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).