Eco-Efficiency of Rural Biodigesters: Mono- and Co-Digestion of Agricultural Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Area and Research Design

- Project 1—15 m3 biodigester supplied exclusively with equine manure (100%), based on total solids (TS).

- Project 2—15 m3 biodigester supplied with 90% equine manure and 10% vegetable waste, based on TS.

- Project 3—20 m3 biodigester supplied exclusively with equine manure (100%), based on TS.

- Project 4—20 m3 biodigester supplied with 90% equine manure and 10% vegetable waste, based on TS.

2.2. Cash Flow Formation: Revenue, Costs, and Expenses

2.3. Techniques for Economic Feasibility Assessment of the Projects

2.4. Analysis of the Environmental Benefits Derived from the Use of the Biodigester

- Volume of CH4 in biogas (m3): Total biogas production (m3) × CH4 content (as a decimal) × 0.95.

- Conversion of CH4 volume to mass (Kg): CH4 volume × CH4 density.

- Conversion of CH4 to CO2 equivalent (Kg CO2eq): CH4 mass × 27.2.

3. Results and Discussion

3.1. Initial Investment for Biodigester Implementation

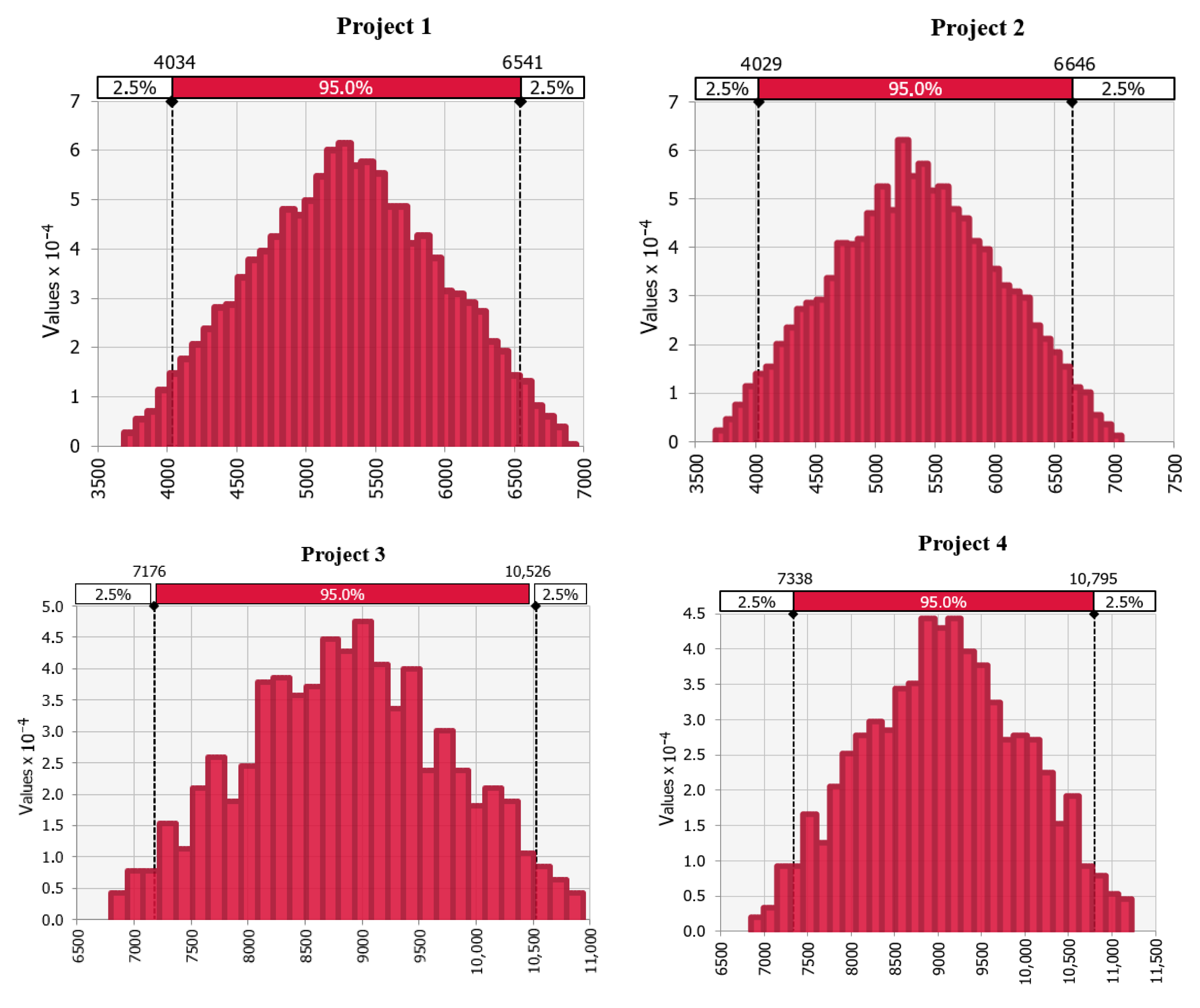

3.2. Economic Evaluation of the Projects

3.3. Environmental Benefits Assessment

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | Anaerobic Digestion |

| B/C | Benefit-Cost Ratio |

| CAPM | Capital Asset Pricing Model |

| COD | Chemical Oxygen Demand |

| DPP | Discounted Payback Period |

| IRR | Internal Rate of Return |

| K | Potassium |

| MAR | Minimum Attractiveness Rate |

| MIRR | Internal Rate of Return Modified |

| M3 | Cubic Meters |

| N | Nitrogen |

| NPV | Net Present Value |

| P | Phosphorus |

| PI | Profitability Index |

| TS | Total Solids |

| VS | Volatile Solids |

References

- FAO—Food and Agriculture Organization. Agricultural Production Statistics 2010–2023; FAO: Rome, Italy, 2023; Available online: https://www.fao.org/statistics/highlights-archive/highlights-detail/agricultural-production-statistics-2010-2023/en (accessed on 22 April 2025).

- Lee, K.T.; Chen, W.H.; Sarles, P.; Park, Y.K.; Ok, Y.S. Recover energy and materials from agricultural waste via thermochemical conversion. One Earth 2022, 5, 1200–1204. [Google Scholar] [CrossRef]

- Holloway, L.A.; Catney, G.; Stockdale, A.; Nelson, R. Sustainable Family Farming Futures: Exploring the challenges of Family Farm Decision Making through an Emotional Lens of Belonging. Sustainability 2021, 13, 12271. [Google Scholar] [CrossRef]

- Nepomoceno, T.A.R.; Carniatto, I. Correlations between climate resilience in family farming and sustainable rural development. Ambio J. Environ. Soc. 2023, 52, 1233–1247. [Google Scholar] [CrossRef]

- Chao, K. Family farming in climate change: Strategies for resilient and sustainable food systems. Heliyon 2024, 10, e28599. [Google Scholar] [CrossRef]

- Ataei, P.; Karimi, H.; Hallaj, Z.; Menatizadeh, M. Agricultural waste recycling by farmers: A behavioral study. Sustain. Futures 2025, 9, 10443. [Google Scholar] [CrossRef]

- Obal, T.M.; de Souza, J.T.; de Jesus, R.H.G.; de Francisco, A.C. Biogascluster: A clustering algorithm to identify potential partnerships between agribusiness properties. Renew. Energy 2023, 206, 982–993. [Google Scholar] [CrossRef]

- Alvarez, Y.C.; Borges, R.J.; Vidal, C.D.P.; Leon, F.M.C.; Buendia, J.S.P.; Nolasco, J.A.S. Design Improvements and Best Practices in Small-Scale Biodigesters for Sustainable Biogas Production: A Case Study in the Chillon Valley, Perú. Energies 2025, 18, 338. [Google Scholar] [CrossRef]

- Mendes, L.F.R.; Júnior, M.E.; Hosken, L.A.L. Selection system for the supply of electricity for coastal rural properties located in the North of the State of Rio de Janeiro. Rev. Prod. Eng. 2016, 4, 338–345. [Google Scholar] [CrossRef][Green Version]

- Barbosa, G.; Langer, M. Uso de biodigestores em propriedades rurais: Uma alternativa à sustentabilidade ambiental. Unoesc Ciência-ACSA 2011, 2, 87–96. [Google Scholar][Green Version]

- Bôas, T.F.V.; Barros, R.M.; Pinto, J.A.; dos Santos, I.F.S.; Lora, E.E.S.; Andrade, R.V.; de Oliveira Machado, G. Energy potential from the generation of biogas from anaerobic digestion of olive oil extraction wastes in Brazil. Clean. Waste Syst. 2023, 4, 100083. [Google Scholar] [CrossRef]

- Borowski, P.F.; Barwicki, J. Efficiency of utilization of wastes for green energy production and reduction of pollution in rural areas. Energies 2022, 16, 13. [Google Scholar] [CrossRef]

- Sganzerla, W.G.; da Rosa, R.G.; Barroso, T.L.C.T.; Castro, L.E.N.; Forster-Carneiro, T. Techno-economic assessment of on-site production of biomethane, bioenergy, and fertilizer from small-scale anaerobic digestion of jabuticaba by-product. Methane 2023, 2, 113–128. [Google Scholar] [CrossRef]

- Allegrini, M.; Zabaloy, M.C. Anaerobic digestate in agricultural soils: A systematic review of their effects on antibiotic resistance genes. Rev. Argent. Microbiol. 2024, 56, 394–401. [Google Scholar] [CrossRef]

- Ketuama, C.T.; Roubík, H. Economic viability and factors affecting farmers’ willingness to pay for adopting small-scale biogas plants in rural areas of Cameroon. Renew. Energy 2024, 230, 120895. [Google Scholar] [CrossRef]

- Albuquerque, J.N.; Ratusznei, S.M.; Rodrigues, J.A.D. Biomethane production by thermophilic co-digestion of sugarcane vinasse and whey in na AnSBBR: Effects of composition, organic load, feed strategy and temperature. J. Environ. Manag. 2019, 251, 109606. [Google Scholar] [CrossRef]

- Silvestre, G.; Gómez, M.P.; Pascual, A.; Ruiz, B. Anaerobic co-digestion of cattle manure with rice straw: Economic & energy feasibility. Water Sci. Technol. 2013, 67, 745–755. [Google Scholar] [CrossRef] [PubMed]

- Cuetos, M.J.; Fernández, C.; Gómez, X.; Morán, A. Anaerobic co-digestion of swine manure with energy crop residues. Biotechnol. Bioprocess Eng. 2011, 16, 1044–1052. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Chen, C.; Liu, G.; He, Y.; Liu, X. Biogas production from co-digestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions. Bioresour. Technol. 2013, 149, 406–412. [Google Scholar] [CrossRef] [PubMed]

- Araujo, G.J.F.; Oliveira, S.V.W.B. Economic, energetic and environmental analysis of the utilization of swine manure in Brazil: Opportunities and challenges. Energy Strategy Rev. 2023, 47, 101089. [Google Scholar] [CrossRef]

- Heller, R.; Hulsemann, B.; Lemmer, A.; Oechsner, H. Enhancing methane yield from agricultural feedstocks including horse manure and residues: Ball mill pretreatment in full-scale biogas plant. Bioresour. Technol. 2025, 435, 132866. [Google Scholar] [CrossRef]

- Coutu, A.; Mottelet, S.; Guérin, S.; Rocher, V.; Pauss, A.; Ribeiro, T. Methane yield optimization using mix response design and bootstrapping: Application to solid-state anaerobic co-digestion process of cattle manure and damp grass. Bioresour. Technol. Rep. 2022, 17, 10883. [Google Scholar] [CrossRef]

- Oliveira, J.D.; Orrico, A.C.A.; Leite, B.K.V.; Schwingel, A.W.; Orrico Junior, M.A.P.; Avila, M.R.; Machado, J.F.; Dias, A.M.F.D.; Santos, W. Anaerobic co-digestion of swine manure and forage at two harvesting ages. Ciência Rural 2022, 52, e20200760. [Google Scholar] [CrossRef]

- Montoro, S.B.; Lucas, J., Jr.; Santos, D.F.L.; Costa, M.S.S.M. Anaerobic co-digestion of sweet potato and dairy cattle manure: A technical and economic evaluation for energy and biofertilizer production. J. Clean. Prod. 2019, 226, 1082–1091. [Google Scholar] [CrossRef]

- de Aragão, S.C.; da Silva Figueiredo, C.V.; de Abreu, R.; Araújo, C.A.D.A.; Mendonça, F.G.; da Silva, E.; de Carvalho Júnior, A.L.L.; Moreira, V.L.C.; de Oliveira, C.M.; Oliveira, M.T.; et al. Agribusiness in the municipality of Dourados and its importance for the state of Mato Grosso do Sul. Int. J. Adv. Eng. Res. Sci. 2022, 9, 149–165. [Google Scholar] [CrossRef]

- Turdera, M.V.; Yura, D. Estudo da viabilidade de um biodigestor no município de dourados. In Proceedings of the 6. Encontro de Energia No Meio Rural, Campinas, Brazil, 2006. Available online: http://www.proceedings.scielo.br/scielo.php?pid=MSC0000000022006000200046&script=sci_abstract (accessed on 15 September 2025).

- Xu, M.; Moe, S.T.; Aasen, I.M.; Hillestad, M. Design optimization of low-solids anaerobic digestion: Increasing retention time through effluent recirculation. Bioresour. Technol. Rep. 2025, 31, 102209. [Google Scholar] [CrossRef]

- Pompermayer, R.S.; De Paula Júnior, D.R. Estimativa do potencial brasileiro de produção de biogás através da biodigestão da vinhaça e comparação com outros energéticos. In Encontro de Energia No Meio Rural; Núcleo Interdisciplinar de Planejamento Energético—NIPE/UNICAMP: Campinas, Brazil, 2003; Available online: http://www.proceedings.scielo.br/scielo.php?pid=MSC0000000022000000200055&script=sci_arttext&tlng=pt (accessed on 20 April 2025).

- Apha—American Public Health Association. Standard Methods for the Examination of Water and Wastewater, 22nd ed.; American Public Health Association: Washington, DC, USA, 2012. [Google Scholar]

- Hadin, A.; Eriksson, O. Horse manure as feedstock for anaerobic digestion. Waste Manag. 2016, 56, 506–518. [Google Scholar] [CrossRef]

- Souza, J.L.; Guimarães, G.P.; Favarato, L.F. Development of vegetables and soil characteristics after green manuring and organic composts under levels of N. Hortic. Bras. 2015, 33, 019–026. [Google Scholar] [CrossRef]

- Conab. Companhia Nacional de Abastecimento. Norma Metodologia do Custo de Produção. 2020; 45p. Available online: https://www.conab.gov.br/ (accessed on 22 April 2025).

- US Department of the Treasury. Treasury Bonds. 2025. Available online: https://home.treasury.gov/resource-center/data-chart-center/interest-rates/TextView?type=daily_treasury_yield_curve&field_tdr_date_value=2025 (accessed on 17 February 2025).

- Martins, F.M.; de Oliveira, P.A. Análise econômica da geração de energia elétrica a partir do biogás na suinocultura. Eng. Agrícola 2011, 31, 477–486. [Google Scholar] [CrossRef]

- Damodaran, A. Damodaran Online. 2025. Available online: https://pages.stern.nyu.edu/~adamodar/ (accessed on 17 February 2025).

- Escalable Capital. 2025. Available online: https://www.welt.de/Advertorials/scalable (accessed on 17 February 2025).

- Investing. Government Bonds. 2025. Available online: https://www.investing.com/rates-bonds/ (accessed on 17 February 2025).

- Statista. 2025. Available online: https://www.statista.com/search/?q=Estimated+U.S.+inflation+&p=1 (accessed on 17 February 2025).

- Hoji, M. Administração Financeira e Orçamentária: Matemática Financeira Aplicada, Estratégias Financeiras, Orçamento Empresarial, 8th ed.; Atlas: São Paulo, Brazil, 2010. [Google Scholar]

- Nwogugu, M.C.; Nwogugu, M.C. Regret theory and asset pricing anomalies in incomplete markets with dynamic unaggregated preferences. In Anomalies in Net Present Value, Returns and Polynomials, and Regret Theory in Decision-Making; Palgrave Macmillan UK: London, UK, 2016; pp. 69–131. [Google Scholar]

- Assaf Neto, A. Matemática Financeira e suas Aplicações, 14th ed.; Atlas: São Paulo, Brazil, 2019. [Google Scholar]

- Ross, S.; Westerfield, R.; Jordan, B.D. Fundamentos de Administração Financeira, 13th ed.; Bookman Editora: New York, NY, USA, 2022. [Google Scholar]

- Ross, S.; Westerfield, R.; Jordan, B.D.; Lamb, R. Fundamentos da Administração Financeira, 9th ed.; Boockam: New York, NY, USA, 2013. [Google Scholar]

- de Rezende, J.L.P.; de Oliveira, A.D. Análise Econômica e Social de Projetos Florestais: Matemática Financeira, Formulação de Projetos, Avaliação de Projetos, Localização de Projetos, Análise de Custo-Benefício, 2nd ed.; UFV: Viçosa, MG, Brazil, 2008; 386p. [Google Scholar]

- Branker, K.; Pathak, M.J.M.; Pearce, J.M. A review of solar photovoltaic levelized cost of electricity. Renew. Sustain. Energy Rev. 2011, 15, 4470–4482. [Google Scholar] [CrossRef]

- Kratky, L.; Zamazal, P. Economic feasibility and sensitivity analysis of fish waste processing biorefinery. J. Clean. Prod. 2020, 243, 118677. [Google Scholar] [CrossRef]

- Woiler, S. Projetos: Planejamento, Elaboração e Análise; Atlas: São Paulo, Brazil, 1996. [Google Scholar]

- Burmaster, D.E.; Thompson, K.M.; Crouch, E.A.; Menzie, C.A.; McKone, T.E. Monte Carlo techniques for quantitative uncertainty analysis in public health risk assessments. In Proceedings of the Superfund’90, 11th National Conference, Washington, DC, USA, 26–28 November 1990; pp. 215–221. [Google Scholar]

- Angelidaki, I.; Ellegaard, L. Codigestion of Manure and Organic Wastes in Centralized Biogas Plants. Appl. Biochem. Biotechnol. 2003, 109, 95–105. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change—IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Volume 2: Energy. Prepared by the National Greenhouse Gas Inventories Programme; IGES: Hayama, Japan, 2006.

- Ali, R.; Al-Sa’ed, R. Economic Feasibility of a Biogas System in a Small Palestinian Poultry Farm. In Advances in Science, Technology and Innovation; Springer International Publishing: Cham, Switzerland, 2018; pp. 1541–1543. [Google Scholar] [CrossRef]

- Sarmento, Z.R.S.; Nazario, C.A.S.; Carneiro, P.H.G.; Nazário, S.L.S. Aproveitamento do potencial energético da cama de frango para uso na atividade avícola. In Proceedings of the XI Congresso Nacional de Excelência em Gestão, Rio de Janeiro, Brazil, 13–14 August 2015; pp. 1–15. [Google Scholar]

- Piñas, J.A.V.; Venturini, O.J.; Lora, E.E.S.; del Olmo, O.A.; Roalcaba, O.D.C. An economic holistic feasibility assessment of centralized and decentralized biogas plants with mono-digestion and co-digestion systems. Renew. Energy 2019, 139, 40–51. [Google Scholar] [CrossRef]

- Trypolska, G.; Kyryziuk, S.; Krupin, V.; Wąs, A.; Podolets, R. Economic feasibility of agricultural biogas production by farms in Ukraine. Energies 2021, 15, 87. [Google Scholar] [CrossRef]

- Geddafa, T.; Melka, Y.; Sime, G. Cost-benefit analysis and financial viability of household biogas plant investment in South Ethiopia. Sustain. Energy Res. 2023, 10, 20. [Google Scholar] [CrossRef]

- Tisocco, S.; Beausang, C.; Zhan, X.; Crosson, P. Integration of anaerobic co-digestion of grass silage and cattle slurry within a livestock farming system in Ireland: Quantification of greenhouse gas emission reduction and nutrient flow. Resour. Conserv. Recycl. 2024, 206, 107650. [Google Scholar] [CrossRef]

- Mickwitz, P.; Melanen, M.; Rosenstrom, U.; Seppala, J. Regional eco-efficiency indicators—A participatory approach. J. Clean. Prod. 2006, 14, 1603–1611. [Google Scholar] [CrossRef]

- ISO NBR 14045; Environmental Management—Eco-Efficiency Assessment of Product Systems—Principles, Requirements and Guidelines. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2014.

- World Business Council for Sustainable Development (WBCSD). Measuring Eco-Efficiency: A Guide to Reporting Company Performance; WBCSD: Geneva, Switzerland, 2000. [Google Scholar]

- Martinelli, G.; Vogel, E.; Decian, M.; Farinha, M.J.U.S.; Bernardo, L.V.M.; Borges, J.A.R.; Gimenes, R.M.T.; Garcia, R.G.; Ruviaro, C.F. Assessing the eco-efficiency of different poultry production systems: An approach using life cycle assessment and economic value added. Sustain. Prod. Consum. 2020, 24, 181–193. [Google Scholar] [CrossRef]

- Pedroso, A.; Cella-de-Oliveira, F.A.; Souza Dutra, I.; Morozini, J.F. Processo ou ações de ecoeficiência em empresas da cadeia produtiva agroindustrial da suinocultura de Toledo—Paraná, Brasil. Rev. Cap. Ciêntifico Eletrônica 2012, 10, 1–17. Available online: https://revistas.unicentro.br/index.php/capitalcientifico/article/view/1945/1724 (accessed on 15 September 2025).

- Munda, G. Indicators and Evaluation Tools for the Assessment of Urban Sustainability; UHE Working Papers, 10; Universitat Autònoma de Barcelona, Departament d’Economia i Història Econòmica, Unitat d’Història Econòmica: Bellaterra, Spain, 2001. [Google Scholar]

- Pearce, D.W.; Atkinson, G.; Mourato, S. Cost-Benefit Analysis and the Environment: Recent Developments; OECD Publishing: Paris, France, 2006; 315p. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Copetti, L.D. Fatores que Dificultam o Acesso dos Agricultores Familiares às Políticas de Crédito Rural: O Caso do Pronaf—Crédito No Município de Alegria-RS. Master’s Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brazil, 2008. Available online: https://lume.ufrgs.br/handle/10183/15638 (accessed on 15 September 2025).

| Biodigester | Biodigester 15 m3 | Biodigester 20 m3 | ||

|---|---|---|---|---|

| Description | Project 1 | Project 2 | Project 3 | Project 4 |

| 100% Equine Manure | 90% Equine Manure and 10% Vegetable Waste | 100% Equine Manure | 90% Equine Manure and 10% Vegetable Waste | |

| Quantity of equine manure to be used in the biodigester (kg/month) | 1153.85 | 1038.47 | 1538.46 | 1384.62 |

| Quantity of vegetable waste to be used in the biodigester (kg/month) | - | 346.15 | - | 461.15 |

| Amount of water added for dilution (L/month) | 13,846.15 | 13,615.39 | 18,461.54 | 18,153.84 |

| Biogas production (m3/month) | 184.92 | 166.43 | 246.55 | 257.13 |

| Equivalent production in LPG cylinders (units/month) | 6.16 | 6.43 | 8.22 | 8.57 |

| Biofertilizer production (liters/month) | 13,500 | 13,500 | 18,000 | 18,000 |

| Biodigester model | Canadian | Canadian | Canadian | Canadian |

| Biodigester material | PVC | PVC | PVC | PVC |

| Parameters | Obtained in: (1) | Value | |

|---|---|---|---|

| Rf | Yield Rate of U.S Treasury Bonds | [33] | 4.69% |

| Unlevered Beta for the Farming/Agriculture sector | [35] | 0.73 | |

| RM | Average Return Rate of the MSCI Emerging Markets Index | [36] | 7.60% |

| Credit Default Swap (CDS) | [37] | 1.71% | |

| Estimated U.S. inflation (2025–2029) | [38] | 2.10% | |

| MAR | Ke (Global CAPM/Benchmarking—real rate) | 6.43% | |

| Biodigester Size | 15 m3 | 20 m3 | ||

|---|---|---|---|---|

| Projects | Project 1 Project 2 | Project 3 Project 4 | ||

| Description | Total Value (USD) | Share (%) | Total Value (USD) | Share (%) |

| Biodigester | 2019.72 | 35.8% | 2464.80 | 39.6% |

| Lagoon | 368.83 | 6.5% | 414.58 | 6.7% |

| Pressure relief valve | 17.56 | 0.3% | 17.56 | 0.3% |

| Geotextile fabric (Bidim) (m2) | 97.53 | 1.7% | 115.26 | 1.9% |

| BGS-2L purifier | 51.42 | 0.9% | 62.06 | 1.0% |

| Flow meter | 63.84 | 1.1% | 77.14 | 1.2% |

| BGS-ARM-05 balloon | 335.14 | 5.9% | 335.14 | 5.4% |

| Biogas pump 220 V AC 15 W | 82.46 | 1.5% | 82.46 | 1.3% |

| Biogas stove with double burner | 82.46 | 1.5% | 82.46 | 1.3% |

| Earthmoving | 88.57 | 1.6% | 122.89 | 2.0% |

| Liquid fertilizer distributor | 2355.02 | 41.8% | 2355.02 | 37.8% |

| Wheelbarrow | 17.56 | 0.3% | 17.56 | 0.3% |

| Bare soil | 57.24 | 1.0% | 76.57 | 1.2% |

| Total investment | 5637.34 | 100% | 6223.48 | 100% |

| Description | Biodigester 15 m3 | |||||

|---|---|---|---|---|---|---|

| Project 1 | Project 2 | |||||

| Year 0 | Year 1–14 | Year 15 | Year 0 | Year 1–14 | Year 15 | |

| 1. Total Revenue | 0.0 | 2309.38 | 2309.38 | 0.0 | 2496.72 | 2496.72 |

| 1.1 Cooking gas production | 0.0 | 1700.86 | 1700.86 | 0.0 | 1778.54 | 1778.54 |

| 1.2 Biofertilizer production | 0.0 | 608.52 | 608.52 | 0.0 | 718.18 | 718.18 |

| 2. Total costs and Expenses | 0.0 | 1428.81 | 1428.81 | 0.0 | 1611.13 | 1611.13 |

| 2.1 Labor | 0.0 | 960.41 | 960.41 | 0.0 | 1142.73 | 1142.73 |

| 2.2 Maintenance cost | 0.0 | 140.93 | 140.93 | 0.0 | 140.93 | 140.93 |

| 2.3 Diesel oil (fertigation) | 0.0 | 9.50 | 9.50 | 0.0 | 9.50 | 9.50 |

| 2.4 Fixed capital insurance | 0.0 | 42.28 | 42.28 | 0.0 | 42.28 | 42.28 |

| 2.5 Rural Property Tax (ITR) | 0.0 | 0.00 | 0.00 | 0.0 | 0.00 | 0.00 |

| 2.6 Depreciation | 0.0 | 275.69 | 275.69 | 0.0 | 275.69 | 275.69 |

| 3. Operating Profit | 0.0 | 880.56 | 880.56 | 0.0 | 885.59 | 885.59 |

| 4. Depreciation | 0.0 | 275.69 | 275.69 | 0.0 | 275.69 | 275.69 |

| 5. Operating Cash Flow | 0.0 | 1156.26 | 1156.26 | 0.0 | 1161.28 | 1161.28 |

| 6. Investments | 5637.34 | 0.00 | 0.00 | 5637.34 | 0.00 | 0.00 |

| 7. Free Cash Flow | −5637.34 | 1156.26 | 1156.26 | −5637.34 | 1161.28 | 1161.28 |

| Description | Biodigester 20 m3 | |||||

| Project 3 | Project 4 | |||||

| Year 0 | Year 1–14 | Year 15 | Year 0 | Year 1–14 | Year 15 | |

| 1. Total Revenue | 0.0 | 3085.01 | 3085.01 | 0.0 | 3350,66 | 3350,66 |

| 1.1 Cooking gas production | 0.0 | 2273.65 | 2273.65 | 0.0 | 2370.46 | 2370.46 |

| 1.2 Biofertilizer production | 0.0 | 811.36 | 811.36 | 0.0 | 980.19 | 980.19 |

| 2. Total costs and Expenses | 0.0 | 1786.38 | 1786.38 | 0.0 | 2029.27 | 2029.27 |

| 2.1 Labor | 0.0 | 1276.83 | 1276.83 | 0.0 | 1519.72 | 1519.72 |

| 2.2 Maintenance cost | 0.0 | 155.59 | 155.59 | 0.0 | 155.59 | 155.59 |

| 2.3 Diesel oil (fertigation) | 0.0 | 10.13 | 10.13 | 0.0 | 10.13 | 10.13 |

| 2.4 Fixed capital insurance | 0.0 | 46.68 | 46.68 | 0.0 | 46.68 | 46.68 |

| 2.5 ITR | 0.0 | 0.00 | 0.00 | 0.0 | 0.00 | 0.00 |

| 2.6 Depreciation | 0.0 | 297.16 | 297.16 | 0.0 | 297.16 | 297.16 |

| 3. Operating Profit | 0.0 | 1298.63 | 1298.63 | 0.0 | 1321.39 | 1321.39 |

| 4. Depreciation | 0.0 | 297.16 | 297.16 | 0.0 | 297.16 | 297.16 |

| 5. Operating Cash Flow | 0.0 | 1595.79 | 1595.79 | 0.0 | 1618.54 | 1618.54 |

| 6. Investments | 6223.48 | 0.00 | 0.00 | 6223.48 | 0.00 | 0.00 |

| 7. Free Cash Flow | −6223.48 | 1595.79 | 1595.79 | −6223.48 | 1618.54 | 1618.54 |

| Evaluation Technique | Results | |||

|---|---|---|---|---|

| Project 1 | Project 2 | Project 3 | Project 4 | |

| NPV | USD 5283.62 | USD 5331.05 | USD 8848.92 | USD 9063.81 |

| IRR | 19.00% | 19.10% | 24.71% | 25.10% |

| MIRR | 9.20% | 9.23% | 10.84% | 10.95% |

| PI | USD 1.94 | USD 1.95 | USD 2.42 | USD 2.46 |

| B/C | USD 1.62 | USD 1.55 | USD 1.73 | USD 1.65 |

| DPP | 6.03 years | 6.00 years | 4.63 years | 4.56 years |

| Description | Results | |||

|---|---|---|---|---|

| Project 1 | Project 2 | Project 3 | Project 4 | |

| Biogas production m3/month | 184.92 | 192.85 | 246.55 | 257.13 |

| CO2 emissions avoided (tons/month) | 2.05 | 2.14 | 2.72 | 2.85 |

| CO2 emissions avoided (tons/year) | 24.60 | 25.68 | 32.64 | 34.20 |

| Project | NPV | CO2eq Avoided (Tons/Year) | Eco-Efficiency (USD/tCO2eq) |

|---|---|---|---|

| Project 1 | 5283.62 | 24.60 | 203.84 |

| Project 2 | 5331.05 | 25.68 | 197.45 |

| Project 3 | 8848.92 | 32.64 | 256.05 |

| Project 4 | 9063.81 | 34.20 | 251.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Souza, V.; Oliveira, J.D.d.; Gimenes, R.M.T.; Orrico, A.C.A.; Santos Júnior, M.C. Eco-Efficiency of Rural Biodigesters: Mono- and Co-Digestion of Agricultural Waste. AgriEngineering 2025, 7, 311. https://doi.org/10.3390/agriengineering7090311

Souza V, Oliveira JDd, Gimenes RMT, Orrico ACA, Santos Júnior MC. Eco-Efficiency of Rural Biodigesters: Mono- and Co-Digestion of Agricultural Waste. AgriEngineering. 2025; 7(9):311. https://doi.org/10.3390/agriengineering7090311

Chicago/Turabian StyleSouza, Vanessa, Juliana Dias de Oliveira, Régio Marcio Toesca Gimenes, Ana Carolina Amorim Orrico, and Moacir Cardoso Santos Júnior. 2025. "Eco-Efficiency of Rural Biodigesters: Mono- and Co-Digestion of Agricultural Waste" AgriEngineering 7, no. 9: 311. https://doi.org/10.3390/agriengineering7090311

APA StyleSouza, V., Oliveira, J. D. d., Gimenes, R. M. T., Orrico, A. C. A., & Santos Júnior, M. C. (2025). Eco-Efficiency of Rural Biodigesters: Mono- and Co-Digestion of Agricultural Waste. AgriEngineering, 7(9), 311. https://doi.org/10.3390/agriengineering7090311