A Comprehensive Systematic Review of Precision Planting Mechanisation for Sesame: Agronomic Challenges, Technological Advances, and Integration of Simulation-Based Optimisation

Abstract

1. Introduction

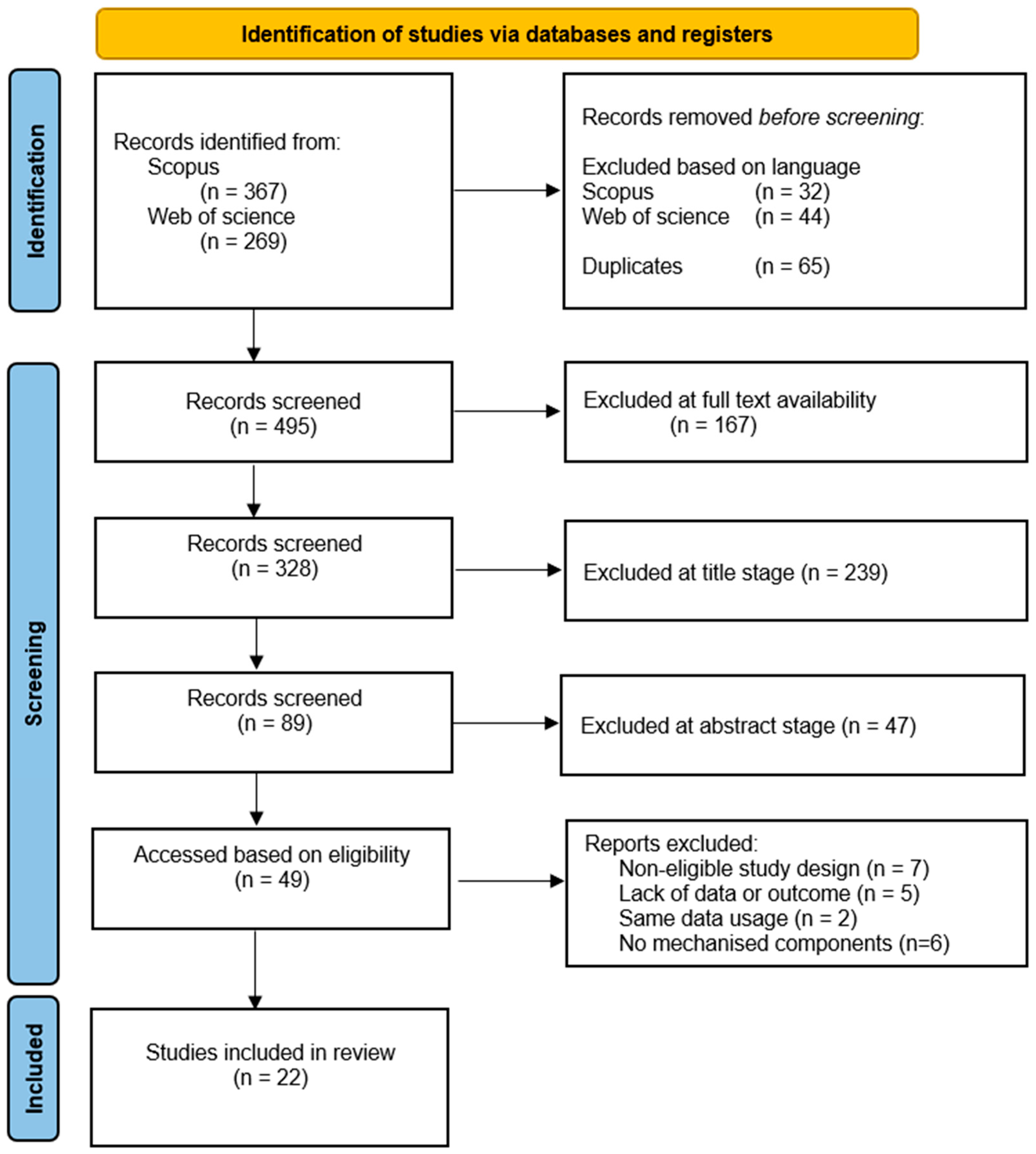

2. Materials and Methods

2.1. Eligibility Criteria

- Studies that presented qualitative and/or quantitative data related to sesame agronomic parameters, sesame planting methods, planting equipment, precision planting practices, and the integration of simulation models (such as DEM).

- Articles published in the English language.

- Publications released from the year 2000 onwards, in order to identify the agronomic requirements.

- Non-peer-reviewed materials such as theses and conference abstracts.

- Studies with a focus completely outside of this scope: studies focused completely on harvesting and post-harvest processing, without reference to plantings.

- Articles that were not available in full text.

2.2. Information Sources

2.3. Search Strategy

2.4. Study Selection

2.5. Data Collection Process and Data Items

- Agronomic variables: Seed characteristics (e.g., seed size, shape, density, thousand seed weight, and moisture content), seed spacing, sowing depth, population rate, and seedling emergence.

- Technological variables: Planter type, seed metering mechanism, seed delivery mechanism, operational speed, seed plate design, vacuum pressure, and singulation rates.

- Simulation data: Particle shape, contact models, restitution and friction coefficients, integration methods for DEM and CFD, and model validation methods.

2.6. Risk of Bias Assessment

2.7. Synthesis Method

3. Results

3.1. Sesame Seed Characteristics and Their Impact on Mechanisation

3.2. Seeding and Crop Establishment of Sesame

3.2.1. Agronomic Requirements of Mechanised Systems for Planting

3.2.2. Germination Process

3.2.3. Planting Depth

3.2.4. Plant Population

3.3. Adaptation of Mechanised Planting Practices in Sesame Cultivation

3.3.1. Broadcast Planting

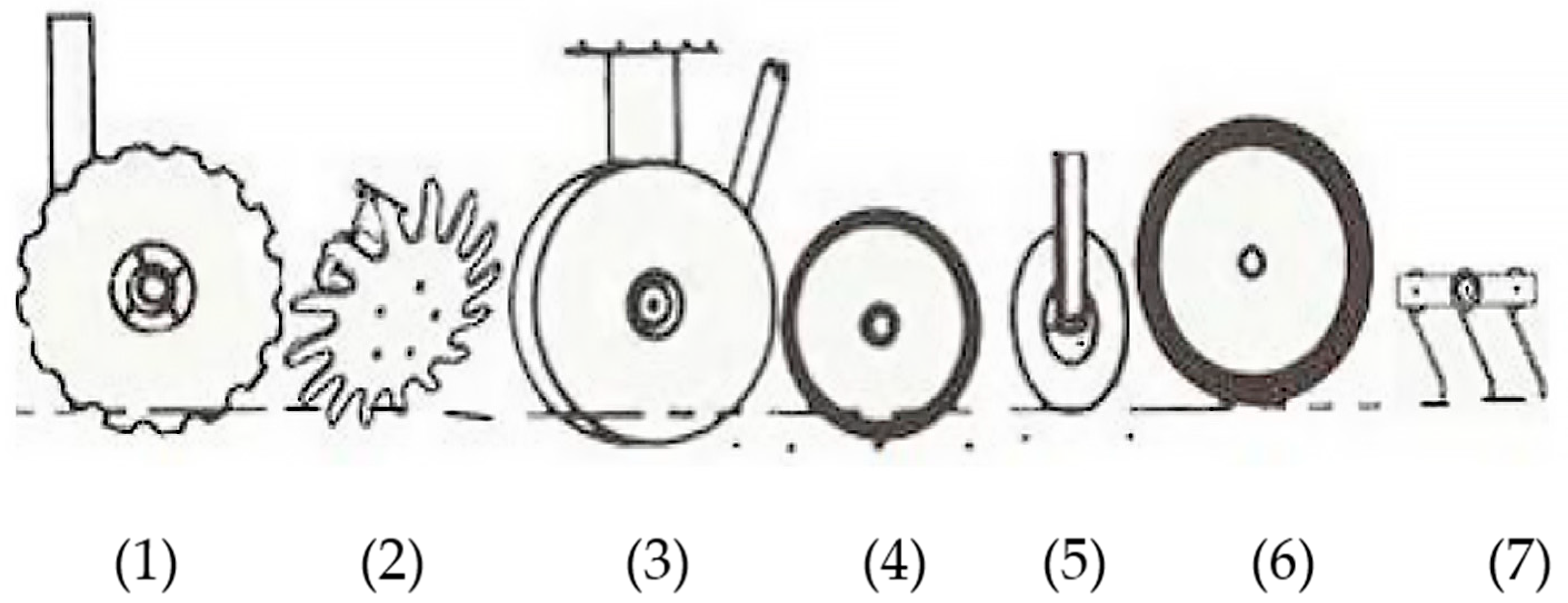

3.3.2. Drill Planters

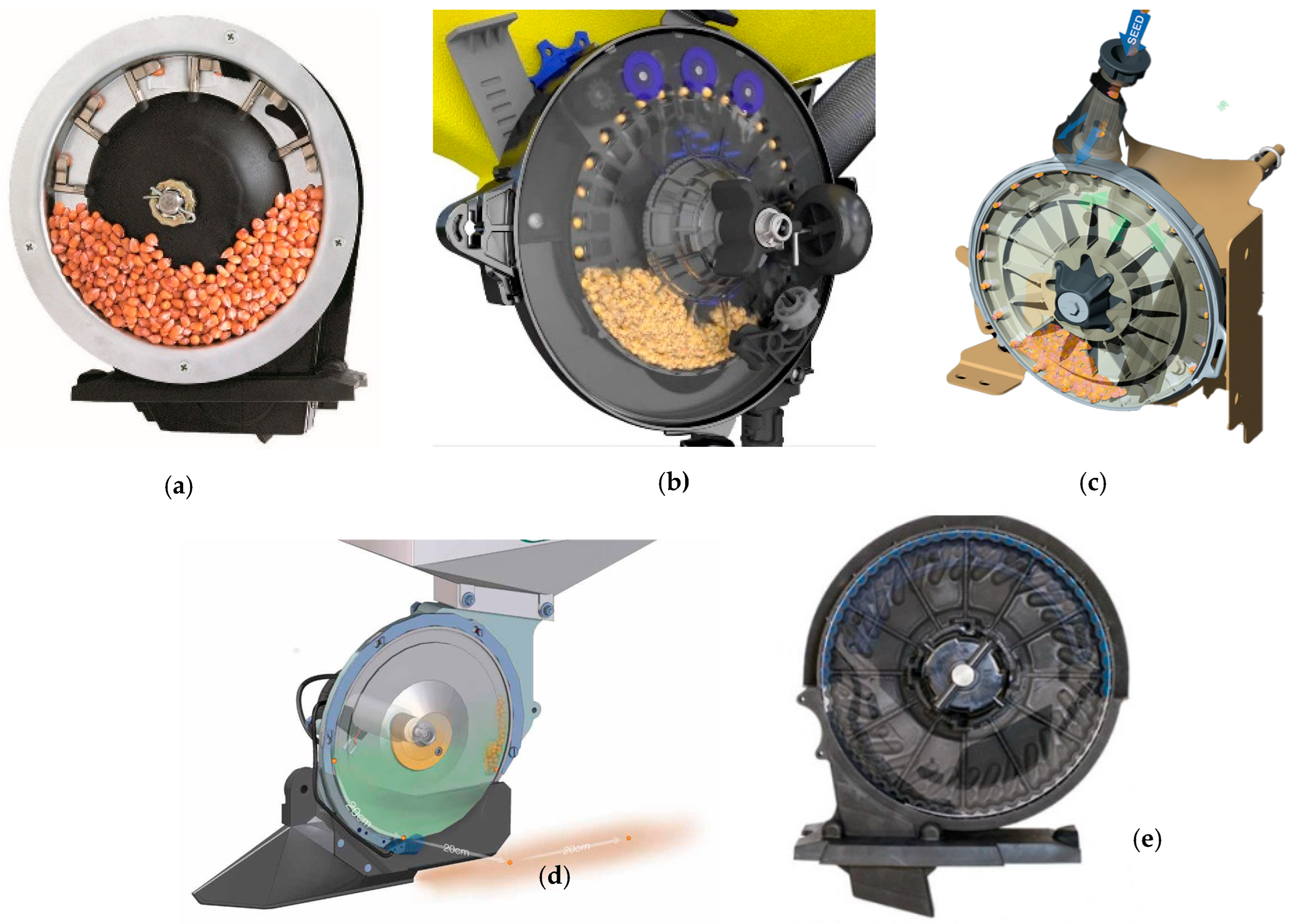

3.3.3. Precision Planters

3.4. State of the Art in the Precision Agriculture Mechanisation of Sesame and Other Small Seed Crops

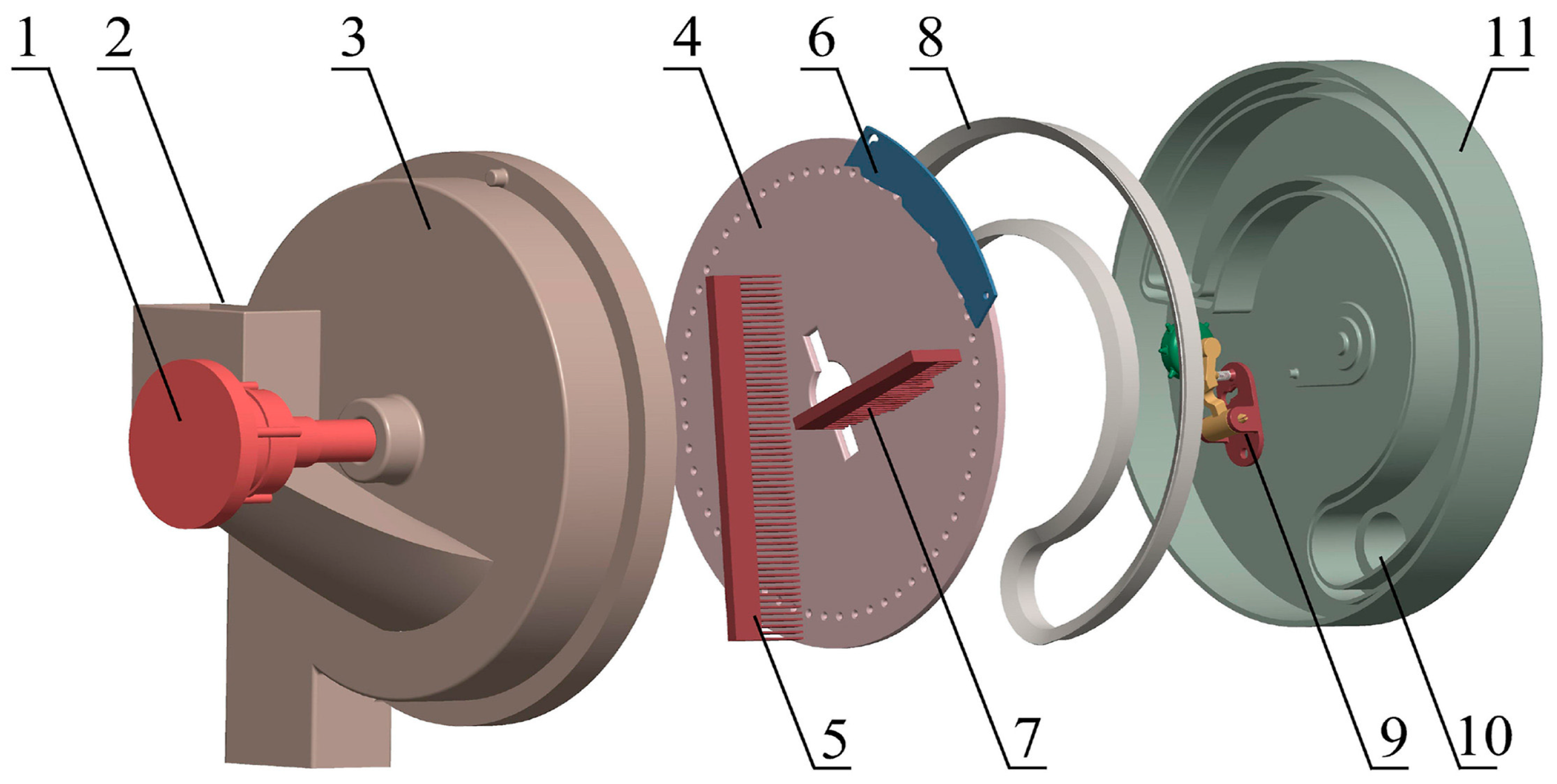

3.5. Functional Requirements of Precision Planting Equipment in Sesame Planting

3.6. Integration of Simulation Techniques in Precision Agriculture

4. Integration of Findings and Recommendations

5. Strengths and Limitations

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

| DEM | Discrete Element Method |

| GPS | Global Positioning System |

References

- Anilkumar, K.R.; Pal, A.; Khanum, F.; Bawa, A.S. Nutritional, Medicinal and IndustrialUses of Sesame (Sesamum indicum L.) Seeds—An Overview. Agric. Conspec. Sci. 2010, 75, 159–168. [Google Scholar]

- Lastra-Ripoll, S.E.; Quintana, S.E.; García-Zapateiro, L.A. Chemical, technological, and rheological properties of hydrocolloids from sesame (Sesamum indicum) with potential food applications. Arab. J. Chem. 2022, 15, 104146. [Google Scholar] [CrossRef]

- Jaffar, H.M.; Akhtar, I.; Saleem, M.Z.; Malik, T.; Ayub, A. A Comprehensive Review of the Health Benefits, Nutritional Composition, and Agricultural Aspects of Sesame Seeds. J. Food Biochem. 2025, 2025, 8713698. [Google Scholar] [CrossRef]

- Lin, X.; Zhou, L.; Li, T.; Brennan, C.; Fu, X.; Liu, R.H. Phenolic content, antioxidant and antiproliferative activities of six varieties of white sesame seeds (Sesamum indicum L.). RSC Adv. 2017, 7, 5751–5758. [Google Scholar] [CrossRef]

- Pathak, N.; Rai, A.K.; Kumari, R.; Thapa, A. Sesame Crop: An Underexploited Oilseed Holds Tremendous Potential for Enhanced Food Value. Agric. Sci. 2014, 5, 519–529. [Google Scholar] [CrossRef]

- Mushtaq, A.; Hanif, M.A.; Ayub, M.A.; Bhatti, I.A.; Jilani, M.I. Chapter 44—Sesame. In Medicinal Plants of South Asia; Hanif, M.A., Nawaz, H., Khan, M.M., Byrne, H.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 601–615. [Google Scholar]

- Muthulakshmi, C.; Sivaranjani, R.; Selvi, S. Modification of sesame (Sesamum indicum L.) for Triacylglycerol accumulation in plant biomass for biofuel applications. Biotechnol. Rep. 2021, 32, e00668. [Google Scholar] [CrossRef]

- Wacal, C.; Musinguzi, S.P.; Ewaju, E.; Atibo, C.; Alowo, D.; Alipa, J.; Basalirwa, D. Unravelling the potential benefits of sesame (Sesamum indicum L.) in cropping systems, nutritional, health, and industrial uses of its seeds—A review. Cogent Food Agric. 2024, 10, 2360766. [Google Scholar] [CrossRef]

- Pearce, D.; Jiang, T. Prospects for Australian Emerging Industries; Agrifutures: Wagga, Australia, 2023. [Google Scholar]

- Myint, D.; Gilani, S.A.; Kawase, M.; Watanabe, K.N. Sustainable Sesame (Sesamum indicum L.) Production through Improved Technology: An Overview of Production, Challenges, and Opportunities in Myanmar. Sustainability 2020, 12, 3515. [Google Scholar] [CrossRef]

- Barut, Z.; Cagirgan, I. Effect of seed coating on the accuracy of single-seed sowing of sesame under field conditions. Aust. J. Exp. Agric. 2006, 46, 71–76. [Google Scholar] [CrossRef]

- Sharaby, N.N.; Doroshenko, A.A.; Butovchenko, A.V. Simulation of Sesame Seeds Outflow in Oscillating Seed Metering Device Using DEM. Eng. Technol. Syst. 2020, 30, 219–231. [Google Scholar] [CrossRef]

- Topakci, M.; Karayel, D.; Canakci, M.; Furat, S.; Uzun, B. Sesame Hill Dropping Performance of a Vacuum Seeder for Different Tillage Practices. Appl. Eng. Agric. 2011, 27, 203–209. [Google Scholar] [CrossRef]

- Wang, B.; Liao, Q.; Wang, L.; Shu, C.; Cao, M.; Du, W. Design and Test of Air-Assisted Seed-Guiding Device of Precision Hill-Seeding Centralized Seed-Metering Device for Sesame. Agriculture 2023, 13, 393. [Google Scholar] [CrossRef]

- Langham, D. Technologies Used in The Cultivation of Mechanized Sesame (Sesamum indicum L.); CIPED: Campina Grande, Brazil, 2019. [Google Scholar]

- Bahnas, O. Requirements of Sesame Precision Planting Method. In Proceedings of the Misr Society of Agricultural Engineering, Egypt, 26–27 October 2011; pp. 513–524. [Google Scholar]

- Langham, D.R. Sesame Mechanization (Sesamum indicum L.)—A Family’s Life Journey. 2019. Available online: https://www.researchgate.net/profile/Derald-Langham/publication/330937574_MECHANIZATION_OF_SESAME_Sesamum_indicum_-_A_family's_life_journey/links/5c5c905892851c48a9c17cc8/MECHANIZATION-OF-SESAME-Sesamum-indicum-A-familys-life-journey.pdf (accessed on 1 July 2025).

- Dossa, K.; Wei, X.; Zhang, Y.; Fonceka, D.; Yang, W.; Diouf, D.; Liao, B.; Cissé, N.; Zhang, X. Analysis of Genetic Diversity and Population Structure of Sesame Accessions from Africa and Asia as Major Centers of Its Cultivation. Genes 2016, 7, 14. [Google Scholar] [CrossRef]

- Day, J. The effect of plant growth regulator treatments on plant productivity and capsule dehiscence in sesame. Field Crops Res. 2000, 66, 15–24. [Google Scholar] [CrossRef]

- Ishpekov, S.S. Releasing of seeds by a lateral mechanical impact for feeding sesame stems into harvester. Agric. Eng. Int. CIGR J. 2017, 19, 54–60. [Google Scholar]

- Day, J.S. Development and maturation of sesame seeds and capsules. Field Crops Res. 2000, 67, 1–9. [Google Scholar] [CrossRef]

- Cagirgan, M. Mutation Techniques in Sesame (Sesamum indicum L.) for Intensive Management: Confirmed Mutants; IAEA: Vienna, Austria, 2001. [Google Scholar]

- Ishpekov, S.S. Inertial detachment of sesame seeds from non-squander genotypes. Agric. Eng. Int. CIGR J. 2015, 17, 83–91. [Google Scholar]

- Doğan, T.; Aykas, E.; Tuvay, N.H.; Zeybek, A. A study on pelleting and planting sesame (Sesamum indicum L.) seeds. Asian J. Plant Sci. 2005, 4, 449–454. [Google Scholar] [CrossRef]

- Dogan, T.; Zeybek, A. Improving the traditional sesame seed planting with seed pelleting. Afr. J. Biotechnol. 2009, 8, 6120–6126. [Google Scholar]

- Barut, Z. Seed coating and tillage effects on sesame stand establishment and planter performance for single seed sowing. Appl. Eng. Agric. 2008, 24, 565–571. [Google Scholar] [CrossRef]

- Chen, K.; Gao, S.; Wang, C.; Yuan, Y.; Zhao, B.; Zhou, L.; Niu, K.; Wang, H.; Zheng, Y. Design and Analysis of a High-Precision Dynamic Compensation System for Seed Dropping Position in Corn Sowing Operations. Appl. Sci. 2023, 13, 7741. [Google Scholar] [CrossRef]

- Terefe, G.; Berhe, M.; Wakjira, A.; Tadese, H. Sesame Production Manual; Ethiopian Institute of Agricultural Research: Addis Ababa, Ethiopia, 2012. [Google Scholar]

- Tugwell, P.; Tovey, D. PRISMA 2020; Elsevier: Amsterdam, The Netherlands, 2021; Volume 134, pp. A5–A6. [Google Scholar]

- Oloniruha, J.; Ogundare, S.; Olajide, K. Growth and yield of sesame (Sesamum indicum) as influenced by plant population density and organo-mineral fertilizer rates. Agro-Sci. 2021, 20, 15–21. [Google Scholar] [CrossRef]

- Tony, M. National Sesame Agronomy Trials: 2020 Field and Pot Trials; AgriFutures: Wagga, Australia, 2023. [Google Scholar]

- Araujo, M.; Barbosa, E.G.; Gomes, F.A.; Teixeira, I.R.; Lisboa, C.F.; Araújo, R.S.; Corrêa, P.C. Physical properties of sesame seeds harvested at different maturation stages and thirds of the plant. Chilean Chil. J. Agric. Res. 2018, 78, 495–502. [Google Scholar] [CrossRef]

- Bennett, M.; Condé, B. Sesame Recommendations for the Northern Territory. Available online: https://daf.nt.gov.au/publications/publications-search/publications-database/primary-industry/crop/657.pdf (accessed on 10 April 2025).

- Elsayed, A.; EL-Wahab, M.A.; Hanan, M.; Allah, W.A. Performance cleaning unit for sesame and clover seeds affecting some physical and mechanical properties. Agric. Eng. Int. CIGR J. 2023, 25, 296–311. [Google Scholar]

- Ali, O.; Gunri, S.K.; Bishnu, P.; Goswami, S.; Roy, D. Effect of Planting Methods in Different Sesame (Sesamum indicum L.) Varieties during the Summer Season. Int. J. Bio-Resour. Stress Manag. 2024, 15, 1–8. [Google Scholar] [CrossRef]

- Shambhu, V.; Thakur, A. Laboratory and field performance of manual seed drill for sowing jute and tiny seeds. Indian J. Agric. Sci. 2019, 89, 129–132. [Google Scholar] [CrossRef]

- Duna, K.; Pragna, G. Evaluation of tractor drawn seed drill for sesame. Agric. Update 2017, 12, 1833–1837. [Google Scholar]

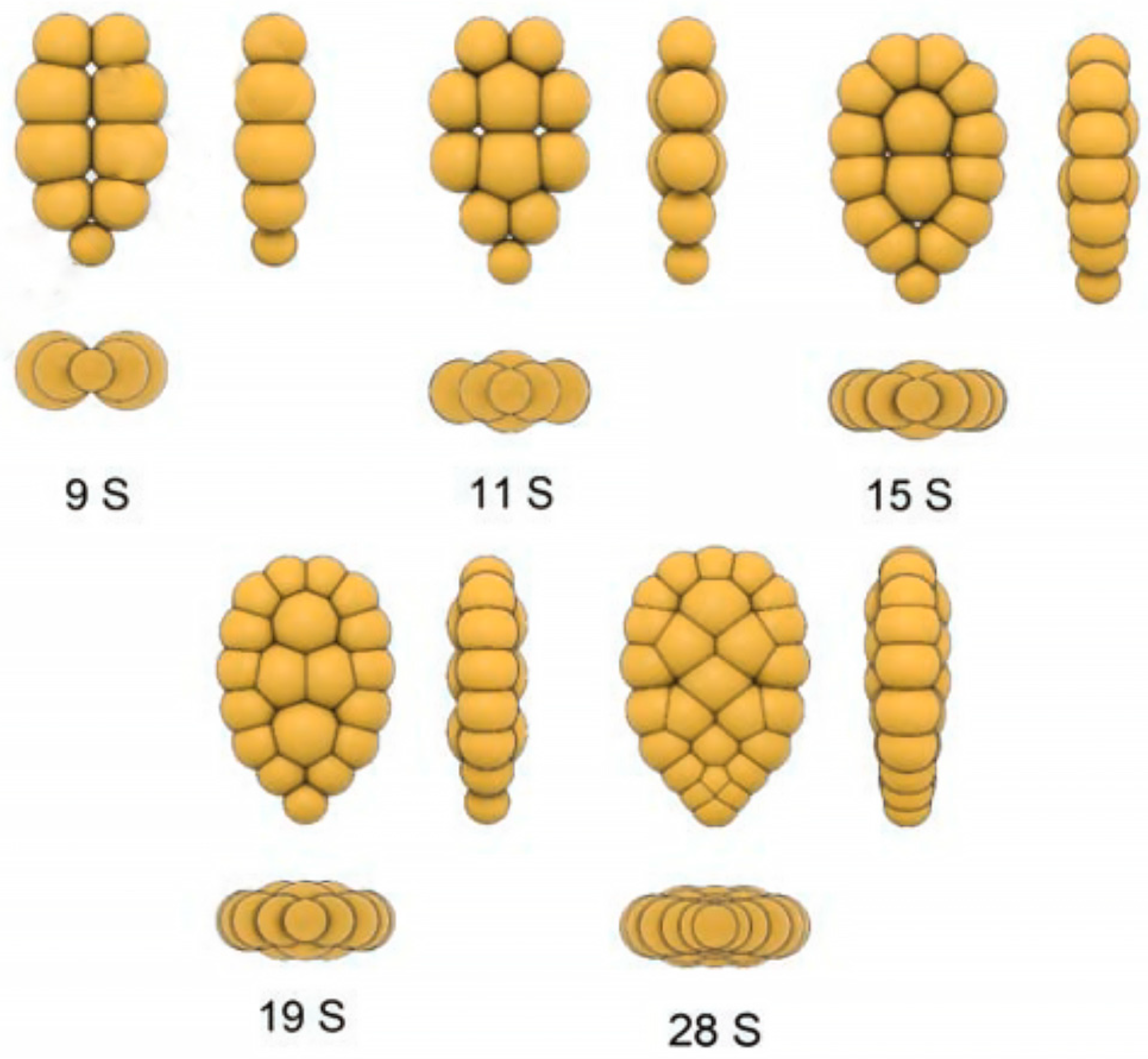

- Sharaby, N.; Doroshenko, A.; Butovchenko, A. Modelling and verification of sesame seed particles using the discrete element method. J. Agric. Eng. 2022, 53. [Google Scholar] [CrossRef]

- Xu, J.; Sun, S.; He, Z.; Wang, X.; Zeng, Z.; Li, J.; Wu, W. Design and optimisation of seed-metering plate of air-suction vegetable seed-metering device based on DEM-CFD. Biosyst. Eng. 2023, 230, 277–300. [Google Scholar] [CrossRef]

- Jianbo, Z.; Junfang, X.; Yong, Z.; Shun, Z. Design and experimental study of the control system for precision seed-metering device. Int. J. Agric. Biol. Eng. 2014, 7, 13–18. [Google Scholar]

- Fisher, K.A.; Momen, B.; Kratochvil, R.J. Is Broadcasting Seed an Effective Winter Cover Crop Planting Method? Agron. J. 2011, 103, 472–478. [Google Scholar] [CrossRef]

- Brennan, E.B.; Leap, J.E. A Comparison of Drill and Broadcast Methods for Establishing Cover Crops on Beds. HortScience Horts 2024, 49, 441–447. (In English) [Google Scholar] [CrossRef]

- Li, Z.; Wu, J.; Du, J.; Duan, D.; Zhang, T.; Chen, Y. Experimenting and Optimizing Design Parameters for a Pneumatic Hill-Drop Rapeseed Metering Device. Agronomy 2023, 13, 141. [Google Scholar] [CrossRef]

- Langham, D.R.; Riney, J.; Aubin, J.; Peeper, D.; Speed, T.; Smith, G.; Wiemers, T. Sesame Harvest Guide; SESACO: Austin, TX, USA, 2010; Available online: www.sesaco.com (accessed on 1 July 2025).

- Arafa, G.K. Some physical and mechanical properties of sesame seeds concerning the selection of separtion unit. Process Eng. 2007, 24, 415–429. [Google Scholar]

- Tang, H.; Xu, C.; Wang, Z.; Wang, Q.; Wang, J. Optimized design, monitoring system development and experiment for a long-belt finger-clip precision corn seed metering device. Front. Plant Sci. 2022, 13, 814747. [Google Scholar] [CrossRef]

- Azeez, M.; Morakinyo, J. Genetic diversity of the seed physical dimensions in cultivated and wild relatives of sesame (genera Sesamum and Ceratotheca). Int. J. Plant Breed. Genet. 2011, 5, 369–378. [Google Scholar] [CrossRef]

- Jack, D.S.; Hesterman, D.C.; Guzzomi, A.L. Precision metering of Santalum spicatum (Australian Sandalwood) seeds. Biosyst. Eng. 2013, 115, 171–183. [Google Scholar] [CrossRef]

- Kaliniewicz, Z.; Anders, A.; Markowski, P.; Tylek, P.; Owoc, D. Analysis of the physical properties of spindle seeds for seed sorting operations. Sci. Rep. 2021, 11, 13625. [Google Scholar] [CrossRef]

- Dun, G.; Mao, N.; Gao, Z.; Wu, X.; Liu, W.; Zhou, C. Model construction of soybean average diameter and hole parameters of seed-metering wheel based on DEM. Int. J. Agric. Biol. Eng. 2022, 15, 101–110. [Google Scholar] [CrossRef]

- Boydas, M. Influence of seed physical properties and speed on the external mechanical damage index and in-row spacing uniformity in an automatic potato planter. J. Agric. Sci. 2012, 18, 126–136. [Google Scholar]

- Tunde-Akintunde, T.; Akintunde, B. Some physical properties of sesame seed. Biosyst. Eng. 2004, 88, 127–129. [Google Scholar] [CrossRef]

- Kailashkumar, B.; Albert, V.A. Optimization of Pertinent Variables for Threshing of Sesame Crop using a Test Rig. Agric. Sci. Digest. 2023, D-5781. [Google Scholar] [CrossRef]

- Wang, Q.; Meng, Z.-J.; Wen, C.-K.; Qin, W.-C.; Wang, F.; Zhang, A.-Q.; Zhao, C.-J.; Yin, Y.-X. Grain combine harvester header profiling control system development and testing. Comput. Electron. Agric. 2024, 223, 109082. [Google Scholar] [CrossRef]

- Soyoye, B.O.; Ademosun, O.C.; Agbetoye, L.A. Determination of some physical and mechanical properties of soybean and maize in relation to planter design. Agric. Eng. Int. CIGR J. 2018, 20, 81–89. [Google Scholar]

- Yamin, M.; Mulyani, S.; Suhadi, S.; RS, T.H. Assesment of Viability of Sesame (Sesamum indicum L.) Seeds Using Germination Method with Paper Media. Agrotech J. 2022, 7, 69–73. [Google Scholar]

- Jing, Z.; Tianlu, W.; Qianqian, C. Mechanical modeling and compression test of sesame seed based on 3D laser scanning technology. Proc. SPIE 2022, 12261, 1226138. [Google Scholar] [CrossRef]

- Qureshi, M.; Langham, D.R.; Lucas, S.J.; Uzun, B.; Yol, E. Breeding history for shattering trait in sesame: Classic to genomic approach. Mol. Biol. Rep. 2022, 49, 7185–7194. [Google Scholar] [CrossRef]

- Langham, D. Shatter Resistance in Sesame; FAO/IAEA Division of Nuclear Techniques in Food and Agriculture: Vienna, Austria, 2001. [Google Scholar]

- Ahmed, J.; Qadir, G.; Ansar, M.; Wattoo, F.M.; Javed, T.; Ali, B.; Marc, R.A.; Rahimi, M. Shattering and yield expression of sesame (Sesamum indicum L.) genotypes influenced by paclobutrazol concentration under rainfed conditions of Pothwar. BMC Plant Biol. 2023, 23, 137. [Google Scholar] [CrossRef]

- Agidew, M.G.; Dubale, A.A.; Atlabachew, M.; Abebe, W. Fatty acid composition, total phenolic contents and antioxidant activity of white and black sesame seed varieties from different localities of Ethiopia. Chem. Biol. Technol. Agric. 2021, 8, 14. [Google Scholar] [CrossRef]

- Wei, P.; Zhao, F.; Wang, Z.; Wang, Q.; Chai, X.; Hou, G.; Meng, Q. Sesame (Sesamum indicum L.): A Comprehensive Review of Nutritional Value, Phytochemical Composition, Health Benefits, Development of Food, and Industrial Applications. Nutrients 2022, 14, 4079. [Google Scholar] [CrossRef] [PubMed]

- Asscheman, A. John Deere announces Furrow Vision for measuring seed depth. In Gateway to the World of Smart Farming; Future Farming: Nottinghamshire, UK, 2023; Volume 2025. [Google Scholar]

- Rani, M.; Kaushik, P.; Bhayana, S.; Kapoor, S. Impact of organic farming on soil health and nutritional quality of crops. J. Saudi Soc. Agric. Sci. 2023, 22, 560–569. [Google Scholar] [CrossRef]

- Rodrigues, A.F.; de Souza, T.A.F.; Marques, L.F.; Souto, J.S.; da Silva, W.P. Agricultural management practices: Effects on soil properties, root growth and sesame yield. Russ. Agric. Sci. 2016, 42, 321–327. [Google Scholar] [CrossRef]

- Langham, D.R.; Riney, J.; Smith, G.; Wiemers, T. Sesame Grower Guide; SESACO: Austin, TX, USA, 2008. [Google Scholar]

- Ahmed, M.; Kheir, A.; Mehmood, M.Z.; Ahmad, S.; Hasanuzzaman, M. Changes in Germination and Seedling Traits of Sesame under Simulated Drought. Phyton 2022, 91, 713–726. [Google Scholar] [CrossRef]

- Gebregergis, Z.; Baraki, F.; Fiseseha, D. Effects of environmental factors and storage periods on sesame seed quality and longevity. CABI Agric. Biosci. 2024, 5, 47. [Google Scholar] [CrossRef]

- Jańczak-Pieniążek, M.; Buczek, J.; Bobrecka-Jamro, D.; Szpunar-Krok, E.; Tobiasz-Salach, R.; Jarecki, W. Morphophysiology, Productivity and Quality of Soybean (Glycine max (L.) Merr.) cv. Merlin in Response to Row Spacing and Seeding Systems. Agronomy 2021, 11, 403. [Google Scholar] [CrossRef]

- Masilamani, P.; Venkatesan, S.; Navamaniraj, K.N.; Rajarathinam, P.; Alagesan, A.; Thiagu, K. Impact of the orientation of seed placement and depth of its sowing on germination: A review. J. Appl. Nat. Sci. 2023, 15, 314. [Google Scholar] [CrossRef]

- Mohamoud, M.; Abdalla, A.; Muna, E.; Yousif, L. Estimation of Water Requirement and Water Productivity of Sesame Crop (Sesamum indicum L.) in Dryland Areas of Sennar State, Sudan. Sudan J. Des. Res. 2019, 11, 1–16. [Google Scholar]

- Brown, P.H.; Zhao, F.-J.; Dobermann, A. What is a plant nutrient? Changing definitions to advance science and innovation in plant nutrition. Plant Soil 2021, 476, 11–23. [Google Scholar] [CrossRef]

- Zhang, X.; Li, S.; An, X.; Song, Z.; Zhu, Y.; Tan, Y.; Guo, X.; Wang, D. Effects of nitrogen, phosphorus and potassium formula fertilization on the yield and berry quality of blueberry. PLoS ONE 2023, 18, e0283137. (In English) [Google Scholar] [CrossRef] [PubMed]

- Soltani, E.; Baskin, C.C.; Gonzalez-Andujar, J.L. An Overview of Environmental Cues That Affect Germination of Nondormant Seeds. Seeds 2022, 1, 146–151. [Google Scholar] [CrossRef]

- Mayer, A.M.; Poljakoff-Mayber, A. The Germination of Seeds; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Jyoti, S.; Patel, J.; Babariya, C. Study the Fresh Seed Dormancy in Sesame (Sesamum indicum L.). Indian J. Pure Appl. Biosci. 2021, 1, 457–462. [Google Scholar] [CrossRef]

- Rathore, J.; Gupta, K.; Verma, B.; Athya, D.P. Effect of weather parameters on disease development of root and stem rot of sesame caused by Sesamum indicum L. Int. J. Chem. Stud. 2021, 9, 2123–2126. [Google Scholar] [CrossRef]

- Bewley, J.D.; Bradford, K.J.; Hilhorst, H.W.; Nonogaki, H. Development and maturation. In Seeds: Physiology of Development, Germination and Dormancy, 3rd ed.; Springer: New York, NY, USA, 2013; pp. 27–83. [Google Scholar]

- Shim, K.-B.; Cho, S.K.; Hwang, J.D.; Pae, S.B.; Lee, M.H.; Ha, T.J.; Byun, J.C. Effect of seed priming treatment on the germination of sesame. Korean J. Crop Sci. 2009, 54, 416–421. [Google Scholar]

- Soureshjani, H.K.; Bahador, M.; Tadayon, M.; Dehkordi, A.G. Modelling seed germination and seedling emergence of flax and sesame as affected by temperature, soil bulk density, and sowing depth. Ind. Crops Prod. 2019, 141, 111770. [Google Scholar] [CrossRef]

- Rixon, C.; Adorada, D.; Umansky, F.; Chauhan, B.; Bhattarai, S.; Biggs, I.; Trotter, T. Sesame Grower Guide. Available online: https://crcna.com.au/wp-content/uploads/2025/03/Sesame-Grower-Guide-Dec-2024.pdf (accessed on 3 June 2025).

- Crawford, L.E.; Williams, M.M. Planting Depth and Seed Size Affect Edamame Emergence Individually. HortScience Horts 2019, 54, 92–94. (In English) [Google Scholar] [CrossRef]

- Ahmed, N.; Yong, L.X.; Yang, J.H.C.; Siow, K.S. Review of Non-Thermal Plasma Technology and Its Potential Impact on Food Crop Seed Types in Plasma Agriculture. Plasma Chem. Plasma Process. 2024, 45, 421–462. [Google Scholar] [CrossRef]

- Wang, S.; Yi, S.; Zhao, B.; Li, Y.; Li, S.; Tao, G.; Mao, X.; Sun, W. Sowing depth monitoring system for high-speed precision planters based on multi-sensor data fusion. Sensors 2024, 24, 6331. [Google Scholar] [CrossRef]

- Roy, N. Population dynamics and economic thresholds based time series for smart pest management of sesame. Int. J. Trop. Insect Sci. 2021, 41, 2573–2584. [Google Scholar] [CrossRef]

- Seay, D.; Szczepanek, A.; De La Fuente, G.N.; Votava, E.; Abdel-Haleem, H. Genetic diversity and population structure of a large USDA sesame collection. Plants 2024, 13, 1765. [Google Scholar] [CrossRef]

- Reshadsedghi, A. The impact of irrigation method on soil salinity distribution. J. Biodivers. Environ. Sci. 2018, 12, 110–118. [Google Scholar]

- Yang, L.; Yan, B.X.; Yu, Y.M.; He, X.T.; Liu, Q.W.; Liang, Z. Global overview of research progress and development of precision maize planters. Int. J. Agric. Biol. Eng. 2016, 9, 9–26. [Google Scholar]

- Karayel, D.; Jotautiené, E.; Sarauskis, E.; Rossi, S.; Scola, I.E.J.R.; Bourges, G. Evaluation of Monitoring Systems for Seeder Seed Spacing Uniformity; International Scientific Publications: Burgas, Bulgaria, 2024. [Google Scholar]

- Liu, R.; Wu, G.; Dong, J.; Yan, B.; Meng, Z. Improving Sowing Uniformity of a Maize High-Speed Precision Seeder by Incorporating Energy Dissipator. Agriculture 2024, 14, 1237. [Google Scholar] [CrossRef]

- Lu, P.; Jiang, B.; Weiner, J. Chapter Three—Crop spatial uniformity, yield and weed suppression. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: San Diego, CA, USA, 2020; Volume 161, pp. 117–178. [Google Scholar]

- Weiner, J. Weed suppression by cereals: Beyond ‘competitive ability’. Weed Res. 2023, 63, 133–138. [Google Scholar] [CrossRef]

- Dhillon, R.; Moncur, Q. Small-scale farming: A review of challenges and potential opportunities offered by technological advancements. Sustainability 2023, 15, 15478. [Google Scholar] [CrossRef]

- Zhang, J.; Hou, Y.; Ji, W.; Zheng, P.; Yan, S.; Hou, S.; Cai, C. Evaluation of a real-time monitoring and management system of soybean precision seed metering devices. Agronomy 2023, 13, 541. [Google Scholar] [CrossRef]

- Machinio. Monosem NG+ 4 Pricing Information. Available online: https://www.machinio.com/models/monosem/ngplus-4 (accessed on 20 July 2025).

- Fue, K.G.; Baitu, G.P.; Jokonya, O.; Banwart, S.; Korsten, L. Digitalization of precision fertilization in East Africa: Adoption, benefits and losses. Front. Sustain. Food Syst. 2025, 9, 1497577. (In English) [Google Scholar] [CrossRef]

- Thentu, T.; Sirisha, A.B.M.; Sreekanth, P.M.; Naik, S.; Reddy, K.M. Enhancing sesame yield and profitability through refurbished tractor-drawn seed drills in coastal Andhra Pradesh. Int. J. Res. Agron. 2024, 7, 82–87. [Google Scholar] [CrossRef]

- Kienzle, J. Precision Agriculture for Smallholder Famers. In Agriculture for Development TAA; TAA: Singapore, 2013; pp. 12–15. ISSN 1759-0604. [Google Scholar]

- Choudhary, S.; Jain, M.; Upadhyay, G.; Rani, V.; Patel, B. Naresh Engineering Properties of Various Seeds for Development of a Multi Crop Seed Metering Mechanism Suitable for Intercropping. J. Inst. Eng. (India) Ser. A 2025, 106, 553–566. [Google Scholar] [CrossRef]

- Murray, J.R.; Tullberg, J.N.; Antille, D.L. Selecting and Managing No-Till Planters and Controlled Traffic Farming in Extensive Grain Production Systems. In No-Till Farming Systems for Sustainable Agriculture: Challenges and Opportunities; Dang, Y.P., Dalal, R.C., Menzies, N.W., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 83–105. [Google Scholar]

- Shaner, D.L.; Beckie, H.J. The future for weed control and technology. Pest Manag. Sci. 2014, 70, 1329–1339. [Google Scholar] [CrossRef] [PubMed]

- Gürsoy, S. Türkiye’de İmal Edilen Doğrudan Anıza Ekim Makinalarının Değerlendirilmesi. Yuz. Yıl Univ. J. Agric. Sci. 2013, 23, 185–192. [Google Scholar]

- Kumar, R.; Raheman, H. Detection of flow of seeds in the seed delivery tube and choking of boot of a seed drill. Comput. Electron. Agric. 2018, 153, 266–277. [Google Scholar] [CrossRef]

- Sharaby, N.; Doroshenko, A.; Butovchenko, A.; Legkonogih, A. A Comparative Analysis of Precision Seed Planters. In Proceedings of the Innovative Technologies in Environmental Science and Education (ITESE-2019), Divnomorskoe Village, Russia, 9–14 September 2019; EDP Sciences: Les Ulis, France, 2019; Volume 135, p. 01080. [Google Scholar] [CrossRef]

- Khan, K.; Moses, S.; Kumar, A. The design and fabrication of a manually operated single row multi-crops planter. J. Agric. Vet. Sci. (IOSR-JAVS) 2015, 8, 147–158. [Google Scholar]

- Li, Y.; Hu, X.; Chen, T.; Zhang, D.; Song, S.; Zhang, R.; Wang, M. Development of mechatronic driving system for seed meters equipped on conventional precision corn planter. Int. J. Agric. Biol. Eng. 2015, 8, 1–9. [Google Scholar] [CrossRef]

- Xing, H.; Cao, X.; Zhong, P.; Wan, Y.; Lin, J.; Zang, Y.; Zhang, G. DEM-CFD coupling simulation and optimisation of rice seed particles seeding a hill in double cavity pneumatic seed metering device. Comput. Electron. Agric. 2024, 224, 109075. [Google Scholar] [CrossRef]

- Ding, B.; Liang, Z.; Qi, Y.; Ye, Z.; Zhou, J. Improving cleaning performance of rice combine harvesters by DEM–CFD coupling technology. Agriculture 2022, 12, 1457. [Google Scholar] [CrossRef]

- Yang, J.; Wu, H.; Guo, A.; Rugerinyange, R.; Liu, C.; Zhao, Z.; Han, W.; Yin, L. Performance Optimization and Simulation Test of No-Tillage Corn Precision Planter Based on Discrete Element Method (DEM). Machines 2024, 12, 465. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, J.; Zhao, X.; Zhang, L.; Zhou, D.; Yu, C.; Hu, W.; Zhang, Q. Optimising maize threshing by integrating DEM simulation and interpretive enhanced predictive modelling. Biosyst. Eng. 2024, 244, 93–106. [Google Scholar] [CrossRef]

- Oliveira, L.; Ortiz, B.; Pate, G.; Way, T.; Silva, R. Soil and crop response to varying planter’s downforce in corn and cotton fields. Smart Agric. Technol. 2025, 10, 100798. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, L.; Yuan, F.; Wang, L. Simulation Study of Rice Cleaning Based on DEM-CFD Coupling Method. Processes 2022, 10, 281. [Google Scholar] [CrossRef]

- Zhao, H.; Huang, Y.; Liu, Z.; Liu, W.; Zheng, Z. Applications of discrete element method in the research of agricultural machinery: A review. Agriculture 2021, 11, 425. [Google Scholar] [CrossRef]

- Tilmor. Wizard Precision Vacuum Planter/Seeder 3PT Hitch—12V Electric; Tilmor LLC: Dalton, OH, USA, 2024; Volume 2025. [Google Scholar]

- Rathod, V. A Review on Seed Sowing Method and Alternative Method for Small Farmers. Int. J. Res. Eng. Sci. Manag. 2023, 2, 194–196. [Google Scholar]

- FAO. Good Agriculture Practices (GAP), Sesame; FAO: Nai Pyi Taw, Myanmar, 2023. [Google Scholar]

- Meng, M.; Yu, L.; Yu, X. Machinery structure, machinery subsidies, and agricultural productivity: Evidence from China. Agric. Econ. 2024, 55, 223–246. [Google Scholar] [CrossRef]

- Monosem. 7x7 NG+4 Series Planters Mounted Rigid Frames; Deere & Company: Moline, IL, USA, 2019. [Google Scholar]

- Trotter, T.; McDonald, A. Growing Sesame in Australia—Planting, Nourishing and Harvesting; AgriFutures: Wagga, Australia, 2024. [Google Scholar]

- Gong, H.; Chen, Y.; Wu, S.; Tang, Z.; Liu, C.; Wang, Z.; Fu, D.; Zhou, Y.; Qi, L. Simulation of canola seedling emergence dynamics under different soil compaction levels using the discrete element method (DEM). Soil Tillage Res. 2022, 223, 105461. [Google Scholar] [CrossRef]

- Narayanan, R.; Bhattarai, S.; Tram, V.H.; Hunter, L. Adapting grain crop seed threshing equipment for processing sesame for streamlining the mechanisation of post-harvest operations. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Philadelphia, PA, USA, 2024; Volume 1290, p. 012015. [Google Scholar]

- Narayanan, R.; Tram, V.H.; Trotter, T.; Rixon, C.; Raveendran, G.; Umansky, F.; Bhattarai, S.P. Adaptation of Grain Cleaning Equipment for Kalonji and Sesame Seeds. AgriEngineering 2025, 7, 179. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

| Author(s) | Year | Title | Study Type | Key Findings | Geographic Focus |

|---|---|---|---|---|---|

| Studies related to agronomic parameters | |||||

| Oloniruha et al. [30] | 2021 | Growth and Yield of Sesame as Influenced by Plant Population Density and Organo-Mineral Fertilizer Rates | Field experiment | Best yield (approximately 1.45 t/ha) achieved with 111,111 plants/ha. Wider spacing improved individual plant yield but reduced yield per hectare. | Nigeria |

| Tony [31] | 2023 | National Sesame Agronomy Trials: 2020 Field and Pot Trials | Field trials (report) | Mid-December sowing gave the highest yields (1.4–1.6 t/ha irrigated). Optimum plant density: 5–10 plants/m2. Emergence and yield were sensitive to sowing date and water availability. Seeding precision is not quantified. | Australia |

| Araujo et al. [32] | 2018 | Physical Properties of Sesame Seeds at Different Maturation Stages and Plant Positions | Field trials (report) | Thousand-seed weight of black: 2.71 g and cream: 2.48 g. Seeds from lower canopy larger than upper. Maximum seed mass at ~70% physiological maturity. Findings guide design of metering and sorting systems considering internal seed variability. | Australia |

| Day [19] | 2000 | The effect of plant growth regulator treatments on plant productivity and capsule dehiscence in sesame | Field experiment | Gibberellic acid increased capsule retention by 10%, but inconsistent yield benefits (5–7%). Increased plant height and delayed maturity. Not recommended under low-input systems. | New Zealand |

| Bennett and Conde [33] | 2003 | Northern Territory Sesame Variety and Agronomy Trial | Agronomy guide/report | Yield ranged from 0.5 to 1.0 t/ha depending on row spacing (30 cm). Mechanisation not tested, but results guided spacing and sowing date for Northern Territory conditions. | Australia |

| Elsayed et al. [34] | 2023 | Performance of a Cleaning Unit for Sesame Seeds Affecting Some Physical and Mechanical Properties | Experimental (machine) | Optimised parameters: sieve with 3 mm holes, 160 rpm oscillation, 3° inclination. Achieved 99.78% seed purity and 95.33% cleaning efficiency at a feed rate of 50 kg/h. Maintained seed integrity. | Egypt |

| Studies related to planting technologies | |||||

| Topakcı et al. [13] | 2011 | Sesame Hill Dropping Performance of a Vacuum Seeder for Different Tillage Practices | Field experiment | Under reduced till: 78% emergence, 86% single-seed hills. Under no-till 62% emergence, 66% single-seed hills. Indicates 16–20% loss in seeding precision with no-till. Tillage improves planter performance significantly. | Turkey |

| Barut [26] | 2008 | Seed Coating and Tillage Effects on Sesame Stand Establishment and Planter Performance | Field experiment | Feed index improved with coating: ~81.3%. Miss rate decreased to 8.6% with coated vs. 11.1% uncoated. Emergence: uncoated seeds 4.5 days and coated 6.2 days. Tillage had negligible impact on feed rate but improved emergence slightly. | Turkey |

| Ali et al. [35] | 2024 | Effect of Planting Methods in Different Sesame Varieties during the Summer Season | Field experiment | Line sowing produced 1.58 t/ha yield, compared to 1.46 t/ha in broadcasting. Although broadcasting had a slightly better benefit–cost ratio (1.82 and 1.76), line sowing improved crop uniformity and emergence. | India |

| Shambhu & Thakur [36] | 2019 | Laboratory and Field Performance of Manual Seed Drill for Sowing Jute and Tiny Seeds | Prototype testing | Required draft: 75 N. Labour requirement: ~6 man-hours/ha. The manual seed drill achieved uniform spacing and better emergence than broadcasting. Shows potential for sesame where mechanised equipment is unavailable. | India |

| Duna & Pragna [37] | 2017 | Evaluation of Tractor-Drawn Seed Drill for Sesame | Field evaluation | Developed a 5-row planter with spacing accuracy ±2 cm. Emergence rate > 85%. Manual labour has reduced significantly. Suitable for broadacre sesame planting. | India |

| Barut & Çagırgan [11] | 2006 | Effect of Seed Coating on the Accuracy of Single-Seed Sowing of Sesame | Field experiment | Coated seeds: emergence around 62%, uncoated seeds: ~85%. Coated seeds had up to 3 days of delay in emergence. Demonstrate coating negatively affects field emergence. | Turkey |

| Bahnas [16] | 2009 | Requirements for Sesame Precision Planting Method | Experiment | Recommended settings: suction pressure −2.5 to −1.5 kPa, suction hole diameter 1.8–2.2 mm, 1 seed/hill, 30 cm row spacing. Based on sesame seed size (2.8 × 2.3 mm). Provides specific design criteria for pneumatic planters. | Egypt |

| Studies focusing on simulation integration | |||||

| Sharaby, Doroshenko & Butovchenko [12] | 2020 | Simulation of Sesame Seeds Outflow in Oscillating Seed Metering Device Using DEM | Simulation (DEM) | DEM simulation of an oscillating hill drop planter showed each seed hole discharged 0–4 seeds (mean ≈ 2 seeds) per cycle, indicating very high variability in seed flow. The model tracks each seed’s trajectory and forces, enabling analysis of how kinematic (oscillation angle, speed) and geometric (hole size, drop height) changes affect output. These results can guide optimisation of planter parameters (e.g., reducing oscillation amplitude or adjusting exit-hole size) to improve singulation and stand uniformity. (Model was validated for sesame seed shape and could inform design of oscillating seeders.) | Egypt/Russia |

| Wang et al. [14] | 2023 | Design and Test of Air-Assisted Seed-Guiding Device of Precision Hill-Seeding Meter for Sesame | Design and testing (CFD/DEM + field) | Developed an air-guided seeder achieving 87% hill accuracy. Simulation and field trials validated optimal airflow and geometry settings, confirming improved precision hill-seeding for sesame. | China |

| Sharaby, Doroshenko & Butovchenko [38] | 2022 | Modelling and Verification of Sesame Seed Particles Using DEM | Simulation (DEM) | Validated multi-sphere DEM model for sesame seed geometry and flow. Optimal oscillation (20°), outlet (9 mm), and timing (0.022 s) achieved precise seed release (2.7 kg/ha). Supports simulation-guided design of metering units. | Egypt/Russia |

| Xu et al. [39] | 2023 | Design and Optimization of Seed-Metering Plate of Air-Suction Vegetable Seed-Metering Device | Simulation (DEM-CFD) | Hole spacing at 1.6× seed length improved single seed pick up from 39% to 75%. Rear air pulse enhanced seed retention. Though tested with cabbage, findings are transferable to sesame based on seed size and mechanics. | China |

| Other contextual studies | |||||

| Jianbo et al. [40] | 2014 | Design of Integrated Control System for Precision Seed-Metering Device | Engineering design | Stepper-motor control achieved >98% plant spacing consistency across speed changes. Eliminated slippage issues found in mechanical ground-wheel drives. System adaptable to sesame planters. | China |

| Fisher et al. [41] | 2011 | Is Broadcasting Seed an Effective Cover Crop Planting Method? | Field study (cover crop) | Drilling improved uniformity and nitrogen uptake (30% more) compared to broadcasting. Broadcasting gave uneven establishment. Sesame is likely to respond similarly due to seed size. | USA |

| Brennan & Leap [42] | 2014 | Cover Crop Establishment on Bed-Formed Systems | Field study (cover crop) | Broadcast seeding without incorporation yielded <10% emergence. Drilling or incorporating seed led to 70–85% stand. Highlights importance of seed-to-soil contact, applicable to sesame planting | Hawaii |

| Li et al. [43] | 2023 | Experimenting and Optimizing Design Parameters for a Pneumatic Hill-Drop Rapeseed Metering Device | CFD Simulation + Experimental validation | CFD (Fluent) and experimental tests optimised suction hole design and operating settings for rapeseed planter. Best results at 30–70 rpm and −2.5 to −1.5 kPa, with >96% qualified holes and <3% empty drop rate. | China |

| Physical Properties | Mean | Standard Deviation | Coefficient of Variance |

|---|---|---|---|

| Length (mm) | 2.5 | 0.160 | 0.04 |

| Width (mm) | 1.65 | 0.130 | 0.02 |

| Thickness (mm) | 0.94 | 0.070 | 0.004 |

| Volume (mm3) | 2.03 | 0.450 | 0.19 |

| Sphericity (%) * | 62.84 | 1.980 | 4.75 |

| Geometric diameter (mm) | 1.57 | 0.089 | 0.011 |

| Arithmetic diameter (mm) | 1.29 | 0.087 | 0.010 |

| Flat surface area (mm2) | 3.24 | 0.840 | 0.718 |

| Transverse surface area (mm2) | 1.22 | 0.150 | 0.016 |

| Mass of 1000 seeds (g) | 10 | - | - |

| Bulk density of seed (kg/m3) | 640 | - | - |

| Moisture content (%) | 6–12 | - | - |

| Physical Properties | Impact on Planting | Impact on Harvesting and Post-Harvesting Processes |

|---|---|---|

| Length, Width, Thickness, Volume | These properties can affect seed placement during the metering of seeds while planting and the calibration of metering devices where the seed plant needs to be changed according to seed size [46]. Large seeds may require adjustments in seed depth depending on soil conditions. | Larger seeds are likely better suited for mechanised processing, while smaller seeds require gentle handling to minimise damage and loss [47]. |

| Sphericity | Better uniformity or singulation could be achieved with higher sphericity [48]. | Better seed flow can be achieved with higher sphericity and is also easy to separate seeds and trashes during the cleaning process [48,49]. |

| Geometric diameter (Dg), Arithmetic diameter (Da) | Seed metering accuracy can be affected [50]. Large diameter seeds are easy to meter. | The probability of seed damage increases with larger Dg and Da [51]. Therefore, it is crucial to adjust the machine settings accordingly. |

| Flat surface area, Transverse surface area | Seed flow could be affected inside the seed metering unit due to friction [52]. | An increase in flat surface area can enhance friction, thereby influencing the separation and seed flow inside the harvester [49,52]. |

| Mass | Influences the planting depth control and the movement of seeds inside the seed metering unit [32]. | Lightweight nature of the seed is susceptible to being blown away with trash [34]. |

| Bulk Density | Higher density facilitates uniform seed distribution; it also results in obstructions in the seed hopper when a larger quantity of seeds is loaded inside. | Higher-density seeds minimise losses which facilitate enhanced separation and collection. |

| Moisture Content | Excessive moisture can lead to clogging in the seed meter unit, while insufficient moisture levels may result in seed damage. | Moist seeds can clog harvesting machinery and extend the processing time [49]. Excessive or insufficient moisture levels may complicate post-harvesting processes [53,54]. |

| Mechanical Properties | Value |

|---|---|

| Friction angle | |

| 22° |

| 34° |

| 40° |

| Coefficient of friction | |

| 0.404 |

| 0.675 |

| 0.839 |

| Angle of repose | 25°–30° |

| Hardness | 11.02 N/mm2 |

| Modulus of elasticity | 1.64–7.06 MPa |

| Maximum deformation under static compression test | 0.23–1.05 mm |

| Crushing load (flat compression) | 12.9 N |

| Crushing load (lateral compression) | Lower than flat, higher than vertical |

| Crushing load (vertical compression) | 1.84 N (minimum) |

| Planter Type | Configuration | Metering Mechanism | Seed Rate (kg/ha) | Farmer Adaptability | Performance | Emergence Rate (%) | Limitations | Reference |

|---|---|---|---|---|---|---|---|---|

| Manual Broadcasting | Broadcast/dibble | Human | 5–6 | Easily adopted, no investment needed. Widely used by smallholders in India and Africa. | Evenness highly variable (around 80–90%), highly reliant on skill and consistency | 30–50 | Labour intensive, time consuming, poor uniformity in placement and excessive seed usage. | [35,42] |

| Single-row drop seeder | Mechanical planter | Belt/roller | 4–5 | Low cost and simple to operate; some training needed. Suitable for small plots. | Emergence rate around 80–90%, skips around 5–10% | 50–65 | Limited to 1–2 rows, requires coated seed to achieve better results. | [26,36] |

| Broadcast drill | 12+ rows, air sowing | Blower plans/shaker | 4–5 | Requires tractor or power-tiller; more suited to small-scale commercial farms. | Low singulation accuracy and poor uniformity | 60–70 | Excessive seed usage, requires smooth seed bed. | [35,42,93] |

| Multi-row air drill | 4–12 rows, air seeder | Seed plate, Air | 3–4 | Effective in medium-to-large farms. May be available via cooperatives. | Variation in seed placement around 15–30% | 70–85 | Better performance in tilled soil, tubes are prone to blockage without air-guides and excessive power consumption. | [13,36] |

| Vacuum precision planter | 4–12+ rows | Vacuum-disc | 2.5–3 | High initial cost and technical complexity limit use by smallholders. Most viable in commercial sesame operations. | Seed singulation around 90%, 50% higher planting speed and lower seed damage rate (with calibration) than conventional drills | <90 | Requires calibration, better performance with good-quality, cleaned seed. Blockage in seed disc holes affects singulation. | [39,40,94,95] |

| Reference | Method | Motivation | Findings and Recommendations |

|---|---|---|---|

| [13] | Field experiment of a modified vacuum hill drop planter. Sesame was sown with no till and reduced and conventional tillage. | Enhance the performance of a vacuum seed drill under reduced or no till condition | No-till condition provides poor hill-spacing and low emergence, while conventional tillage provides good spacing with higher emergence. For no-till, the design of opener and furrow-closer must be enhanced to achieve optimal depth and consistency. Also, some seed blockage in tubes encountered. |

| [12] | Discrete Element Method to model and analyse sesame seed dynamics in an oscillating metering device. | To forecast and enhance the consistency of seed discharge in oscillating seed metering systems | The simulation model examined seed outflow from an oscillating mechanism, considering seed morphology and interactions. Results indicate that optimising device parameters may improve seed distribution uniformity. |

| [38] | Employed Discrete Element Method (EDEM) simulations to model non-uniform sesame seed particles, facilitating the design of seed metering machinery. | To create a model and simulate sesame seed particles for the purpose of equipment design | The ideal settings for the oscillating seed metering device were determined to be a hole clearance of 9 mm, an angle of 20°, and an opening duration of 0.022 s, resulting in a sesame seed application rate of 2.7 kg/ha. While these parameters enhanced planting efficiency and seedling emergence, additional research is required to optimise them for varying conditions and sesame cultivars. |

| [14] | Design and optimisation of an air-assisted seed-guiding model for centralised hill drop planter. CFD-DEM simulation was used to optimise the design. | Optimise the design of the model including guide depth, tube diameter, and air flow speed to reduce the seed block in the metering tube | Optimised the design (guide depth = 2.6 mm and tube diameter = 19 mm and air speed = 6.3 m/s). This study suggested using the parameter values for optimal metering performance. However, there will be 2 ± 1 seeds per hill, which might negatively impact the overall yield. |

| [31] | An assessment was conducted on sowing time and density in four distinct environments in northern Australia, examining various sowing dates and densities for both white sesame (Equinom) and black sesame (AgriVentis) varieties | To assess the impact of planting time and population density on sesame production in northern Australia | Sowing in mid-December at moderate densities, resulting in 1.5 tonnes per hectare, was identified as the most effective method. Effective weed control, including both pre-plant and in-crop management, is crucial for maximising yields. |

| [43] | CFD simulation and bench experiments on pneumatic (air suction) hill drop seed meter. Fluent used to model airflow with different hole shapes and diameters. | Enhance the high-density precision planting of small rapeseeds by optimising the design of air suction seed meter. | Achieved over 96% of single drop and less than 3% of misses. However, smaller seeds than rapeseed, such as sesame, may encounter blockage. |

| [99] | In a controlled laboratory experiment, a seed metering system was evaluated using seeds of various sizes. The experimental study did not incorporate sesame seeds; however, the results, especially regarding seed damage and the rate of seed cell filling, can be relevant to sesame seeds by making comparisons with the mustard seeds utilised in the research. | The physical characteristics of the seeds were measured and analysed, focusing on key outcomes such as seed-cell filling rate, seed damage extent, and germination rate. | The seed damage significantly increases with the peripheral velocity of the seed meter, which affects the germination of the seed. For mustard seed, seed-cell filling rate reduced and damage increased with increasing peripheral velocity. Germination rate also decreased after the seeds passed through the seed metering device when operated at high speed. |

| Components | Functional Requirements | Operational Requirements |

|---|---|---|

| Soil Cutting Device | Cut and loosen soil to facilitate seed placement | Should operate efficiently in varying soil conditions with minimal clogging |

| Row Preparation | Prepare a suitable seedbed with optimal tilth and moisture retention | Must break clod, remove weeds, and retain moisture for uniform emergence |

| Furrow Opening Device | Create a furrow of the right depth and width for seed placement | Should be adjustable for different crops and soil types |

| Seed Firming Device | Ensure proper seed-to-soil contact to enhance germination | Should apply uniform pressure to prevent seed displacement |

| Row-Specific Seedbed Firming Devices | Firm the soil in the seed row to maintain consistent seed depth | Should exert controlled pressure along the seed row for uniform emergence |

| Non-Row-Specific Seedbed Firming Devices | Level the entire seedbed to provide uniform field conditions | Should smoothen the surface to avoid water stagnation and erosion |

| Seed Metering Types | Metering System | Working Principle |

|---|---|---|

| Finger pick-up | Mass metering * | Spring-loaded fingers in the seed hopper pick up and release seeds onto a stationary disc. Seeds then drop onto a placement belt for transport to the seed tube. |

| Air pressure | Mass metering | Seeds are securely held within cells located around the circumference of a rotating disc by positive pressure from a blower. As the seeds approach the seed tube, a gentle brush cuts off the airflow, causing the seeds to fall into the seed tube. |

| Vacuum | Precision metering | Seeds are held in cells on a rotating disc using negative pressure. They are then released into the seed tube with the assistance of a cutoff wiper, which stops the vacuum once the seed reaches the outlet. |

| Plate seed meter | Precision metering | Plate has multiple holes or cells. During the rotation of the plate, the seed cells will pick the seeds from the seed chamber. Seed will be delivered to the seed tube and travelled downwards by gravity. |

| Brush seed meter | Precision metering | Single seeds in each grove will be held by the brush and excess seeds will be removed to the seed chamber and picked seed will be delivered into seed tube. |

| Parameter | Units | Levels (min, max) | Rationale |

|---|---|---|---|

| Ground speed | km/h | 4, 8 | Minimal speeds (around 4 km/h) will increase the singulation of smaller seeds and will minimise skipping and bouncing. For the most precise planting, Monosem advises a speed of 5–7 km/h; in light stands, this speed could reach up to 8–10 km/h. Increased speed could have the danger of producing doubles or missing seeds [118]. |

| Vacuum Pressure | kPa | 3.7, 5.0 | In order to prevent damage and ensure correct pickup, Monosem advises using 15–20 inches of H2O (equivalent to 3.7-5.0 kPa) vacuum for smaller seeds; higher vacuum or speed could split seeds or clog the meter [66,118]. |

| Seed plate hole Diameter | mm | 0.8, 1 | Depending on seed size, a plate needs to be selected that causes the least damage and breakage to the seed as possible, while ensuring that only one seed is placed on each hole for best singulation when planting. Other considerations for plate selection include hole blockage. |

| Scraper | Indicator | −1, +1 | A setting of −1 to +1 is recommended for smaller seeds, such as canola, to balance missing and doubles [118]. The settings can go up to −5 (fully engaged with seed hole) and +5 (fully disengaged with seed hole). |

| Population | Seeds | 250,000, 350,000 | Aim for about 300,000 plants per hectare for weed control and maximum output. Yield could decrease below 250,000; lodging and stress could result in above 350,000. To meet the objective, use seed rate of about 3–3.5 kg/ha [33,81,119]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raveendran, G.; Narayanan, R.; Sul, J.-H.; Trotter, T. A Comprehensive Systematic Review of Precision Planting Mechanisation for Sesame: Agronomic Challenges, Technological Advances, and Integration of Simulation-Based Optimisation. AgriEngineering 2025, 7, 309. https://doi.org/10.3390/agriengineering7090309

Raveendran G, Narayanan R, Sul J-H, Trotter T. A Comprehensive Systematic Review of Precision Planting Mechanisation for Sesame: Agronomic Challenges, Technological Advances, and Integration of Simulation-Based Optimisation. AgriEngineering. 2025; 7(9):309. https://doi.org/10.3390/agriengineering7090309

Chicago/Turabian StyleRaveendran, Gowrishankaran, Ramadas Narayanan, Jung-Hoon Sul, and Tieneke Trotter. 2025. "A Comprehensive Systematic Review of Precision Planting Mechanisation for Sesame: Agronomic Challenges, Technological Advances, and Integration of Simulation-Based Optimisation" AgriEngineering 7, no. 9: 309. https://doi.org/10.3390/agriengineering7090309

APA StyleRaveendran, G., Narayanan, R., Sul, J.-H., & Trotter, T. (2025). A Comprehensive Systematic Review of Precision Planting Mechanisation for Sesame: Agronomic Challenges, Technological Advances, and Integration of Simulation-Based Optimisation. AgriEngineering, 7(9), 309. https://doi.org/10.3390/agriengineering7090309