Research and Optimization of Key Technologies for Manure Cleaning Equipment Based on a Profiling Wheel Mechanism

Abstract

1. Introduction

2. Materials and Methods

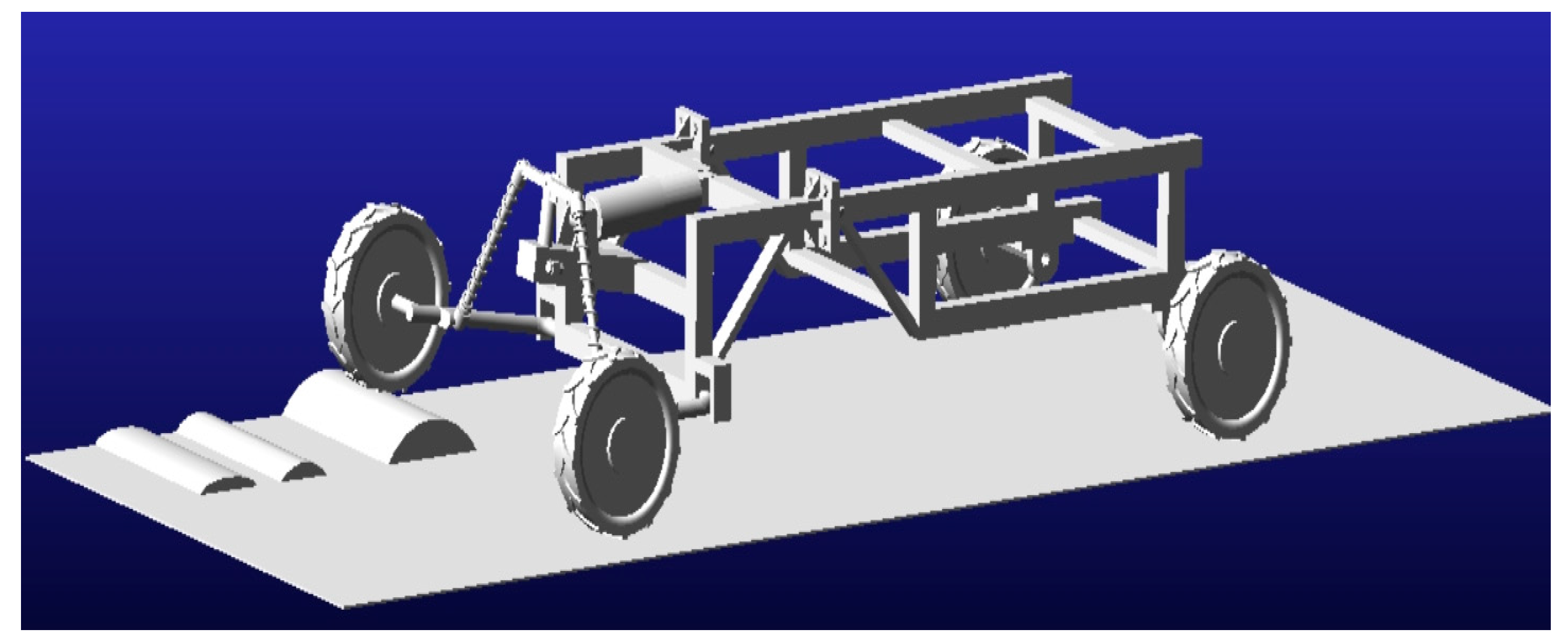

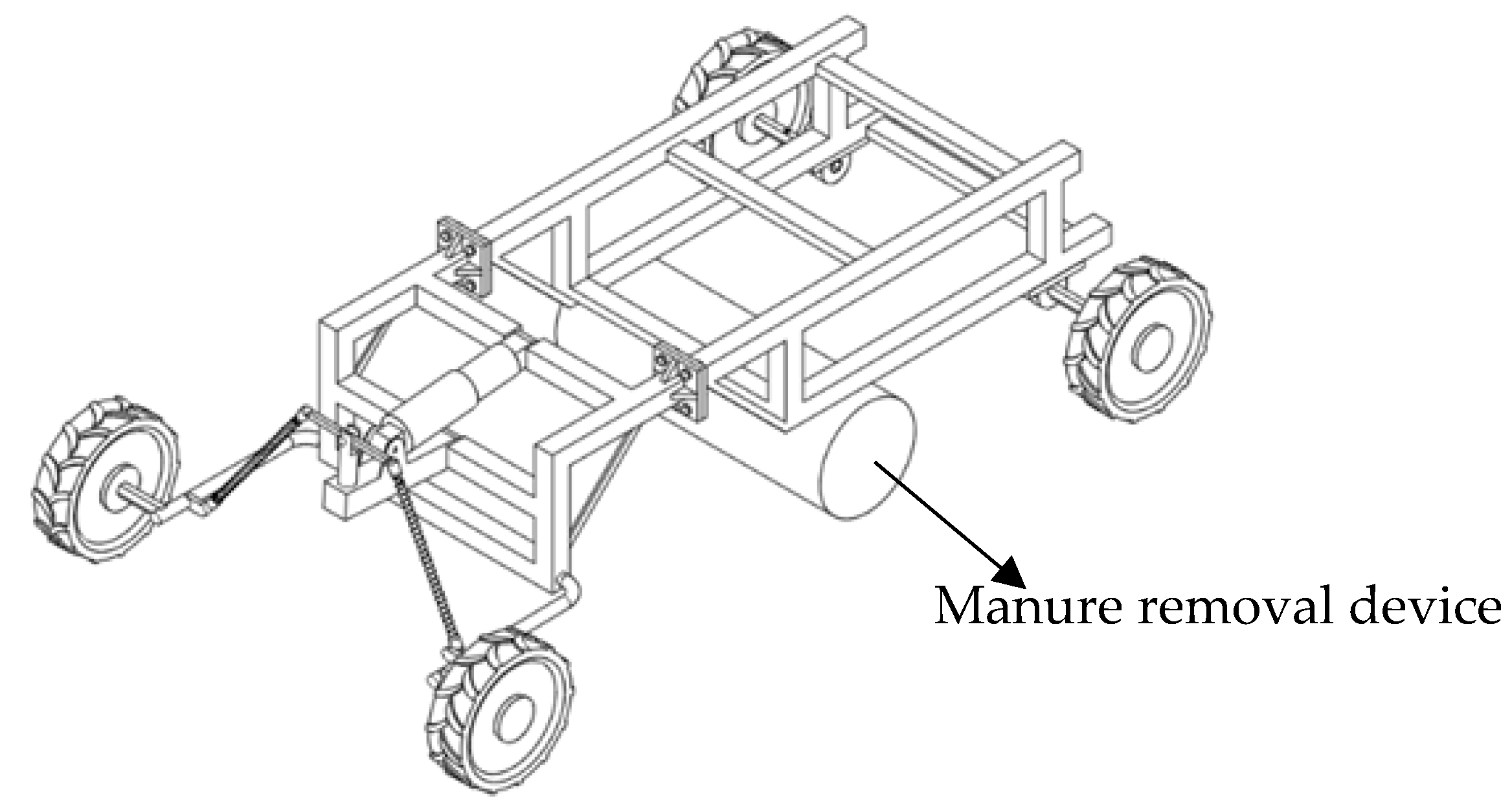

2.1. Parametric Geometric Design

2.1.1. Rocker Arm Mechanism

2.1.2. Double-Ball Head Balancing Mechanism

2.1.3. Hydraulic Damping Unit

2.2. Kinematic Compensation Model

2.2.1. Rocker Arm Motion Compensation

2.2.2. Balancing Mechanism Response

2.2.3. Dynamic Matching of Damping System

2.3. System Vibration Model Construction

2.3.1. Dynamics Equation Derivation

2.3.2. Frequency-Domain Response Analysis

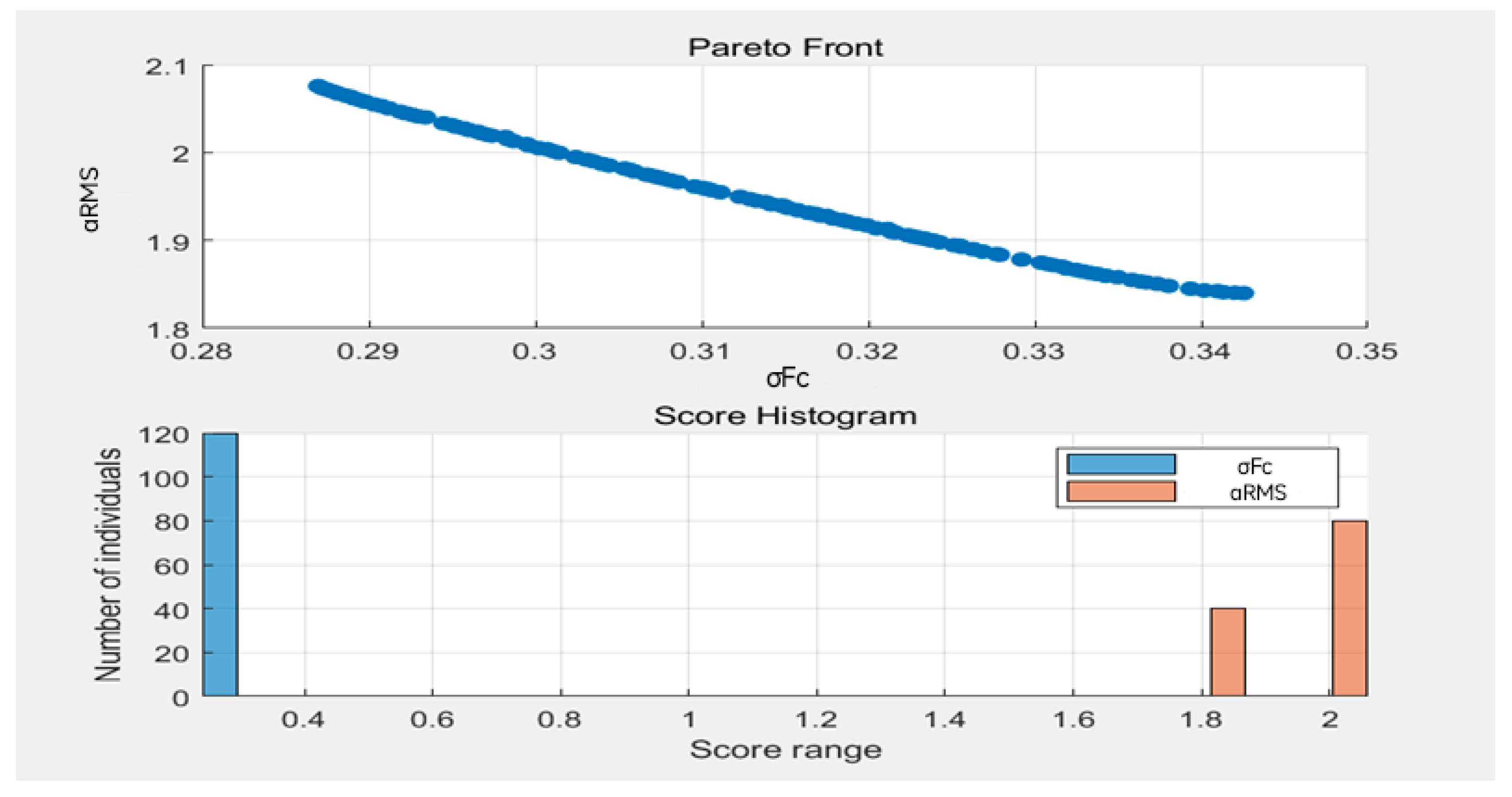

2.4. NSGA-II Multi-Objective Optimization Design

2.4.1. Optimization Problem Modeling

2.4.2. Algorithm Implementation and Hyperparameter Tuning

3. Results

3.1. Kinematic Simulation Validation

3.1.1. Model Construction and Parameter Setting

3.1.2. Simulation Results and Validation

3.1.3. Error Analysis

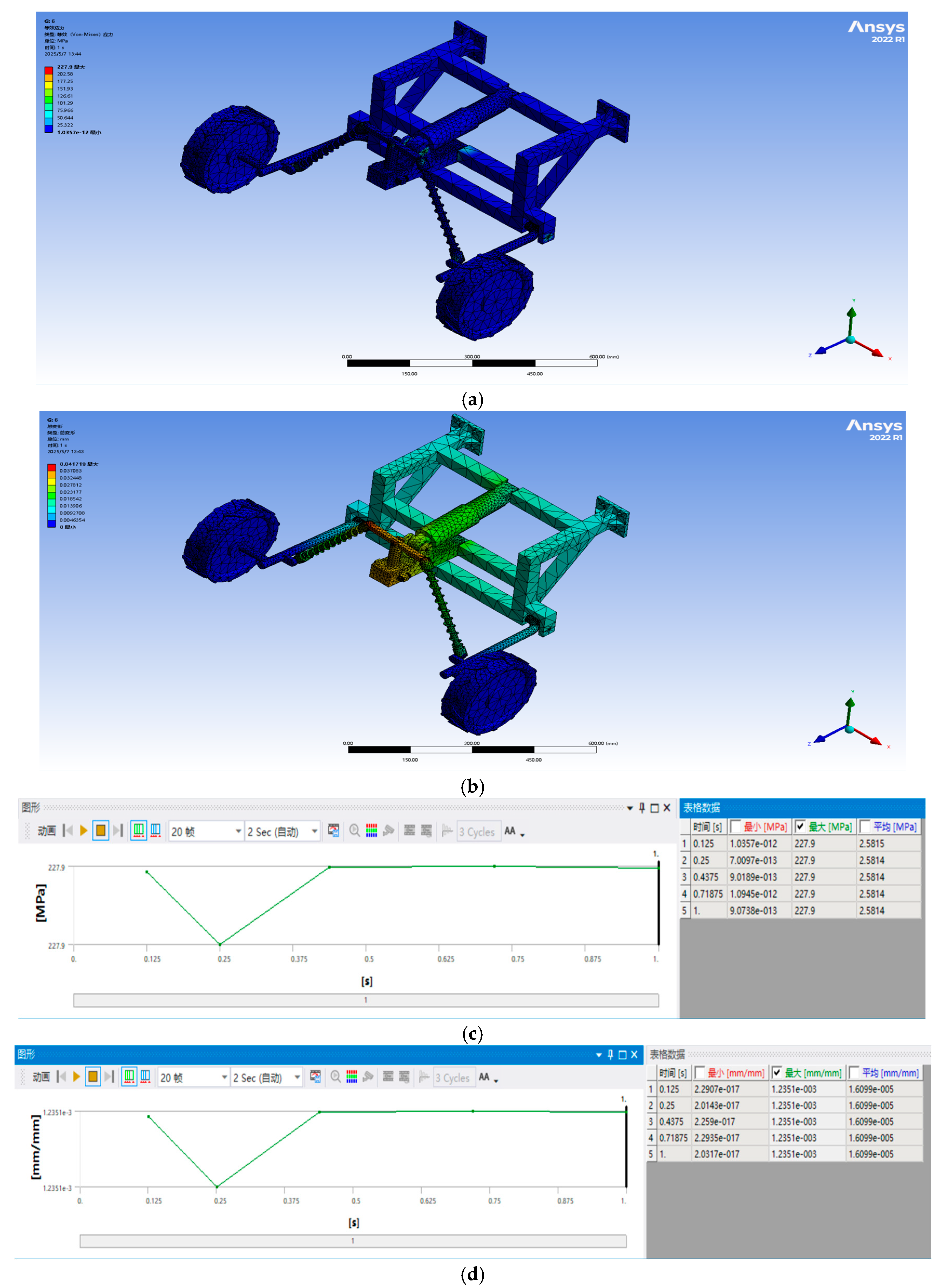

3.2. Finite Element Strength Check

3.2.1. Static Analysis

3.2.2. Result Analysis

3.2.3. Fatigue Life Evaluation

3.2.4. Reliability Enhancement Measures

3.3. Stability Analysis and Resonance Avoidance

3.3.1. Modal Analysis

3.3.2. Harmonic Response Analysis

3.3.3. Hierarchical Damping Optimization

3.4. Optimization Result Analysis

3.5. Vibration Suppression Effect Verification

4. Discussion

4.1. Application Example

4.2. Operation Process and Working Mode

5. Conclusions

5.1. Main Conclusions

5.1.1. Significant Performance Improvement of Profiling Wheel Mechanism

5.1.2. Rich Methodological Innovations

5.2. Innovations

5.3. Future Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Wang, X.T.; Xin, X.F.; Wang, J.M. Research on Global Broiler Production, Trade and Industrial Economic Development in 2024. Chin. J. Anim. Sci. 2025, 61, 371–377. [Google Scholar] [CrossRef]

- Lu, J.X. Problems and countermeasures in broiler chicken farming. Chin. J. Anim. Health 2025, 27, 155–156. [Google Scholar] [CrossRef]

- Wang, S.H.; Dai, J.Y.; Zhao, G.H.; Zhang, Y.Q. New technologies for the treatment of manure from large-scale broiler chicken farms. Livest. Environ. 2021, 13, 9. [Google Scholar]

- Zhang, S.; Zhang, J.; Cao, C.; Cai, Y.; Li, Y.; Song, Y.; Bao, X.; Zhang, J. Effects of Different Rearing Systems on Lueyang Black-Bone Chickens: Meat Quality, Amino Acid Composition, and Breast Muscle Transcriptome. Genes 2022, 13, 1898. [Google Scholar] [CrossRef]

- Zhang, D.X. Hazards of livestock and poultry farming to the environment and control measures. North. Anim. Husb. 2023, 3, 28. [Google Scholar]

- Luo, J.F. Design and Research on the Transmission System of the Scraper Manure Cleaner in Chicken Houses. Master’s Thesis, Wuhan Polytechnic University, Wuhan, China, 2021. [Google Scholar] [CrossRef]

- Jiang, X.M.; Huang, L.; Li, H.; Li, X.W.; Xia, C.D.; Mei, S.H.; Zhang, Y.L. Improved design of the manure belt device in laying hen houses. China Poult. 2018, 40, 70–72. [Google Scholar] [CrossRef]

- Li, X.J.; Yan, F.X.; Hu, K.; He, X.; Ma, Z.F.; Yuan, Q.Y.; Mirzoev, S.I. Development of a self-propelled integrated machine for manure collection, cleaning, and bagging in broiler flat-raising chicken houses. Trans. Chin. Soc. Agric. Eng. 2024, 40, 251–261. [Google Scholar] [CrossRef]

- Fang, T.; Jin, H.; An, M.H.; Tian, Z.X.; Zhou, P. A push-type manure picking combined operation machine for farms. Hubei Agric. Sci. 2017, 56, 4141–4145. [Google Scholar] [CrossRef]

- Xia, C.G.; Gao, X.C. Kinematic and elastokinematic analysis of double wishbone suspension based on ADAMS/car. Mach. Des. Manuf. 2010, 7, 58–60. [Google Scholar] [CrossRef]

- Zhao, X.; Su, T.X.; Liu, X.Y.; Zhang, X. Multi-objective optimization of main bearing assembly structure based on improved NSGA-II. Energy Sci. Eng. 2022, 10, 43–63. [Google Scholar] [CrossRef]

- Wozniak, M.; Siczek, K.; Ozuna, G.; Kubiak, P. A Study on Wear and Friction of Passenger Vehicles Control Arm Ball Joints. Energies 2021, 14, 3238. [Google Scholar] [CrossRef]

- Song, S.Z.; Dong, D.W.; Huang, Y.; Xu, F.H.; Zhang, W.; Yan, B. Vibration energy decoupling method and application of flexible double-layer isolation system. J. Southwest Jiaotong Univ. 2023, 58, 304–313. [Google Scholar] [CrossRef]

- Archila Diaz, J.F. Design of a Rover to Precision Agriculture Applications. Doctoral Thesis, Escola de Engenharia de São Carlos, Universidade de São Paulo, São Carlos, Brazil, 2016. [Google Scholar] [CrossRef]

- Wang, H.X.; Cheng, J.H.; Wang, Y. Design and simulation of vehicle-mounted hydraulic manipulator based on SolidWorks and ADAMS. Mech. Eng. 2016, 5, 17–19. [Google Scholar] [CrossRef]

- Liang, X.F.; Hu, Z.; Zheng, L.W.; Wang, Y.W. Optimization of discrete element contact model for tidal flat soil and field cutting test. Trans. Chin. Soc. Agric. Eng. 2024, 40, 107–115. [Google Scholar] [CrossRef]

- Liu, H.J.; Zhang, Q.F. Deformation and vibration simulation analysis of flexible parallel mechanisms based on ADAMS. Manuf. Autom. 2012, 34, 75–77. [Google Scholar] [CrossRef]

- Peng, J.H.; Zhang, H.C.; Zhu, X.L.; Wang, S.Z. Motion characteristics and error analysis of the pendulum projectile mechanism. J. Ordnance Equip. Eng. 2020, 41, 91–94. [Google Scholar] [CrossRef]

- Zhao, Z.X.; Liu, J. Reliability and sensitivity analysis of contact stress in point-contact bearings. Agric. Equip. Veh. Eng. 2023, 61, 40–45. [Google Scholar] [CrossRef]

- Du, Y.Y.; Ma, Y.P. Study on hardness and parameter optimization of 65Mn steel during heat treatment. Foundry Technol. 2015, 36, 2001–2002. [Google Scholar] [CrossRef]

- Arena, M.; Ambrogiani, P.; Raiola, V.; Bocchetto, F.; Tirelli, T.; Castaldo, M. Design and Qualification of an Additively Manufactured Manifold for Aircraft Landing Gears Applications. Aerospace 2023, 10, 69. [Google Scholar] [CrossRef]

- Liu, Y.X.; Zheng, C. Discussion on safety design of 20CrMnTi steel for connecting rods based on fatigue S-N curve. Phys. Test. Chem. Anal. (Part A Phys. Test.) 2015, 51, 402–405. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, K.; He, A.M.; Sun, Y.Z.; Shi, W.K. Linear fatigue life prediction model based on dynamic residual S-N curve. J. Chongqing Univ. 2023, 46, 84–93. [Google Scholar] [CrossRef]

- Kong, L.C.; Zhong, C.B.; Wang, C.K. Research on modal simulation analysis of a six.Koint industrial robot based on ADAMS. Mach. Build. Autom. 2024, 53, 182–187. [Google Scholar] [CrossRef]

- Li, Y.; Jin, B.; Zhao, M.Y.; Yang, F.L. Design and optimization of the resonator in a resonant accelerometer based on mode and frequency analysis. Micromachines 2021, 12, 530. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, M.; Gao, F.Y. Optimal design of subsynchronous additional damping controller based on improved NSGA-II algorithm. J. Syst. Sci. Math. Sci. 2020, 40, 751–760. [Google Scholar]

- Xu, Z.; Wang, Q.C.; Jia, G.C. Multi-objective trajectory optimization of robotic arm based on NSGA-Ⅱ algorithm. Manuf. Autom. 2023, 45, 180–184. [Google Scholar] [CrossRef]

- Marano, G.C.; Quaranta, G.; Greco, R. Multi-objective optimization by genetic algorithm of structural systems subject to random vibrations. Struct. Multi-Discip. Optim. 2009, 39, 385–399. [Google Scholar] [CrossRef]

- Li, H.Y.; Jing, Y.W. A collaborative optimization method with multi-objective sub-disciplines based on NSGA-II. Control. Decis. 2015, 30, 1497–1503. [Google Scholar] [CrossRef]

- Tao, W.H.; Liu, H.T. Multi-objective optimization algorithm based on differential evolution and NSGA-II. Comput. Eng. 2016, 42, 219–224. [Google Scholar] [CrossRef]

- Zhao, P.; Lyu, H.; Wang, L.; Zhang, H.; Li, Z.; Li, K.; Xing, C.; Guoyao, B. Optimization Design of Straw-Crushing Residual Film Recycling Machine Frame Based on Sensitivity and Grey Correlation Degree. Agriculture 2024, 14, 764. [Google Scholar] [CrossRef]

- Xu, W.; Zang, M.Y. Research on dynamic coupling algorithm of DEM and FEM. Chin. J. Comput. Mech. 2013, 5, 671–676. [Google Scholar] [CrossRef]

- Yu, J.H. Research Progress on Application of Carbon Fiber Composite Materials in Automotive Structural Components. Fiber Compos. 2023, 40, 71–75. [Google Scholar] [CrossRef]

| Parameter | Theoretical Value | Simulation Value | Error | Data Source |

|---|---|---|---|---|

| 12.8° | 12.5° | 2.34% | EDEM2022 rigid-flexible coupling model | |

| 0.457 kN | 0.460 kN | 0.65% | Hertz contact model | |

| 198.7 MPa | 227.9 MPa | 14.7% | ANSYS2022 multi-condition analysis |

| Order | Natural Frequency/Hz | Relative Deformation Peak/mm | Vibration Mode Characteristics |

|---|---|---|---|

| 1 | 26.91 | 5.06 | Bend around the x-axis |

| 2 | 89.32 | 6.25 | Bend around the y-axis |

| 3 | 140.71 | 14.60 | twist around the x-axis |

| 4 | 150.90 | 16.77 | twist around the y-axis |

| 5 | 196.40 | 35.41 | bend around the y-axis |

| 6 | 210.93 | 12.67 | bend around the z-axis |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, F.; Gao, C.; Ren, L.; Li, J.; Gao, Y. Research and Optimization of Key Technologies for Manure Cleaning Equipment Based on a Profiling Wheel Mechanism. AgriEngineering 2025, 7, 287. https://doi.org/10.3390/agriengineering7090287

Yan F, Gao C, Ren L, Li J, Gao Y. Research and Optimization of Key Technologies for Manure Cleaning Equipment Based on a Profiling Wheel Mechanism. AgriEngineering. 2025; 7(9):287. https://doi.org/10.3390/agriengineering7090287

Chicago/Turabian StyleYan, Fengxin, Can Gao, Lishuang Ren, Jiahao Li, and Yuanda Gao. 2025. "Research and Optimization of Key Technologies for Manure Cleaning Equipment Based on a Profiling Wheel Mechanism" AgriEngineering 7, no. 9: 287. https://doi.org/10.3390/agriengineering7090287

APA StyleYan, F., Gao, C., Ren, L., Li, J., & Gao, Y. (2025). Research and Optimization of Key Technologies for Manure Cleaning Equipment Based on a Profiling Wheel Mechanism. AgriEngineering, 7(9), 287. https://doi.org/10.3390/agriengineering7090287