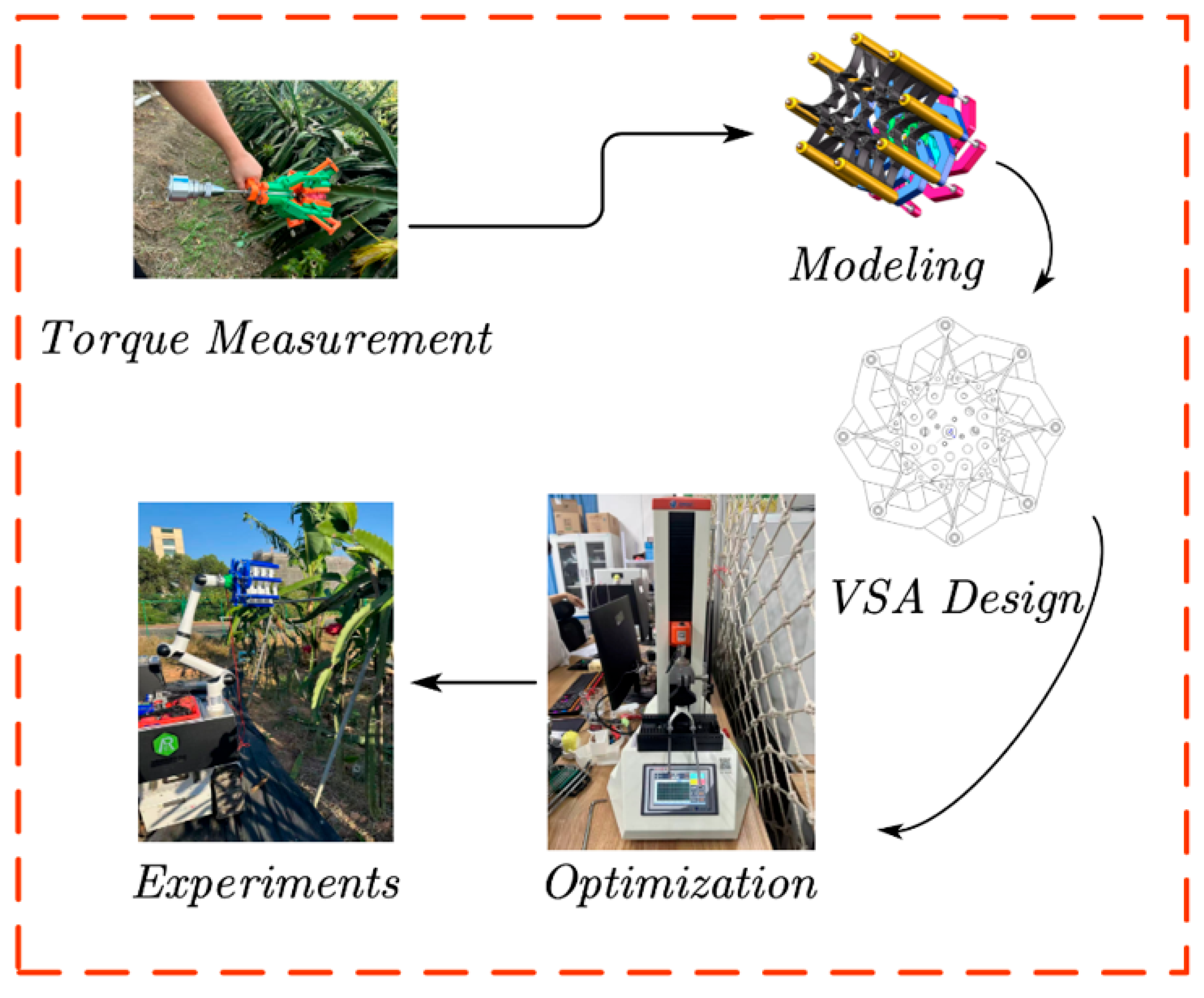

Design and Performance Validation of a Variable-Span Arch (VSA) End-Effector for Dragon Fruit Harvesting

Abstract

1. Introduction

- (1)

- Introducing the VSA geometry for the first time to achieve linear and compliant adjustment of clamping forces, thereby alleviating stress concentration issues inherent to rigid grippers with limited contact points.

- (2)

- Employing a multi-layer redundant design that combines material and structural compliance, which significantly improves adaptability to irregular fruit geometries and reduces the risk of fruit damage.

2. Dragon Fruit Characteristics and Fruit Detachment Principle

2.1. Morphological and Structural Characteristics of Dragon Fruit

2.2. Stem Structure and Detachment Principle

3. Case Study and Analysis of a Preliminary End-Effector Design

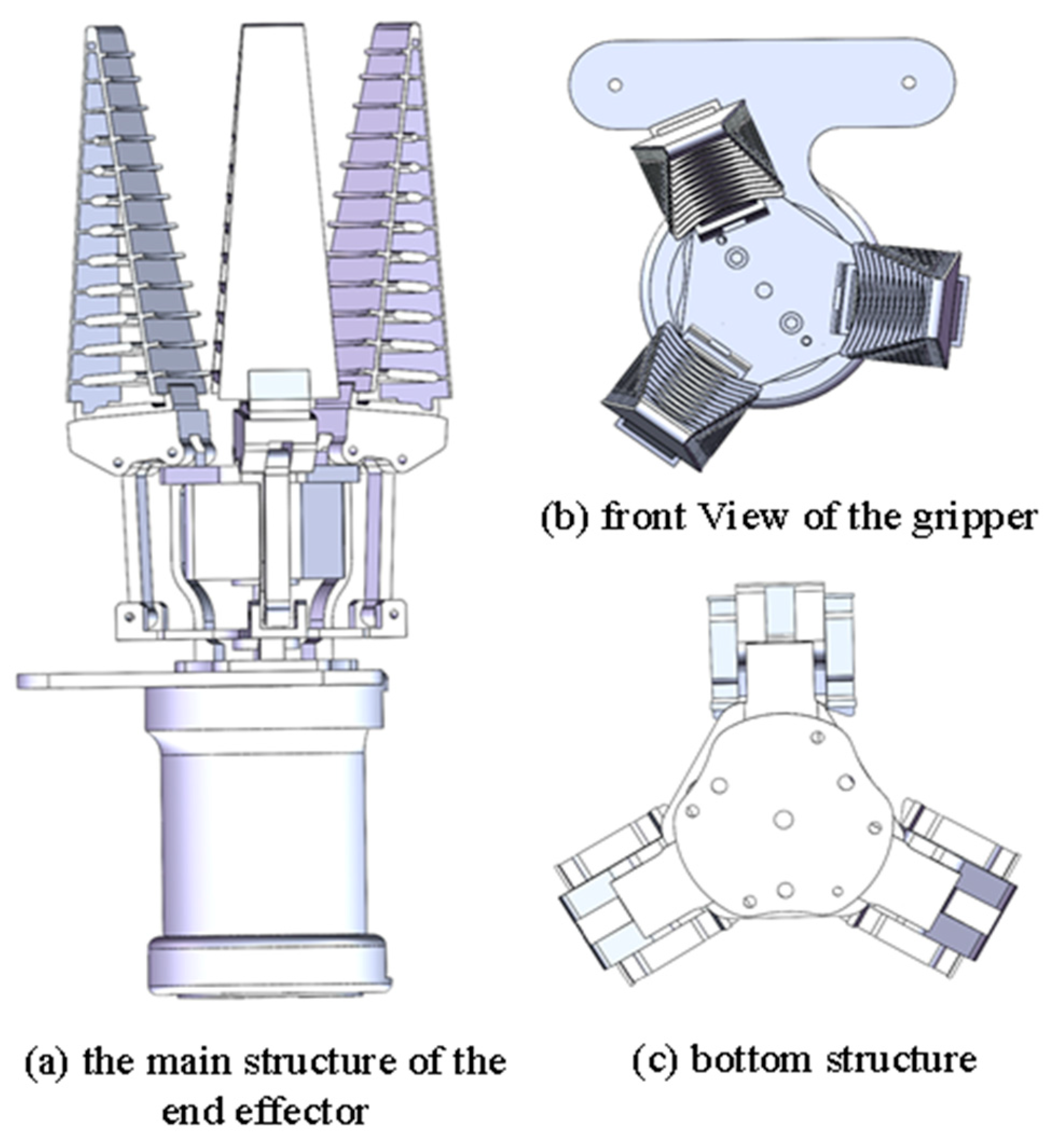

3.1. Structure and Limitations of an Underactuated Three-Jaw Flexible End-Effector

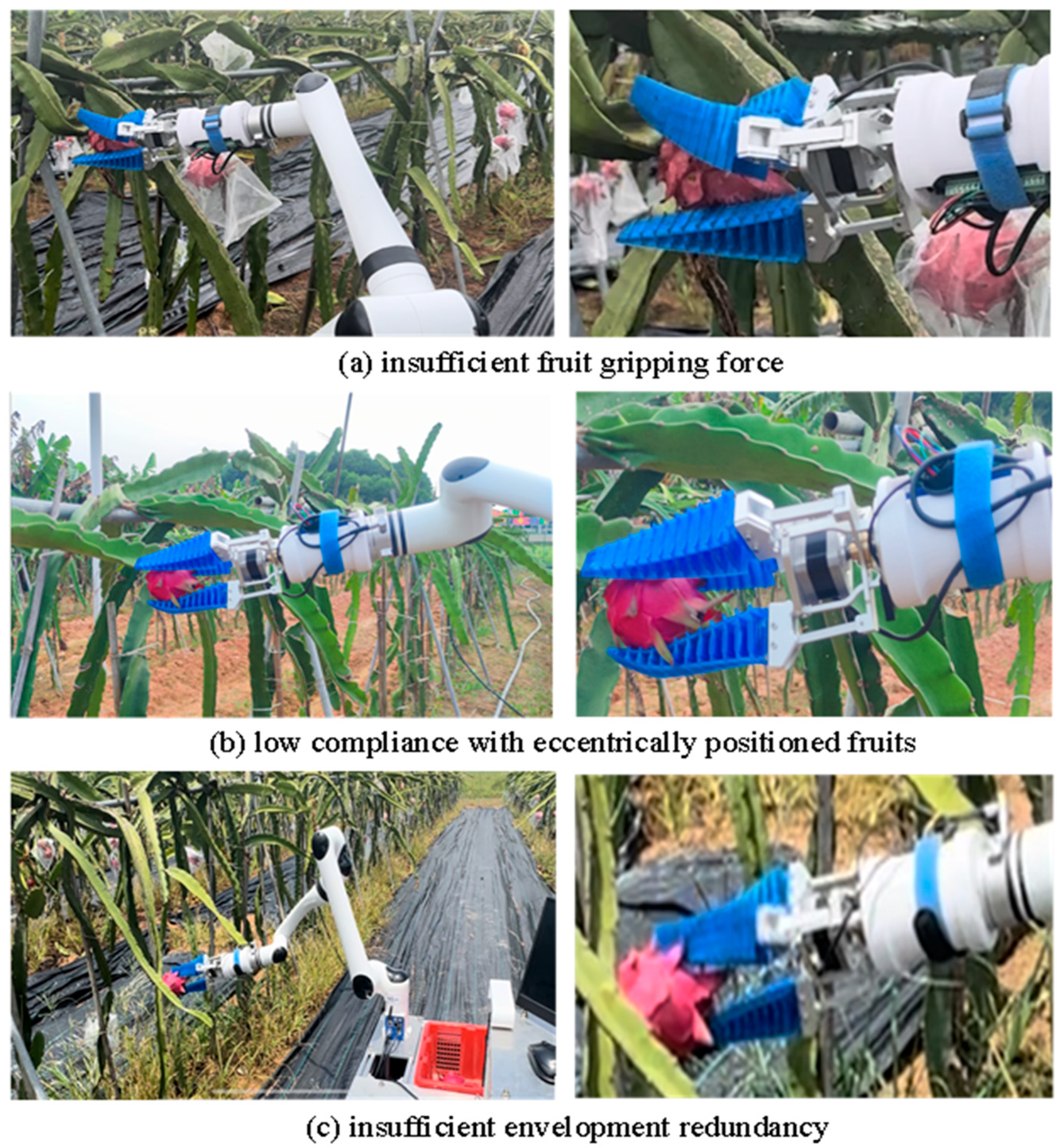

- (1)

- Insufficient gripping force. Due to the highly elastic material of the jaws, the overall structure was prone to significant deformation when external forces were applied. This was particularly evident during the twisting motion required to detach the dragon fruit from its stem, where the jaw’s insufficient torsional stiffness prevented the effective transmission of torque, often resulting in slippage or grip failure (as shown in Figure 3a).

- (2)

- Poor adaptability to off-Center Fruits. In practical operations, due to factors such as visual positioning errors and the randomness of fruit postures, the central axis of the end-effector is often difficult to align perfectly with the stem. Under such non-ideal poses, the three-jaw structure, with its linear and non-enveloping contraction, is unable to form a stable, all-encompassing contact. This leads to an uneven distribution of clamping force, causing the fruit to shift or be dropped (as shown in Figure 3b).

- (3)

- Insufficient envelopment redundancy. The contact area during the gripping pro cess of this structure is limited, relying primarily on localized force at the tips of the jaws to complete the grasp. This results in concentrated stress on the fruit’s surface, which can easily cause indentations or internal damage. Concurrently, the three-jaw structure has inherent limitations in terms of its coverage area and gripping redundancy, making it unable to effectively adapt to fruits of varying sizes and postures (as shown in Figure 3c).

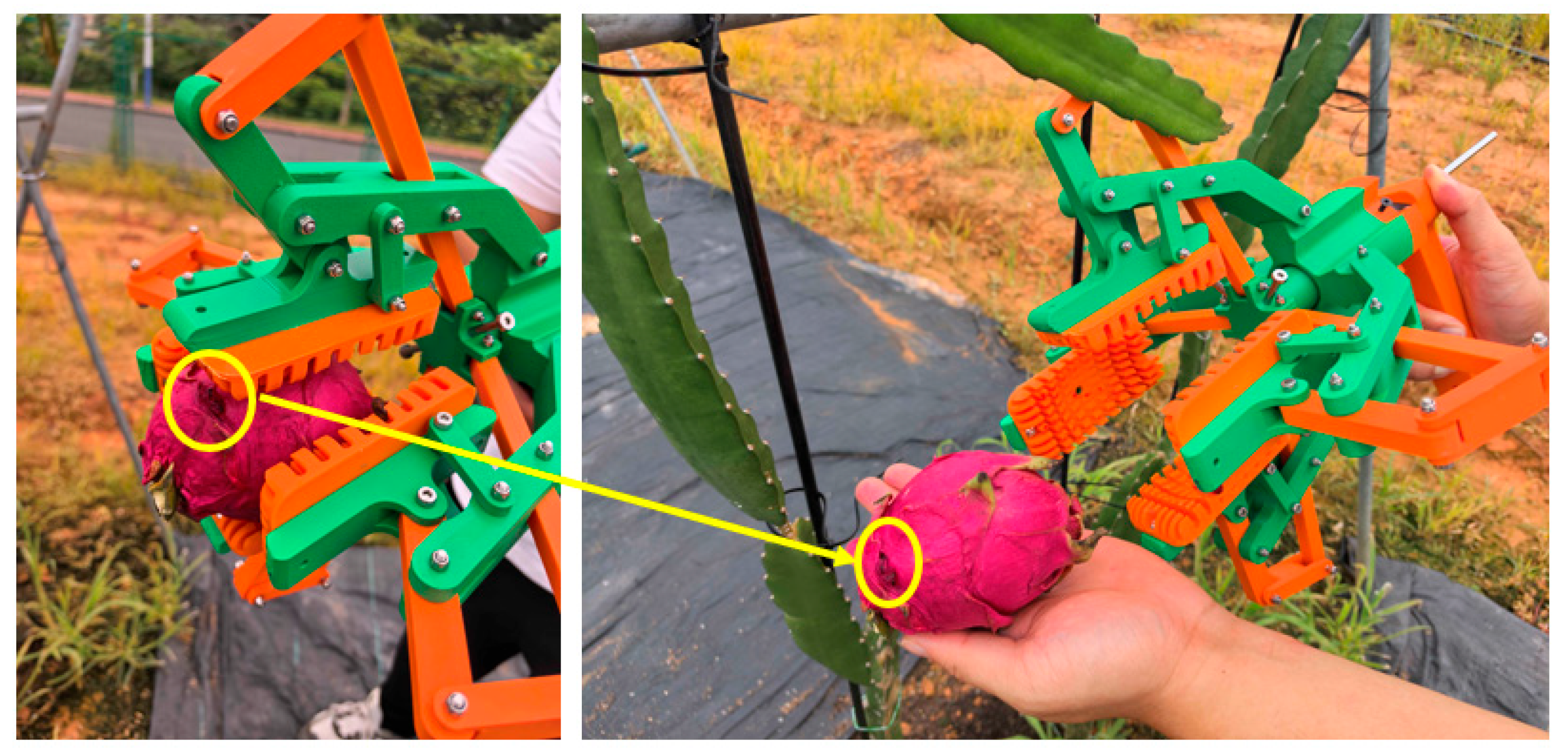

3.2. Design and Performance Evaluation of an Underactuated Four-Jaw Gripping Structure

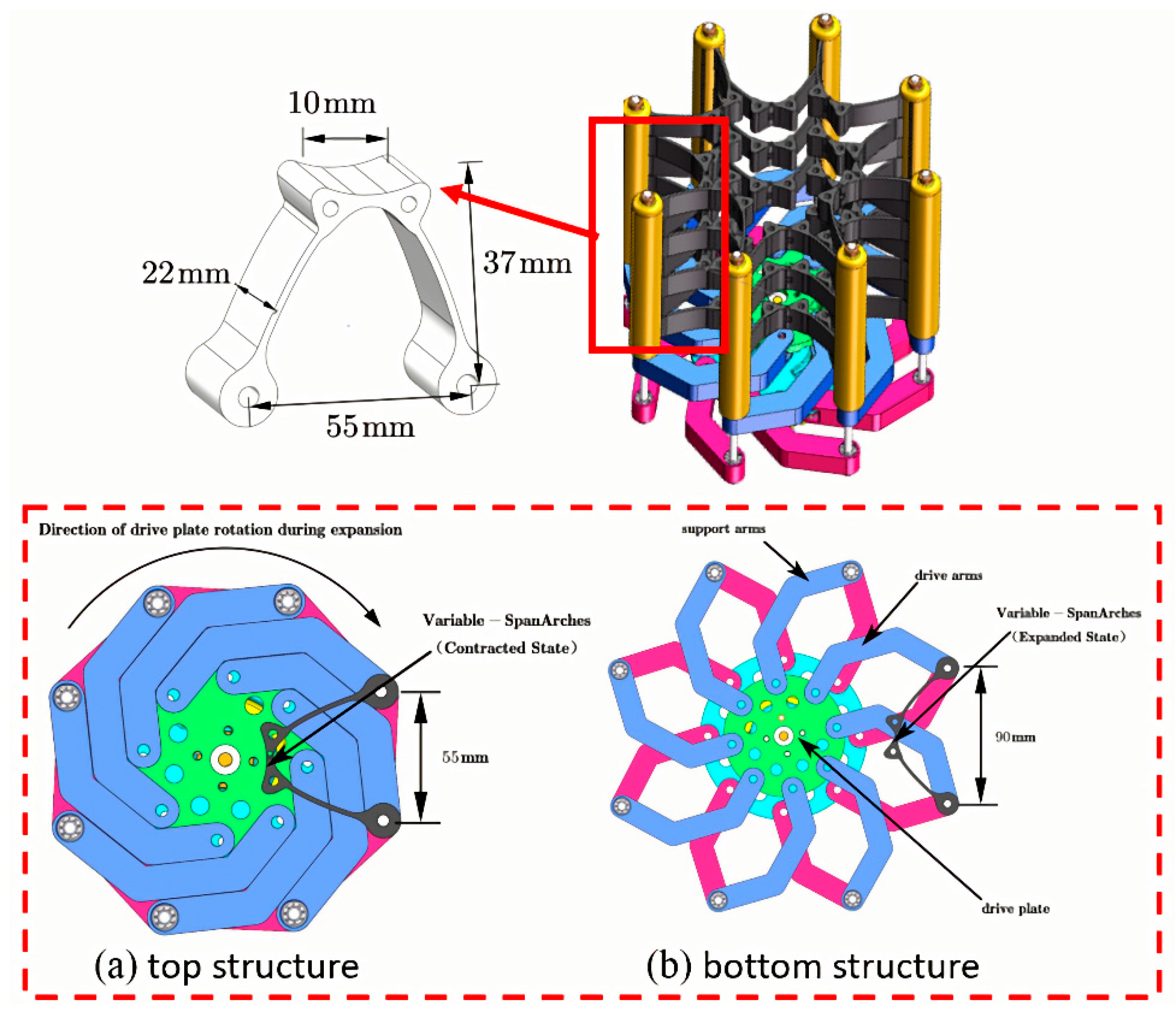

4. Design of the Enveloping End-Effector

4.1. Overall Structural Design

4.2. Force Analysis of the Flexible Arch Structure

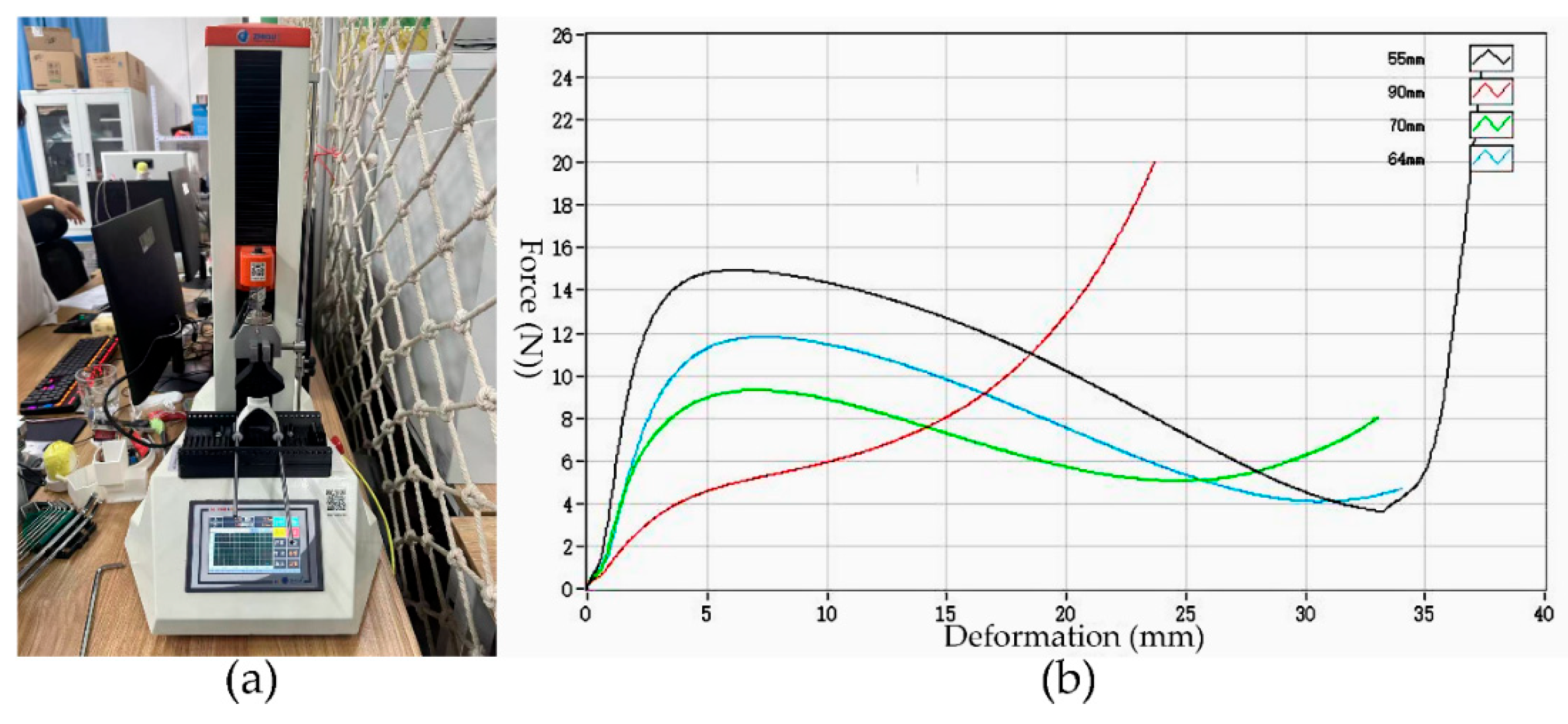

4.2.1. Static Compression Test and Force Response Analysis

4.2.2. Static Modeling of Fruit Gripping

- is the clamping force exerted by the VSA on the dragon fruit (N).

- is the coefficient of friction.

- H is the frictional torque generated by the VSA on the fruit’s surface (N·cm).

- is the component of an individual force (where = 1, 2, 3, or 4) projected onto the x-axis in the coordinate plane.

- is the resultant force of and along the x-axis.

- is the component of an individual force fi projected onto the y-axis in the coordinate plane.

- is the resultant force of and along the y-axis.

- is the moment of an individual force fi about point .

- is the resultant moment of and about point .

- is the angle between the lines of action of the VSA forces.

- is the torque, in units of kgf·cm.

- is the support force of the VSA, in Newtons (N).

- is the coefficient of friction.

- is the radial diameter of the contact area between the fruit and the VSA, in meters (m).

4.2.3. Determination of the Coefficient of Friction Between Dragon Fruit and TPU Material

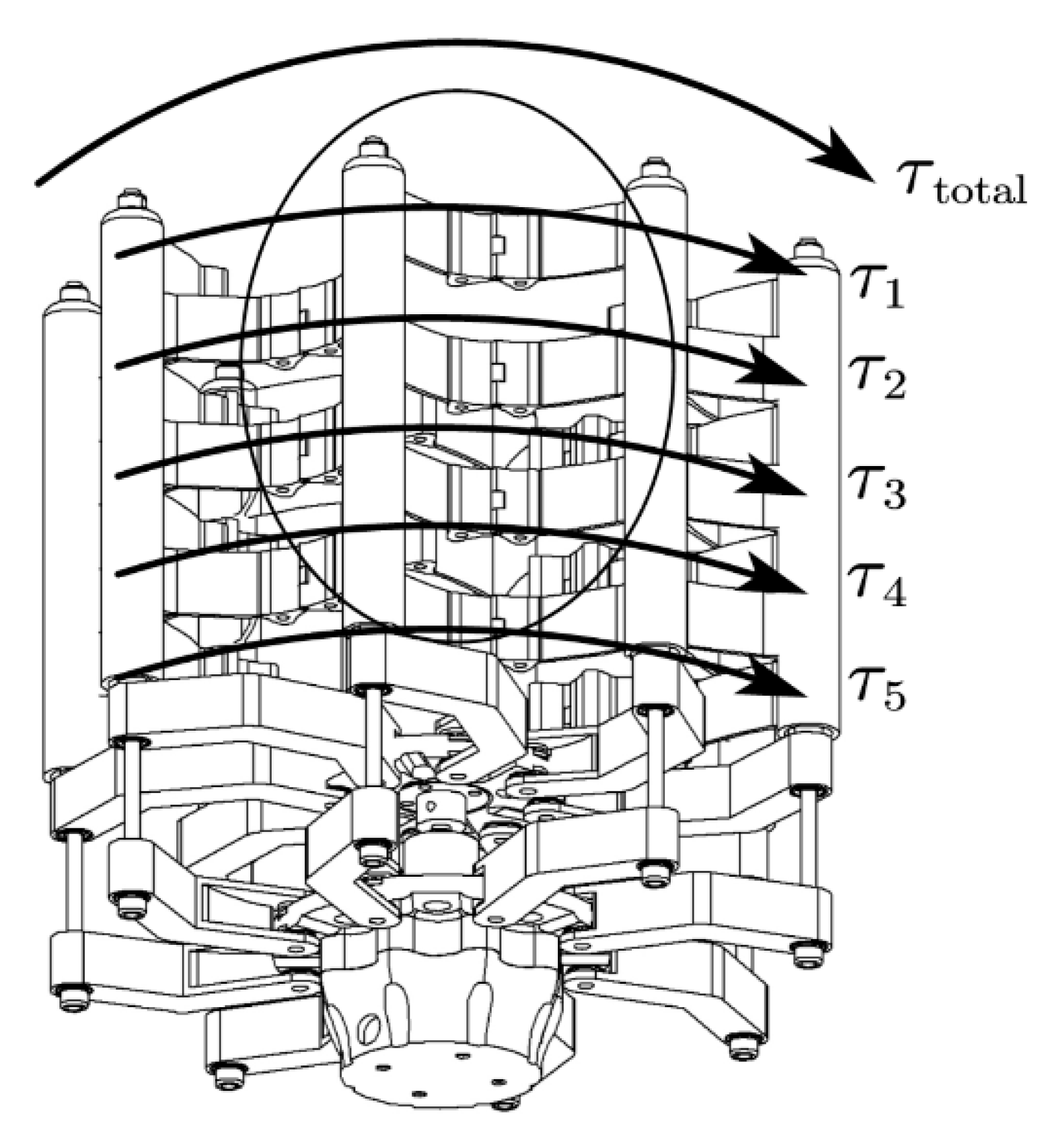

4.2.4. Calculation of Total Torque for the Multi-Layer Gripping Structure

4.3. Motor Selection and Parameter Rationale

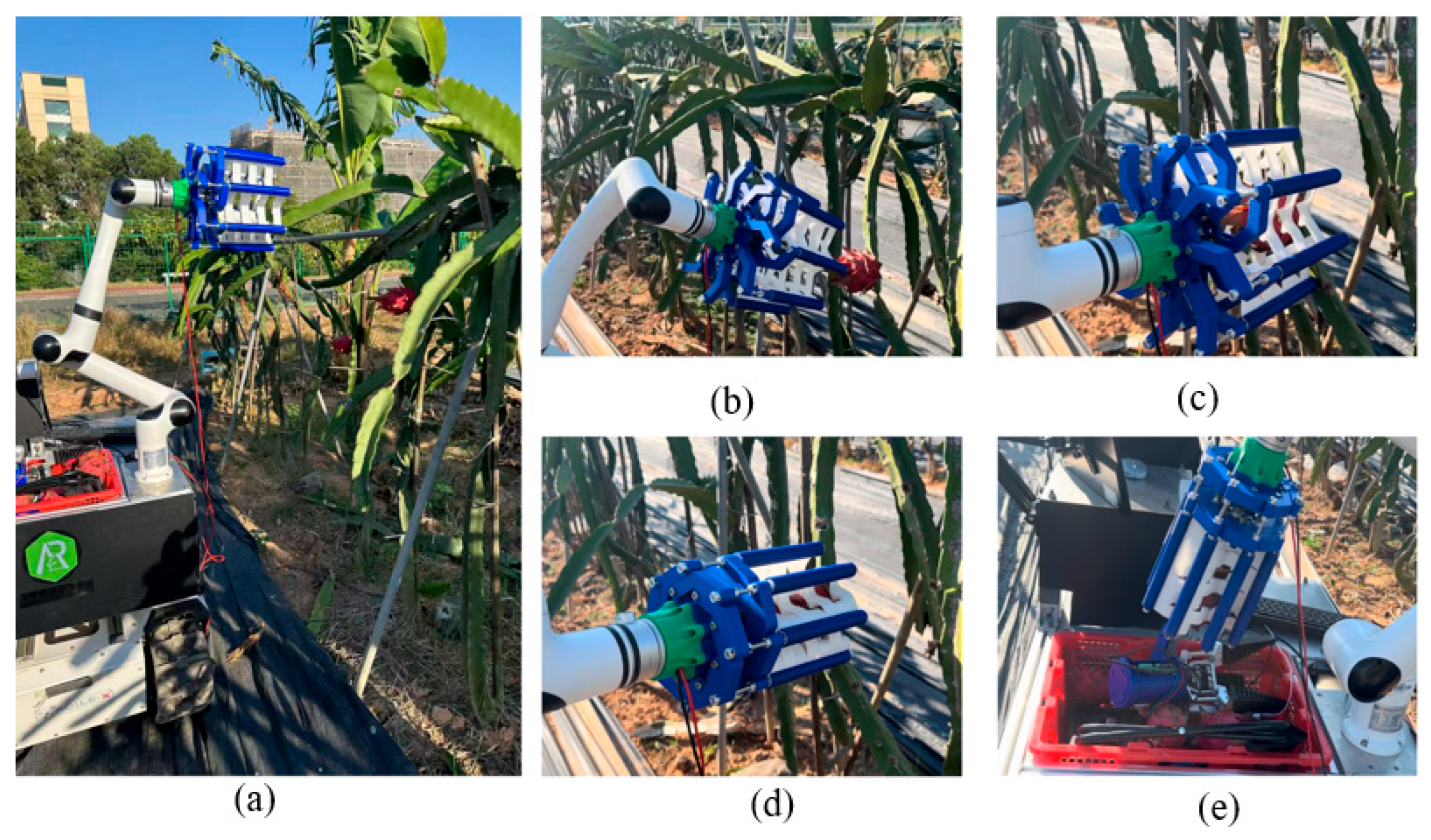

5. Field Gripping and Harvesting Trials and Analysis

5.1. Experimental Method

5.1.1. Experimental Platform, Samples, and Environment

5.1.2. Operational Workflow and Damage Assessment

- Level 0 (No Damage): Fruit skin intact, stem detachment point smooth, no pulp bruising.

- Level 1 (Slight Damage): Slight indentations on the fruit skin but no breakage.

- Level 2 (Moderate Damage): Fruit skin broken or obvious tearing at the stem.

- Level 3 (Severe Damage): Severe damage to the pulp tissue.

6. Results

6.1. Harvesting Success Rate and Efficiency

6.2. Assessment of Static Pressure Bruising and Torsional Harvesting Damage

7. Discussion

7.1. Challenges and Design Limitations in Field Trials

7.2. Future Outlook

- Structural Optimization and Miniaturization: Addressing the accessibility challenges identified, a primary task for future work will be to optimize and miniaturize the end-effector’s structure. This aims to reduce its overall size and weight without compromising its enveloping performance.

- Enhanced Perception and Adaptability: Integrating flexible tactile sensors to achieve closed-loop adaptive control of gripping force. Concurrently, visual algorithms will be improved to enhance robustness in complex environments.

- Expanded Application Scope: Extending the design concept to the harvesting of other irregularly shaped, high-value fruits, such as mangoes and avocados. Furthermore, its scalability and application in large-scale industrial harvesting robots will be explored.

8. Conclusions

- (1)

- Significantly Improved Gripping Reliability and Reduced Fruit Damage Rate: Benefiting from the VSA structure’s linear force control and multi-point flexible envelopment features, the end-effector effectively overcomes the damage and slippage issues caused by stress concentration and off-center gripping, which are common in traditional rigid jaws. Field trials showed that its optimal harvesting success rate reached 95%, with the pulp of harvested samples remaining completely undamaged, achieving genuinely low-damage harvesting.

- (2)

- Achieved More Efficient Harvesting Operations: The average harvesting time per fruit is approximately 15 s, which is a significant improvement in operational efficiency compared to traditional harvesting structures reported in the literature. The successful application of the 10 Nm motor, while ensuring the completion of harvesting tasks for the largest fruit samples, also validates the rational matching of the structure in terms of energy efficiency and lightweight design, ensuring stability during continuous operation.

- (3)

- Demonstrated Broad Application Potential: The principles of adaptive gripping and force control based on the VSA, as proposed in this study, are not limited to dragon fruit. This design concept can provide an important technical reference and an efficient, reliable solution for the automated harvesting of other high-value fruits with irregular shapes and fragile skins (such as mangoes, avocados, etc.).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, G.; Ji, C.; Zhai, L. Research progress and analysis of end-effector for fruits and vegetables picking robot. J. Chin. Agric. Mech. 2014, 35, 231–236, 240. [Google Scholar] [CrossRef]

- Wu, J.; Fan, S.; Gong, L.; Yuan, J.; Zhou, Q.; Liu, C. Research Status and Development Direction of Design and Control Technology of Fruit and Vegetable Picking Robot System. Smart Agric. 2020, 2, 17–40. [Google Scholar] [CrossRef]

- Li, W.; Liao, L. An Analysis of the Current Situation and Strategies for the Development of the Dragon Fruit Industry in Guangxi. South China Agric. 2024, 18, 202–205. [Google Scholar] [CrossRef]

- Yang, H.; Xing, Y.; Chen, C.; Xie, F.; Zhang, Z.; Zhoa, J.; Hu, G.; Qin, Y.; Zhang, Z. Analysis and Evaluation of Fruit Quality of Different Batches of Dragon Fruit. South China Fruits 2023, 52, 36–46. [Google Scholar] [CrossRef]

- Vrochidou, E.; Tsakalidou, V.N.; Kalathas, I.; Gkrimpizis, T.; Pachidis, T.; Kaburlasos, V.G. An Overview of End Effectors in Agricultural Robotic Harvesting Systems. Agriculture 2022, 12, 1240. [Google Scholar] [CrossRef]

- Qiu, L.; Yu, J.; Zhang, X.; Zhao, J. Automatic Picking and Harvesting Machine for Pitaya Fruit. South Agric. Mach. 2022, 53, 4–6+19. [Google Scholar] [CrossRef]

- Chen, Q.; Xiao, C.; Luo, D.; Gao, J.; Ouyang, C.; Zeng, C.; Li, W.; Zhou, X. Design of Shear End Effector for Dragon Fruit Picking Based on Oval Claw. J. Agric. Sci. Technol. 2025, 27, 113–121. [Google Scholar] [CrossRef]

- Park, H.; Kang, H.; Hwang, B.; Joe, S.; Kim, B. A Fruit Harvesting Mechanism Capable of Multidimensional Movements: A Preliminary Study on the Integrated Mechanism with a Hexacopter. Aerospace 2024, 11, 203. [Google Scholar] [CrossRef]

- Deng, L.; Liu, T.; Jiang, P.; Qi, A.; He, Y.; Li, Y.; Yang, M.; Deng, X. Design and Testing of Bionic-Feature-Based 3D-Printed Flexible End-Effectors for Picking Horn Peppers. Agronomy 2023, 13, 2231. [Google Scholar] [CrossRef]

- Navas, E.; Fernández, R.; Armada, M.; Gonzalez-De-Santos, P. Diaphragm-Type Pneumatic-Driven Soft Grippers for Precision Harvesting. Agronomy 2021, 11, 1727. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, W.; Xu, B.; Yu, X. Optimizing Contact Force on an Apple Picking Robot End-Effector. Agriculture 2024, 14, 996. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Z.; Wang, Y.; Bao, R.; Chen, X.; Fu, S.; Tian, M.; Zhang, Y. Research on Flexible End-Effectors with Humanoid Grasp Function for Small Spherical Fruit Picking. Agriculture 2023, 13, 123. [Google Scholar] [CrossRef]

- Zhao, Y.; Geng, D.; Liu, X.; Sun, G. Kinematics Analysis and Experiment on Pneumatic Flexible Fruit and Vegetable Picking Manipulator. Trans. Chin. Soc. Agric. Mach. 2019, 50, 31–42. [Google Scholar] [CrossRef]

- Liu, J.; Li, P.; Li, Z. A Multi-Sensory End-Effector for Spherical Fruit Harvesting Robot. In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007; IEEE: New York, NY, USA, 2007; pp. 258–262. [Google Scholar]

- Xu, Y.; Lv, M.; Xu, Q.; Xu, R. Design and Analysis of a Robotic Gripper Mechanism for Fruit Picking. Actuators 2024, 13, 338. [Google Scholar] [CrossRef]

- Mu, L.; Cui, G.; Liu, Y.; Cui, Y.; Fu, L.; Gejima, Y. Design and simulation of an integrated end-effector for picking kiwifruit by robot. Inf. Process. Agric. 2020, 7, 58–71. [Google Scholar] [CrossRef]

- Li, Z.; Yuan, X.; Yang, Z. Design, simulation, and experiment for the end effector of a spherical fruit picking robot. Int. J. Adv. Robot. Syst. 2023, 20, 17298806231213442. [Google Scholar] [CrossRef]

- Jin, S.; Xu, G.; Wang, M. Research and Design of the Robotic Harvesting Manipulator for Pitaya. Mold Manuf. 2025, 25, 204–206. [Google Scholar] [CrossRef]

- Ye, M.; Zou, X.; Cai, P.; Zou, H. Design of a General Gripping Mechanism for Fruit-Picking Robots. Trans. Chin. Soc. Agric. Mach. 2011, 42, 177–180. [Google Scholar]

- Chen, Y.; Jiang, z.; Li, W.; Wang, J.; Liu, W.; Zou, X. Design and Testing of Litchi Picking End-effector Integrated Clamping and Cutting Performance. Trans. Chin. Soc. Agric. Mach. 2018, 49, 35–41. [Google Scholar] [CrossRef]

- Masood, M.U.; Haghshenas-Jaryani, M. A Study on the Feasibility of Robotic Harvesting for Chile Pepper. Robotics 2021, 10, 94. [Google Scholar] [CrossRef]

- Yu, Y.; Xie, H.; Zhang, K.; Wang, Y.; Li, Y.; Zhou, J.; Xu, L. Design, Development, Integration, and Field Evaluation of a Ridge-Planting Strawberry Harvesting Robot. Agriculture 2024, 14, 2126. [Google Scholar] [CrossRef]

- Yi, W.; Shun, F.; Zhe, Z.; Ma, T.; Xu, H. Design and Experimentation on End-effector of Citrus Picking Robot. J. Agric. Sci. Technol. 2018, 20, 69–77. [Google Scholar] [CrossRef]

- Xu, L.; Liu, X.; Zhang, K.; Xing, J.; Yuan, Q.; Chen, J.; Duan, Z.; Zhuang, M.S.; Yu, C.C. Design and Testing of the End-Effector for a Navel Orange Harvesting Robot. Trans. Chin. Soc. Agric. Eng. 2018, 34, 53–61. [Google Scholar]

- Lou, K.; Wang, Z.; Zhang, B.; Xu, Q.; Fu, W.; Gu, Y.; Liu, J. Analysis and Experimentation on the Motion Characteristics of a Dragon Fruit Picking Robot Manipulator. Agriculture 2024, 14, 2095. [Google Scholar] [CrossRef]

- Zhang, Y.; Tian, J.; Wang, W.; Zhou, J.; Hu, H. Design and experiments of end-effector for dragon fruit picking robot. J. For. Eng. 2023, 8, 144–150. [Google Scholar] [CrossRef]

- Zhu, L.; Deng, W.; Lai, Y.; Guo, X.; Zhang, S. Research on Improved Road Visual Navigation Recognition Method Based on DeepLabV3+ in Pitaya Orchard. Agronomy 2024, 14, 1119. [Google Scholar] [CrossRef]

- Huang, Y.; Brennan, M.A.; Kasapis, S.; Richardson, S.J.; Brennan, C.S. Maturation Process, Nutritional Profile, Bioactivities and Utilisation in Food Products of Red Pitaya Fruits: A Review. Foods 2021, 10, 2862. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Xu, J.; He, Y.; Shi, M.; Han, X.; Li, W.; Zhang, X.; Wen, X. Metabolic Profiling of Pitaya (Hylocereus polyrhizus) during Fruit Development and Maturation. Molecules 2019, 24, 1114. [Google Scholar] [CrossRef]

- Fotuhi, M.J.; Hazem, Z.B.; Bingül, Z. Comparison of joint friction estimation models for laboratory 2 DOF double dual twin rotor aero-dynamical system. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 2231–2236. [Google Scholar]

- Huang, M.; Zhao, J. Recent advances in postharvest storage and preservation technology of pitaya (dragon fruit). J. Hortic. Sci. Biotechnol. 2024, 99, 115–129. [Google Scholar]

- Zhu, L.; Lai, Y.; Zhang, S.; Wu, R.; Deng, W.; Guo, X. Image Segmentation and Pose Estimation Method for Pitaya Picking Robot Based on Enhanced U-Net. Trans. Chin. Soc. Agric. Mach. 2023, 54, 180–188. [Google Scholar]

| No. | Torsional Separation Angle (°) | Maximum Torque (kgf·cm) | No. | Torsional Separation Angle (°) | Maximum Torque (kgf·cm) |

|---|---|---|---|---|---|

| 1 | 360 | 4.6 | 9 | 540 | 11.2 |

| 2 | 540 | 14.1 | 10 | 720 | 9 |

| 3 | 720 | 13.2 | 11 | 540 | 8.2 |

| 4 | 270 | 9.2 | 12 | 640 | 9.5 |

| 5 | 720 | 10 | 13 | 540 | 10.5 |

| 6 | 480 | 11 | 14 | 480 | 11.8 |

| 7 | 540 | 7.8 | 15 | 540 | 9.4 |

| 8 | 540 | 8.8 | 16 | 720 | 12.3 |

| VSA Span (mm) | Maximum Force (N) | Deformation at Maximum Force (mm) | Stiffness (N/cm) |

|---|---|---|---|

| 55 | 24.610 | 37.399 | 60.937 |

| 90 | 20.026 | 23.704 | 4.305 |

| 70 | 9.326 | 6.825 | 39.622 |

| 64 | 11.827 | 7.066 | 45.342 |

| No. | Inclination Angle (°) | No. | Inclination Angle (°) | No. | Inclination Angle (°) |

|---|---|---|---|---|---|

| 1 | 22.2 | 6 | 19.6 | 11 | 19.1 |

| 2 | 18.7 | 7 | 21.3 | 12 | 21.0 |

| 3 | 20.9 | 8 | 20.1 | 13 | 19.4 |

| 4 | 19.5 | 9 | 19.8 | 14 | 22.8 |

| 5 | 21.3 | 10 | 20.9 | 15 | 20.3 |

| Layer No. | Cross-Sectional Diameter (mm) | Deformation (mm) | Support Force (N) |

|---|---|---|---|

| 1 | 55.2 | 9.98 | 14.1 |

| 2 | 84.32 | 24.54 | 7.7 |

| 3 | 92 | 28.38 | 4.4 |

| 4 | 84.32 | 24.54 | 7.7 |

| 5 | 55.2 | 9.98 | 14.1 |

| Dimensional Parameter | Minimum Value (mm) | Maximum Value (mm) | Average Value (mm) | Standard Deviation (mm) |

|---|---|---|---|---|

| Axial Length | 75 | 87.8 | 81.9 | 3.2 |

| Maximum Radial Width | 74.5 | 88.1 | 81.6 | 3.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, L.; Chen, Y.; Lv, Q.; Zhang, S.; Feng, X.; Kong, S.; Fu, G.; Chen, T. Design and Performance Validation of a Variable-Span Arch (VSA) End-Effector for Dragon Fruit Harvesting. AgriEngineering 2025, 7, 327. https://doi.org/10.3390/agriengineering7100327

Zhu L, Chen Y, Lv Q, Zhang S, Feng X, Kong S, Fu G, Chen T. Design and Performance Validation of a Variable-Span Arch (VSA) End-Effector for Dragon Fruit Harvesting. AgriEngineering. 2025; 7(10):327. https://doi.org/10.3390/agriengineering7100327

Chicago/Turabian StyleZhu, Lixue, Yipeng Chen, Qiuhui Lv, Shiang Zhang, Xinqi Feng, Shaoting Kong, Genping Fu, and Tianci Chen. 2025. "Design and Performance Validation of a Variable-Span Arch (VSA) End-Effector for Dragon Fruit Harvesting" AgriEngineering 7, no. 10: 327. https://doi.org/10.3390/agriengineering7100327

APA StyleZhu, L., Chen, Y., Lv, Q., Zhang, S., Feng, X., Kong, S., Fu, G., & Chen, T. (2025). Design and Performance Validation of a Variable-Span Arch (VSA) End-Effector for Dragon Fruit Harvesting. AgriEngineering, 7(10), 327. https://doi.org/10.3390/agriengineering7100327