Interplay of Fogponics and Artificial Intelligence for Potential Application in Controlled Space Farming

Abstract

1. Introduction

- Technical feasibility of the fogponics system in a microgravity environment. This study analyzed the effectiveness of nutrient delivery mechanisms via fog, assessing factors such as particle generation and dispersion, environmental control, and nutrient uptake by plants. By examining these technical aspects, this study aimed to explore fogponics system design to ensure reliable and efficient crop cultivation under unconventional conditions;

- Strategic recommendations for integrating fogponics technology into future space missions or planetary colonization efforts. By elucidating the adaptability and effectiveness of fogponics for microgravity-conditioned crop cultivation, this study lays the groundwork for enhancing food security and self-sufficiency in isolated or resource-scarce environments, both on Earth and beyond.

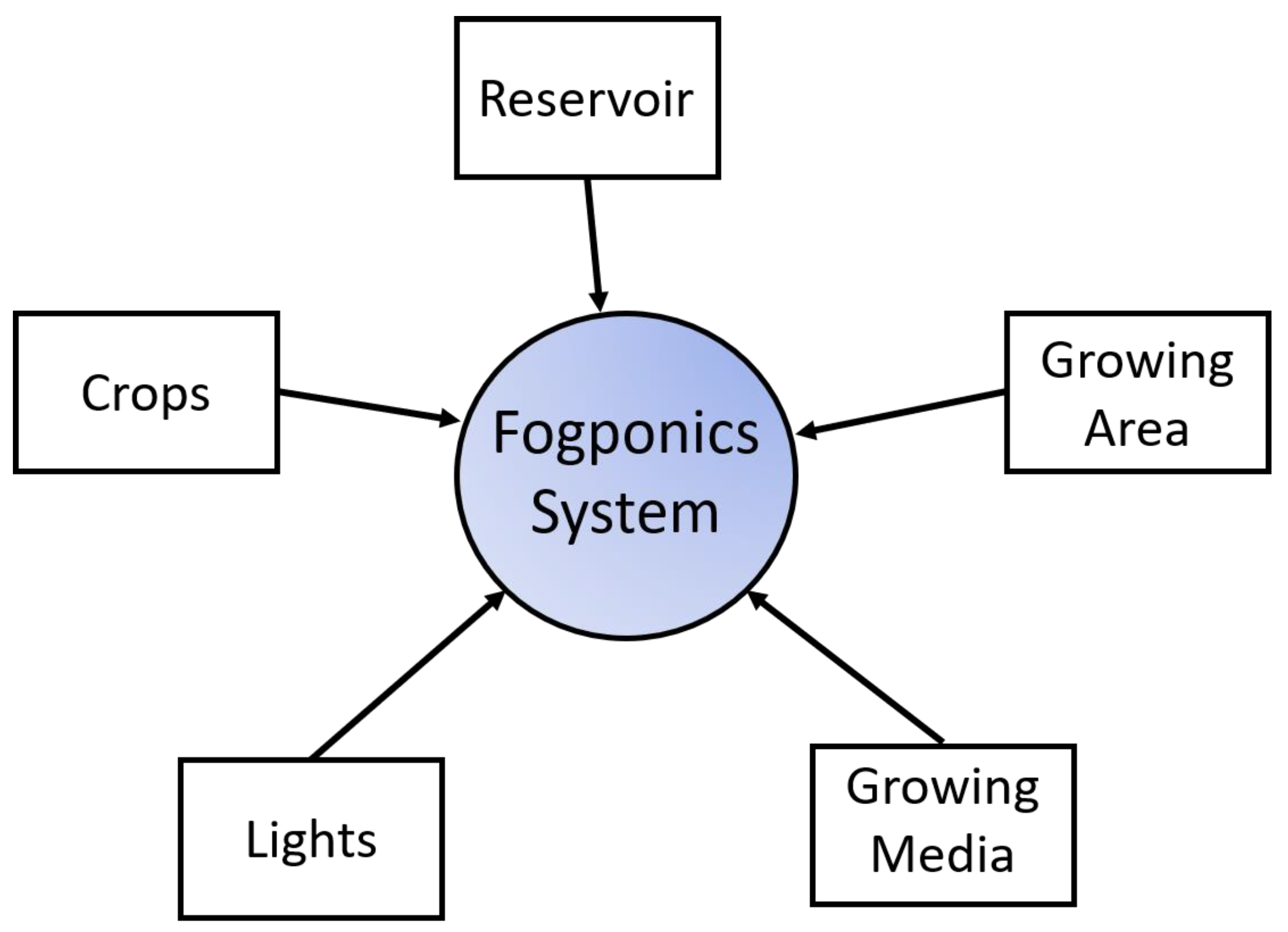

2. Terrestrial Fogponics System

2.1. Fogponics System Advancements in Recent Years

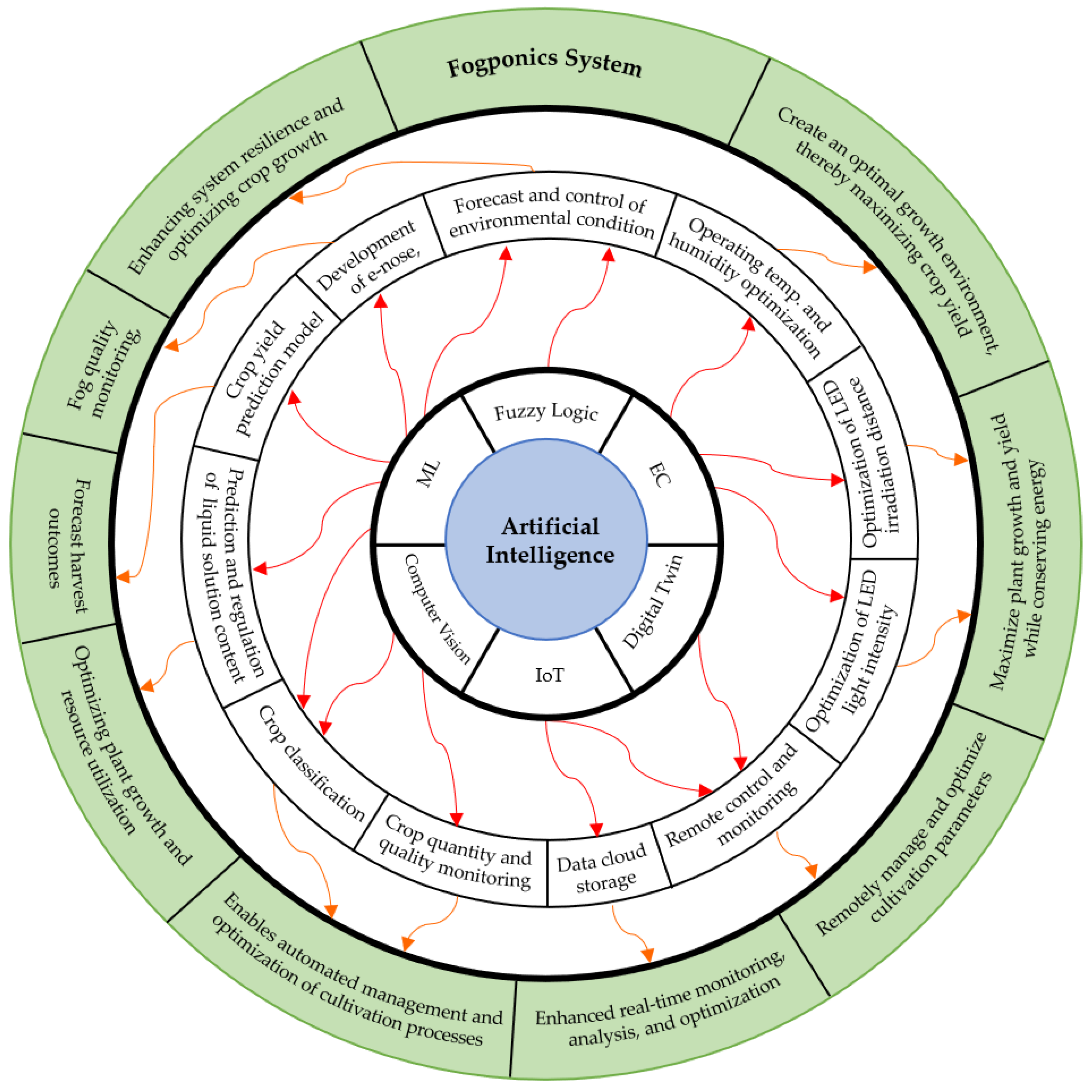

2.2. Applied Industrial Revolution 4.0 Technologies in Fogponics System

- Internet of Things (IoT). The term “IoT” denotes a network comprising interconnected physical entities or “things” that are equipped with software, sensors, and other technological components. This enables these objects to gather and exchange data with other systems and devices via the Internet [47,48]. These objects can collect and transmit data via IoT technology, allowing for automation, remote control, and monitoring. By embedding sensors, actuators, and connectivity features, IoT devices collect and transmit data about their environment, usage, and performance, enabling real-time monitoring, control, and automation of various processes and systems. One study [26] was able to create a fogponics system that was operationalized with IoT technology. The system used IoT to control environmental conditions, allowing it to automatically read temperature, humidity, and pH data. The IoT technology was also employed to store the processed data and results on an IoT platform, which was then accessed through Internet-connected devices such as mobile phones and computers. This allows remote monitoring and control of their fogponics farming system. However, this study acknowledges the need for further system enhancements, aiming to utilize the technology on a real farming application.

- Fuzzy logic. This system facilitates reasoning and decision-making in circumstances characterized by uncertainty, imprecision, or ambiguity through the utilization of multivalued logic. Situations in which conditions or variables are difficult to classify into binary terms but can be expressed in hues of gray are ideal candidates for fuzzy logic [49,50]. It finds effectiveness in a multitude of domains, encompassing expert systems, control systems, artificial intelligence, and decision support systems, where it helps model complex, real-world problems that involve ambiguity and uncertainty [51,52]. The system comprises a collection of fuzzy IF-THEN rules that define the relationship between input and output in the networks [49]. The main components of fuzzy logic include fuzzification, an inference engine that transforms precise inputs into fuzzy values; rule-based reasoning, which utilizes a fuzzy reasoning mechanism to produce a fuzzy output based on rules; and defuzzification, which converts the fuzzy output subsequently to a precise value. Input membership functions that define the mapping of system input values from 0 to 1 constitute fuzzification. Rule-based reasoning employs the membership values of fuzzy input to categorize fuzzy output using a table that consists of if-then rules. Rules can be quantitatively expressed as a logical implication p → q, where p represents the condition or premise of the rule, and q indicates the result or outcome. The process of defuzzification generates precise values for single system outputs through the utilization of a defuzzification formula and fuzzy output membership outputs. The FIS computing framework is based on the fundamental ideas of fuzzy reasoning, fuzzy set theory, and fuzzy if-then logic. In line with this, the study [26] utilized Sugeno fuzzy logic in the system that it developed. The logic serves as a control algorithm that would regulate the environmental conditions in the fogponics farming system based on the inputs from temperature, humidity, and pH sensors. The actuators can be activated or deactivated by the system by transmitting fuzzy results to each output device. The findings of their research indicate that the actuators’ responses are consistent with the established fuzzy rules. The actuators are activated for each data point by the results of the fuzzy algorithm processing, ensuring that the value of each data point falls within the established normal value range.

- Cyber-physical systems. These sophisticated technological systems are expansive, interconnected systems that are built upon the interactions between physical and cyber elements. They consist of three fundamental components: communications, control, and computing [53]. It is intricately linked with the operational, monitoring, coordinating, integrating, and controlling physical processes. Its fundamental attributes traverse both the physical and digital realms, employing actuators for control and sensors for computation [54]. This technology was utilized by [27], where an LCD display plays a crucial role in the digital–physical interaction by providing real-time feedback and data visualization. Manual actuation of their developed system relies on the information given by the digital interface of real physical cultivation. With this, the environmental conditions of the system were able to be controlled.

3. Other Soilless Irrigation and Fertigation System Technologies

Advanced Technologies Applied on Hydroponics and Aeroponics System

4. Fog Behavior in Microgravity Environment

5. Fog Generation and Dispersion Mechanisms

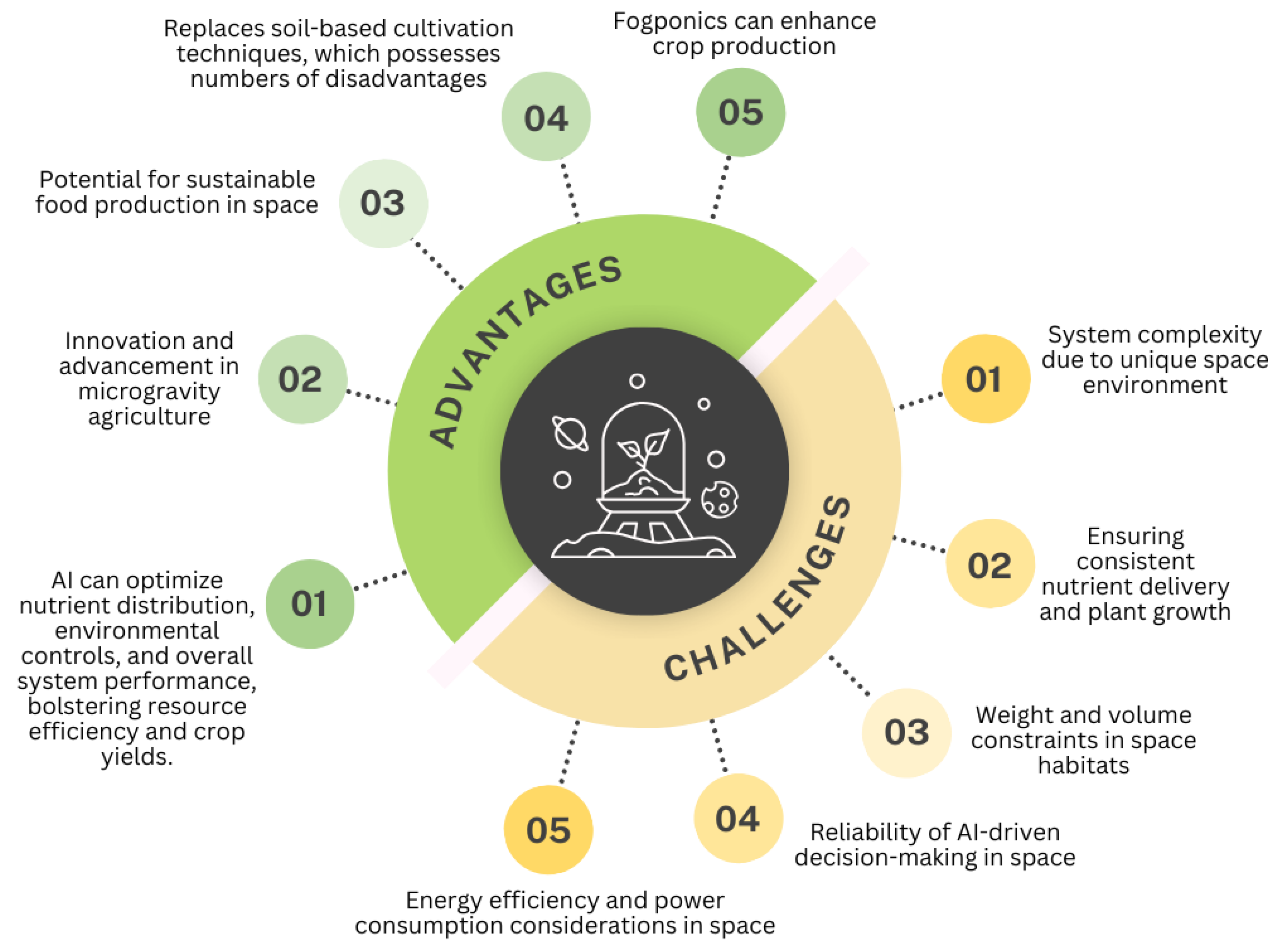

6. Challenges and Advantages of Integrated AI and Fogponics in Microgravity Cultivation

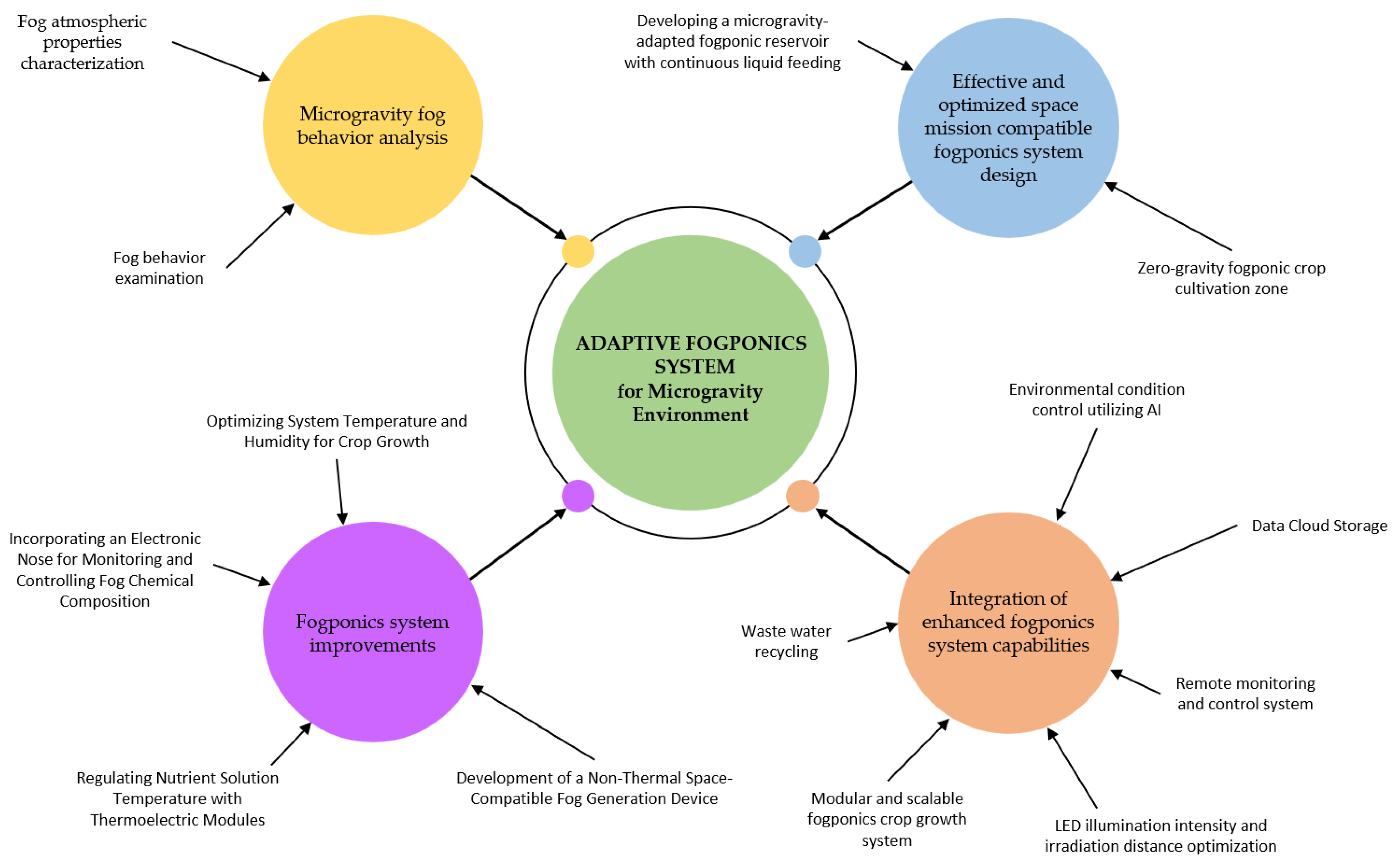

7. Discussion and Future Directions

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reneau, A. Introduction to Space Exploration. In Moon First and Mars Second; SpringerBriefs in Space Development; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–5. ISBN 978-3-030-54229-0. [Google Scholar]

- Dionela, M.J.; Tan, J.M.; Paran, L.M.; Concepcion, R.; Bandala, A.; Gennaro, L. Design of a Hypergravity Simulation Platform with Speed and Axis Stability Control Systems. In Proceedings of the 2022 IEEE 14th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Boracay Island, Philippines, 1–4 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Monje, O.; Stutte, G.W.; Goins, G.D.; Porterfield, D.M.; Bingham, G.E. Farming in Space: Environmental and Biophysical Concerns. Adv. Space Res. 2003, 31, 151–167. [Google Scholar] [CrossRef]

- ISS National Laboratory. Studying Plant Growth in Microgravity and on the Moon. 2019. Available online: https://www.issnationallab.org/studying-plant-growth-in-microgravity-and-on-the-moon/ (accessed on 17 February 2024).

- Huston, C.; National Aeronautics and Space Administration. Growing Plants in Space. 2023. Available online: https://www.nasa.gov/exploration-research-and-technology/growing-plants-in-space/ (accessed on 10 May 2024).

- Musgrave, M.E. Growing Plants in Space. CAB Rev. Perspect. Agric. Vet. Sci. Nutr. Nat. Resour. 2007, 2. [Google Scholar] [CrossRef]

- Qin, J.; Monje, O.; Nugent, M.R.; Finn, J.R.; O’Rourke, A.E.; Wilson, K.D.; Fritsche, R.F.; Baek, I.; Chan, D.E.; Kim, M.S. A Hyperspectral Plant Health Monitoring System for Space Crop Production. Front. Plant Sci. 2023, 14, 1133505. [Google Scholar] [CrossRef]

- Mohanta, T.K.; Mishra, A.K.; Mohanta, Y.K.; Al-Harrasi, A. Space Breeding: The Next-Generation Crops. Front. Plant Sci. 2021, 12, 771985. [Google Scholar] [CrossRef] [PubMed]

- Caporale, A.G.; Paradiso, R.; Liuzzi, G.; Arouna, N.; De Pascale, S.; Adamo, P. Can Peat Amendment of Mars Regolith Simulant Allow Soybean Cultivation in Mars Bioregenerative Life Support Systems? Plants 2022, 12, 64. [Google Scholar] [CrossRef] [PubMed]

- Concepcion, R.; Josh Ramirez, T.; Alejandrino, J.; Janairo, A.G.; Jahara Baun, J.; Francisco, K.; Relano, R.-J.; Enriquez, M.L.; Grace Bautista, M.; Vicerra, R.R.; et al. A Look at the Near Future: Industry 5.0 Boosts the Potential of Sustainable Space Agriculture. In Proceedings of the 2022 IEEE 14th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Boracay Island, Philippines, 1–4 December 2022; IEEE: Boracay Island, Philippines, 2022; pp. 1–6. [Google Scholar]

- Hall, L.; National Aeronautics and Space Administration. NASA Is Everywhere: Farming Tech with Roots in Space. 2019. Available online: https://www.nasa.gov/technology/tech-transfer-spinoffs/nasa-is-everywhere-farming-tech-with-roots-in-space/ (accessed on 31 October 2023).

- Böhmer, M.; Schleiff, E. Microgravity Research in Plants: A Range of Platforms and Options Allow Research on Plants in Zero or Low Gravity That Can Yield Important Insights into Plant Physiology. EMBO Rep. 2019, 20, e48541. [Google Scholar] [CrossRef] [PubMed]

- Harvey, B.; Zakutnyaya, O. Orbiting Space Stations. In Russian Space Probes; Praxis: New York, NY, USA, 2011; pp. 301–374. ISBN 978-1-4419-8149-3. [Google Scholar]

- National Aeronautics and Space Administration. Plant Growth/Plant Phototropism. 1973. Available online: https://nlsp.nasa.gov/view/lsdapub/lsda_experiment/f498d8e1-1eab-5159-82bd-67cc5820d0be (accessed on 19 April 2024).

- The National Aeronautics and Space Administration Skylab. Available online: https://www.nasa.gov/skylab/ (accessed on 12 June 2024).

- Zabel, P.; Bamsey, M.; Schubert, D.; Tajmar, M. Review and Analysis of over 40 Years of Space Plant Growth Systems. Life Sci. Space Res. 2016, 10, 1–16. [Google Scholar] [CrossRef]

- Evans, C.; Robinson, J.; Tate-Brown, J.; Thumm, T.; Crespo-Richey, J.; Baumann, D.; Rhatigan, J. International Space Station Science Research Accomplishments during the Assembly Years: An Analysis of Results from 2000–2008. In NASA/TP—2009—213146—REVISION A; NASA: Washington, DC, USA, 2009. [Google Scholar]

- Yano, S.; Kasahara, H.; Masuda, D.; Tanigaki, F.; Shimazu, T.; Suzuki, H.; Karahara, I.; Soga, K.; Hoson, T.; Tayama, I.; et al. Improvements in and Actual Performance of the Plant Experiment Unit Onboard Kibo, the Japanese Experiment Module on the International Space Station. Adv. Space Res. 2013, 51, 780–788. [Google Scholar] [CrossRef]

- Preu, P.; Braun, M. German SIMBOX on Chinese Mission Shenzhou-8: Europe’s First Bilateral Cooperation Utilizing China’s Shenzhou Programme. Acta Astronaut. 2014, 94, 584–591. [Google Scholar] [CrossRef]

- Porterfield, D.M.; Neichitailo, G.S.; Mashinski, A.L.; Musgrave, M.E. Spaceflight Hardware for Conducting Plant Growth Experiments in Space: The Early Years 1960–2000. Adv. Space Res. 2003, 31, 183–193. [Google Scholar] [CrossRef]

- Massa, G.D.; Newsham, G.; Hummerick, M.E.; Morrow, R.C.; Wheeler, R.M. Plant Pillow Preparation for the Veggie Plant Growth System on the International Space Station. Gravitational Space Res. 2017, 5, 24–34. [Google Scholar] [CrossRef]

- Oluwafemi, F. Space Food on Celestial Bodies and on the Way There. In Future Foods; Elsevier: Amsterdam, The Netherlands, 2022; pp. 451–468. ISBN 978-0-323-91001-9. [Google Scholar]

- NASA Science Editorial Team, National Aeronautics and Space Administration. Q: How Do You Water Plants in Space? A: Omni-Gravitational Hydroponics. 2021. Available online: https://science.nasa.gov/science-research/science-enabling-technology/technology-highlights/how-do-you-water-plants-in-space/ (accessed on 31 October 2023).

- Dutta, A.; Kumar, P.K. Aeroponics: An artificial plant cultivation technique. Authorea Preprints, 2023. [CrossRef]

- Vacharadze, A. Innovative Technologies in Agriculture and Economic Challenges (On the Example of Aeroponics). Econ. Profile 2021, 16, 82–91. [Google Scholar] [CrossRef]

- Suwastika, N.A.; Helmi, M.; Aulia, M.M.S.; Wardana, A.A. Design of a Fogponics Farming System Based on the Internet of Things and Fuzzy Logic. In Proceedings of the 2022 2nd International Conference on Intelligent Cybernetics Technology & Applications (ICICyTA), Bandung, Indonesia, 15–16 December 2022; IEEE: Bandung, Indonesia, 2022; pp. 99–104. [Google Scholar]

- Rakib Uddin, M.; Suliaman, M.F. Energy Efficient Smart Indoor Fogponics Farming System. IOP Conf. Ser. Earth Environ. Sci. 2021, 673, 012012. [Google Scholar] [CrossRef]

- Zelenkov, P.V.; Brezitskaya, V.V.; Kovalev, I.V.; Karaseva, M.V.; Voroshilova, A.A. Use of Innovative Space Technology in Progressive Crop Production. IOP Conf. Ser. Earth Environ. Sci. 2019, 315, 072019. [Google Scholar] [CrossRef]

- He, J. Integrated Vertical Aeroponic Farming Systems for Vegetable Production in Space Limited Environments. Acta Hortic. 2017, 1176, 25–36. [Google Scholar] [CrossRef]

- Čížek, M.; Komárková, Z. Comparison of Aeroponics and Conventional System of Production of Potato Mini-Tubers in the Conditions of the Czech Republic. Plant Soil Environ. 2022, 68, 366–374. [Google Scholar] [CrossRef]

- Ferrini, F.; Donati Zeppa, S.; Fraternale, D.; Carrabs, V.; Annibalini, G.; Verardo, G.; Gorassini, A.; Albertini, M.C.; Ismail, T.; Fimognari, C.; et al. Characterization of the Biological Activity of the Ethanolic Extract from the Roots of Cannabis sativa L. Grown in Aeroponics. Antioxidants 2022, 11, 860. [Google Scholar] [CrossRef] [PubMed]

- National Aeronautics and Space Administration. NASA—Progressive Plant Growing Is a Blooming Business. In Environmental and Agricultural Resources; Spinoff NASA: New York, NY, USA, 2006; pp. 64–77. [Google Scholar]

- Nguyen, M.T.P.; Knowling, M.; Tran, N.N.; Burgess, A.; Fisk, I.; Watt, M.; Escribà-Gelonch, M.; This, H.; Culton, J.; Hessel, V. Space Farming: Horticulture Systems on Spacecraft and Outlook to Planetary Space Exploration. Plant Physiol. Biochem. 2023, 194, 708–721. [Google Scholar] [CrossRef] [PubMed]

- Modu, F.; Aliyu, F.; Mabu, A. A Survey of Smart Hydroponic Systems. Adv. Sci. Technol. Eng. Syst. J. 2020, 5, 233–248. [Google Scholar] [CrossRef]

- Ke, W.; Xiong, Z. Difference of Growth, Copper Accumulation and Mineral Element Uptake in Two Elsholtzia Haichowensis Populations under Copper and Mineral Nutrition Stress. In Proceedings of the 2008 2nd International Conference on Bioinformatics and Biomedical Engineering, Shanghai, China, 16–18 May 2008; IEEE: Shanghai, China, May, 2008; pp. 4704–4708. [Google Scholar]

- Wang, H.; Wang, Y.; Yang, Y. Effects of Exogenous Phenolic Acids on Roots of Poplar Hydroponic Cuttings. In Proceedings of the 2011 International Conference on Remote Sensing, Environment and Transportation Engineering, Nanjing, China, 24–26 June 2011; IEEE: Nanjing, China, 2011; pp. 8245–8249. [Google Scholar]

- Suzui, N.; Kawachi, N.; Yamaguchi, M.; Ishioka, N.S.; Fujimaki, S. A Monitoring System of Radioactive Tracers in Hydroponic Solution for Research on Plant Physiology. In Proceedings of the 2009 1st International Conference on Advancements in Nuclear Instrumentation, Measurement Methods and their Applications, Marseille, France, 7–10 June 2009; IEEE: Marseille, France, 2009; pp. 1–3. [Google Scholar]

- Liu, M.Y.; Xi, X.Y.; Wang, S.F.; Xu, Y.; Song, W.L. Research on Differences of Component and Quantity of Organic Acids in the Root Exudates among the Three Green Manures. In Proceedings of the World Automation Congress 2012, Puerto Vallarta, Mexico, 24–28 June 2012. [Google Scholar]

- Sanchez, E.; Berghage, R.; Flax, N.; Ford, T.; Di Gioia, F. Hydroponics Systems and Principles Of Plant Nutrition: Essential Nutrients, Function, Deficiency, and Excess. Penn State Ext. Fact Sheet 2023, 1–5. [Google Scholar]

- Kaewwiset, T.; Yooyativong, T. Estimation of Electrical Conductivity and pH in Hydroponic Nutrient Mixing System Using Linear Regression Algorithm. In Proceedings of the 2017 International Conference on Digital Arts, Media and Technology (ICDAMT), Chiang Mai, Thailand, 1–4 March 2017; IEEE: Chiang Mai, Thailand, 2017; pp. 1–5. [Google Scholar]

- Wootton-Beard, P. Growing without Soil: An Overview of Hydroponics. Farming Connect 2019. [Google Scholar]

- Bouchard, S. Systems and Methods for Efficient Fogponics Agriculture. U.S. Patent 11,576,310, 14 February 2023. [Google Scholar]

- Lin, J.; Wang, J.; Zhang, X.; Lin, T. Greenhouse Wireless-Detection Fogponics System That Comprises a Nutrient Solution Supply Unit, a Mist-Generating Device, a Control Module, a Cultivation Carrier, a Mist-Conveying Device. Taiwan Patent 20,203,726, 16 October 2020. [Google Scholar]

- Watson, M. Fogponic Plant Growth System. U.S. Patent 10,999,985, 11 May 2021. [Google Scholar]

- Shyam, D.; Sivamani, D.; Ramkumar, R.; Premkumar, K.; Jayashree, K.; Lakshmi Priya, M. Agro Based Fogponic System for Indian Subcontinent. In Proceedings of the 2022 International Conference on Computer, Power and Communications (ICCPC), Chennai, India, 14–16 December 2022; IEEE: Chennai, India, 2022; pp. 355–360. [Google Scholar]

- Kang, I.; Jo, W.; Jo, Y. Smart Farm Using Fogponic with Adjustable Light Irradiation Distance. Korea Patent 20230045907A, 5 April 2023. [Google Scholar]

- Ramasamy, L.K.; Kadry, S. Internet of Things (IoT). In Blockchain in the Industrial Internet of Things; IOP Series in Next Generation Computing; IOP Publishing: Bristol, UK, 2021; pp. 1–16. ISBN 978-0-7503-3663-5. [Google Scholar]

- Kiran, D.R. Internet of Things. In Production Planning and Control; Elsevier: Amsterdam, The Netherlands, 2019; pp. 495–513. ISBN 978-0-12-818364-9. [Google Scholar]

- Zadeh, L.A. Fuzzy Logic. Computer 1988, 21, 83–93. [Google Scholar] [CrossRef]

- Zadeh, L.A. Is There a Need for Fuzzy Logic? Inf. Sci. 2008, 178, 2751–2779. [Google Scholar] [CrossRef]

- Makkar, R. Application of Fuzzy Logic: A Literature Review. Int. J. Stat. Appl. Math. 2018, 3, 3. [Google Scholar]

- Mittal, K.; Jain, A.; Vaisla, K.S.; Castillo, O.; Kacprzyk, J. A Comprehensive Review on Type 2 Fuzzy Logic Applications: Past, Present and Future. Eng. Appl. Artif. Intell. 2020, 95, 103916. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, X.; Chen, H. Theoretical Foundations and Applications of Cyber-Physical Systems: A Literature Review. LHT 2019, 38, 95–104. [Google Scholar] [CrossRef]

- Nandy, T.; Coutu, R.; Ababei, C. Carbon Monoxide Sensing Technologies for Next-Generation Cyber-Physical Systems. Sensors 2018, 18, 3443. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Díaz, J.; Ivanov, O.; Peshev, Z.; Álvarez-Valenzuela, M.; Valiente-Blanco, I.; Evgenieva, T.; Dreischuh, T.; Gueorguiev, O.; Todorov, P.; Vaseashta, A. Fogs: Physical Basis, Characteristic Properties, and Impacts on the Environment and Human Health. Water 2017, 9, 807. [Google Scholar] [CrossRef]

- Wang, X.; Tsuchiya, K. Frequency Specificity of Liquid-Fountain Swinging with Mist Generation: Effects of Ultrasonic Irradiation Angle. Fluids 2022, 7, 306. [Google Scholar] [CrossRef]

- Sin, H. Micro Fog Formation Device and Fog Formation Means. Korea Patent 101525600B1, 4 June 2015. [Google Scholar]

- Xu, H. Fog Bubble Machine. China Patent 209137981U, 4 June 2020. [Google Scholar]

- Kim, K. Fog Producing Device. Korea Patent 20160138636A, 12 June 2016. [Google Scholar]

- Kozai, T.; Niu, G.; Masabni, J. Hydroponics. In Plant Factory Basics, Applications and Advances; Academic Press: Cambridge, MA, USA, 2022; pp. 153–165. ISBN 978-0-323-85152-7. [Google Scholar]

- Mungin, R.M.; Weislogel, M.M.; Hatch, T.R. Omni-Gravity Hydroponics for Space Exploration. In Proceedings of the International Conference on Environmental Systems (ICES), Boston, MA, USA, 7–11 July 2019. [Google Scholar]

- Liu, Z.; Zhao, B.; Ning, D.; Qin, A.; Liu, Z.; Li, S.; Xiao, J. A Kind of Soilless Culture Nutrient Solution Circulating Irrigation System and Irrigation Method. China Patent 10,990,693, 21 June 2019. [Google Scholar]

- Liu, Z.; Xu, Q. An Automatic Irrigation Control System for Soilless Culture of Lettuce. Water 2018, 10, 1692. [Google Scholar] [CrossRef]

- Kang, P.; Gao, Y.; Wu, S.; Wu, Z.; Xia, J.; Xue, W.; Zhou, H. Compound Soil-Less Cultivation Irrigation System. China Patent 10,496,984, 14 October 2015. [Google Scholar]

- Sadek, N.; Kamal, N.; Shehata, D. Internet of Things Based Smart Automated Indoor Hydroponics and Aeroponics Greenhouse in Egypt. Ain Shams Eng. J. 2024, 15, 102341. [Google Scholar] [CrossRef]

- Tang, H.C.K.; Cheng, T.Y.S.; Wong, J.C.Y.; Cheung, R.C.C.; Lam, A.H.F. Aero-Hydroponic Agriculture IoT System. In Proceedings of the 2021 IEEE 7th World Forum on Internet of Things (WF-IoT), New Orleans, LA, USA, 14 June–31 July 2021; IEEE: New Orleans, LA, USA, 2021; pp. 741–746. [Google Scholar]

- Mehra, M.; Saxena, S.; Sankaranarayanan, S.; Tom, R.J.; Veeramanikandan, M. IoT Based Hydroponics System Using Deep Neural Networks. Comput. Electron. Agric. 2018, 155, 473–486. [Google Scholar] [CrossRef]

- Srinidhi, H.K.; Shreenidhi, H.S.; Vishnu, G.S. Smart Hydroponics System Integrating with IoT and Machine Learning Algorithm. In Proceedings of the 2020 International Conference on Recent Trends on Electronics, Information, Communication & Technology (RTEICT), Bangalore, India, 12–13 November 2020; IEEE: Bangalore, India, 2020; pp. 261–264. [Google Scholar]

- Suhardiyanto, H.; Arif, C.; Setiawan, B.I. Optimization of EC Values of Nutrient Solution for Tomato Fruits Quality in Hydroponics System Using Artificial Neural Network and Genetic Algorithms. ITB J. Sci. 2009, 41, 38–49. [Google Scholar] [CrossRef][Green Version]

- Pabiania, M.D.; Caluyo, F.S.; Linsangan, N.B. Wireless Data Acquisition and pH and Conductivity Levels Prediction Using Genetic Algorithm for Hydroponics. In Proceedings of the World Congress on Engineering and Computer Science 2011, San Francisco, CA, USA, 19–21 October 2011; Volume 11. [Google Scholar]

- Khafajeh, H.; Banakar, A.; Minaei, S.; Delavar, M. A Hydroponic Greenhouse Fuzzy Control System: Design, Development and Optimization Using the Genetic Algorithm. Span. J. Agric. Res. 2023, 21, e0201. [Google Scholar] [CrossRef]

- Fuangthong, M.; Pramokchon, P. Automatic Control of Electrical Conductivity and PH Using Fuzzy Logic for Hydroponics System. In Proceedings of the 2018 International Conference on Digital Arts, Media and Technology (ICDAMT), Phayao, Thailand, 25–28 February 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 65–70. [Google Scholar]

- Lakshmi, J.V.N. Optimizing Crop Yield Using Hydroponic Farming on Tomato Plants by Applying Deep Neural Networks. J. Krishi Vigyan 2020, 9, 264–269. [Google Scholar] [CrossRef]

- Mara, M.N.; Helmy; Nursyahid, A.; Setyawan, T.A.; Sriyanto, A. Adjustment Pattern of pH Using Random Forest Regressor for Crop Modelling of NFT Hydroponic Lettuce. J. Phys. Conf. Ser. 2021, 1863, 012075. [Google Scholar] [CrossRef]

- Méndez-Guzmán, H.A.; Padilla-Medina, J.A.; Martínez-Nolasco, C.; Martinez-Nolasco, J.J.; Barranco-Gutiérrez, A.I.; Contreras-Medina, L.M.; Leon-Rodriguez, M. IoT-Based Monitoring System Applied to Aeroponics Greenhouse. Sensors 2022, 22, 5646. [Google Scholar] [CrossRef]

- Francis, F.; Vishnu, P.L.; Jha, M.; Rajaram, B. IOT-Based Automated Aeroponics System. In Intelligent Embedded Systems; Thalmann, D., Subhashini, N., Mohanaprasad, K., Murugan, M.S.B., Eds.; Lecture Notes in Electrical Engineering; Springer: Singapore, 2018; Volume 492, pp. 337–345. ISBN 978-981-10-8574-1. [Google Scholar]

- Jamhari, C.A.; Wibowo, W.K.; Annisa, A.R.; Roffi, T.M. Design and Implementation of IoT System for Aeroponic Chamber Temperature Monitoring. In Proceedings of the 2020 Third International Conference on Vocational Education and Electrical Engineering (ICVEE), Surabaya, Indonesia, 3–4 October 2020; IEEE: Surabaya, Indonesia, 2020; pp. 1–4. [Google Scholar]

- Pala, M.; Mizenko, L.; Mach, M.; Reed, T. Aeroponic Greenhouse as an Autonomous System Using Intelligent Space for Agriculture Robotics. In Robot Intelligence Technology and Applications 2; Kim, J.-H., Matson, E.T., Myung, H., Xu, P., Karray, F., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2014; Volume 274, pp. 83–93. ISBN 978-3-319-05581-7. [Google Scholar]

- Argo, B.D.; Hendrawan, Y.; Ubaidillah, U. A Fuzzy Micro-Climate Controller for Small Indoor Aeroponics Systems. TELKOMNIKA 2019, 17, 3019. [Google Scholar] [CrossRef]

- Alimuddin, A.; Arafiyah, R.; Subrata, D.M.; Huda, N. Development and Performance of a Fuzzy Logic Control System for Temperature and Carbon Dioxide for Red Chili Cultivation in an Aeroponic Greenhouse System. Int. J. Adv. Sci. Eng. Inf. Technol. 2020, 10, 2355–2361. [Google Scholar] [CrossRef]

- Torres-Tello, J.; Venkatachalam, S.; Moreno, L.; Ko, S.-B. Ensemble Learning for Improving Generalization in Aeroponics Yield Prediction. In Proceedings of the 2020 IEEE International Symposium on Circuits and Systems (ISCAS), Seville, Spain, 12–14 October 2020; IEEE: Seville, Spain, 2020; pp. 1–5. [Google Scholar]

- Rajendiran, G.; Rethnaraj, J. Lettuce Crop Yield Prediction Analysis Using Random Forest Regression Machine Learning Model in Aeroponics System. In Proceedings of the 2023 Second International Conference on Augmented Intelligence and Sustainable Systems (ICAISS), Trichy, India, 23–25 August 2023; IEEE: Trichy, India, 2023; pp. 565–572. [Google Scholar]

- Durgin, W.; Matthews, J. Fluid Behavior in Microgravity. In Proceedings of the National Aeronautics and Space Administration, Greenbelt, MD, USA, 12 August 2013. [Google Scholar]

- Steub, L.; Kollmer, J.; Paxson, D.; Sack, A.; Pöschel, T.; Bartlett, J.; Berman, D.; Richardson, Y.; Louge, M.Y. Microgravity Spreading of Water Spheres on Hydrophobic Capillary Plates. EPJ Web Conf. 2017, 140, 16001. [Google Scholar] [CrossRef]

- Nishii, K.; Hattori, A.; Koizumi, H.; Komurasaki, K. Low-Pressure-Vaporization of Water Droplets on Wall under Normal and Microgravity Conditions. Acta Astronaut. 2021, 186, 508–516. [Google Scholar] [CrossRef]

- Azzolin, M.; Bortolin, S.; Le Nguyen, L.P.; Lavieille, P.; Glushchuk, A.; Queeckers, P.; Miscevic, M.; Iorio, C.S.; Del Col, D. Experimental Investigation of In-Tube Condensation in Microgravity. Int. Commun. Heat Mass Transf. 2018, 96, 69–79. [Google Scholar] [CrossRef]

- Meseguer, J.; Sanz-Andrés, A.; Pérez-Grande, I.; Pindado, S.; Franchini, S.; Alonso, G. Surface Tension and Microgravity. Eur. J. Phys. 2014, 35, 055010. [Google Scholar] [CrossRef]

- Karri, S.R. Experimental Study of Simulated Micro-Gravity Vapor-Liquid Flow Regimes; University of New Hampshire: Durham, NH, USA, 1998. [Google Scholar]

- Yerkes, K.; Michalak, T.; Silk, E.; Swanson, T.; McQuillen, J.; Golliher, E. Investigation into the Micro-Gravity Effects on Two-Phase Spray Thermophysics; Fluid Mechanics and Thermodynamics; NASA Technical Reports Server: Hampton City, VA, USA, 2002. [Google Scholar]

- Pötschke, J.; Hohenstein, K. Preparation of Dispersed Alloys under Micro-Gravity Conditions. Acta Astronaut. 1982, 9, 261–264. [Google Scholar] [CrossRef]

- National Aeronautics and Space Administration. Plant Biology Program. 2020. Available online: https://science.nasa.gov/biological-physical/focus-areas/plant-biology/ (accessed on 1 November 2023).

- Naumov, V.; Parang, M.; Edwards, S.; Jean, L.; Mueller, E. Forced Flow Condensation Simulation and Investigation in Microgravity Saturated Air/Liquid Flow. In 43rd AIAA Aerospace Sciences Meeting and Exhibit; American Institute of Aeronautics and Astronautics: Reno, NV, USA, 2005. [Google Scholar]

- Blood, J.C.; Herbert, N.W.; Wayne, M.R. Reliability Assurance for AI Systems. In Proceedings of the 2023 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 23–26 January 2023; IEEE: Orlando, FL, USA, 2023; pp. 1–6. [Google Scholar]

- De Pascale, S.; Arena, C.; Aronne, G.; De Micco, V.; Pannico, A.; Paradiso, R.; Rouphael, Y. Biology and Crop Production in Space Environments: Challenges and Opportunities. Life Sci. Space Res. 2021, 29, 30–37. [Google Scholar] [CrossRef] [PubMed]

- Taneja, A.; Nair, G.; Joshi, M.; Sharma, S.; Sharma, S.; Jambrak, A.R.; Roselló-Soto, E.; Barba, F.J.; Castagnini, J.M.; Leksawasdi, N.; et al. Artificial Intelligence: Implications for the Agri-Food Sector. Agronomy 2023, 13, 1397. [Google Scholar] [CrossRef]

- Arumugam, D.T.; Sandeep, G.; Maheswari, D.M.U. Soilless Farming of Vegetable Crops: An Overview. Pharma Innov. J. 2021, 10, 773–785. [Google Scholar]

- Karagöz, F.P.; Dursun, A.; Karaşal, M. A Review: Use of Soilless Culture Techniques in Ornamental Plants. Ornam. Hortic. 2022, 28, 172–180. [Google Scholar] [CrossRef]

- Banerjee, A.; Paul, K.; Varshney, A.; Nandru, R.; Badhwar, R.; Sapre, A.; Dasgupta, S. Soilless Indoor Smart Agriculture as an Emerging Enabler Technology for Food and Nutrition Security amidst Climate Change. In Plant Nutrition and Food Security in the Era of Climate Change; Elsevier: Amsterdam, The Netherlands, 2022; pp. 179–225. ISBN 978-0-12-822916-3. [Google Scholar]

- Nikolaou, G.; Neocleous, D.; Kitta, E.; Katsoulas, N. Advances in Irrigation/Fertigation Techniques in Greenhouse Soilless Culture Systems (SCS). In Advances in Horticultural Soilles Culture; Burleigh Dodds Science Publishing: Cambridge, UK, 2020; pp. 249–275. ISBN 978-1-00-304820-6. [Google Scholar]

- Zhaopeng, Z.; Yueping, L.; Fang, W. Soilless Cultivation Irrigation Circulating Control System. China Patent 104472334B, 11 January 2017. [Google Scholar]

- Xiaochan, W.; Guoxiang, S.; Jiao, D.; Yongbo, L.; Man, C.; Zhang, Y.; Yinyan, S. Intelligent Greenhouse Soilless Cultivation Fertilizer Water Irrigation System; Editorial Office of Acta Agriculturae Shanghai: Shanghai, China, 2014. [Google Scholar]

- Barbieri, G. A Small-Scale Flexible Test Bench for the Investigation of Fertigation Strategies in Soilless Culture. Int. J. Agric. Biosyst. Eng. 2019, 13, 5–9. [Google Scholar]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization, and Machine Learning; Addison-Wesley: Boston, MA, USA, 2012; ISBN 978-0-201-15767-3. [Google Scholar]

- Orlandi, G.; Calvini, R.; Foca, G.; Pigani, L.; Vasile Simone, G.; Ulrici, A. Data Fusion of Electronic Eye and Electronic Tongue Signals to Monitor Grape Ripening. Talanta 2019, 195, 181–189. [Google Scholar] [CrossRef]

- Tan, J.; Xu, J. Applications of Electronic Nose (e-Nose) and Electronic Tongue (e-Tongue) in Food Quality-Related Properties Determination: A Review. Artif. Intell. Agric. 2020, 4, 104–115. [Google Scholar] [CrossRef]

- Chen, H.; Huo, D.; Zhang, J. Gas Recognition in E-Nose System: A Review. IEEE Trans. Biomed. Circuits Syst. 2022, 16, 169–184. [Google Scholar] [CrossRef] [PubMed]

| Key Areas | Subject Matter | References |

|---|---|---|

| Fogponics background research | Terrestrial fogponics system and its advancement | [26,27,34,35,36,37,38,39,40,41,42,43,44,45,46] |

| Applied industrial revolution 4.0 technologies | [26,27,47,48,49,50,51,52,53,54] | |

| Fog generation and dispersion mechanisms | [26,27,42,53,55,56,57,58,59] | |

| Other soilless irrigation and fertigation systems | Hydroponics | [23,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74] |

| Aeroponics | [64,65,75,76,77,78,79,80,81,82] | |

| Microgravity fog behavior analysis | Fog Behavior in Microgravity Environment | [83,84,85,86,87,88,89,90,91,92] |

| Integration of AI with fogponics | Challenges and advantages of integrated AI and fogponics in microgravity cultivation | [22,23,26,93,94,95] |

| Reference | Year Published | Necessity | Solution |

|---|---|---|---|

| [42] | 2020 | To ensure uniform mist distribution, both low and high-pressure aeroponics necessitate an excessive quantity of nozzles per plant. Furthermore, the utilization of low pressure to deliver nutrients tends to obstruct these nozzles. Conventional aeroponics has been uneconomical in nature, posing difficulties in terms of design, operation, and maintenance when applied to large-scale cultivation. | The invention provides cheap methods and systems for fogponics; the system utilizes pumps for nutrient dispersion and sensors for environment monitoring. It integrates scalable and modular fogponics crop cultivation systems. The novelty it possesses is the implementation of a dispenser that utilizes a booster pump and a high-pressure pump to atomize the nutrient mixture into a nutrient vapor. These pumps can produce an approximate range of 800 PSI to 1500 PSI. |

| [43] | 2020 | The improper formulation of nutrient solutions in hydroponic cultivation, which can lead to resource waste and lower-quality harvests. | Provided a greenhouse wireless sensing fog farming system, where the target concentration value of liquid fertilizer can be set according to the growth stage of the plant, the required concentration ratio of the culture liquid mist can be effectively and accurately supplied during the growth stage of the plant, thus having better harvest quality, and reducing the improper mixing of the culture liquid. |

| [27] | 2021 | Absence of sunlight for indoor fogponics system. It is necessary to provide a suitable light quantity of up to 8 h to 10 h a day to produce a healthy plant production. | Integration and optimization of LED lamps as a replacement for sunlight energy. |

| [44] | 2021 | The invention fulfills a requirement for a method and system that enables the bulk production of plants in a controlled environment while monitoring each plant individually. | The fogponics growing system that has been devised is a scalable and modular approach to plant cultivation within a mass production setting, enabling individual plant monitoring. Individual plant separation allows for targeted adjustments in nutrient and moisture delivery, ensuring optimal growth conditions for each plant compared with shared cultivation chamber. |

| [45] | 2022 | Scarcity of land and water for agriculture in the Indian subcontinent due to urbanization and technological advancements. | The developed system is a cutting-edge innovation that allows for the cultivation of agricultural goods in an enclosed environment using minimal water resources and recycling wastewater from air conditioning condensers and reverse osmosis plants. |

| [26] | 2022 | The obstacle faced in fogponics is maintaining environmental conditions that support plant development. | Utilization of AI Technology. The fuzzy algorithm becomes an automatic regulator for actuator activation to maintain fogponics environmental conditions. The results of each data reading and calculation of the processed data using fuzzy logic are stored on the IoT platform, which can be accessed using devices connected to the Internet. |

| [46] | 2023 | There is a need for a fogponics system that can adjust the light (LED) irradiation distance and improve the supply and circulation of nutrient solution in the form of fog, resulting in better crop growth. | Improved the supply and circulation structure of nutrient solution in the form of fog, which can be circulated and recycled, by using an ultrasonic vibration module in the cultivation bed trays, allowing for the adjustment of light irradiation distance. |

| Technology | Description | Function | Hydroponics | Aeroponics |

|---|---|---|---|---|

| IoT | A network comprising interconnected physical entities or “things” that are equipped with software, sensors, and other technological components. This enables these objects to gather and exchange data with other systems and devices via the Internet [47,48]. | The IoT platform was used to monitor, automate, store system parameters, and/or provide graphical interface remote access. | [65,66,67,68] | [65,75,76,77] |

| Genetic Algorithm (GA) | GA is an advanced optimization method that can handle intricate objective functions. It mimics the process of biological evolution by employing genetic crossing and mutation [103]. | GA was utilized to determine the optimal value of the dependent parameter in generative plant growth. | [69,70,71] | [78] |

| Fuzzy Logic | Fuzzy logic is a form of multivalued logic that allows for reasoning and decision-making in situations where there is uncertainty, imprecision, or vagueness [49]. | Fuzzy logic was applied as an environmental control system. | [71,72] | [79,80] |

| Machine Learning (ML) | Deep Neural Network (DNN) is a type of ML and a refined version of Artificial Neural Network (ANN) with increased hidden layers, which has been demonstrated to attain superior accuracy in comparison to ANN [67]. | Utilized DNN to forecast the optimal control action for system regulation. | [67] | - |

| Crop yield prediction model. | - | [81] | ||

| Crop yield optimization model. | [73] | - | ||

| K-nearest Neighbour (KNN) is a straightforward and intuitive machine learning algorithm utilized for regression and classification tasks [68]. | Utilized KNN to control decision-making based on the predefined data set values. | [68] | - | |

| Lasso Regression is a linear regression technique used for feature selection and regularization [68]. | Lasso Regression is utilized to estimate the relationships between variables and make predictions | [68] | - | |

| ANN is a computational model that is designed based on the structure and operation of biological neural networks [69]. | The relationship between various EC value treatments and TSS value and fruit weight was identified using ANN. | [69] | - | |

| The Random Forest algorithm is a robust ensemble learning technique that may be applied to both regression and classification tasks [82]. | The algorithm is utilized for yield prediction. | - | [82] | |

| Variable pattern adjustment for crop modeling | [74] | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suganob, N.J.; Arroyo, C.L.; Concepcion, R., II. Interplay of Fogponics and Artificial Intelligence for Potential Application in Controlled Space Farming. AgriEngineering 2024, 6, 2144-2166. https://doi.org/10.3390/agriengineering6030126

Suganob NJ, Arroyo CL, Concepcion R II. Interplay of Fogponics and Artificial Intelligence for Potential Application in Controlled Space Farming. AgriEngineering. 2024; 6(3):2144-2166. https://doi.org/10.3390/agriengineering6030126

Chicago/Turabian StyleSuganob, Newton John, Carey Louise Arroyo, and Ronnie Concepcion, II. 2024. "Interplay of Fogponics and Artificial Intelligence for Potential Application in Controlled Space Farming" AgriEngineering 6, no. 3: 2144-2166. https://doi.org/10.3390/agriengineering6030126

APA StyleSuganob, N. J., Arroyo, C. L., & Concepcion, R., II. (2024). Interplay of Fogponics and Artificial Intelligence for Potential Application in Controlled Space Farming. AgriEngineering, 6(3), 2144-2166. https://doi.org/10.3390/agriengineering6030126