Enhancing Dust Control for Cage-Free Hens with Electrostatic Particle Charging Systems at Varying Installation Heights and Operation Durations

Abstract

1. Introduction

- (a)

- Test the effect of EPI on dust control with a particular emphasis on the influence of varying electric supply durations and system installation heights in research CF facilities.

- (b)

- Investigate the optimal management of EPI system for dust control for CF hens;

- (c)

- Analyze the power consumption of the EPI system and its correlation with the duration of electric supply employed within CF hen facilities.

2. Materials and Methods

2.1. Ethical Approval

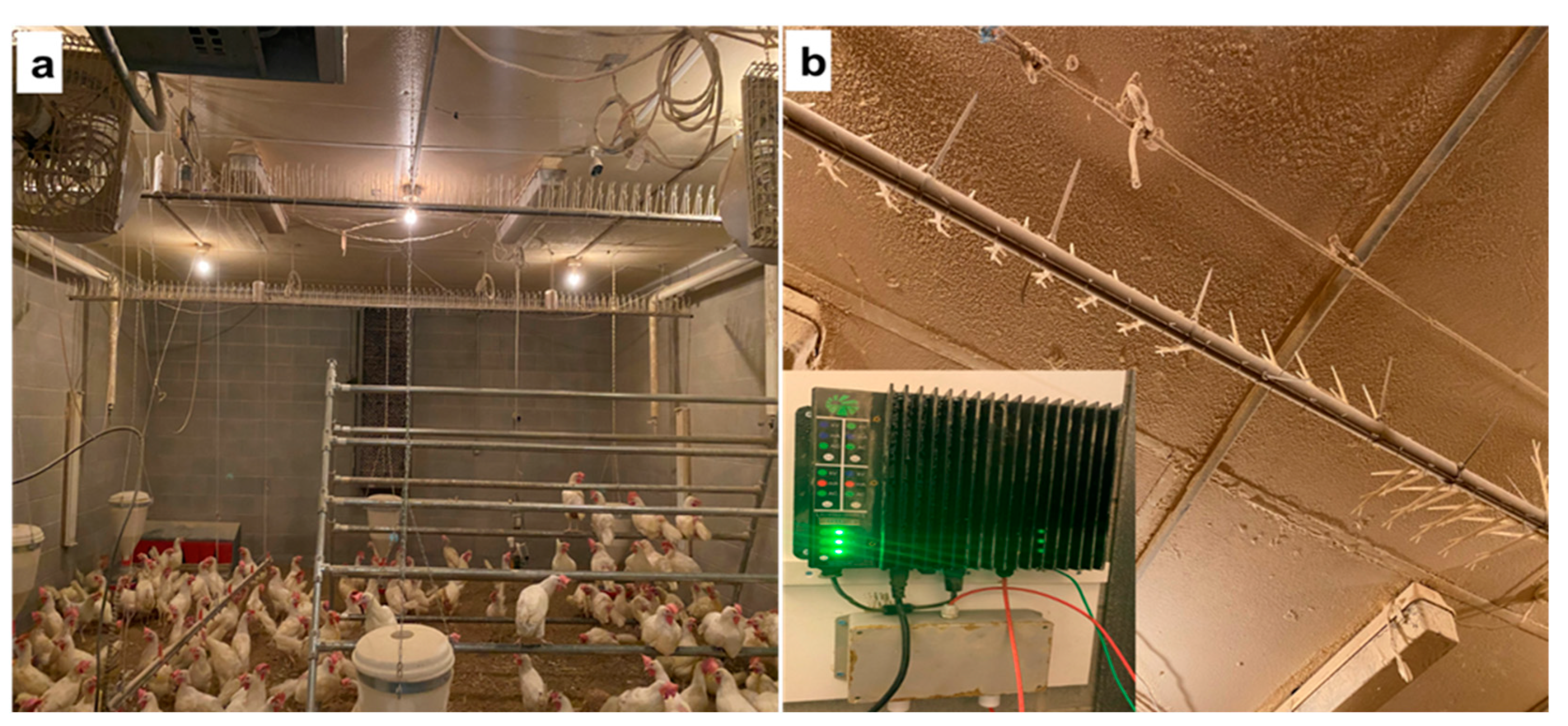

2.2. Experimental Setup

2.2.1. Experiment 1

2.2.2. Experiment 2

2.3. Working Mechanism of EPI

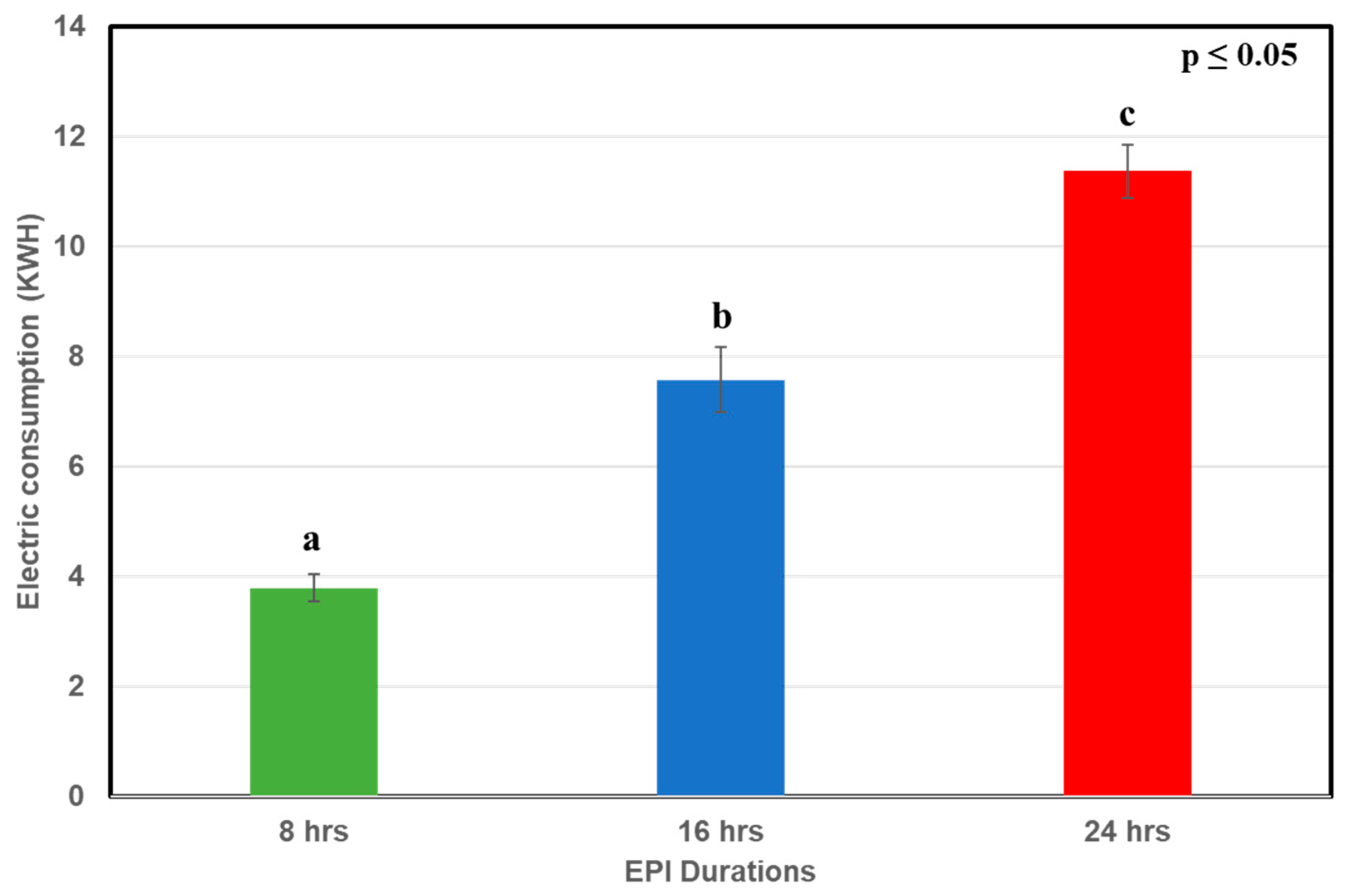

2.4. Electricity Consumption by EPI

2.5. Environment Parameter Measurements

2.6. Particulate Matter Measurement

2.7. Statistical Analysis

3. Results and Discussion

3.1. Experiment 1

3.1.1. Environment Parameters

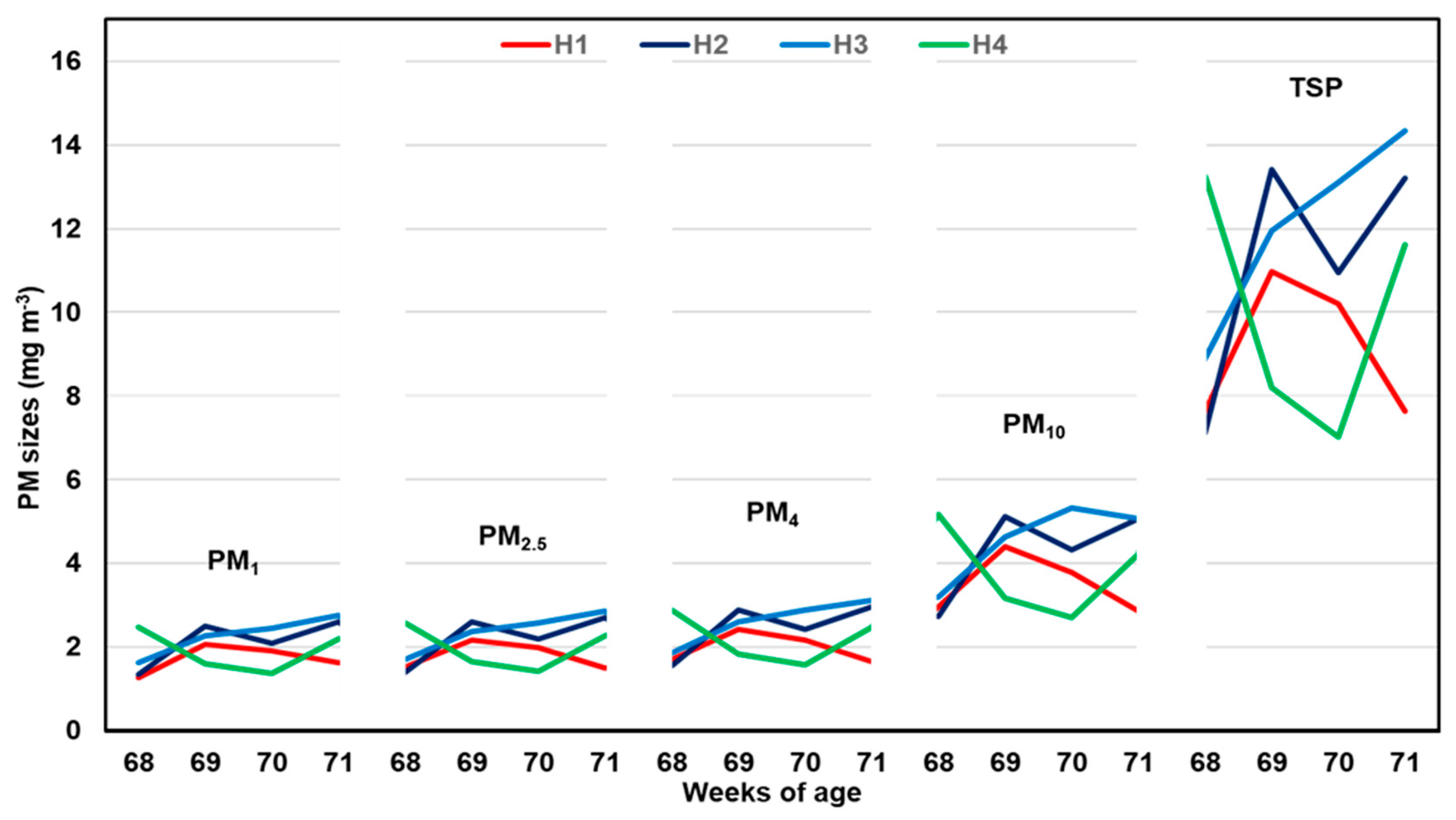

3.1.2. PM Concentration

3.2. Experiment 2

3.2.1. Environment Parameters

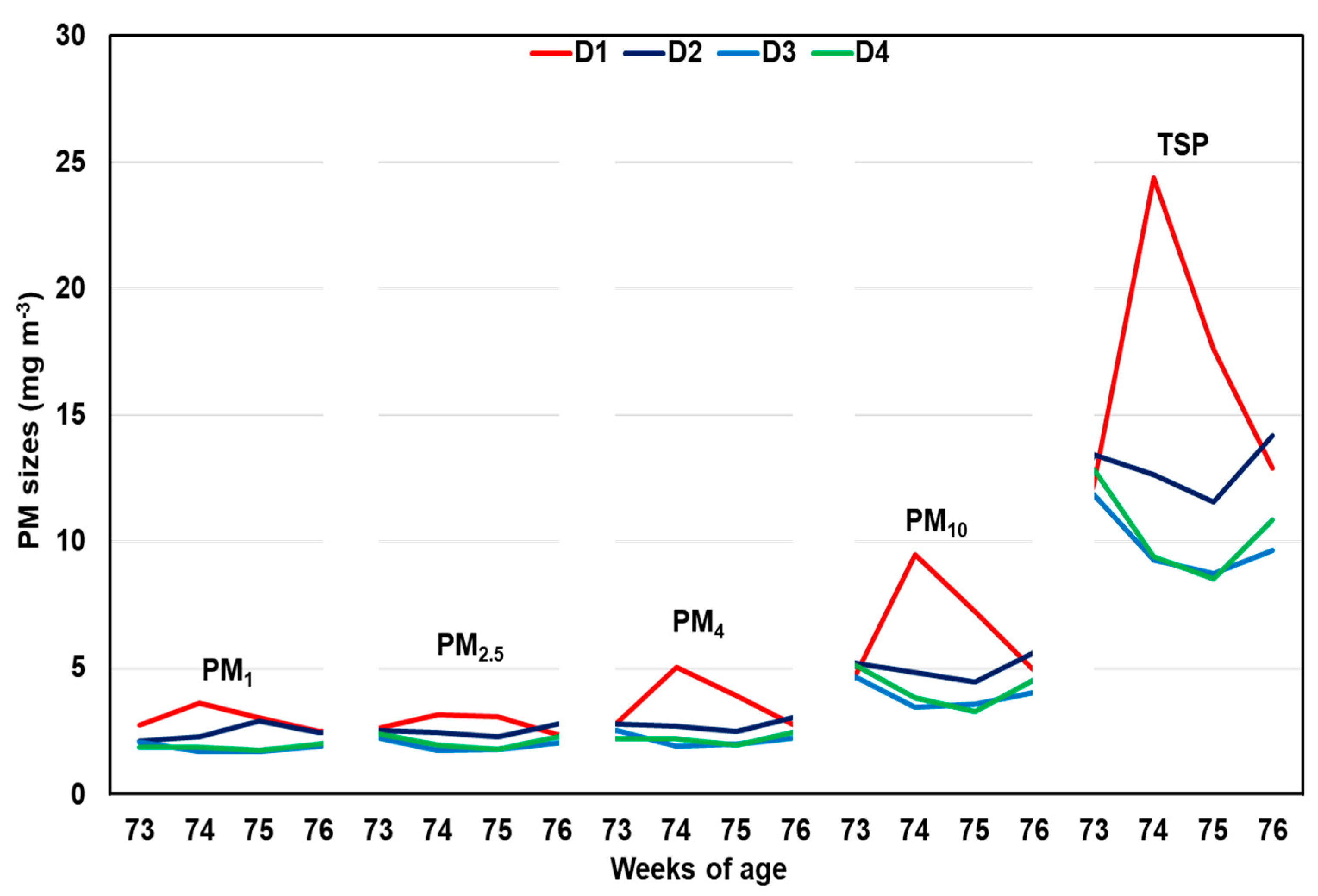

3.2.2. PM Concentration

3.2.3. Electricity Consumption

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- USDA. USDA Graded Cage-Free Eggs: All They’re Cracked Up to Be. Available online: https://www.usda.gov/media/blog/2016/09/13/usda-graded-cage-free-eggs-all-theyre-cracked-be (accessed on 11 May 2023).

- UEP. CF-UEP-Guidelines_17-3.Pdf. Available online: https://uepcertified.com/wp-content/uploads/2021/08/CF-UEP-Guidelines_17-3.pdf (accessed on 18 August 2022).

- Mintus, C. More States in the United States to Switch to Cage-Free Eggs. Available online: https://www.thepoultrysite.com/news/2021/06/more-states-in-the-united-states-to-switch-to-cage-free-eggs (accessed on 1 April 2023).

- Bist, R.B.; Chai, L.; Yang, X.; Subedi, S.; Guo, Y. Air Quality in Cage-Free Houses during Pullets Production; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2022; p. 1. [Google Scholar]

- Chai, L.; Xin, H.; Zhao, Y.; Wang, T.; Soupir, M.; Liu, K. Mitigating Ammonia and PM Generation of Cage-Free Henhouse Litter with Solid Additive and Liquid Spray. Trans. ASABE 2018, 61, 287–294. [Google Scholar] [CrossRef]

- Bist, R.B.; Chai, L. Advanced Strategies for Mitigating Particulate Matter Generations in Poultry Houses. Appl. Sci. 2022, 12, 11323. [Google Scholar] [CrossRef]

- Bist, R.B.; Subedi, S.; Chai, L.; Yang, X. Ammonia Emissions, Impacts, and Mitigation Strategies for Poultry Production: A Critical Review. J. Environ. Manag. 2023, 328, 116919. [Google Scholar] [CrossRef] [PubMed]

- Bist, R.B.; Yang, X.; Subedi, S.; Sharma, M.K.; Singh, A.K.; Ritz, C.W.; Kim, W.K.; Chai, L. Temporal Variations of Air Quality in Cage-Free Experimental Pullet Houses. Poultry 2023, 2, 320–333. [Google Scholar] [CrossRef]

- Qi, R.; Manbeck, H.; Maghirang, R. Dust Net Generation Rate in a Poultry Layer House. Trans. ASAE 1992, 35, 1639–1645. [Google Scholar] [CrossRef]

- Cambra-López, M.; Hermosilla, T.; Lai, H.T.; Aarnink, A.J.A.; Ogink, N. Particulate Matter Emitted from Poultry and Pig Houses: Source Identification and Quantification. Trans. ASABE 2011, 54, 629–642. [Google Scholar] [CrossRef]

- Ahaduzzaman, M.; Milan, L.; Morton, C.L.; Gerber, P.F.; Walkden-Brown, S.W. Characterization of Poultry House Dust Using Chemometrics and Scanning Electron Microscopy Imaging. Poult. Sci. 2021, 100, 101188. [Google Scholar] [CrossRef] [PubMed]

- Cambra-López, M.; Aarnink, A.J.; Zhao, Y.; Calvet, S.; Torres, A.G. Airborne Particulate Matter from Livestock Production Systems: A Review of an Air Pollution Problem. Environ. Pollut. 2010, 158, 1–17. [Google Scholar] [CrossRef]

- Michiels, A.; Piepers, S.; Ulens, T.; Van Ransbeeck, N.; Sacristán, R.D.P.; Sierens, A.; Haesebrouck, F.; Demeyer, P.; Maes, D. Impact of Particulate Matter and Ammonia on Average Daily Weight Gain, Mortality and Lung Lesions in Pigs. Prev. Vet. Med. 2015, 121, 99–107. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, D.; Ma, H.; Liu, K.; Atilgan, A.; Xin, H. Environmental Assessment of Three Egg Production Systems–Part III: Airborne Bacteria Concentrations and Emissions. Poult. Sci. 2016, 95, 1473–1481. [Google Scholar] [CrossRef]

- EPA, O. Health and Environmental Effects of Particulate Matter (PM). Available online: https://www.epa.gov/pm-pollution/health-and-environmental-effects-particulate-matter-pm (accessed on 15 June 2023).

- US EPA, O. Particulate Matter (PM) Basics. Available online: https://www.epa.gov/pm-pollution/particulate-matter-pm-basics (accessed on 30 September 2022).

- Donham, K. Occupational Health Hazards and Recommended Exposure Limits for Workers in Poultry Buildings; National Poultry Waste Management Symposium Committee: Iowa City, IA, USA, 2000; pp. 92–109. Available online: https://www.cabidigitallibrary.org/doi/pdf/10.5555/20073020230 (accessed on 22 July 2023).

- Radon, K.; Weber, C.; Iversen, M.; Danuser, B.; Pedersen, S.; Nowak, D. Exposure Assessment and Lung Function in Pig and Poultry Farmers. Occup. Environ. Med. 2001, 58, 405–410. [Google Scholar] [CrossRef]

- WHO (World Health Organization). Ambient (Outdoor) Air Pollution. Available online: https://www.who.int/news-room/fact-sheets/detail/ambient-(outdoor)-air-quality-and-health (accessed on 30 September 2022).

- Almuhanna, E.A. Dust Control in Livestock Buildings with Electrostatically-Charged Water Spray. Kansas State University: Manhattan, KS, USA, 2007; ISBN 1-109-97127-3. [Google Scholar]

- Aarnink, A.; van Harn, J.; Van Hattum, T.; Zhao, Y.; Ogink, N. Dust Reduction in Broiler Houses by Spraying Rapeseed Oil. Trans. ASABE 2011, 54, 1479–1489. [Google Scholar] [CrossRef]

- Aarnink, A.J.A.; Van Harn, J.; Winkel, A.; De Buisonje, F.E.; Van Hattum, T.G.; Ogink, N.W.M. Spraying rapeseed oil reduces dust in poultry houses. In Precision Livestock Farming; Wageningen Academic: Wageningen, The Netherlands, 2009; pp. 71–79. [Google Scholar]

- Chai, L.; Xin, H.; Wang, Y.; Oliveira, J.; Wang, K.; Zhao, Y. Mitigating particulate matter generation in a commercial cage-free hen house. Trans. ASABE 2019, 62, 877–886. [Google Scholar] [CrossRef]

- Zhao, Y.; Aarnink, A.; De Jong, M.; Ogink, N.; Koerkamp, P.G. Effectiveness of Multi-Stage Scrubbers in Reducing Emissions of Air Pollutants from Pig Houses. Trans. ASABE 2011, 54, 285–293. [Google Scholar] [CrossRef]

- Demmers, T.; Saponja, A.; Thomas, R.; Phillips, G.; McDonald, A.; Stagg, S.; Bowry, A.; Nemitz, E. Dust and Ammonia Emissions from UK Poultry Houses. In Proceedings of the XVII-th World Congress of the International Commission of Agricultural and Biosystems Engineering (CIGR), Québec City, QC, Canada, 13–17 June 2010. [Google Scholar]

- Mostafa, E.; Buescher, W. Indoor Air Quality Improvement from Particle Matters for Laying Hen Poultry Houses. Biosyst. Eng. 2011, 109, 22–36. [Google Scholar] [CrossRef]

- Winkel, A.; Mosquera, J.; Koerkamp, P.W.G.; Ogink, N.W.; Aarnink, A.J. Emissions of Particulate Matter from Animal Houses in the Netherlands. Atmos. Environ. 2015, 111, 202–212. [Google Scholar] [CrossRef]

- Nimmermark, S.; Lund, V.; Gustafsson, G.; Eduard, W. Ammonia, Dust and Bacteria in Welfare-Oriented Systems for Laying Hens. Ann. Agric. Environ. Med. 2009, 16, 103–113. [Google Scholar]

- Shepherd, T.A.; Zhao, Y.; Li, H.; Stinn, J.P.; Hayes, M.D.; Xin, H. Environmental Assessment of Three Egg Production Systems—Part II. Ammonia, Greenhouse Gas, and Particulate Matter Emissions. Poult. Sci. 2015, 94, 534–543. [Google Scholar] [CrossRef]

- Mitchell, B.; Richardson, L.; Wilson, J.; Hofacre, C. Application of an Electrostatic Space Charge System for Dust, Ammonia, and Pathogen Reduction in a Broiler Breeder House. Appl. Eng. Agric. 2004, 20, 87. [Google Scholar] [CrossRef]

- Ritz, C.; Mitchell, B.; Fairchild, B.; Czarick, M., III; Worley, J. Improving In-House Air Quality in Broiler Production Facilities Using an Electrostatic Space Charge System. J. Appl. Poult. Res. 2006, 15, 333–340. [Google Scholar] [CrossRef]

- Mitchell, B.W.; Baumgartner, J.W. Electrostatic Space Charge System for Reducing Dust in Poultry Production Houses and the Hatchery. In Proceedings of the International Conference How to Improve Air Quality, Paphos, Cyprus, 27–29 March 2007; pp. 23–24. [Google Scholar]

- Jerez, S.B.; Mukhtar, S.; Faulkner, W.; Casey, K.D.; Borhan, M.S.; Smith, R.A. Evaluation of Electrostatic Particle Ionization and BioCurtainTM Technologies to Reduce Air Pollutants from Broiler Houses. Appl. Eng. Agric. 2013, 29, 975–984. [Google Scholar]

- Winkel, A.; Mosquera, J.; Aarnink, A.J.; Koerkamp, P.W.G.; Ogink, N.W. Evaluation of Oil Spraying Systems and Air Ionisation Systems for Abatement of Particulate Matter Emission in Commercial Poultry Houses. Biosyst. Eng. 2016, 150, 104–122. [Google Scholar] [CrossRef]

- Ogink, N.W.; Melse, R.W.; Mosquera, J. Multi-Pollutant and One-Stage Scrubbers for Removal of Ammonia, Odor, and Particulate Matter from Animal House Exhaust Air; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2009; p. 37. [Google Scholar]

- Veenhuizen, M.; Bundy, D.; Electrostatic Precipitation Dust Removal System for Swine Housing. Pap. Am. Soc. Agric. Eng. 1990. No. 90-4066, p. 18. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/19912449563 (accessed on 12 July 2023).

- Mitchell, B.W.; Waltman, W.D. Reducing Airborne Pathogens and Dust in Commercial Hatching Cabinets with an Electrostatic Space Charge System. Avian Dis. 2003, 47, 247–253. [Google Scholar] [CrossRef]

- Cambra-López, M.; Winkel, A.; Van Harn, J.; Ogink, N.; Aarnink, A. Ionization for Reducing Particulate Matter Emissions from Poultry Houses. Trans. ASABE 2009, 52, 1757–1771. [Google Scholar] [CrossRef]

- Bist, R.B.; Yang, X.; Subedi, S.; Ritz, C.W.; Kim, W.K.; Chai, L. Electrostatic Particle Ionization for Suppressing Air Pollutants in Cage-Free Layer Facilities. Poult. Sci. 2024, 103, 103494. [Google Scholar] [CrossRef]

- Knight, R.M.; Zhao, L.; Zhu, H. Modelling and Optimisation of a Wire-Plate ESP for Mitigation of Poultry PM Emission Using COMSOL. Biosyst. Eng. 2021, 211, 35–49. [Google Scholar] [CrossRef]

- EPIAir FAQ’s about EPI Air System|Agricultural Dust Reduction. EPI AIR 2023. Available online: https://epiair.com/faqs/ (accessed on 22 April 2023).

- Corkery, G.; Ward, S.; Kenny, M.C.; Hemmingway, P. Of Submission: Monitoring Environmental Parameters in Poultry Production Facilities. In Proceedings of the Computer Aided Process Engineering, CAPE Forum 2013, Styria, Austria, 7–10 April 2013; Available online: https://researchrepository.ucd.ie/server/api/core/bitstreams/1b53ad1b-932d-4c7b-a095-c9b3815d2c8c/content (accessed on 16 July 2023).

- Verma, K.K.; Singh, V.; Gupta, S.L.; Yadav, J.; Verma, A.K. Environmentally Controlled House-In Poultry Production. Poult. Line 2014, 1, 29–32. [Google Scholar]

- Ellen, H.; Bottcher, R.; Von Wachenfelt, E.; Takai, H. Dust Levels and Control Methods in Poultry Houses. J. Agric. Saf. Health 2000, 6, 275. [Google Scholar] [CrossRef]

- Sklyar, A.; Marinchenko, T.; Davydova, M.; Asryan, G. Improving the Energy System of a Poultry Enterprise; IOP Publishing: Bristol, UK, 2019; Volume 403, p. 012043. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/403/1/012043/pdf (accessed on 2 June 2023).

| Trial/WOA | Room 1 | Room 2 | Room 3 | Room 4 |

|---|---|---|---|---|

| 1 (68) | H1 | H2 | H4 | H3 |

| 2 (69) | H4 | H3 | H1 | H2 |

| 3 (70) | H2 | H4 | H3 | H1 |

| 4 (71) | H3 | H1 | H2 | H4 |

| Trial/WOA | Room 1 | Room 2 | Room 3 | Room 4 |

|---|---|---|---|---|

| 1 (73) | D1 | D2 | D4 | D3 |

| 2 (74) | D4 | D3 | D1 | D2 |

| 3 (75) | D2 | D4 | D3 | D1 |

| 4 (76) | D3 | D1 | D2 | D4 |

| Parameters | H1 | H2 | H3 | H4 |

|---|---|---|---|---|

| Temperature (°C) | 23.19 ± 1.52 | 21.82 ± 1.15 | 22.54 ± 1.46 | 22.88 ± 1.39 |

| RH (%) | 47.64 ± 10.39 | 43.94 ± 10.99 | 45.11 ± 10.83 | 44.08 ± 9.05 |

| LMC (%) | 10.05 ± 0.81 | 10.30 ± 0.89 | 10.15 ± 1.28 | 10.36 ± 0.51 |

| Treatments | PM1 | PM2.5 | PM4 | PM10 | TSP |

|---|---|---|---|---|---|

| H1 | 1.71 ± 0.36 | 1.79 ± 0.34 | 1.98 ± 0.37 | 3.50 ± 0.72 | 9.12 ± 1.73 |

| H2 | 2.14 ± 0.57 | 2.22 ± 0.59 | 2.46 ± 0.64 | 4.31 ± 1.11 | 11.20 ± 2.93 |

| H3 | 2.28 ± 0.48 | 2.37 ± 0.49 | 2.61 ± 0.55 | 4.56 ± 0.95 | 12.10 ± 2.33 |

| H4 | 1.91 ± 0.52 | 1.98 ± 0.53 | 2.19 ± 0.60 | 3.82 ± 1.11 | 10.00 ± 2.92 |

| p-value | 0.2530 | 0.2664 | 0.2845 | 0.3080 | 0.2976 |

| Parameters | D1 | D2 | D3 | D4 |

|---|---|---|---|---|

| Temperature (%) | 23.24 ± 1.26 | 22.71 ± 1.38 | 23.23 ± 1.25 | 22.54 ± 1.40 |

| RH (%) | 43.58 ± 12.33 | 47.66 ± 10.04 | 44.87 ± 11.79 | 48.10 ± 12.10 |

| LMC (%) | 11.00 ± 1.04 | 10.89 ± 0.89 | 10.55 ± 1.46 | 11.12 ± 1.80 |

| Treatments | PM1 | PM2.5 | PM4 | PM10 | TSP |

|---|---|---|---|---|---|

| D1 | 2.98 ± 0.49 a | 2.83 ± 0.39 a | 3.63 ± 1.1 a | 6.59 ± 2.25 | 16.8 ± 5.59 |

| D2 | 2.45 ± 0.35 ab | 2.52 ± 0.21 ab | 2.79 ± 0.24 ab | 5.03 ± 0.49 | 12.98 ± 1.12 |

| D3 | 1.86 ± 0.18 b | 1.97 ± 0.24 b | 2.19 ± 0.27 b | 3.94 ± 0.54 | 9.89 ± 1.36 |

| D4 | 1.89 ± 0.12 b | 2.12 ± 0.28 b | 2.23 ± 0.23 b | 4.20 ± 0.80 | 10.43 ± 1.90 |

| p-value | 0.0103 | 0.0074 | 0.0473 | 0.0738 | 0.0535 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bist, R.B.; Yang, X.; Subedi, S.; Paneru, B.; Chai, L. Enhancing Dust Control for Cage-Free Hens with Electrostatic Particle Charging Systems at Varying Installation Heights and Operation Durations. AgriEngineering 2024, 6, 1747-1759. https://doi.org/10.3390/agriengineering6020101

Bist RB, Yang X, Subedi S, Paneru B, Chai L. Enhancing Dust Control for Cage-Free Hens with Electrostatic Particle Charging Systems at Varying Installation Heights and Operation Durations. AgriEngineering. 2024; 6(2):1747-1759. https://doi.org/10.3390/agriengineering6020101

Chicago/Turabian StyleBist, Ramesh Bahadur, Xiao Yang, Sachin Subedi, Bidur Paneru, and Lilong Chai. 2024. "Enhancing Dust Control for Cage-Free Hens with Electrostatic Particle Charging Systems at Varying Installation Heights and Operation Durations" AgriEngineering 6, no. 2: 1747-1759. https://doi.org/10.3390/agriengineering6020101

APA StyleBist, R. B., Yang, X., Subedi, S., Paneru, B., & Chai, L. (2024). Enhancing Dust Control for Cage-Free Hens with Electrostatic Particle Charging Systems at Varying Installation Heights and Operation Durations. AgriEngineering, 6(2), 1747-1759. https://doi.org/10.3390/agriengineering6020101