1. Introduction

Over the past few decades, global reliance on natural resources has escalated remarkably, recording an upsurge of about 254% since 1970 [

1]. This considerable increase underscores the need for efficient and sustainable resource utilization, energy conservation, and environmental protection. Among the problems we face is waste accumulation, particularly fish waste, which poses detrimental environmental impacts and public health concerns.

With increased consumer awareness and demand for healthier and nutritionally balanced diets, fish products have gained remarkable recognition for their essential nutrients, contributing to a marked increase in global consumption. This rise reflects not only an awareness of the health benefits of fish but also changing societal norms and dietary habits. Forecasts suggest that global individual fish consumption is expected to rise to 21.2 kg by 2030, marking an increase from the 20.5 kg average reported between 2018 and 2020 [

2]. This surge in fish production and consumption has resulted in a considerable increase in fish waste, raising serious environmental and economic concerns. Interestingly, biomass waste, including fish waste, can contribute substantially to a green economy, emphasizing material recycling and waste reduction to bolster value-added chains. Various studies have identified fish waste as a rich source of valuable compounds such as proteins, fatty acids, minerals, collagen, bioactive peptides, chitin, enzymes, and biopolymers [

3,

4,

5,

6,

7]. These compounds have potential applications in multiple fields, from the agri-food industry to pharmaceuticals and cosmetics [

3,

8,

9,

10].

Drying is a traditional method used for preserving and recycling fish waste, transforming it into valuable by-products. Industrially, several drying methods exist, such as oven, microwave, vacuum, and freeze-drying. Although these well-known methods guarantee high-quality dried products, they are energy-intensive, costly, and environmentally detrimental due to high greenhouse gas emissions [

11,

12,

13,

14,

15,

16]. In fact, the drying of food products consumes a considerable portion of energy in the processing industry, accounting for 20–25% of total energy use [

16,

17]. The high cost of these traditional drying methods makes it increasingly necessary to use renewable energy sources to reduce energy intensity and increase equipment efficiency. So, there are combined types of dryers (hybrid dryers) with different heat energy sources that are very often used [

18,

19,

20]. In this context, [

21] pointed out that the air solar collector combined with the heat exchanger led to an increase in the drying temperature agent at the outlet by another 10 °C without extra costs from electrical energy consumption.

As for the phenomenon of GHG emissions as a result of energy consumption, both [

22,

23] indicated that the use of fossil fuel sources for energy purposes leads to an increase in pollutants with different GHG emissions, such as CO

2, CO, SO

x, NO

x, etc., that cause global warming and have other negative impacts. Therefore, in the last century, the use of fossil fuels in energy production was predominantly marked, as mentioned by [

24]. In this regard, at the beginning of the 21st century, many efforts were taken to mitigate the CO

2 emissions in the atmosphere that contribute to the global warming phenomenon [

25].

This increased energy consumption in drying processes has led to a global call for reducing energy usage and greenhouse gas emissions and minimizing the carbon footprint of drying processes while still desiring high-quality, environmentally friendly products. One such energy-efficient alternative is sun drying, an ancient food preservation method where fresh food is exposed to sunlight, and ambient air removes the moisture content. However, this technique has several limitations, such as exposure to dust, atmospheric pollution, and infestations by insects and rodents [

11].

To address these limitations, advanced solar drying systems, or solar dryers, have been developed [

26,

27,

28,

29]. These systems use air collectors to capture and store solar energy, thereby promoting hot air circulation within the drying chamber and overcoming the shortcomings of traditional sun drying. However, solar drying also has its own limitations, particularly emanating from the unpredictability of solar radiation intensity, especially during rainy and cloudy days.

To overcome these limitations and reduce energy consumption in drying processes, hybrid solar drying systems that integrate an auxiliary heat source and a forced convection system have been proposed. These systems ensure reliability, sustainability, and control and have shown promising results in terms of reducing energy consumption, emissions, and drying times while maintaining the quality of dried products [

28,

29,

30,

31,

32,

33,

34,

35]. Nevertheless, there is a noticeable lack of comprehensive research on the application of hybrid solar drying systems to fish waste. In this proposed dryer, the hybrid solar dryer concept implies the production of thermal energy for drying fish waste through the combined use of solar collectors and solar panels. The primary objective of this study is to fill this gap by investigating the potential of a new hybrid solar drying system for recycling fish waste. By doing so, the aim is to add value to fish waste in an innovative, environmentally friendly manner while minimizing the carbon footprint. The potential of this method to effectively manage fish waste while creating a sustainable source of valuable by-products is also explored. This approach can contribute to a more sustainable and circular economy by addressing urgent environmental issues and promoting better waste management.

2. Material and Methods

The set of experiments for this study was conducted at the Testing and Research Station for Tractor and Farm Machinery in Sabahia, Alexandria, Egypt, with a latitude of 31.23341N and longitude of 29.97559E, Agricultural Engineering Research Institute (AEnRI), Agricultural Research Center (ARC). The details of the methodology and specific tools used during this research are discussed in the following subsections.

2.1. Raw Material

Particles of fish flesh, skin, bones, entrails, shells, and fish scales were used as a source of raw material for fish waste. These raw materials were obtained from the Bakkous market in Alexandria, Egypt. To maintain freshness and prevent decay, the biomass was immediately transported in refrigerated packages and then stored at −18 °C. Prior to experimentation, the fish waste samples were allowed to equilibrate to room temperature under ambient conditions.

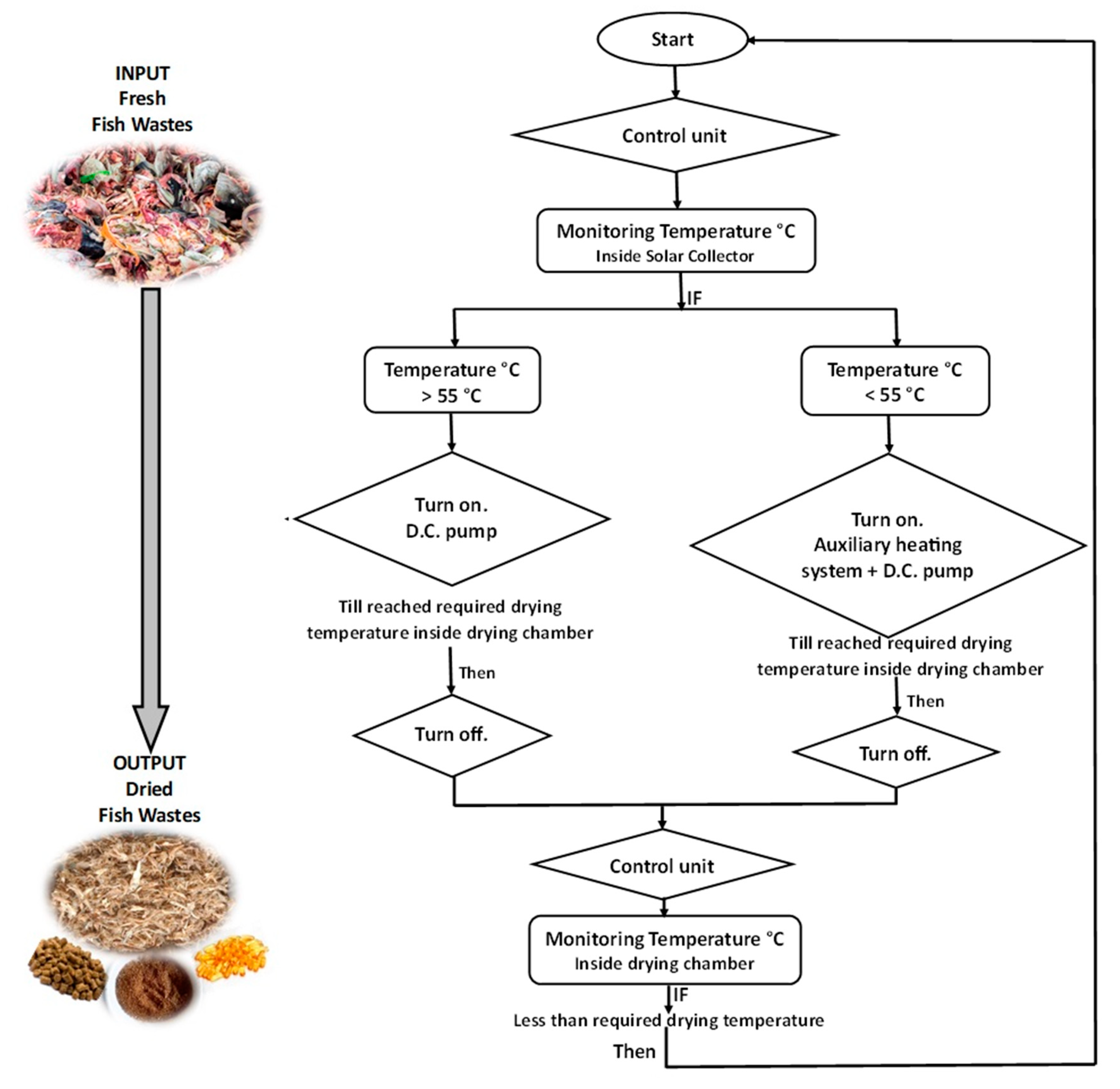

2.2. Automatic Hybrid Solar Dryer

In this study, we utilized an automatic hybrid solar dryer (HSD), specifically designed to accommodate a range of conditions. The dryer incorporates a solar collector that uses water as the primary heating medium and an auxiliary heating system powered by solar panels and equipped with a 500 W induction coil. This setup ensures continuous operation even during low solar radiation intensity periods, such as overcast conditions. The key components of this system include a solar collector, a drying chamber outfitted with a 7.5 cm diameter chimney in the center of the top surface, an auxiliary heating system with an induction coil heater, solar panels, a 12 V—200 A lead acid battery, a 12 V—15 W direct current (D.C.) pump, a heating tank, a control panel, and a 100 A—12 V charging unit. The layout of these elements within the automatic HSD used in this research is depicted in

Figure 1. The following subsections will intricately detail the key components and methodologies of the HSD.

2.3. Solar Collector

The solar collector, a fundamental component of the HSD, operates on the principle of heat absorption and transfer using water as the medium. The primary elements of the solar collector are a glass cover, an aluminum absorbing plate, and aluminum pipes.

The solar collector, with dimensions of 75 cm × 75 cm × 10 cm (length × width × height), was crafted from thin 6 mm plywood with rectangle-shaped wooden sides of 2 cm thickness. An aluminum pipe, measuring 32 m in length and having a riser tube diameter of 0.6 cm, was laid from the center to the edge of the collector base, ensuring efficient water flow to the plate. The distance between the tubes was 0.5 cm. The aluminum pipe was set on aluminum sheets with a 2 mm thickness and used as absorber plates with an Emissivity (εp)/Absorbance (α) of 0.95. To maximize heat absorption, both the aluminum pipe and plate were painted black. The solar collector was topped with a 5 mm thick transparent glazing panel, allowing solar radiation to penetrate while minimizing heat loss.

The HSD was energized by three solar panels, each measuring 83 cm × 160 cm. These panels had a maximum power output of 200 W, with a rated voltage and current of 18.1 V and 11 A, respectively. They were interconnected with a charger control unit to charge a 12 V—200 A lead acid battery. The charged battery in turn powered both the induction coil heater and a DC pump (12 V, 15 W). The pump, which had a flow rate of 6.7 × 10

−3 kg/s, was responsible for circulating water from the flat plate solar water heater through the drying chamber and subsequently into the tank. The setup is schematically depicted in

Figure 2.

2.4. Drying Chamber

The drying chamber, a rectangular plywood structure with dimensions of 100 cm × 50 cm × 50 cm (length × width × height), was constructed with a thickness of 2 cm. This chamber houses three galvanized iron mesh trays, each measuring 90 cm × 45 cm and featuring a 0.1 cm-hole perforated metal mesh. The first tray was positioned 5 cm above the chamber floor, with a 10 cm gap maintained between successive trays. Each tray rested on a heat exchanger mainframe, 0.3 cm thick and 1000 cm long, arranged in a zigzag pattern. These heat exchangers were set 5 cm apart, with a width of 45 cm and a length of 90 cm, forming the primary structure for each shelf. Support for the heat exchangers was provided by 0.1 cm thick metal rods, installed at 1 cm intervals from the top and bottom of the chamber to augment the heat exchange process for each tray. Additionally, three fans (12 V, 0.1 A; the specification of the fan is rater speed = 2200 rpm, air flow = 37.7 CFM, and air pressure = 2.23 mmHg) were installed at the rear of the drying chamber. These fans facilitated hot air convection and ensured uniform heat distribution within the drying chamber. The arrangement is depicted in

Figure 3.

2.5. Auxiliary Heating System (Induction Coil)

The auxiliary heating system was comprised of a typical induction heater with a power supply, resistance circuit, water tank, and induction coil. The high induction coil contained a brass bar with dimensions of 45 cm × 1 cm in length and thickness with a maximum power of 500 W (12 V induction heating). The induction heating coil, a conductive material, had D.C. passed through it, generating a variable magnetic field. This magnetic field created friction within conductive materials, causing them to heat up. Primarily, the induction coil was employed to heat the water contained in the water tank.

Whether the drying process is performed using only the induction coil dryer or a hybrid solar system, this auxiliary heating system reliably serves during periods of low solar radiation intensity and shifting weather conditions.

2.6. Control Unit

The control unit was crucial for monitoring and maintaining the temperature within the drying chamber according to the specified temperature range for the drying process. The employed unit consisted of three alloy steel thermostats (TR2 9934 type, Italy) with a temperature range of 0 to 110 °C and an accuracy of ±1 °C. These thermostats enabled temperature adjustment within the 0 to 110 °C range for both the solar collector, the water tank, and the drying chamber. Furthermore, the control unit was equipped with three temperature sensors that continuously monitored and managed the drying temperature. The first sensor was installed within the drying chamber, ensuring the regulation of pre-determined drying temperatures (35, 45, and 55 °C). If the drying room temperature dropped below the permitted level, the hot water pump was activated immediately to readjust the drying room temperature back to the acceptable range before shutting off. The second sensor was located inside the solar collector to monitor its temperature. In the event of a temperature drop inside the solar collector, the induction coil was instantly activated to increase the water drying medium’s temperature to an acceptable level, after which it was shut off.

The third sensor is placed within the water tank to observe the water temperature. If the temperature dropped below the permitted level, the D.C. pump was activated to draw water from the solar collector if hot water was available. If not, the induction coil was used to elevate the water temperature to the acceptable limit. The control unit also controlled three fans (12 V—0.1 A) to circulate the hot air and ensure even heat distribution within the drying chamber. Additionally, it managed two series of motorized valves, HTW-W27, that regulated the flow of hot water from the solar collector to the drying chamber. If the solar collector’s temperature decreased, the water from the induction-heated tank flowed into the drying chamber, and the D.C. pump was activated to draw water from the solar collector, given that the temperature was adequate.

2.7. System Setup and Operational Procedures

The HSD system, as mentioned earlier, underwent evaluation at the Testing and Research Station for Tractor and Farm Machinery situated in Sabahia, Alexandria. The HSD was strategically oriented towards the south with a constant tilt angle of 31°, and the testing period spanned from 10 to 21 June 2022. Solar radiation intensity was recorded in half-hour intervals using a solar power meter (model: SPM-1116SD). Furthermore, to measure wind speed and relative humidity, an environment meter (model: EM-9300SD) was employed.

Data on temperature were gathered at half-hourly intervals, facilitated by a network of twelve sensors linked to an Arduino-Uno microcontroller board, underpinned by the AT-mega 328 platform. Seven temperature sensors (LM32, ranging from 0 to 140 °C) were interfaced with the Arduino-Uno microcontroller board to record temperatures every 5 min and calculate the average every 30 min at various points: ambient air, drying chamber, solar collector, water entering and leaving the drying chamber, tempered glass, and aluminum plate.

Initially, the lead acid battery received its charge via a regulator connected to the solar panel. Subsequently, the pressure of the D.C. pump was fine-tuned utilizing a specially engineered electronic circuit. Water was then circulated from the feed tank through the pump to the aluminum pipe inside the solar collector, finally passing inside the drying chamber, as illustrated in

Figure 4.

To initiate the drying experiments, the control unit facilitated reaching the requisite drying temperature through three different strategies. The first approach leveraged the solar collector; the temperature inside the collector was monitored, and if it exceeded 55 °C, the D.C. pump and fans were activated to raise the drying chamber temperature to the specified drying temperature of 35, 45, or 55 °C. However, the first method had limitations in controlling the temperatures under study.

The second approach utilized the induction coil. The drying chamber’s temperature was monitored, and if it fell below the required drying temperature, the induction coil, D.C. pump, and fans were activated to bring the drying chamber temperature to the desired level.

The final method, a hybrid approach, combines the solar collector, solar panels, and induction coil for the production of thermal energy. This method was used when the solar collector alone could not attain the required drying chamber temperature. In such instances, the control unit activated the induction coil to supplement the thermal deficiency, ensuring the drying chamber temperature reached the required level.

2.8. Methodology

The energy balance of the local flat plate solar water heater collector can be expressed through the following equations (Equations (1)–(5)):

The useful heat gain of the solar collector was measured using the following equation:

where

is the solar radiation (W/m

2),

is the glass cover transmittance (%),

is the absorber flat plate absorptive (%),

is the heat gain useful (W),

is the absorber plate heat loss from the solar collector to the atmospheric (W),

is the area of solar collector (m

2),

is the collector solar flux absorbed (W/m

2),

is the coefficient of overall top loss heat transfer (W/m

2 K),

is the absorber plate temperature (K), and

is the ambient temperature (K).

The collector solar flux absorbed is given by the following:

The heat loss from the absorber plate of the solar collector to the atmosphere can be represented as follows:

Then the flat plate solar collector efficiency

η (%) can be calculated by the following equation:

2.9. Overall Top Heat Transfer Coefficient Losses Calculations

The overall top heat transfer coefficient losses (

Uot) for the local solar collector (LSC) were determined using (Equation (6)) [

36]:

In the equation,

R1 indicates the thermal resistance amidst the ambient temperature and the single glass cover (m

2 K/W), incorporating influences from both radiation and wind. Meanwhile,

R2 is the thermal resistance from the single glass cover to the absorber plate (m

2 K/W). These were calculated by using Equations (7)–(11). The wind convection heat transfer coefficient (

, W/m

2 K),

is the wind speed (m/s), the radiation heat transfer coefficient

, W/m

2 K),

is the Stefan-Boltzmann constant (5.67 × 10

−8 W/m

2 K

4),

is the glass cover emissivity (%),

is the glass temperature (K), and the

Tsky (K), were all determined using Equations (8)–(10).

In the Equations (11)–(13),

expresses the natural convection heat transfer coefficient between the absorber plates to glass (W/m

2 K),

is the radiation heat transfer coefficient between the absorber plate to the glass (W/m

2 K),

is the thermal conductivity of air (W/mK),

is the Nusselt number,

is the distance between the solar collector plate and the tempered glass (m),

is the Rayleigh number, and

is the solar collector tilt angle.

As well as,

is the Grashof number,

is the Prondtle number,

is the gravitational acceleration (m/s

2),

is the volumetric expansion coefficient (K

−1), and all air properties were evaluated at average temperature (

Tav, K).

Furthermore, the radiation heat transfer coefficient (

) between the absorber plate and the cover is also calculated. Additional considerations include the glass cover emissivity (

εg1), absorber plate emissivity (

εp1), and glass temperature (

Tg1)

. The Stefan–Boltzmann constant,

σ, (5.67 × 10

−8 W/m

2 K

4), also comes into play in these calculations [

36,

37,

38,

39].

2.10. Dryer Efficiency and Energy Consumption Calculations

The dryer’s performance, a crucial parameter, hinges on the fluctuations in the moisture content of the drying samples throughout the drying process until equilibrium moisture content is reached. During this process, the moisture content is continuously altered and is generally calculated on a wet basis (Equation (19)). The final moisture content and drying rate can be determined according to Equations (20) and (21), respectively.

The efficiency of the HSD and the induction heater dryer (IHD) were calculated according to Equations (22) and (23) respectively. Drying efficiency is conceptualized as the proportion of energy required for water evaporation compared to the total power consumption necessary for the dryer’s operation.

where the amount of moisture removed (kg), and the initial mass of the fresh sample (kg) are represented by

and

, respectively. While

and

are the initial and final moisture content (wet basis, %,). The initial and final mass of the fish waste sample before and after drying were denoted by

and

, respectively. Also,

and

are the drying rate kg water/(kg drymatter × h), and drying time (h), respectively. Finally, the

and

represented the efficiency (%) of the HSD and induction heater efficiency,

is the latent heat of vaporized water (kJ/kg).

is the operation time of the solar collector (h), and the induction heater energy consumption (kWh) is represented by

E [

33,

37,

40].

Energy consumption for the HSD and IHD was calculated according to Equation (25).

where,

denotes the energy consumption for the IHD and HSD (kWh), respectively.

,

, and

are the power (kW) required for the pump, induction heater, and air fans, respectively. On the other hand,

,

represent the operation time (h) for the pump, induction heater, and air fans, respectively.

2.11. Quality Analysis

2.11.1. Microbial Load

One of the most important quality parameters of the drying process of food materials is determining the microbial load before and after drying processing. Microbiological analyses of fresh and dried samples were carried out in triplicate on 50 g samples preprocessed by subjecting them to steam cooking for a short period of 20 min. This step aimed to eliminate potential pathogens and reduce excess fat. The bacterial growth was assessed by depositing aliquots of 100 µL of suitable serial dilutions (30–300 colony-forming Unit (CFU) each plate) onto Tryptic Soy Agar (TSA) media, followed by incubation for 48–72 h at 32 °C. The resultant colonies were counted, with the total bacterial count recorded as CFU/mL. The final count was obtained by calculating the mean colony count multiplied by 40 times the duration in minutes [

41].

2.11.2. Proximate Composition Analysis of Fish Wastes

Crude protein, crude lipid, ash, and moisture contents of fresh and dried fish wastes were analyzed according to the Association of Official Analytical Chemists [

42]. The crude protein content of the fresh and dried fish wastes was determined by the guidelines of the Kjeldahl method, digestion, distillation, and titration. The crude lipid content of the fresh and dried fish waste was estimated by the Soxhlet instrument using acetone as a solvent. The determination of total ash content was conducted employing a muffle furnace set at 550 °C, aligning with the AOAC official method 930.05 [

42]. The moisture content of fresh and dried fish waste was estimated using a hot air oven at 105 °C for 16 h.

3. Results and Discussions

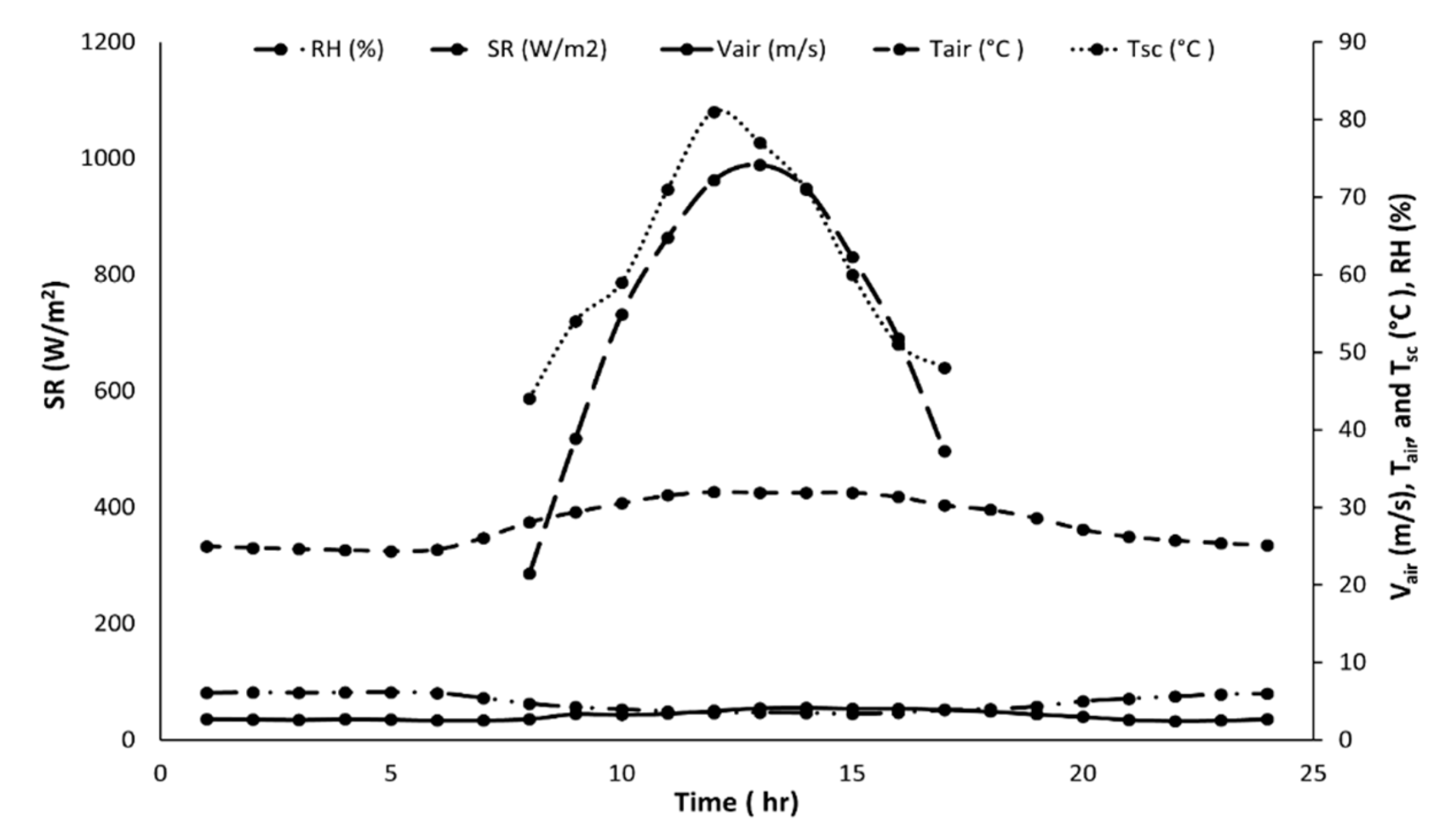

During the testing phase of the HSD based on a closed hot water circulation cycle, the intensity of solar radiation was continuously monitored in conjunction with various environmental conditions such as ambient air temperature, internal solar collector temperature, air velocity, and relative humidity (

Figure 5). Solar radiation intensity peaked between 10 a.m. and 2 p.m., reaching a maximum of 988 W/m

2 at 1 p.m. Following this period, there was a gradual decline in solar radiation intensity until sunset.

The fluctuating solar radiation intensity influenced the ambient air temperature and relative humidity. Hourly measurements revealed the highest air temperature to be 32 °C at noon. In contrast, relative humidity was at its peak in the morning and evening hours, with the lowest values observed around midday. The monitored air velocity throughout the day ranged between 2.5 and 4.2 m/s.

Meanwhile, the cyclic fluctuation in solar radiation intensity throughout the day contributed to the parallel variation in the temperatures inside the solar collector. The solar collector’s peak temperatures corresponded to the highest solar radiation intensity between 10 a.m. and 2 p.m. The internal temperature of the solar collector began to climb at 8 a.m., starting at 44 °C and hitting its peak at noon with a temperature of 81 °C. Following this peak, a gradual decrease ensued, reaching the day’s lowest temperature of 48 °C at 5 p.m., still within the period of solar radiation. This remarkable temperature variation inside the solar collector can be attributed to the heat stored within, stemming from the high thermal absorption coefficient of the aluminum plate and tubes. In terms of the heat loss coefficient for the solar flat plate collector, the highest overall top loss heat transfer coefficient (

Uot, Equation (6)) was noted at 5.327 W/m

2 K at 1 p.m. during the drying process. Influencing factors of this coefficient include wind velocity, solar radiation, and the distance separating the absorber plate and the glass cover. Simultaneously, at 1 p.m., the flat plate solar collector registered its peak useful heat gain (

Quhg, Equation (2)) at 597 W, as shown in

Figure 6.

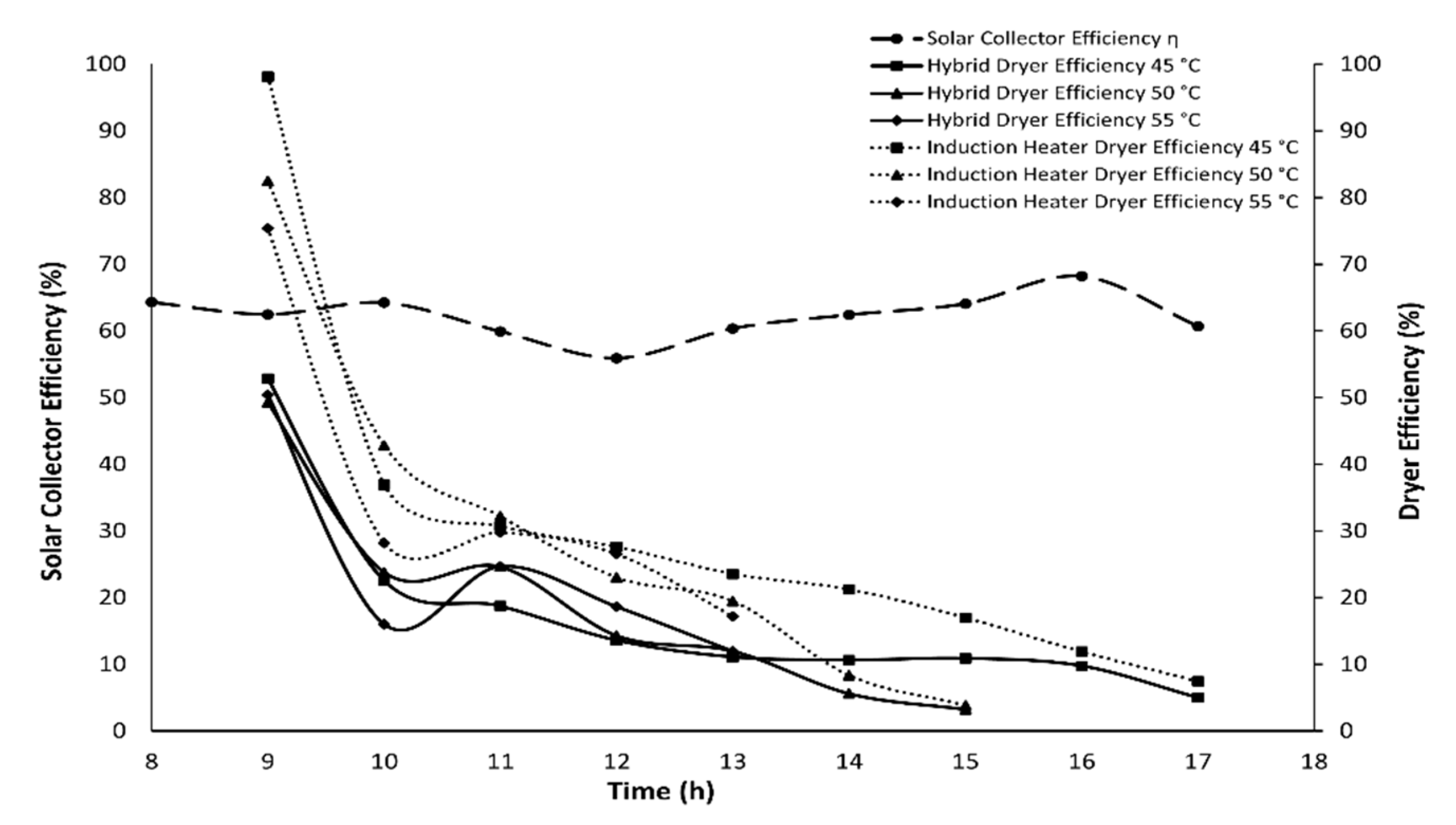

The calculation of the solar collector and drying process’s efficiency was enabled by measurements of the solar radiation intensity, overall top heat transfer coefficient, and the flat solar collector’s useful heat gain, as depicted in

Figure 7. The efficiency of the local flat-plate solar collector oscillated between 56% and 68%. The dip in solar collector efficiency could be attributed to the elevated top loss heat transfer coefficient, coupled with the declining intensity of solar rays during early morning and sunset hours when solely dependent on solar drying.

The highest efficiencies noted for the hybrid dryer were 52.9%, 49.3%, and 50.4%, while for the induction heater-based dryer, they were 98.1%, 82.5%, and 75.4% at drying temperatures of 45, 50, and 55 °C, respectively. These peak efficiencies progressively diminished over time, hitting their lowest values after the drying process. For the hybrid dryer, these values were 4.98%, 3.24%, and 11.94%, and for the induction heater-based dryer, 7.44%, 3.83%, and 17.16% at 45, 50, and 55 °C, respectively.

As observed in

Figure 7, maximum drying efficiency is achieved at the onset of the drying process and then diminishes over time. Such a trend can be attributed to fluctuations in solar radiation intensity, weather conditions, and energy consumption. Moreover, the average efficiencies of the hybrid dryer and IHD at drying temperatures of 45, 50, and 55 °C were 17.23%, 18.97%, and 24.34%, and 30.3%, 30.5%, and 35.4%, respectively.

This variation in efficiency between the induction coil-based dryer and the hybrid dryer can be attributed to the high intensity of solar radiation, which often surpasses the required level (Equation (5)). The efficiency values for the drying process align with those found in previous research [

33,

43,

44,

45,

46], which ranged from 20 to 38.61%.

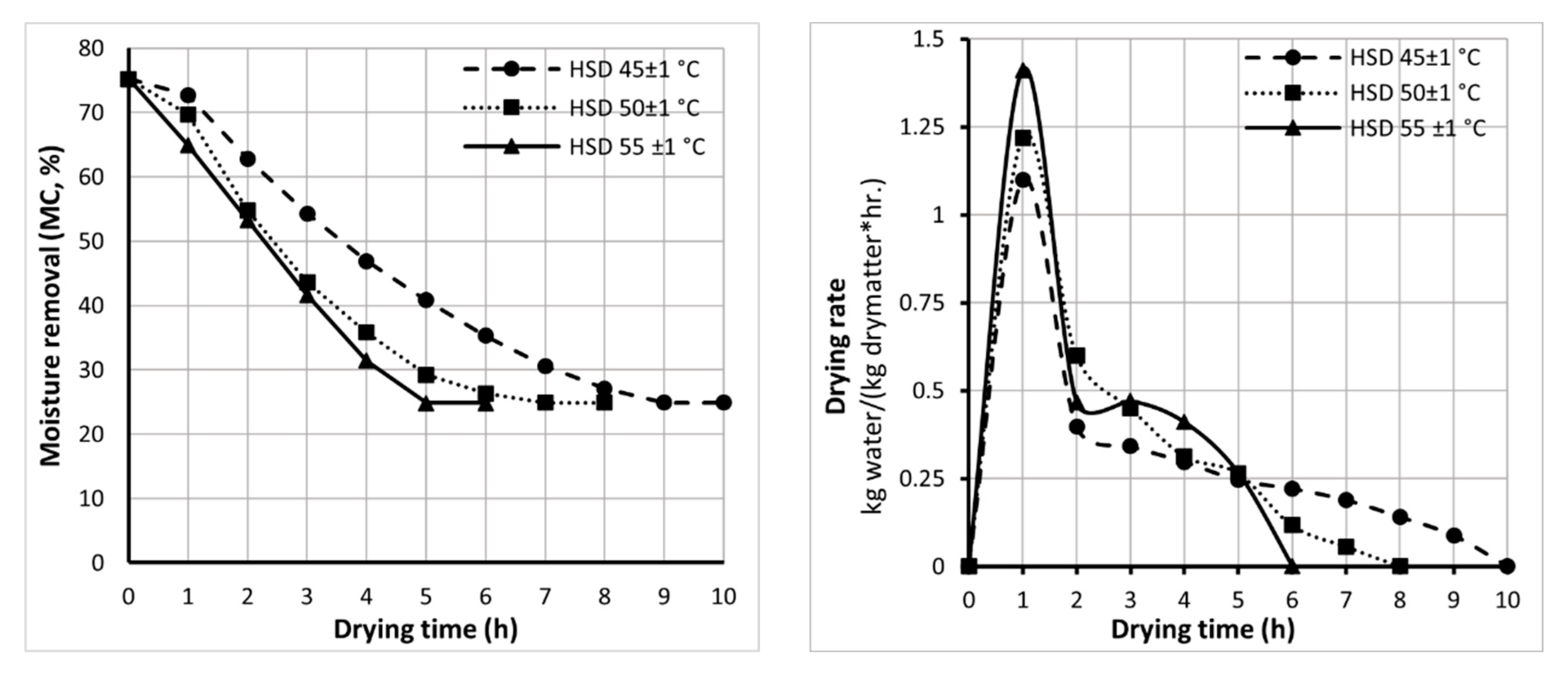

Figure 8 presents the trends of moisture content and drying rate over time at various drying temperatures. The initial moisture content was 75.2%, and as the drying process proceeded at temperatures of 45, 50, and 55 °C, this moisture content steadily decreased until it stabilized. The final moisture contents for fish waste during the drying process were recorded at 24.9%, 24.9%, and 24.8% over durations of 10, 7, and 5 h at 45, 50, and 55 °C, respectively.

The increased temperature corresponds to faster moisture removal, which can be attributed to the fact that as the temperature rises, so does the rate of evaporation. As indicated by the drying rate curve over time in

Figure 8, a higher drying temperature accelerates the drying process. It was also noted that the drying rates were initially high at the start of the drying process and gradually decreased as the drying continued. This is attributable to the initial ease of removing free moisture content from the dried material’s surface, leaving bonded water that was more difficult to remove, thus lowering the drying rate. The maximum drying rates at 45, 50, and 55 °C were 1.10, 1.22, and 1.41 kg H

2O/kg dry material/h, respectively, while the average drying rate values were 0.30, 0.38, and 0.50 kg H

2O/kg dry material/h, aligning with several previous studies [

33,

43,

47,

48,

49,

50,

51,

52].

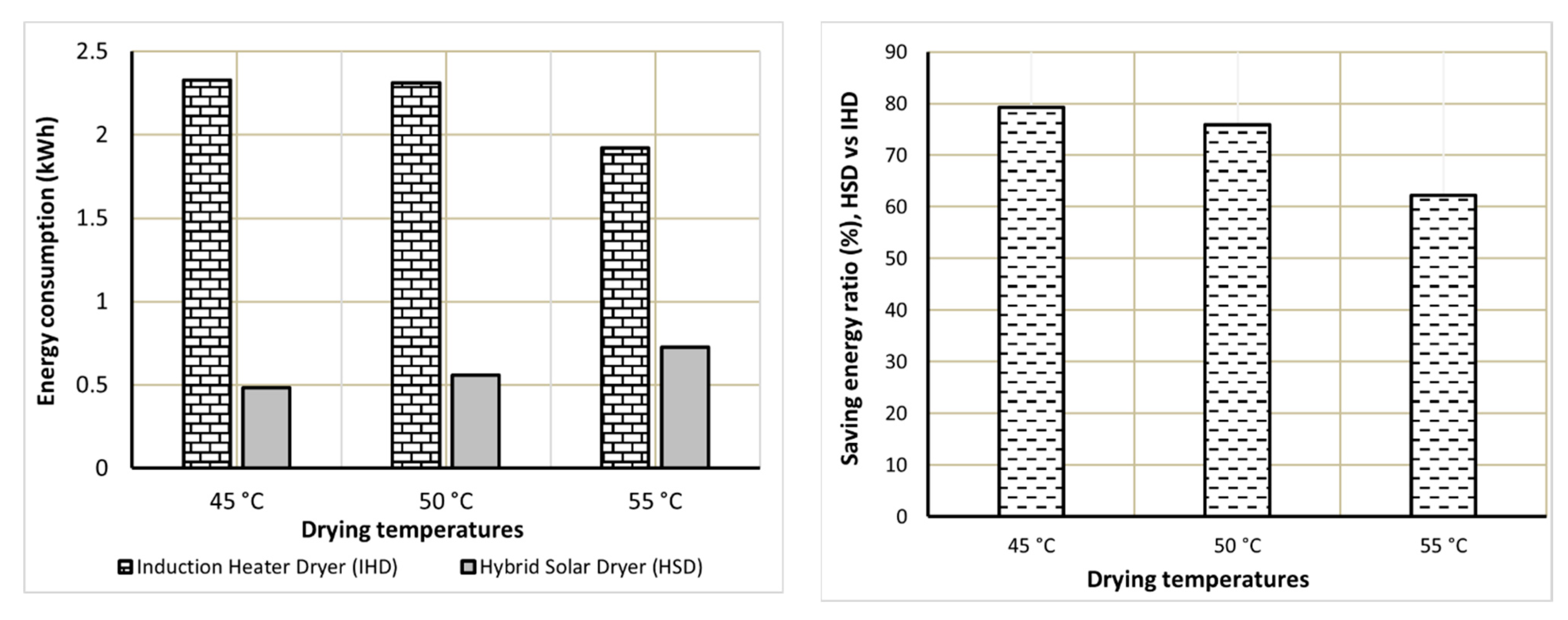

Regarding energy consumption,

Figure 9 presents a notable difference in the energy consumed by the HSD and IHD at various drying temperatures of 45, 50, and 55 °C. The HSD consumed the least amount of energy compared to the IHD. The lowest energy consumed by the HSD was 0.48, 0.56, and 0.73 kWh, while 2.33, 2.31, and 1.921 kWh were consumed by the IHD at 45, 50, and 55 °C, respectively.

The HSD’s higher energy consumption at higher temperatures can be attributed to its primary reliance on the intensity of solar radiation, and in cases of insufficient solar radiation, it triggers the conventional heating system. Conversely, the highest energy consumption at lower temperatures was recorded by the IHD, as the time required to complete the drying process was longer at lower temperatures, clocking 10, 7, and 5 h at temperatures of 45, 50, and 55 °C, respectively. The substantial discrepancy in energy consumption between the induction coil dryer and the HSD is due to the hybrid dryer’s reliance on solar radiation intensity. When solar radiation intensity is lacking and weather conditions fluctuate, the hybrid dryer operates based on the traditional drying method. Overall, the hybrid dryer design resulted in energy savings of 79.2%, 75.8%, and 62.2% at 45, 50, and 55 °C, respectively, as shown in

Figure 9.

The fresh and dried fish waste underwent assessments of microbial load and proximate composition, as listed in

Table 1. This quality analysis was intended to evaluate the efficacy of the proposed drying method in achieving optimal quality parameters for dried fish waste, which include microbial load, crude protein, crude lipids, ash, and moisture content.

Table 1 presents the quantitative microbial load results for fresh and dried fish waste at various drying temperatures. The total microbial load count serves as an important indicator of the quality of the drying process.

The highest microbial load was found in fresh samples, registering a count of 25 ± 2.65 × 106 CFU/mL. This microbial load decreased dramatically as the drying temperature increased, plummeting to its lowest at 1.0 ± 1.75 × 101 CFU/mL at 55 °C.

Crude protein and crude lipids are the primary nutrients in both fish and fish waste, and preserving their levels is a crucial goal of processing methods. The analysis revealed that protein content in both fresh and dried fish waste samples ranged between 41.61 ± 1.13 and 44.46 ± 1.03% for fresh samples and dried samples at 55 °C, respectively. The increase in protein content with rising drying temperatures could be attributed to a reduction in moisture content and the denaturation and subsequent release of proteins caused by the heating process [

53,

54,

55]. Conversely, the levels of crude lipids declined as the drying temperature escalated, with lipid values ranging from 26.72 ± 1.19% for fresh fish waste samples and progressively diminishing to 20.9 ± 0.76% for dried samples at 55 °C. This phenomenon occurs because higher drying temperatures induce lipid oxidation [

56,

57,

58].

4. Outlook and Future Work

The promising findings of this study reveal exciting pathways for future research and potential practical applications. Our HSD has displayed notable results in transforming fish waste into a value-added byproduct while reducing the processing operation’s carbon footprint. Nevertheless, a wealth of opportunities exist to refine and optimize this system.

Although the HSD system used demonstrated enhanced efficiency, improving HSD systems will remain an important priority in the drying field. Future research could focus on refining the design of the solar collector and the auxiliary heating system. These adjustments could potentially improve the HSD’s energy efficiency and drying rate.

Building on insights from previous work in the digital innovation area [

59], these technologies present a compelling case for enhancing the HSD’s capabilities. The agri-food industry has seen substantial improvements by integrating advanced sensors and automation technologies, which could be similarly applied to optimize the drying process in the HSD, allowing for more precise control of drying parameters. Drawing on established practices in machine learning [

59,

60], the adoption of these algorithms could facilitate predictive analysis and improve the operational efficiency of the drying process.

Beyond the scope of fish waste, the HSD’s potential could be harnessed for a variety of other waste materials. Future investigations could explore the effectiveness of the HSD for drying different types of waste, both within and outside of the food industry. Such broadened applications could vastly increase the system’s practical utility.

Given the considerable changes in the fish waste’s nutritional composition observed throughout the drying process, further examination of these changes could open up exciting avenues for the utilization and valorization of these products. For instance, the increased protein content with rising drying temperatures implies that the dried fish waste could be a potential protein-rich additive for animal feed, enhancing the nutritional value of such feeds. This protein enrichment can be especially valuable in areas where sources of animal protein are scarce or expensive. On the other hand, the observed decline in lipid content with increased drying temperatures might be beneficial in certain applications. Reduced lipid content can prolong the product’s shelf life as it reduces the risk of lipid oxidation, a primary cause of spoilage in fish products. Furthermore, these nutrient-rich by-products could find use in soil amendment or fertilization, contributing to a circular economy by returning valuable nutrients to the soil. Thus, the developed HSD, while addressing waste management issues, might also contribute to other sectors like animal husbandry and agriculture.

Furthermore, it would be fascinating to evaluate the feasibility of scaling up the HSD for industrial applications. The current form of the HSD is tailored to laboratory-scale experiments. However, with careful cost analysis and potential design modifications to accommodate larger waste volumes, the HSD could become a viable tool for industrial waste management.

A comprehensive understanding of the HSD’s environmental impact could be gained through an extensive life-cycle analysis. Although this study has discussed the environmental benefits of the HSD qualitatively, such an analysis could illuminate the complete environmental footprint of the HSD, including aspects like the production and end-of-life management of solar panels and batteries.

Lastly, considering the reliance of our HSD on solar power, future research could delve into its integration with renewable energy grids. The exploration of methods to best store and utilize excess energy generated during peak sunlight hours could yield more efficient energy usage, ultimately contributing to the system’s sustainability.

By addressing these areas, we have the potential to harness the sun’s power to manage waste more effectively, create valuable by-products, and foster a more sustainable and circular economy. The incorporation of digital solutions will also be pivotal in driving this technological advancement.