Experimental Investigation of Methane Generation in the Presence of Surface and Un-Surface Nanoparticles of Iron Oxide

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Substrate and Nanoparticles Preparation

2.3. Experimental Setup

2.4. Regression Model

3. Results and Discussion

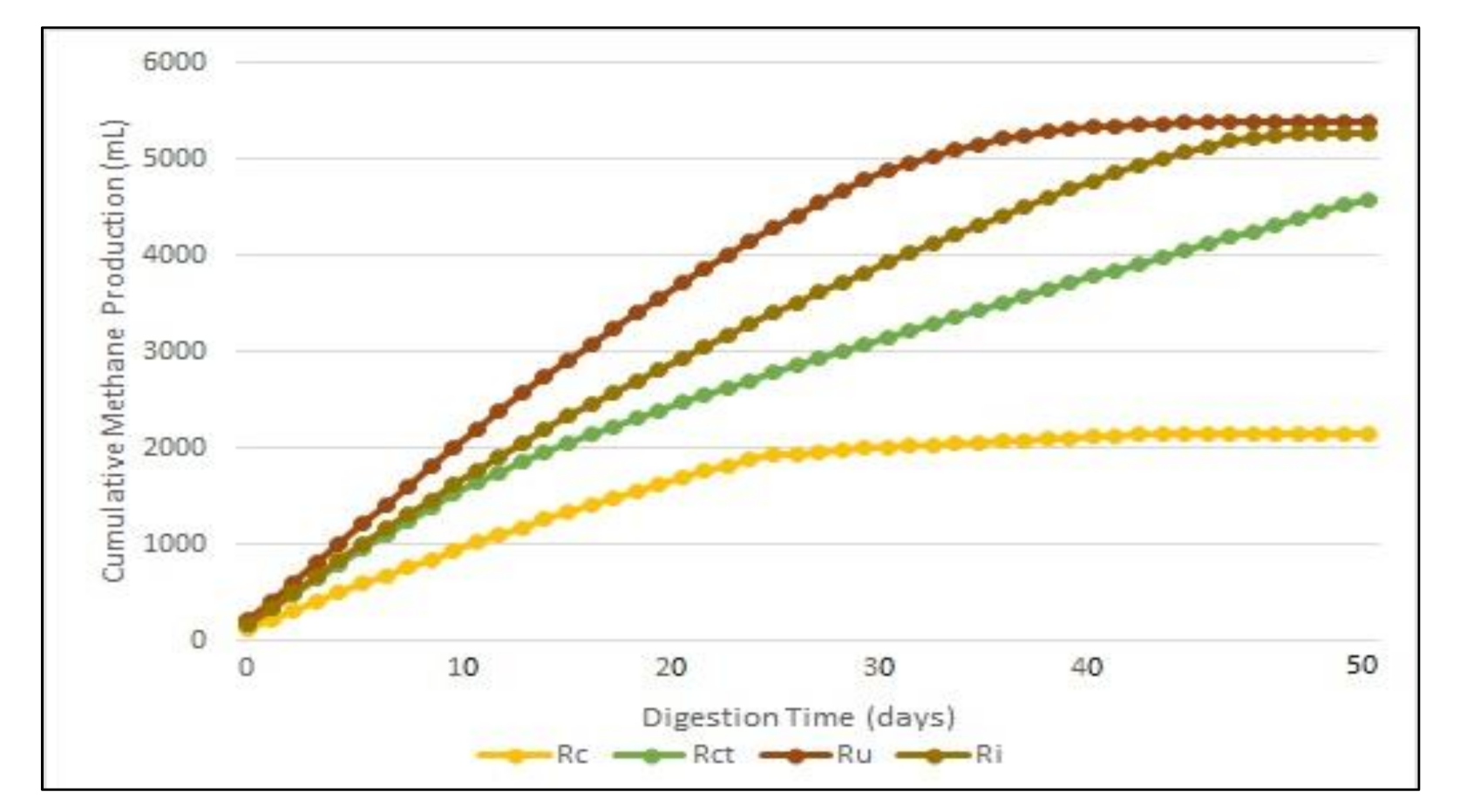

3.1. Nanoparticles vs. Methane Generation

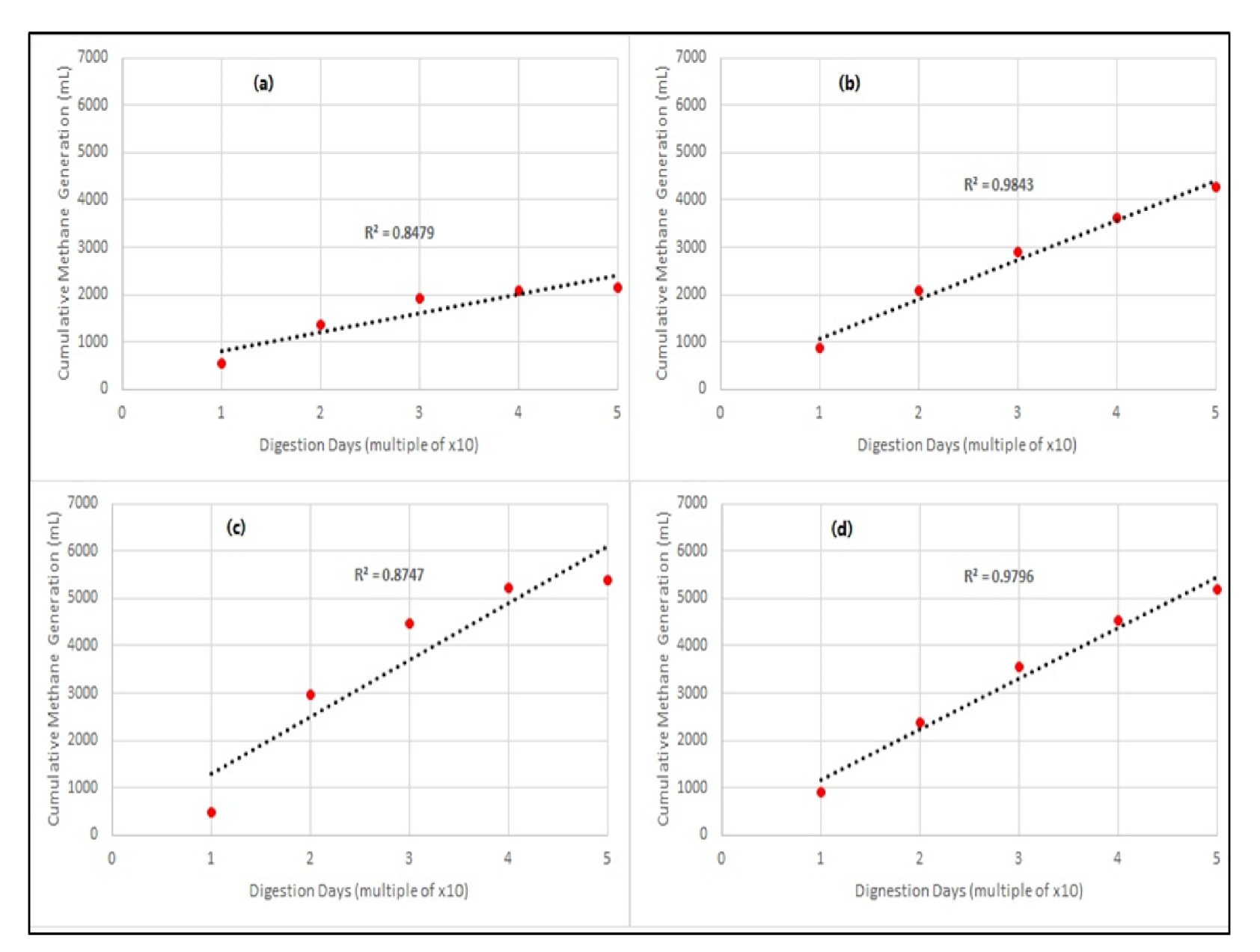

3.2. Linear Regression Analysis (LRA)

3.3. Multiple Regression Analysis (MAR)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ali, A.; Mahar, R.B.; Sheerazi, S.T.H. Renewable Electricity Generation from Food Waste through Anaerobic Digestion in Pakistan: A Mini-Review. Earth Syst. Environ. 2019, 3, 95–100. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of renewable energy sources in environmental protection: A review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Dincer, I.; Midilli, A.; Hepbasli, A.; Karakoc, T.H. (Eds.) Global Warming: Engineering Solutions; Springer Science & Business Media: Oshawa, CA, USA, 2009. [Google Scholar]

- Ali, A.; Mahar, R.B.; Soomro, R.A.; Sherazi, S.T.H. Fe3O4 nanoparticles facilitated anaerobic digestion of organic fraction of municipal solid waste for enhancement of methane production. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1815–1822. [Google Scholar] [CrossRef]

- Baek, G.; Kim, J.; Kim, J.; Lee, C. Role and potential of direct interspecies electron transfer in anaerobic digestion. Energies 2018, 11, 107. [Google Scholar] [CrossRef] [Green Version]

- Salminen, E.A.; Rintala, J.A. Semi-continuous anaerobic digestion of solid poultry slaughterhouse waste: Effect of hydraulic retention time and loading. Water Res. 2002, 36, 3175–3182. [Google Scholar] [CrossRef]

- Ye, Q.; Zhang, Z.; Huang, Y.; Fang, T.; Cui, Q.; He, C.; Wang, H. Enhancing electron transfer by magnetite during phenanthrene anaerobic methanogenic degradation. Int. Biodeterior. Biodegrad. 2018, 129, 109–116. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Samer, M.; Attia, Y.A.; Abdel-Hadi, M.A.; Hassan, H.E.; Badr, Y. Influence of zero valent iron nanoparticles and magnetic iron oxide nanoparticles on biogas and methane production from anaerobic digestion of manure. Energy 2017, 120, 842–853. [Google Scholar] [CrossRef]

- Gong, L.; Yang, X.; You, X.; Wang, J.; Zhou, J.; Zhou, Y.; Yang, J. Explore the effect of Fe3O4 nanoparticles (NPs) on anaerobic digestion of sludge. Environ. Technol. 2020, 11, 4093–4107. [Google Scholar] [CrossRef]

- Panhwar, S.; Aftab, A.; Keerio, H.A.; Sarmadivaleh, M.; Tamer, U. A Novel Approach for Real-Time Enumeration of Escherichia coli ATCC 47076 in Water through High Multi-Functional Engineered Nano-Dispersible Electrode. J. Electrochem. Soc. 2021, 168, 037514. [Google Scholar] [CrossRef]

- Panhwar, S.; Aftab, A.; Muqeet, M.; Keerio, H.A.; Solangi, G.S.; Suludere, Z.; Tamer, U. High-Performance E. coli Antibody-Conjugated Gold Nanorods for the Selective Electrochemical Detection of Pathogens in Drinking Water. J. Electron. Mater. 2021, 50, 7119–7125. [Google Scholar] [CrossRef]

- Ali, A.; Mahar, R.B.; Abdelsalam, E.M.; Sherazi, S.T.H. Kinetic Modeling for Bio augmented Anaerobic Digestion of the Organic Fraction of Municipal Solid Waste by Using Fe3O4 Nanoparticles. Waste Biomass Valorization 2018, 10, 1–12. [Google Scholar] [CrossRef]

- Nweke, C.N.; Nwabanne, J.T.; Igbokwe, P.K. Kinetics of batch anaerobic digestion of vegetable oil wastewater. Open J. Water Pollut. Treat. 2014, 1, 1–10. [Google Scholar] [CrossRef]

- Nwabanne, J.T.; Okoye, A.C.; Ezedinma, H.C. Kinetics of anaerobic digestion of palm oil mill effluent. Can. J. Pure Appl. Sci. 2012, 6, 1877. [Google Scholar]

- Keerio, H.A.; Bae, W.; Park, J.; Kim, M. Substrate uptake, loss, and reserve in ammonia-oxidizing bacteria (AOB) under different substrate availabilities. Process Biochem. 2020, 91, 303–310. [Google Scholar] [CrossRef]

- Keerio, H.A.; Bae, W. Experimental Investigation of Substrate Shock and Environmental Ammonium Concentration on the Stability of Ammonia-Oxidizing Bacteria (AOB). Water 2020, 12, 223. [Google Scholar] [CrossRef] [Green Version]

- Jeyaseelan, S. A simple mathematical model for anaerobic digestion process. Water Sci. Technol. 1997, 35, 185–191. [Google Scholar] [CrossRef]

- Ali, A.; Mahar, R.B.; Sherazi, S.T.H. Methane Augmentation of Anaerobic Digestion of Food Waste in the Presence of Fe3O4 and Carbamide Capped Fe3O4 Nanoparticles. Waste Biomass Valorization 2019, 11, 1–15. [Google Scholar] [CrossRef]

- Sung, S.; Liu, T. Ammonia inhibition on thermophilic anaerobic digestion. Chemosphere 2003, 53, 43–52. [Google Scholar] [CrossRef]

- Kafle, G.K.; Chen, L. Comparison on batch anaerobic digestion of five different livestock manures and prediction of biochemical methane potential (BMP) using different statistical models. Waste Manag. 2016, 48, 492–502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ariunbaatar, J.; Panico, A.; Esposito, G.; Pirozzi, F.; Lens, P.N. Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl. Energy 2014, 123, 143–156. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association (APHA): Washington, DC, USA, 1998. [Google Scholar]

- Keerio, H.A.; Panhwar, S.; Shah, S.A.; Naji, A.M.; Ali, A.; Aftab, A. Investigation of Climate Change Variability under Climate Change Conditions over the Semi-Arid Region. J. Mech. Contin. Math. Sci. 2020, 15, 46–54. [Google Scholar] [CrossRef]

- Khalid, M.J.; Waqas, A.; Nawaz, I. Synergistic effect of alkaline pretreatment and magnetite nanoparticle application on biogas production from rice straw. Bioresour. Technol. 2019, 275, 288–296. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Feng, Y.; Quan, X. Zero-valent iron enhanced methanogenic activity in anaerobic digestion of waste activated sludge after heat and alkali pretreatment. Waste Manag. 2015, 38, 297–302. [Google Scholar] [CrossRef] [PubMed]

- Panhwar, S.; Sahito, A.R.; Solangi, G.S.; Mahar, R.B.; Lal, J. Methane production by anaerobic digestion of spent wash in continuous stirred tank reactor. Mehran Univ. Res. J. Eng. Technol. 2019, 38, 791–798. [Google Scholar] [CrossRef] [Green Version]

- Bouallagui, H.; Touhami, Y.; Cheikh, R.B.; Hamdi, M. Bioreactor performance in anaerobic digestion of fruit and vegetable wastes. Process Biochem. 2005, 40, 989–995. [Google Scholar] [CrossRef]

- Plotts, T. A Multiple Regression Analysis of Factors Concerning Superintendent Longevity and Continuity Relative to Student Achievement. Ph.D. Thesis, Seton Hall University, South Orange, NJ, USA, 2011. [Google Scholar]

- Turóczy, Z.; Marian, L. Multiple regression analysis of performance indicators in the ceramic industry. Procedia Econ. Financ. 2012, 3, 509–514. [Google Scholar] [CrossRef] [Green Version]

- Kulcsar, E. Multiple regression analysis of main economic indicators in tourism. Rev. Tur.—Stud. Cercet. Tur. 2009, 8, 59–64. [Google Scholar]

| Model | Sum of Squares | df | Mean Square | F | Sig-F | |

|---|---|---|---|---|---|---|

| 1 | Regression | 19,412,872.36 | 3 | 6,470,957.453 | 3448.952147 | 0.00 a |

| Residual | 86,305.64594 | 46 | 1876.209694 | |||

| Total | 19,499,178.01 | 49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, A.; Keerio, H.A.; Panhwar, S.; Ahad, M.Z. Experimental Investigation of Methane Generation in the Presence of Surface and Un-Surface Nanoparticles of Iron Oxide. AgriEngineering 2022, 4, 134-140. https://doi.org/10.3390/agriengineering4010009

Ali A, Keerio HA, Panhwar S, Ahad MZ. Experimental Investigation of Methane Generation in the Presence of Surface and Un-Surface Nanoparticles of Iron Oxide. AgriEngineering. 2022; 4(1):134-140. https://doi.org/10.3390/agriengineering4010009

Chicago/Turabian StyleAli, Asim, Hareef Ahmed Keerio, Sallahuddin Panhwar, and Muhammad Zeshan Ahad. 2022. "Experimental Investigation of Methane Generation in the Presence of Surface and Un-Surface Nanoparticles of Iron Oxide" AgriEngineering 4, no. 1: 134-140. https://doi.org/10.3390/agriengineering4010009

APA StyleAli, A., Keerio, H. A., Panhwar, S., & Ahad, M. Z. (2022). Experimental Investigation of Methane Generation in the Presence of Surface and Un-Surface Nanoparticles of Iron Oxide. AgriEngineering, 4(1), 134-140. https://doi.org/10.3390/agriengineering4010009