Design and Experimental Study of a Wine Grape Covering Soil-Cleaning Machine with Wind Blowing

Abstract

1. Introduction

2. Materials and Methods

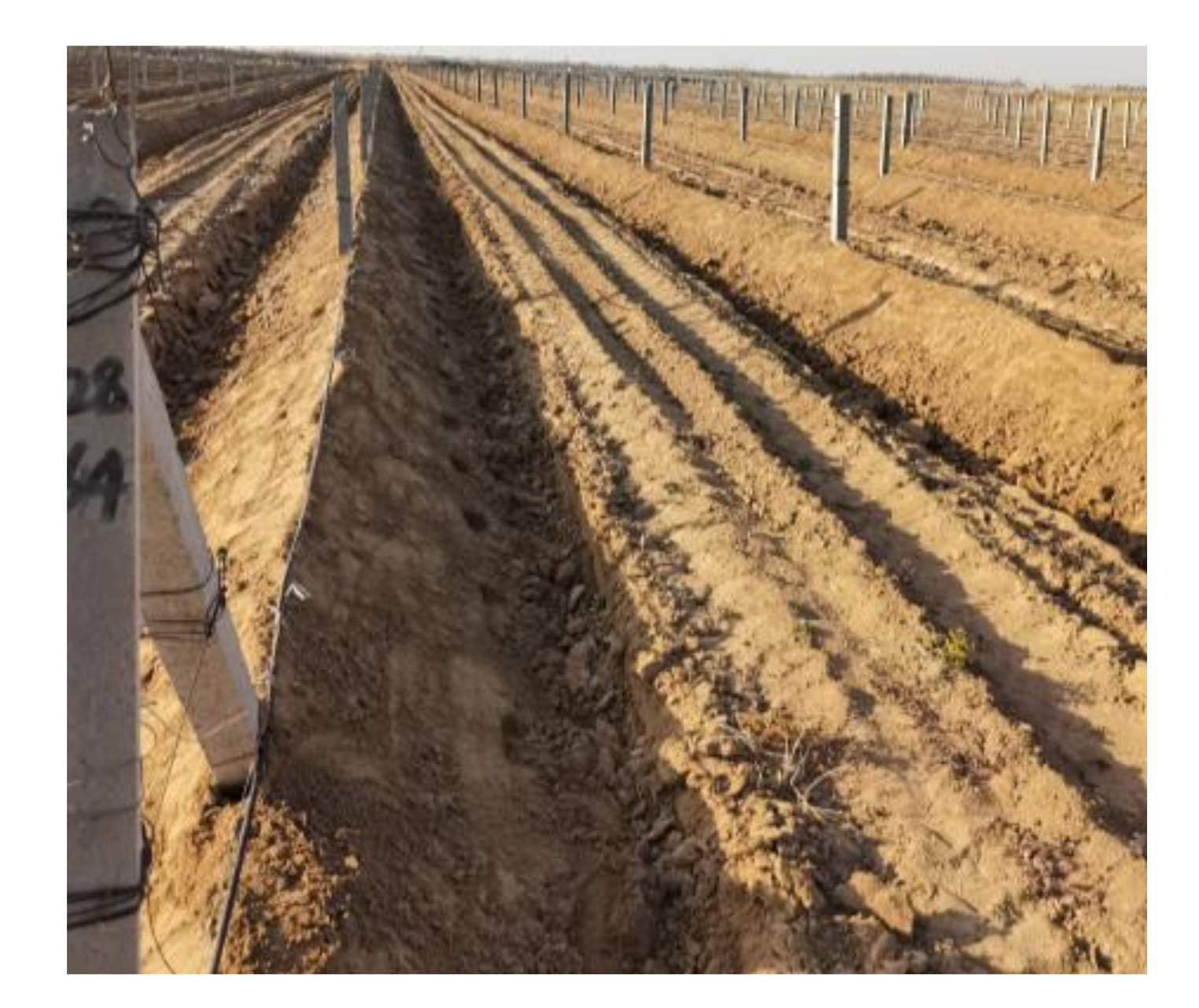

2.1. Agronomic Requirements

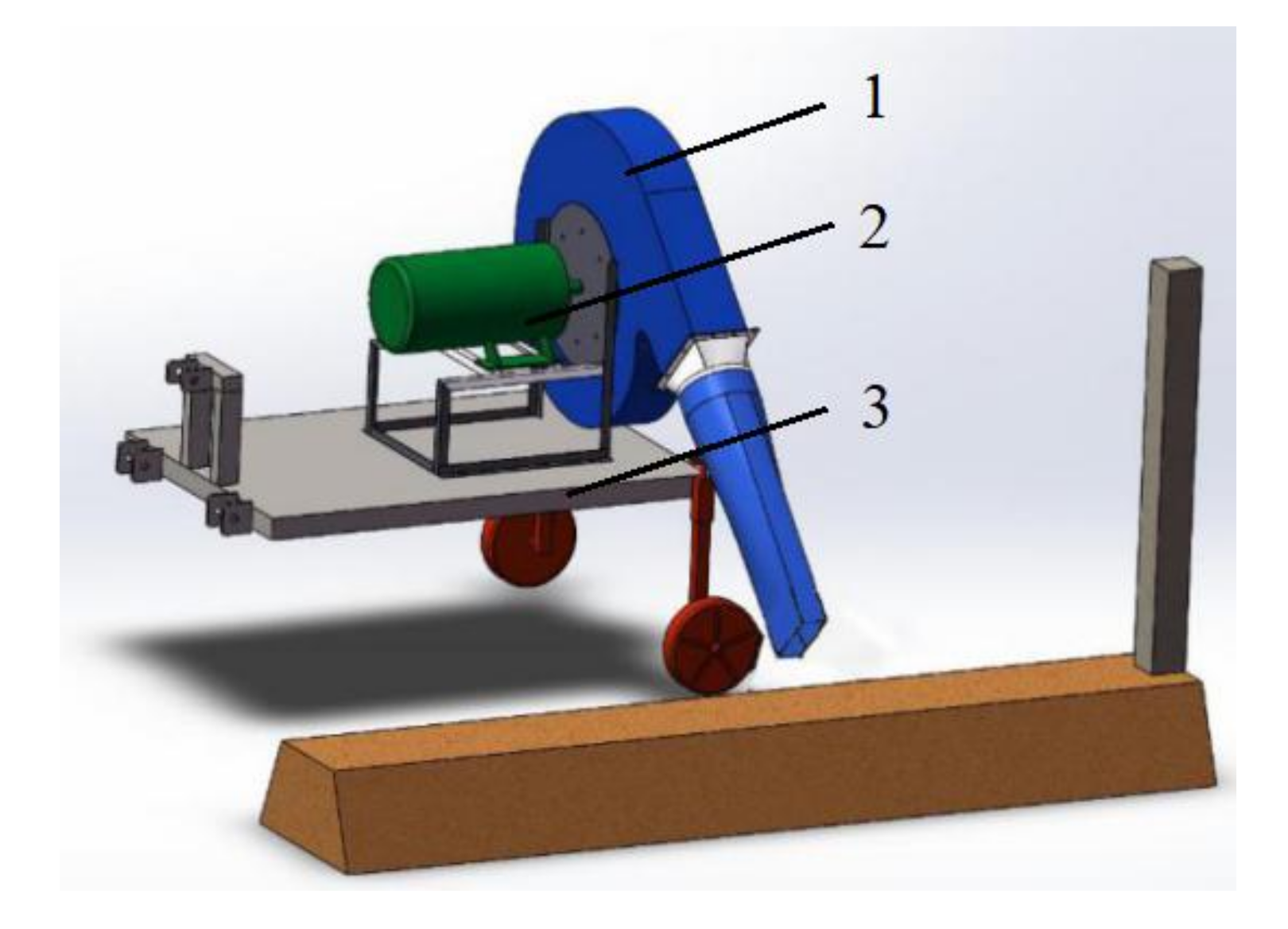

2.2. The Schematic Design of the Wind-Blown Soil Cleaner

2.2.1. Design of Wind-Blowing Device

2.2.2. Power Selection

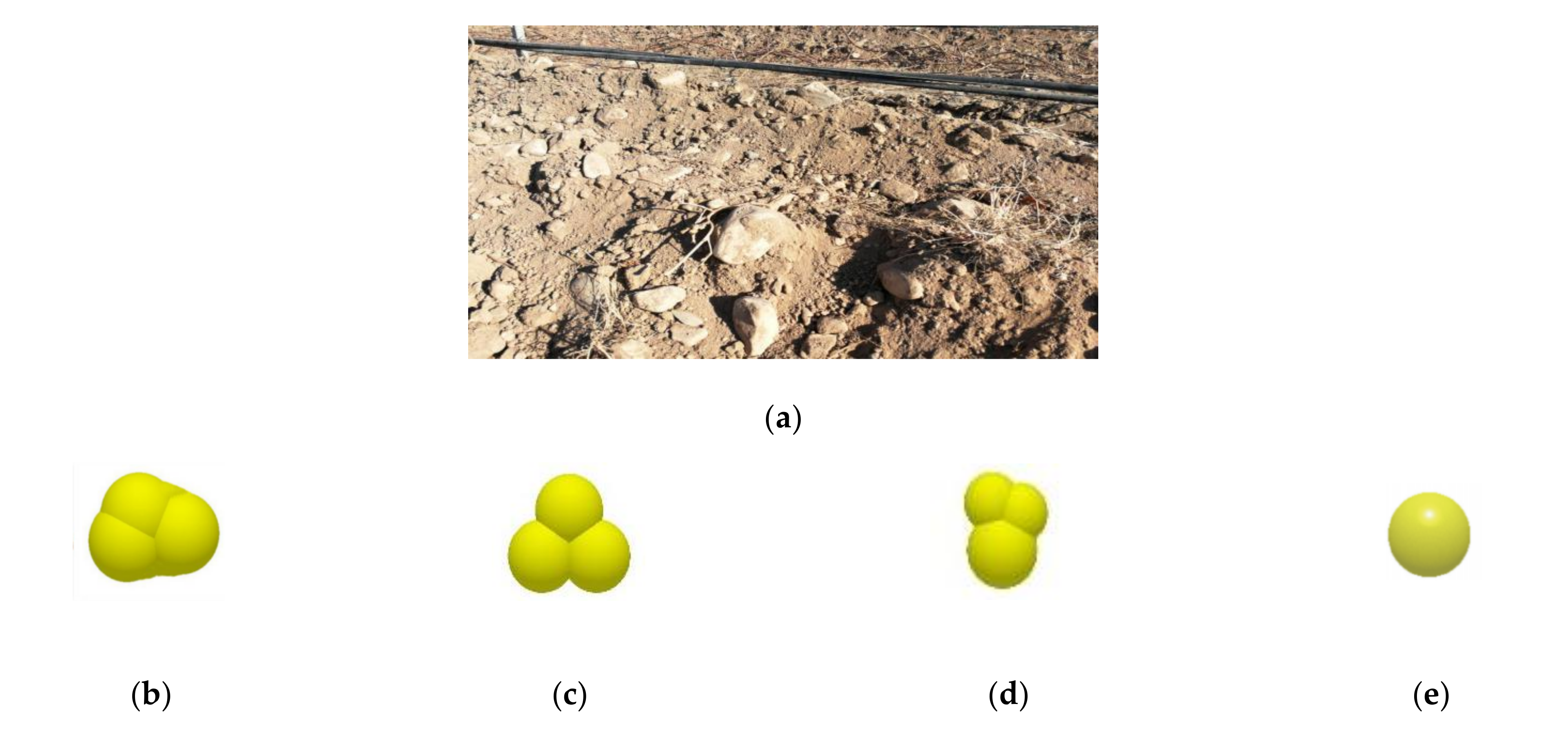

2.3. Determination of EDEM Simulation Model Parameters

2.3.1. Acquisition of Soil Parameters

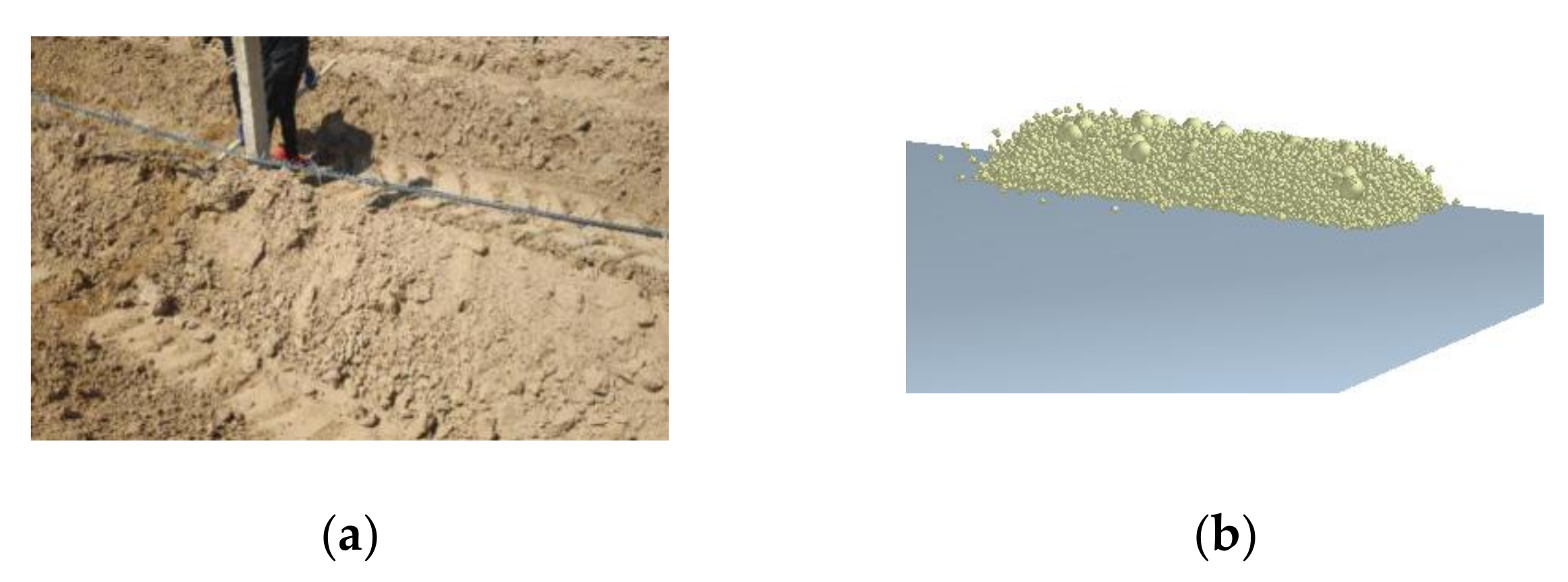

Measurement of Soil Physical Parameters

Calculation of Soil Physical Parameters

Analysis and Modeling of Soil Particle Size

2.3.2. Determination of Simulation Parameters

Selection and Calculation of Fan

= 972.56 N

= 583.54 J

Selection of Power Source

- (1)

- Power selection

- (2)

- Cable selection

Determination of Duct Size

2.4. Square Tube Fluid Simulation

- (1)

- Both air inlet and outlet were 2.15 × 102 × 1.8 × 102 mm rectangular tubes

- (2)

- Inlet 2.15 × 102 × 1.8 × 102 mm, outlet 1.8 × 102 × 1.8 × 102 mm tapered square tube

- (3)

- Imported 2.15 × 102 × 1.8 × 102 mm, outlet 1.6 × 102 × 1.6 × 102 mm tapered square tube

2.5. Pipe Coupling Fluid Simulation

- (1)

- Import 2.15 × 102 × 1.8 × 102 mm, export φ 1.8 × 102 mm

- (2)

- Import 2.15 × 102 × 1.8 × 102 mm, export φ 1.6 × 102 mm

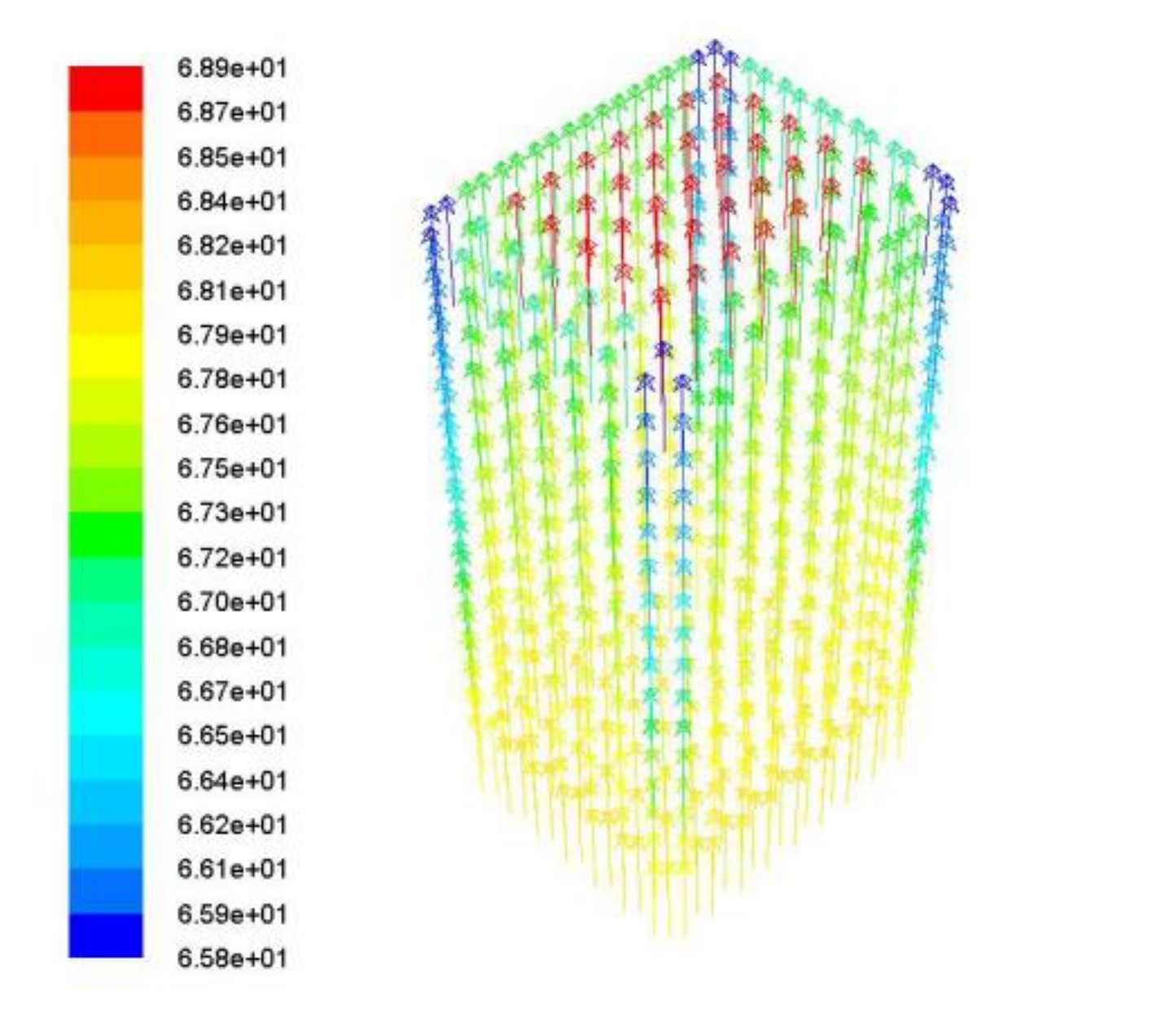

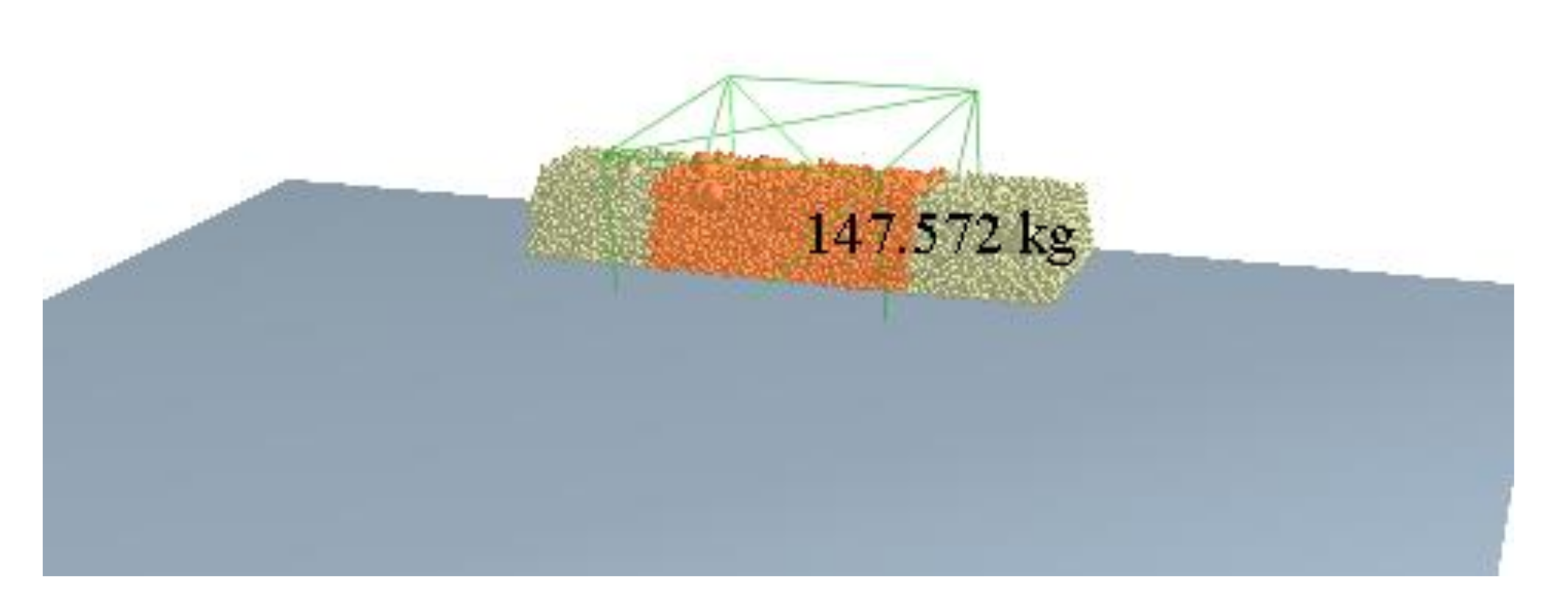

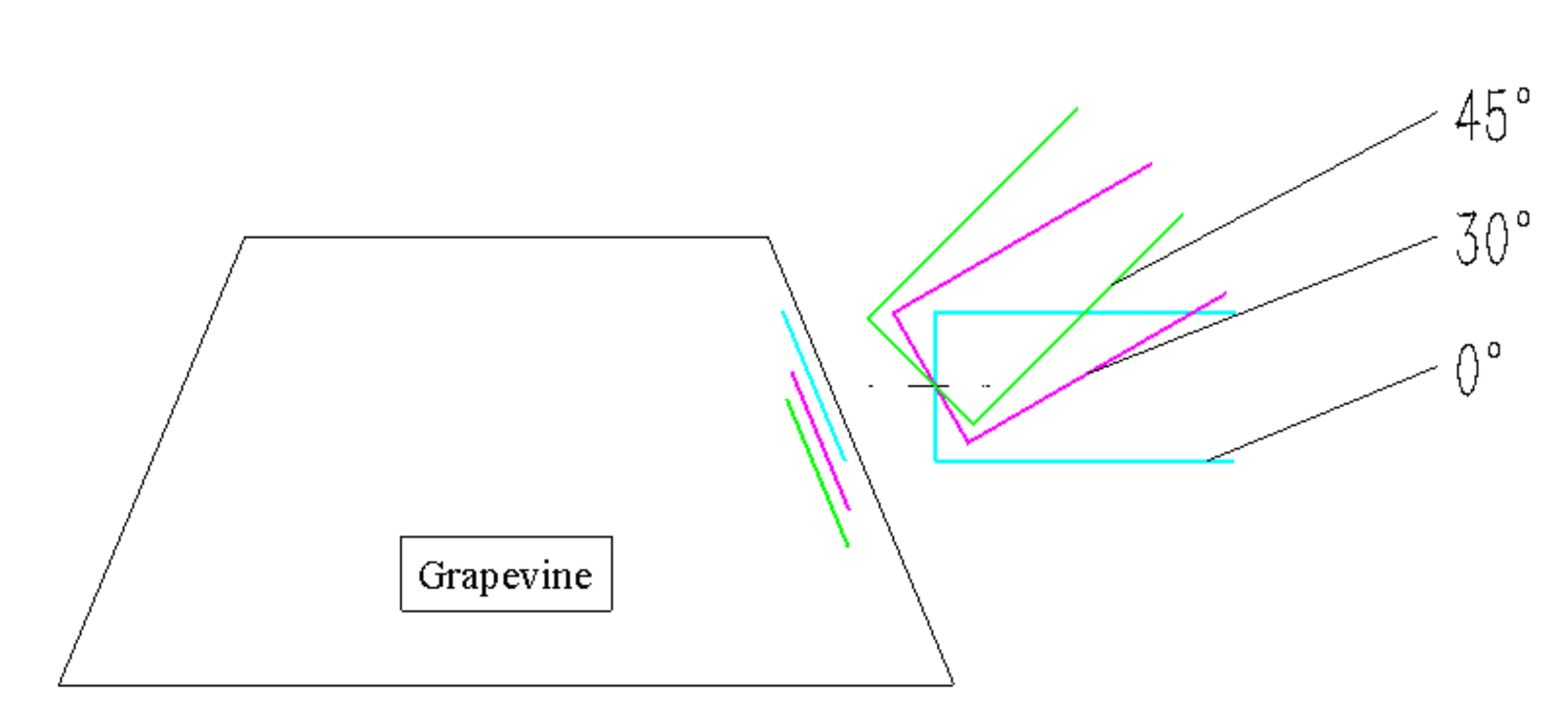

2.6. Dynamic Simulation Analysis of Soil Particle Group Under Wind Blowing

2.6.1. Soil Ridge Modeling and Flow Field Modeling

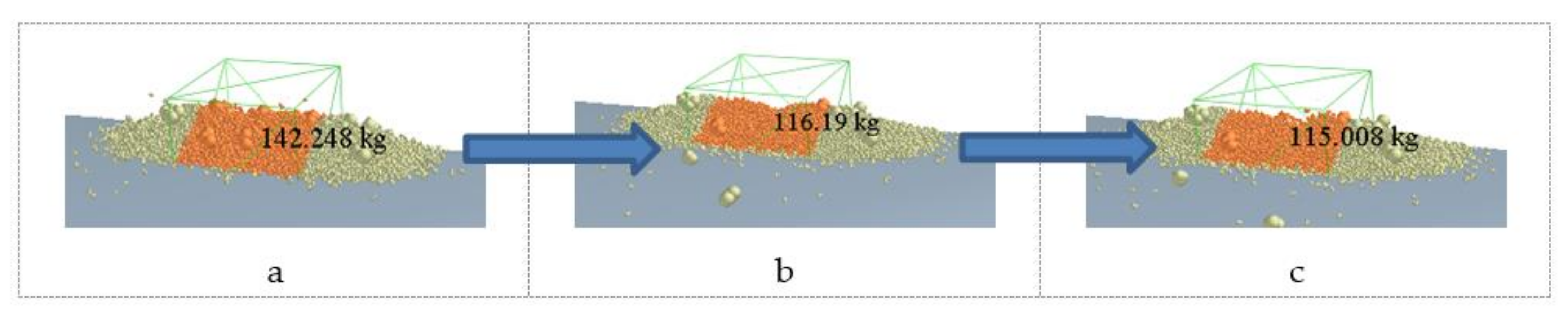

2.6.2. Simulation Process

2.7. Development and Test of Principle Prototype

2.7.1. Development of the Principle Prototype

2.7.2. Principle Prototype Test Method

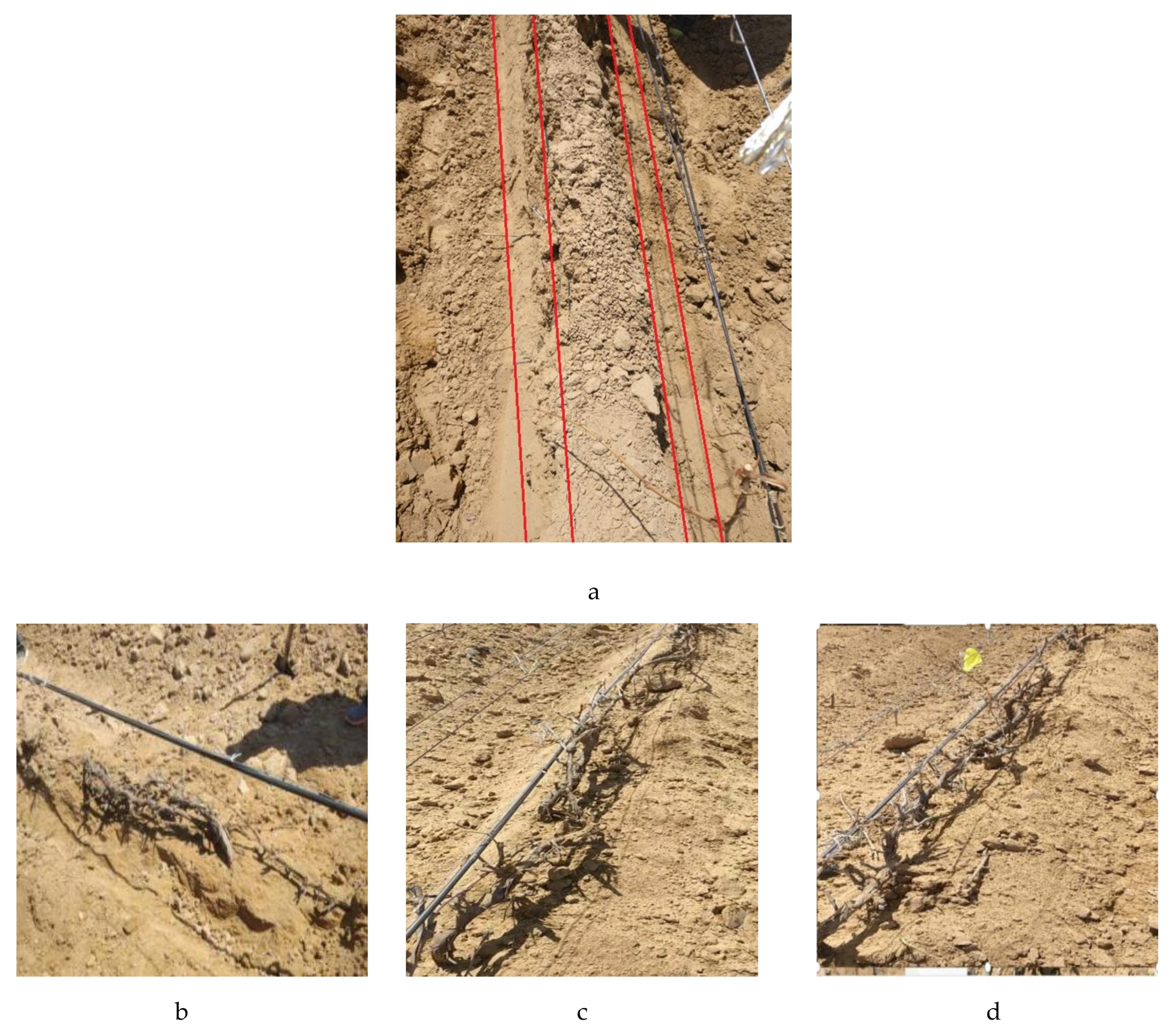

2.7.3. Field Simulation Test

2.7.4. Field Test on Grape Plantation of Yuquanying Farm in Ningxia, China

3. Results

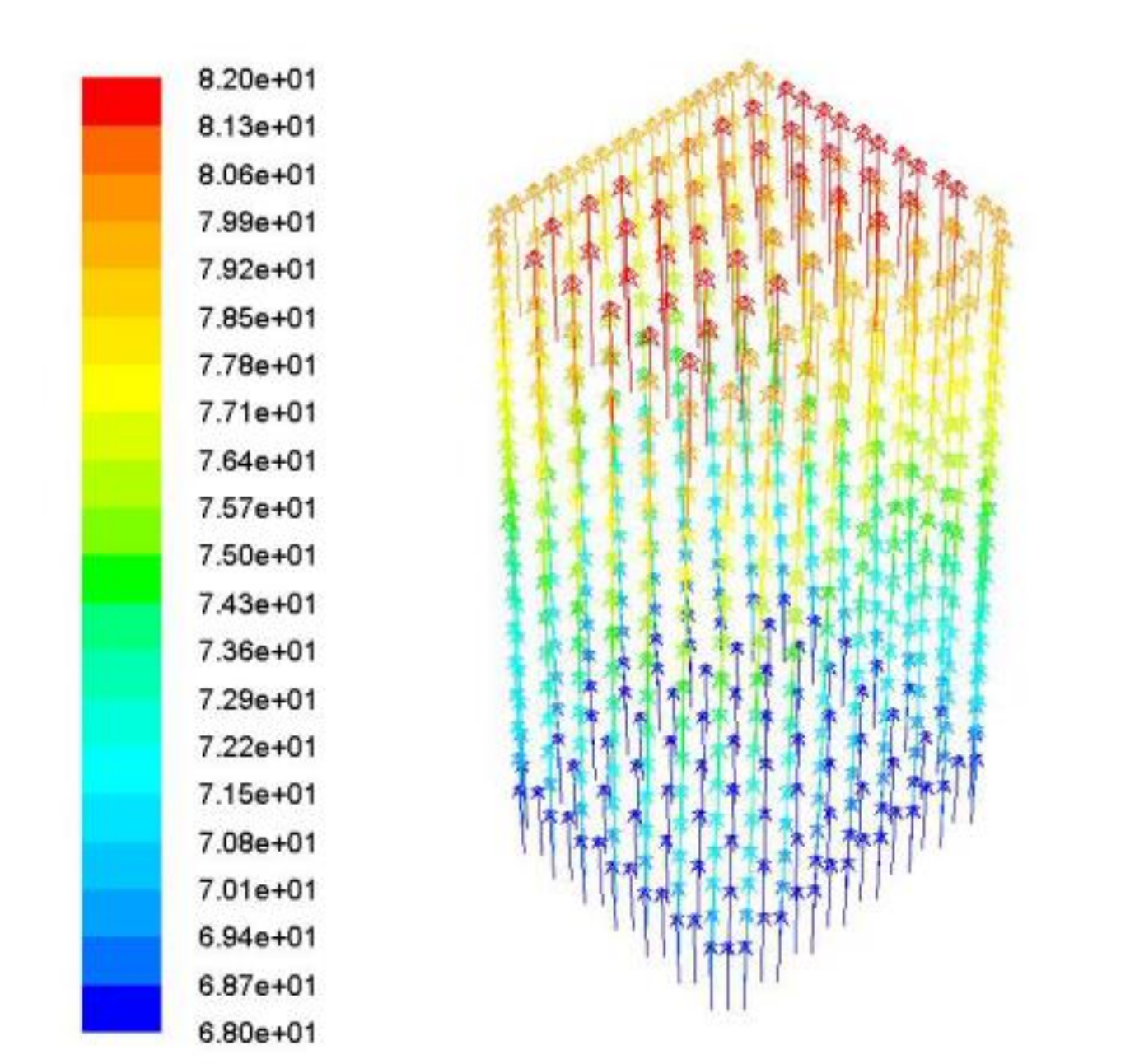

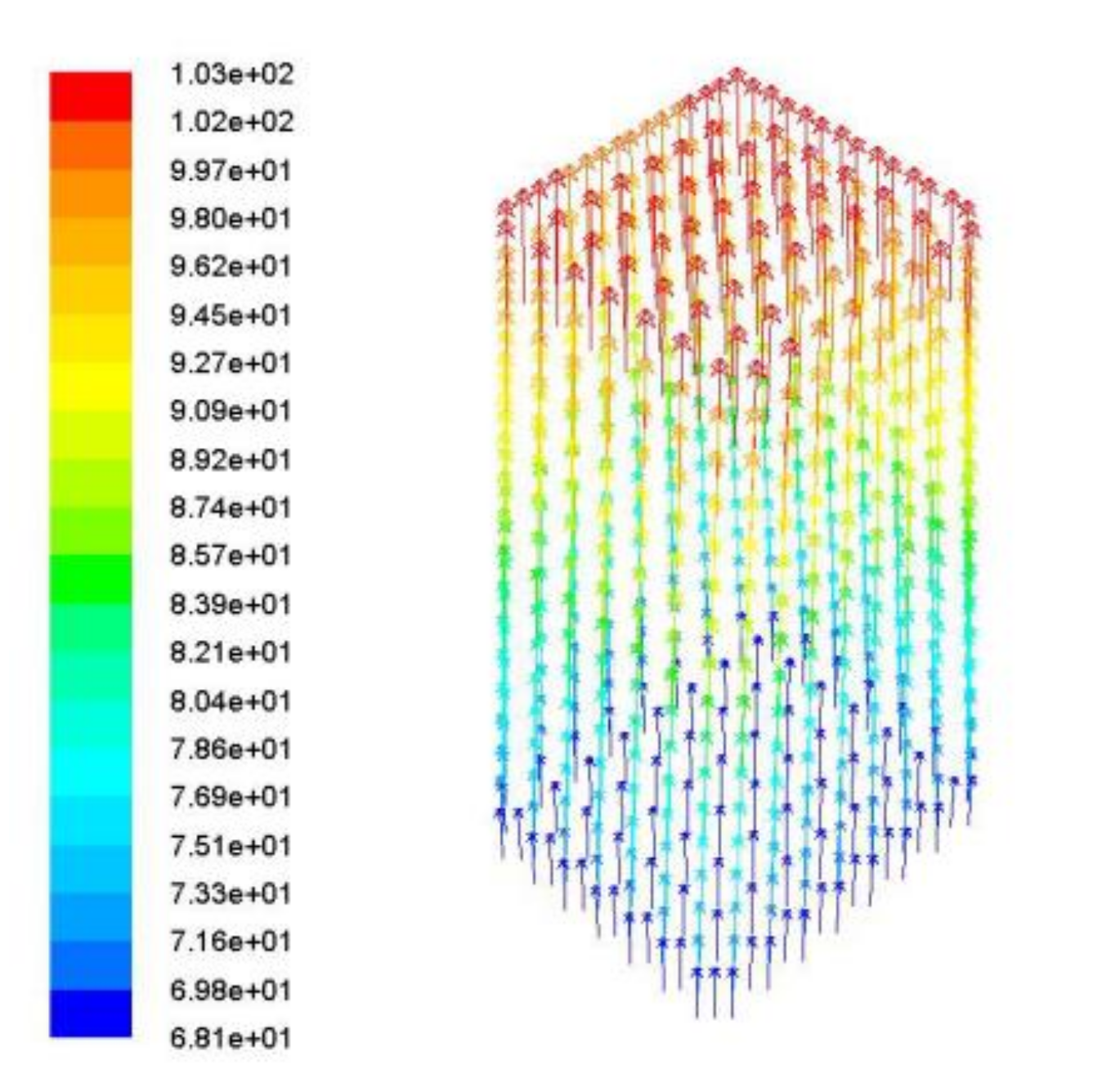

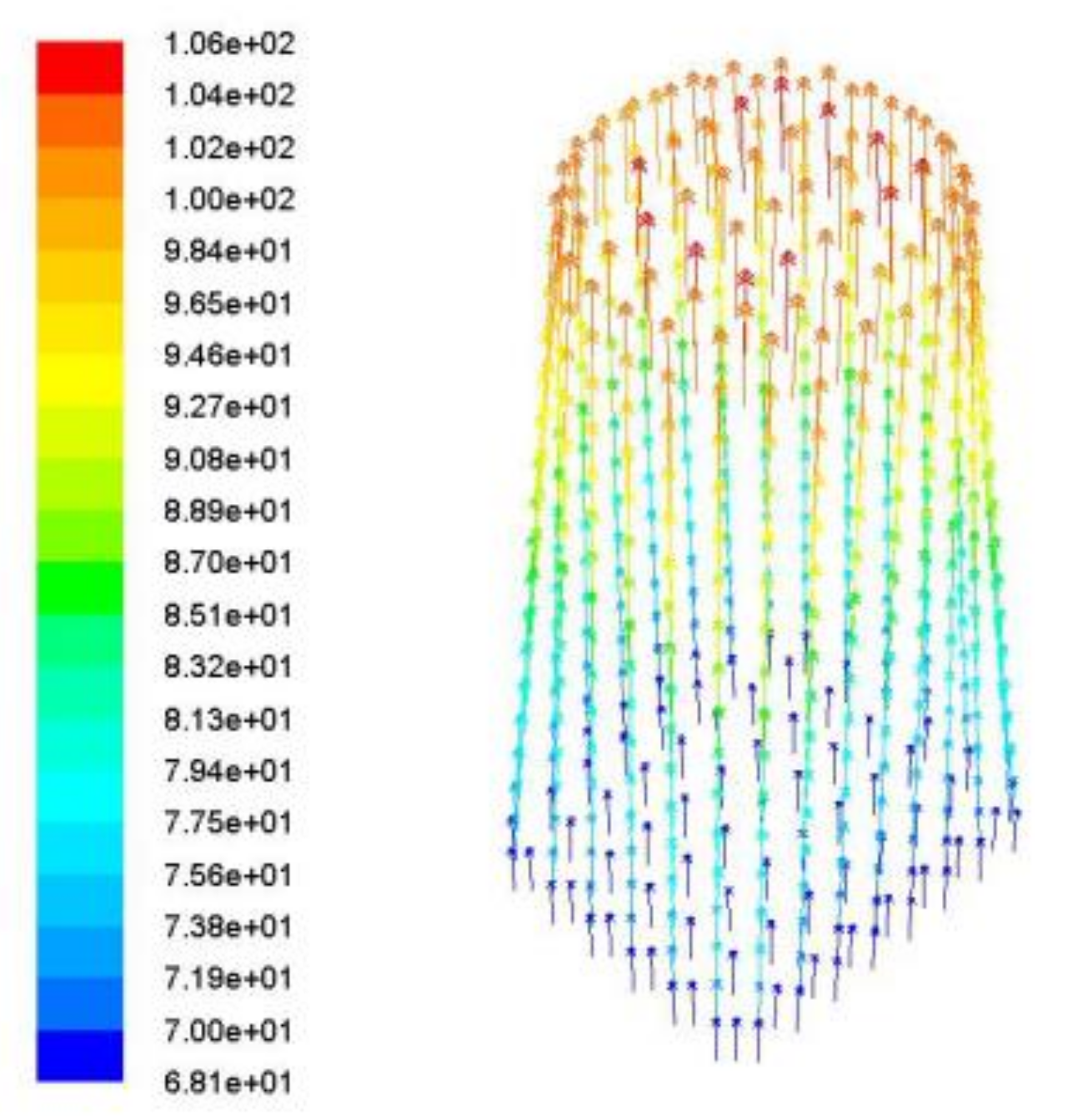

3.1. Simulation Analysis of the Square Tube

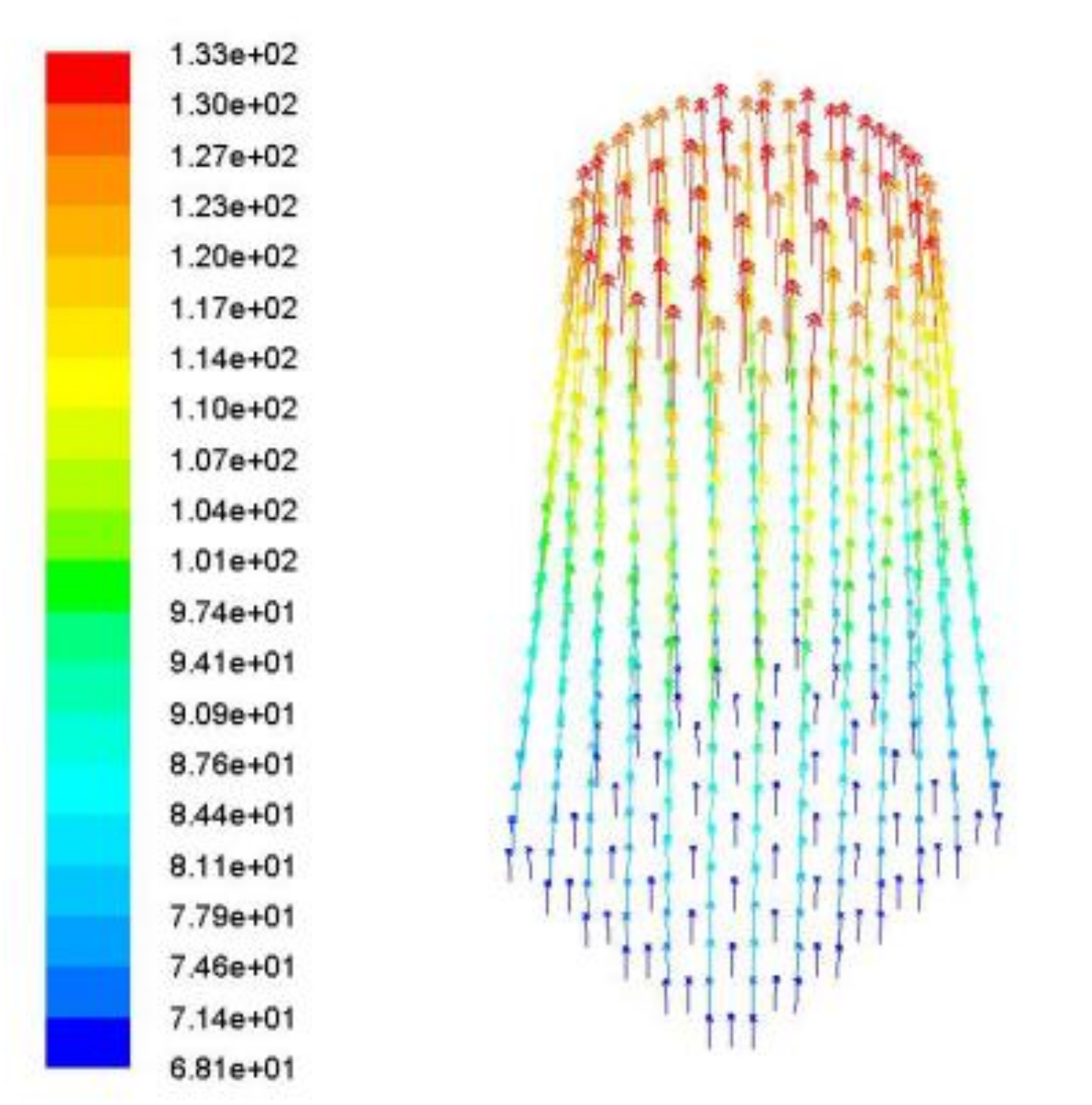

3.2. Simulation Analysis of the Combined Taper Pipe

3.3. Simulation Results of Duct Fluid

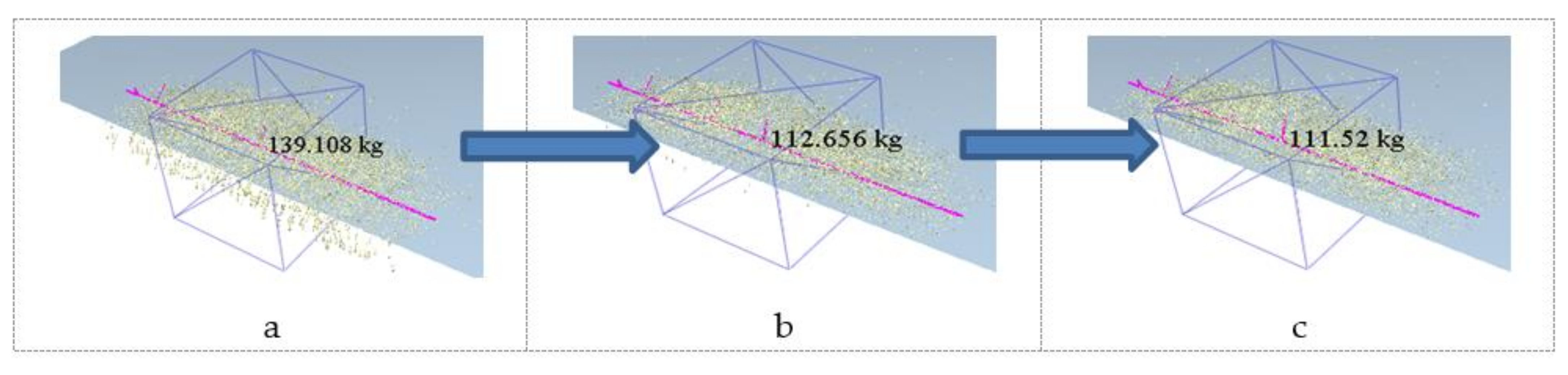

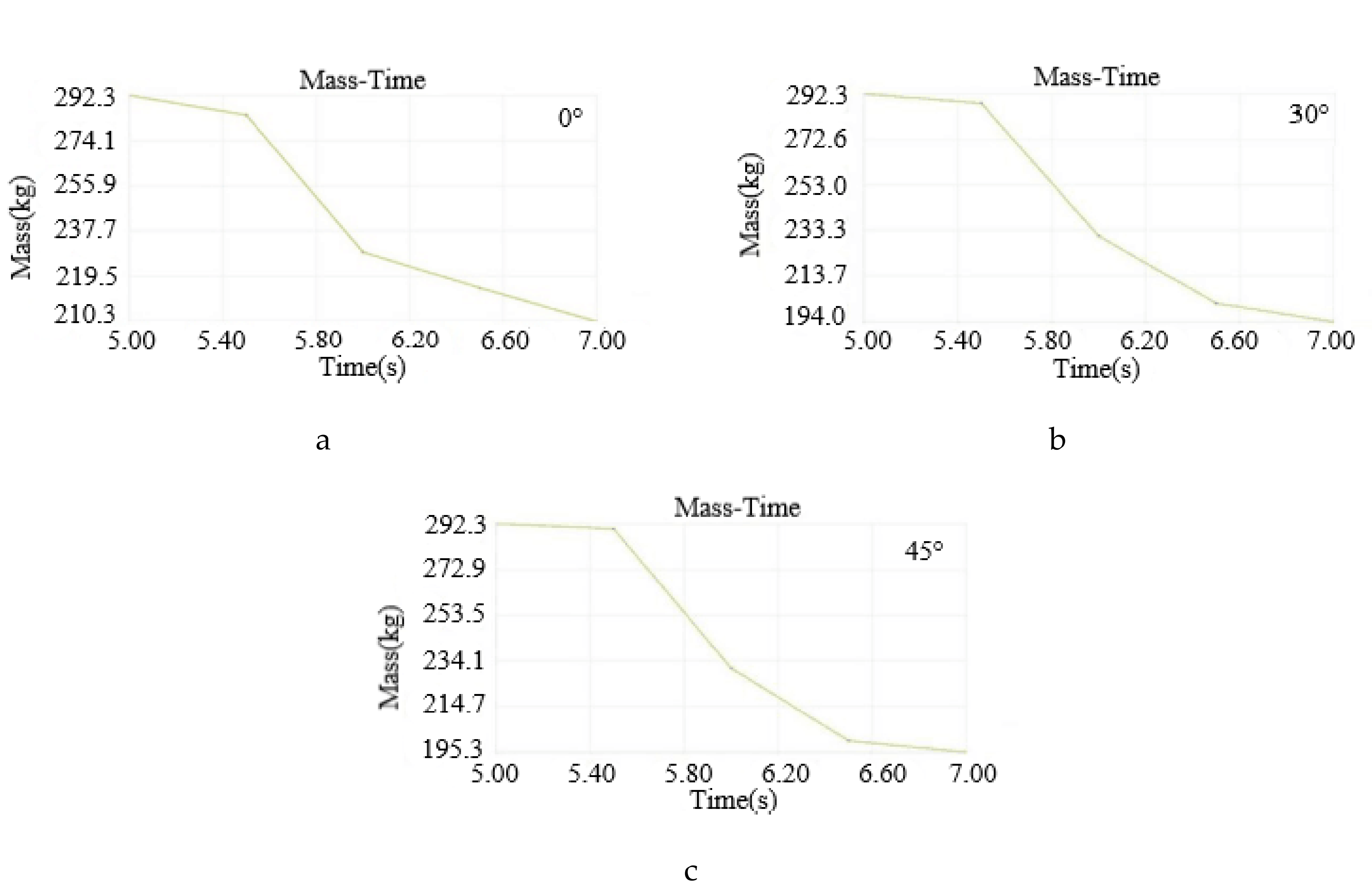

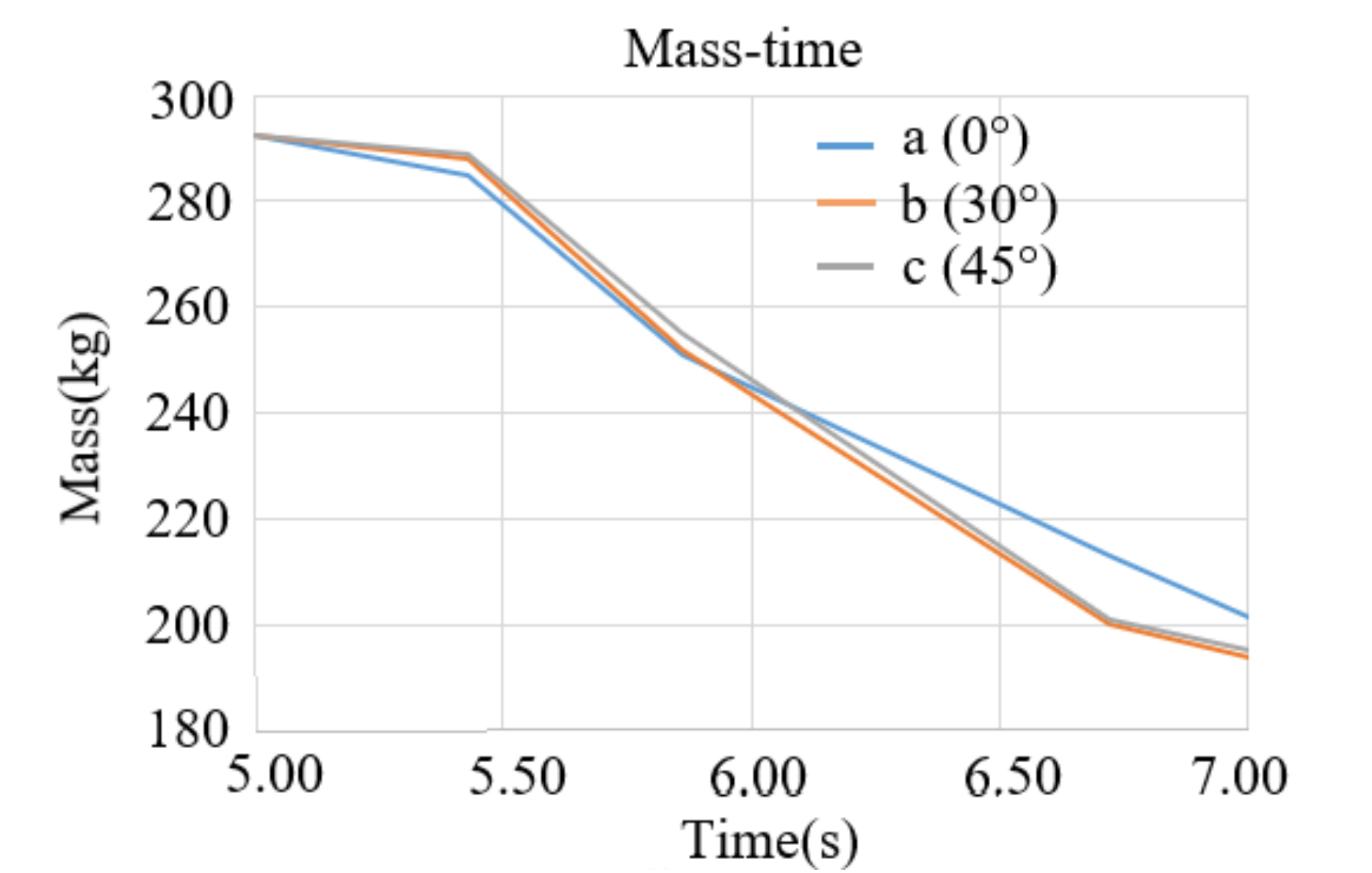

3.4. Result Analysis of Soil Particle Group under Wind Blowing

3.5. The Results of Tests

3.5.1. The Results of Field Simulation Test

- ①

- Under the action of wind, the surface layer of floating soil was immediately blown away, and the overburden in the central area of the vine edge was subsequently stripped and collapsed layer by layer, which was consistent with the simulation results.

- ②

- In the first group of site simulation tests, the soil ridge with a low water content had a good soil-cleaning effect, with a soil-cleaning rate of over 70%.

- ③

- In the second group of field simulation tests, when the whole machine moved at a speed of 0.5 m/s, the average soil removal rate in the core area of the vines could reach 80%, that is, the wind force of the fan can ensure that most of the covering soil above the vines was blown away, exposing the vines, and a few areas with loose soil can even be completely cleaned.

3.5.2. The Results of Field Test on Grape Plantation of Yuquanying Farm in Ningxia, China

3.5.3. Analysis of Test Results

4. Discussion and Conclusions

- (1)

- Combined with the climate, soil and wine grape planting patterns in Central Asia, the overall design requirements were proposed. The designed principle prototype included a blower, a power device and a chassis. Based on the overall design requirements and through a field demonstration, the overall design of the wind-blown wine grape cleaning machine suitable for Central Asia was determined.

- (2)

- Through the experiments, the physical and physical property parameters of the wine-growing vineyard soil in Ningxia, Northwest China, were measured, and the soil particle model and the soil-covered ridge model were established in the EDEM software. Through the Fluent-EDEM coupling method, the dynamic simulation analysis of the soil of the wine grape plantation under the action of wind-blowing was completed, and the original design parameters of the wind-blowing device were obtained.

- (3)

- Based on the overall design scheme and the size of the soil ridges in the core area around the vines of the wine grape plantations in Northwest China, the prototype was developed and tested. The average cleaning speed was 0.5 m·s−1. The average soil-cleaning rate was stable at about 80%, which could completely reveal the grapevine without hurting the vines or buds.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeng, B.N.; Tian, Z.D.; Zhao, R.L. Design and development of grape vine machine. Chin. J. Agric. Mach. Chem. 2013, 34, 230–232. [Google Scholar]

- Liu, S. Design and experimental research on conical spiral type grape vine digging machine. Master’s Thesis, Xinjiang Agricultural University, Urumqi, China, 2014. [Google Scholar]

- Liu, F.J.; Liu, Z.J.; Wang, J.J.; Mi, Y.; Liu, H.K.; Liu, X.Q. Design and experimental research of automatic obstacle avoidance grapevine digging machine. Agric. Mech. Res. 2018, 40, 87–90. [Google Scholar]

- Zhou, W.B. Design of Grape Vine Machine. Master’s Thesis, Ningxia University, Yinchuan, China, 2017. [Google Scholar]

- Yang, D. Design and Experimental Research of Pneumatic Horizontal Disc Potato Seeder. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2016. [Google Scholar]

- Lu, J.Q.; Yi, S.J.; Tao, G.X.; Mao, X. Design and experiment of potato pneumatic precision planter. Trans. Chin. Soc. Agric. Eng. 2018, 34, 16–24. [Google Scholar]

- Zulin, Z.; Upadhyaya, S.K. A hydropneumatic seeder for primed seed. Trans. ASAE 1998, 41, 307–314. [Google Scholar] [CrossRef]

- Karayel, D.; Wiesehoff, M.; Ozmerzi, A.; Muller, J. Laboratoiy measurement of seed drill seed spacing and velocity of fall of seeds using high-speed camera system. Comput. Electron. Agric. 2006, 50, 89–96. [Google Scholar] [CrossRef]

- Karayel, D.; Barut, Z.B.; Ozmerzi, A. Mathematical modeling of vacuum pressure on a precision seeder. Biosyst. Eng. 2004, 87, 437–444. [Google Scholar] [CrossRef]

- Karayel, D. Performance of a modified precision vacuum seeder for no-till sowing of maize and soybean. Soil Tillage Res. 2009, 104, 121–125. [Google Scholar] [CrossRef]

- Wen, X.Y.; Jia, H.L.; Zhang, S.W.; Yuan, H.F.; Wang, G.; Chen, T.Y. Experiment on measuring the suspension velocity of granular fertilizer based on EDEM-Fluent coupling. Trans. Chin. Soc. Agric. Mach. 2020, 51, 69–77. [Google Scholar]

- Huang, S.; Huang, J.X.; Mo, Y.S.; Zhang, Z.F. Research on the wear characteristics of the overflow part of the centrifugal pump based on EDEM-Fluent coupling. Therm. Power Eng. 2020, 35, 62–69. [Google Scholar]

- Han, D.D.; Zhang, D.X.; Yang, L. Optimization and experiment of internal aerated blow seed metering device based on EDEM-CFD coupling. Trans. Chin. Soc. Agric. Mach. 2017, 48, 43–51. [Google Scholar]

- Lan, S.Q.; Gao, K.; Lei, N.Z.; Fu, Y.D.; Liu, W.Q. Experimental study on the correlation between soil moisture content and landslide risk. Exp. Mech. 2020, 35, 300–308. [Google Scholar]

- Yang, W.; Dang, X.K.; Yang, J.; Mo, J.L. Study on Inverse Method of Soil Elastic Modulus Based on Multi-material ALE Fluid-structure Interaction. IOP Conf. Ser. Mater. Sci. Eng. 2017, 229. [Google Scholar] [CrossRef]

- Wang, J.W.; Li, X.; Gao, P.X.; Na, M.J.; Wang, Q.; Zhou, W.Q. Design and test of high-efficiency drag reduction loosening shovel for carrot combine harvester. J. Agric. Mach. 2020, 51, 93–103. [Google Scholar]

- Ma, S.; Xu, L.M.; Yuan, Q.C.; Niu, C.; Zeng, J.; Chen, C.; Wang, S.S.; Yuan, X.T. Discrete element simulation parameter calibration of the interaction between vine cold-proof soil and clear soil components. Trans. Chin. Soc. Agric. Eng. 2020, 36, 40–49. [Google Scholar]

- Li, M.F. Selection and calculation of commonly used cables. Electron. Prod. 2015, 3, 203–204. [Google Scholar]

- Yu, B.; Wang, Q.; Wang, S. Simulation of airflow field in a wind screen cleaning chamber based on Fluent. Jiangsu Agric. Sci. 2016, 44, 358–361. [Google Scholar]

- Xu, H. FLUENT software analyzes the role of the deflector in the wind speed distribution of the fan outlet. South. Agric. Mach. 2015, 46, 31–32. [Google Scholar]

- Zhao, C.; Wu, X.M. Analysis of soil and fertilizer mixing process based on EDEM discrete element method. Chin. J. Agric. Mach. Chem. 2019, 40, 178–182. [Google Scholar]

- Lai, Q.H.; Yu, Q.X.; Dong, J.Y. Dynamic analysis of rotary tiller gearbox based on EDEM, ADAMS and ANSYS. J. Intell. Fuzzy Syst. 2018, 36, 1153–1160. [Google Scholar] [CrossRef]

- Yang, L.W.; Chen, L.S.; Zhang, J.Y.; Zhang, J.Y.; Liu, H.J.; Sun, Z.C.; Sun, H.; Zheng, L.H. Fertilizer sowing simulation of a variable-rate fertilizer applicator based on EDEM. IFAC PapersOnLine 2018, 51, 418–423. [Google Scholar] [CrossRef]

- Morris-Togo, J.; Wang, D.C.; Ma, W.P. Design and Optimization of the Vertical Plate Metering Device for Alfalfa Seeds Precision Based on Engineering Discrete Element Method (EDEM). Innov. Syst. Des. Eng. 2018, 9, 16–22. [Google Scholar]

- Yang, Q.Z.; Shi, L.; Du, G.Y.; Shi, A.P.; Li, W.; Jia, C.P.; Hu, X. A Coupled Simulation Modeling Method of the Working Process of a Wind-Blown Soil Clearing Rattan Machine. Chinese Invention Patent CN 110516307 A, 29 November 2019. [Google Scholar]

| Technical Parameters of the Machine | Parameter Value |

|---|---|

| Chassis width (working along the axis between ridges) | ≤1800 mm |

| Horizontal extension length of airduct (from chassis axis) | ≤1650 mm |

| Length of the whole machine | ≤2000 mm |

| Length of operating system (including tractor) | ≤6000 mm |

| Machine advancement speed | ≥0.4 m·s−1 |

| Electric fan power | 3–20 kW |

| Fan speed | 2500–3500 r·min−1 |

| The fan impeller diameter | 500 mm |

| The airduct section at the end of the airduct | 275 × 180 mm |

| The air speed range | 15–25 m·s−1 |

| Number | Aluminum Box Weight/(g) | Original Soil Weight/(g) | Dry Soil Weight/(g) | Water Weight/(g) | Moisture Content/(%) |

|---|---|---|---|---|---|

| 1 | 11.05 | 41.39 | 37.78 | 3.61 | 8.70 |

| 2 | 11.23 | 40.52 | 37.88 | 3.29 | 8.10 |

| 3 | 10.62 | 41.34 | 36.14 | 5.20 | 12.58 |

| 4 | 11.46 | 40.87 | 35.92 | 4.95 | 12.11 |

| 5 | 10.85 | 40.89 | 37.65 | 3.24 | 7.90 |

| 6 | 10.62 | 40.77 | 37.55 | 3.22 | 7.90 |

| average value | 10.97 | 40.96 | 37.15 | 3.92 | 9.55 |

| Soil Depth/(cm) | Soil Density/(g·cm−3) |

|---|---|

| 0–5 cm | 1.655 |

| 5–10 cm | 1.680 |

| 10–30 cm | 1.645 |

| Parameter | Particle Size Name | |||

|---|---|---|---|---|

| Clod | 10 mm Aggregate | 5 mm Aggregate | Fine Sand | |

| Particle quality/(kg) | 4.8 | 9.2 | 20.7 | 12.3 |

| Percentage of particles/(%) | 10.2 | 19.6 | 44 | 26.2 |

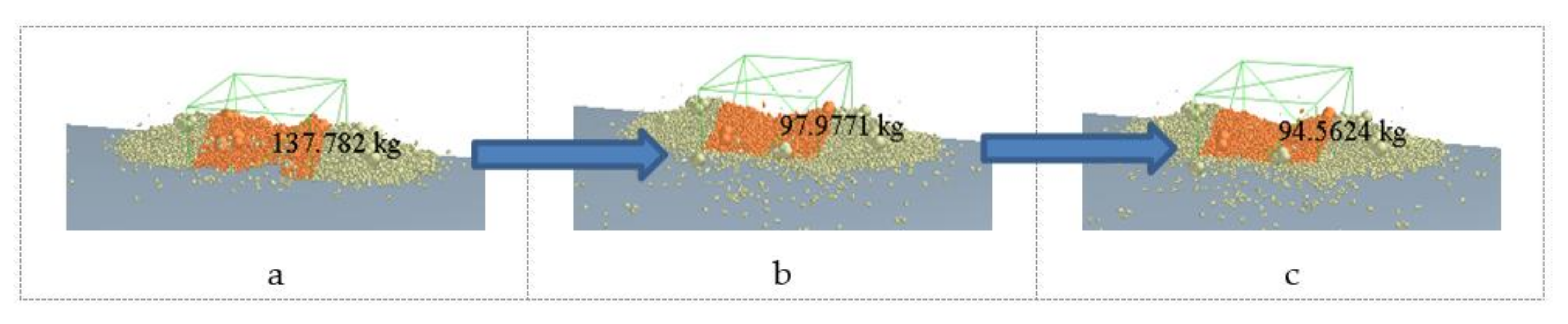

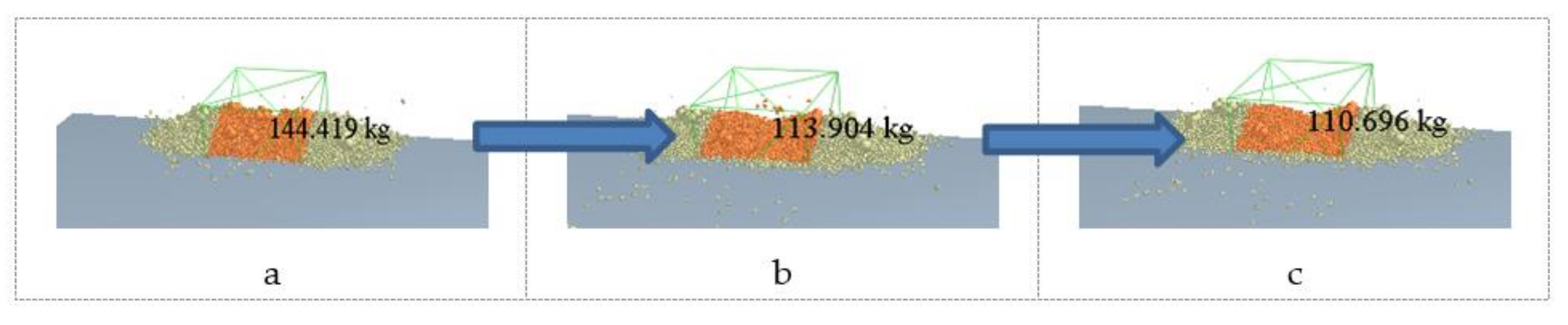

| The Direction Angle of the Duct Mouth | Initial Mass of Soil Ridge/(kg) | Soil Ridge Mass at 0.5 s/(kg) | Soil Ridge Mass at 1.5 s/(kg) | Soil Ridge Mass at 2 s/(kg) |

|---|---|---|---|---|

| 0° | 147.572 | 142.248 | 116.19 | 115.008 |

| 30° | 147.572 | 137.782 | 97.977 | 94.5624 |

| 45° | 147.572 | 144.419 | 113.904 | 110.696 |

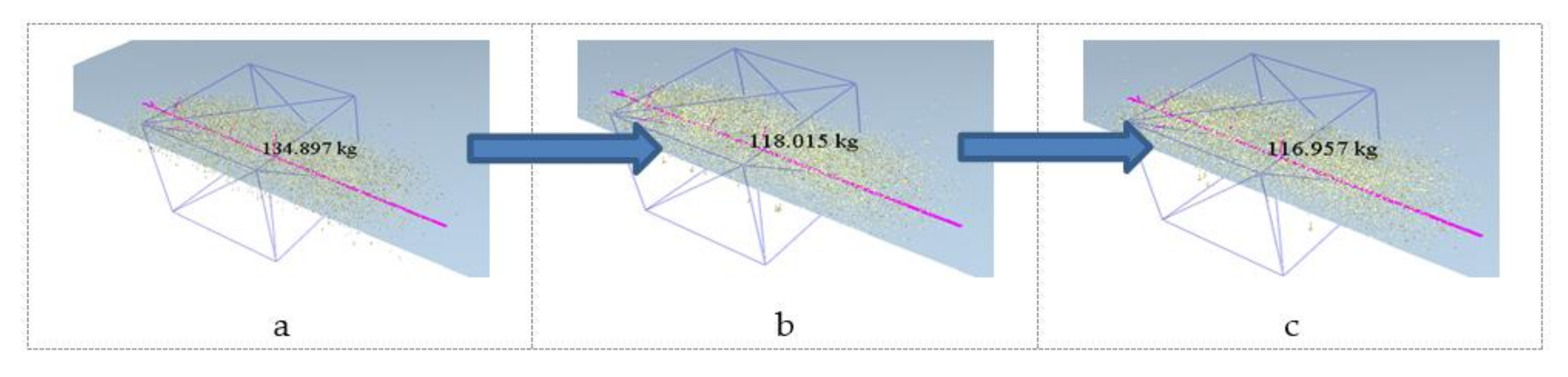

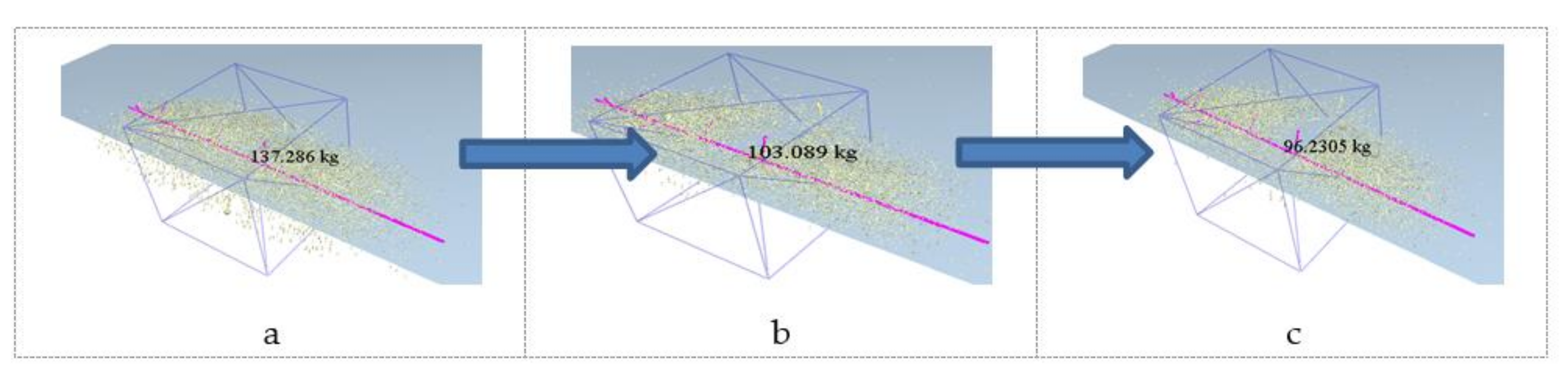

| The Direction Angle of the Duct Mouth | Initial Mass of Soil Ridge/(kg) | Soil Ridge Mass at 0.5 s/(kg) | Soil Ridge Mass at 1.5 s/(kg) | Soil Ridge Mass at 2 s/(kg) |

|---|---|---|---|---|

| 0° | 147.572 | 134.897 | 118.015 | 116.957 |

| 30° | 147.572 | 137.286 | 103.089 | 96.2305 |

| 45° | 147.572 | 139.108 | 112.656 | 111.520 |

| Symbol | Significance | Unit |

|---|---|---|

| φ | The static friction angle | ° |

| nu | The soil Poisson’s ratio | none |

| K0 | The soil lateral pressure coefficient | none |

| Ø | The effective static friction angle of soil | ° |

| G | The soil shear modulus | MN·m−2 |

| E | The soil elastic modulus | kPa |

| v | The moving speed | m·s−1 |

| V | The volume | m3 |

| m | The mass | kg |

| ρ1 | The soil density | kg·m−3 |

| F1 | The force required to push the soil ridge | N |

| s | The covering soil ridge was pushed horizontally along the width | m |

| P | The minimum power required to push the soil ridge | kW |

| W1 | The work required to achieve the above effect | J |

| W2 | Kinetic energy of the fan | J |

| ρ2 | Air density | kg·m−3 |

| Q | Air volume | m3·h−1 |

| v0 | Air outlet speed of fan duct | m·s−1 |

| S | Cross-sectional area of air outlet | m2 |

| I | The wire current | A |

| P’ | Motor-rated power | kW |

| U | Voltage | V |

| Duct Size | Wind Speed Value (m·s−1) |

|---|---|

| Both air inlet and outlet were 215 × 180 mm rectangular tubes | 68.9 |

| Inlet 215 × 180 mm, outlet 180 × 180 mm tapered square tube | 80 |

| Imported 215 × 180 mm, outlet 160 × 160 mm tapered square tube | 103 |

| The Direction Angle of the Duct Mouth | Initial Mass of Soil Ridge/(kg) | Soil Ridge Mass at 0.43 s/(kg) | Soil Ridge Mass at 0.86 s/(kg) | Soil Ridge Mass at 1.72 s/(kg) | Soil Ridge Mass at 2 s/(kg) |

|---|---|---|---|---|---|

| 0° | 292.3 | 285.0 | 251.0 | 213.0 | 201.3 |

| 30° | 292.3 | 288.0 | 252.0 | 200.0 | 194.0 |

| 45° | 292.3 | 289.0 | 255.0 | 201.0 | 195.3 |

| Wind-Blowing Type Soil Cleaner | ||

|---|---|---|

| Cross-Sectional Area before Cleaning/cm2 | Cross-Sectional Area After Cleaning/cm2 | Cleaning Efficiency/% |

| 1111 | 245 | 77.95 |

| 1502 | 354 | 76.43 |

| 1425 | 328 | 76.98 |

| 1175 | 260 | 77.87 |

| 1645 | 390 | 76.29 |

| Average cleaning efficiency/% | 77.10 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; He, M.; Du, G.; Shi, L.; Zhao, X.; Shi, A.; Addy, M. Design and Experimental Study of a Wine Grape Covering Soil-Cleaning Machine with Wind Blowing. AgriEngineering 2021, 3, 50-72. https://doi.org/10.3390/agriengineering3010004

Yang Q, He M, Du G, Shi L, Zhao X, Shi A, Addy M. Design and Experimental Study of a Wine Grape Covering Soil-Cleaning Machine with Wind Blowing. AgriEngineering. 2021; 3(1):50-72. https://doi.org/10.3390/agriengineering3010004

Chicago/Turabian StyleYang, Qizhi, Mingsheng He, Guangyu Du, Lei Shi, Xiaoqi Zhao, Aiping Shi, and Min Addy. 2021. "Design and Experimental Study of a Wine Grape Covering Soil-Cleaning Machine with Wind Blowing" AgriEngineering 3, no. 1: 50-72. https://doi.org/10.3390/agriengineering3010004

APA StyleYang, Q., He, M., Du, G., Shi, L., Zhao, X., Shi, A., & Addy, M. (2021). Design and Experimental Study of a Wine Grape Covering Soil-Cleaning Machine with Wind Blowing. AgriEngineering, 3(1), 50-72. https://doi.org/10.3390/agriengineering3010004