Comparison of Soil–Water Characteristic Curves in One-Dimensional and Isotropic Stress Conditions

Abstract

:1. Introduction

2. Experimental Study

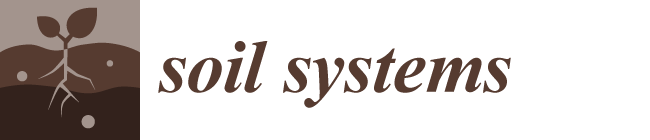

2.1. Soil Material and Specimens

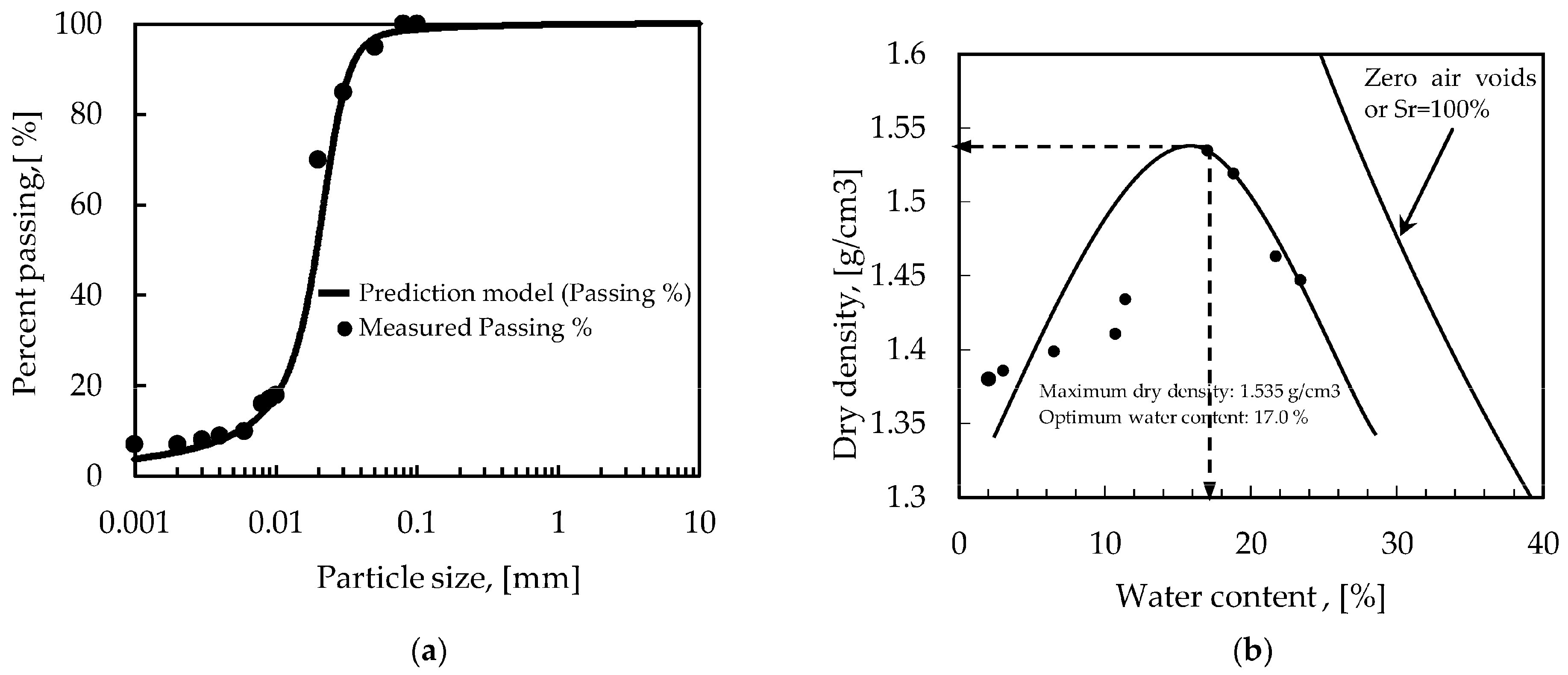

2.2. Apparatus

3. Test Methodology

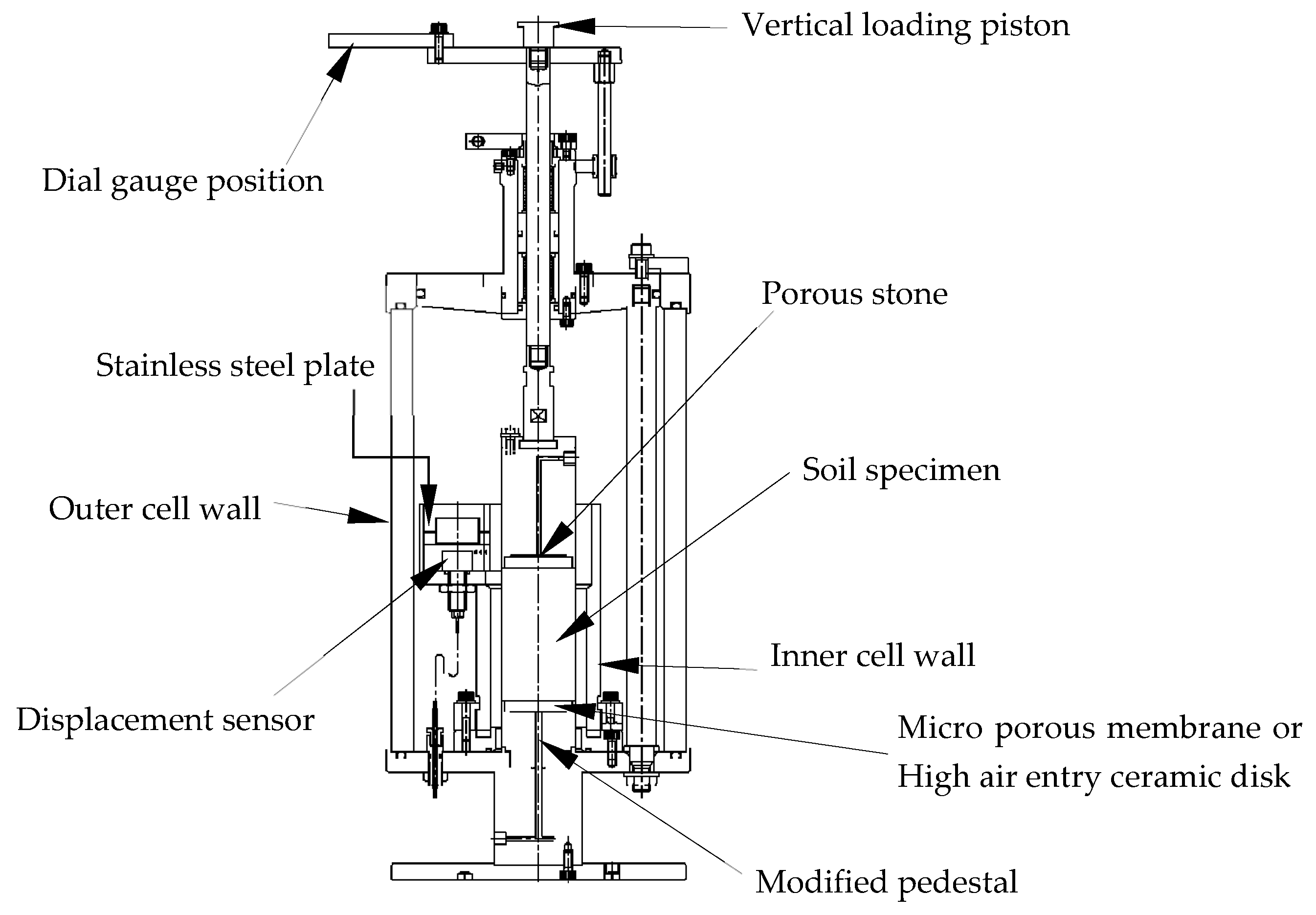

3.1. Microporous Membrane Filter Technique

3.2. Pressure Plate Technique

3.3. Vapour Pressure Technique

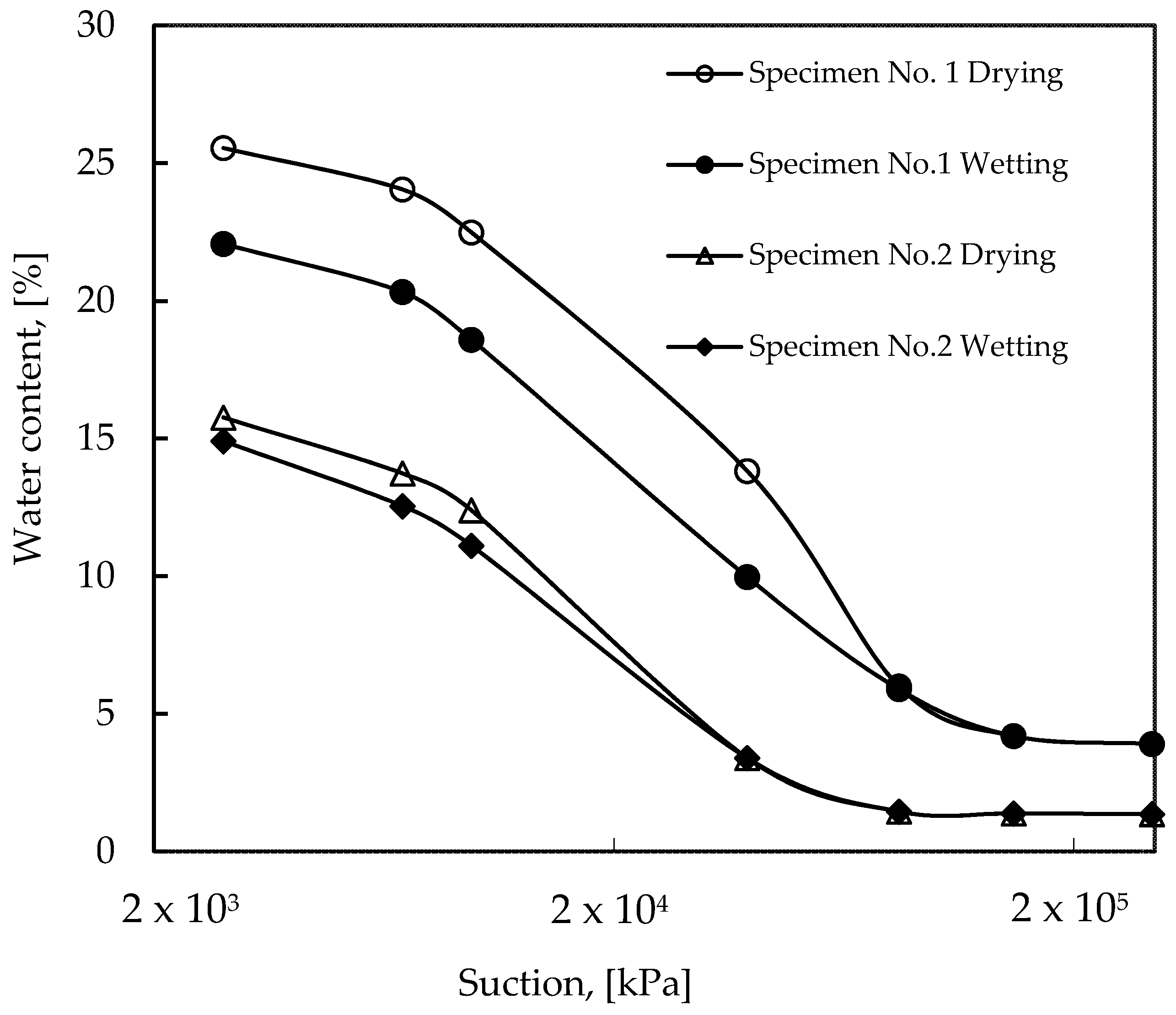

4. Results and Discussion

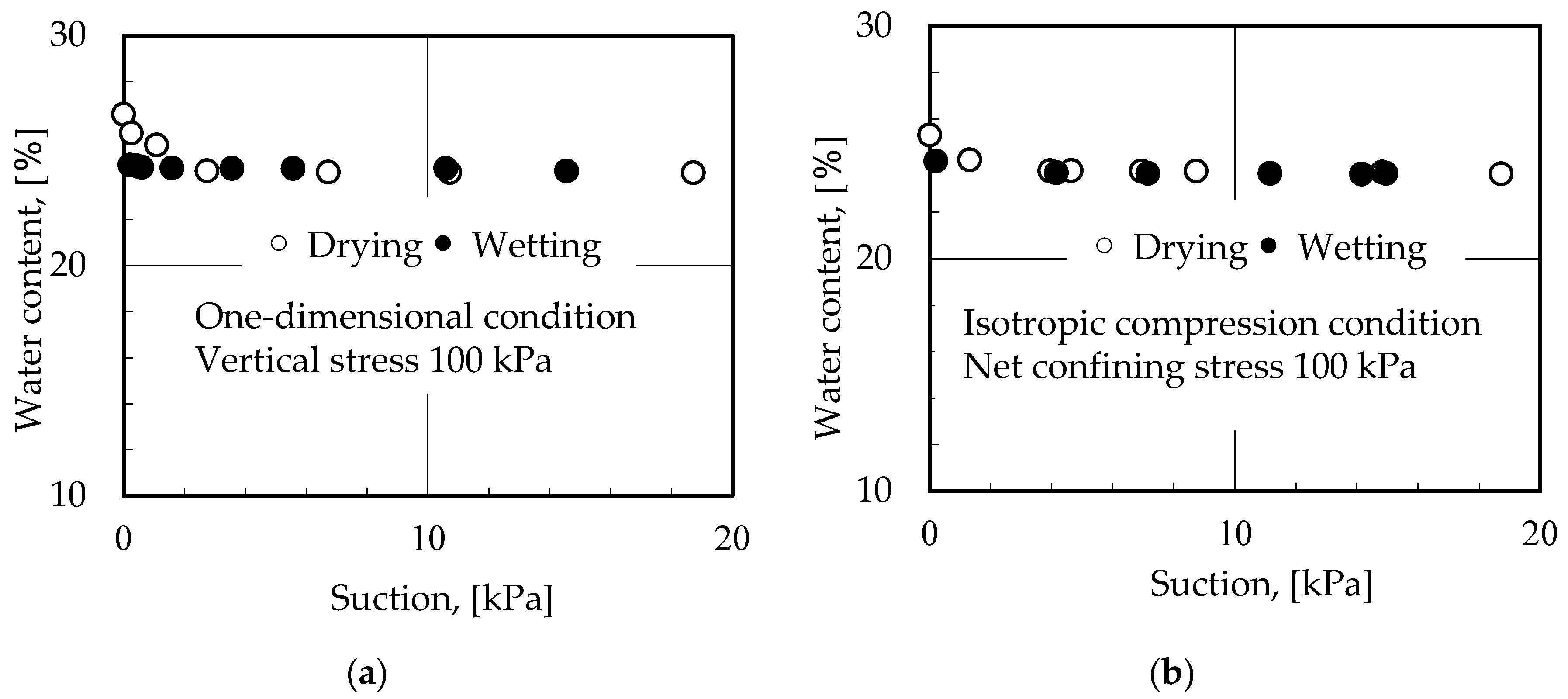

4.1. Relationship between Suction and Water Content of DL-Clay at 100 kPa Stress Conditions

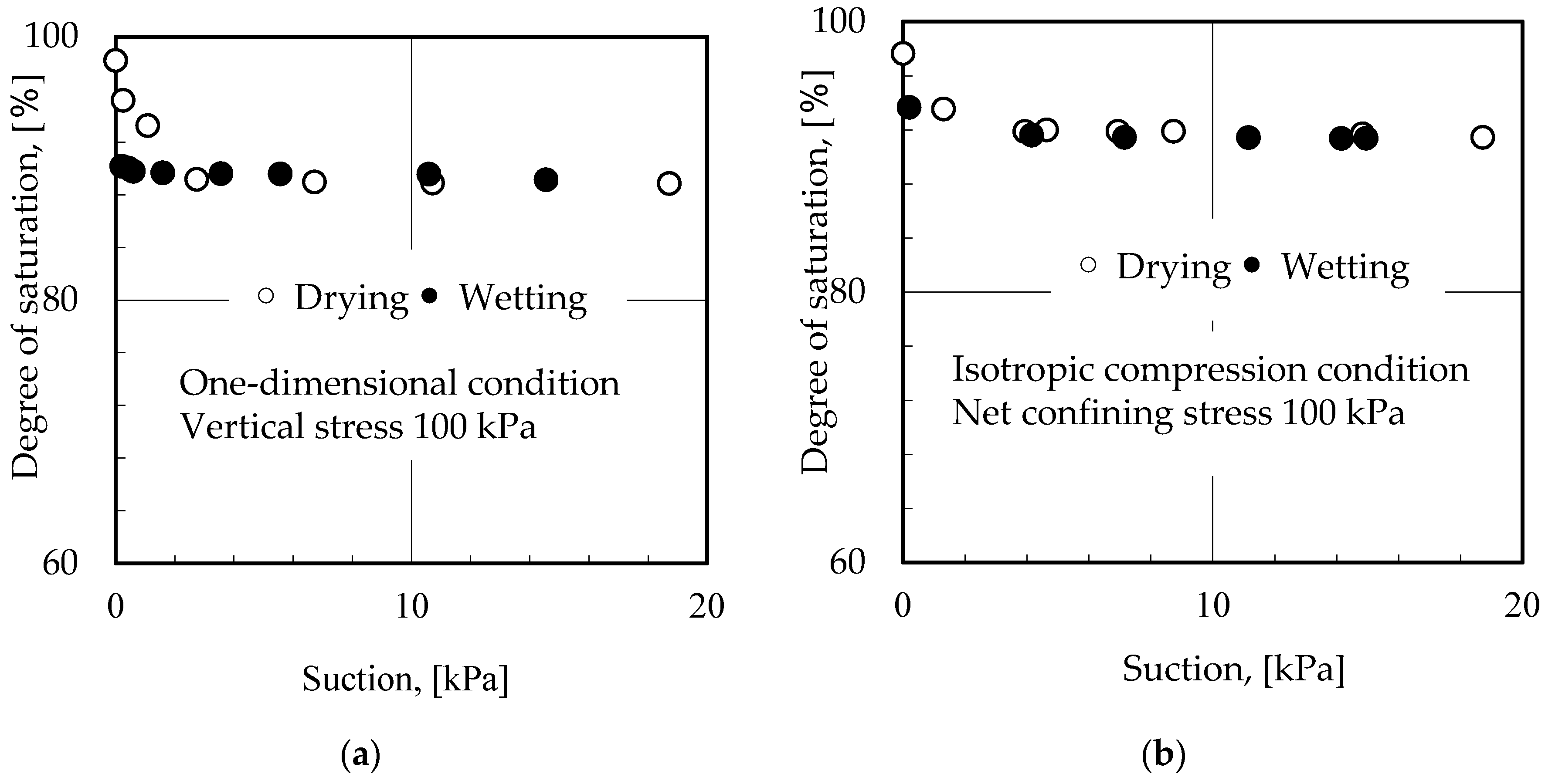

4.2. Relationship between Suction and Degree of Saturation of DL-Clay at 100 kPa Stress Conditions

4.3. Relationship between Suction and Void Ratio of DL-Clay at 100 kPa Stress Conditions

4.4. Soil–Water Characteristic Curves of DL Clay at 300 kPa and 600 kPa Confining Stress Conditions

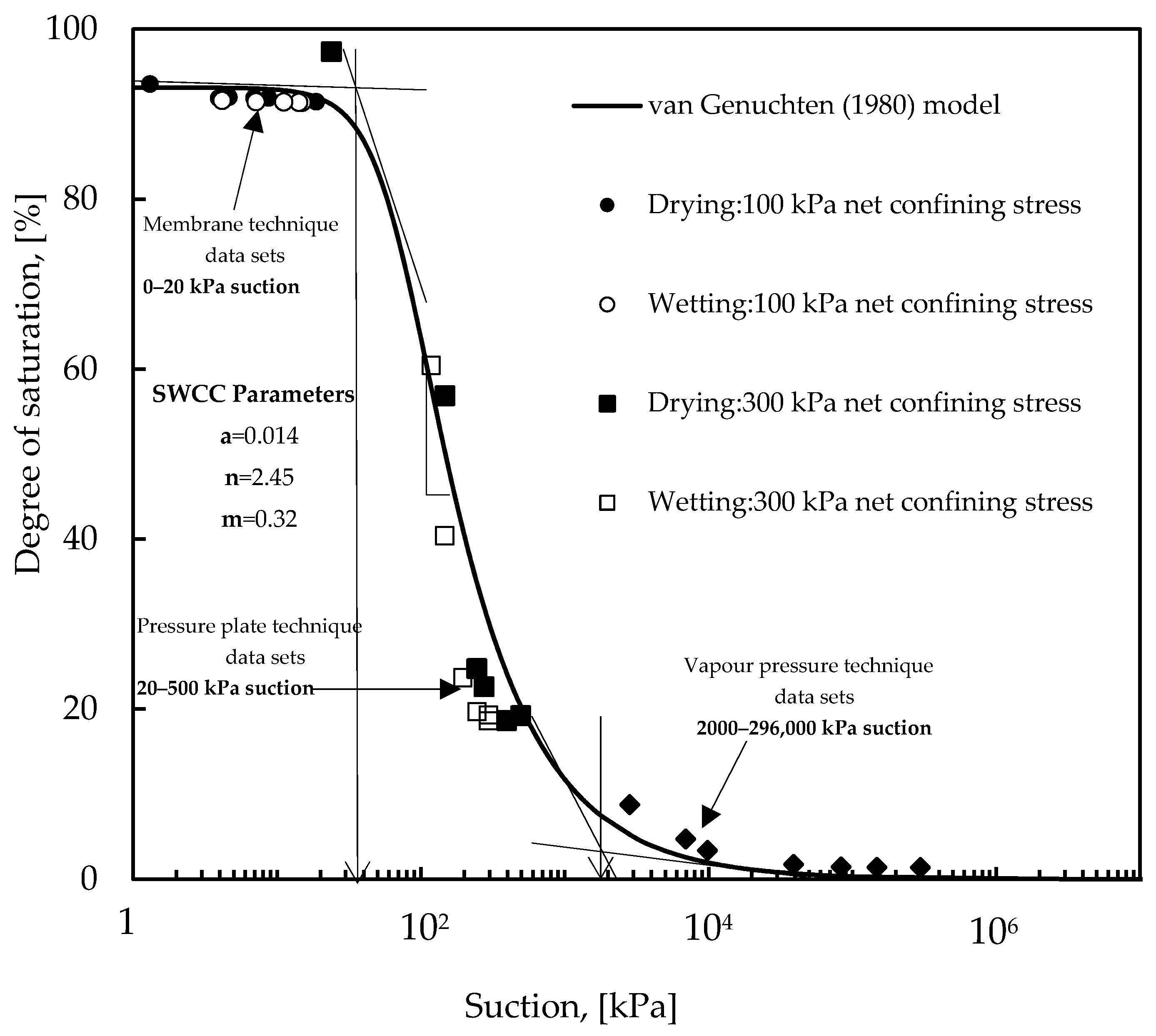

4.5. Soil–Water Characteristic Curves of DL Clay Independent of Stress Conditions

5. Conclusions

- (1)

- The obtained soil–water characteristic curves appears to be affected by the influence of stress conditions (i.e., one-dimensional and isotropic stress conditions). Lateral pressure and confinement of the soil specimen probably induced high retention activities in the soil specimens. Isotropic stress caused the specimen’s void structure to become dense and hence soil moisture flow movement also decreased.

- (2)

- There was negligible hysteresis of the soil–water characteristic curves obtained between void ratio and suction in both stress conditions. Therefore, void ratio seems to have no effect on the shape of the SWCC in both stress conditions. However, void ratio had a significant influence on the relationship between suction and degree of saturation. Furthermore, different stress conditions may not only affect void ratio but also affect the pore structure, pore size distribution, pore shape and pore orientation of the soil specimen. This may have an influence on the soil–water characteristic curves measured.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Fredlund, D.G.; Rahardjo, H. Measurement of soil suction. In Soil Mechanics for Unsaturated Soils; John Wiley & Sons: Hoboken, NJ, USA, 1993; Chapter 4; pp. 64–106. [Google Scholar]

- Leong, E.C.; Rahardjo, H. Review of soil-water characteristic curve equations. J. Geotech. Geoenviron. Eng. ASCE 1997, 123, 1106–1117. [Google Scholar] [CrossRef]

- Escario, V.; Saez, J. The shear strength of partly saturated soils. Geotechnique 1986, 36, 453–456. [Google Scholar] [CrossRef]

- Li, B.; Chen, Y. Influence of dry density on soil-water retention curve of unsaturated soils and its mechanism based on mercury intrusion porosimetry. Trans. Tianjin Univ. 2016, 22, 268–272. [Google Scholar] [CrossRef]

- Nishimura, T.; Koseki, J.; Fredlund, D.G.; Rahardjo, H. Microporous membrane technology for measurement of soil-water characteristic curve. Geotech. Test. J. 2012, 35, 201–208. [Google Scholar]

- Ng, C.W.W.; Wang, B. A new triaxial apparatus for studying stress effects on soil-water characteristics of unsaturated soils. In Proceedings of the 15th International Conference on Soil Mechanics and Geotechnical Engineering, Istanbul, Turkey, 27–31 August 2001; pp. 611–614. [Google Scholar]

- Vanapalli, S.K.; Fredlund, D.G.; Pufahl, D.E. The influence of soil structure and stress history on the soil-water characteristics of a compacted till. Geotechnique 1999, 49, 143–159. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Pang, Y.W. Influence of stress state on soil water characteristics and slope stability. J. Geotech. Geoenviron. 2000, 126, 157–166. [Google Scholar] [CrossRef]

- Chen, Y.L.; Huang, D. Influence of pore structure characteristics on soil-water characteristic curves under different stress states. Chin. J. Eng. 2017, 39, 147–154. [Google Scholar]

- Tavakoli, D.M.H.; Habibagahi, G.; Nikooee, E. Effect of confining stress on soil water retention curve and its impact on the shear strength of unsaturated soils. Vadose Zone J. 2014, 13, 1–11. [Google Scholar]

- Oh, S.; Lu, N. Uniqueness of the suction stress characteristic curve under different confining stress conditions. Vadose Zone J. 2014, 13. [Google Scholar] [CrossRef]

- Zhou, J.; Yu, J.L. Influences affecting the soil-water characteristic curve. J. Zhejiang Univ. Sci. 2005, 6, 797–804. [Google Scholar] [CrossRef]

- Nishimura, T.; Fredlund, D.G. Failure envelope of a desiccated, unsaturated silty soil. In Proceedings of the 15th International Conference on Soil Mechanics and Geotechnical Engineering, Istanbul, Turkey, 27–31 August 2001; Volume 1, pp. 615–618. [Google Scholar]

- Uchimura, T.; Gizachew, G.; Wang, L.; Nishie, S.; Seko, I. Deformation and water seepage observed in a natural slope during failure process by artificial heavy rainfall. In Proceedings of the 18th International Conference for Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013; pp. 2273–2274. [Google Scholar]

- Ishikawa, T.; Zhang, Y.; Tokoro, T.; Miura, S. Medium-size triaxial apparatus for unsaturated granular subbase course materials. Soils Found. 2014, 54, 67–80. [Google Scholar] [CrossRef]

- Wang, H.; Koseki, J.; Sato, T.; Chiaro, G.; Tan, T.J. Effect of saturation on liquefaction resistance of iron ore fines and sandy soils. Soils Found. 2016, 56, 732–744. [Google Scholar] [CrossRef]

- Wenjing, S.; De’an, S.; Lei, F.; Shiqing, L. Soil-water characteristics of Gaomiaozi bentonite by vapour equilibrium technique. J. Rock Mech. Geotech. Eng. 2014, 6, 48–54. [Google Scholar]

- Oteo, M.C.; Saez, A.; Esteban, F. Laboratory tests and equipment with suction control. In Proceedings of the 1st International Conference on Unsaturated Soils, Paris, France, 6–8 September 1995; Volume 3, pp. 1509–1515. [Google Scholar]

- Delage, P.; Romero, E.E.; Tarantino, A. Recent developments in the techniques of controlling and measuring suction in unsaturated soils. In Proceedings of the 1st European Conference on Unsaturated Soils, Durham, UK, 2–4 July 2008; pp. 33–52. [Google Scholar]

- Nishimura, T.; Fredlund, D.G. A new triaxial apparatus for high total suction using relative humidity control. In Proceedings of the 12th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering, Singapore, 4–8 August 2003; pp. 65–68. [Google Scholar]

- Vanapalli, S.K.; Sillers, W.S.; Fredlund, M.D. The meaning and relevance of residual water content to unsaturated soils. In Proceedings of the 51st Canadian Geotechnical Conference, Edmonton, AB, Canada, 4–7 October 1998; pp. 101–108. [Google Scholar]

- Delage, P.; Lefebvre, G. Study of the structure of a sensitive Champlain clay and of its evolution during consolidation. Can. Geotech. J. 1984, 21, 21–35. [Google Scholar] [CrossRef]

- Zhou, C.; Ng, C.W.W. A new and simple stress-dependent water retention model for unsaturated soil. Comput. Geotech. 2014, 62, 216–222. [Google Scholar] [CrossRef]

| Specific gravity | 2.65 |

| Percentage of sand fraction % | 1.00 |

| Percentage of silt fraction % | 87.00 |

| Percentage of clay fraction % | 12.00 |

| Fine component % | 99.00 |

| Mean grain diameter of silt D50 mm | 0.02 |

| Void ratio | 0.726 |

| Liquid limit % | 24.70 |

| Plastic limit % | 22.80 |

| Plasticity index | 1.90 |

| Unified Soil Classification System | ML |

| Maximum dry density g/cm3 | 1.53 |

| Optimum water content % | 17.00 |

| Measurement Method | Authors | Suction Range (kPa) | Total Number of Tests Conducted |

|---|---|---|---|

| Membrane Filter Technique | Nishimura et al. 2012 | 0–20 | 14 |

| Pressure Plate Technique | Fredlund & Rahardjo, 1993 | 20–500 | 1 |

| Vapour Pressure Technique, VPT | Delage et al. 1998 | 2000–296,000 | 1 |

| Membrane Type | Membrane Pore Size (μm) | Membrane Thickness (μm) | Provided AEV (kPa) | Supplied Air Pressure (kPa) | Enduring Time (h) |

|---|---|---|---|---|---|

| Supor 450 | 0.45 | 140 | 250 | 20 | 240 |

| Salt Solution Name | Chemical Name | Real RH% at Atmospheric Temp | Real RH% at Vacuum | Suction in Theory kPa | Suction in Theory MPa |

|---|---|---|---|---|---|

| Potassium Sulphate | K2SO4 | 99 | 81 | 2830 | 2.83 |

| Potassium Nitrate | KNO3 | 99 | 94 | 6940 | 6.94 |

| Ammonium Dihydrogenphosphate | NH4H2PO4 | 48 | 45 | 9800 | 9.8 |

| Sodium Chloride | NaCl | 89 | 51 | 39,000 | 39 |

| Magnesium Nitrate | Mg(NO3)2·6H2O | 66 | 59 | 83,400 | 83.4 |

| Magnesium Chloride | MgCl2·6H2O | 39 | 38 | 148,000 | 148 |

| Lithium Chloride | LiCl | 40 | 21 | 296,000 | 296 |

| Name of Soil | Initial Water Content (%) | Residual Water Content (%) | Air Entry Value, ψi (kPa) | Residual Suction, ψr (kPa) |

|---|---|---|---|---|

| Silt | 17 | 2 | 1000 | 2200 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habasimbi, P.; Nishimura, T. Comparison of Soil–Water Characteristic Curves in One-Dimensional and Isotropic Stress Conditions. Soil Syst. 2018, 2, 43. https://doi.org/10.3390/soilsystems2030043

Habasimbi P, Nishimura T. Comparison of Soil–Water Characteristic Curves in One-Dimensional and Isotropic Stress Conditions. Soil Systems. 2018; 2(3):43. https://doi.org/10.3390/soilsystems2030043

Chicago/Turabian StyleHabasimbi, Paul, and Tomoyoshi Nishimura. 2018. "Comparison of Soil–Water Characteristic Curves in One-Dimensional and Isotropic Stress Conditions" Soil Systems 2, no. 3: 43. https://doi.org/10.3390/soilsystems2030043

APA StyleHabasimbi, P., & Nishimura, T. (2018). Comparison of Soil–Water Characteristic Curves in One-Dimensional and Isotropic Stress Conditions. Soil Systems, 2(3), 43. https://doi.org/10.3390/soilsystems2030043