Enhancing Diesel Engine Performance Through Hydrogen Addition

Abstract

1. Introduction

2. Materials and Methods

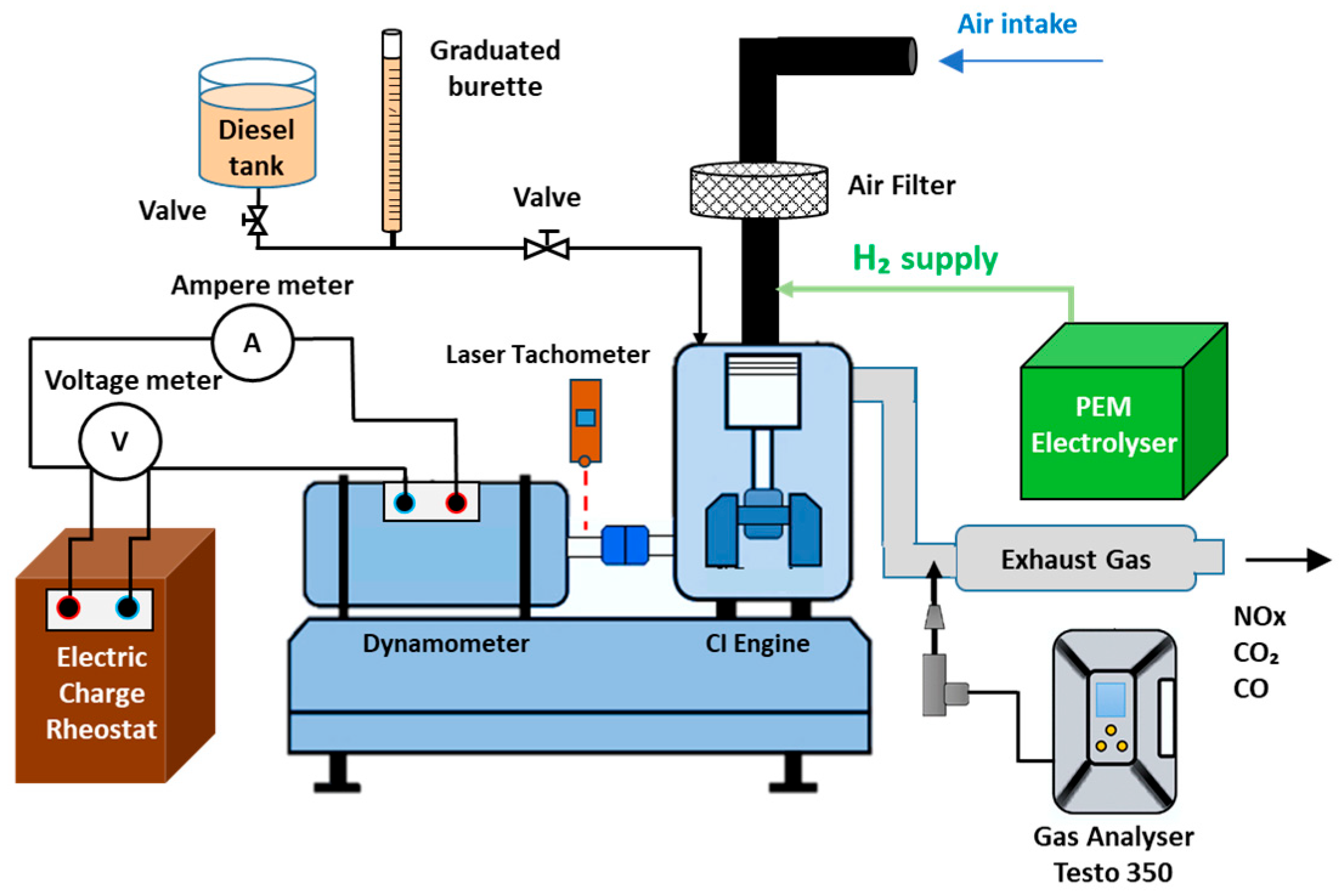

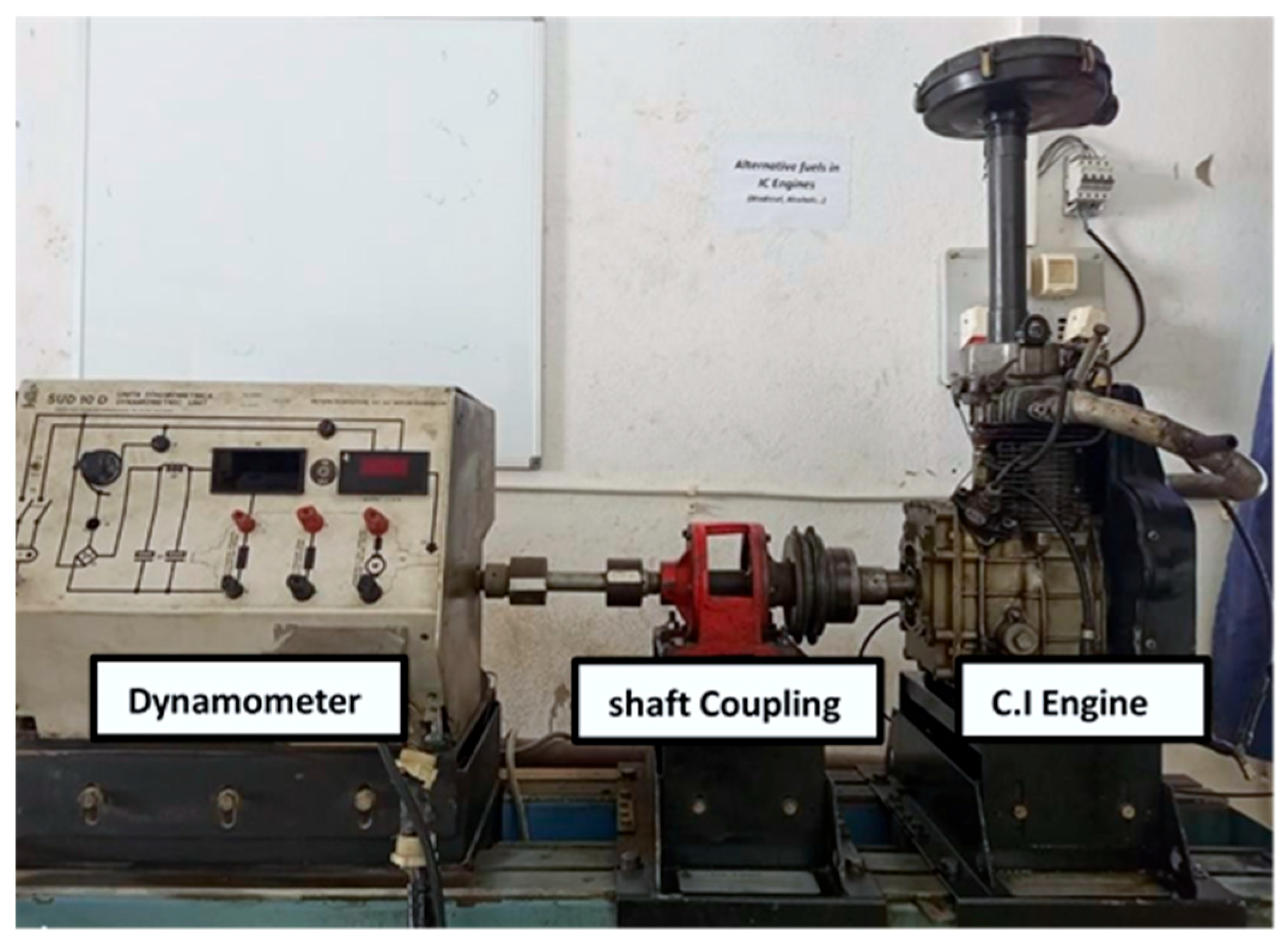

2.1. Experimental Setup

2.2. Engine Characteristics

2.3. Uncertainty Analysis

2.4. Definition of Important Parameters

3. Results and Discussion

3.1. Performance Characteristics

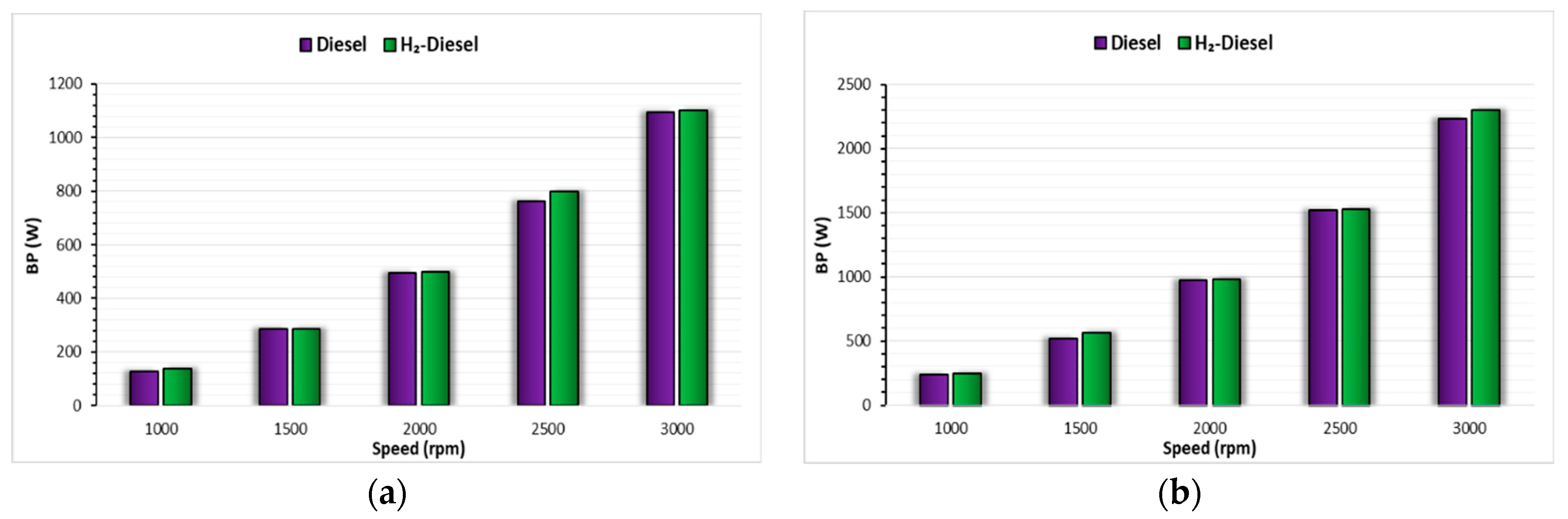

3.1.1. Brake Power

3.1.2. Specific Fuel Consumption

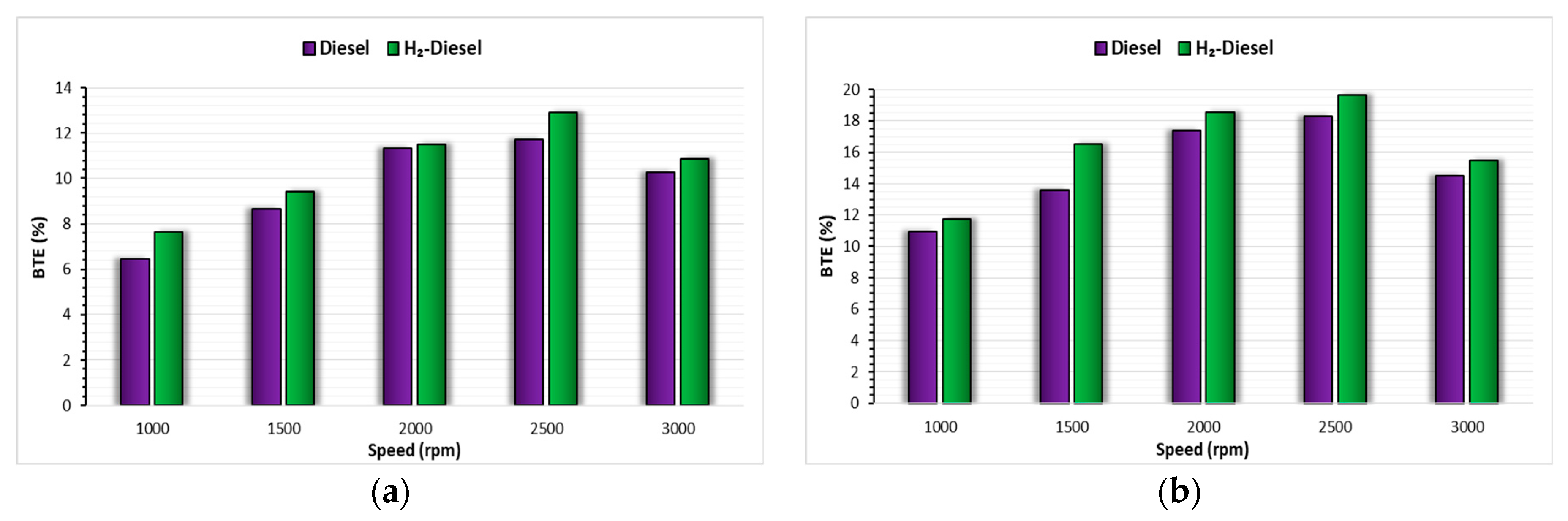

3.1.3. Brake Thermal Efficiency

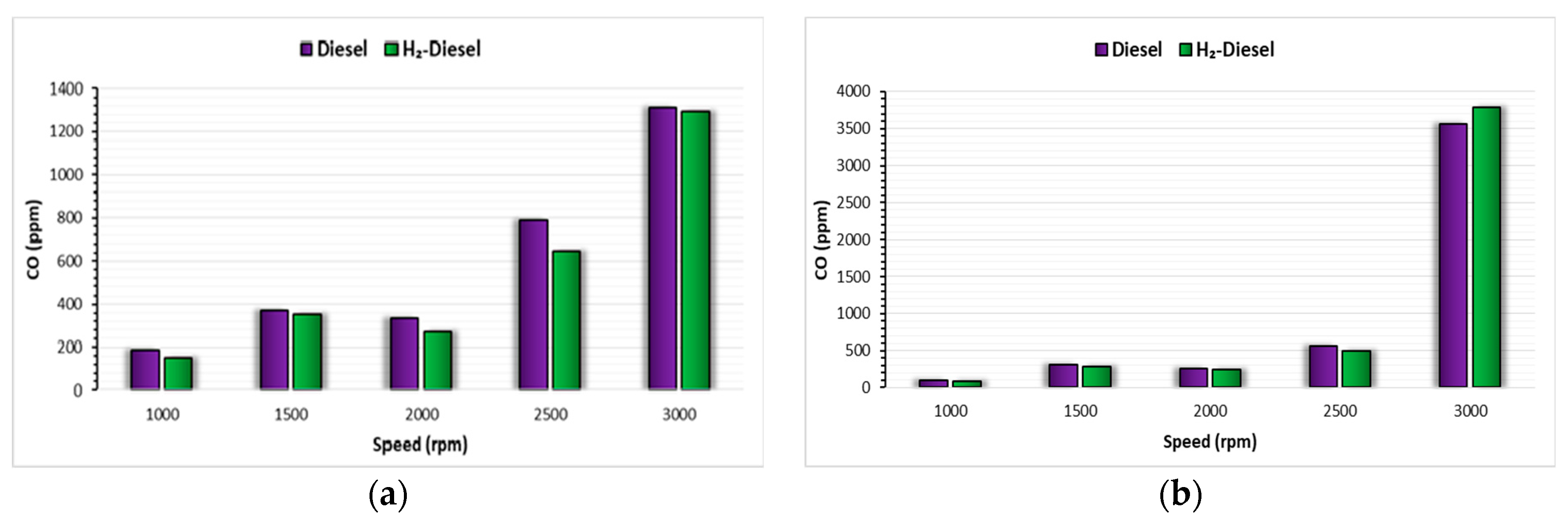

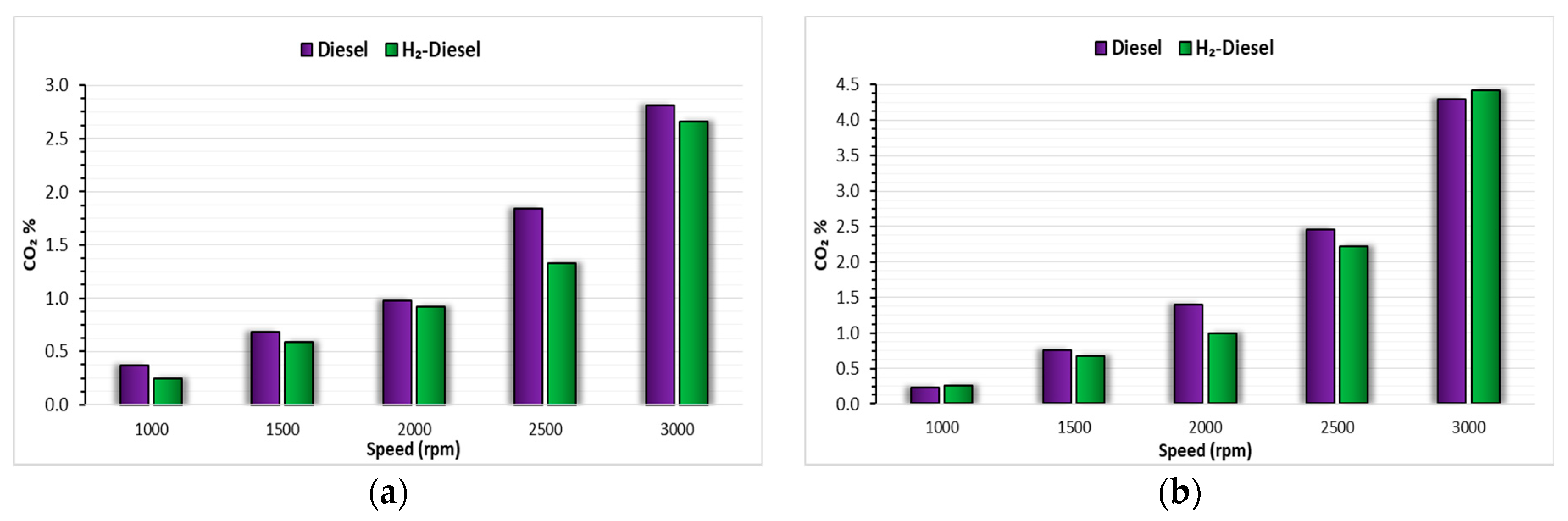

3.2. Emission Characteristics

3.2.1. Carbon Monoxide

3.2.2. Carbon Dioxide

3.2.3. Nitrogen Oxides

3.3. Comparison of Emission Levels with Standard Limits

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, M.B.; Kazim, A.H.; Farooq, M.; Javed, K.; Shabbir, A.; Zahid, R.; Fatima, S.; Danish, M.R.; Ali, Q.; Chaudhry, I.A.; et al. Impact of HHO Gas Enrichment and High Purity Biodiesel on the Performance of a 315 Cc Diesel Engine. Int. J. Hydrogen Energy 2021, 46, 19633–19644. [Google Scholar] [CrossRef]

- Kumar, G.; Sivagurunathan, P.; Pugazhendhi, A.; Thi, N.B.D.; Zhen, G.; Chandrasekhar, K.; Kadier, A. A Comprehensive Overview on Light Independent Fermentative Hydrogen Production from Wastewater Feedstock and Possible Integrative Options. Energy Convers. Manag. 2017, 141, 390–402. [Google Scholar] [CrossRef]

- Kalghatgi, G. Is it the end of combustion and engine combustion research? Should it be? Transp. Eng. 2022, 10, 100142. [Google Scholar] [CrossRef]

- Yuan, H.; Ma, M.; Zhou, N.; Xie, H.; Ma, Z.; Xiang, X.; Ma, X. Battery Electric Vehicle Charging in China: Energy Demand and Emissions Trends in the 2020s. Appl. Energy 2024, 365, 123153. [Google Scholar] [CrossRef]

- Amer, M.; Masri, J.; Dababat, A.; Sajjad, U.; Hamid, K. Electric Vehicles: Battery Technologies, Charging Standards, AI Communications, Challenges, and Future Directions. Energy Convers. Manag. X 2024, 24, 100751. [Google Scholar] [CrossRef]

- Alaya, M.; Ennetta, R.; Said, R. Numerical Investigation of the Effect of Hydrogen Addition on Methane Flame Velocity and Pollutant Emissions Using Several Detailed Reaction Mechanisms. Emiss. Control Sci. Technol. 2018, 4, 321–329. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Verma, T.N.; Pugazhendhi, A. Performance and Emission Analysis of a Diesel Engine Using Hydrogen Enriched N-Butanol, Diethyl Ester and Spirulina Microalgae Biodiesel. Fuel 2020, 271, 117645. [Google Scholar] [CrossRef]

- Ulugbekovich, Y.S. Influence of High Oxygenated Biofuelson Micro Gas Turbine Engine for Reduced Emission. In Proceedings of the International Conference on Modern Science and Scientific Studies, Online, 4–5 May 2023; Volume 2, pp. 220–223. [Google Scholar]

- Huang, H.; Sun, X.; Li, J.; Yu, B.; Wang, X.; Pu, M.; Ma, L. Economic Analysis of Blending Hydrogen into Natural Gas Pipelines: Supply Chain and Station Modification. Int. J. Hydrogen Energy 2025, 118, 300–311. [Google Scholar] [CrossRef]

- Zacepins, A.; Kotovs, D.; Komasilovs, V.; Kviesis, A. Economic Modelling of Mixing Hydrogen with Natural Gas. Processes 2024, 12, 262. [Google Scholar] [CrossRef]

- Bakar, R.A.; Kadirgama, K.; Ramasamy, D.; Yusaf, T.; Kamarulzaman, M.K.; Aslfattahi, N.; Samylingam, L.; Alwayzy, S.H. Experimental Analysis on the Performance, Combustion/Emission Characteristics of a DI Diesel Engine Using Hydrogen in Dual Fuel Mode. Int. J. Hydrogen Energy 2024, 52, 843–860. [Google Scholar] [CrossRef]

- Liu, X.; Srna, A.; Yip, H.L.; Kook, S.; Chan, Q.N.; Hawkes, E.R. Performance and Emissions of Hydrogen-Diesel Dual Direct Injection (H2DDI) in a Single-Cylinder Compression-Ignition Engine. Int. J. Hydrogen Energy 2021, 46, 1302–1314. [Google Scholar] [CrossRef]

- Dimitriou, P.; Kumar, M.; Tsujimura, T.; Suzuki, Y. Combustion and Emission Characteristics of a Hydrogen-Diesel Dual-Fuel Engine. Int. J. Hydrogen Energy 2018, 43, 13605–13617. [Google Scholar] [CrossRef]

- Gültekin, N.; Gülcan, H.E.; Ciniviz, M. Investigation of the Effects of Hydrogen Energy Ratio and Valve Lift Amount on Performance and Emissions in a Hydrogen-Diesel Dual-Fuel Compression Ignition Engine. Int. J. Hydrogen Energy 2024, 49, 352–366. [Google Scholar] [CrossRef]

- Luo, J.; Liu, Z.; Wang, J.; Xu, H.; Tie, Y.; Yang, D.; Zhang, Z.; Zhang, C.; Wang, H. Investigation of Hydrogen Addition on the Combustion, Performance, and Emission Characteristics of a Heavy-Duty Engine Fueled with Diesel/Natural Gas. Energy 2022, 260, 125082. [Google Scholar] [CrossRef]

- Gültekin, N.; Ciniviz, M. Experimental Investigation of the Effect of Hydrogen Ratio on Engine Performance and Emissions in a Compression Ignition Single Cylinder Engine with Electronically Controlled Hydrogen-Diesel Dual Fuel System. Int. J. Hydrogen Energy 2023, 48, 25984–25999. [Google Scholar] [CrossRef]

- Abdelwahed, S.B.; Gassoumi, M.; Hamdi, F.; Ennetta, R. Experimental Assessment of the Effects of Water Quality and PV Panel Orientation on Green Hydrogen Production. Int. J. Thermofluids 2025, 26, 101118. [Google Scholar] [CrossRef]

- Hamdi, F.; Yahya, I.; Gassoumi, M.; Fazal, A.; Ennetta, R.; Soyhan, H.S. Engine Performance and Emission Characteristics of Microwave-Produced Biodiesel Blends. Therm. Sci. 2024, 28, 1753–1766. [Google Scholar] [CrossRef]

- Hamdi, F.; Yahya, I.; Gassoumi, M.; Boutar, Z.; Shah, R.M.R.A.; Al Qubeissi, M.; Ennetta, R.; Soyhan, H.S. Effects of Ethanol Addition to Diesel–Biodiesel Blends on the CI Engine Characteristics. Sci. Technol. Energy Transit. 2024, 79, 33. [Google Scholar] [CrossRef]

- Zhou, J.H.; Cheung, C.S.; Zhao, W.Z.; Leung, C.W. Diesel–Hydrogen Dual-Fuel Combustion and Its Impact on Unregulated Gaseous Emissions and Particulate Emissions under Different Engine Loads and Engine Speeds. Energy 2016, 94, 110–123. [Google Scholar] [CrossRef]

- Akhtar, M.U.S.; Asfand, F.; Khan, M.I.; Mishra, R.; Ball, A.D. Performance and Emissions Characteristics of Hydrogen-Diesel Dual-Fuel Combustion for Heavy-Duty Engines. Int. J. Hydrogen Energy 2025, in press. [Google Scholar] [CrossRef]

- Haroun, A.K.; Abdul-Hadi, S.N. Experimental Investigation of the Effect of Hydrogen Manifold Injection on the Performance of Compression Ignition Engines World Academy of Science. Eng. Technol. 2011, 76, 277–282. [Google Scholar]

- Ghazal, O.H. Combustion Analysis of Hydrogen-Diesel Dual Fuel Engine with Water Injection Technique. Case Stud. Therm. Eng. 2019, 13, 100380. [Google Scholar] [CrossRef]

- Shadidi, B.; Najafi, G.; Yusaf, T. A Review of Hydrogen as a Fuel in Internal Combustion Engines. Energies 2021, 14, 6209. [Google Scholar] [CrossRef]

- Ghazal, O.H. Performance and Combustion Characteristic of CI Engine Fueled with Hydrogen Enriched Diesel. Int. J. Hydrogen Energy 2013, 38, 15469–15476. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Aydin, M. Experimental Investigation on the Performance, Combustion and Exhaust Emission Characteristics of a Compression-Ignition Engine Fueled with Cottonseed Oil Biodiesel/Diethyl Ether/Diesel Fuel Blends. Energy Convers. Manag. 2020, 205, 112355. [Google Scholar] [CrossRef]

- Aldarwish, Z.; Aghkhani, M.H.; Sadrnia, H.; Zareei, J. Investigation of the Optimal Timing and Amount of Fuel Injection on the Efficiency and Emissions of a Diesel Engine through Experimentation and Numerical Analysis. Heliyon 2024, 10, e38790. [Google Scholar] [CrossRef]

- Hamdan, M.O.; Selim, M.Y.; Al-Omari, S.-A.; Elnajjar, E. Hydrogen Supplement Co-Combustion with Diesel in Compression Ignition Engine. Renew. Energy 2015, 82, 54–60. [Google Scholar] [CrossRef]

- Karagöz, Y.; Sandalcı, T.; Yüksek, L.; Dalkılıç, A.S.; Wongwises, S. Effect of Hydrogen–Diesel Dual-Fuel Usage on Performance, Emissions and Diesel Combustion in Diesel Engines. Adv. Mech. Eng. 2016, 8, 168781401666445. [Google Scholar] [CrossRef]

- Debnath, B.K.; Saha, U.K.; Sahoo, N. Effect of Hydrogen-Diesel Quantity Variation on Brake Thermal Efficiency of a Dual Fuelled Diesel Engine. J. Power Technol. 2012, 92, 55. [Google Scholar]

- Deheri, C.; Acharya, S.K.; Thatoi, D.N.; Mohanty, A.P. A Review on Performance of Biogas and Hydrogen on Diesel Engine in Dual Fuel Mode. Fuel 2020, 260, 116337. [Google Scholar] [CrossRef]

- Salek, F.; Babaie, M.; Hosseini, S.V.; Bég, O.A. Multi-Objective Optimization of the Engine Performance and Emissions for a Hydrogen/Gasoline Dual-Fuel Engine Equipped with the Port Water Injection System. Int. J. Hydrogen Energy 2021, 46, 10535–10547. [Google Scholar] [CrossRef]

- He, L.; Jingyuan, L.; Xiumin, Y.; Mengliang, L.; Tian, Y. Numerical Study on Combustion and Emission Characteristics of a PFI Gasoline Engine with Hydrogen Direct-Injection. Energy Procedia 2019, 158, 1449–1454. [Google Scholar] [CrossRef]

- Gültekin, N.; Ciniviz, M. Examination of the Effect of Combustion Chamber Geometry and Mixing Ratio on Engine Performance and Emissions in a Hydrogen-Diesel Dual-Fuel Compression-Ignition Engine. Int. J. Hydrogen Energy 2023, 48, 2801–2820. [Google Scholar] [CrossRef]

- Köse, H.; Ciniviz, M. An Experimental Investigation of Effect on Diesel Engine Performance and Exhaust Emissions of Addition at Dual Fuel Mode of Hydrogen. Fuel Process. Technol. 2013, 114, 26–34. [Google Scholar] [CrossRef]

- Jamrozik, A.; Grab-Rogaliński, K.; Tutak, W. Hydrogen Effects on Combustion Stability, Performance and Emission of Diesel Engine. Int. J. Hydrogen Energy 2020, 45, 19936–19947. [Google Scholar] [CrossRef]

- Saxena, M.R.; Maurya, R.K.; Mishra, P. Assessment of Performance, Combustion and Emissions Characteristics of Methanol-Diesel Dual-Fuel Compression Ignition Engine: A Review. J. Traffic Transp. Eng. (Engl. Ed.) 2021, 8, 638–680. [Google Scholar] [CrossRef]

- Ge, J.C.; Kim, J.Y.; Yoo, B.O.; Song, J.H. Effects of Engine Load and Ternary Mixture on Combustion and Emissions from a Diesel Engine Using Later Injection Timing. Sustainability 2023, 15, 1391. [Google Scholar] [CrossRef]

- Al-Shahrany, A.S.; Hassan, A.S. Influence of Combustion Chamber Design Parameters and Intake Environments on Spark Ignition Engine Performance and Exhaust Gas Emission. Open J. Appl. Sci. 2022, 12, 930–943. [Google Scholar] [CrossRef]

- Cernat, A.; Pana, C.; Negurescu, N.; Lazaroiu, G.; Nutu, C.; Fuiorescu, D. Hydrogen—An Alternative Fuel for Automotive Diesel Engines Used in Transportation. Sustainability 2020, 12, 9321. [Google Scholar] [CrossRef]

- Hassan, A.S.A.; Al-Shahrany, A.S. Effect of Intake Conditions and Combustion Factors on Gasoline and Diesel Engines Performance and Exhaust Emissions. J. Eng. Appl. Sci. 2024, 11, 133–140. [Google Scholar] [CrossRef]

- Diaz, G.J.A.; Montoya, J.P.G.; Martinez, L.A.C.; Olsen, D.B.; Navarro, A.S. Influence of Engine Operating Conditions on Combustion Parameters in a Spark Ignited Internal Combustion Engine Fueled with Blends of Methane and Hydrogen. Energy Convers. Manag. 2019, 181, 414–424. [Google Scholar] [CrossRef]

- Kakoee, A.; Bakhshan, Y.; Aval, S.M.; Gharehghani, A. An Improvement of a Lean Burning Condition of Natural Gas/Diesel RCCI Engine with a Pre-Chamber by Using Hydrogen. Energy Convers. Manag. 2018, 166, 489–499. [Google Scholar] [CrossRef]

- Gad, M.S.; Razek, S.A. Impact of HHO Produced from Dry and Wet Cell Electrolyzers on Diesel Engine Performance, Emissions and Combustion Characteristics. Int. J. Hydrogen Energy 2021, 46, 22277–22291. [Google Scholar] [CrossRef]

- Talibi, M.; Hellier, P.; Morgan, R.; Lenartowicz, C.; Ladommatos, N. Hydrogen-Diesel Fuel Co-Combustion Strategies in Light Duty and Heavy Duty CI Engines. Int. J. Hydrogen Energy 2018, 43, 9046–9058. [Google Scholar] [CrossRef]

- Regulation-2016/1628-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/eli/reg/2016/1628/oj/eng (accessed on 9 May 2025).

- Pilusa, T.J.; Mollagee, M.M.; Muzenda, E. Reduction of Vehicle Exhaust Emissions from Diesel Engines Using the Whale Concept Filter. Aerosol Air Qual. Res. 2012, 12, 994–1006. [Google Scholar] [CrossRef]

| Parameter | Specification |

|---|---|

| Engine model | Lombardini 6LD325N |

| Power | 5 kW |

| Maximum speed | 3500 rpm |

| Maximum torque | 14 Nm at 2100 rpm |

| Stroke | 4 |

| Capacity | 325 cm3 |

| Compression ratio | 18:1 |

| Injection type | Direct |

| Cooling type | Forced air-cooled system |

| Measured Parameter | Measurement Instrument | Uncertainty |

|---|---|---|

| Engine speed | VT-8204 optical tachometer | ±0.3 |

| Diesel flow rate | Graduated burette | ±1.0 |

| Torque | Dynamometer | ±1.0 |

| CO | Testo 350 gas analyzer | ±3.4 |

| CO2 | Testo 350 gas analyzer | ±0.34 |

| NOx | Testo 350 gas analyzer | ±0.1 |

| Properties | Hydrogen | Diesel |

|---|---|---|

| Critical pressure (Pa) | 1.3 × 106 | 2.46 × 106 |

| Critical temperature (K) | 33.2 | 569.4 |

| Lower heating value (MJ/kg) | 120 | 43 |

| Stoichiometric air–fuel ratio (kg/kg) | 34.3 | 14.5 |

| Density (g/L) | 0.09 | 830 |

| Autoignition temperature (K) | 813 | 530 |

| Adiabatic flame temperature (K) | 2483 | 1993 |

| Carbon atoms per molecule | 0 | 13.5 |

| Hydrogen atoms per molecule | 2 | 23.6 |

| Oxygen atoms per molecule | 0 | 0 |

| CO (g/kWh) | NOx (g/kWh) | |

|---|---|---|

| Stage V emission limits | <8 | <7.5 |

| Engine emissions_diesel fuel | 2.17 | 0.25 |

| Engine emissions_diesel–hydrogen fuel | 1.97 | 0.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben Abdelwahed, S.; Hamdi, F.; Gassoumi, M.; Yahya, I.; Moussa, N.; Alrasheedi, N.H.; Ennetta, R.; Louhichi, B. Enhancing Diesel Engine Performance Through Hydrogen Addition. Fire 2025, 8, 206. https://doi.org/10.3390/fire8050206

Ben Abdelwahed S, Hamdi F, Gassoumi M, Yahya I, Moussa N, Alrasheedi NH, Ennetta R, Louhichi B. Enhancing Diesel Engine Performance Through Hydrogen Addition. Fire. 2025; 8(5):206. https://doi.org/10.3390/fire8050206

Chicago/Turabian StyleBen Abdelwahed, Sahbi, Fakher Hamdi, Mehrez Gassoumi, Ilham Yahya, Noomen Moussa, Nashmi H. Alrasheedi, Ridha Ennetta, and Borhen Louhichi. 2025. "Enhancing Diesel Engine Performance Through Hydrogen Addition" Fire 8, no. 5: 206. https://doi.org/10.3390/fire8050206

APA StyleBen Abdelwahed, S., Hamdi, F., Gassoumi, M., Yahya, I., Moussa, N., Alrasheedi, N. H., Ennetta, R., & Louhichi, B. (2025). Enhancing Diesel Engine Performance Through Hydrogen Addition. Fire, 8(5), 206. https://doi.org/10.3390/fire8050206