Impact of Flame Tube Convergent Segment Wall Configurations on Main Combustor Performance

Abstract

1. Introduction

2. Materials

2.1. Reference Model

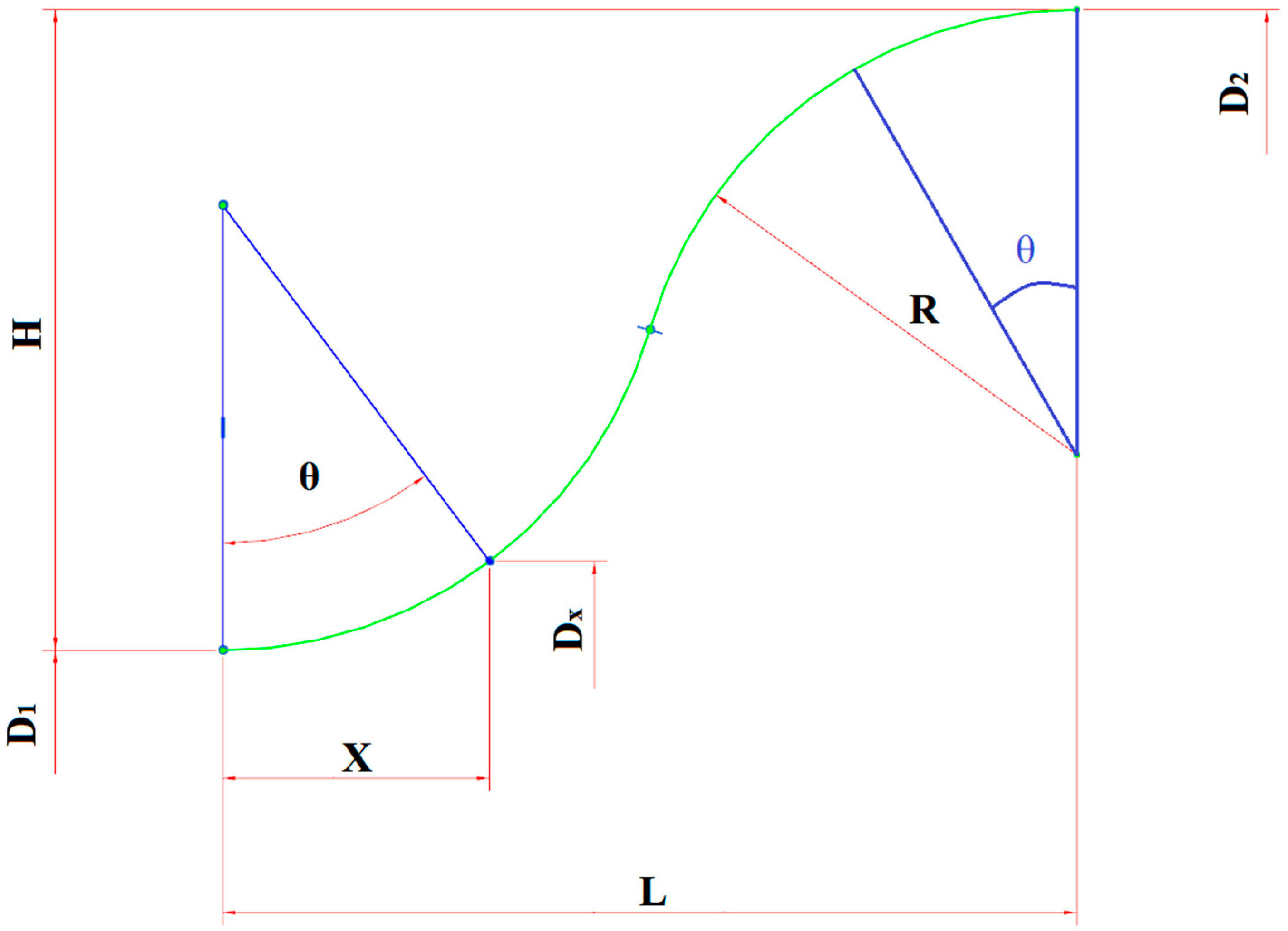

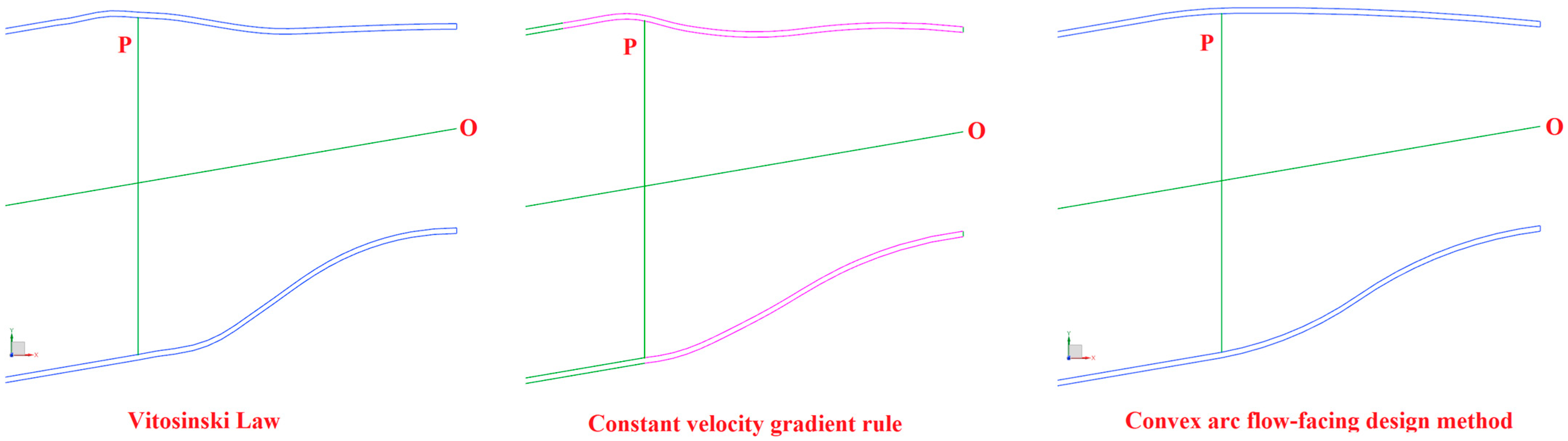

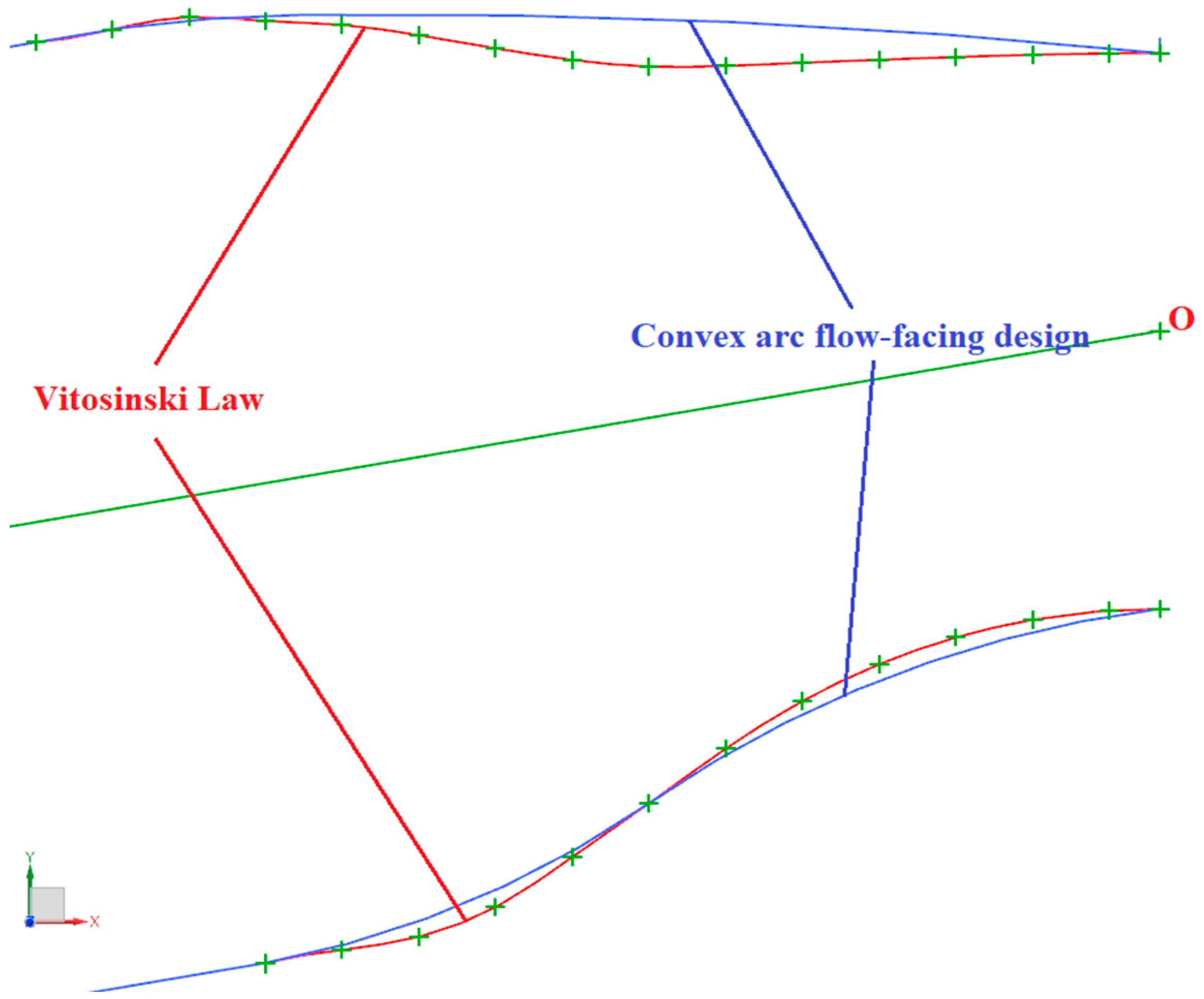

2.2. Wall Configuration Design Law of Flame Tube Convergent Segment

2.3. Comparative Summary of Design Philosophies

3. Methods

3.1. Numerical Model

3.1.1. RANS Method

3.1.2. Turbulent Flow Model and Radiation Model

3.1.3. Discrete Phase Model and Combustion Model

3.2. Grids Division and Boundary Conditions

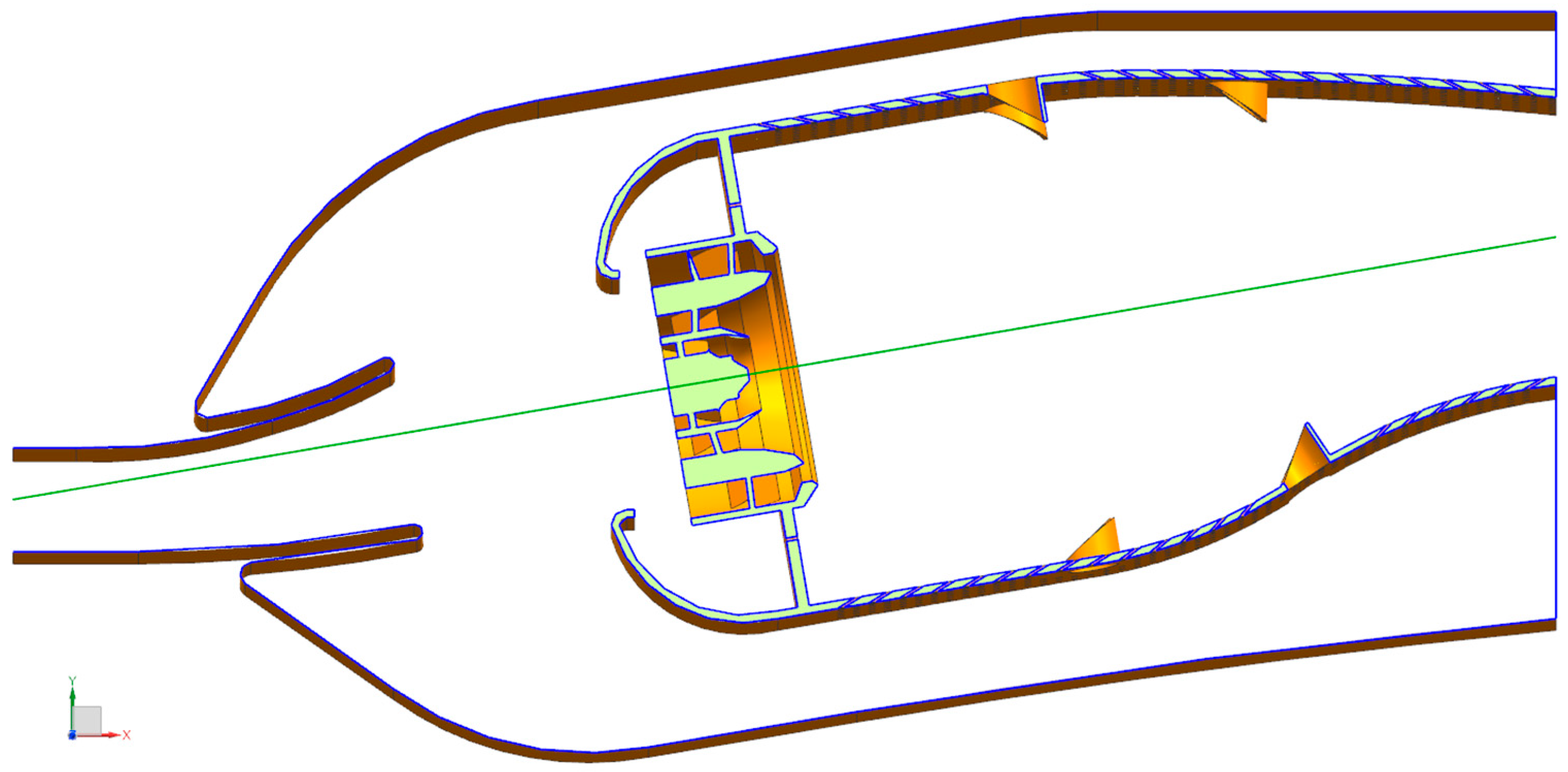

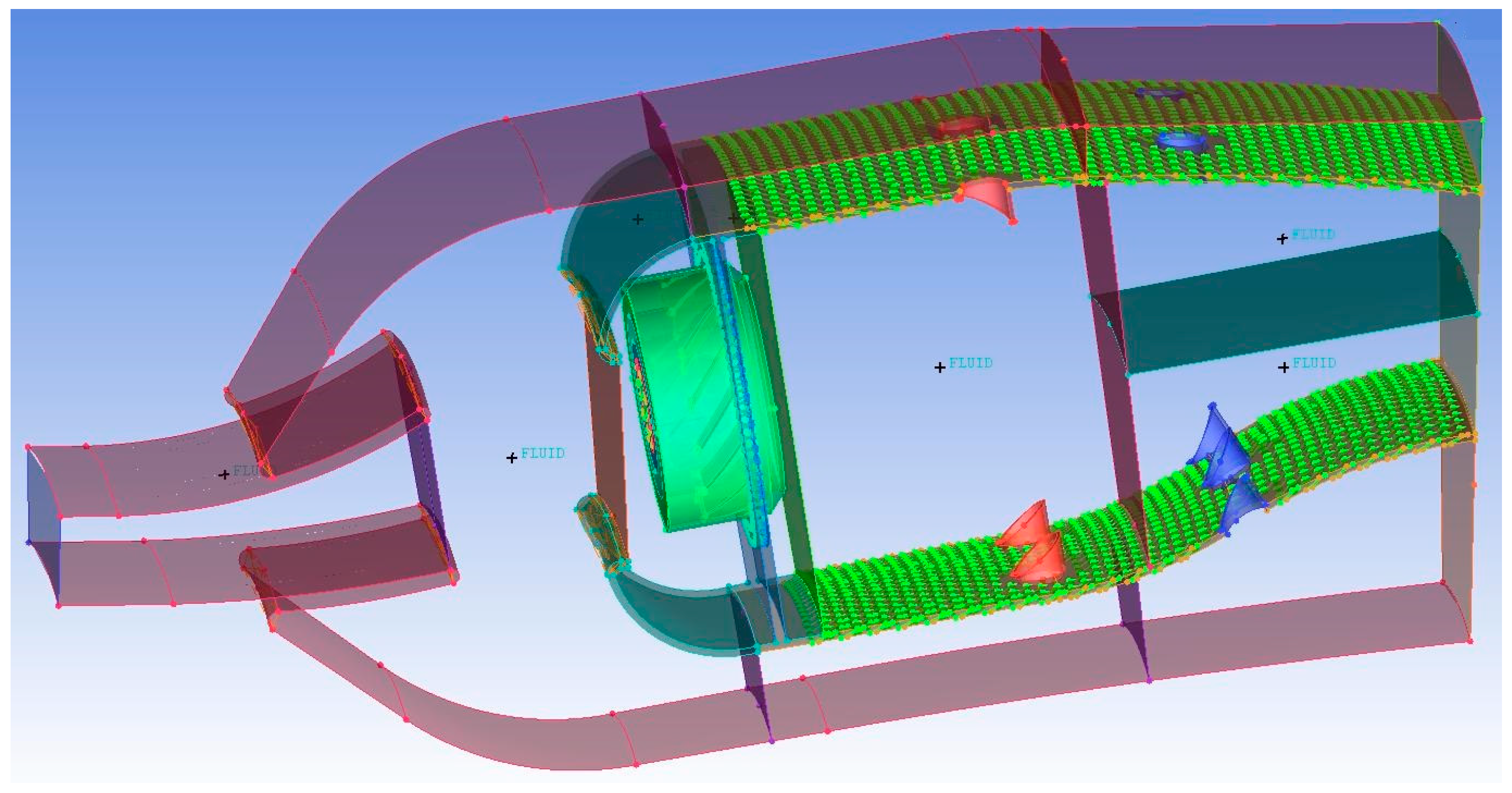

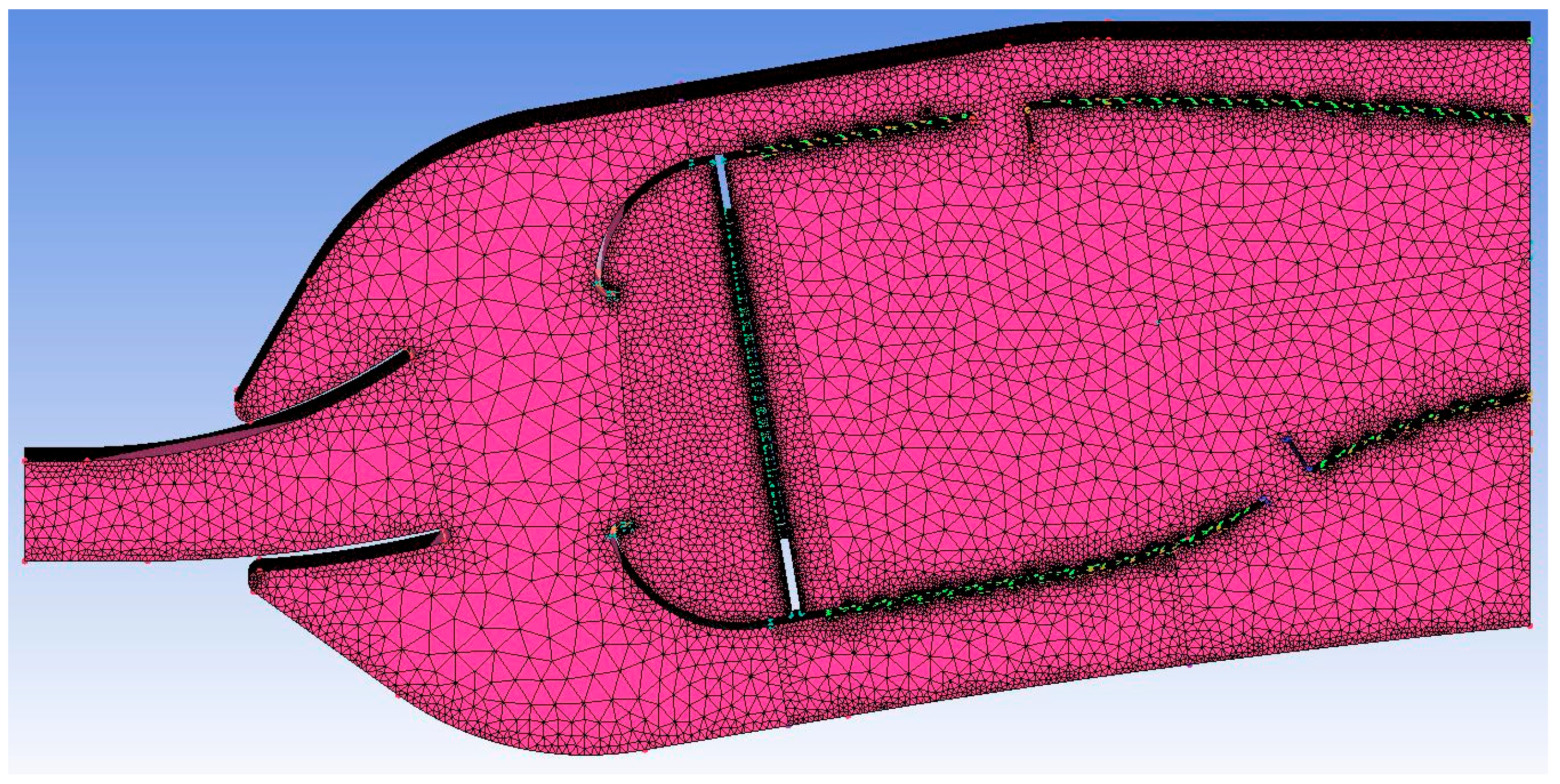

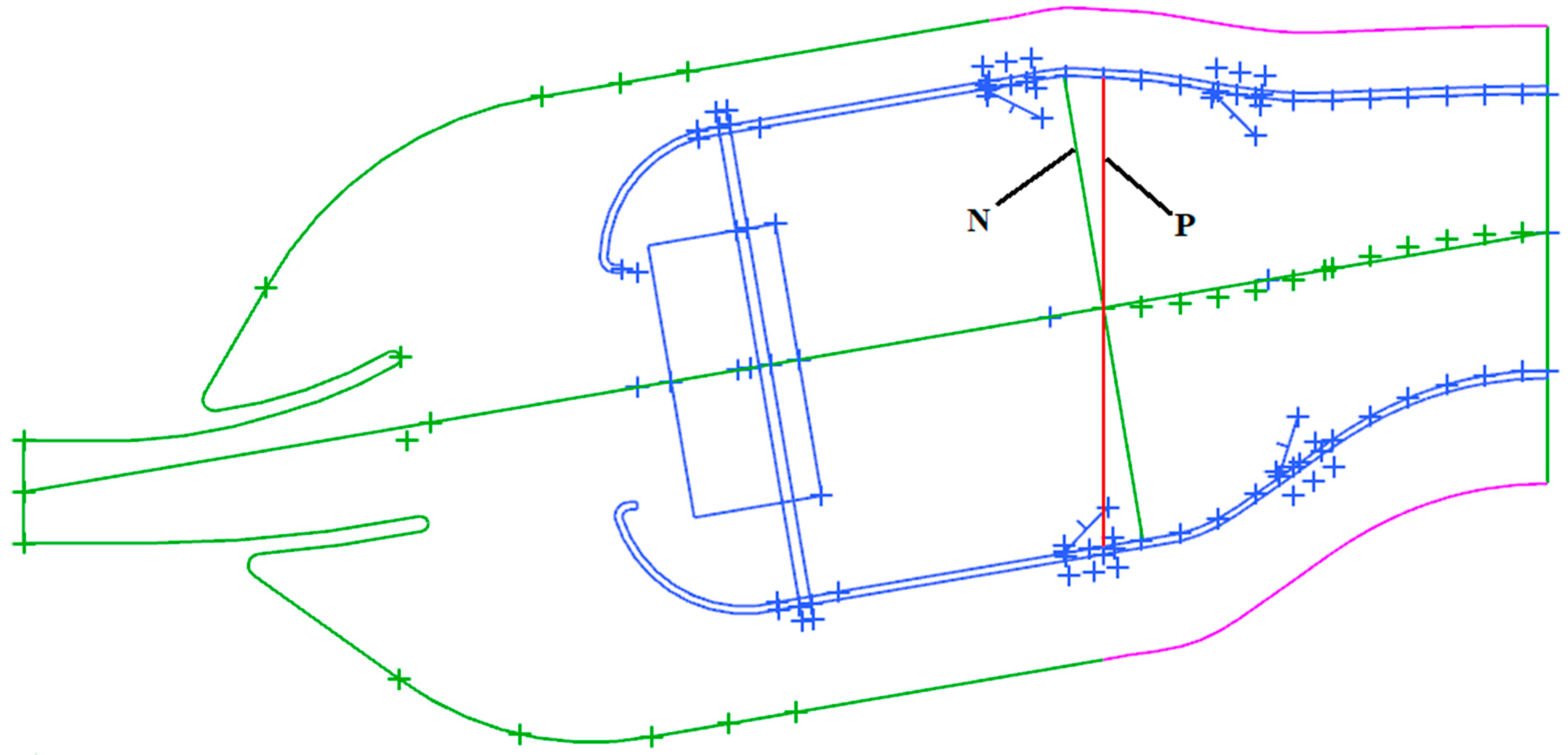

3.2.1. Partition Processing and Grids Division

3.2.2. Boundary Conditions and Solution Methods

3.3. Comparative Evaluation

3.3.1. Total Pressure Recovery Coefficient

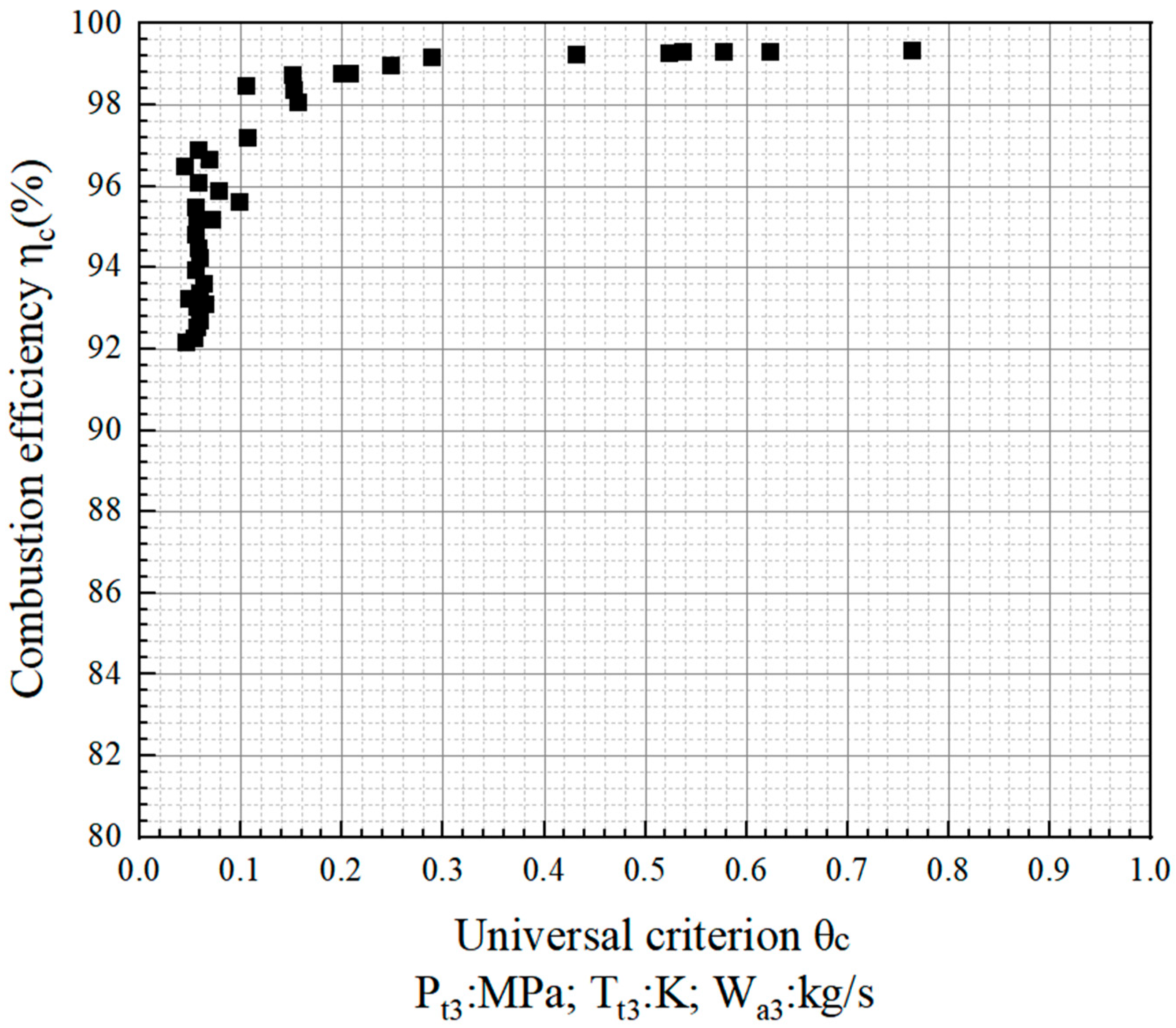

3.3.2. Combustion Efficiency

3.3.3. Overall Temperature Distribution Factor

3.3.4. Radial Temperature Distribution Factor

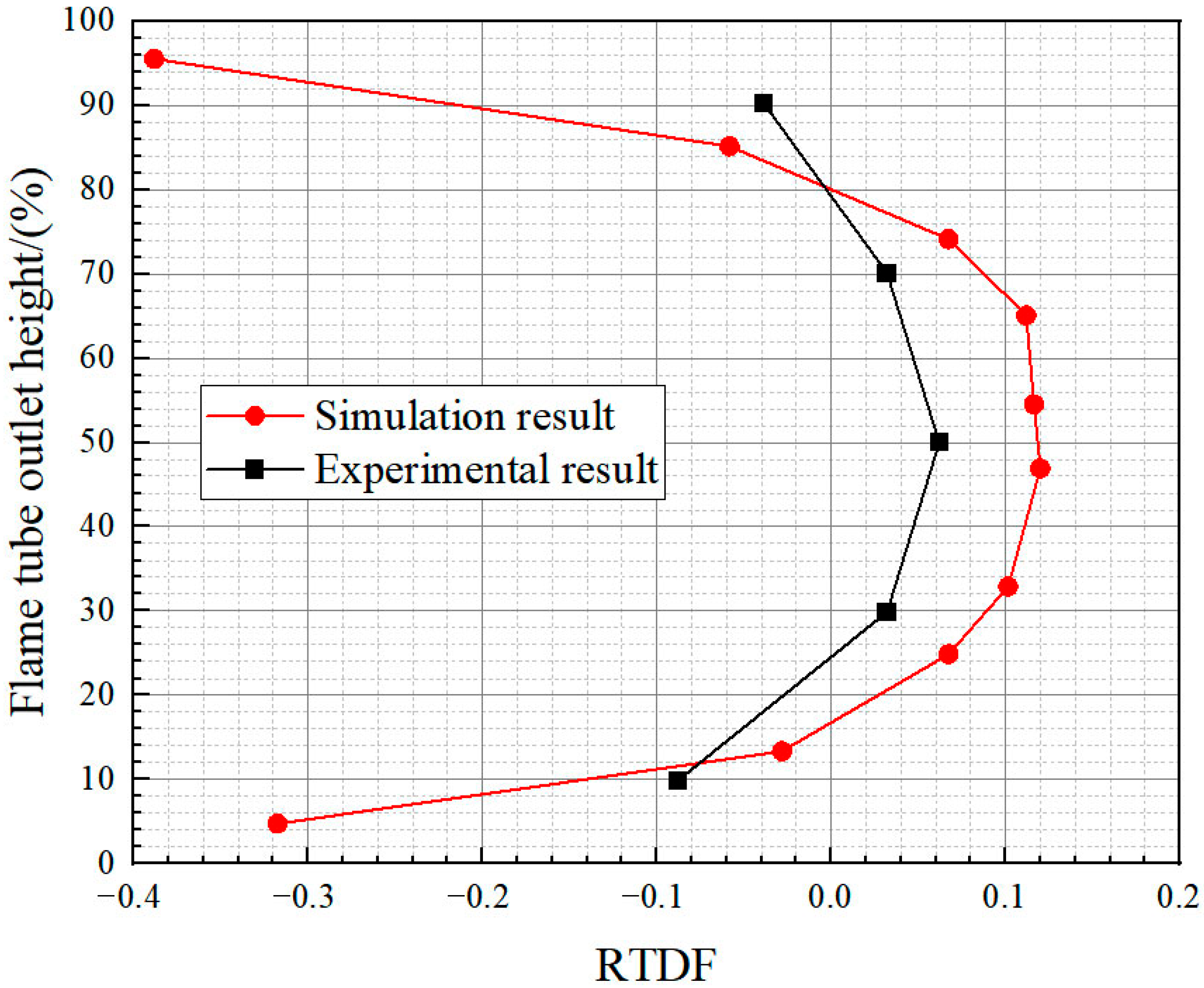

3.4. Outlet Section Data Extraction Methodology

- 1.

- Division Basis and Geometric Definition

- 2.

- Data Extraction and Processing ProcedureFor each distribution zone (the i-th zone), the following procedure is executed:

- (1)

- Data Acquisition: Extract the total pressure values (for OPDF and RPDF analysis) or the total temperature values (for RTDF analysis) at all grid nodes within the corresponding annulus.

- (2)

- Circumferential averaging: Calculate the circumferentially averaged value of the acquired data to obtain a representative total pressure value P4avc,i or total temperature value T4avc,i for that specific radial location.

- (3)

- Result Application: The set of these 20 circumferentially averaged values at different radial locations is precisely the data used to calculate the OPDF/RPDF/RTDF values and to plot the RPDF/RTDF curves. The abscissa (X-axis) of the RPDF/RTDF curves is the RPDF/RTDF value of the distribution zone, and the ordinate (Y-axis) is the corresponding radial height normalized by the total radial height H (expressed as a percentage).

- 3.

- Rationale for the Number of Zones (N = 20)

4. Results and Discussion

4.1. Comparison of Two Conventional Design Law Schemes

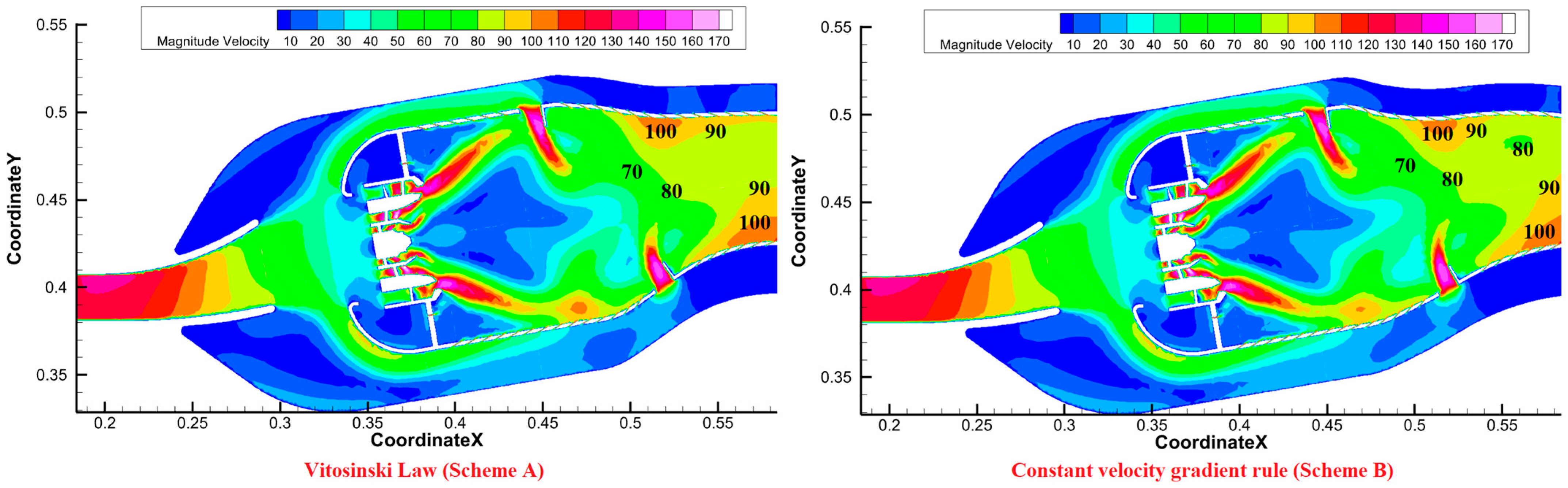

4.1.1. Comparison of Flow Field Distributions for Scheme A and Scheme B

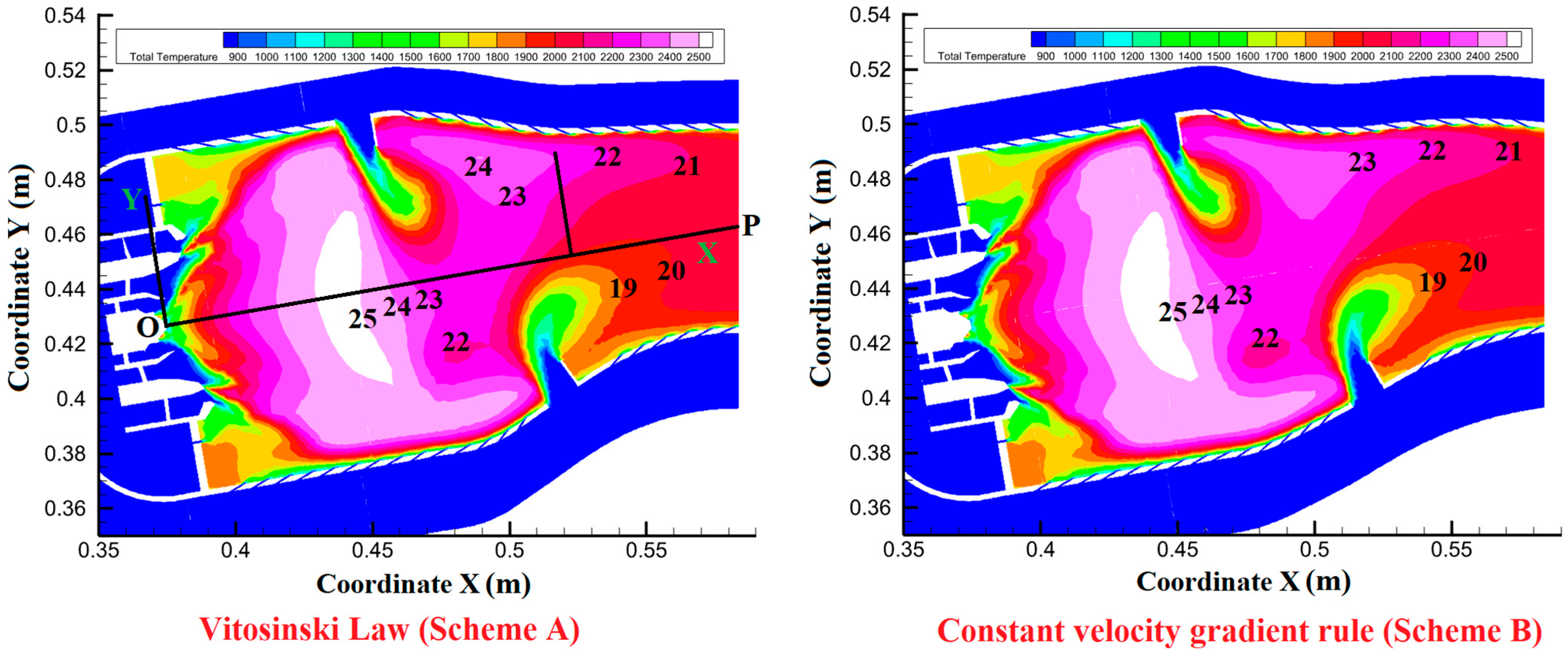

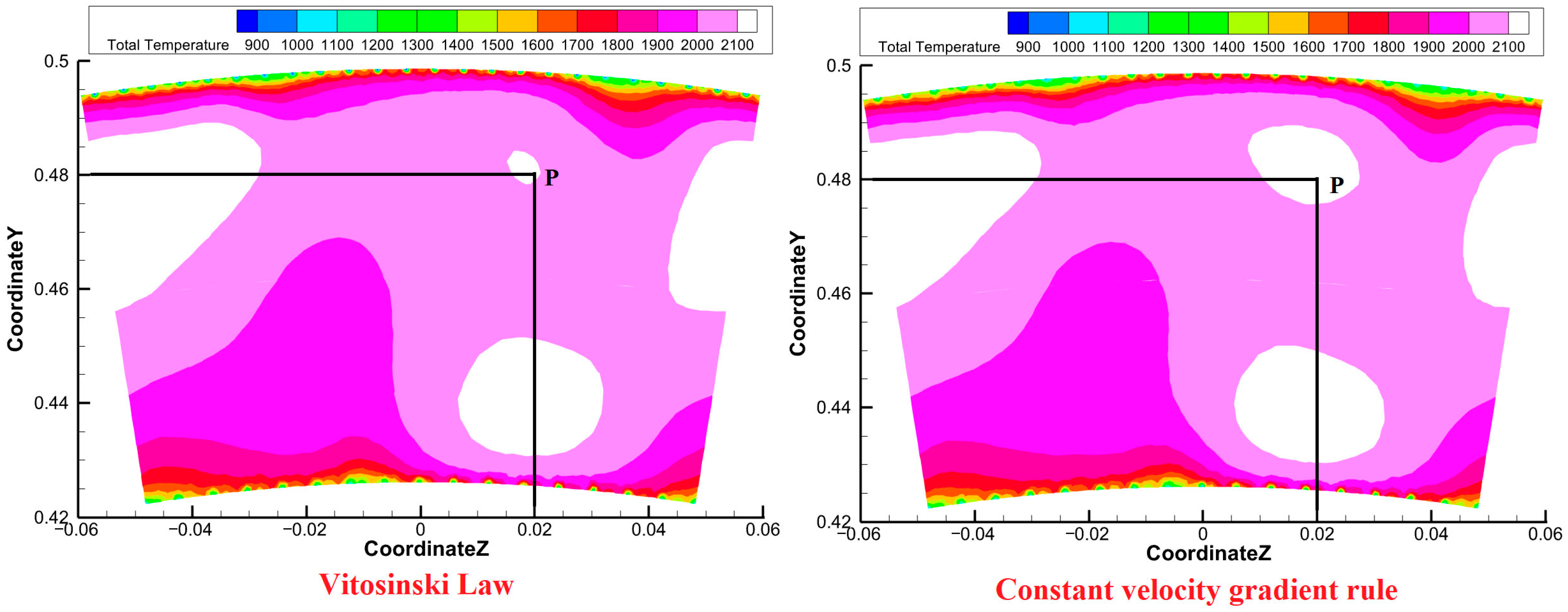

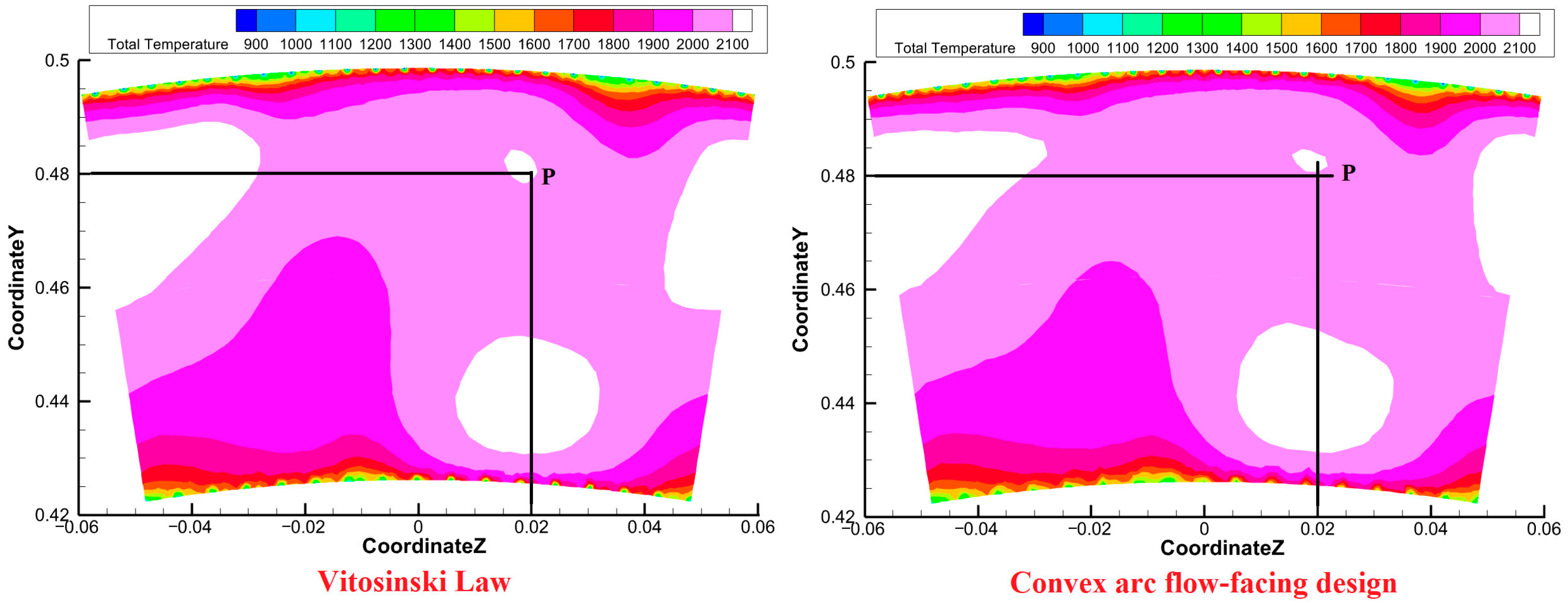

4.1.2. Comparison of Temperature Distributions for Scheme A and Scheme B

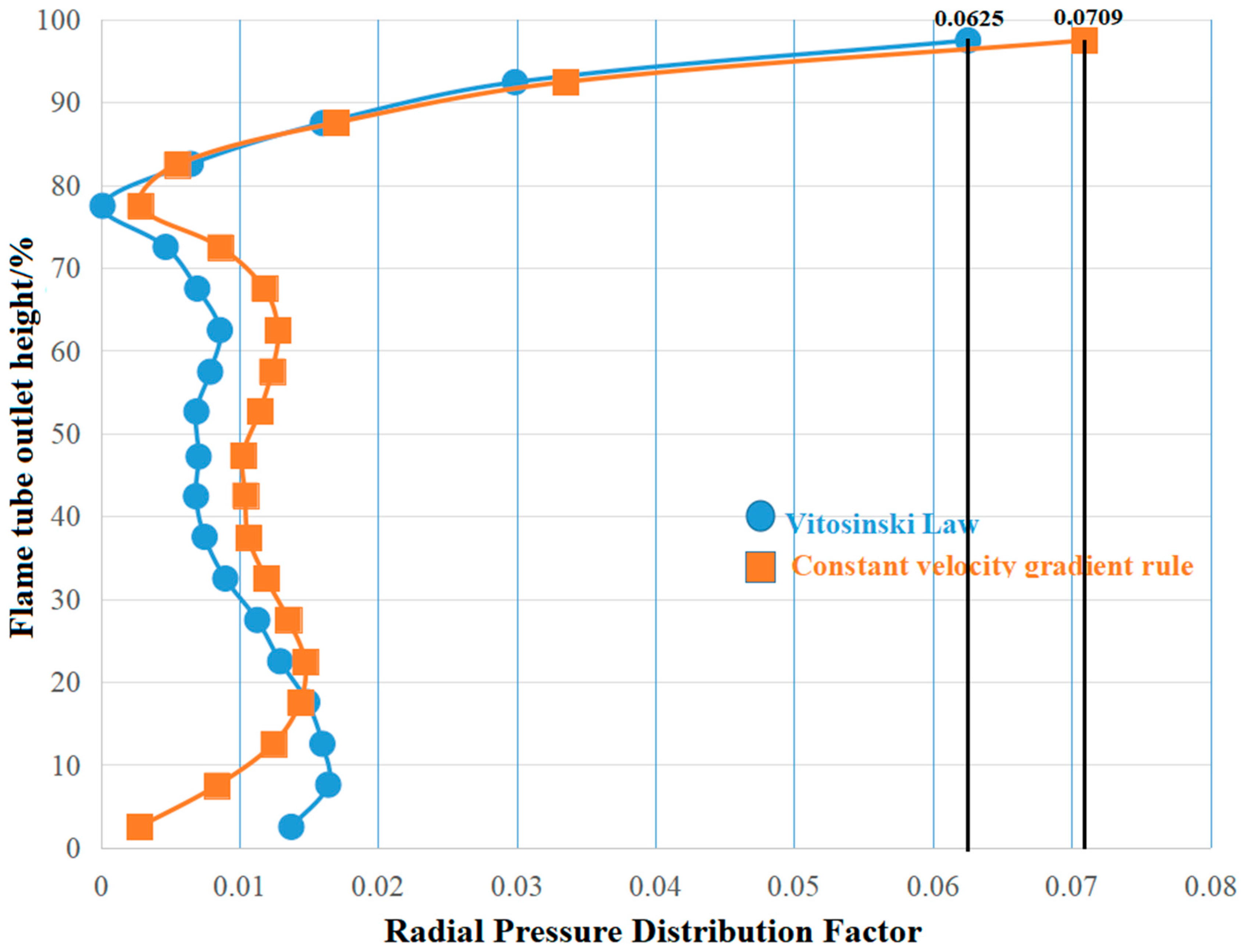

4.1.3. Comparison of Various Outlet Performance Indicators for Scheme A and Scheme B

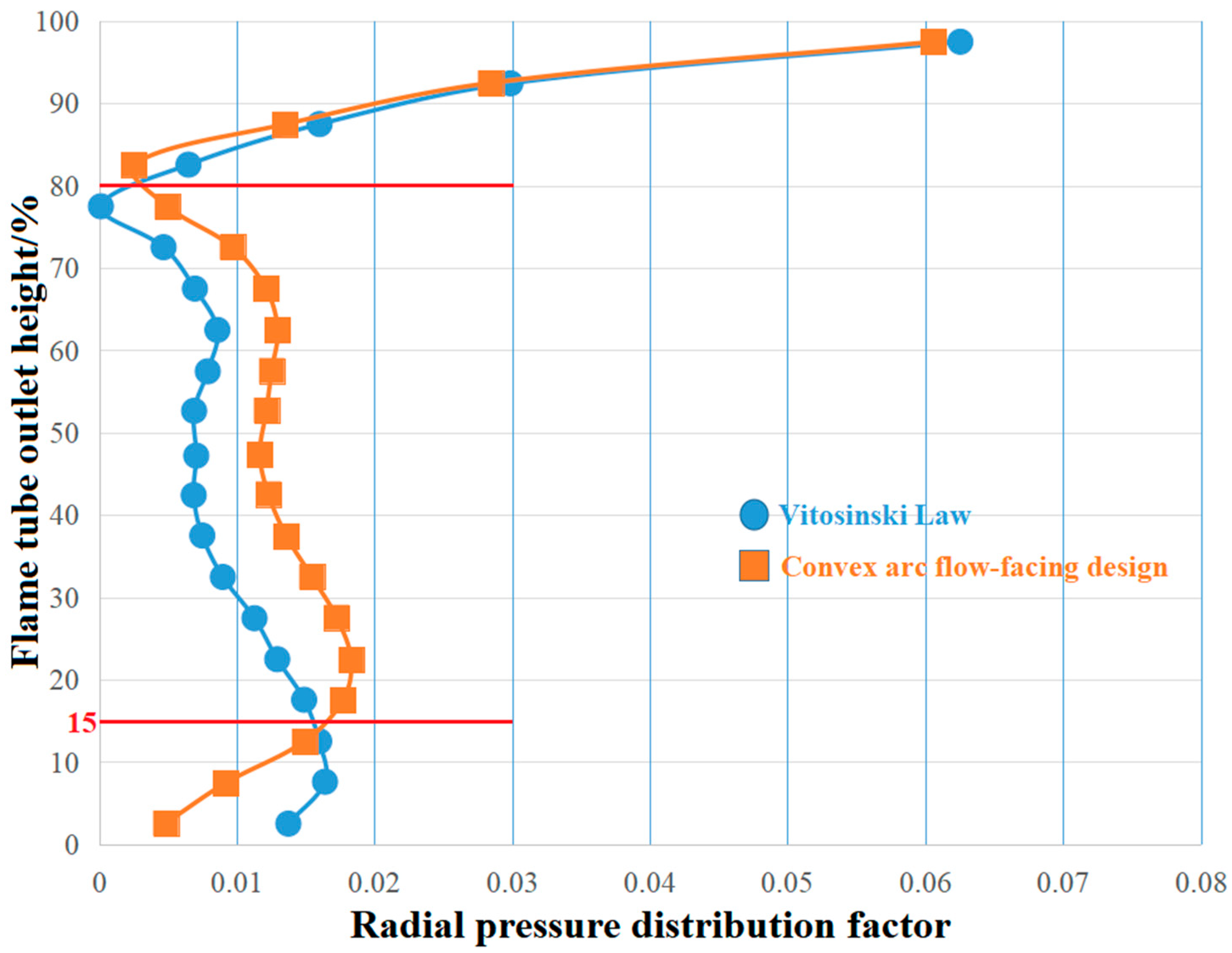

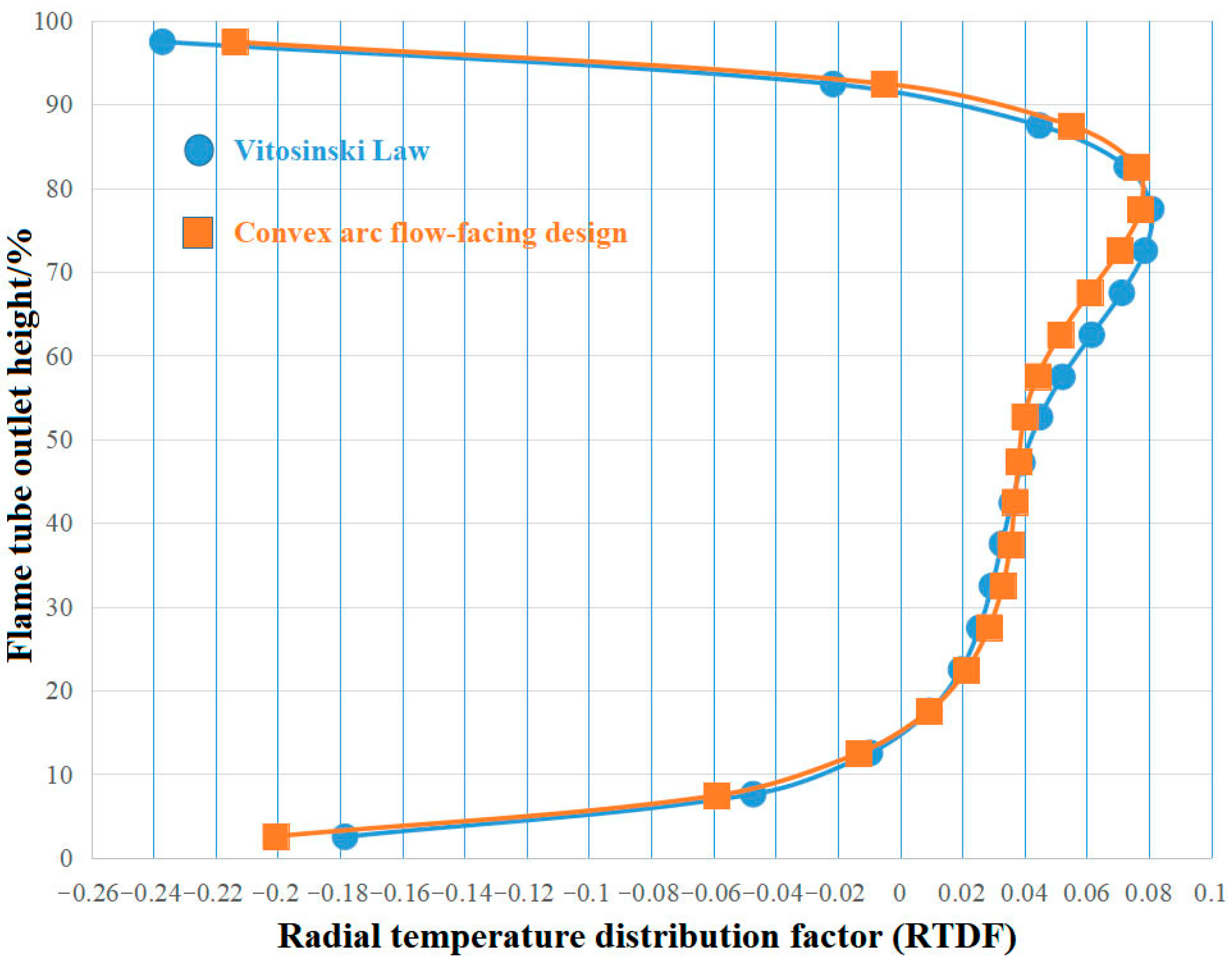

4.2. Comparison of the Optimal Conventional and Convex-Arc Flow-Facing Schemes

4.2.1. Comparison of Flow Field Distributions for Scheme A and Scheme C

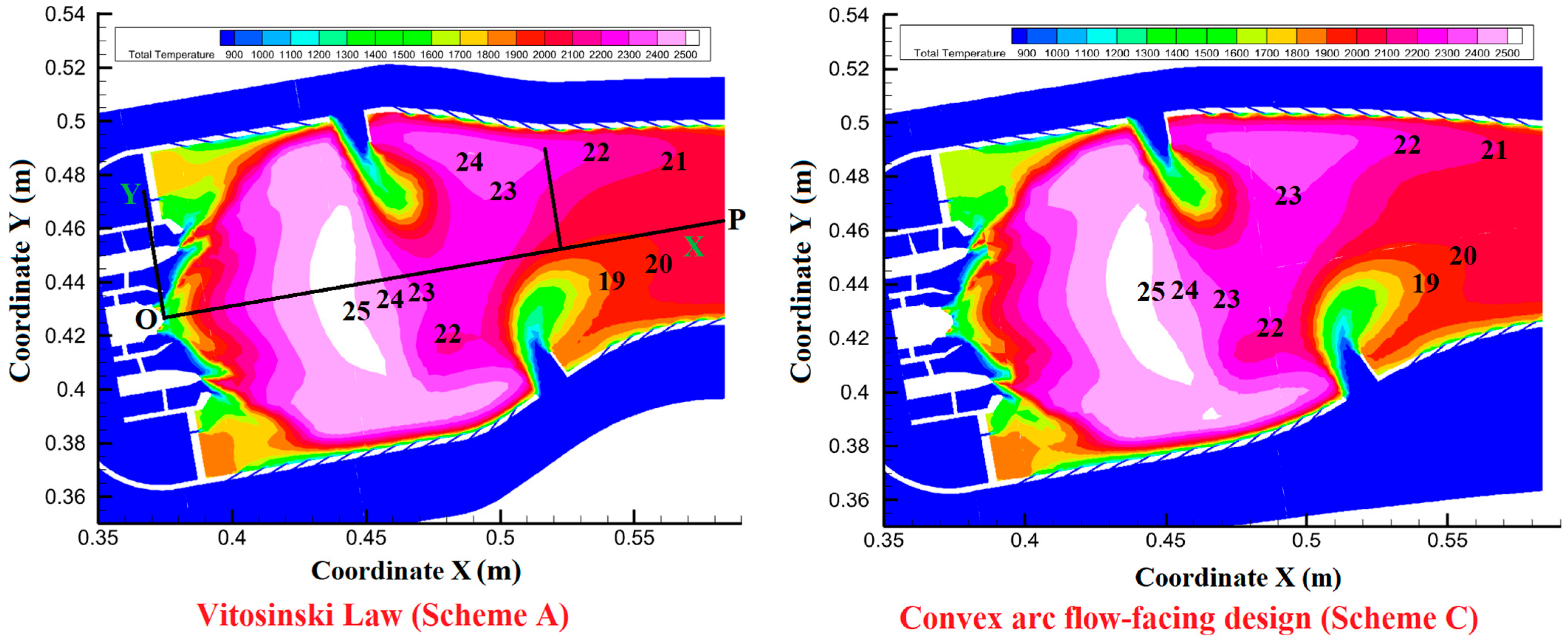

4.2.2. Comparison of Temperature Distributions for Scheme A and Scheme C

4.2.3. Comparison of Various Outlet Performance Indicators for Scheme A and Scheme C

5. Conclusions

- (1)

- Geometric Root Cause: The inflection point on the upper wall contour is a key geometric defect that induces local flow acceleration and separation, compromising flow uniformity.

- (2)

- Flow Field Effect: The presence of an inflection point leads to localized high-velocity regions in the convergent segment, whereas a smooth convex-arc profile produces uniform and gradual flow acceleration.

- (3)

- Performance Outcome: The uniformity of the flow field directly determines the efficiency of mixing. By employing an inflection-free design, Scheme C achieves the most uniform flow field, which translates into the best outlet temperature distribution factors (OTDF, RTDF) and the highest combustion efficiency, while maintaining the lowest pressure loss due to its hydraulically smooth flow path.

- (1)

- The Inflection Point as a Fundamental Geometric Defect. The comparative analysis confirms that the inflection point—a geometric feature inherent to the conventional design principles governing Schemes A and B (as defined in Table 4)—acts as a critical source of flow non-uniformity. The velocity distributions in Figure 13 provide direct evidence that this geometric discontinuity induces abrupt flow turning and localized acceleration, which subsequently compromises the uniformity of the outlet flow field.

- (2)

- Superiority of the Inflection-Free Design Paradigm. In stark contrast, the smooth, inflection-free profile of Scheme C successfully eliminates this adverse feature. This fundamental geometric optimization yields a remarkably uniform and gradual flow acceleration, completely avoiding the localized high-speed regions observed in Schemes A and B. The superior flow management strategy of Scheme C is quantitatively reflected in its performance metrics (Table 12), manifesting as a significant reduction in the TPLC within the convergent segment (εcs), higher combustion efficiency, and superior outlet temperature distribution quality (lower OTDF and RTDF).

- (3)

- A Validated Mechanistic Pathway to Performance Enhancement. The synergy of reduced component pressure loss and enhanced combustion performance stems from the improved flow uniformity enabled by Scheme C’s design. This uniformity promotes more effective mixing in the dilution zone. The resultant, more uniform temperature distribution is quantitatively evidenced by the superior outlet temperature distribution factors (OTDF and RTDF, Table 12), even though the absolute rate of temperature contour retreat for Scheme C is intermediate between the other schemes. The larger combustion flow space near the outlet in Scheme C (Figure 21) further provides the residence time necessary for more complete combustion. This mechanistic chain—from geometry to flow field to performance—effectively demonstrates that the elimination of the inflection point, a geometric feature that induces abrupt flow turning and adverse pressure gradients, is the key to achieving synergistic performance gains.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Roman letters | |

| Absorption coefficient, [m−1] | |

| Diffusion coefficient of species , [m2/s] | |

| Mixture fraction | |

| Body force term, [m/s2] | |

| Fuel–Air Ratio, defined as the ratio of the mass flow rate of fuel to the mass flow rate of air | |

| Generation of turbulent kinetic energy induced by buoyancy, [kg/(m·s3)] | |

| Generation of turbulent kinetic energy induced by the mean velocity gradients, [kg/(m·s3)] | |

| Radiation intensity dependent on position () and direction (), [W/(m2·sr)] | |

| Turbulent kinetic energy, [m2/s2] | |

| Molar mass of species , [kg/mol] | |

| Refractive index, [sr−1/2] | |

| Outlet Total Pressure Distribution Factor, defined by Equation (26) | |

| Overall Temperature Distribution Factor, defined by Equation (23) | |

| Pressure, [Pa] | |

| Heat absorbed by a fluid per unit mass per unit time via radiation, [J/(kg·s)] | |

| Universal gas constant, = 8.314 [J/(mol·K)] | |

| Net mass generation rate of species from chemical reactions, [kg/(s·m3)] | |

| Radial Total Pressure Distribution Factor, defined by Equation (28) | |

| Radial Temperature Distribution Factor, defined by Equation (24) | |

| Strain rate tensor, [s−1] | |

| User-defined source term, [kg/(m·s3)] | |

| Combustor performance severity index, defined by Equation (22) | |

| Time, [s] | |

| Temperature, [K] | |

| Mass-weighted average temperature at the combustor inlet, [K] | |

| Circumferentially averaged radial temperature at the flame tube outlet, [K] | |

| Mass-weighted average temperature at the flame tube outlet, [K] | |

| Maximum temperature at the flame tube outlet, [K] | |

| Fluid internal energy per unit mass, [J/kg] | |

| Velocity, [m/s] | |

| Available air volume of the full annular main combustor, [kg/s] | |

| Contribution of fluctuating dilatation to the overall dissipation rate in compressible turbulence, [kg/(m·s3)] | |

| Mass fraction of species | |

| Greek Letters | |

| Surface forces(pressure and viscous forces), [N/m2] | |

| Kronecker delta function | |

| Combustor temperature rise (), [K] | |

| Turbulent dissipation rate, [m2/s3] | |

| Total pressure loss coefficient of the combustor, defined by Equation (29) | |

| Total pressure loss coefficient of the flame tube convergent segment, defined by Equation (30) | |

| Combustion efficiency | |

| Universal combustion efficiency criterion parameter, defined by Equation (21) | |

| Thermal conductivity, [W/(m·K)] | |

| Dynamic viscosity, [Pa·s] | |

| Turbulent viscosity, [Pa·s] | |

| Density, [kg/m3] | |

| Stefan–Boltzmann constant, = 5.669 × 10−8 [W/(m2·K4)] | |

| Turbulent Prandtl numbers for and | |

| Scattering coefficient, [m−1] | |

| Equivalence ratio, defined as the ratio of the actual fuel–air ratio to the stoichiometric fuel–air ratio | |

| Phase function | |

| Solid angle, [sr] | |

| Sub-Superscripts | |

| Oxidizer | |

| - | Favre mean (density-averaged) variable |

| Vector | |

| Diffuser inlet | |

| Flame tube outlet | |

| Maximum value at the flame tube outlet | |

| Mass-weighted average value at the flame tube outlet | |

| Mass-weighted average value at the combustor inlet | |

| Circumferentially averaged radial value at the flame tube outlet | |

| Related to combustor | |

| Related to flame tube convergent segment | |

References

- Kress, E.J.; Taylor, J.R.; Dodds, W.J. Multiple Swirler Dome Combustor for High Temperature Rise Applications. In Proceedings of the 26th Joint Propulsion Conference, Orlando, FL, USA, 16–18 July 1990. AIAA Paper 90-2159. [Google Scholar] [CrossRef]

- Shang, S.; Gao, X.; Guo, R.; Guo, D.; Gao, W.; Li, F. Capability Prediction of High Temperature Rise Center-stage Combustor. J. Aerosp. Power 2014, 29, 1001–1007. [Google Scholar]

- Chang, F.; Suo, J.; Liang, H.; Wu, X. Numerical Study of Co-Axial Pilot and Main Module Combustor. J. Propuls. Technol. 2012, 33, 760–764. [Google Scholar]

- Yuan, Y.; Lin, Y.; Liu, G. Combustor Dome Design with Three Swirlers for Widening the Operation Stability Range. J. Aerosp. Power 2004, 1, 142–147. [Google Scholar]

- Hu, G.; Qin, Q.; Jin, W.; Li, J. Large Eddy Simulation of the Influences of the Pilot-Stage Structure on the Flow Characteristics in a Centrally Staged High-Temperature-Rise Combustor. Aerospace 2022, 9, 782. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, P.; Xin, X.; Chen, B.; Chen, K. Measurement of triple-stage swirler cup combustor flow field based on PIV technology. J. Aerosp. Power 2015, 30, 1032–1039. [Google Scholar]

- Mongia, H.C. Engineering Aspects of Complex Gas Turbine Combustion Mixers. Part I: High ΔT. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. AIAA-2011-107. [Google Scholar] [CrossRef]

- Mongia, H.C. Engineering Aspects of Complex Gas Turbine Combustion Mixers Part II: High T3. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. AIAA-2011-106. [Google Scholar]

- Mongia, H.C. Engineering Aspects of Complex Gas Turbine Combustion Mixers Part III: 30 OPR. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. AIAA-2011-5525. [Google Scholar]

- Mongia, H.C. Engineering Aspects of Complex Gas Turbine Combustion Mixers Part IV: Swirl Cup. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. AIAA-2011-5526. [Google Scholar]

- Mongia, H.C. Engineering Aspects of Complex Gas Turbine Combustion Mixers Part V: 40 OPR. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. AIAA-2011-5527. [Google Scholar]

- Wang, D.; Li, F.; Lin, H.; Zhou, T. High Temperature Rise Triple-Swirler Combustor. China Patent CN202211681365.6, 27 June 2025. [Google Scholar]

- Liu, K.; Wang, J.; Zeng, W.; Sun, L. Research on Effect of Dilution Holes Structures on Combustor Performance. J. Eng. Therm. Energy Power 2022, 37, 64–69+92. [Google Scholar]

- Shen, L. Influence of the Geometrical Parameters of Mixing Holes on the Exit Characteristics of the Combustor. Master’s Thesis, Shenyang Aerospace University, Shenyang, China, 2018. [Google Scholar]

- Ding, G.; He, X.; Xue, C.; Hong, L. Experiment on effect of dome and dilution holes on outlet temperature distribution for triple swirler combustor. J. Aerosp. Power 2015, 30, 807–813. [Google Scholar]

- Ding, G.; He, X.; Zhao, Z.; An, B.; Song, Y.; Zhu, Y. Effect of dilution holes on the performance of a triple swirler combustor. Chin. J. Aeronaut. 2014, 27, 1421–1429. [Google Scholar] [CrossRef]

- Yao, J.; Zhao, N.; Xu, H. Research on Influence of Primary Hole Position on the Performance of Combustor. Gas Turbine Technol. 2023, 36, 27–32. [Google Scholar]

- Chen, J.; Li, J.; Xue, J.; Dong, Q.; Hu, J. Numerical Simulation on the Influence of the Primary Holes Position on Flow and Combustion Characteristics of High Temperature Rise Combustor Based on RQL. Aeroengine 2023, 49, 27–34. [Google Scholar]

- Wang, X.; Lin, Y.; Zhang, C. Effects of Primary Jet Position on Combustor Aerodynamic Characteristics and Ignition/LBO Performance. J. Propuls. Technol. 2017, 38, 2020–2028. [Google Scholar]

- Yang, H.; Guo, S.; Zhan, Z.; Wen, J.; Wang, J. Numerical Simulation Research on the Influence of Cooling Hole Structure on Combustor Performance and Liner Wall Cooling Effect. J. Xi’an Jiaotong Univ. 2024, 58, 98–108. [Google Scholar]

- Luo, S.; Huang, X.; Zhao, N.; Zheng, H. Numerical Simulation of Cooling Characteristics of Combustion Chamber Wall. J. Eng. Therm. Energy Power 2020, 35, 92–98. [Google Scholar]

- Ji, Y. Conjugate Heat Transfer Characteristics of Gas Turbine Combustor Effusion Cooling. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2019. [Google Scholar]

- Ben Sik Ali, A.; Kriaa, W.; Mhiri, H.; Bournot, P. Analysis of the influence of cooling hole arrangement on the protection of a gas turbine combustor liner. Meccanica 2018, 53, 2257–2271. [Google Scholar] [CrossRef]

- Hu, Z. Aircraft Engine Design Handbook—Volume 9: Main Combustion Chamber; Aviation Industry Press: Beijing, China, 2000. [Google Scholar]

- Wang, D.; Li, F.; Lin, H.; Zhang, S.; Wang, D. Convex Arc Flow-Facing Design Method of Flame Tube Convergence Section. China Patent CN202310851327.9, 22 September 2023. [Google Scholar]

- Bahr, D.W. Technology for the Design of High Temperature Rise Combustors. J. Propuls. Power 1987, 3, 179–186. [Google Scholar] [CrossRef]

- Lin, Y.; Lin, Y.; Zhang, C.; Xu, Q. Discussion on Combustion Airflow Distribution of Advanced Staged Combustor. J. Aerosp. Power 2010, 25, 1923–1931. [Google Scholar]

- Lefebvre, A.H. Gas Turbine Combustion, 2nd ed.; Taylor & Francis: Philadelphia, PA, USA, 1999. [Google Scholar]

- Hinze, J.O. Turbulence, 2nd ed.; McGraw-Hill Publishing Co.: New York, NY, USA, 1975. [Google Scholar]

- Celik, I.B.; Ghia, U.; Roache, P.J.; Freitas, C.J.; Coleman, H.; Raad, P.E. Procedure for Estimation and Reporting of Uncertainty Due to Discretization in CFD Applications. J. Fluids Eng. 2008, 130, 078001–078004. [Google Scholar] [CrossRef]

- Wang, D.; Wang, J.; Lin, H.; Li, F.; Wang, D.; Zhao, Y.; Tan, Y.; Zhao, K. Comprehensive analysis of the impact of swirl-sensitive parameters on main combustor performance. Phys. Fluids 2025, 37, 115106. [Google Scholar] [CrossRef]

- Gao, X. Numerical Simulation and Performance Analysis of Complex Swirler Combustor. Master’s Thesis, Beihang University, Beijing, China, 2014; pp. 18–26. [Google Scholar]

- Yang, F.; Feng, X.; Ruan, L.; Chen, J.; Xia, R.; Chen, Y.; Jin, Z. Correlation Study of Water Tree and VLF tanδ Based on Pearson Correlation Coefficient. High Volt. Appar. 2014, 50, 21–25+31. [Google Scholar]

| Parameters | Takeoff | Idle |

|---|---|---|

| Inlet total pressure Pt3 [MPa] | 3.141 | 0.505 |

| Inlet total temperature Tt3 [K] | 845 | 489 |

| Inlet mass flow rate Wt3 [kg/s] | 3.91 | 0.94 |

| Fuel flow rate Wf [kg/s] | 0.1445 | 0.01 |

| FAR | 0.037 | 0.0106 |

| Inlet Mach number Ma3 | 0.26 | 0.26 |

| Dome height Hd [mm] | 123.4 | |

| Flame tube length Lf [mm] | 230 |

| Combustor Component | Proportion | ||

|---|---|---|---|

| Dome air mdome 45.05% | Dome cooling air mdc | 3.05% | |

| Main stage air msw3 | 24% | ||

| Pilot stage air | Inner swirler msw1 | 5.5% | |

| Outer swirler msw2 | 12.5% | ||

| Intake air amount in the primary holes mp,h | 16.9% | ||

| Intake air amount in the dilution holes md,h | 17.0% | ||

| Cooling air amount of flame tube mc | 21.05% | ||

| Reference Model | Pilot Stage S1 | Pilot Stage S2 | Main Stage S3 |

|---|---|---|---|

| Inner radius Ri [mm] | 7.50 | 13.30 | 26.40 |

| Outer radius Ro [mm] | 11.30 | 18.90 | 34.32 |

| Blade number n | 8 | 10 | 15 |

| Blade angle θ | 35° | 45° | 50° |

| Rotational direction | - | + | + |

| Design Scheme | Underlying Principle | Key Geometric Feature (Upper Wall) | Primary Aerodynamic Goal |

|---|---|---|---|

| Scheme A (Vitosinski) | Empirical area convergence rule | A profile with an inflection point | To minimize total pressure loss by adhering to a historical area convergence rule. |

| Scheme B (Equal Velocity Gradient) | Theoretical linear velocity control | A profile with an inflection point | To achieve a constant velocity gradient by enforcing a linear area contraction. |

| Scheme C (Proposed Convex-Arc) | Phenomenon-driven aerodynamic contouring | A smooth, inflection-free profile | To ensure a smooth and gradual variation in flow parameters by actively avoiding geometric discontinuities. |

| N1 | N2 | N3 | |

|---|---|---|---|

| Grid quantity | 30,629,782 | 11,893,063 | 4,257,305 |

| Representative grid size h | 0.5554 | 0.7612 | 1.0721 |

| Grid refinement factor r | - | 1.3705 | 1.4084 |

| φ (TPLC) | 5.16% | 5.27% | 5.96% |

| Approximate relative error ea | - | 2.1318% | 13.0930% |

| Extrapolated relative error eext | - | 0.5020% | 2.6446% |

| Fine-grid convergence index GCIfine | - | 0.6244% | 3.2205% |

| Radial Position r/R | Experimental Value Xi | Simulation Value Yi | rp |

|---|---|---|---|

| 10% | −0.0880 | −0.141 | 0.89 |

| 30% | 0.0320 | 0.0892 | |

| 50% | 0.0620 | 0.118 | |

| 70% | 0.0320 | 0.0876 | |

| 90% | −0.0386 | −0.212 | |

| Mean value | −0.00012 | −0.01164 |

| Outlet Total Pressure Distribution Uniformity Index | OPDF | RPDF |

|---|---|---|

| Scheme A | 0.1075 | 0.0625 |

| Scheme B | 0.1184 | 0.0709 |

| Contour Line | Scheme A | Scheme B |

|---|---|---|

| 2100 [K] | 198.83 | 205.14 |

| 2200 [K] | 170.48 | 178.48 |

| 2300 [K] | 149.82 | 153.02 |

| Research Protocols | Scheme A | Scheme B |

|---|---|---|

| εc [%] | 5.50 | 5.45 |

| εcs [%] | 0.38 | 0.35 |

| T4ave [K] | 2004.0 | 2003.7 |

| T4max [K] | 2182.0 | 2184.0 |

| OTDF | 0.154 | 0.156 |

| RTDF | 0.0808 | 0.0844 |

| ηc [%] | 99.86% | 99.85% |

| Outlet Total Pressure Distribution Uniformity Index | OPDF | RPDF |

|---|---|---|

| Scheme A | 0.1075 | 0.0625 |

| Scheme C | 0.1118 | 0.0606 |

| Contour Line | Scheme A | Scheme C |

|---|---|---|

| 2100 [K] | 198.83 | 201.61 |

| 2200 [K] | 170.48 | 173.37 |

| 2300 [K] | 149.82 | 153.13 |

| Research Protocols | Scheme A | Scheme C |

|---|---|---|

| εc [%] | 5.50 | 5.50 |

| εcs [%] | 0.38 | 0.31 |

| T4ave [K] | 2004.0 | 2004.6 |

| T4max [K] | 2182.0 | 2174.0 |

| OTDF | 0.154 | 0.146 |

| RTDF | 0.0808 | 0.0771 |

| ηc [%] | 99.86% | 99.88% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Wang, J.; Lin, H.; Li, F.; Zhao, Y.; Wang, D.; Tan, Y.; Zhao, K. Impact of Flame Tube Convergent Segment Wall Configurations on Main Combustor Performance. Fire 2025, 8, 476. https://doi.org/10.3390/fire8120476

Wang D, Wang J, Lin H, Li F, Zhao Y, Wang D, Tan Y, Zhao K. Impact of Flame Tube Convergent Segment Wall Configurations on Main Combustor Performance. Fire. 2025; 8(12):476. https://doi.org/10.3390/fire8120476

Chicago/Turabian StyleWang, Duo, Juan Wang, Hongjun Lin, Feng Li, Yinze Zhao, Dichang Wang, Yunchuan Tan, and Kai Zhao. 2025. "Impact of Flame Tube Convergent Segment Wall Configurations on Main Combustor Performance" Fire 8, no. 12: 476. https://doi.org/10.3390/fire8120476

APA StyleWang, D., Wang, J., Lin, H., Li, F., Zhao, Y., Wang, D., Tan, Y., & Zhao, K. (2025). Impact of Flame Tube Convergent Segment Wall Configurations on Main Combustor Performance. Fire, 8(12), 476. https://doi.org/10.3390/fire8120476