Fire Risk Assessment of Lithium-Ion Power Battery Shipping Containers in Maritime Transportation Scenarios

Abstract

1. Introduction

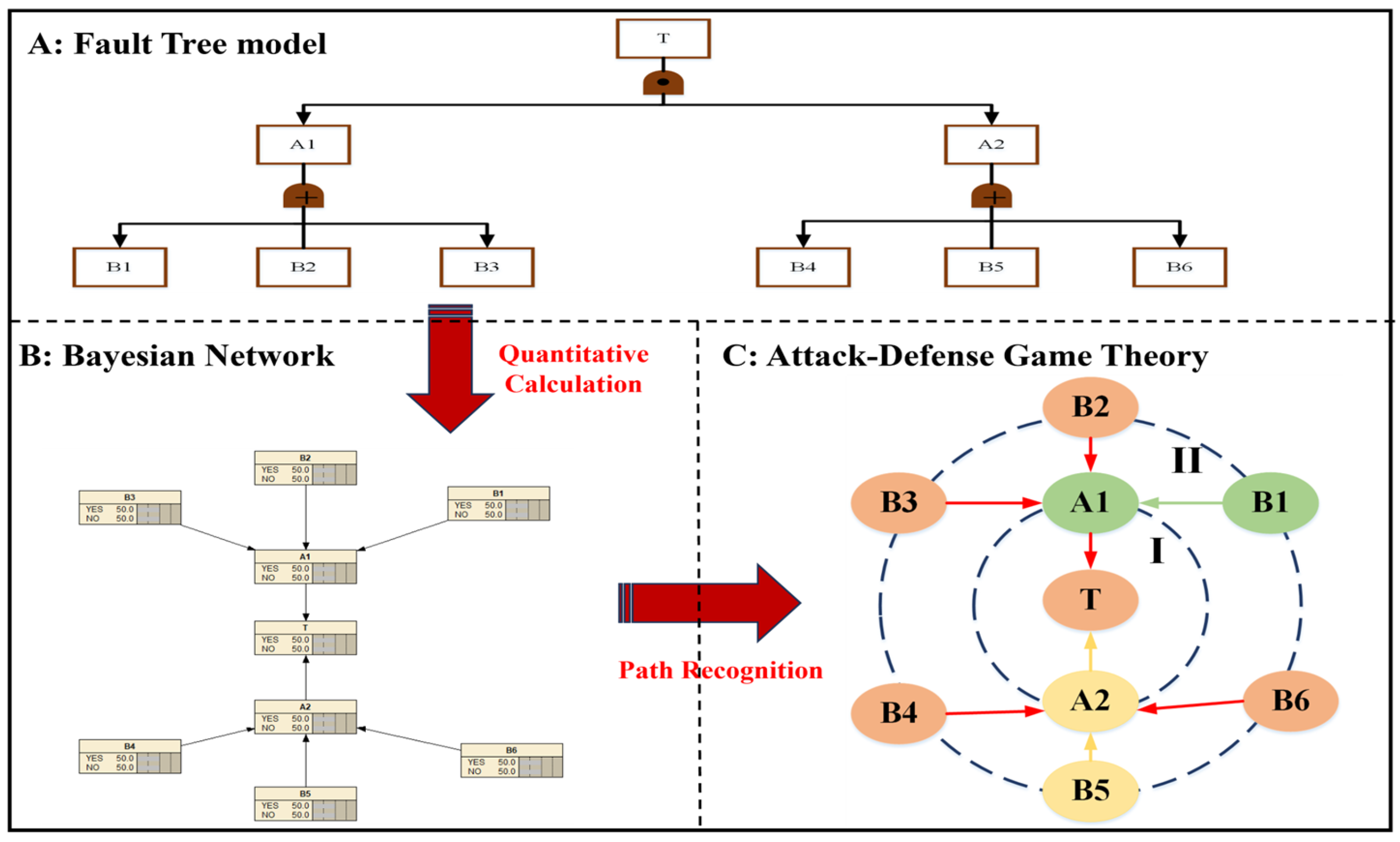

2. Methods

- (1)

- Fault Tree model

- (2)

- Bayesian Network model

- (3)

- Attack–Defense Game Theory

- (a)

- The initial assessment probabilities (i.e., prior probabilities) of root nodes at the same hierarchical level were determined.

- (b)

- A specific root node was assumed to have occurred, with its occurrence probability set to 100%. Using this as the analytical starting point, the conditional probabilities of the corresponding next level were clarified.

- (c)

- A layer-by-layer iteration method was employed to construct a complete causal network for the causal branches of each root node.

- (d)

- The prior probability of each root node was cumulatively multiplied stepwise with the posterior probabilities of its subsequent levels, yielding the overall occurrence probability of the corresponding induced terminal event.

- (e)

- All overall occurrence probabilities were compared, and the root node with the highest probability value was selected; the extended pathway of the causal branch corresponding to this node was identified as the key risk evolution pathway.

3. Results

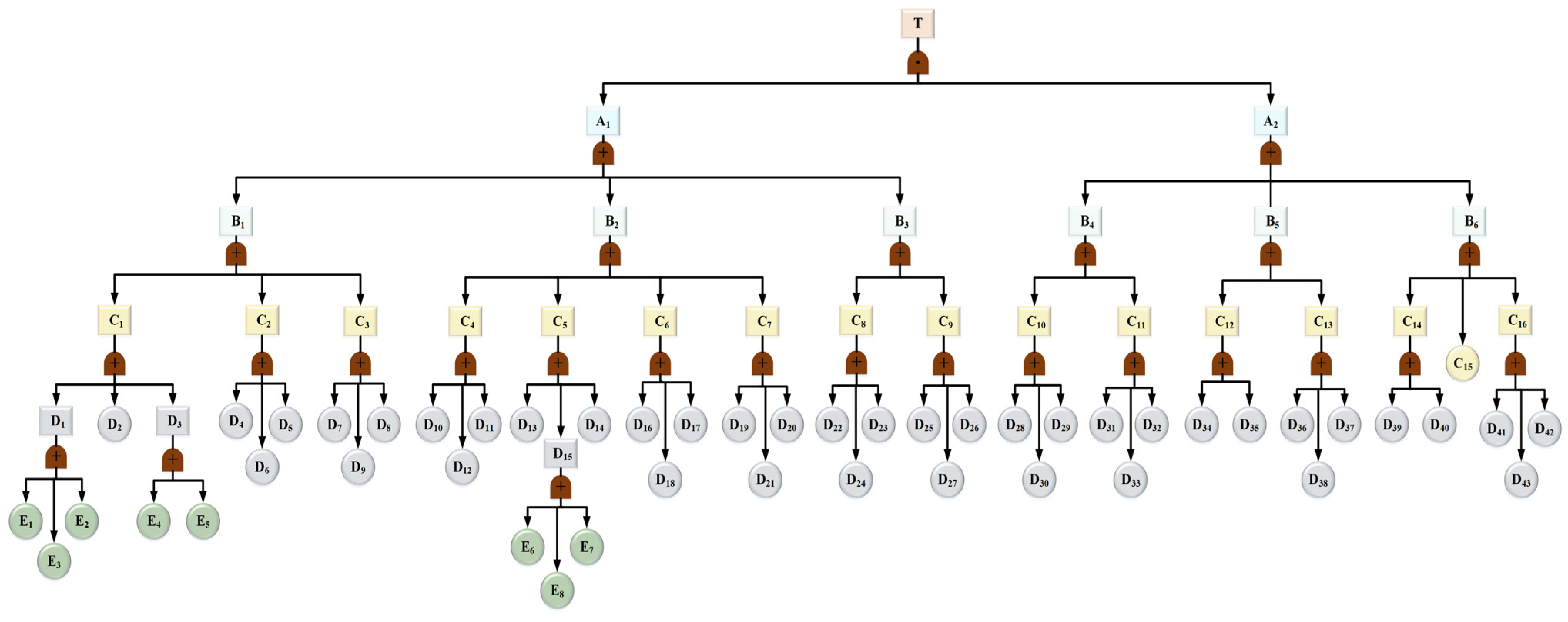

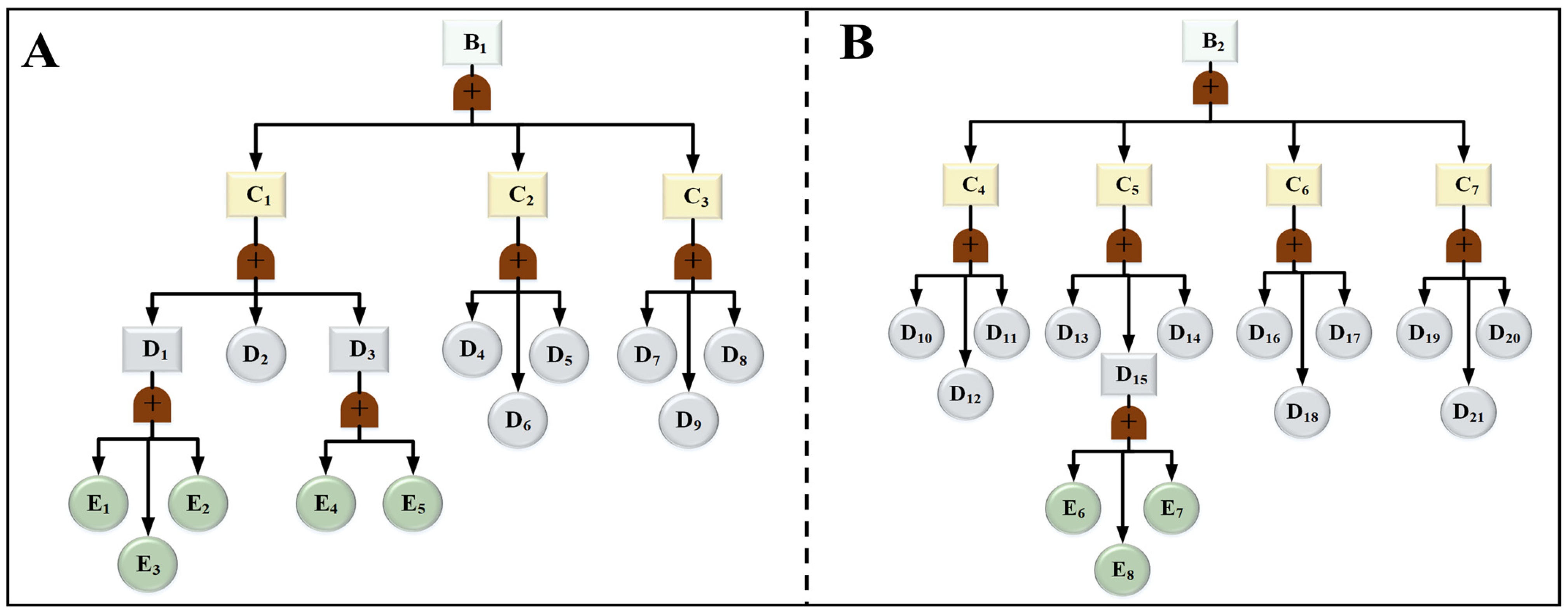

3.1. Factors Resulting from the Battery Quality and Maritime Transportation

- (1)

- Sources of quality risks in batteries themselves

- (2)

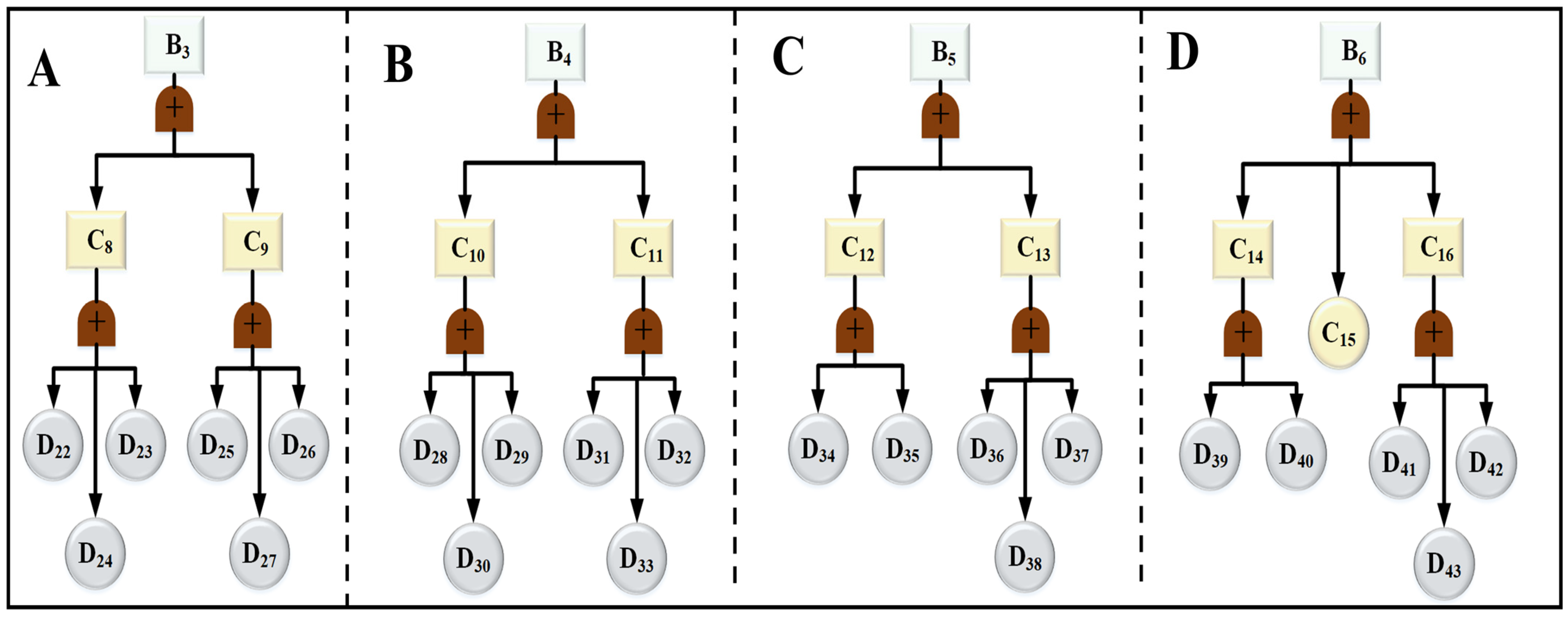

- Impact of maritime transportation on power battery shipping containers

- (3)

- Failure of shipping container protection systems

3.2. Factors Resulting from Pre-Fire Emergency Response Measures

- (1)

- Failure of early detection and warning

- (2)

- Failure of fire suppression systems

- (3)

- Delays in emergency rescue

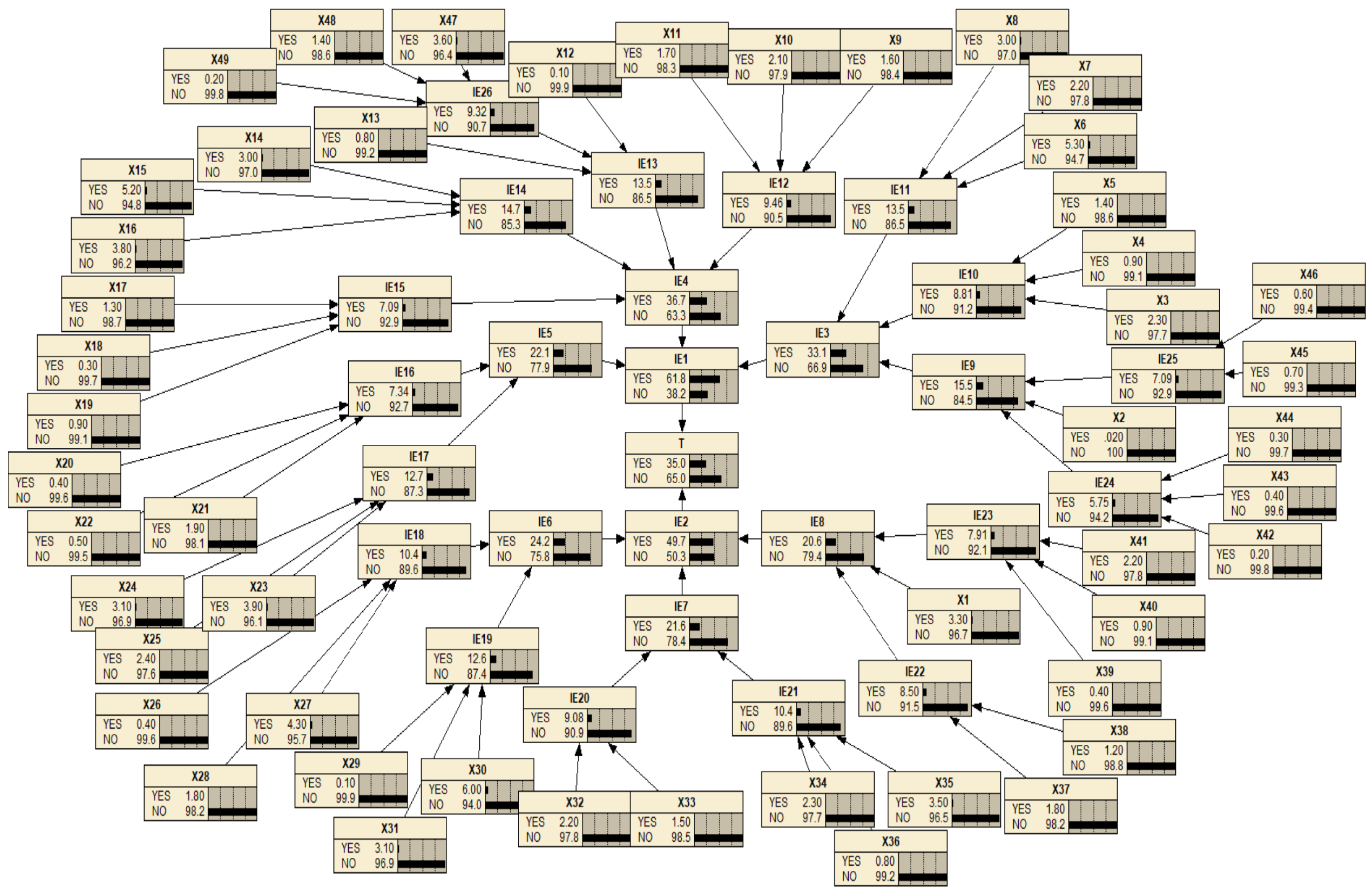

3.3. Conversion of FT to BN

4. Discussion

4.1. Quantitative Assessment and Analysis

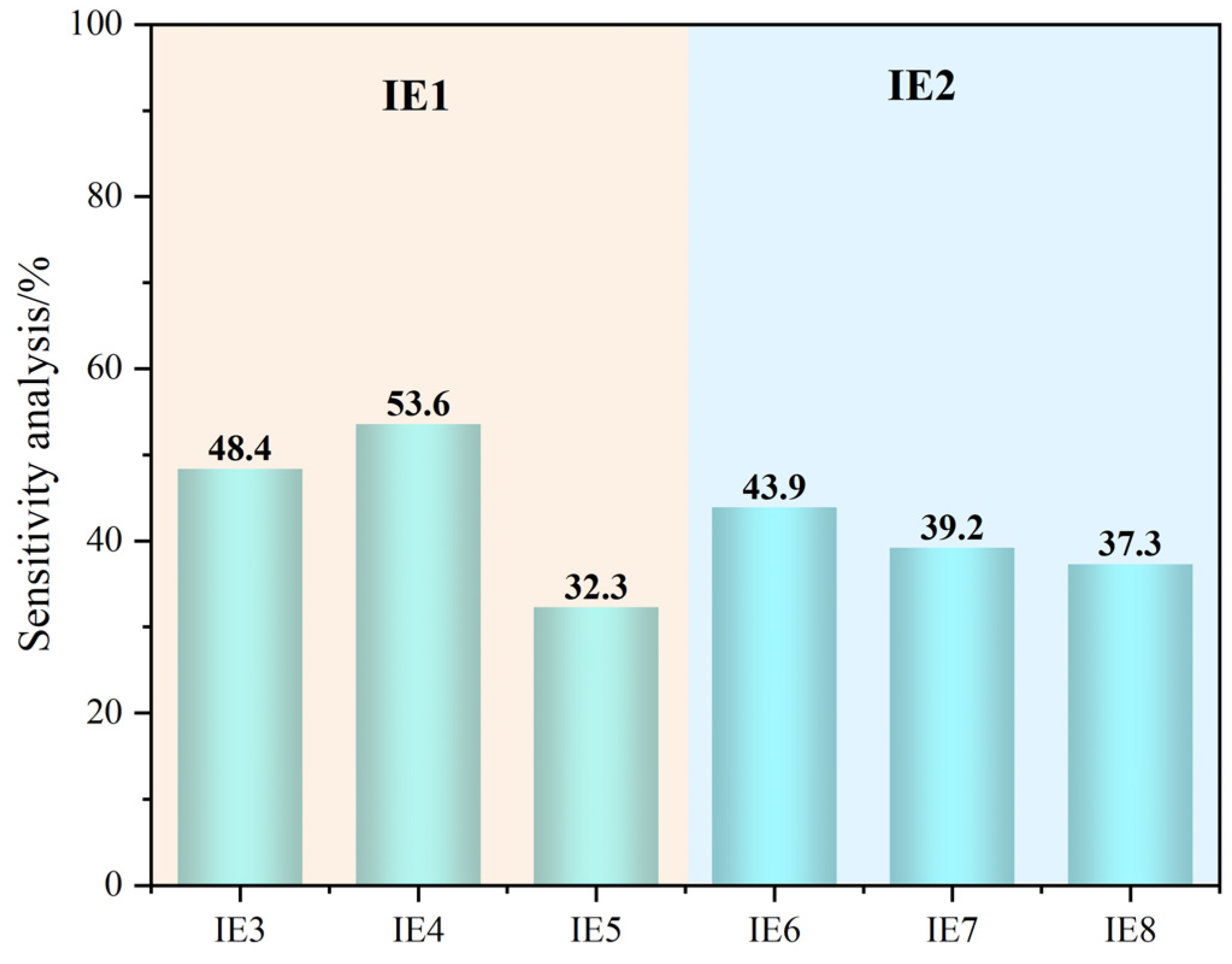

4.2. Identification of Key Risk Evolution Paths

5. Conclusions

- (1)

- A systematic analysis was performed on the accident-causing factors of maritime fire accidents involving lithium-ion power battery shipping containers from three dimensions: the battery quality, maritime transportation characteristics, and pre-fire emergency measures. The logical correlations among the various factors were qualitatively elucidated via a fault tree model. Based on the transformation criteria concerning FT-BN, a Bayesian network model consisting of five hierarchical levels, 26 intermediate nodes, and 49 root nodes was established.

- (2)

- According to the Bayesian network model, the probability of fire accidents involving lithium-ion power battery shipping containers on the target route was estimated to be 35%. Via posterior probability inference of the Bayesian network, two root nodes exerting the most prominent influence on the top event were identified, namely X15 (Blockage of the container ventilation device) and X30 (Omission in inspection by patrol personnel).

- (3)

- Attack–defense game theory was employed to qualitatively identify the critical risk evolution pathways, namely X15-IE14-IE4-IE1 and X30-IE19-IE6-IE2, while their occurrence probabilities were quantitatively estimated to be 3.77% and 4.35%, respectively. From a systematic perspective, the intrinsic mechanisms were revealed: failure of container ventilation facilities triggered battery thermal runaway, and mission failure in personnel inspection resulted in the failure of pre-fire emergency response. Targeted optimization suggestions for risk prevention and control were put forward, targeting these mechanisms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tian, Y.; Zhan, X.; Zhang, Y.X.; Qiao, Z.; Lu, Y.; Xia, Q.; Lu, J.; Zhang, X.; Chen, Z. Thermal Decomposition Mechanism of PF5 and POF3 with Carbonate-Based Electrolytes During Lithium-Ion Batteries’ Thermal Runaway. Fire 2025, 8, 370. [Google Scholar] [CrossRef]

- Frkovic, L.; Cosic, B.; Puksec, T.; Vladimir, N. Vehicle-to-Ship: Enhancing the Energy Transition of Maritime Transport with the Synergy of All-Electric Vehicles and Ferries. IEEE Trans. Transp. Electrific. 2024, 10, 6010–6023. [Google Scholar] [CrossRef]

- Lee, S.; Choi, D.; Jeong, Y.; Moon, M.; Kwon, H.; Han, K.; Kim, H.; Im, H.; Park, Y.; Shin, D.; et al. Assessing Fire Dynamics and Suppression Techniques in Electric Vehicles at Different States of Charge: Implications for Maritime Safety. Case Stud. Therm. Eng. 2024, 64, 105474. [Google Scholar] [CrossRef]

- Waskito, D.H.; Kurt, R.E.; Gusti, A.P.; Bowo, L.P. Assessing the Risk of Transporting Battery Electric Vehicles Through Water Transportation Modes by Integrating System Theory and Bayesian Network Approach. Ocean Eng. 2025, 341, 122606. [Google Scholar] [CrossRef]

- Geronimo-Miguel, J.C.; Sanchez-Mondargon, J.; Cruces-Giron, A.R.; Hernandez-Hernandez, J. Analysis of Vessel Hybrid Engine Upgrade by a CFD Study. Ships Offshore Struct. 2022, 17, 448–456. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, X.; Xia, Q.; Chen, Z. Oxidation Mechanisms of Electrolyte and Fire Gas Generation Laws During a Lithium-Ion Battery Thermal Runaway. Fire 2025, 8, 226. [Google Scholar] [CrossRef]

- Tian, Y.; Zhao, Y.; Kang, Y.Q.; Wu, J.; Meng, Y.; Hu, X.; Huang, M.; Lan, B.; Kang, F.; Li, B. Quantum Chemical Calculation Study on the Thermal Decomposition of Electrolyte During Lithium-Ion Battery Thermal Runaway. Front. Energy Res. 2024, 12, 120497. [Google Scholar] [CrossRef]

- Liu, Y.H.; Sun, P.Y.; Lin, S.R.; Niu, H.; Huang, X. Self-Heating Ignition of Open-Circuit Cylindrical Li-Ion Battery Pile: Towards Fire-Safe Storage and Transport. J. Energy Storage 2020, 32, 101842. [Google Scholar] [CrossRef]

- Yan, Y.F.; Wang, L.; Wu, Z.Z.; Dong, J.; Yuan, Z.; Han, J.; Li, J. Thermal Runaway and Combustion of Lithium-Ion Batteries in Engine Room Fires on Oil/Electric-Powered Ships. Appl. Therm. Eng. 2024, 254, 123838. [Google Scholar] [CrossRef]

- Huang, Y.B.; Xu, P.; Dong, B.Y.; Zhong, H.; Zhu, D.; Liu, Y. Thermal Runaway Characteristics of Lithium-Ion Batteries in a Branched Tunnel: Impact of Longitudinal Ventilation and Cell State of Charge. Energy 2025, 335, 138097. [Google Scholar] [CrossRef]

- Hoffmann, H.J.; Burr, M.T.; Swonder, E.M.; Hoffmann, D.J. Forensic Analysis of Multi-Cell Lithium-Ion Battery Packs Exposed to Flashover Fire Conditions. Fire Technol. 2025, 61, 3705–3718. [Google Scholar] [CrossRef]

- Kim, S.W.; Park, S.G.; Lee, E.J. Assessment of the Explosion Risk During Lithium-Ion Battery Fires. J. Loss Prev. Process Ind. 2022, 90, 104851. [Google Scholar] [CrossRef]

- Ghiji, M.; Novozhilov, V.; Moinuddin, K.; Joseph, P.; Burch, I.; Suendermann, B.; Gamble, G. A Review of Lithium-Ion Battery Fire Suppression. Energies 2020, 13, 5117. [Google Scholar] [CrossRef]

- Hu, Z.W.; He, X.Z.; Restuccia, F.; Yuan, H.; Rein, G. Numerical Study of Scale Effects on Self-Heating Ignition of Lithium-Ion Batteries Stored in Boxes, Shelves and Racks. Appl. Therm. Eng. 2021, 190, 116780. [Google Scholar] [CrossRef]

- Liu, Y.H.; Niu, H.C.; Li, Z.; Liu, J.; Xu, C.; Huang, X. Thermal Runaway Characteristics and Failure Criticality of Massive Ternary Li-Ion Battery Piles in Low-Pressure Storage and Transport. Process Saf. Environ. Prot. 2021, 155, 486–497. [Google Scholar] [CrossRef]

- Cao, Y.F.; Wang, K.; Wang, Z.R.; Wang, J.; Yang, Y.; Xu, X. Utilization of Liquid Nitrogen as Efficient Inhibitor Upon Thermal Runaway of 18650 Lithium Ion Battery in Open Space. Renew. Energy 2023, 206, 1097–1105. [Google Scholar]

- Majeed, F.; Jamal, H.; Kamaran, U.; Noman, M.; Ali, M.M.; Shahzad, T.; Baig, M.M.; Akhtar, F. Review-Recent Advances in Fire-Suppressing Agents for Mitigating Lithium-Ion Battery Fires. J. Electrochem. Soc. 2024, 171, 060522. [Google Scholar] [CrossRef]

- Kim, S.; Choi, H.; Song, Y.K.; Kim, S.; Noh, S.M.; Lee, K.C. Thermoresponsive Microcapsules with Fire-Extinguishing Composites for Fire Prevention. ACS Appl. Polym. Mater. 2024, 6, 3373–3378. [Google Scholar] [CrossRef]

- Barowy, A.; Schraiber, A.; Zalosh, R. Explosion Protection for Prompt and Delayed Deflagrations in Containerized Lithium-Ion Battery Energy Storage Systems. J. Loss Prev. Process Ind. 2022, 80, 104893. [Google Scholar] [CrossRef]

- Yang, J.; Tong, J.C.; Yang, Y.; Zhang, Q.; Niu, J. Characteristics of Thermal Runaway and Propagation for 18650 Lithium Batteries in Top-Confined Space. Int. J. Heat Mass Transf. 2025, 241, 126663. [Google Scholar] [CrossRef]

- Tang, X.J.; Hu, J.; Liu, T.; Hu, S.; Zhu, P.; Wang, X. Experimental Investigation on the Cooling Effect of Fully Submerged Fine Water Mist on Lithium-Ion Batteries in Confined Space. Appl. Therm. Eng. 2024, 239, 122166. [Google Scholar] [CrossRef]

- Mao, B.B.; Yu, S.H.; Zhang, X.K.; Shi, J.; Zhang, Y. Characterization of the Deflagration Behavior of the Lithium-Ion Battery Module Within a Confined Space Under Different Ventilation Conditions. Process. Saf. Environ. Prot. 2024, 184, 1034–1040. [Google Scholar] [CrossRef]

- Zhang, C.C.; Sun, H.; Zhang, Y.Y.; Li, G.; Li, S.; Chang, J.; Shi, G. Fire Accident Risk Analysis of Lithium Battery Energy Storage Systems During Maritime Transportation. Sustainability 2023, 15, 14198. [Google Scholar] [CrossRef]

- Jiang, X.D.; Ren, W.; Xu, H.B.; Zheng, S.; Wu, S. Mechanism-Based Fire Hazard Chain Risk Assessment for Roll-on/Roll-off Passenger Vessels Transporting Electric Vehicles: A Fault Tree-Fuzzy Bayesian Network Approach. J. Mar. Sci. Eng. 2025, 13, 227. [Google Scholar] [CrossRef]

- Wu, B.; Tang, Y.H.; Yan, X.P.; Soares, C.G. Bayesian Network Modelling for Safety Management of Electric Vehicles Transported in RoPax Ships. Reliab. Eng. Syst. Saf. 2021, 209, 107466. [Google Scholar] [CrossRef]

- RoozBahani, A.; Ghanian, T. Risk Assessment of Inter-Basin Water Transfer Plans Through Integration of Fault Tree Analysis and Bayesian Network Modelling Approaches. J. Environ. Manag. 2024, 356, 120703. [Google Scholar] [CrossRef] [PubMed]

- Benomar, F.; Aissani, N.; Lounis, Z.; Bekrar, A. A Novel Semi-Coherent FTA Approach to Assessing the Thermal Runaway in Chemical Reactor. J. Loss Prev. Process Ind. 2026, 99, 105807. [Google Scholar] [CrossRef]

- Meng, H.X.; Hu, M.Q.; Kong, Z.Y.; Niu, Y.; Liang, J.; Nie, Z.; Xing, J. Risk Analysis of Lithium-Ion Battery Accidents Based on Physics-Informed Data-Driven Bayesian Networks. Reliab. Eng. Syst. Saf. 2024, 251, 110294. [Google Scholar] [CrossRef]

- Cox, L.A. Game Theory and Risk Analysis. Risk Anal. 2009, 29, 1062–1068. [Google Scholar] [CrossRef]

- Yoon, H.J.; Thukkaraju, A.R.; Matsumoto, S.; Ferrari, J.F.; Lee, D.; Kil Ahn, M.; Costa, P.; Cho, J.-H. Subjective-Bayesian-Network-Based Interdependent Mission Impact Assessment With Game-Theoretic Attack-Defense Interactions. IEEE Internet Things J. 2025, 12, 6548–6562. [Google Scholar] [CrossRef]

- Li, Y.Y.; Wu, J.; Yuan, W.Y.; Gonzalez, E.D.S. Securing Transportation of Hazardous Materials Against Terrorism: A Novel Game-Based Approach. Comput. Ind. Eng. 2022, 169, 108156. [Google Scholar] [CrossRef]

| Symbol | Meaning | Symbol | Meaning | Symbol | Meaning |

|---|---|---|---|---|---|

| T | Fire accidents of lithium-ion power battery shipping containers in maritime transportation | A1 | Thermal runaway in power battery shipping containers causing open flames | A2 | Failure to handle the initial stage of thermal runaway, leading to further fire expansion |

| B1 | Abnormality in the quality and status of the power battery itself | B2 | Effect of internal and external inducing factors on the container | B3 | Failure of the container protection system in waterway transportation |

| B4 | Early fire detection and warning failure | B5 | Failure of the container and ship fire extinguishing system | B6 | Lag in emergency rescue response for waterway transportation |

| C1 | Substandard manufacturing quality of power batteries | C2 | Abnormality in the pre-delivery storage/pretreatment status of the power battery | C3 | Violation of the pre-transportation loading status of the power battery |

| C4 | Improper operation in container loading and unloading | C5 | External mechanical impact during ship navigation | C6 | Loss of control of environmental parameters inside the container |

| C7 | Electrical connection failure of the power battery pack | C8 | Impaired structural integrity of the container | C9 | Failure of special protective accessories for the container in the waterway |

| C10 | Fault of the fire detection device built in the container | C11 | Inadequate on-site personnel monitoring and inspection | C12 | Failure of the container-built-in fire extinguishing system |

| C13 | Ship deck fire-fighting equipment fails to provide effective coverage | C14 | Failure of emergency organizational coordination within the vessel | C15 | Delay in the linkage of shore-based rescue forces |

| C16 | Restriction of rescue operations by the waterway environment | D1 | Deficiencies in power battery design | D2 | Counterfeit power batteries |

| D3 | Deficiency in quality control during the production process | D4 | Excessive temperature and humidity in the power battery storage environment | D5 | Overcharge/discharge during power battery storage |

| D6 | Power battery storage period exceeds shelf life | D7 | Mixed loading of power battery cells | D8 | Loose fixing of the battery pack |

| D9 | Failure to remove batteries with apparent damage during loading | D10 | Personnel have not received special training on power batteries | D11 | Over-limit operation of the shore bridge/gantry crane |

| D12 | Container collision occurs during stacking | D13 | The ship encounters severe sea conditions, inducing severe rolling | D14 | Collision between the ship and the dock during berthing/departing |

| D15 | Loss of stability and collapse of container stacks | D16 | Failure of the container temperature control system | D17 | Blockage of the container ventilation device |

| D18 | Excessive humidity inside the container caused by water accumulation | D19 | Insulation layer breakage and short-circuit of the battery pack connecting wires | D20 | Poor contact of the external power supply lines connected to the battery pack |

| D21 | Failure of the battery management system | D22 | Substandard structural strength of the container at the factory | D23 | Uninspected and unrepaired dents/cracks on the container body before transportation |

| D24 | Container wall perforation due to seawater corrosion | D25 | Aging and cracking of the waterproof sealing strip of the container | D26 | Blockage/damage of the waterproof and air-permeable valve |

| D27 | Failure to install anti-seawater immersion pads at the bottom of the container | D28 | Wrong selection of fire detectors | D29 | False alarm/missed alarm caused by non-periodic calibration of the detector |

| D30 | Fracture of the detection signal transmission line due to vibration | D31 | No scheduled inspection system formulated | D32 | Omission in inspection by patrol personnel |

| D33 | Inspection interruption in low-visibility environments | D34 | The fire extinguishing device expired | D35 | Improper selection of the fire extinguishing medium |

| D36 | Insufficient pressure of the ship’s fire hydrant | D37 | Aging and leakage of the fire hose/interface | D38 | The fire extinguishing range cannot cover the upper containers |

| D39 | Internal communication system failure of the vessel | D40 | Insufficiency of crew emergency drills | D41 | Fire occurrence area far from the coastline |

| D42 | Wind waves/tides hinder rescue vessels’ approach | D43 | The container fire spreads and causes rescue channel blockages | E1 | Inferior thermal stability of battery cathode materials |

| E2 | Short service life of SEI film design | E3 | Insufficient compressive strength of the battery casing | E4 | Absence of an effective quality management system certification |

| E5 | Failure to implement the latest power battery production standards | E6 | Loosening of container stacking and fixing fixtures | E7 | Failure of anti-skid measures on the ship’s cargo hold deck |

| E8 | The stacking height exceeds the ship’s stability requirements |

| Bayesian Code | Fault Tree Code | Bayesian Code | Fault Tree Code | Bayesian Code | Fault Tree Code |

|---|---|---|---|---|---|

| IE1 | A1 | IE2 | A2 | IE3 | B1 |

| IE4 | B2 | IE5 | B3 | IE6 | B4 |

| IE7 | B5 | IE8 | B6 | IE9 | C1 |

| IE10 | C2 | IE11 | C3 | IE12 | C4 |

| IE13 | C5 | IE14 | C6 | IE15 | C7 |

| IE16 | C8 | IE17 | C9 | IE18 | C10 |

| IE19 | C11 | IE20 | C12 | IE21 | C13 |

| IE22 | C14 | IE23 | C16 | IE24 | D1 |

| IE25 | D3 | IE26 | D15 | ||

| X1 | C15 | X2 | D2 | X3 | D4 |

| X4 | D5 | X5 | D6 | X6 | D7 |

| X7 | D8 | X8 | D9 | X9 | D10 |

| X10 | D11 | X11 | D12 | X12 | D13 |

| X13 | D14 | X14 | D16 | X15 | D17 |

| X16 | D18 | X17 | D19 | X18 | D20 |

| X19 | D21 | X20 | D22 | X21 | D23 |

| X22 | D24 | X23 | D25 | X24 | D26 |

| X25 | D27 | X26 | D28 | X27 | D29 |

| X28 | D30 | X29 | D31 | X30 | D32 |

| X31 | D33 | X32 | D34 | X33 | D35 |

| X34 | D36 | X35 | D37 | X36 | D38 |

| X37 | D39 | X38 | D40 | X39 | D41 |

| X40 | D42 | X41 | D43 | X42 | E1 |

| X43 | E2 | X44 | E3 | X45 | E4 |

| X46 | E5 | X47 | E6 | X48 | E7 |

| X49 | E8 |

| Expert Type | Weight Proportion |

|---|---|

| Regulatory Representatives | 0.214 |

| Shipping Managers | 0.286 |

| Frontline Operators | 0.286 |

| University Researchers | 0.214 |

| Root Node | Evolution Path | Occurrence Probability (%) |

|---|---|---|

| X15 | X15-IE14-IE4-IE1 | 3.77 |

| X30 | X30-IE19-IE6-IE2 | 4.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, Z.; Zhan, X.; Tian, Y.; Gao, Y.; He, L.; Lu, Y. Fire Risk Assessment of Lithium-Ion Power Battery Shipping Containers in Maritime Transportation Scenarios. Fire 2025, 8, 453. https://doi.org/10.3390/fire8120453

Qiao Z, Zhan X, Tian Y, Gao Y, He L, Lu Y. Fire Risk Assessment of Lithium-Ion Power Battery Shipping Containers in Maritime Transportation Scenarios. Fire. 2025; 8(12):453. https://doi.org/10.3390/fire8120453

Chicago/Turabian StyleQiao, Zhen, Xiaotiao Zhan, Yao Tian, Yuan Gao, Longjun He, and Yuxiang Lu. 2025. "Fire Risk Assessment of Lithium-Ion Power Battery Shipping Containers in Maritime Transportation Scenarios" Fire 8, no. 12: 453. https://doi.org/10.3390/fire8120453

APA StyleQiao, Z., Zhan, X., Tian, Y., Gao, Y., He, L., & Lu, Y. (2025). Fire Risk Assessment of Lithium-Ion Power Battery Shipping Containers in Maritime Transportation Scenarios. Fire, 8(12), 453. https://doi.org/10.3390/fire8120453