Safe Treatment of Surface Coalfield Fires Above Shallow-Buried Goaf in Steeply Dipping Coal Seams

Abstract

1. Introduction

2. Materials and Methods

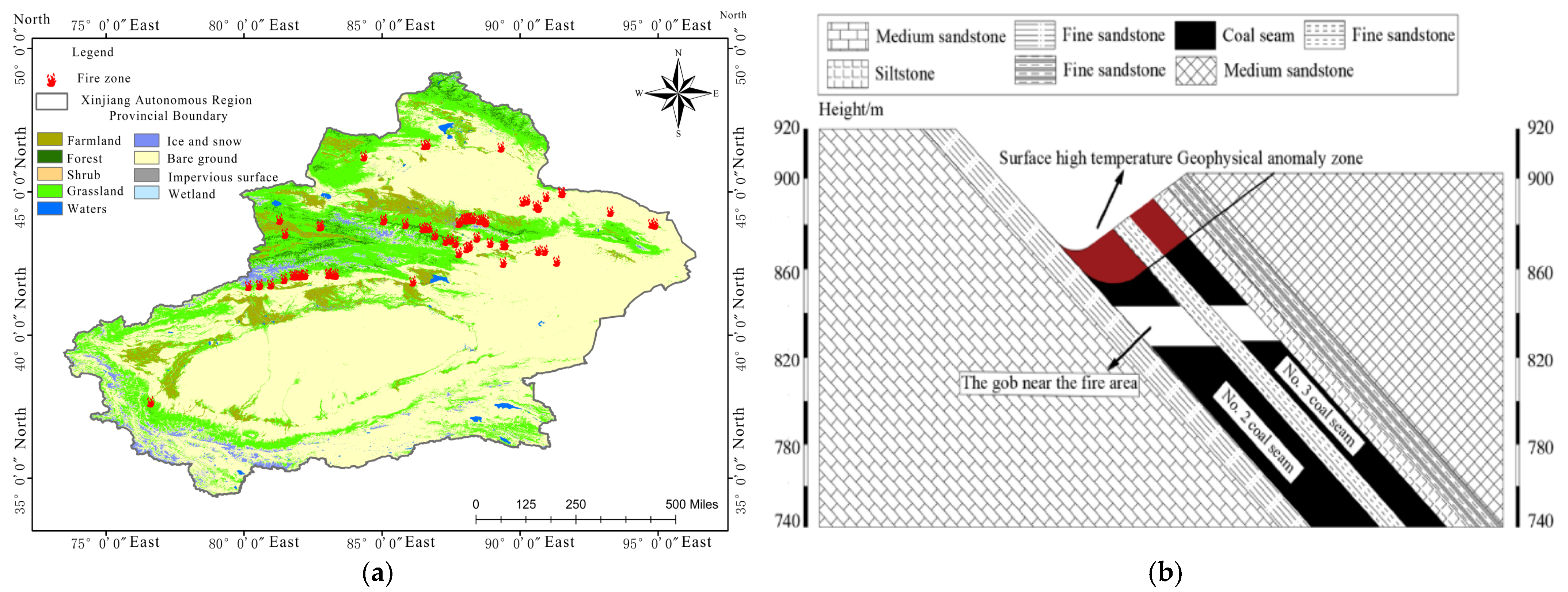

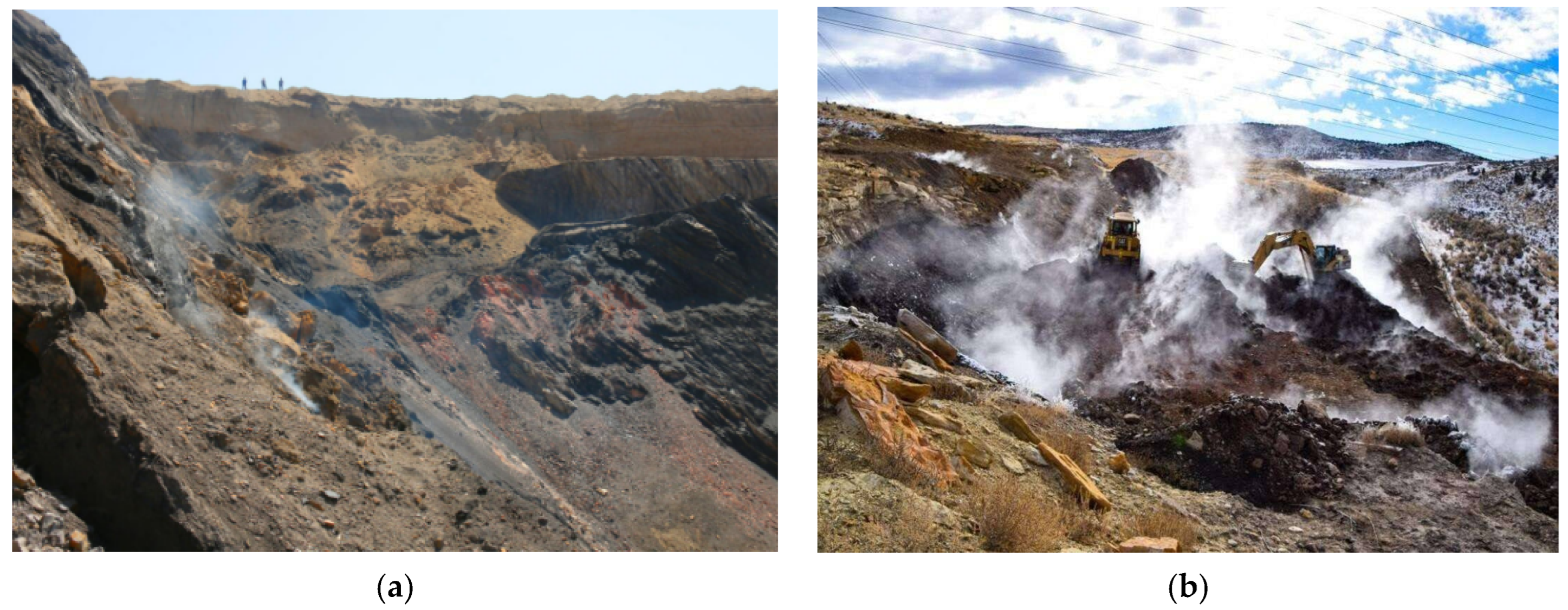

2.1. Engineering Background

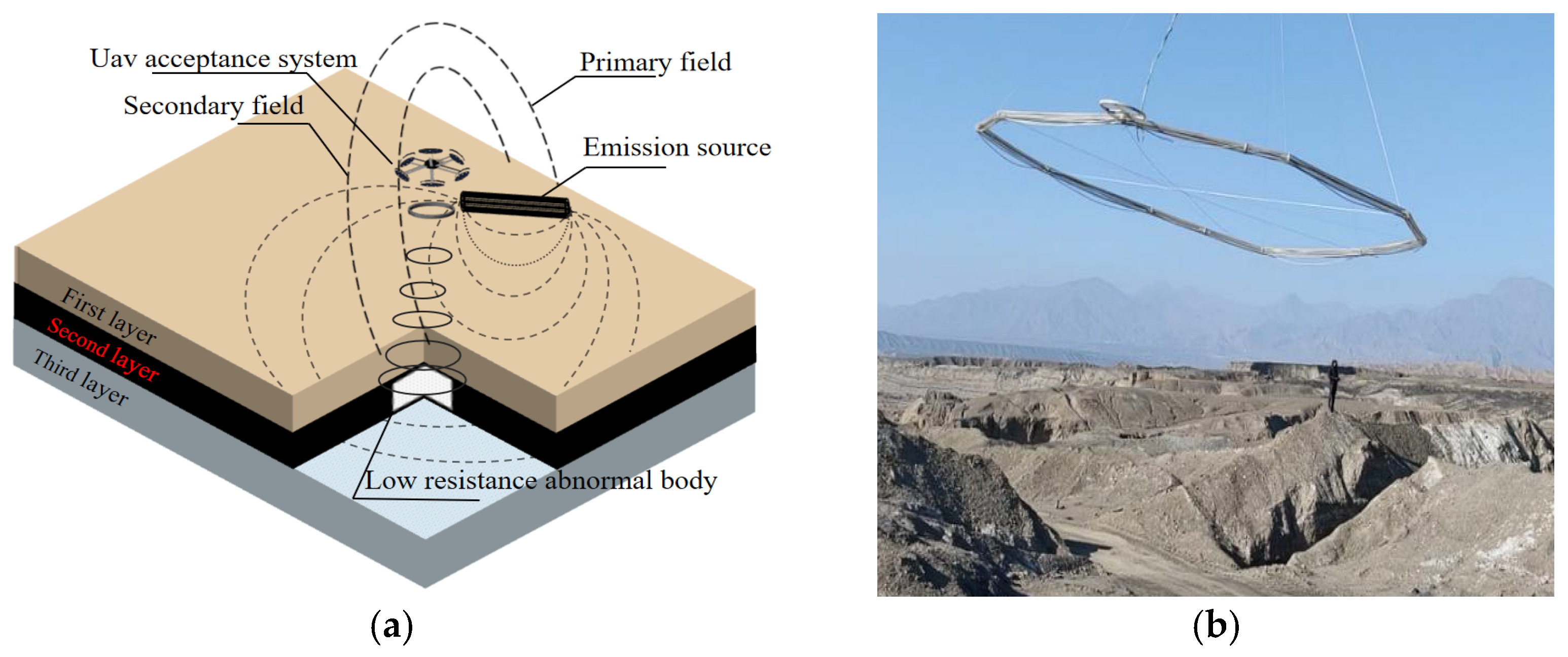

2.2. Airborne Transient Electromagnetic Measurement

2.2.1. Exploration Principles

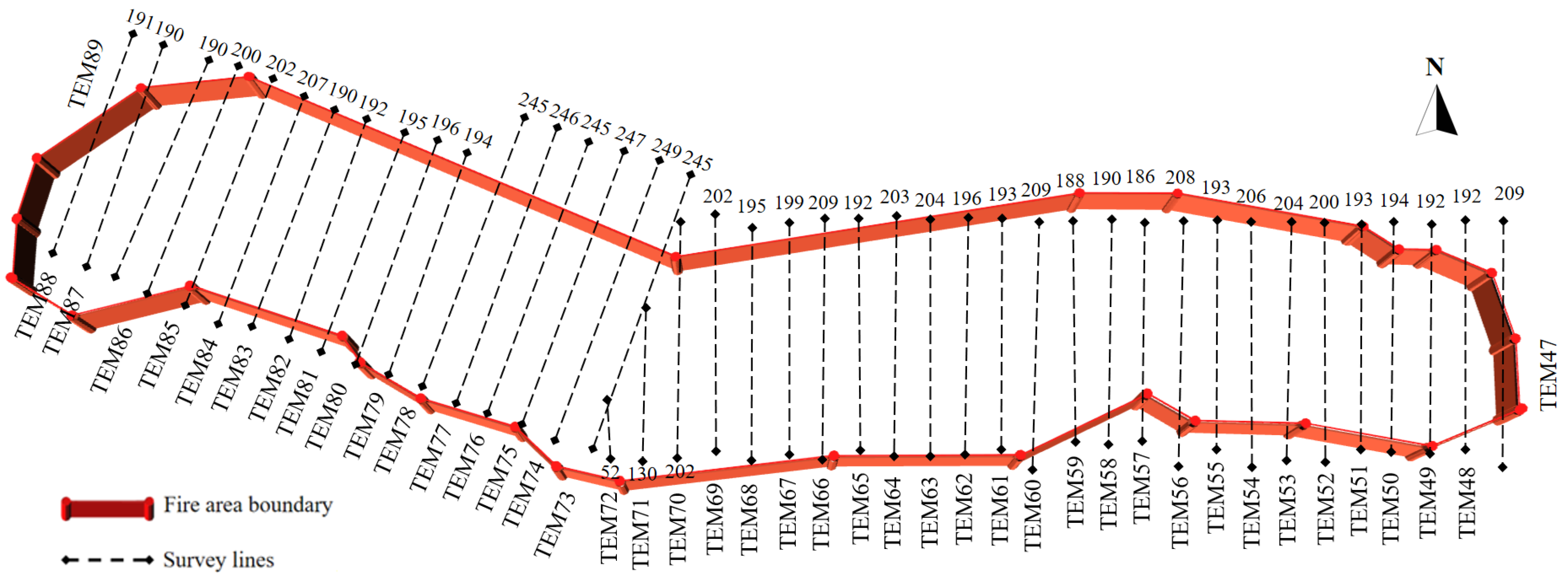

2.2.2. Layout of Geophysical Exploration Lines

2.3. Numerical Simulation

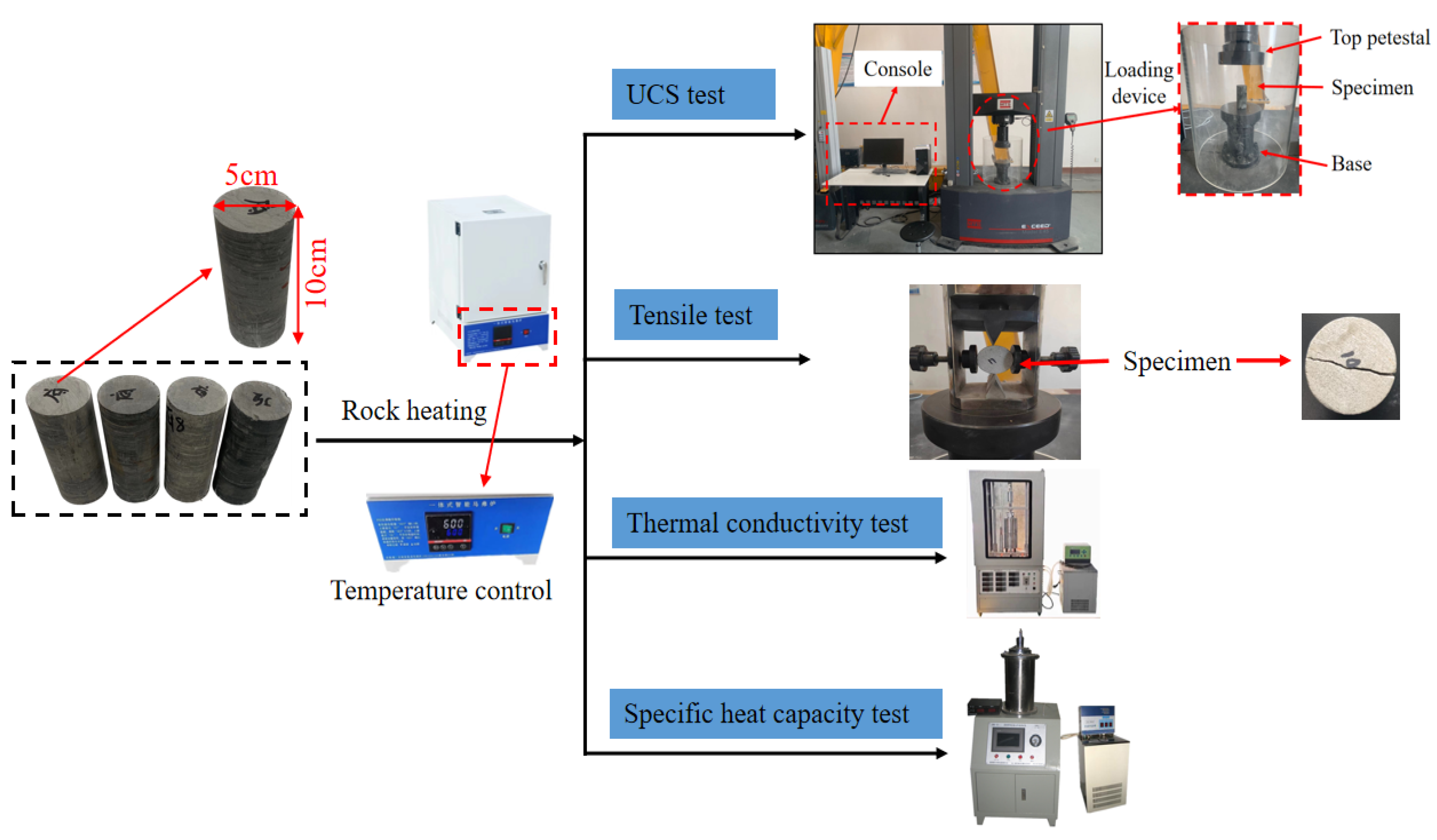

2.3.1. Properties of Overlying Rocks

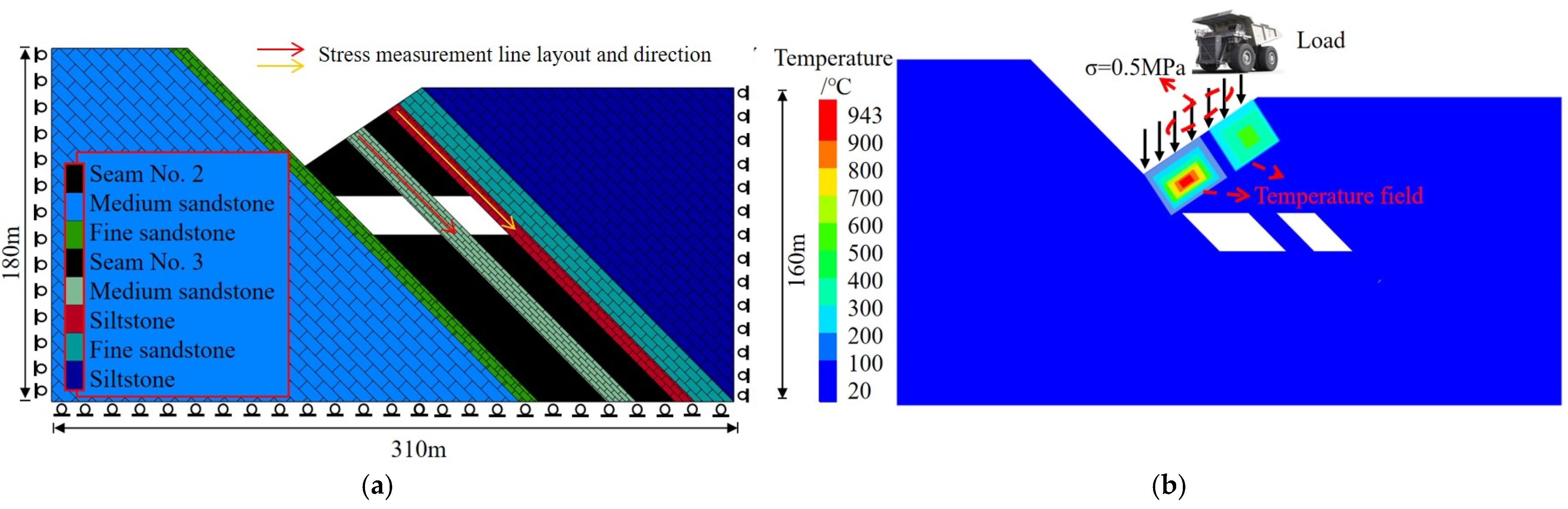

2.3.2. Numerical Calculation Model and Scheme

3. Results

3.1. Location and Dimensions of the Goaf

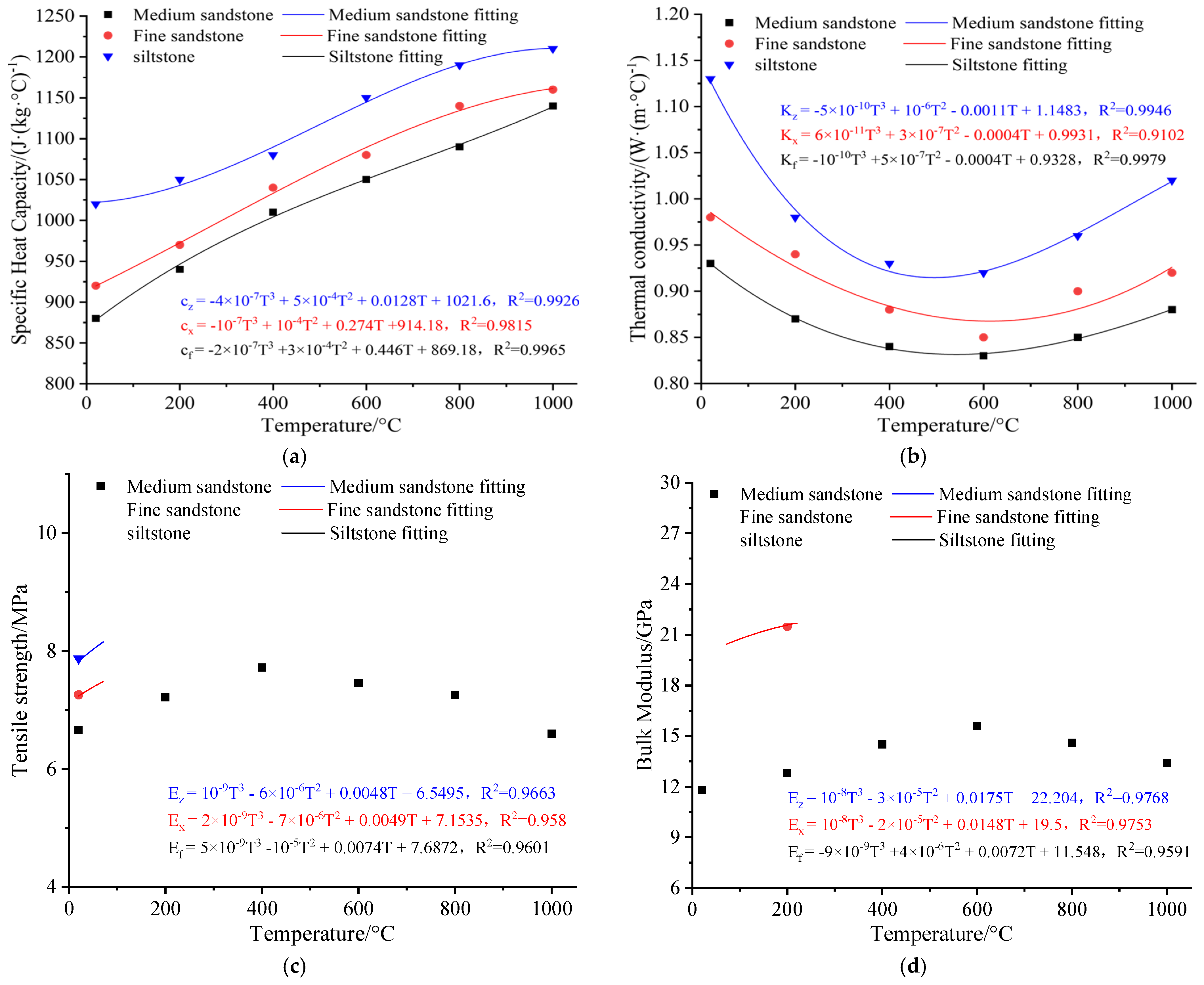

3.2. Thermophysical Properties of Overlying Rocks at Different Temperatures

3.3. Stability Analysis of Overburden Above Goafs

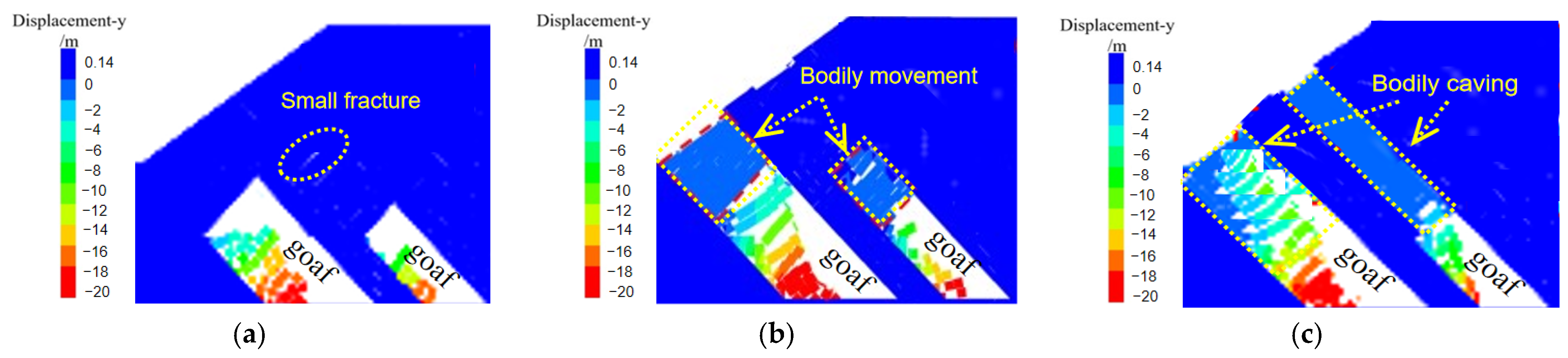

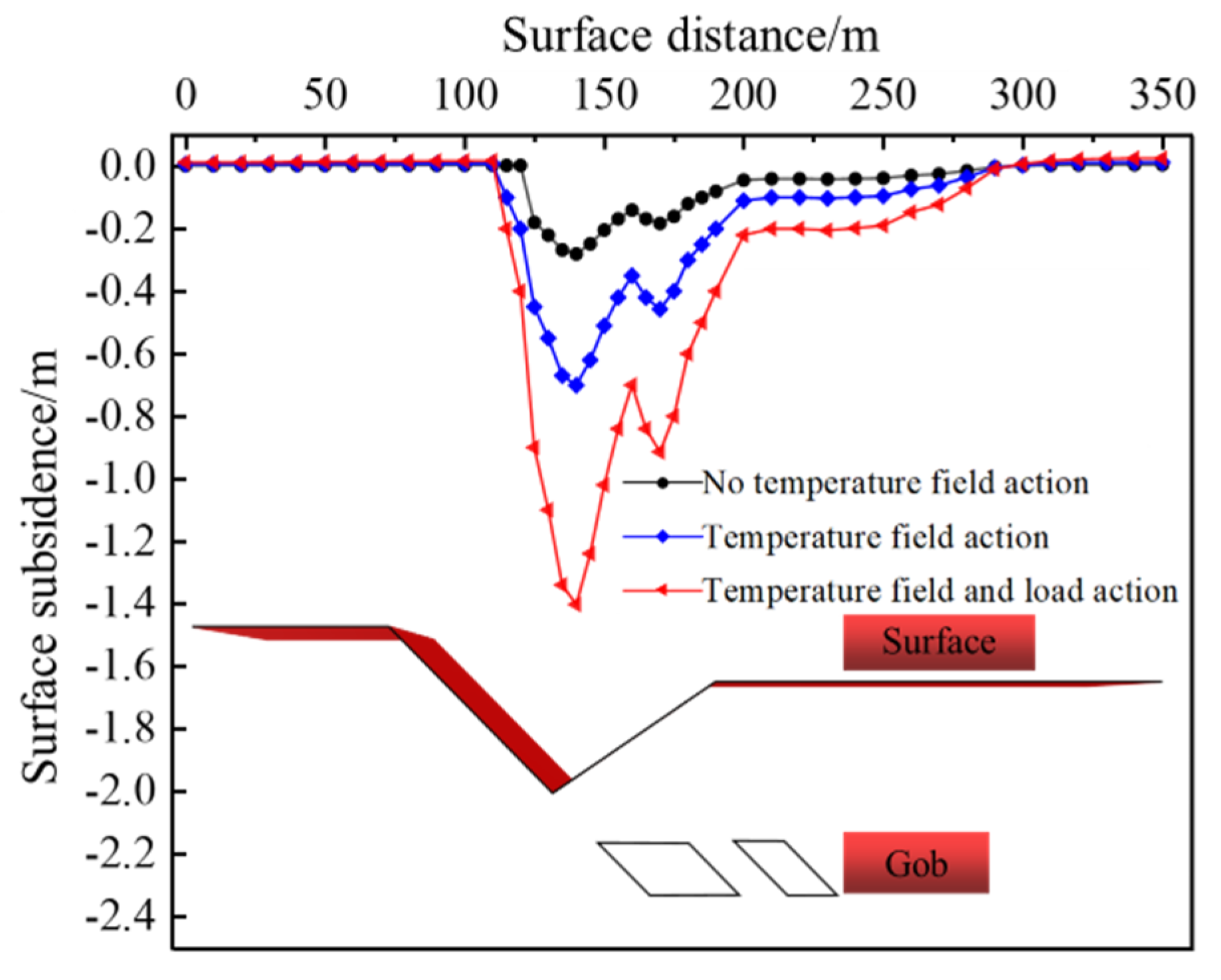

3.3.1. Analysis of Overburden Movement Law

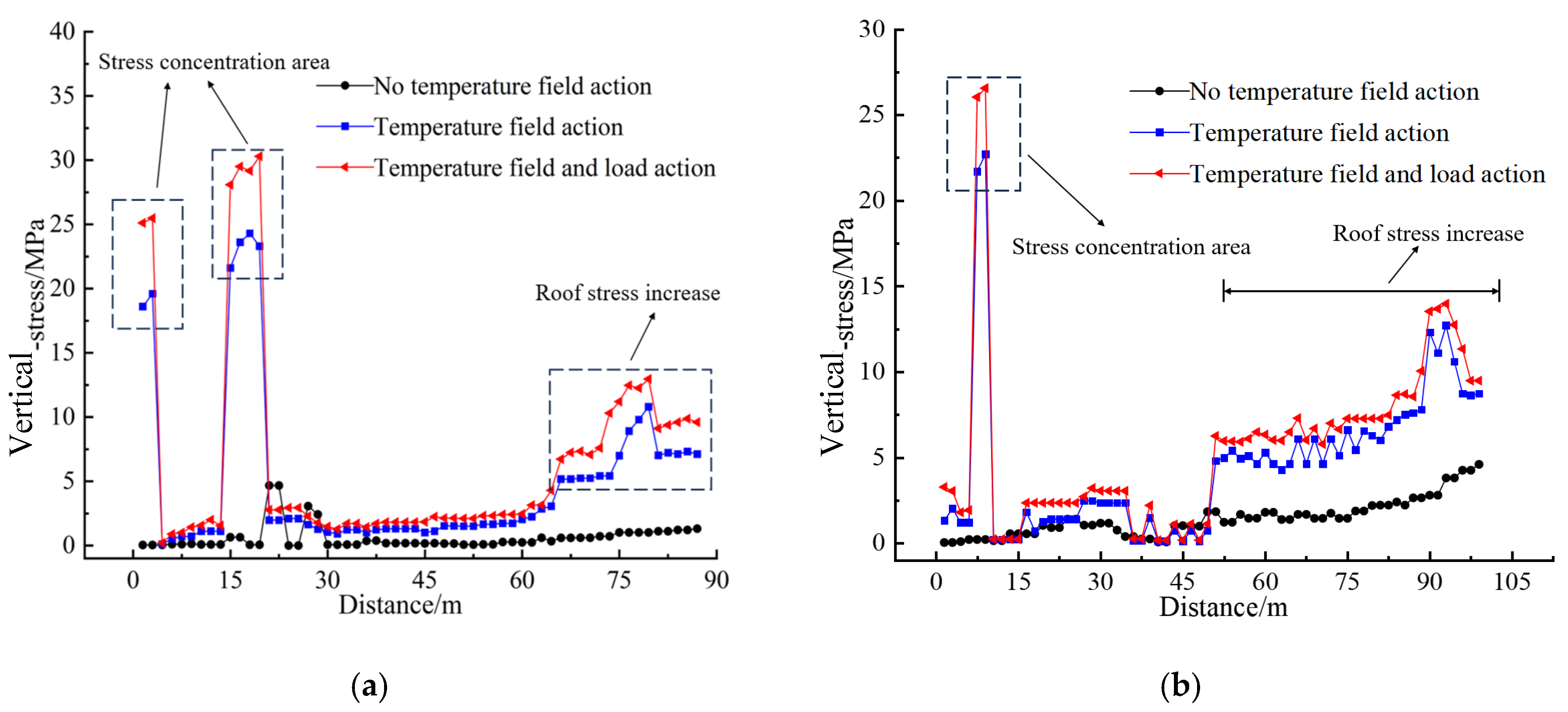

3.3.2. Analysis of Overburden Stress Evolution

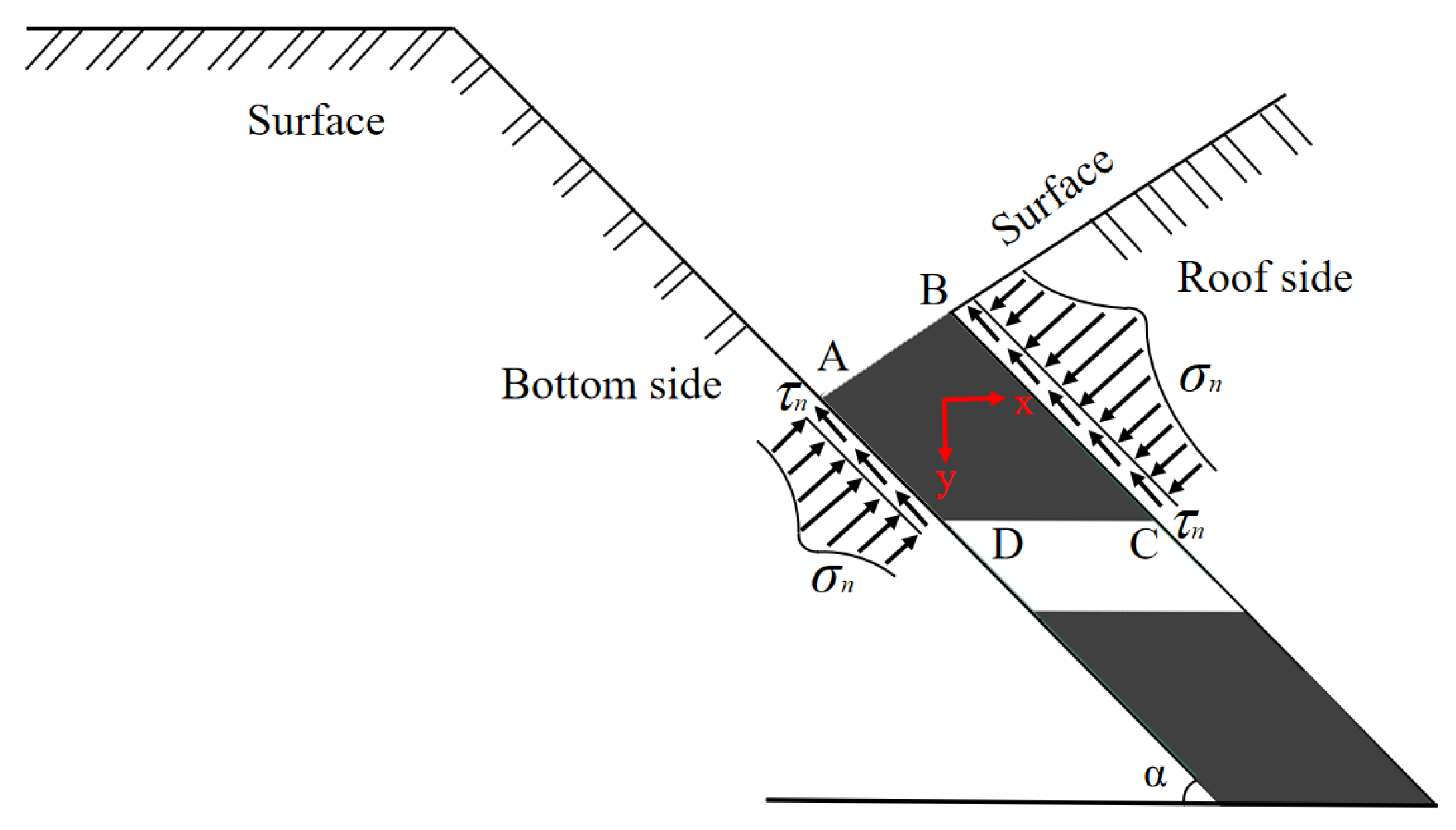

3.3.3. Analysis of Overburden Mechanical Structure

4. Field Application

- Injecting water into the surface high-temperature zones of the fire area to extinguish surface flames and reduce ground temperatures, thereby establishing a foundation for mechanical operations to be conducted within a safe temperature range.

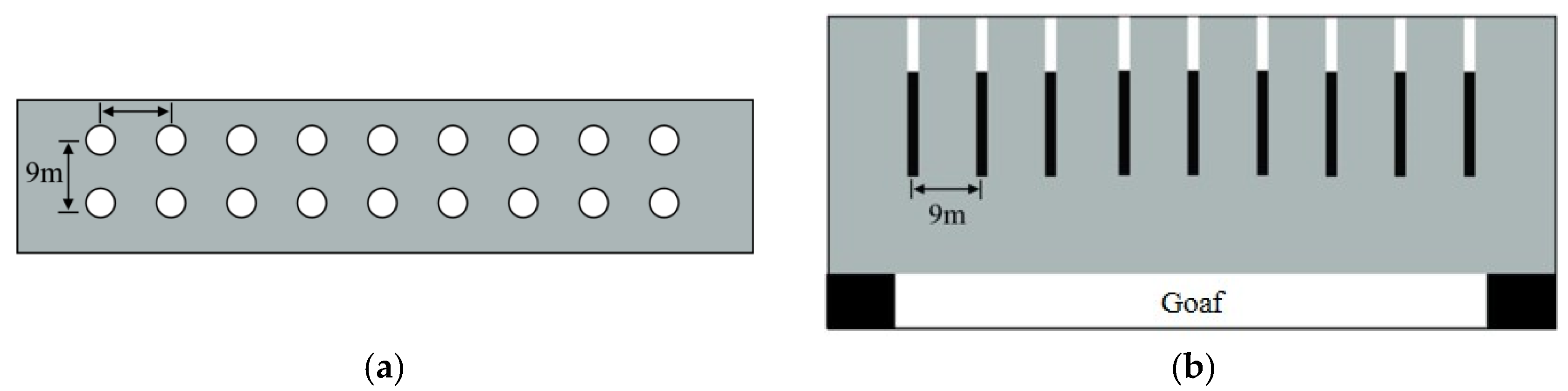

- Conducting management of the goaf based on its exploration results by arranging boreholes for blasting. Vibration management should be applied to shallow goafs to ensure the complete collapse of the goaf tunnels in one go, eliminating safety hazards for machinery and ensuring the safety of stripping operations. Figure 14 shows the layout of the goaf management plan, with boreholes arranged vertically to the ground and spaced 9 m apart to mitigate the adverse effects of blasting on tunnel stability. The explosive used is a mining-grade water gel explosive, with a detonation velocity of 3600 m/s and a power factor of 239 mL. The blasting hole depth is 30 m, the blasting hole diameter is 75 mm, the Charging diameter is 63 mm, the Charging length is 13 mm and the sealing length is 17 m.

- Combining bulldozers, excavators, and shallow-hole blasting drills to carry out surface stripping and leveling work in the fire area. This involves filling-in collapse pits, cracks, and shallow goafs to create a working face, thereby establishing a suitable construction site for subsequent operations such as soil covering.

- Implementing water injection in fish-scale-like pits on the surface of the fire area to reduce the temperature of the deep fire source to the levels required by the Specification for Fire Extinguishing in Coalfields.

- Conducting compaction of the stripped surface to ensure the closure of gaps between the goaf and the surface.

- Covering the leveled management area with loess and performing a second compaction using machinery.

5. Discussion

- The estimated budget of the fire extinguishing project in the Chatekale Fire Area (Xingliang II Mine Field) is CNY 95.4595 million. The implementation of the fire extinguishing project will protect 37.62 million tons of coal resources from the threat of coal field fires, reduce the coal burning loss by 254.23 million tons per year, and reduce the annual economic loss by CNY 50.85 million based on the coal price of 200 CNY/t. After thorough treatment, the loss of CNY 7.524 billion can be directly reduced, and the economic benefits are remarkable.

- The Chatekale Fire Area (Xingliang II Mine Field) annually emits 661,060 tons of CO2, 2491 tons of hydrocarbons, 1881 tons of nitrogen oxides, and 2162 tons of SO2 due to combustion. Additionally, it releases a large amount of harmful elements such as fluorine and arsenic. After the completion of the fire area project, the large amounts of toxic and harmful gases produced by the combustion of coal seams in the fire area will be eliminated, effectively improving the local air quality and the ecological environment of the surrounding atmosphere, water bodies, and soil.

- After the fire extinguishing project is completed, the subsidence and fissures on the surface of the fire area will be stripped, leveled, and filled, which will transform the topography of the fire area, reduce the occurrence of geological disasters around the fire area, reduce soil desertification and soil erosion, and improve the local ecological environment, with significant ecological benefits.

6. Conclusions

- The use of the airborne transient electromagnetic method enabled precise exploration of the goaf beneath the No. 1 sub-fire area in the Chatekale Fire Area (Xinjiang II Mine Field). The exploration results indicated no goaf beyond the mining boundary of +825 to +845 m, aligning with drilling verification results. This demonstrates the superiority of the airborne transient electromagnetic method in exploring goafs.

- The presence of the temperature field markedly affects the stability of the overburden above the goaf, primarily manifested in the increased displacement of the coal body above the goaf, greater concentration of stress in the coal body, and higher likelihood of key rock blocks in the coal body experiencing rotation, sliding, and tipping. After the application of the temperature field, the maximum surface displacement increased from 0.45 to 0.78 m. Following the application of load, the maximum surface displacement rose from 0.45 to 1.42 m, representing an increase of up to 216%. Additionally, after applying the temperature field, the peak vertical stress in the goaf increased from 8.5 to 32 MPa, and after loading, the peak stress rose to 36 MPa.

- In the subsequent management of near-surface goaf fire areas, a strategy has been proposed that involves first conducting precise blasting treatments in the goaf, followed by comprehensive fire-fighting measures. Monitoring results indicate successful management of the fire area.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Guo, J.; Gao, B.; Liu, Y.; Chen, C.; Cai, G.; Wang, L. Research and Application of CO2 Fire Prevention Mechanism and Key Technologies in Mines: A Review. Fire 2024, 7, 353. [Google Scholar] [CrossRef]

- Szurgacz, D.; Tutak, M.; Brodny, J.; Sobik, L.; Zhironkina, O. The method of combating coal spontaneous combustion hazard in goafs—A case study. Energies 2020, 12, 4538. [Google Scholar] [CrossRef]

- Mohalik, N.K.; Singh, R.V.K.; Pandey, J.; Singh, V.K. Application of nitrogen as preventive and controlling subsurface fire—Indian context. J. Sci. Ind. Res. India 2005, 64, 273–280. [Google Scholar]

- Bajestani, M.S.; Nasir, O.; Coulson, C. Analysis of Long-Term Thermo–Hydro–Mechanical Behavior in the Near-Field of a Deep Geological Repository System. Minerals 2024, 14, 1262. [Google Scholar] [CrossRef]

- Shao, H.; Radeisen, E.; Hesser, J.; Wang, W.; Kolditz, O. Coupled Processes at Micro- and Macroscopic Levels for Long-Term Performance Assessment Studies of Nuclear Waste Repositories. Minerals 2024, 14, 453. [Google Scholar] [CrossRef]

- Shang, X.; Zhang, Z.; Xu, X.; Liu, T.; Xing, Y. Mineral Composition, Pore Structure, and Mechanical Characteristics of Pyroxene Granite Exposed to Heat Treatments. Minerals 2019, 9, 553. [Google Scholar] [CrossRef]

- Yang, Y.L.; Zheng, K.Y.; Li, Z.W.; Li, Z.H.; Si, L.L.; Hou, S.S.; Duan, Y.J. Experimental study on pore-fracture evolution law in the thermal damage process of coal. Int. J. Rock Mech. Min. Sci. 2019, 116, 13–24. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Sun, Q.; Zhu, S.Y.; Wang, B. Experimental study on mechanical and porous characteristics of limestone affected by high temperature. Appl. Therm. Eng. 2017, 110, 356–362. [Google Scholar] [CrossRef]

- Liu, P.; Cui, S.G.; Li, Z.H.; Xu, X.F.; Guo, C. Influence of surrounding rock temperature on mechanical property and pore structure of concrete for shotcrete use in a hot-dry environment of high-temperature geothermal tunnel. Constr. Build. Mater. 2019, 207, 329–337. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, W.Q.; Su, T.M.; Zhu, S.Y. Variation of wave velocity and porosity of sandstone after high temperature heating. Acta Geophys. 2016, 64, 633–648. [Google Scholar] [CrossRef]

- Pan, C.; Xia, B.; Zuo, Y.; Yu, B.; Ou, C. Mechanism and control technology of strong ground pressure behaviour induced by high–position hard roofs in extra–thick coal seam mining. Int. J. Min. Sci. Technol. 2022, 32, 499–511. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, W.; Xu, J.; Wu, J.; Li, Y. High–intensity longwall mining-induced ground subsidence in Shendong coalfield, China. Int. J. Rock Mech. Min. Sci. 2021, 141, 104730. [Google Scholar] [CrossRef]

- Zhang, B.; Xiao, F.; Jin, W. Burnt coal field detection via magnetic exploration. Environ. Earth Sci. 2023, 82, 160. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Wang, W.; Duan, P.; He, X.; Lu, Q. Distribution, Occurrence and Enrichment Causes of Sodium in Middle Jurassic Coal from Zhundong Coalfield, Xinjiang. Minerals 2024, 14, 146. [Google Scholar] [CrossRef]

- Saadat, M.; Khishvand, M.; Seccombe, A. FLAC3D Simulation of Caving Mechanism and Strata Fracture Response in Underground Mining. Mining 2024, 4, 818–840. [Google Scholar] [CrossRef]

- Karanam, V.; Motagh, M.; Garg, S.; Jain, K. Multi-sensor remote sensing analysis of coal fire induced land subsidence in Jharia Coalfields, Jharkhand, India. Int. J. Appl. Earth Obs. Geoinf. 2021, 102, 102439. [Google Scholar] [CrossRef]

- Moros, J.; Gaona, I.; Laserna, J.J. Remotely Exploring Deeper-Into-Matter by Non-Contact Detection of Audible Transients Excited by Laser Radiation. Sensors 2017, 17, 2960. [Google Scholar] [CrossRef] [PubMed]

- Massone, Q.; Druon, S.; Triboulet, J. A Novel 3D Reconstruction Sensor Using a Diving Lamp and a Camera for Underwater Cave Exploration. Sensors 2024, 24, 4024. [Google Scholar] [CrossRef]

- Anghelescu, L.; Diaconu, B.M. Advances in Detection and Monitoring of Coal Spontaneous Combustion: Techniques, Challenges, and Future Directions. Fire 2024, 7, 354. [Google Scholar] [CrossRef]

- Syed, T.H.; Riyas, M.J.; Kuenzer, C. Remote sensing of coal fires in India: A review. Earth-Sci. Rev. 2018, 187, 338–355. [Google Scholar] [CrossRef]

- Shevtsova, A.; Stanchits, S.; Filev, E.; Karamov, T.; Stukachev, V.; Spasennykh, M. Assessment of Saturation Effect on Hydraulic Fracturing in Sandstone and Thermally Treated Granite. Minerals 2023, 13, 777. [Google Scholar] [CrossRef]

- Sanchez-Barra, A.; Zambrano-Narvaez, G.; Chalaturnyk, R. An In-Depth Analysis of Strength and Stiffness Variability in 3D-Printed Sandstones: Implications for Geomechanics. Energies 2023, 16, 5406. [Google Scholar] [CrossRef]

- Jendryś, M.; Hadam, A.; Ćwiękała, M. Directional Hydraulic Fracturing (DHF) of the Roof, as an Element of Rock Burst Prevention in the Light of Underground Observations and Numerical Modelling. Energies 2021, 14, 562. [Google Scholar] [CrossRef]

- Rajwa, S.; Janoszek, T.; Świątek, J.; Walentek, A.; Bałaga, D. Numerical Simulation of the Impact of Unmined Longwall Panel on the Working Stability of a Longwall Using UDEC 2D—A Case Study. Energies 2022, 15, 1803. [Google Scholar] [CrossRef]

| Stratum | Density /Kg/m3 | Elastic Modulus /GPa | Shear Modulus /GPa | Angle of Internal friction/° | Cohesion /MPa | Tensile Strength /MPa |

|---|---|---|---|---|---|---|

| Siltstone | 2700 | 22.6 | 18.4 | 36 | 8.2 | 7.8 |

| Fine sandstone | 2600 | 19.8 | 16.3 | 35 | 7.3 | 7.2 |

| Medium sandstone | 2450 | 11.6 | 8.5 | 36 | 6.8 | 6.6 |

| Coal | 1470 | 4.5 | 3.4 | 33 | 1.9 | 1.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Chen, R.; Zhu, G.; Yang, D.; Li, X.; Jiang, W.; Liu, H.; Zhang, Z. Safe Treatment of Surface Coalfield Fires Above Shallow-Buried Goaf in Steeply Dipping Coal Seams. Fire 2025, 8, 33. https://doi.org/10.3390/fire8010033

Zhang P, Chen R, Zhu G, Yang D, Li X, Jiang W, Liu H, Zhang Z. Safe Treatment of Surface Coalfield Fires Above Shallow-Buried Goaf in Steeply Dipping Coal Seams. Fire. 2025; 8(1):33. https://doi.org/10.3390/fire8010033

Chicago/Turabian StyleZhang, Pihong, Ruchang Chen, Guoqing Zhu, Dezhi Yang, Xin Li, Wei Jiang, Hao Liu, and Zhiyi Zhang. 2025. "Safe Treatment of Surface Coalfield Fires Above Shallow-Buried Goaf in Steeply Dipping Coal Seams" Fire 8, no. 1: 33. https://doi.org/10.3390/fire8010033

APA StyleZhang, P., Chen, R., Zhu, G., Yang, D., Li, X., Jiang, W., Liu, H., & Zhang, Z. (2025). Safe Treatment of Surface Coalfield Fires Above Shallow-Buried Goaf in Steeply Dipping Coal Seams. Fire, 8(1), 33. https://doi.org/10.3390/fire8010033