Experimental and Numerical Studies on the Efficacy of Water Mist to Suppress Hydrocarbon Fires in Enclosures

Abstract

1. Introduction

- Exploring conducted experiments and their outcomes to understand the state-of-the-art in fire-suppression mechanisms facilitated by water-mist spray;

- Identifying computational fluid dynamics (CFD) models capable of simulating fire extinguishment, facilitated by water-mist systems.

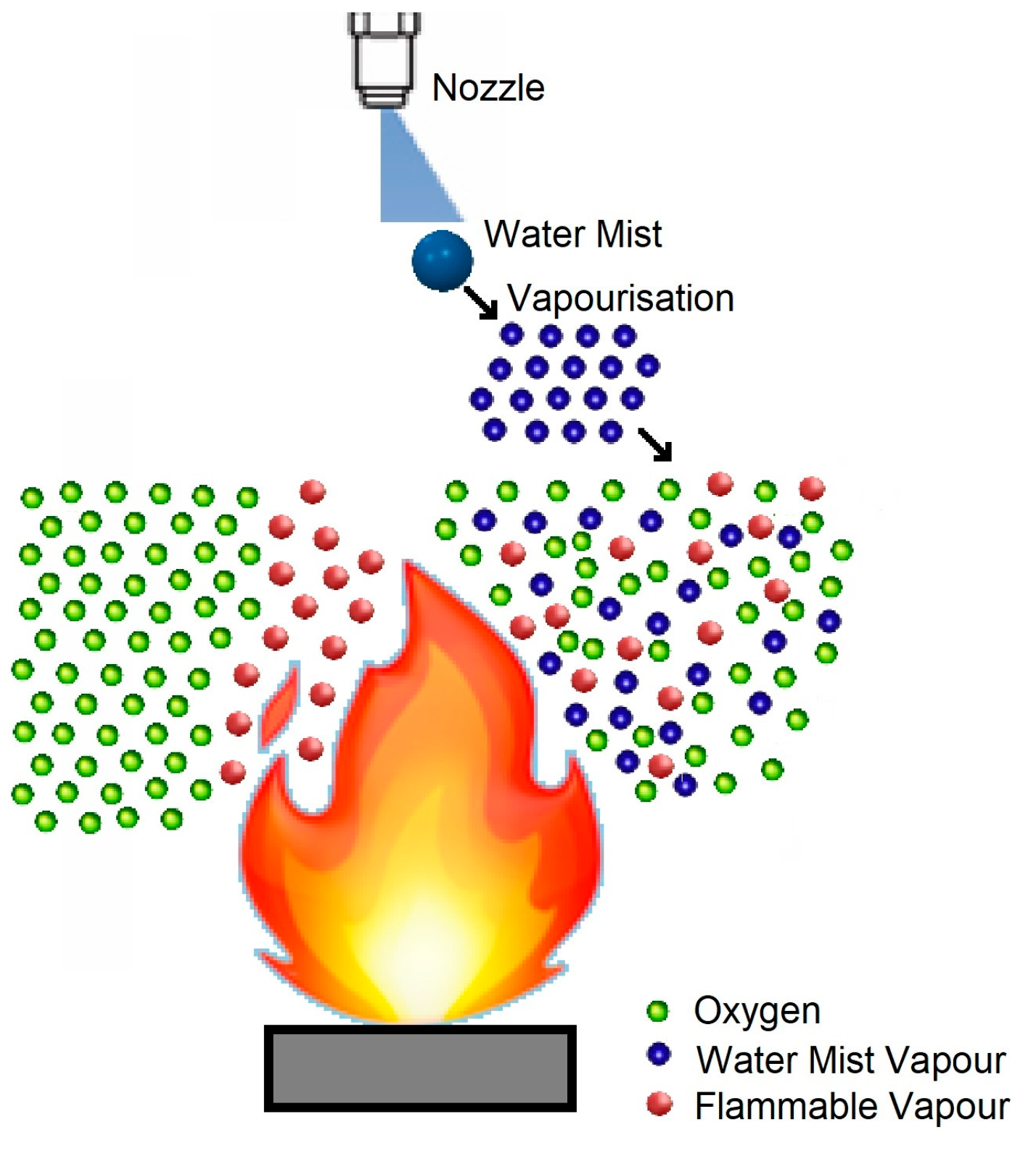

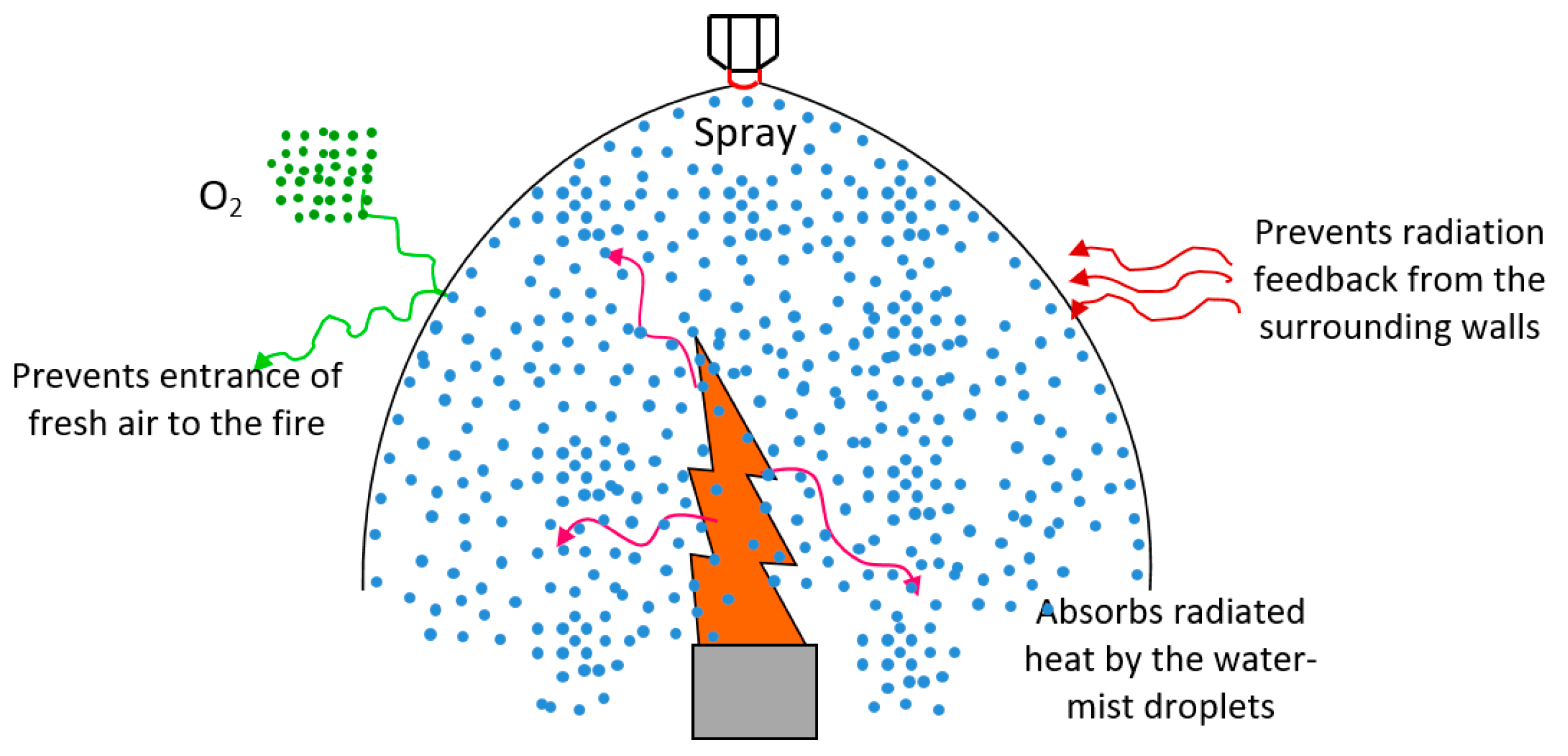

2. Mechanism for Water-Mist Fire Suppression

- Gas-phase cooling;

- Oxygen displacement and flammable vapour dilution;

- The wetting and cooling of the fuel surface;

- Radiation attenuation;

- Kinetic effects.

2.1. Gas-Phase Cooling

2.2. Oxygen Depletion and Flammable Vapour Dilution

2.3. The Wetting and Cooling of the Fuel Surface

2.4. Radiation Attenuation

2.5. Kinetic Effects

3. Literature Review of Maritime Standards

- Engine room volume ≥ 500 m3;

- Floor area ≥ 100 m2, Height ≥ 5 m;

- Ventilation: 2 m × 2 m door;

- Fuel ≥ 50 mm on water base;

- 5 to 15 s pre-burn if using heptane as fuel;

- Ambient room temperature of between 10 °C and 30 °C at the start of each test;

- A continuous supply of water ≥30 min;

- The water-mist suppression system shall be set up with a 2 m × 2 m or 3 m × 3 m nozzle grid to allow for variable test configurations. It is the manufacturer’s responsibility to determine the minimum and maximum nozzle-separation distances, specified as “the distance between the nozzle grid and the fuel spray nozzle”.

4. Methodology for Reviewing the Academic Literature

- Inclusion of papers published within the past 15 years (i.e., from 2005 onwards), with any seminal papers with significant citations also incorporated, even if published prior to 2005;

- Focus on compartment fires, with consideration given to fires in open spaces if they involved shielding, given the interest in fire suppression within shielded environments;

- Emphasis on fire sizes exceeding 50 kW, unless specific papers provided critical insights regarding device positioning for measurement purposes;

- Inclusion of studies specifically utilising water-mist spray for fire suppression.

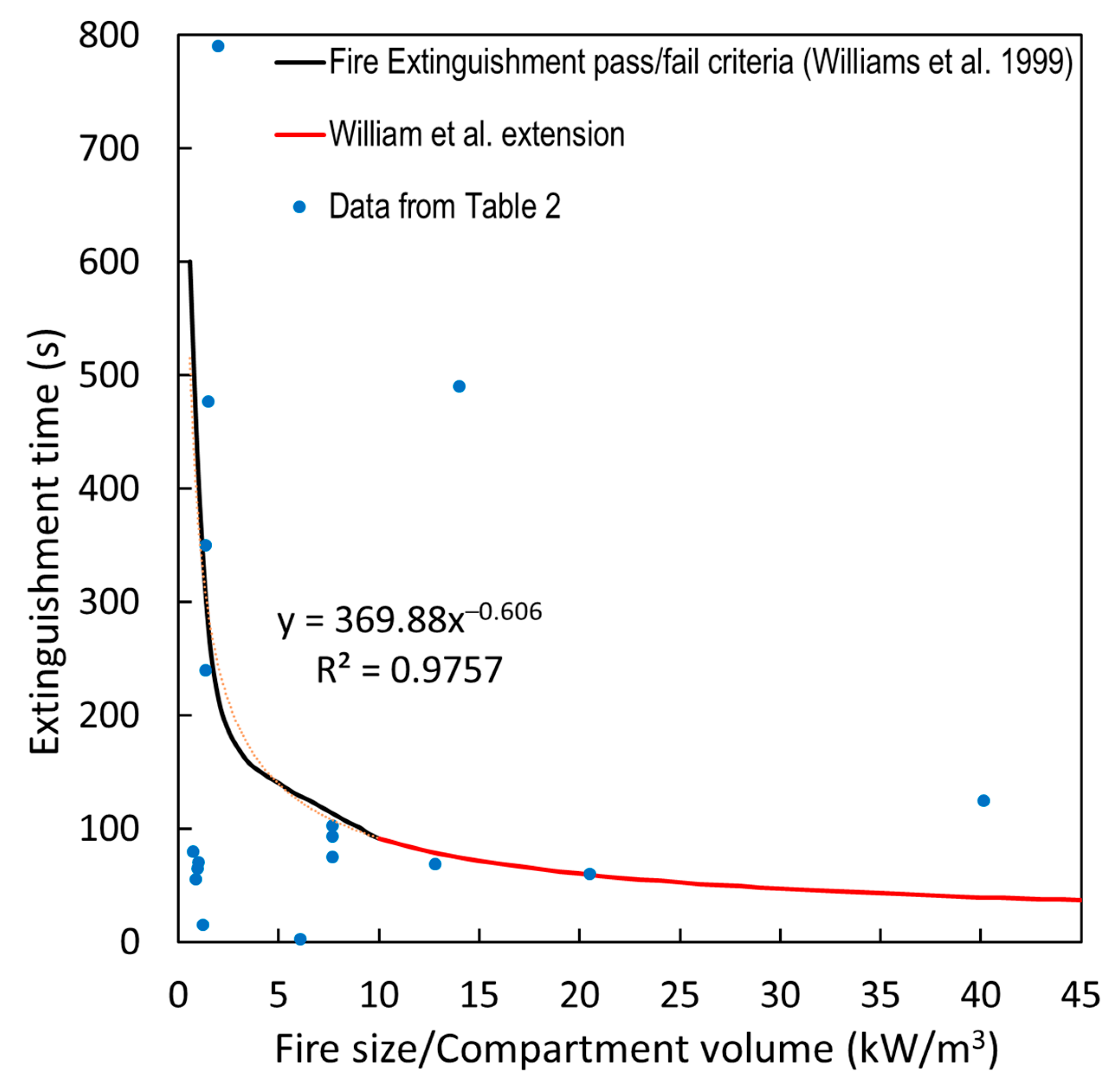

5. Literature Review of Experimental Studies

- With the exception of Back et al. [24], Xu et al. [27], Zhu et al. [33], and Ren et al. [41], the majority of studies investigated fire sizes ≤1000 kW (1 MW), with some instances where fire sizes were below 100 kW. Xu et al. [27] and Ren et al. [41] utilised solid fuels for their experiments. Xu et al. [27] reported fires with HRRs of 3030 and 5409 kW in their Tests 1 and 2, respectively. However, questions arise regarding whether the oxygen supply within the enclosure used (an ISO room) could sustain such large fires, particularly those exceeding 5 MW, unless a substantial amount of pyrolysed fuel burned outside the door.

- The majority of experiments were conducted within enclosure volumes not exceeding 50 m3. Some specific experimental setups are depicted in Figure 3.

- Only Xu et al. [27] (listed as serial 5 in Table 1 and indicated by underline) directly measured the fire size (HRR) using oxygen calorimetry. In most cases, mass-loss rate (MLR) was measured, which was subsequently converted to HRR using the equation HRR = MLR × heat of combustion × combustion efficiency. It should be noted that once water mist is activated, mass measurements include the mass of water. Therefore, HRR during the extinction phase cannot be estimated based on mass-loss measurement;

- The parameters often measured using devices are the following:

- ○

- Gas and fuel-layer temperature;

- ○

- Concentrations of O2, CO, CO2, and smoke;

- ○

- Radiation heat flux.

- Mean droplet sizes ranged from 6 to 400 µm, and the water supply working pressures predominantly varied between 70 and 135 bar.

- The suppression of fires using shielding was observed in approximately 30% of experiments;

- Some of these experiments were combined with numerical modelling, some were modelled by other researchers, and some have not been modelled;

- The studies which contained only experiments were mainly aimed at exploring the efficiency of water-mist spray with different water-flow pressures and droplet diameters, for instance, the following:

- ○

- Beihua et al. [26] investigated the extinction limit of diesel-pool fires by water-mist spray based on spray pressure and fire size;

- ○

- Lal et al. [29] investigated varied droplet sizes for the suppression of a n-heptane-pool fire;

- ○

- Zhang et al. [35] examined pressure variations from 20 to 100 bar, with increments of 10 bar, for the suppression of an ethanol-pool fire.

- The optimal performing water-mist nozzle was a modified nozzle operating at 70 bar (1000 psi);

- The most effective performance was achieved when nozzles were positioned immediately below the overhead of each level (i.e., deck head or ceiling);

- The recommended nozzle spacing was nominally 2.5 m apart, with an adequate number of nozzles to generate a total water flow of 0.4 Lpm/m3;

- Extinguishment times were typically under one minute, except for small obstructed fires or instances where forced ventilation was intentionally sustained;

- Compartment temperatures dropped from 500 °C to 50 °C within seconds after mist activation;

- The small residual fires that could not be extinguished by the water mist were easily approached and extinguished using a standard hand-held portable extinguisher. This was considered acceptable, with the criterion specifying a maintained compartment temperature below 60 °C after 60 s from the initial mist discharge.

6. Literature Review of Numerical Modelling

6.1. CFD Modelling Technique

6.2. Previous Studies Using CFD Modelling

- Predominantly, investigations were conducted utilising the FDS, with fewer instances employing FireFOAM and a scant number employing FLUENT and other codes;

- The vast majority of simulations used the Eddy Dissipation Concept (EDC) as the combustion model; the Lagrangian–Eulerian-mist model (Lagrangian for the liquid phase and Eulerian for the gas phase); and a Radiation Transport Equation (RTE) model for radiation. Adiga et al. [25] employed Lagrangian and Eulerian separately for mist simulation. FDS versions prior to version 6 utilised a mixture-controlled combustion model;

- For extinction modelling, FDS uses Critical Flame Temperature (CFT); whereas FireFOAM uses the Damkohler number (Da). This will be discussed further;

- While FDS employed a default set of heat- and mass-transfer equations for evaporation, FireFOAM offered multiple options for this process;

- Except for serials #6, 7, 9, 14, and 16 in Table 3 (highlighted with blue font), the HRR was prescribed in the model either based on experimental data or calculated HRR obtained from the mass-loss rate. Some special techniques for the prescribed HRR used are as follows:

- ○

- In serials #3 and 8, Jenft and co-workers adopted a methodology wherein the HRR in the numerical model was determined based on the experimental MLR in the absence of water-mist spray application. The HRR calculation relied on the measured MLR before the introduction of water-mist spray, and during mist application, the HRR was adjusted to follow an exponential reduction trajectory through some correlations. The reduction factors were estimated considering the characteristic time to suppression, defined as the duration for the HRR to diminish to zero in accordance with the experimental suppression time;

- ○

- In serials #10, 11, and 12, the HRR growth was prescribed as a t2 function, with the peak value derived from theoretical computations. The post-activation of the spray and the decay of the HRR were simulated by incorporating an extinction coefficient for fire suppression. This coefficient was iteratively adjusted within the model to synchronize the numerical suppression time with the experimental counterpart.

- In some instances, model validation was omitted, as exemplified by the investigations detailed in serials #11 and 12 of Table 3. In serial #11, the study explored the impact of door aspect ratio (door width/height) and opening ratio (reduced area/original area) on fire suppression using the FDS. Conversely, serial #12 examined the influence of the distance between the fire and the nozzle;

- In some instances, validation procedures entailed dry-fire tests, conducted without the application of water-mist spray, followed by subsequent explorations of parametric effects using the model. In serial #3 of Table 3, investigations delved into the influence of early and late applications of water spray on fire suppression times, examined both experimentally and via numerical simulations utilising FDS. Serial #17 involved a sensitivity analysis for FDS, wherein variations in extinction coefficient, droplets per second (DPS), and peak heat release rate (HRR) were assessed for their impacts on the rate of HRR reduction and suppression duration. In serial #18, the efficacy of water mist in suppressing shielded fires was investigated by altering the height and dimensions of obstructions, alongside estimations of suppression time, HRR, and temperature;

6.3. Sensitivity of Numerical Parameters for FDS

- Large Eddy Simulation (LES);

- Very Large Eddy Simulation (VLES);

- Simplified Very Large Eddy Simulation (SVLES);

7. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Charchalis, A.; Czyż, S. Analysis of fire hazard and safety requirements of a sea vessel engine rooms. J. KONES Powertrain Transp. 2011, 18, 49–56. [Google Scholar]

- Bellas, R.; Gómez, M.A.; González-Gil, A.; Porteiro, J.; Míguez, J.L. Assessment of the Fire Dynamics Simulator for Modeling Fire Suppression in Engine Rooms of Ships with Low-Pressure Water Mist. Fire Technol. 2020, 56, 1315–1352. [Google Scholar] [CrossRef]

- Allianz. Safety and Shipping Review 2021; Allianz Global Corporate & Specialty SE: Munich, Germany, 2021. [Google Scholar]

- IMO. Global Integrated Shipping Information System (GISIS); International Maritime Organization (IMO): London, UK, 2019. [Google Scholar]

- Kennett, S.R.; Gamble, G.I.; Li, J. Modelling of the HMAS Westralia Fire; DSTO-TR-0698; Defence Science and Technology Organisation (DSTO): Melbourne, Australia, 1998. [Google Scholar]

- Darwin, R.L.; Williams, F.W. The Development of Water Mist Fire Protection Systems for U.S. Navy Ships. Nav. Eng. J. 2000, 112, 49–57. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Liu, T.; Ma, J.; Li, G.; Zhao, Z. Preliminary study on extinguishing shielded fire with water mist. Process. Saf. Environ. Prot. 2020, 141, 344–354. [Google Scholar] [CrossRef]

- Montreal-Protocol. The Montreal Protocol on Substances that Deplete the Ozone Layer. Available online: https://ozone.unep.org/treaties/montreal-protocol-substances-deplete-ozone-layer/text (accessed on 5 January 2024).

- Department of Environment and Energy. Australian Halon Management Strategy 2019; Department of Environment and Energy, Australian Government: Canberra, Australia, 2019.

- Burch, I. Water Mist for Ship Machinery Spaces; DSTO-TR-1852; Maritime Platforms Division, Defence Science and Technology Organisation: Victoria, Australia, 2006. [Google Scholar]

- Farrell, K.; Hassan, M.K.; Hossain, M.D.; Ahmed, B.; Rahnamayiezekavat, P.; Douglas, G.; Saha, S. Water Mist Fire Suppression Systems for Building and Industrial Applications: Issues and Challenges. Fire 2023, 6, 40. [Google Scholar] [CrossRef]

- Mawhinney, J.R.; Back, G.G., III. Water mist fire suppression systems. In SFPE Handbook of Fire Protection Engineering; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1587–1645. [Google Scholar]

- NFPA 750; Standard for Water Mist Fire Suppression Systems. NFPA: Quincy, MA, USA, 2010.

- Mawhinney, J.; Dlugogorski, B.; Kim, A. A closer look at the fire extinguishing properties of water mist. Fire Saf. Sci. 1994, 4, 47–60. [Google Scholar] [CrossRef]

- Mahmud, H. Simulation of the Suppression of Fires Using Water Mists; Victoria University: Melbourne, Australia, 2016. [Google Scholar]

- Julien, C.; Mauger, A.; Vijh, A.; Zaghib, K. Lithium batteries. In Lithium Batteries; Springer: Berlin/Heidelberg, Germany, 2016; pp. 29–68. [Google Scholar]

- Back, G.G., III; Beyler, C.L.; Hansen, R. A quasi-steady-state model for predicting fire suppression in spaces protected by water mist systems. Fire Saf. J. 2000, 35, 327–362. [Google Scholar] [CrossRef]

- Ghiji, M.; Novozhilov, V.; Moinuddin, K.; Joseph, P.; Burch, I.; Suendermann, B.; Gamble, G. A review of lithium-ion battery fire suppression. Energies 2020, 13, 5117. [Google Scholar] [CrossRef]

- Dembele, S.; Wen, J.; Sacadura, J.-F. Experimental study of water sprays for the attenuation of fire thermal radiation. J. Heat Transf. 2001, 123, 534–543. [Google Scholar] [CrossRef]

- MSC/Circ 1165, Revised Guidelines for the Approval of Equivalent Waterbased Fire-Extinguishing Systems for Machinery Spaces and Cargo Pump Rooms; International Maritime Organisation: London, UK, 2005.

- MSC/Circ.1387. Revised Guidelines for the Approval of Fixed Water-Based Local Application Fire-Fighting Systems for Use in Category a Machinery Spaces; International Maritime Organisation: London, UK, 2010.

- Back, G.G.; Beyler, C.L.; Hansen, R. The Capabilities and Limitations of Total Flooding, Water Mist Fire Suppression Systems in Machinery Space Applications. Fire Technol. 2000, 36, 8–23. [Google Scholar] [CrossRef]

- Williams, F.; Beck, G., III; DiNenno, P.; Darwin, R.; Hill, S. Full-Scale Machinery Space Water Mist Tests: Final Design Validation; Navy Technology Center for Safety and Survivability: Washington, DC, USA, 1999. [Google Scholar]

- Back, G.G.; Beyler, C.L.; DiNenno, P.J.; Hansen, R.L. Full-Scale Water Mist Design Parameters Testing; CG-D-03-99; Coast Guard Research and Development Center: Groton, CT, USA, 1999; p. 294. [Google Scholar]

- Adiga, K.C.; Hatcher, R.F.; Sheinson, R.S.; Williams, F.W.; Ayers, S. A computational and experimental study of ultra fine water mist as a total flooding agent. Fire Saf. J. 2007, 42, 150–160. [Google Scholar] [CrossRef]

- Beihua, C.; Guangxuan, L.; Zhen, H. Extinction Limit of Diesel Pool Fires Suppressed by Water Mist. J. Fire Sci. 2009, 27, 5–26. [Google Scholar] [CrossRef]

- Xu, Q.; Griffin, G.J.; Que, X.; Cao, L.; Yong, J.; Preston, C.; Bicknell, A.D.; Bradbury, G.P.; White, N. Suppress flashover of GRP fire with water mist inside ISO 9705 Room. Therm. Sci. 2011, 15, 353–366. [Google Scholar] [CrossRef]

- Byström, A.; Cheng, X.; Wickström, U.; Veljkovic, M. Full-scale experimental and numerical studies on compartment fire under low ambient temperature. Build. Environ. 2012, 51, 255–262. [Google Scholar] [CrossRef]

- Lal, S.; Gupta, M.; Kushari, A.; Kapoor, J.C.; Maji, S. Suppression of Pool Fire in a Large Enclosure with Water Mist. Int. J. Spray Combust. Dyn. 2013, 5, 181–200. [Google Scholar] [CrossRef]

- Jenft, A.; Collin, A.; Boulet, P.; Pianet, G.; Breton, A.; Muller, A. Experimental and numerical study of pool fire suppression using water mist. Fire Saf. J. 2014, 67, 1–12. [Google Scholar] [CrossRef]

- Jeong, H.J.; Gwak, J.H.; Kim, H.Y.; Park, M.H.; Jeong, J.H. Fire verification experiment study of water mist fire extinguishing system for fire suppression in diesel generator room. In Proceedings of the Korea Institute of Fire Science and Engineering Conference; Korea Institute of Fire Science and Engineering: Seoul, Republic of Korea, 2014; Volume 2014, pp. 103–104. [Google Scholar]

- Ha, G.; Shin, W.G.; Lee, J. Numerical analysis to determine fire suppression time for multiple water mist nozzles in a large fire test compartment. Nucl. Eng. Technol. 2021, 53, 1157–1166. [Google Scholar] [CrossRef]

- Zhu, P.; Wang, X.; Wang, Z.; Cong, H.; Ni, X. Experimental and numerical study on attenuation of thermal radiation from large-scale pool fires by water mist curtain. J. Fire Sci. 2015, 33, 269–289. [Google Scholar] [CrossRef]

- Chiu, C.-W.; Li, Y.-H. Full-scale experimental and numerical analysis of water mist system for sheltered fire sources in wind generator compartment. Process. Saf. Environ. Prot. 2015, 98, 40–49. [Google Scholar] [CrossRef]

- Zhang, P.; Tang, X.; Tian, X.; Liu, C.; Zhong, M. Experimental study on the interaction between fire and water mist in long and narrow spaces. Appl. Therm. Eng. 2016, 94, 706–714. [Google Scholar] [CrossRef]

- White, J.P.; Verma, S.; Keller, E.; Hao, A.; Trouvé, A.; Marshall, A.W. Water mist suppression of a turbulent line fire. Fire Saf. J. 2017, 91, 705–713. [Google Scholar] [CrossRef]

- White, J.P.; Link, E.D.; Trouvé, A.; Sunderland, P.B.; Marshall, A.W. A general calorimetry framework for measurement of combustion efficiency in a suppressed turbulent line fire. Fire Saf. J. 2017, 92, 164–176. [Google Scholar] [CrossRef]

- White, J.P.; Vilfayeau, S.; Marshall, A.W.; Trouvé, A.; McDermott, R.J. Modeling flame extinction and reignition in large eddy simulations with fast chemistry. Fire Saf. J. 2017, 90, 72–85. [Google Scholar] [CrossRef]

- Jenft, A.; Boulet, P.; Collin, A.; Trevisan, N.; Mauger, P.-N.; Pianet, G. Modeling of fire suppression by fuel cooling. Fire Saf. J. 2017, 91, 680–687. [Google Scholar] [CrossRef]

- Lee, J. Numerical analysis on the rapid fire suppression using a water mist nozzle in a fire compartment with a door opening. Nucl. Eng. Technol. 2019, 51, 410–423. [Google Scholar] [CrossRef]

- Ren, N.; Meredith, K.V.; Yu, H.Z.; Zhou, X.; Wang, Y.; Dorofeev, S.B. Water Mist Fire Suppression Modeling of Rack Storage Fires in Open Space. In Proceedings of the 11th Asia-Oceania Symposium on Fire Science and Technology, 22–24 October, Taipei, Taiwan; Wu, G.Y., Tsai, K.C., Chow, W.K., Eds.; Springer: Singapore, 2018; pp. 767–779. [Google Scholar]

- Bu, R.; Yang, H.; Xie, Y.; Zhao, W.; Fan, C.; Guo, Z.; Zhou, Y. Application of the high-pressure water mist system in a railway tunnel rescue station. Therm. Sci. Eng. Prog. 2022, 35, 101467. [Google Scholar] [CrossRef]

- Abu Bakar, A.S.; Cran, M.; Wadhwani, R.; Moinuddin, K.A.M. Characterisation of pyrolysis and combustion parameters of charring materials most frequently found in buildings. J. Therm. Anal. Calorim. 2020, 139, 2985–2999. [Google Scholar] [CrossRef]

- Moinuddin, K.A.; Nguyen, T.D.; Mahmud, H. Designing an experimental rig for developing a fire severity model using numerical simulation. Fire Mater. 2017, 41, 871–883. [Google Scholar] [CrossRef]

- Gorokhovski, M.; Herrmann, M. Modeling primary atomization. Annu. Rev. Fluid Mech. 2008, 40, 343–366. [Google Scholar] [CrossRef]

- Bong, C.H. Numerical and Experimental Analysis of Diesel Spray Dynamics Including the Effects of Fuel Viscosity. Ph.D. Thesis, University of Tasmania, Tasmania, Australia, 2010. [Google Scholar]

- Kaario, O.; Vuorinen, V.; Hulkkonen, T.; Keskinen, K.; Nuutinen, M.; Larmi, M.; Tanner, F.X. Large Eddy Simulation of High Gas Density Effects in Fuel Sprays. At. Sprays 2013, 23, 297–325. [Google Scholar] [CrossRef]

- Vuorinen, V.; Yu, J.; Tirunagari, S.; Kaario, O.; Larmi, M.; Duwig, C.; Boersma, B.J. Large-eddy simulation of highly underexpanded transient gas jets. Phys. Fluids (1994-Present) 2013, 25, 016101. [Google Scholar] [CrossRef]

- Trouvé, A.; Wang, Y. Large eddy simulation of compartment fires. Int. J. Comput. Fluid Dyn. 2010, 24, 449–466. [Google Scholar] [CrossRef]

- McGrattan, K.; Miles, S. Modeling fires using computational fluid dynamics (CFD). In SFPE Handbook of Fire Protection Engineering; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1034–1065. [Google Scholar]

- Vilfayeau, S.; Myers, T.; Marshall, A.W.; Trouvé, A. Large eddy simulation of suppression of turbulent line fires by base-injected water mist. Proc. Combust. Inst. 2017, 36, 3287–3295. [Google Scholar] [CrossRef]

- Lee, J. Numerical analysis of how ventilation conditions impact compartment fire suppression by water mist. Ann. Nucl. Energy 2020, 136, 107021. [Google Scholar] [CrossRef]

- Lee, J.; Moon, J. Numerical analysis of the effect of horizontal distance between a water mist nozzle and ignition source on reduction in heat release rate. Ann. Nucl. Energy 2020, 144, 107560. [Google Scholar] [CrossRef]

- Hamzehpour, A.; Verda, V.; Borchiellini, R. CFD Modeling of Water Mist Systems for Suppressing Shielded fires in Enclosures Using FDS. In Proceedings of the 21st International Water Mist Conference, Madrid, Spain, 9–10 November 2022. [Google Scholar]

- McKeen, L.W. Introduction to Permeation of Plastics and Elastomers. In Permeability Properties of Plastics and Elastomers, 4th ed.; McKeen, L.W., Ed.; William Andrew Publishing: Norwich, NY, USA, 2017; pp. 1–19. [Google Scholar]

- Vilfayeau, S. Large Eddy Simulation of Fire Extinction Phenomena; University of Maryland: College Park, MD, USA, 2015. [Google Scholar]

- Ren, N.; Zeng, D.; Meredith, K.V.; Wang, Y.; Dorofeev, S.B. Modeling of flame extinction/re-ignition in oxygen-reduced environments. Proc. Combust. Inst. 2019, 37, 3951–3958. [Google Scholar] [CrossRef]

- Lecoustre, V.; Narayanan, P.; Baum, H.R.; Trouve, A. Local extinction of diffusion flames in fires. In Fire Safety Science-Proceedings of the Tenth International Symposium; University of Maryland: College Park, MD, USA, 2011; Volume 10, pp. 583–595. [Google Scholar]

- Roache, P.J. Perspective: A Method for Uniform Reporting of Grid Refinement Studies. J. Fluids Eng. 1994, 116, 405–413. [Google Scholar] [CrossRef]

| Test Compartment Volume (m3) | Pool Fire Scenario (Nominal HRR) (MW) | Fuel Tray Diameter (cm) | Fuel Tray Area (m2) | Size of Obstruction Steel Plate (m × m) |

|---|---|---|---|---|

| Not specified | 0.5 | 62 | 0.30 | 2.0 × 2.0 |

| 500 | 1 | 83 | 0.54 | 2.0 × 2.0 |

| 1000 | 2 | 112 | 0.99 | 2.0 × 2.0 |

| 1500 | 3 | 136 | 1.45 | 2.25 × 2.25 |

| 2000 | 4 | 156 | 1.90 | 2.25 × 2.25 |

| 2500 | 5 | 173 | 2.36 | 2.5 × 2.5 |

| 3000 | 6 | 189 | 2.81 | 2.5 × 2.5 |

| Sl. No. | Publication Details | Compartment Details | Fire Details | Water-Mist Details | Results | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Authors and Associated Details | Publication Year | Compartment Size (m3) | Opening Size (m) | Fuel Tray (m) | Fuel Type (Solid/Liquid/Sand Burner) Obstruction, and Suppression Time (s) | HRR (kW) | Nozzle Spacing (m) Number of Nozzles Operating Pressure (bar) | Flow Rate (Lpm) | Mean Droplet Size (µm) | Measured Parameters | Was It Modelled? | |

| 1 | Back, Beyler et al.; report CG-D-03-99 [24] | 1999 | 10 × 10 × 5 | 2 × 2 one door | 0.7 × 3.5 m | Heptane-pool fire 0.7 × 3.5 m obst.@1.7 m height 490 s | 7000 | 4 × 4 m spacing A cluster of 9 nozzles 8 bar | 9 × 15.5 = 140 | 1 VMD 100 | Temp and Extinction time | Yes (Bellas and Gomez [2]) |

| 2 | Back, Beyler et al.; report CG-D-03-99 [24] | 1999 | 10 × 10 × 5 | 2 × 1 two doors | 0.74 × 0.74 m | Diesel-pool fire 0.7 × 3.5 m obst. at 1.7 m height 792 s | 1000 | 4 × 4 m spacing 36 single 7 bar | 36 × 11 = 396 | 1 VMD 390 | Temp and Extinction time | Yes (Bellas and Gomez [2]) |

| 3 | Adiga et al.; Fire Saf. J [25] | 2007 | 3 × 3 × 3 steel-walled compartment | 1 supply vent 2 exhaust vent | 0.3 m dia | Heptane, Methanol | 120 (Heptane) 75 (Methanol) | ~1.8 m × 0.6 m | 0.66 | 10 | Comb efficiency; Rad and Convec fraction, mass fraction and Extinction time | Yes |

| 4 | Beihua et al., J. Fire Sci [26] | 2009 | 3 × 3 × 3 | Exhaust fan & 0.2 m-high opening along the wall | 0.15 to 0.35 m square pan with 0.025 m increment | Diesel-pool fire No obst 25 to 150 s | 8.5~90 | Single nozzle operated at different flow rates and pressures | Flow rate varied at 0.53 ~ 0.83 | 2 SMD 135 | 2 SMD by 4 LDV Temp, O2, CO2 and Extinction time | No |

| 5 | Xu et al. Thermal Sci, 15(2):353–366; CSIRO [27] | 2011 | ISO Room 3.6 × 2.4 × 2.4 | 2 × 0.8 one door | Solid fuel | Wood crib + 5 GRP layer on wall No obst 24, 30, and 14 s for test 1, 2, and 3, respectively | 3030 (Test 1) 5409 (Test 2) 1125 (Test 3) | 1.4 × 1.9 m spacing 4 single nozzles 17.2 bar | 4 × 15 = 60 | 2 VMD 100 | Temperature O2 and CO2 extinction time | No |

| 6 | Bystrom et al. Fire Saf J. [28] | 2012 | 9 × 5 × 4.8 | 2 × 2 m ventilation | Solid fuel | Wood crib No obst 200 s | 900 | Water application by firefighters | –– | –– | 6 MLR Temp | Yes |

| 7 | Lal et al., spray and comb dyna, 5(3):181–200 [29] | 2013 | 3.6 × 3.5 × 3.1 | 1.1 × 1.94 door and two 0.4 × 0.3 exhaust fan | 0.46 m dia 0.56 m dia 0.66 m dia | Heptane-pool fire No obst 75, 69, 60 s | 300, 500, 800 | 1.63 m dia circ ring– spacing 61 mm 6 single nozzles 2 bar | 6 × 1 = 6 | 2 SMD 40, 80, 120 | 2 SMD by laser-diffraction technique, Temp, O2, CO, CO2 | No |

| 8 | Jenft et al. Fire Safety J. 67:1–12 [30] | 2014 | 4.2 × 4.3 × 3.05 | 0.3 × 0.4 and a blower | 0.35 m dia | Diesel-pool fire No obst 65 s | 75 | 1.2 × 0.9 m spacing 4 nozzles 10 bar | 4 × 6.3 = 25.2 | 1 SMD 112 | MLR Temp O2 | Yes |

| 9 | Jeong et al., Korea Inst. of Fire Sci. and Eng. Confer, 2014 [31] | 2014 | 18 × 18 × 16.5 | 2 × 2 door | 0.7 × 3 m | Heptane pool, 0.7 × 3.5 m at 1.75 m height 477 s | –– | 4 × 3 m spacing 22 nozzles 10 bar | 22 × 22.5 = 495 | 1 VMD 125 | Extinction time | Yes (Ha et al. [32]) |

| 10 | Zhu et al. J. of Fire Sci. [33] | 2015 | Room 1- 5 × 6 × 3.6 Room 2- 8 × 6 × 8 | 8 × 8 | 1.0 × 1.0 m | Diesel | 1810 | 2 nozzles, 2 m apart Pressure varied | 0.74 to 1.75 | 2 SMD 53 to 88 | Temp, Rad and Extinction time | Yes |

| 11 | Chiu and Li, Pro Saf and Env Prot, 98:40–49 [34] | 2015 | 6.05 × 2.43 × 2.5 | 2.0 × 0.9 door and 2.15 × 0.2 air inlet at a wall | 0.63 × 0.63 m | Diesel | 113 | T1 2 nozzles T2 3 nozzles 1 m spacing | 220 | No information | Temperature | Yes |

| 12 | Zhang et al., App Ther Eng 94:706–714 [35] | 2016 | 3.6 × 1.5 × 0.6 | 1.5 × 0.2 m vent | 0.5 m dia | Ethanol-pool fire, and 0.14 × 0.14 m rubber pad as additional fuel No Obst 60 to 500 s for differ pressure | 130 | 2 different single nozzles, cluster of 7, 20 to 100 bar | 2.25 to 10 | 2 SMD 200 ~ 350 | 2 SMD and droplet velocity by PIV system, MLR, Temp, Rad, O2, H2 | No |

| 13 | White et al. Fire Saf. J. 91:705–713 [36] | 2017 | 2 × 2 × 2 m | Air supplied by a blower | 0.05 × 0.5 m burner | Methane | 50 | Unusual arrangement; 0.5 × 0.75 m opening levelled with fuel area, mist projected upward | NA | 2 SMD 6 | 3 DSD by laser, Comb efficiency; mass fraction and extinction time | yes |

| 14 | White et al. Fire Saf. J. 92:164–176 [37] | 2017 | Open * | Open | 0.05 × 0.5 m burner | Methane | 50 | Co-flowing oxidizer with N2 to reduce O2 mole fraction | –– | –– | HRR, O2 mole fraction, and comb efficiency, | Yes (White et al. [38]) |

| 15 | Jenft et al. Fire Saf. J., 91:680–687 [39] | 2017 | 4.2 × 4.3 × 3.05 | 0.3 × 0.4 m ventilation and a 0.3 m dia blower | 0.25 and 0.35 m dia | Diesel-pool fire No obst 23 to 437 s for different test conditions | 45 to 75 based on different conditions | 1.2 × 0.9 m spacing A cluster of 4 | 4 × 6.3 = 17.2 | 1 SMD 112 | MLR Fuel-surface Temp | Yes |

| 16 | Lee, Nucl Eng and Tech 51: 410–423 [40] | 2019 | 5.4 × 3.1 × 2.4 | 1.1 × 1.9 m door | 0.3 × 0.3 m | Heptane-pool fire No Obst. 2.5 s | 244 | Single nozzle | 22.45 | 3 VMD 125 | 2 DSD by laser, Extinction time | Yes |

| 17 | Liu et al. Pros Saf Env Prot., IChemE [7] | 2020 | 10 × 6 × 4 | Open | 0.25 m dia | Propane sand-burner 0.1 m dia, 1.5 m height 35 s in one case | 40~72 | 1 nozzle Pressure was varied from 20 bar to 40 bar | Flow was varied 1.08~1.44 | 3 VMD 40 | MLR Temperature, | Yes |

| 18 | Ren et al., 11th AOSFST [41] | 2020 | Open * | Open | Solid fuel | 16 pallet loads arranged to be two-tiers high. Each pallet load is a corrugated cardboard box sitting on a hardwood pallet. 75 s | T1 1700 T2 1700 T3 1700 | T1 and T2 with 4 nozzles at 3 × 3 m spacing T1: 44.8 bar T2: 20 bar T3 with 4 nozzles at 2.6 × 2.6 m spacing T3: 100 bar | T1 3 × 6.1 = 18.3 T2 3 × 4.1 = 12.3 T3 3 × 6.1 = 18.3 | 3 VMD T1 177 T2 210 T3 70 | HRR, Rad | Yes |

| 19 | Bu et al., Ther Sci and Eng Prog 35:101467 [42] | 2022 | T1 50 × 7.7 × 6.2 T2 19 × 2.8 × 2.7 | Exhaust fan 1.5 m/s and 2.5 m/s | 0.7 × 0.7 m | Oil-pool fire Obstructed under train seat 60 s | 400 | 2.5 × 5.2 m grid 18 nozzles in 2 rows 50 and 80 bar | 18 × 3.5 = 63 to 18 × 13.5 = 243 | 180 | HRR, Temp, Smoke Conc | Yes |

| Sl. No. | Publication Details | Experiment Modelled | Computational Model Details | Model Application Details | Results | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Authors and Associated Details | Publication Year | This Serial Is from Table 2 | Software Name | Turbulence Model | Mist Model | Combustion Model | Radiation Model | Evaporation Model | Grid Size (mm) | HRR Prescribed? | D*/dx | 1 SA | 2 DPS | Computational Resources | What Parameter Compared (HRR, MLR, Temp, O2, Rad) | Was the Fire Suppressed? | |

| 1 | Adiga et al.; Fire Saf. J [25] | 2007 | Serial 3 | FLUENT | k-epsilon | Lagrangian Discrete-Phase Model (DPM), Eulerian Dense Gaseous (DG) | none | none | default | 72.5 | Yes | 5 | default | default | No record | Temp, Extinction time | 100 deg C gas temp reduction = suppression |

| 2 | Bystrom et al. Fire Saf J. [28] | 2012 | Serial 6 | FDS 5.5.3 | LES | Lagrangian–Euler | Mixture-fraction with 3 CFT extinc | 4 RTE | default | 50 100 | Yes | 18 | default | default | No record | MLR Temp | Fire was suppressed by firefighter |

| 3 | Jenft et al. Fire Saf. J. 67:1–12 [30] | 2014 | Serial 8 | FDS 5.5.3 | LES | Lagrangian–Euler | Mixture-fraction with CFT extinction | RTE | default | 50 | Yes | 6.8 | default | default | No record | Extinction time Temp O2 | HRR was forced to reduce to zero by using a MLR-reduction factor at the activation of spray based on the experimental extinction time. |

| 4 | Zhu et al. J. of Fire Sci. [33] | 2015 | Serial 10 | FDS 6.1.1 | LES | Lagrangian–Euler | 5 EDC with CFT extinction | RTE | default | 100 | Yes | 12 | 500 | 50,000 | No record | Rad, 6 CNF, Temp | No suppression modelled |

| 5 | Chiu and Li, Pro Saf and Env Prot, 98:40–49 [34] | 2015 | Serial 11 | FDS (version not reported) | LES | Lagrangian–Euler | Unclear as version unknown | RTE | default | 120 × 50 × 40 cells (not a square grid) | No information (seems that prescribed) | –– | default | default | No record | Extinction time, Temp | Suppression of fire claimed based on temperature reduction. However, no HRR or flame extinction was reported either in experiment nor in simulation |

| 6 | White et al. Fire Saf. J. 90:72–86 [38] | 2017 | Serial 14 | FDS 6 | LES | Lagrangian–Euler | 5 EDC with CFT extinc | RTE, with simplification using the concept of GRLF 7 | default | 5 | No | 58 | default | NA as dilatation of O2 with N2 used | 40 processors UMD Deepthought2 HPC cluster. 1 Sim, 30 s = 1080 CPU hours using Intel Ivy Bridge E5-2680v2 2.80 GHz processors. | Temp, O2, and Comb efficiency | Yes, combustion efficiency was reduced with dilution of O2 and matched with the exp data |

| 7 | White et al. Fire Saf. J. 91:705–713 [36] | 2017 | Serial 13 | FireFOAM | Epsilonε model | Lagrangian–Euler | EDC with Damkohler number (Da)-based extinction | RTE | Ranz–Marshall | 4 | No | 17 | –– | 1,000,000 | 100 processors UMD Deepthought2 HPC cluster. 1 Sim = 15,000 CPU hours using Intel Ivy Bridge E5-2680v2 2.80 GHz processors. | Comb efficiency; O2 mass fraction and Extinc time | Yes; qualitative comparison |

| 8 | Jenft et al. Fire Saf. J. 91:680–687 [39] | 2017 | Serial 15 | FDS 6 | LES | Lagrangian–Euler | EDC with CFT extinc | RTE | default | 50 | Yes | 7 | default | default | No record | Temp O2 | The same is serial #3 |

| 9 | Vilfayeau et al., Combustion Institute 36, 3287–3295 [51] | 2017 | No experiment | FireFOAM3 | Epsilon model | Lagrangian–Euler | EDC with Damköhler number based extinction | RTE | Ranz–Marshall | 4 8 16 | No | 70 35 18 | default | default | 14 s simulation, Used 40 processors Linux cluster, 1500 h CPU time. | Flame-cooling and evaporation-cooling power: Comb efficiency; HRR | Flame extinction was achieved by the Model when mist entrained into the flame-base region |

| 10 | Lee, Nucl Eng and Tech 51: 410–423 [40] | 2019 | Serial 16 | FDS 6.3.2 | LES | Lagrangian–Euler | EDC with CFT extinc | RTE | default | 50 | Yes | 11 | default | 1000~5,00,000 | No record | Extinction time, Temp, O2 | HRR prescribed as t2 with calculated peak value. The HRR after spray activation was modelled using an extinction coefficient. |

| 11 | Lee, Annals of Nucl Ener 136:107021 [52] | 2020 | No experiment | FDS 6.4.0 and CFAST 7.1.1 (two-zone model) | LES | Lagrangian–Euler | EDC with CFT extinc | RTE | default | 22 | Yes | 24 | default | 50,000 | No record | Temp, Suppression time | HRR prescribed as t2 with calculated peak value. Extinct coeff. was varied to match experimental suppression time. |

| 12 | Lee and Moon, Annals of Nucl Ener 144 [53] | 2020 | No experiment | FDS 6.5.2 | LES | Lagrangian–Euler | EDC with CFT extinc | RTE | default | 40 | Yes | 10 | default | 5000 | No record | Temp, Suppression time | Same as serial #9 |

| 13 | Liu et al., Pros Saf Env Prot., IChemE [7] | 2020 | Serial 17 | FDS 6.3.2 | LES | Lagrangian–Euler | EDC with CFT extinc | RTE | default | 100 | Yes | 3.5 | default | default | No record | Temp, O2 | HRR was prescribed |

| 14 | Bellas and Gomez, Fire Tech [2] | 2020 | Serial 1 | FDS 6.7.0 | LES | Lagrangian–Euler | EDC with CFT extinc | RTE | default | 100 | No | 21 | default | default | 11 meshes, 2 core per mesh; 22 × 18 h CPU core time for a 240 s simulation | Temp, O2 | HRR was reduced to 1000 kW, but not completely suppressed. |

| 15 | Bellas and Gomez, Fire Tech [2] | 2020 | Serial 2 | FDS 6.7.0 | LES | Lagrangian–Euler | EDC with CFT extinction | RTE | default | 50/100 | Yes | 19 | default | default | 11 meshes, 2 core per mesh; 22 × 18 h CPU core time for a 240 s simulation | Temp, O2 | HRR was prescribed |

| 16 | Ren et al., 11th AOSFST [41] | 2020 | Serial 18 | FireFOAM3 | k equation | Lagrangian–Euler | EDC with Da-based extinction | RTE | reactive volume fraction (RVF) model | 25.4 | No | 46 | default | default | No record | HRR, Rad | The numerical results followed the experimental trend, but fire was not suppressed. |

| 17 | Ha et al., Nucl Eng and Tech 53: 1157–1166 [32] | 2021 | Serial 9 | FDS 6.5.2 | LES | Lagrangian–Euler | EDC with CFT extinction | RTE | default | 50 | Yes | 4.5 | default | 5000 | No record | Extinction coefficient (EC),Temp, Suppression time | Extinction coefficient was used |

| 18 | Hamzehpour et al., WMC, Spain [54] | 2022 | Serial 8 | FDS 6 | LES | Lagrangian–Euler | EDC with CFT extinction | RTE | default | 50 | Yes | 7 | default | default | No record | Temp O2 | Yes, The validation was on a dry test, without the application of water mist. |

| 19 | Bu et al., Ther Sci and Eng Prog 35:101467 [42] | 2022 | Serial 19 | SIMTEC developed by Lund Uni | LES | Lagrangian–Euler | EDC | RTE | default | 200 | Yes | 3.3 | default | default | No record | Temp, Smoke Conc | HRR was prescribed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moinuddin, K.; Mahmud, H.M.I.; Joseph, P.; Gamble, G.; Suendermann, B.; Wilkinson, C.; Bossard, J. Experimental and Numerical Studies on the Efficacy of Water Mist to Suppress Hydrocarbon Fires in Enclosures. Fire 2024, 7, 83. https://doi.org/10.3390/fire7030083

Moinuddin K, Mahmud HMI, Joseph P, Gamble G, Suendermann B, Wilkinson C, Bossard J. Experimental and Numerical Studies on the Efficacy of Water Mist to Suppress Hydrocarbon Fires in Enclosures. Fire. 2024; 7(3):83. https://doi.org/10.3390/fire7030083

Chicago/Turabian StyleMoinuddin, Khalid, H. M. Iqbal Mahmud, Paul Joseph, Grant Gamble, Brigitta Suendermann, Cameron Wilkinson, and James Bossard. 2024. "Experimental and Numerical Studies on the Efficacy of Water Mist to Suppress Hydrocarbon Fires in Enclosures" Fire 7, no. 3: 83. https://doi.org/10.3390/fire7030083

APA StyleMoinuddin, K., Mahmud, H. M. I., Joseph, P., Gamble, G., Suendermann, B., Wilkinson, C., & Bossard, J. (2024). Experimental and Numerical Studies on the Efficacy of Water Mist to Suppress Hydrocarbon Fires in Enclosures. Fire, 7(3), 83. https://doi.org/10.3390/fire7030083