Application of Factorial Analysis to the Study of Vented Dust Explosions in Large Biomass Storage Silos

Abstract

1. Introduction

2. Materials and Methods

2.1. CFD Code

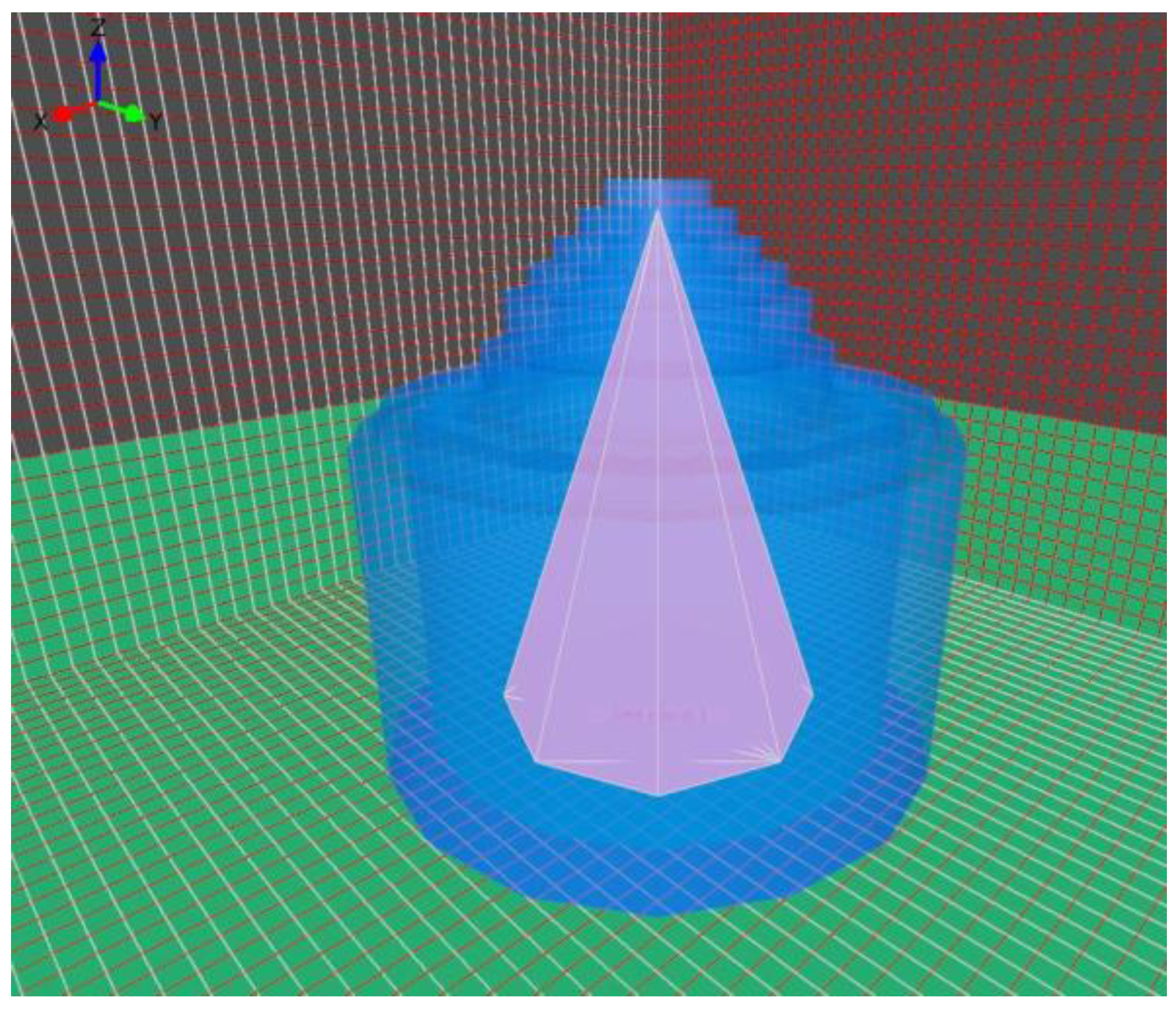

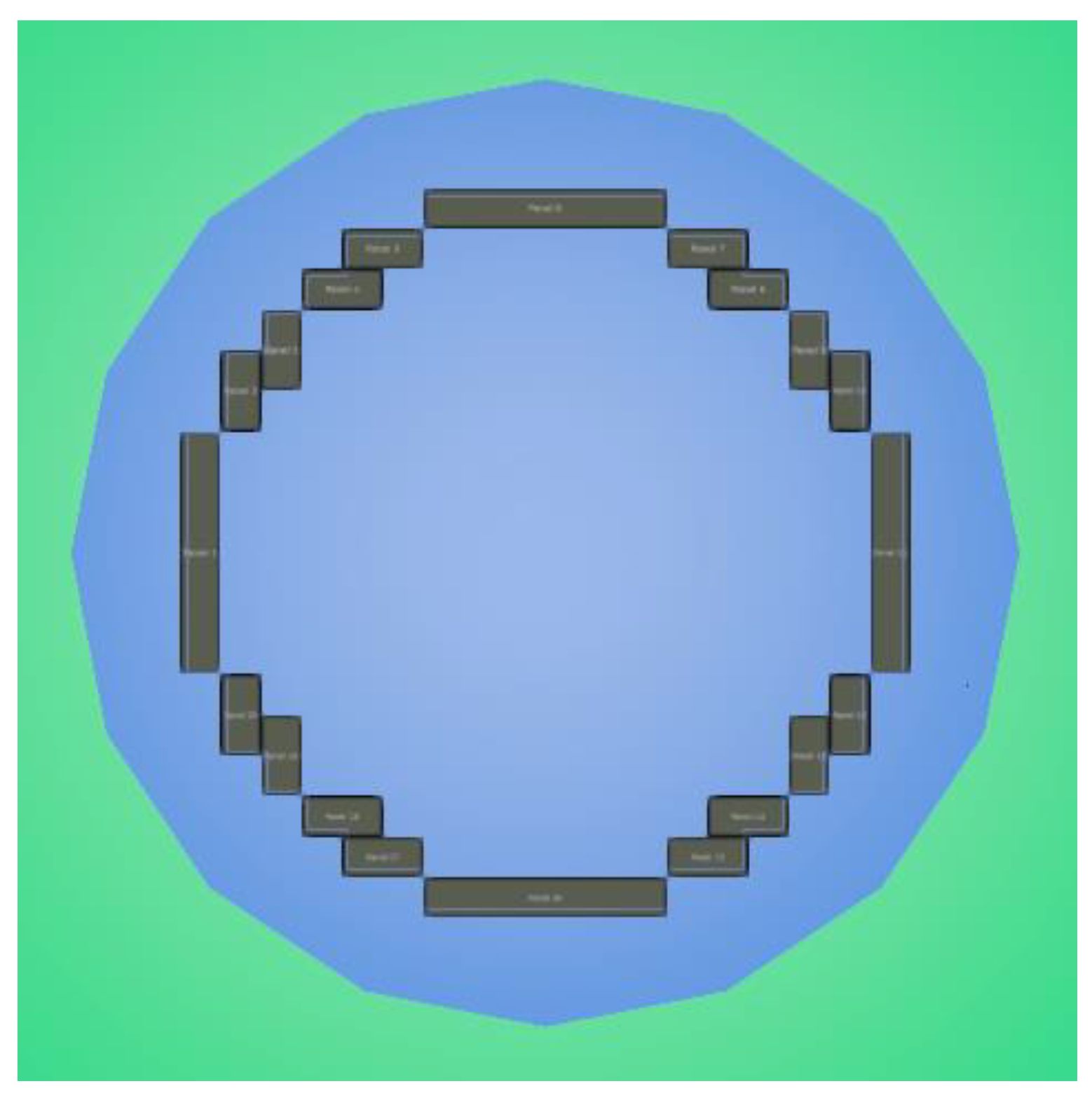

2.2. Scenario

2.3. Factorial Design

2.3.1. Vent Area

2.3.2. Ignition Location

- Top: ignition in the upper third of the cloud height (at 19.75 m above the silo bottom);

- Bottom: ignition in the lower third of the cloud height (at 1.25 m above the silo bottom).

2.3.3. Initial Turbulence

- Low: the three parameters had lower values, resulting in weak initial turbulence.

- High: this corresponded to a more severe turbulent flow.

2.3.4. Dust Concentration

2.4. Factorial Analysis

- q: the sum of the products of Pred,sim and the corresponding contrast coefficient, considering the 16 cases;

- Q: calculated as q divided by the number of cases (16);

- Q2: the square of Q (the total Q2 is the sum of all Q2 values);

- Y: the percentage of each Q2 in relation to the total Q2.

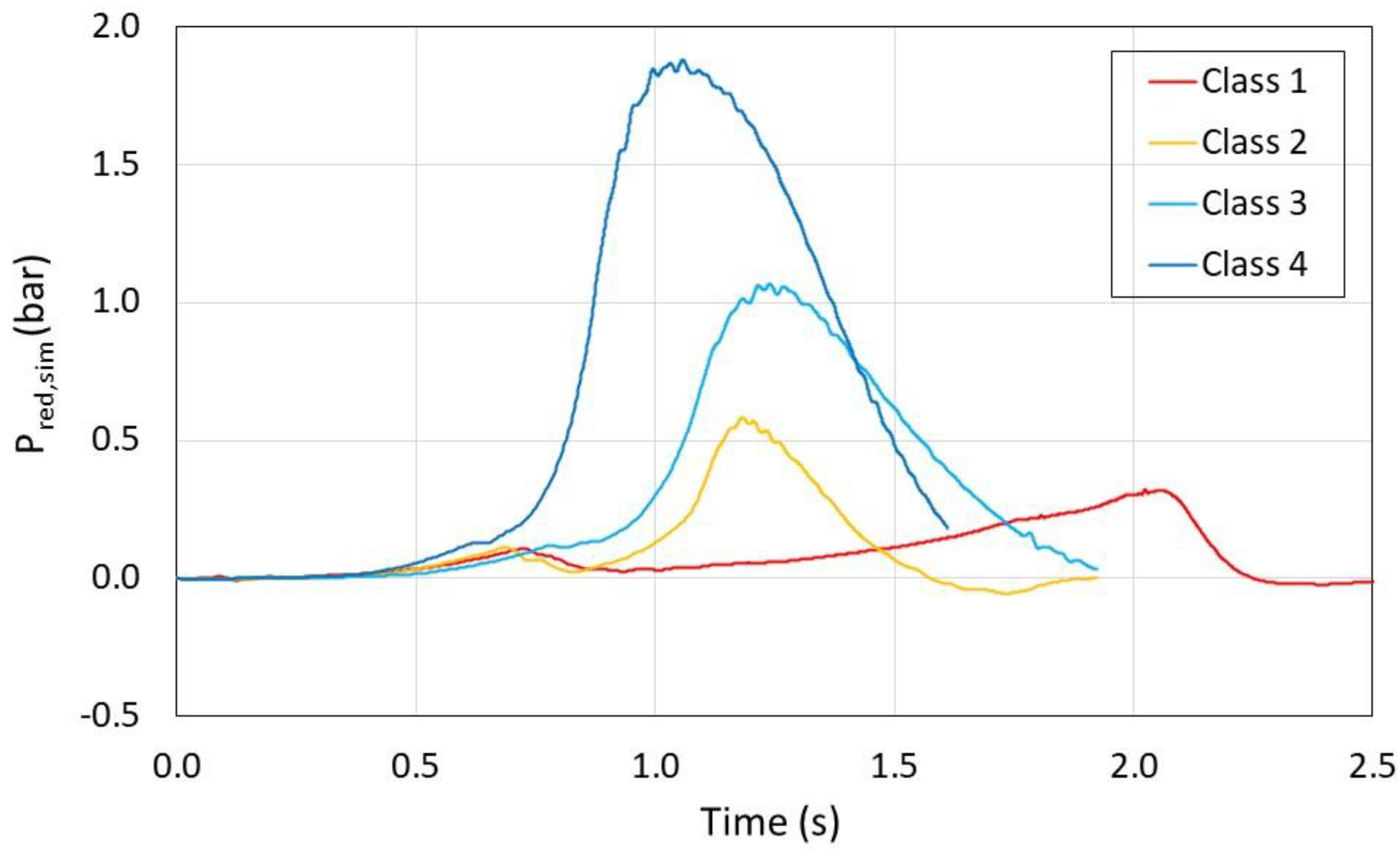

3. Results

- Class 1: Pred,sim ≤ 0.5 bar;

- Class 2: 0.5 bar < Pred,sim ≤ 1.0 bar;

- Class 3: 1.0 bar < Pred,sim ≤ 1.5 bar;

- Class 4: 1.5 bar < Pred,sim.

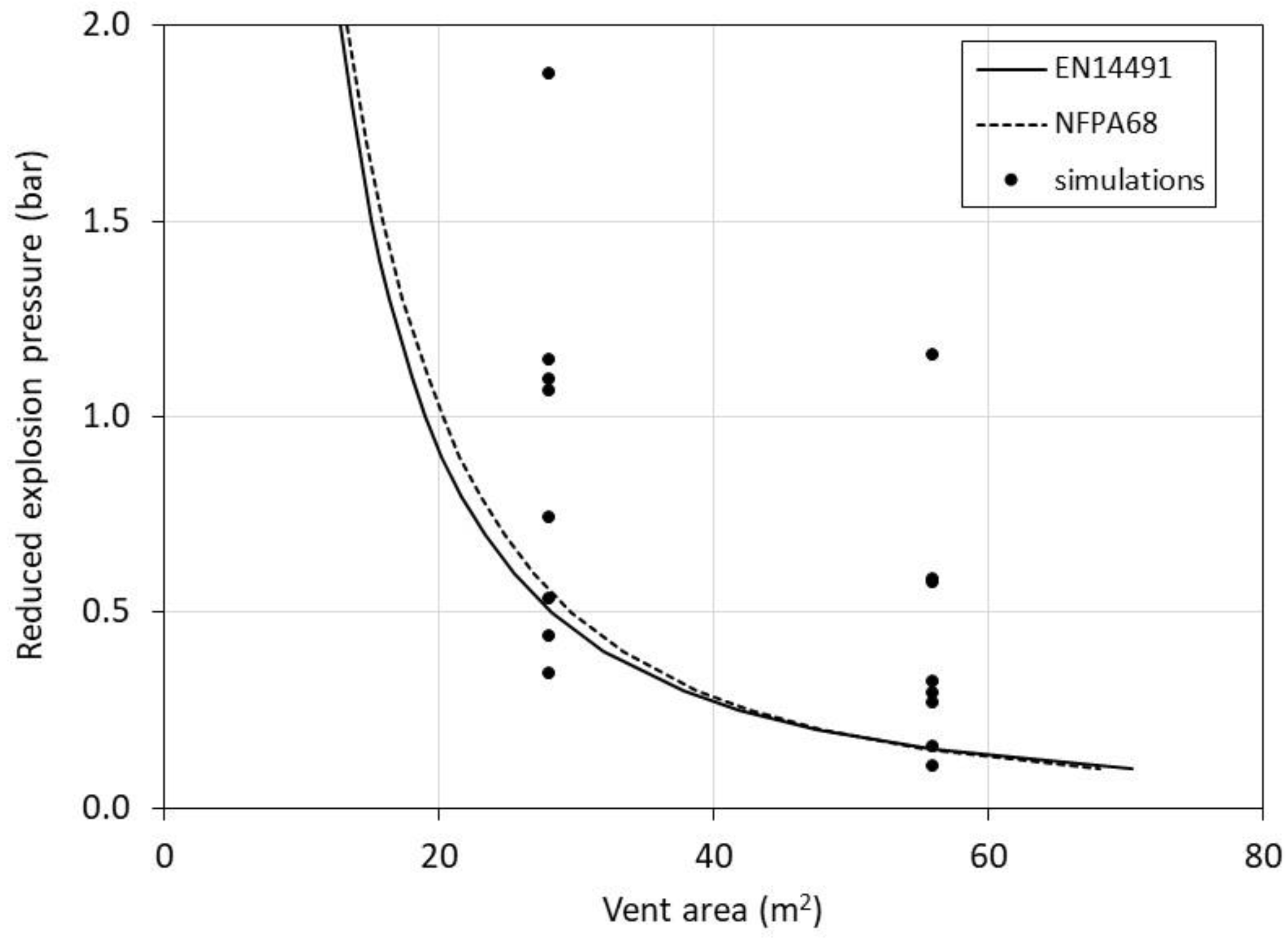

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eckhoff, R.K. Understanding dust explosions. The role of powder science and technology. J. Loss Prev. Process Ind. 2009, 22, 105–116. [Google Scholar] [CrossRef]

- Klippel, A.; Schmidt, M.; Krause, U. Dustiness in workplace safety and explosion protection—Review and outlook. J. Loss Prev. Process Ind. 2015, 34, 22–29. [Google Scholar] [CrossRef]

- Ilea, C.G.; Kosinski, P.; Hoffmann, A.C. The effect of polydispersity on dust lifting behind shock waves. Powder Technol. 2009, 196, 194–201. [Google Scholar] [CrossRef]

- Amyotte, P.R.; Eckhoff, R.K. Dust explosion causation, prevention and mitigation: An overview. J. Chem. Health Saf. 2010, 17, 15–28. [Google Scholar] [CrossRef]

- Eckhoff, R.K. Dust Explosions in the Process Industries, 3rd ed.; Gulf Professional Publishing/Elsevier: Amsterdam, The Netherlands, 2003; pp. 20–25. [Google Scholar]

- Abbasi, T.; Abbasi, S.A. Dust explosions—Cases, causes, consequences, and control. J. Hazard. Mater. 2007, 40, 7–44. [Google Scholar] [CrossRef]

- García Torrent, J.; Ramírez-Gómez, A.; Fernandez-Anez, N.; Medic Pejic, L.; Tascón, A. Influence of the composition of solid biomass in the flammability and susceptibility to spontaneous combustion. Fuel 2016, 184, 503–511. [Google Scholar] [CrossRef]

- Ferreira, T.; Marques, E.; Monney, J.M.; Pinho, C. A Study on the spontaneous ignition of some ligneous pellets. Fire 2023, 6, 153. [Google Scholar] [CrossRef]

- Casson Moreno, V.; Cozzani, V. Major accident hazard in bioenergy production. J. Loss Prev. Process Ind. 2015, 35, 135–144. [Google Scholar] [CrossRef]

- Krigstin, S.; Wetzel, S.; Jayabala, N.; Helmeste, C.; Madrali, S.; Agnew, J.; Volpe, S. Recent health and safety incident trends related to the storage of woody biomass: A need for improved monitoring strategies. Forests 2018, 9, 538. [Google Scholar] [CrossRef]

- Coffey, C.J.; Price, D.W. Probabilistic risk assessment in combination with CFD modelling of biomass dust explosions within large bulk storage volumes. In Proceedings of the Hazards XXIII Symposium, Southport, UK, 12–15 November 2012. [Google Scholar]

- Siwek, R. Explosion venting technology. J. Loss Prev. Process Ind. 1996, 9, 81–90. [Google Scholar] [CrossRef]

- Yuan, Z.; Khakzad, N.; Khan, F.; Amyotte, P. Domino effect analysis of dust explosions using Bayesian networks. Process Saf. Environ. Prot. 2016, 100, 108–116. [Google Scholar] [CrossRef]

- EN 14491; Dust Explosion Venting Protective Systems. European Committee for Standardization: Brussels, Belgium, 2012.

- NFPA 68; Standard on Explosion Protection by Deflagration Venting. National Fire Protection Association: Quincy, MA, USA, 2023.

- Zalosh, R. Explosion Venting Data and Modeling—Literature Review; The Fire Protection Research Foundation: Quincy, MA, USA, 2008. [Google Scholar]

- Siwek, R. New revised VDI guideline 3673 “Pressure release of dust explosions”. Process Saf. Prog. 1994, 13, 190–201. [Google Scholar] [CrossRef]

- EN 14034-1; Determination of Explosion Characteristics of Dust Clouds—Part 1: Determination of the Maximum Explosion Pressure pmax of Dust Clouds. European Committee for Standardization: Brussels, Belgium, 2011.

- EN 14034-2; Determination of Explosion Characteristics of Dust Clouds—Part 2: Determination of the Maximum Rate of Explosion Pressure Rise (dp/dt)max of Dust Clouds. European Committee for Standardization: Brussels, Belgium, 2011.

- Tascón, A. Design of silos for dust explosions: Determination of vent area sizes and explosion pressures. Eng. Struct. 2017, 134, 1–10. [Google Scholar] [CrossRef]

- Tascón, A.; Aguado, P.J.; Ramírez, A. Dust explosion venting in silos: A comparison of standards NFPA 68 and EN 14491. J. Loss Prev. Process Ind. 2009, 22, 204–209. [Google Scholar] [CrossRef]

- Middha, P.; Samaraweera, R.; Coffey, C.; Price, D.W. The Influence of Explosion Relief Vent Layouts on Explosion Overpressures in Large Biomass Storage Vessels. Chem. Eng. Trans. 2016, 48, 205–210. [Google Scholar] [CrossRef]

- Tascón, A.; Aguado, P.J. Simulations of vented dust explosions in a 5 m3 vessel. Powder Technol. 2017, 321, 409–418. [Google Scholar] [CrossRef]

- Proust, C.; Leprette, E.; Snoeys, J. The role of turbulence in explosion vent system design. In Proceedings of the Hazards XXII Symposium, Liverpool, UK, 11–14 April 2011. [Google Scholar]

- Tamanini, F. Aspect Ratio Effects in Unvented and Vented Dust Explosions. Ind. Eng. Chem. Res. 2012, 51, 7636–7642. [Google Scholar] [CrossRef]

- Tascón, A.; Ramírez-Gómez, A.; Aguado, P.J. Dust explosions in an experimental test silo: Influence of length/diameter ratio on vent area sizes. Biosyst. Eng. 2016, 148, 18–33. [Google Scholar] [CrossRef]

- Castellanos, D.; Skjold, T.; van Winggerden, K.; Echkoff, R.K.; Mannan, M.S. Validation of the DESC code in simulating the effect of vent ducts on dust explosions. Ind. Eng. Chem. Res. 2013, 52, 6057–6067. [Google Scholar] [CrossRef]

- Klippel, A.; Schmidt, M.; Muecke, O.; Krause, U. Dust concentration measurements during filling of a silo and CFD modeling of filling processes regarding exceeding the lower explosion limit. J. Loss Prev. Process Ind. 2014, 29, 122–137. [Google Scholar] [CrossRef]

- Rani, S.I.; Aziz, B.A.; Gimbun, J. Analysis of dust distribution in silo during axial filling using computational fluid dynamics: Assessment on dust explosion likelihood. Process Saf. Environ. Prot. 2015, 96, 14–21. [Google Scholar] [CrossRef]

- Reding, N.S.; Shiflett, M.B. Consequence prediction for dust explosions involving interconnected vessels using computational fluid dynamics modeling. J. Loss Prev. Process Ind. 2020, 65, 104149. [Google Scholar] [CrossRef]

- Olugbemide, D.I. A CFD study of the effects of pipe bending angle on pressure piling in coal dust explosions in interconnected vessels. Fire Saf. J. 2022, 128, 103540. [Google Scholar] [CrossRef]

- Abuswer, M.; Amyotte, P.; Khan, F.; Imtiaz, S. Retrospective risk analysis and controls for Semabla grain storage hybrid mixture explosion. Process Saf. Environ. Prot. 2016, 100, 49–64. [Google Scholar] [CrossRef]

- Ghaffari, M.; van Wingerden, K.; Gjøvåg Hagen, J.T.; Skjold, T.; Storvik, I. Sensitivity Analysis of Dust Explosion Consequences in a Roller Mill using FLACS-DustEx. Chem. Eng. Trans. 2016, 53, 157–162. [Google Scholar] [CrossRef]

- Tascón, A.; Ruiz, A.; Aguado, P.J. Dust explosions in vented silos: Simulations and comparisons with current standards. Powder Technol. 2011, 208, 717–724. [Google Scholar] [CrossRef]

- Huang, C.; Bloching, M.; Lipatnikov, A.N. A vented corn starch dust explosion in an 11.5 m3 vessel: Experimental and numerical study. J. Loss Prev. Process Ind. 2022, 75, 104707. [Google Scholar] [CrossRef]

- Ogunfuye, S.; Sezer, H.; Kodakoglu, F.; Farahani, H.F.; Rangwala, A.S.; Akkerman, V. Dynamics of explosions in cylindrical vented enclosures: Validation of a computational model by experiments. Fire 2021, 4, 9. [Google Scholar] [CrossRef]

- Feroukas, K.; Chiapolino, A.; Saurel, R. Simplified interfacial area modeling in polydisperse two-phase flows under explosion situations. Fire 2023, 6, 21. [Google Scholar] [CrossRef]

- FLACS-CFD v22.1r2 User’s Manual; Gexcon: Bergen, Norway, 2022.

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Hjertager, B.H.; Solberg, T.; Nymoen, K.O. Computer modelling of gas explosion propagation in offshore modules. J. Loss Prev. Process Ind. 1992, 5, 165–174. [Google Scholar] [CrossRef]

- Tascón, A.; Aguado, P.J. CFD simulations to study parameters affecting dust explosion venting in silos. Powder Technol. 2015, 272, 132–141. [Google Scholar] [CrossRef]

- Skjold, T.; Arntzen, B.J.; Hansen, O.R.; Taraldset, O.J.; Storvik, I.E.; Eckhoff, R.K. Simulating dust explosions with the first version of DESC. Process Saf. Environ. Prot. 2005, 83, 151–160. [Google Scholar] [CrossRef]

- Skjold, T. Review of the DESC project. J. Loss Prev. Process Ind. 2007, 20, 291–302. [Google Scholar] [CrossRef]

- Hauert, F.; Vogl, A.; Radant, S. Dust cloud characterization and its influence on the pressure-time-history in silos. Process Saf. Prog. 1996, 15, 178–184. [Google Scholar] [CrossRef]

- Dean, A.; Voss, D.; Draguljić, D. Design and Analysis of Experiments, 2nd ed.; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; Wiley: Hoboken, NJ, USA, 2013; pp. 255–259. [Google Scholar]

- Bartknecht, W. Effectiveness of explosion venting as a protective measure for silos. Plant/Oper. Prog. 1985, 4, 4–13. [Google Scholar] [CrossRef]

- Eckhoff, R.K. Use of (dP/dt)max from closed-bomb tests for predicting violence of accidental dust explosions in industrial plants. Fire Saf. J. 1985, 8, 159–168. [Google Scholar] [CrossRef]

- Skjold, T. Dust explosions modeling: Status and prospects. Part. Sci. Technol. 2018, 36, 489–500. [Google Scholar] [CrossRef]

- Dorofeev, S.B. Flame acceleration and explosion safety applications. Proc. Combust. Inst. 2011, 33, 2161–2175. [Google Scholar] [CrossRef]

- Dafnomilis, I.; Lodewijks, G.; Junginger, M.; Schott, D.L. Evaluation of wood pellet handling in import terminals. Biomass Bioenergy 2018, 117, 10–23. [Google Scholar] [CrossRef]

- Brown, K.R.; Whelan, C.; Murray, G.; Laturnus, B.; Yazdanpanah, F.; Cloney, C.; Amyotte, P. Application of process hazard analysis and inherently safer design in wood pellet production. ACS Omega 2022, 7, 47720–47733. [Google Scholar] [CrossRef] [PubMed]

- Jägers, J.; Wirtz, S.; Scherer, V.; Behr, M. Experimental analysis of wood pellet degradation during pneumatic conveying processes. Powder Technol. 2020, 359, 282–291. [Google Scholar] [CrossRef]

- van Wingerden, K. Mechanical sparks as an ignition source of gas and dust explosions. Chem. Eng. Trans. 2019, 77, 133–138. [Google Scholar] [CrossRef]

- Castellanos, D.; Carreto, V.; Skjold, T.; Yuan, S.; Chaudhari, P.; Mannan, M.S.; Mashuga, C. Construction of a 36 L dust explosion apparatus and turbulence flow field comparison with a standard 20 L dust explosion vessel. J. Loss Prev. Process Ind. 2018, 55, 113–123. [Google Scholar] [CrossRef]

| Level | Characteristic Velocity (m/s) | Relative Turbulence Intensity | Turbulence Length Scale (m) |

|---|---|---|---|

| Low | 0.15 | 0.80 | 0.03 |

| High | 0.50 | 1.00 | 0.10 |

| A (Vent Area) | B (Ignition Location) | C (Initial Turbulence) | D (Dust Concentration) | |

|---|---|---|---|---|

| −1 | 56 m2 | Top | Low | 300 g/m3 |

| +1 | 28 m2 | Bottom | High | 500 g/m3 |

| Case | A | B | C | D |

|---|---|---|---|---|

| 01 | −1 | −1 | −1 | −1 |

| 02 | −1 | −1 | −1 | +1 |

| 03 | −1 | −1 | +1 | −1 |

| 04 | −1 | −1 | +1 | +1 |

| 05 | −1 | +1 | −1 | −1 |

| 06 | −1 | +1 | −1 | +1 |

| 07 | −1 | +1 | +1 | −1 |

| 08 | −1 | +1 | +1 | +1 |

| 09 | +1 | −1 | −1 | −1 |

| 10 | +1 | −1 | −1 | +1 |

| 11 | +1 | −1 | +1 | −1 |

| 12 | +1 | −1 | +1 | +1 |

| 13 | +1 | +1 | −1 | −1 |

| 14 | +1 | +1 | −1 | +1 |

| 15 | +1 | +1 | +1 | −1 |

| 16 | +1 | +1 | +1 | +1 |

| Case | Vent Area (m2) | Ignition Location | Initial Turbulence | Dust Concentration (g/m3) | Pred,sim (Bar) | Class |

|---|---|---|---|---|---|---|

| 03 | 56 | Top | High | 300 | 0.108 | 1 |

| 01 | 56 | Top | Low | 300 | 0.155 | 1 |

| 05 | 56 | Bottom | Low | 300 | 0.270 | 1 |

| 02 | 56 | Top | Low | 500 | 0.293 | 1 |

| 04 | 56 | Top | High | 500 | 0.321 | 1 |

| 09 | 28 | Top | Low | 300 | 0.344 | 1 |

| 11 | 28 | Top | High | 300 | 0.439 | 1 |

| 13 | 28 | Bottom | Low | 300 | 0.534 | 2 |

| 07 | 56 | Bottom | High | 300 | 0.578 | 2 |

| 06 | 56 | Bottom | Low | 500 | 0.584 | 2 |

| 10 | 28 | Top | Low | 500 | 0.744 | 2 |

| 15 | 28 | Bottom | High | 300 | 1.067 | 3 |

| 14 | 28 | Bottom | Low | 500 | 1.096 | 3 |

| 12 | 28 | Top | High | 500 | 1.146 | 3 |

| 08 | 56 | Bottom | High | 500 | 1.159 | 3 |

| 16 | 28 | Bottom | High | 500 | 1.878 | 4 |

| A | B | C | D | BC | |

|---|---|---|---|---|---|

| q | 3.780 | 3.616 | 2.676 | 3.726 | 1.720 |

| Q | 0.236 | 0.226 | 0.167 | 0.233 | 0.108 |

| Q2 (a) | 0.056 | 0.051 | 0.028 | 0.054 | 0.012 |

| Y | 26% | 24% | 13% | 25% | 5% |

| Ignition | Turbulence | Additional Effect on Pred,sim |

|---|---|---|

| −1 | −1 | Increment |

| −1 | +1 | Decrement |

| +1 | −1 | Decrement |

| +1 | +1 | Increment |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varela, A.; Arbizu-Milagro, J.; Tascón, A. Application of Factorial Analysis to the Study of Vented Dust Explosions in Large Biomass Storage Silos. Fire 2023, 6, 226. https://doi.org/10.3390/fire6060226

Varela A, Arbizu-Milagro J, Tascón A. Application of Factorial Analysis to the Study of Vented Dust Explosions in Large Biomass Storage Silos. Fire. 2023; 6(6):226. https://doi.org/10.3390/fire6060226

Chicago/Turabian StyleVarela, Alejandro, Julia Arbizu-Milagro, and Alberto Tascón. 2023. "Application of Factorial Analysis to the Study of Vented Dust Explosions in Large Biomass Storage Silos" Fire 6, no. 6: 226. https://doi.org/10.3390/fire6060226

APA StyleVarela, A., Arbizu-Milagro, J., & Tascón, A. (2023). Application of Factorial Analysis to the Study of Vented Dust Explosions in Large Biomass Storage Silos. Fire, 6(6), 226. https://doi.org/10.3390/fire6060226