Flashover in Aircraft Cargo Compartment at Different Pressures: Experimental and Modeling Study

Abstract

:1. Introduction

2. Experiment and Numerical Simulation

2.1. Experimental Setup

2.2. Numerical Simulation

3. Results and Discussion

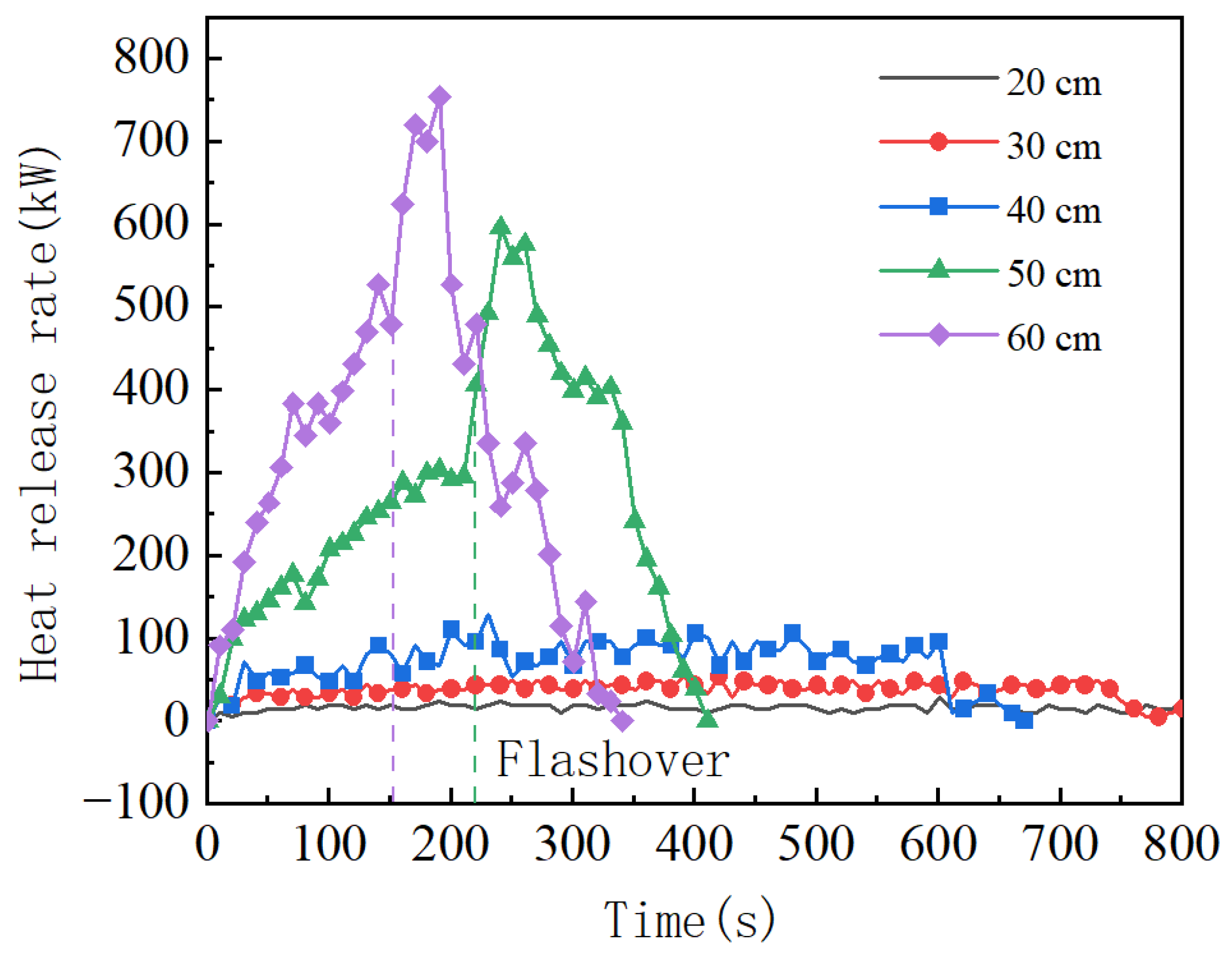

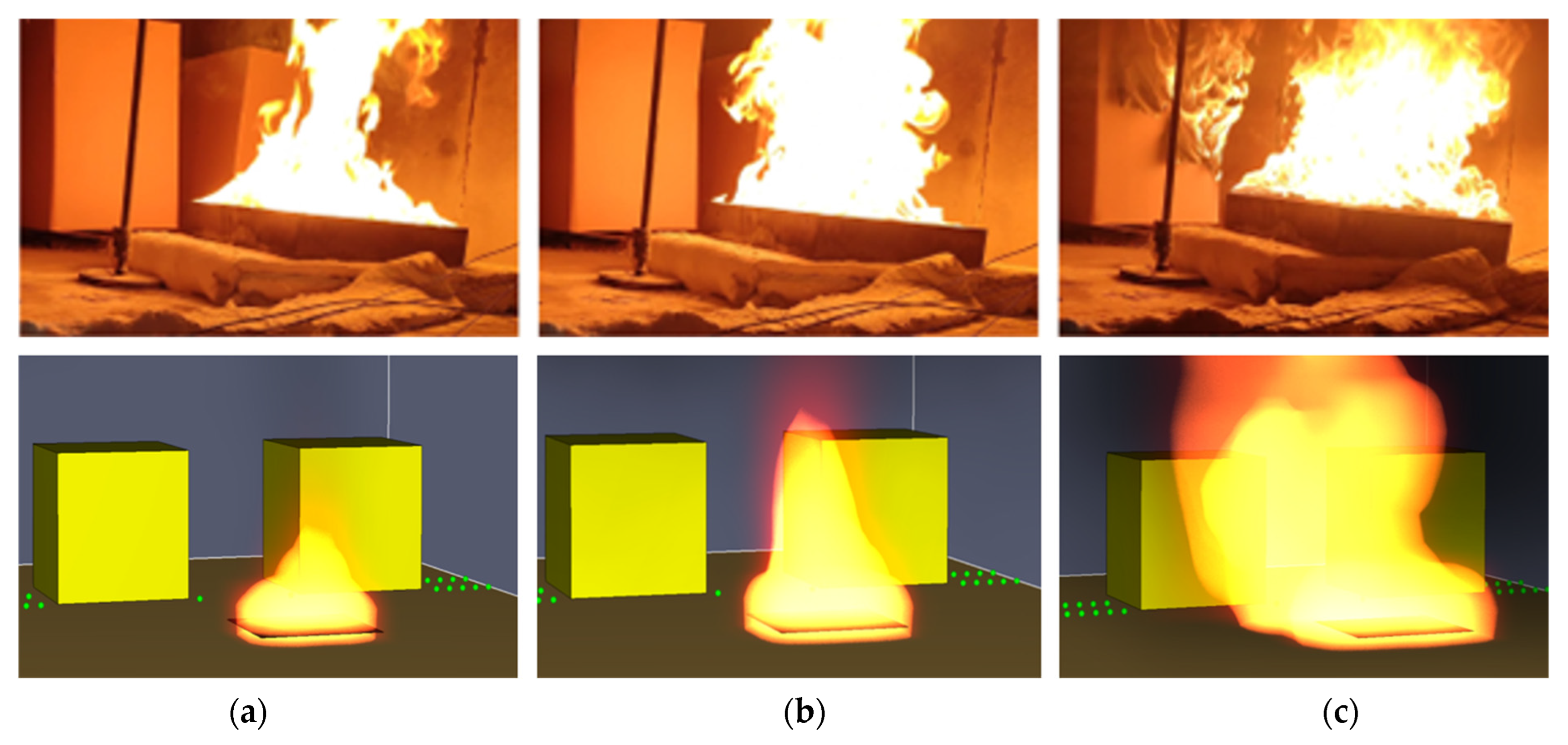

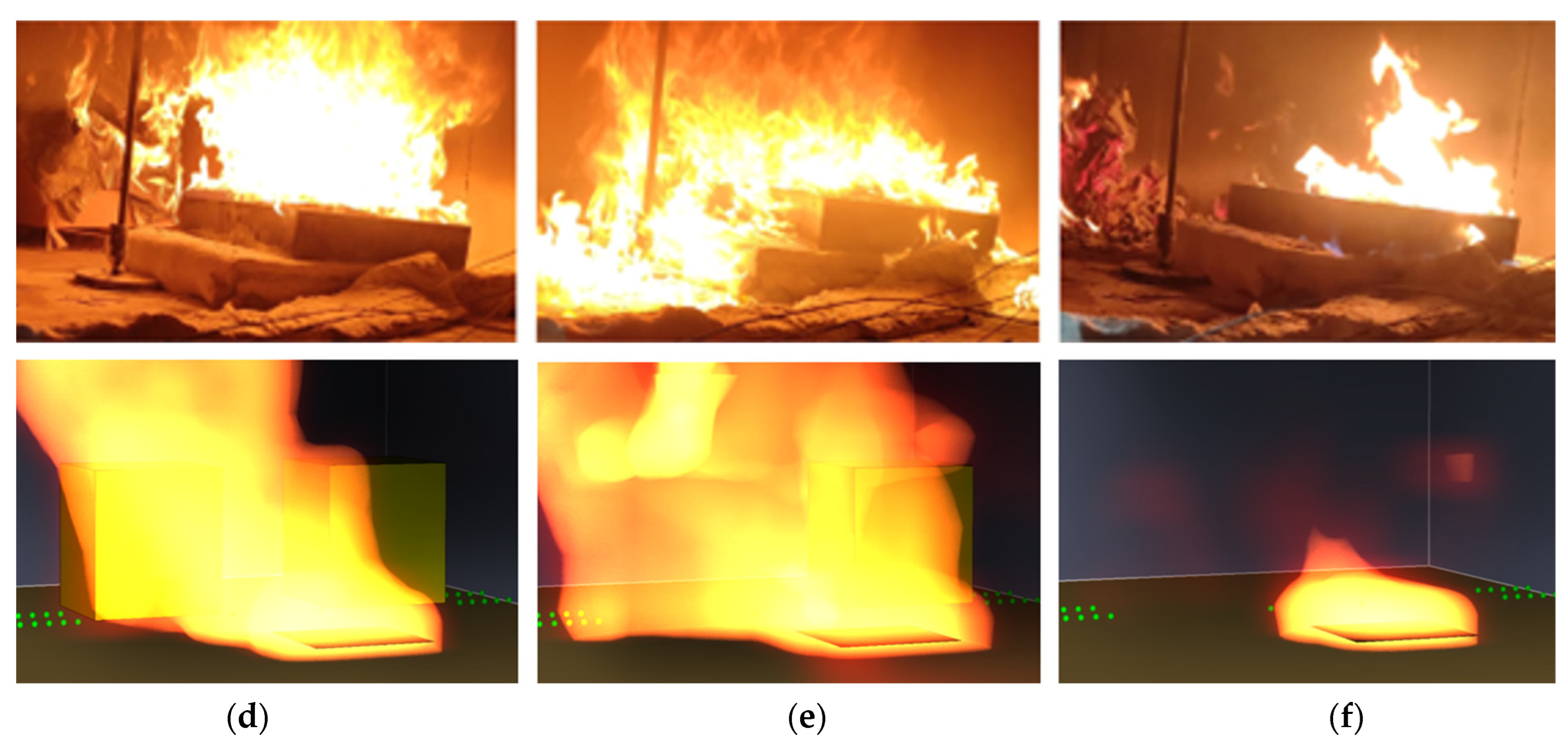

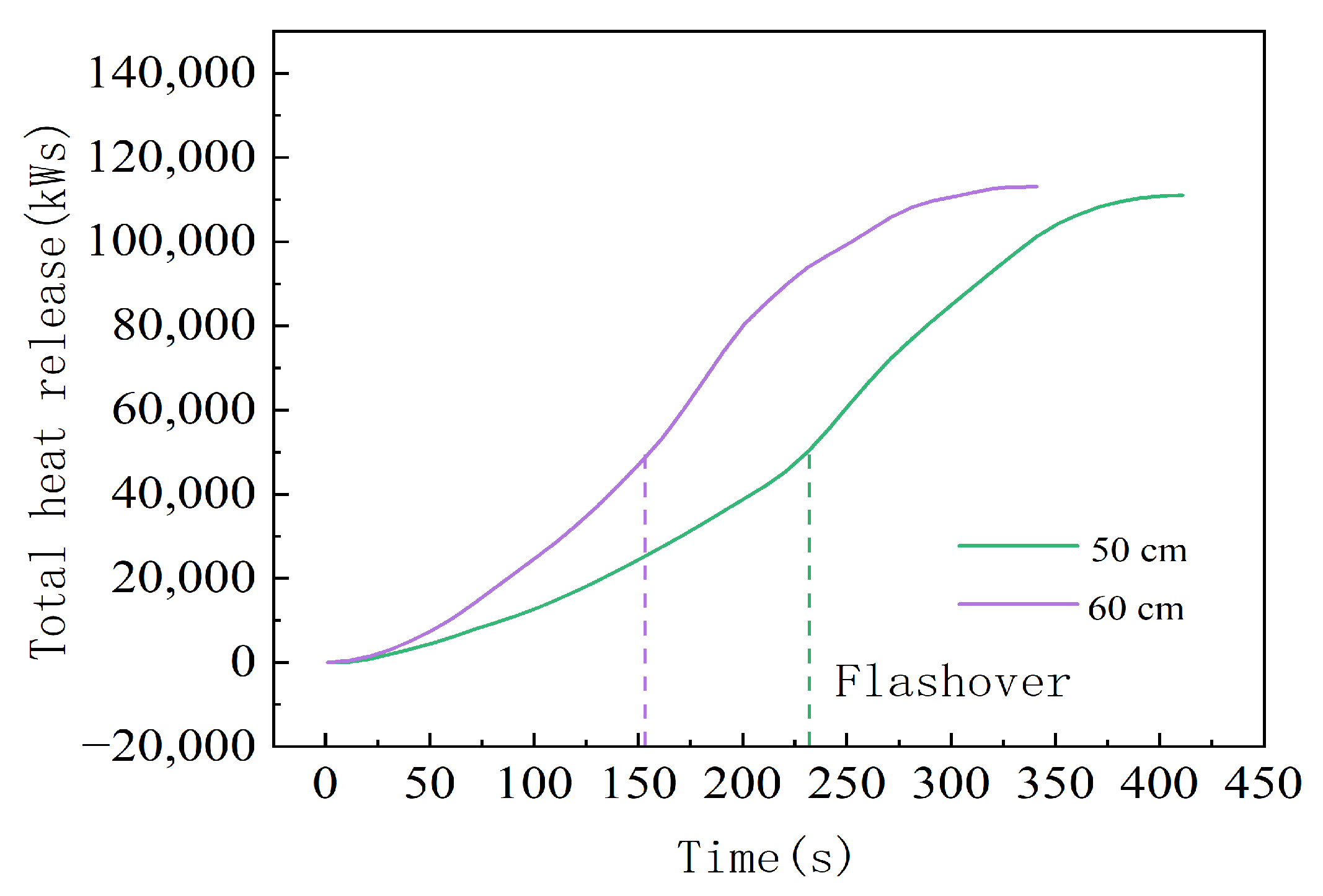

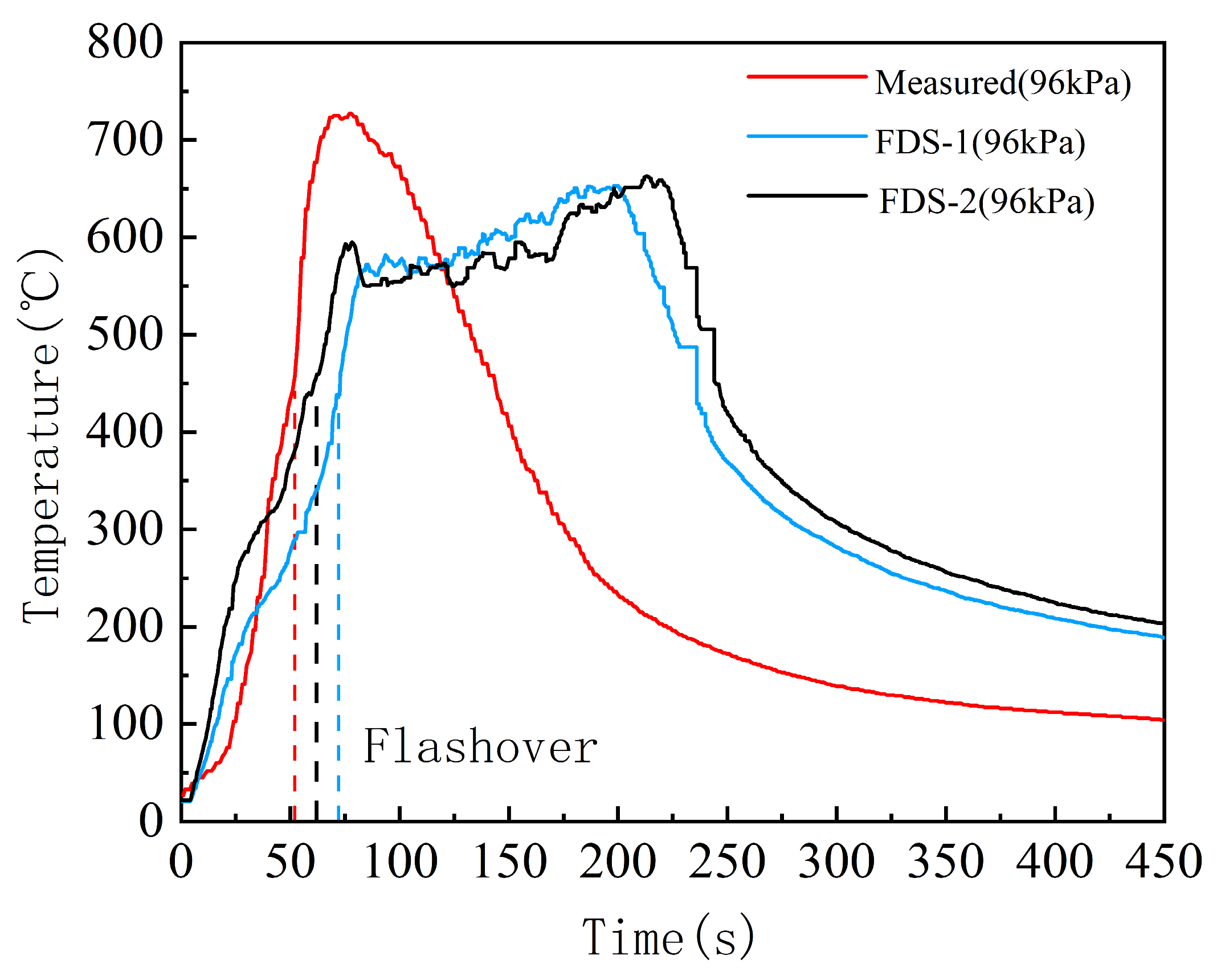

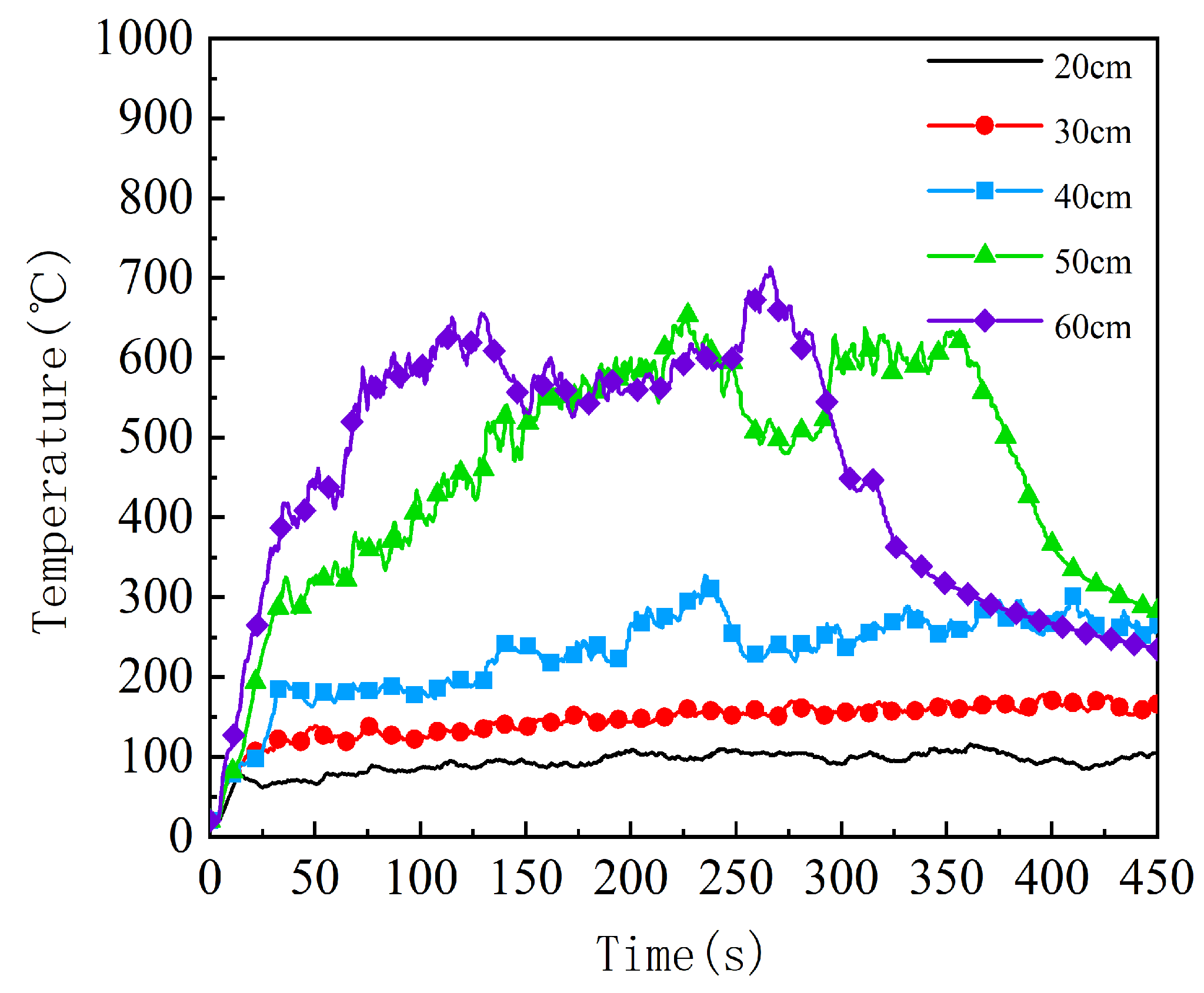

3.1. Effects of Pressure

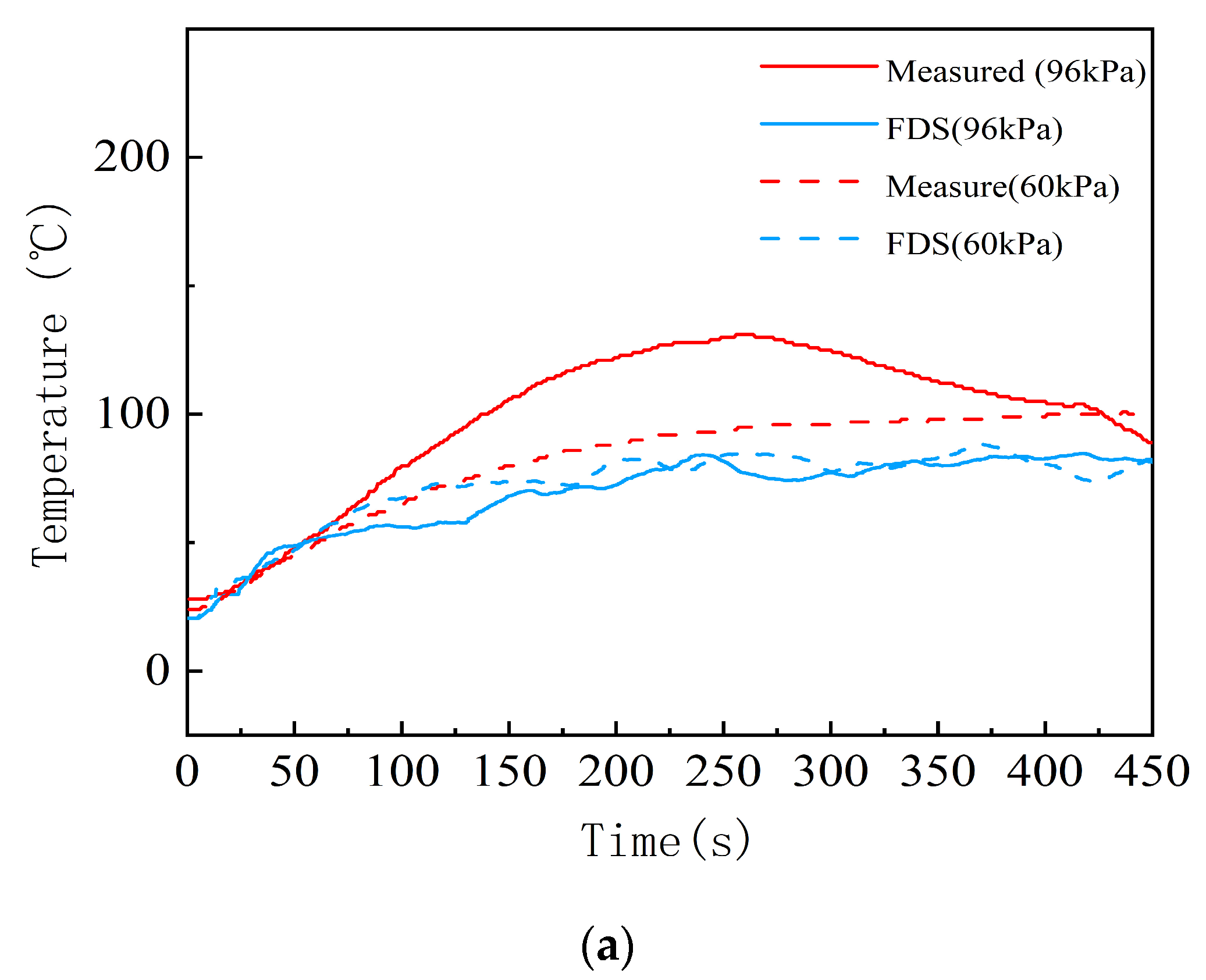

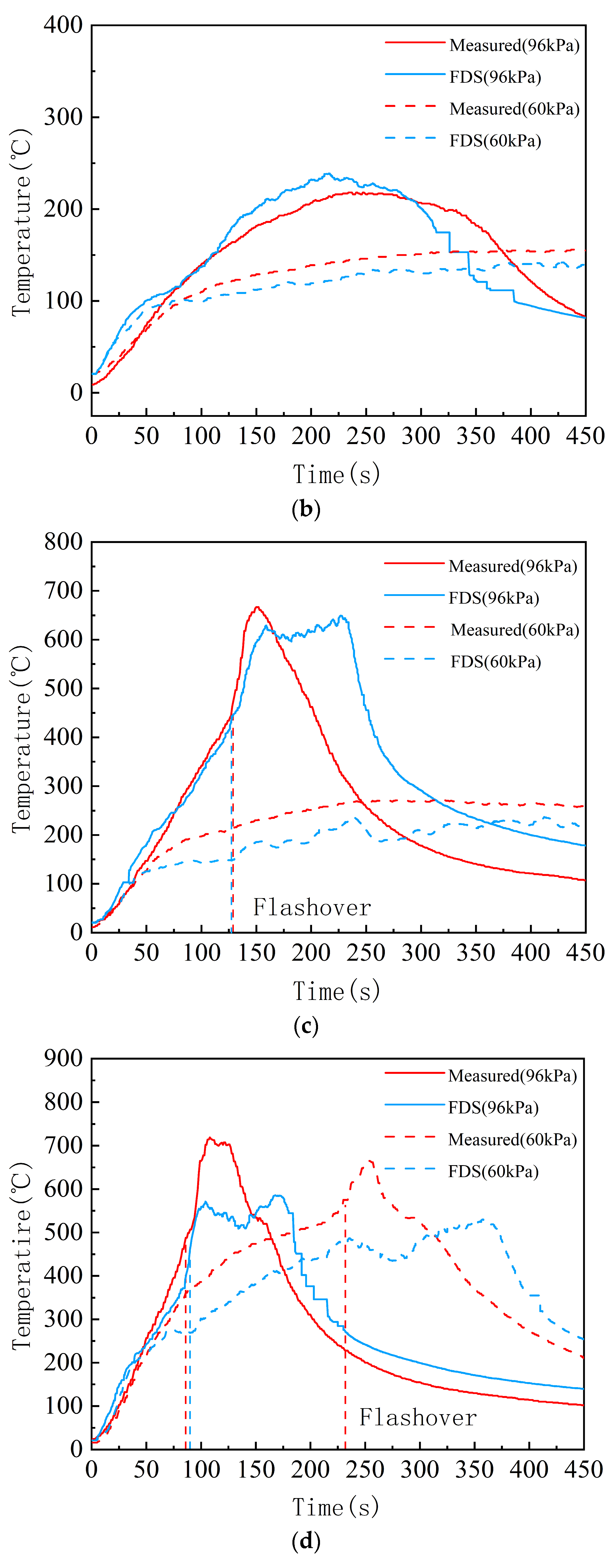

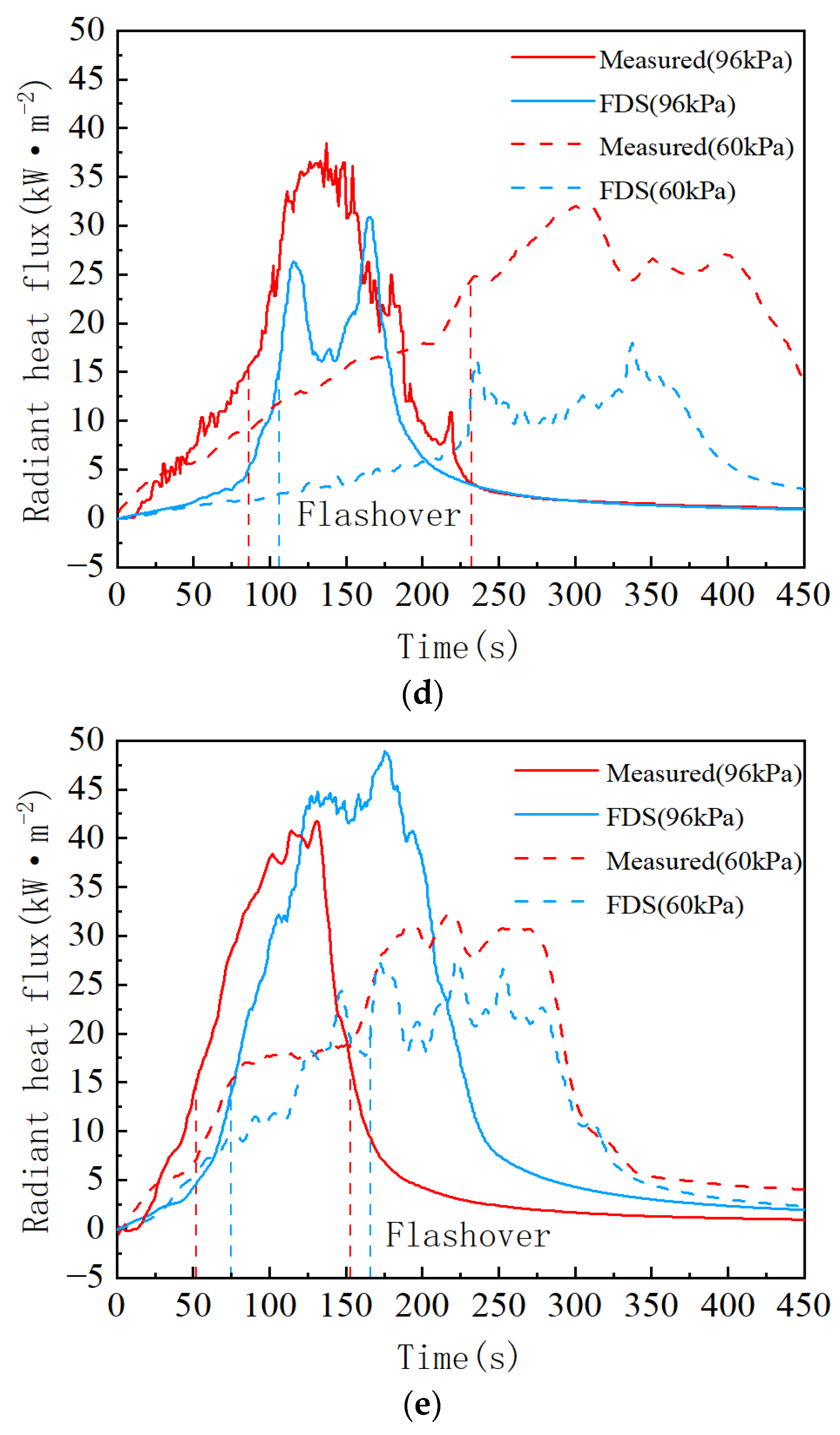

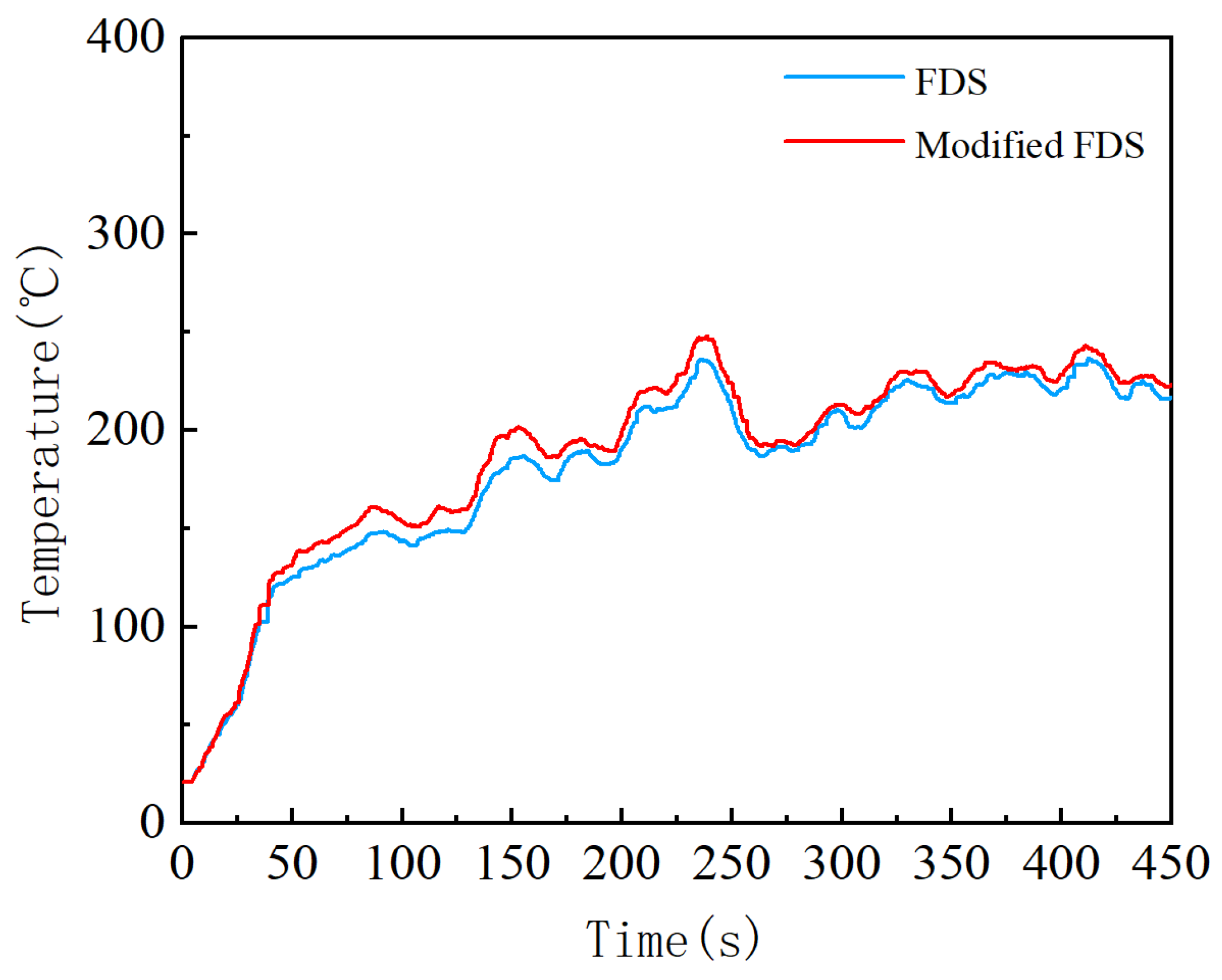

3.2. Comparison of Average Upper Layer Temperatures between Experiments and Simulations

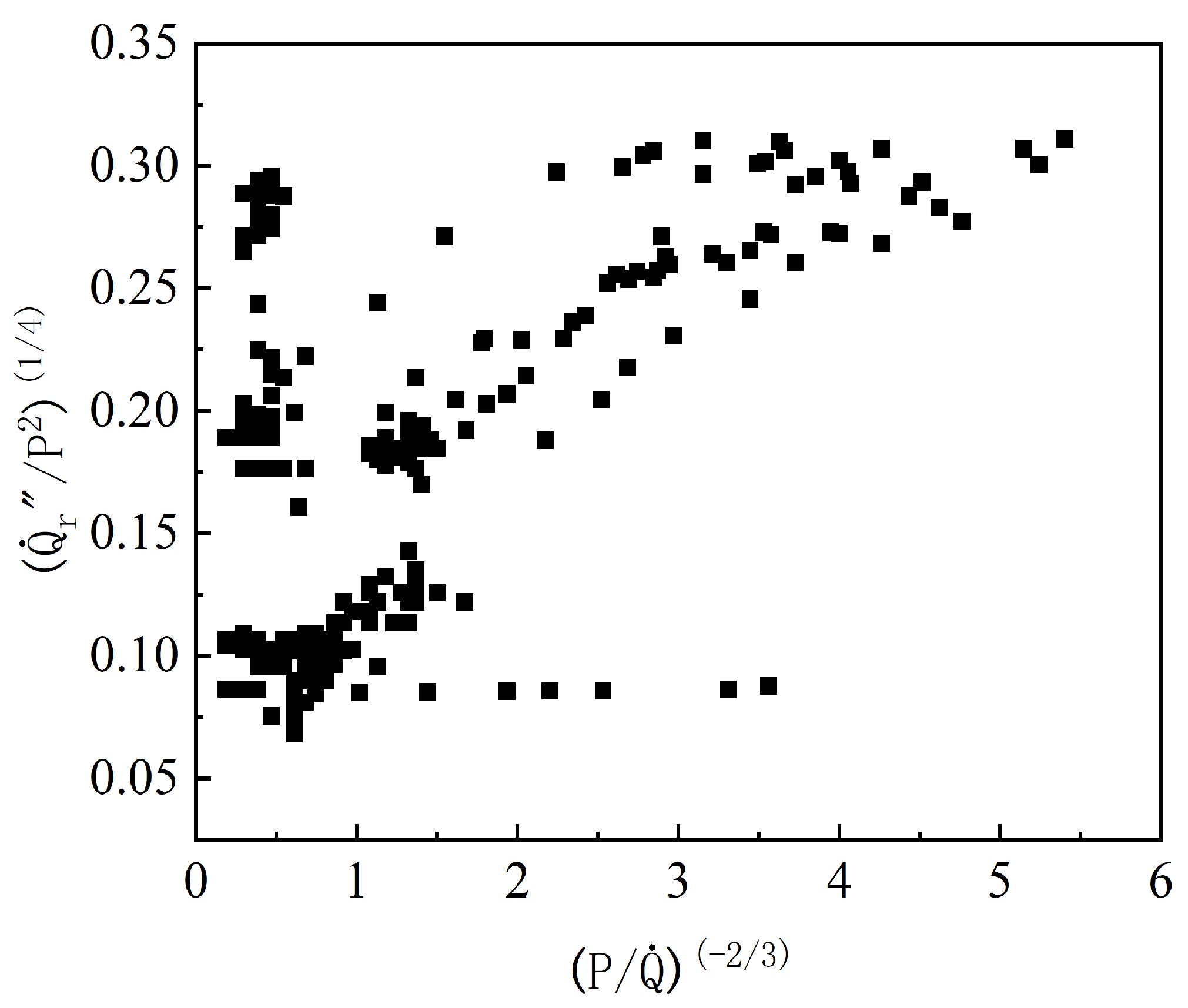

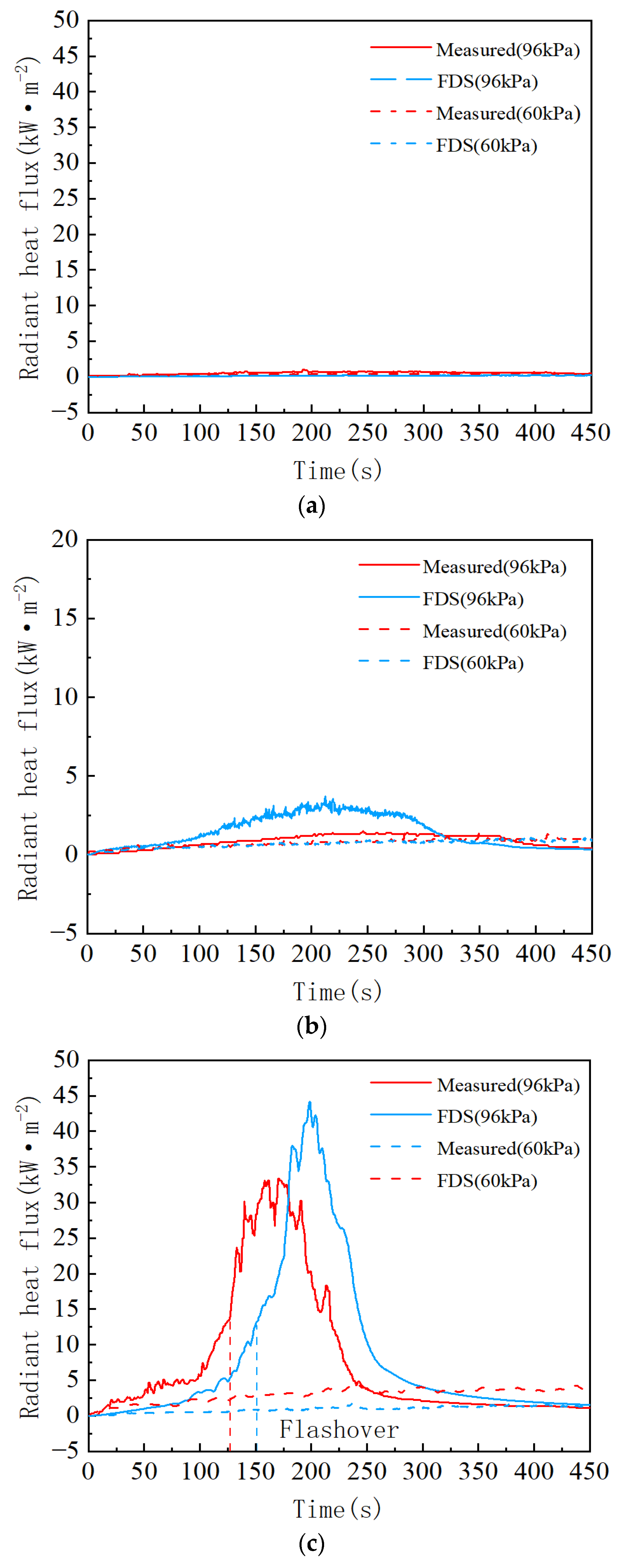

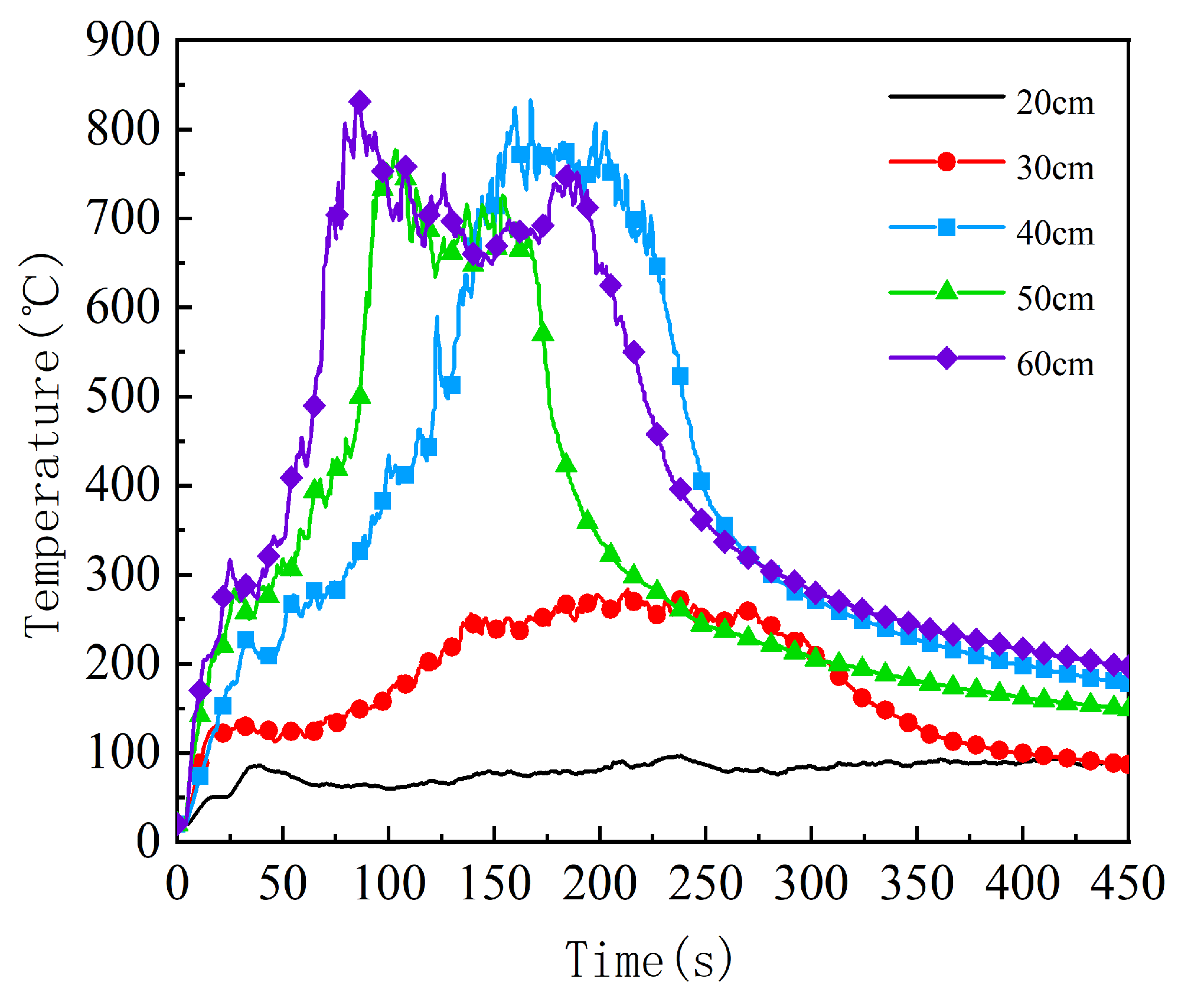

3.3. Comparison of the Radiant Heat Flux at Floor Level between Experiments and Simulations

3.4. Uncertainty and Error Analysis

4. Conclusions

- The critical conditions for the onset of flashover phenomena in a 1/4 MPS compartment were found to be (1) an average upper layer temperature of around 450 °C at 96 kPa and around 550 °C at 60 kPa, and (2) radiant heat flux at floor level of about 10 to 15 kW/m2 at 96 kPa and 20 to 25 kW/m2 at 60 kPa.

- For the same size of pool, fires were less likely to occur at lower pressure and the flashover phenomena occurred much later.

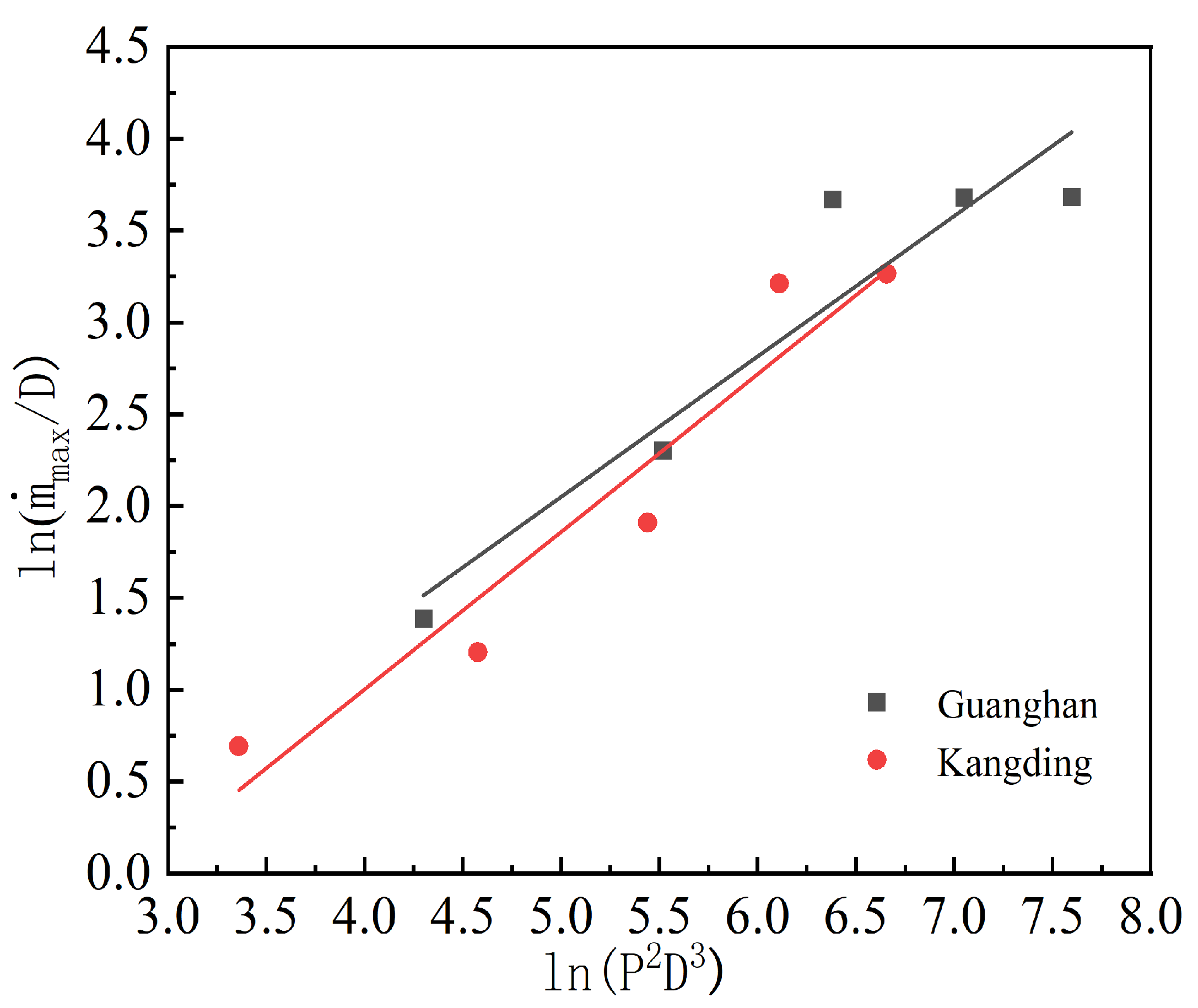

- The dimensionless burning rate of n-heptane is correlated by to the power of 0.48 in Guanghan and 0.58 in Kangding. They are only valid in the quasi-steady burning stage.

- Peak burning rate can be scaled with as in Guanghan and in Kangding.

- When FDS was applied to predict flashover, the average upper layer temperature criterion usually performed better than heat flux at floor level as a criterion. This agrees with the statement made by the developers in [41], that the prediction of heat flux is less accurate. However, the heat flux may sometimes be referred to when the average upper layer temperature malfunctions. It would be wise to analyze both of them simultaneously. The prediction of flashover onset time was less accurate at low pressure with a delay of about 25 s.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aviation Safety Network. Available online: https://aviation-safety.net/ (accessed on 22 September 2023).

- Willey, A.E. NFPA 921 Guide for Fire and Explosion Investigations, 2004th ed.; National Fire Protection Association: Quincy, MA, USA, 2021. [Google Scholar]

- International Organization for Standardization. Fire Tests. Full-Scale Room Test for Surface Products, Designation ISO 9705: 1993(E); American National Standards Institute: Boston, MA, USA, 1993. [Google Scholar]

- Zou, G.W.; Chow, W.K. Evaluation of the field model, fire dynamics simulator, for a specific experimental scenario. J. Fire Prot. Eng. 2005, 15, 77–92. [Google Scholar] [CrossRef]

- Khalil, E.E.; Othman, M.A. On the Computations of Aircraft Postcrash Fires. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; p. 0994. [Google Scholar]

- Zong, R.; Li, S.; Wei, T.; Zhi, Y.; Liao, G. The Simulation and Reconstruction of Flashover in the Confined Space. In Proceedings of the Eleventh Annual Conference of China Association for Science and Technology on Independent Innovation and Sustained Growth, Chongqing, China, 8 September 2009. [Google Scholar]

- Li, S.; Zong, R.; Liao, G. Experimental and Modeling Study on Flashover in the Typical Compartment of Extra-high Building Construction. In Proceedings of the 2010 International Forum on Fire Safety and Comprehensive Disaster Prevention Technology of Extra-high Buildings, Guangzhou, China, 20 November 2010. [Google Scholar]

- Han, R.; Zhu, G.; Zhang, G.; Zhang, L. Reliability study on characteristics of flashover based on large eddy simulation. Fire Sci. Technol. 2013, 32, 499–507. [Google Scholar]

- Bishop, S.R.; Holborn, P.G.; Beard, A.N.; Drysdale, D.D. Nonlinear dynamics of flashover in compartment fires. Fire Saf. J. 1993, 21, 11–45. [Google Scholar] [CrossRef]

- Chow, W.K. New inspection criteria for flashover in compartmental fires. Fire Mater. 1999, 23, 13–15. [Google Scholar] [CrossRef]

- Chow, W.K. Predictability of flashover by zone models. J. Fire Sci. 1998, 16, 335–350. [Google Scholar] [CrossRef]

- Chow, W.K. Do standard fire curves include flashover? J. Appl. Fire Sci. 1998, 7, 353–359. [Google Scholar] [CrossRef]

- Hasemi, Y. Thermal Theory of Flashover, Report 111; Building Research Institute: Tsukuba, Japan, 1986. [Google Scholar]

- Chow, W.K. Study on the flashover criteria for compartmental fires. J. Fire Sci. 1997, 15, 95–107. [Google Scholar] [CrossRef]

- Chow, W.K. Study of flashover using a single zone model. J. Appl. Fire Sci. 1998, 8, 159–175. [Google Scholar] [CrossRef]

- Waterman, T.E. Room flashover—Criteria and synthesis. Fire Technol. 1968, 4, 25–31. [Google Scholar] [CrossRef]

- Thomas, P.H.; Bullen, M.L.; Quintiere, J.G.; McCaffrey, B.J. Flashover and instabilities in fire behavior. Combust. Flame 1980, 1, 159–171. [Google Scholar] [CrossRef]

- Thomas, P.H. The growth of fire-ignition to full involvement. In Combustion Fundamentals of Fire; Academic Press: London, UK, 1995; pp. 275–296. [Google Scholar]

- Fang, J.B. Fire Buildup in a Room and the Role of Interior Finish Materials; TN879; US Department of Commerce, National Bureau of Standards: Gaithersburg, MD, USA, 1975.

- Heselden, A.J.; Melinek, S.J. The early stages of fire growth in a compartment a co-operative research programme of the international du batiment (commission w 14). first phase. Fire Res. Note 1975, 1029, 1. [Google Scholar]

- Lee, B.T.; Breese, J.N. Submarine Compartment Fire Study Performance Evaluation of Hull Insulation; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1979.

- Quintiere, J.G.; Mccaffrey, B.J. The burning of wood and plastic cribs in an enclosure. Final. Rep. 1980, 1, 2–4. [Google Scholar]

- Parker, W.J.; Lee, B.T. Fire Build-Up In Reduced Size Enclosures. In Fire Safety Research: Proceedings of a Symposium Gaithersburg, MD, USA, 22 August 1973; National Bureau of Standards: Gaithersburg, MD, USA, 1974; p. 139. [Google Scholar]

- Klopovic, S.; Turan, O.F. Flames venting externally during full-scale flashover fires: Two sample ventilation cases. Fire Saf. J. 1998, 31, 117–142. [Google Scholar] [CrossRef]

- Peacock, R.D.; Reneke, P.A.; Bukowski, R.W. Defining flashover for fire hazard calculations. Fire Saf. J. 1999, 32, 331–345. [Google Scholar] [CrossRef]

- Niu, Y.; He, Y.; Hu, X.; Zhou, D.; Lin, C.H.; Yin, J.; Yao, W.; Wang, J. Experimental study of burning rates of cardboard box fires near sea level and at high altitude. Proc. Combust. Inst. 2013, 34, 2565–2573. [Google Scholar] [CrossRef]

- Zhou, R.; Zhao, H.; Ye, J.; Zhang, H. A new approach based on the modified FDS to numerically simulate cardboard box combustion under low pressure. Fire Mater. 2019, 43, 1010–1021. [Google Scholar] [CrossRef]

- Liu, Q.; Yao, W.; Yin, J.; Yang, R.; Zhang, H. Modeling on n-Heptane pool fire behavior in an altitude chamber. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, San Diego, CA, USA, 15–21 November 2013. [Google Scholar]

- Wang, Z.; Zhu, J. Fire and smoke law of A320 cabin in low pressure environment. Fire Sci. Technol. 2022, 41, 468. [Google Scholar]

- Xu, L.; Zheng, W. Numerical simulation on the influence of low air pressure upon smoke spread and fire alarm process. Case Stud. Therm. Eng. 2021, 26, 101004. [Google Scholar] [CrossRef]

- U.S. Department of Transportation Federal Aviation Administration. Minimum Performance Standard for Aircraft Cargo Compartment Halon Replacement Fire Suppression Systems (2012 Update); National Technical Information Services: Springfield, VA, USA, 2012.

- Blake, D.; Suo-Anttila, J. Aircraft cargo compartment fire detection and smoke transport modeling. Fire Saf. J. 2008, 43, 576–582. [Google Scholar] [CrossRef]

- He, Y. On experimental data reduction for zone model validation. J. Fire Sci. 1997, 15, 144–161. [Google Scholar] [CrossRef]

- He, Y.; Li, J.; Wang, J.; Wang, K. Experimental study on Flashover Law of Aircraft Cargo Hold in Low Pressure Environment. Fire Sci. Technol. 2022, 41, 1030–1035. [Google Scholar]

- McGrattan, K.B.; Hostikka, S.; McDermott, R.; Floyd, J.; Weinschenk, C.; Overholt, K. NIST Special Publication 2019 sixth Edition Fire Dynamics Simulator User’s Guide; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2019.

- De Ris, J.; Kanury, A.M.; Yuen, M.C. Pressure modeling of fires. Symp. (Int.) Combust. 1973, 14, 1033–1044. [Google Scholar] [CrossRef]

- Zhou, Z.; Yao, W.; Hu, X.; Yuen, R.; Wang, J. Experimental study of the burning behavior of n-heptane pool fires at high altitude. Fire Mater. 2016, 40, 80–88. [Google Scholar] [CrossRef]

- Yin, J.; Yao, W.; Liu, Q.; Wu, N.; Zhou, Z.; Wu, Y.; Zhang, H. Experimental Study of N-Heptane Pool Fire Behaviors under Dynamic Pressures in an Altitude Chamber. Procedia Eng. 2013, 52, 548–556. [Google Scholar]

- McGrattan, K.B.; Baum, H.R.; Rehm, R.G. Large eddy simulations of smoke movement. Fire Saf. J. 1998, 30, 161–178. [Google Scholar] [CrossRef]

- Zhang, W.; Hamer, A.; Klassen, M.; Carpenter, D.; Roby, R. Turbulence statistics in a fire room model by large eddy simulation. Fire Saf. J. 2002, 37, 721–752. [Google Scholar] [CrossRef]

- McGrattan, K.B.; Peacock, R.; Overholt, K. Fire model validation–eight lessons learned. Fire Saf. Sci. 2014, 11, 958–968. [Google Scholar] [CrossRef]

| Calcium Silicate | Corrugated Cardboard | |

|---|---|---|

| Density, kg/m3 | 720 | 323.5 |

| Specific heat, kJ/(kg·K) | 1.25~1.55 1 | 0.87~3.04 1 |

| Conductivity, W/(m·k) | 0.12 | 0.08~0.1 1 |

| Heat of combustion, kJ/kg | N/A 2 | 16,460 |

| Heat of reaction, kJ/kg | N/A | 171.88 |

| Reference temperature, °C | N/A | 338.6 |

| Heating rate, K/min | N/A | 5 |

| Pyrolysis range, °C | N/A | 200 |

| Pressure, kPa | Pool Size, cm | Experimental, s | Simulated (Average Upper Layer Temperature as Criterion), s | Simulated (Average Upper Layer Temperature as Criterion), s |

|---|---|---|---|---|

| 96 | 20 | N/A 1 | N/A | N/A |

| 30 | N/A | N/A | N/A | |

| 40 | 127 | 129 | 152 | |

| 50 | 86 | 90 | 107 | |

| 60 | 52 | 73 | 74 | |

| 60 | 20 | N/A | N/A | N/A |

| 30 | N/A | N/A | N/A | |

| 40 | N/A | N/A | N/A | |

| 50 | 232 | N/A | N/A | |

| 60 | 153 | N/A | 166 |

| Case | Pressure, kPa | Pool Size, cm | Total Heat Release, kWh/m2 |

|---|---|---|---|

| 1 | 96 | 20 | 95.3 |

| 2 | 96 | 30 | 92.5 |

| 3 | 96 | 40 | 150.2 |

| 4 | 96 | 50 | 93.9 |

| 5 | 96 | 60 | 106 |

| 6 | 60 | 20 | 93.6 |

| 7 | 60 | 30 | 93.4 |

| 8 | 60 | 40 | 83.5 |

| 9 | 60 | 50 | 123.4 |

| 10 | 60 | 60 | 87.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Chen, Y.; Zhao, Y.; Wang, J. Flashover in Aircraft Cargo Compartment at Different Pressures: Experimental and Modeling Study. Fire 2023, 6, 415. https://doi.org/10.3390/fire6110415

Li M, Chen Y, Zhao Y, Wang J. Flashover in Aircraft Cargo Compartment at Different Pressures: Experimental and Modeling Study. Fire. 2023; 6(11):415. https://doi.org/10.3390/fire6110415

Chicago/Turabian StyleLi, Mengling, Yinglong Chen, Yudie Zhao, and Jingdong Wang. 2023. "Flashover in Aircraft Cargo Compartment at Different Pressures: Experimental and Modeling Study" Fire 6, no. 11: 415. https://doi.org/10.3390/fire6110415

APA StyleLi, M., Chen, Y., Zhao, Y., & Wang, J. (2023). Flashover in Aircraft Cargo Compartment at Different Pressures: Experimental and Modeling Study. Fire, 6(11), 415. https://doi.org/10.3390/fire6110415