2.1. Wooden Homes

A characteristic of Norway is the widespread use of wood as external and partly internal panelling [

8]. Nowadays, only Canada and the USA have an equal fraction of wooden homes compared to the remaining building mass [

8]. While still widely used, internal wooden cladding is especially evident in older wooden houses. Norway has over 200 densely built wooden home heritage sites [

21], which manifest a long tradition and several hundred years of constructional engineering development. By definition, these sites contain a minimum of 20 wooden single-structure homes with less than eight meters of separation. In addition, the buildings should primarily be constructed before the 1900s [

22]. Norway does not have a tradition of high-rise buildings. Thus, low-rise single-structure wooden homes dominate how people live. Even today, wood is the primary construction material for low-rise homes [

23]. While older wooden homes used wood for all internal surfaces, nowadays it is common to combine materials, and gypsum boards have become quite popular in recent years. Recently, the use of decorative wooden wall laths has gained popularity and reintroduced wood as a modern internal cladding material. In the coming years, it is not unlikely that wood as an interior building material will be increasingly used for new and refurbished homes as increased attention is brought toward its potential health effects as an indoor humidity buffer [

24] and as a sustainable material.

Figure 1 presents parts of a wooden home heritage site in Bergen, Norway (top), as well as a typical modern Norwegian neighbourhood in Haugesund (bottom). While both pictures present wooden homes, the old homes in Bergen are situated closer together and with can be expected to have widespread use of wood as interior panelling. The newer homes in Haugesund, while being wooden homes, are more likely to vary with respect to the indoor materials. In general, such wooden heritage sites are far more susceptible to conflagration events due to the short separation distance and use of wood as both an exterior and interior material. Additionally, many heritage sites and other wooden towns and villages are in areas without permanently manned fire stations, resulting in quite long deployment times.

2.2. Conflagrations

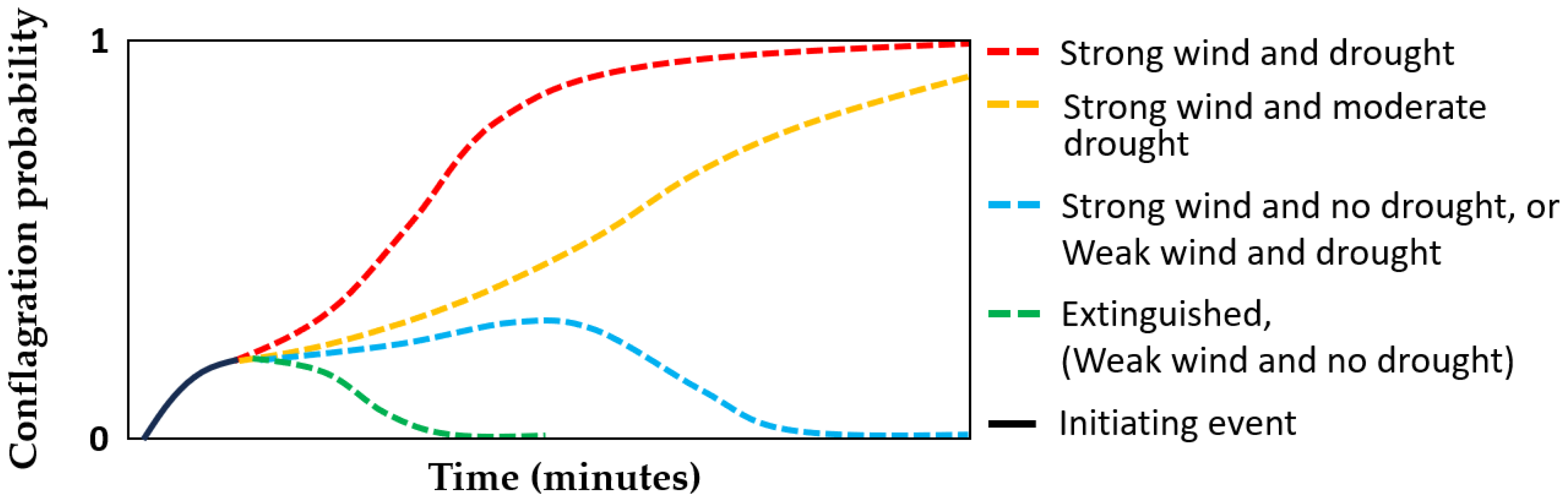

Town fire conflagrations involving several homes or other structures can originate from different scenarios contributing to fire spread. Every conflagration starts with an initiating event involving ignition, which can be separated into structure-related or vegetation-related initiating events, referring to the object or area where the initial fire originated. Structure-related events might be a house on fire, typically a fire starting within the structure, spreading to the building envelope, and then spreading further to new objects. A vegetation-related initiating event could be, e.g., a grass fire initiated by a grid failure causing sparks. Despite the initiating event, the fire may spread within a combination of vegetation and structures, i.e., a WUI fire, or only within one of the two, i.e., a wildfire or a town fire, as evident from many historical fires. Two critical factors associated with the formation of a conflagration event appear to be (1) dry fuel conditions and (2) strong wind [

9,

25]. The latter factor is related to wind strong enough to cause flame spread by ember transport (firebrands) or flame impingement on nearby structures or objects. This discontinuous fire spread mechanism has been a dominant fire spread mechanism for many town fire conflagrations, such as the wind-driven fires in London in 1666, Grand Forks in 1997, and the more recent Lærdal fire in 2014 [

25,

26].

A conflagration is imminent when the fire spreads over horizontal distances faster than firefighters can respond, quickly outgrowing the available resources. As stated in [

25], “Conflagrations occur generally when strong winds drive a fire to overwhelm human suppression efforts”. This concerns vegetation fires and rapid fire spread in, e.g., cured grass, and relates to the spread of resources over larger areas as well. Flame spread by firebrands from structure-to-structure (wooden home to wooden home) was in the Lærdal fire recorded at above 200 m distance [

9]. During the more recent Sotra fire in Bergen 2021, a fire spread about 270 m across a fjord to the vegetation on the opposite side [

27]. Such large leaps have been recorded for previous conflagrations as well, such as the crossing of the Chicago River during the 1871 Chicago Fire or the San Diego Freeway during the 1961 Bel-Air Fire [

25]. Such rapid fire spread over large distances causes significant challenges for the fire brigade with respect to resources and resource redistribution. Typically, a conflagration event is of such an extent that it is not stopped or controlled by human interaction. It ends when the line of fuel ends or when the dominating mechanism for fire spread reduces in potential, e.g., reduced wind strengths or precipitation.

Figure 2 illustrates potential scenarios following an initiating fire event, possibly towards a conflagration.

The Lærdal fire in Norway in January 2014 is an example of a wooden town conflagration where the fire spread from structure to structure during strong wind. Over 60 buildings were damaged, of which at least 40 were lost [

9]. The first home to catch fire was next to the fire station. When the part-time firefighters passed this home upon mustering at the station, 90–120 s after the emergency call, flashover had already occurred and the external wooden sidings were already burning [

9]. Within an hour, two-story buildings burned to the ground. The fire risk for Lærdal at the time was reported as non-existent [

28]. This reported risk was related to vegetation fire, however, and had nothing to do with the fire risk of the wooden homes in Lærdal at the time. However, in the aftermath of that fire it was found that the houses had very dry external and internal wooden panelling [

9,

26].

More recently, the Marshal fire in Boulder County, USA on 30 December 2021, was a wildland–urban interface (WUI) conflagration. The fire initially spread through vegetation and then secondarily from structure to structure. Estimated losses exceeded a thousand buildings, including homes and shopping centres. A moist spring and dry summer had resulted in abundant cured grass. This, combined with snow-free ground and wind gusts reaching 50 m/s on the day of the fire, resulted in large amounts of dry fuel, rapid fire spread into the town area, and loss of many wooden structures [

29].

2.3. Dry Wood Fire Dynamics

It is necessary to consider the involved fire dynamics in order to understand the modelling approach for the indoor wooden home fire risk, which may be associated with the risk related to initiating a conflagration event. It is assumed that the reader is familiar with enclosure fires and how these fires may develop very differently depending on variables such as HRR, type of fuel, orientation of fuel with respect to ignition, location of fuel, ignition source, layout, volume and height of the compartment, and ventilation conditions, to mention a few. Nevertheless, the basics are provided here.

An enclosure fire typically develops through four stages [

30]. The initial stage, involving ignition, lasts until the fire has been established. In this phase, average compartment temperatures are low and the heat transport is dominated by convection from hot gases and conduction within the solid materials involved. When the fire has been established, it enters the second phase, the growth phase. Heat radiation from the smoke layer becomes increasingly dominant within the growth phase, as it is proportional to the absolute temperature to the 4th power. As the fire grows in size and the temperature of the smoke layer trapped beneath the ceiling increases, a rapid, severe, and self-induced acceleration in fire development may occur, i.e., flashover. The flashover phenomenon marks the transition from the growth phase to the stage of a fully developed fire. Typically, at this stage the HRR within the enclosure becomes controlled by ventilation and all combustible surfaces become involved in the fire [

31]. There are several criteria used for flashover, e.g., average smoke layer temperatures at about 550–600 °C, heat fluxes at floor level at about 20

, or visible flames escaping through compartment openings (indicating insufficient oxygen supply within compartment). Quite often all of these criteria are met within a short period. The last phase is the decay phase, where the fire intensity declines. This phase is not considered further in the present context.

The HRR is considered the most important parameter characterising fire behaviour [

32]. It may be expressed as [

30]

where

is the fuel surface area (

),

is the mass flow per unit area from the fuel surface (

),

is the combustion efficiency, known to be less than unity, and

is the heat of combustion (

).

A heat balance for the production of volatiles for gas phase oxidation may be expressed as

where the net heat fluxes to the surface involve the heat flux from flames

(

), any external heat supply

(

), i.e., the hot smoke layer, and heat lost from water evaporation and other heat transport mechanisms is provided by

(

), and

(

) is the latent heat of vaporisation and pyrolysis.

The following briefly describes an enclosure fire developing inside a living room where walls and ceiling are covered with untreated wooden panels. A potentially established fire will produce hot gases rising towards the wooden ceiling. The convective heat release is typically described by

where

is the convective fraction of the heat released by combustion. Most of the heat released interacts with the wooden ceiling, followed by the wooden walls post formation of the smoke layer. It is not unlikely that the walls are involved in a very early phase, as many fires originate close to the walls due to, e.g., electric apparatuses, socket short-circuits, candles, old fireplaces, or stove fires. The moisture content of the wooden panels interacting with the hot gases influences fire development. In principle, the wooden panels may either restrict fire development or contribute to a more rapid fire development (ignoring a possible neutral state). Restricting fire development is consistent with high FMC values. For such a scenario, the heat of combustion

and the combustion efficiency

presented in Equation (

1) decrease as a function of increasing water content in the panels [

9]. This reduces the HRR and provides less external heat flux

and preheating. Increased water levels increase the heat loss

, through increased thermal conductivity as well as increasing the latent heat of vaporisation and pyrolysis

, as energy is consumed in the evaporation of water. Further, the evaporated water increases the heat capacity of the smoke layer and dilutes oxygen. Hence, increased FMC values reduce temperatures, and may result in prolonged time until flashover. Although this brief description emphasises wooden panels, it relates to other fuels with hygroscopic properties as well.

If the wooden panels contribute to fire development through low FMC, the wooden surfaces participate in the production of volatiles and thereby increase the net energy released within the compartment at an early stage. This would increase the smoke layer temperature and thereby the external heat flux , causing increased preheating and potentially further accelerating the fire growth rate.

It should be mentioned that post-flashover combustion within the compartment is usually restricted by air access. Uncombusted hot gases exiting the ventilation openings burn on the outside of the vent openings. These external flames then represent a strong ignition source for neighbouring buildings, in addition to further accelerating fire spread on the initial structure. The drier the compartment wooden fuel is, the more combustion generally takes place outside the vent openings.

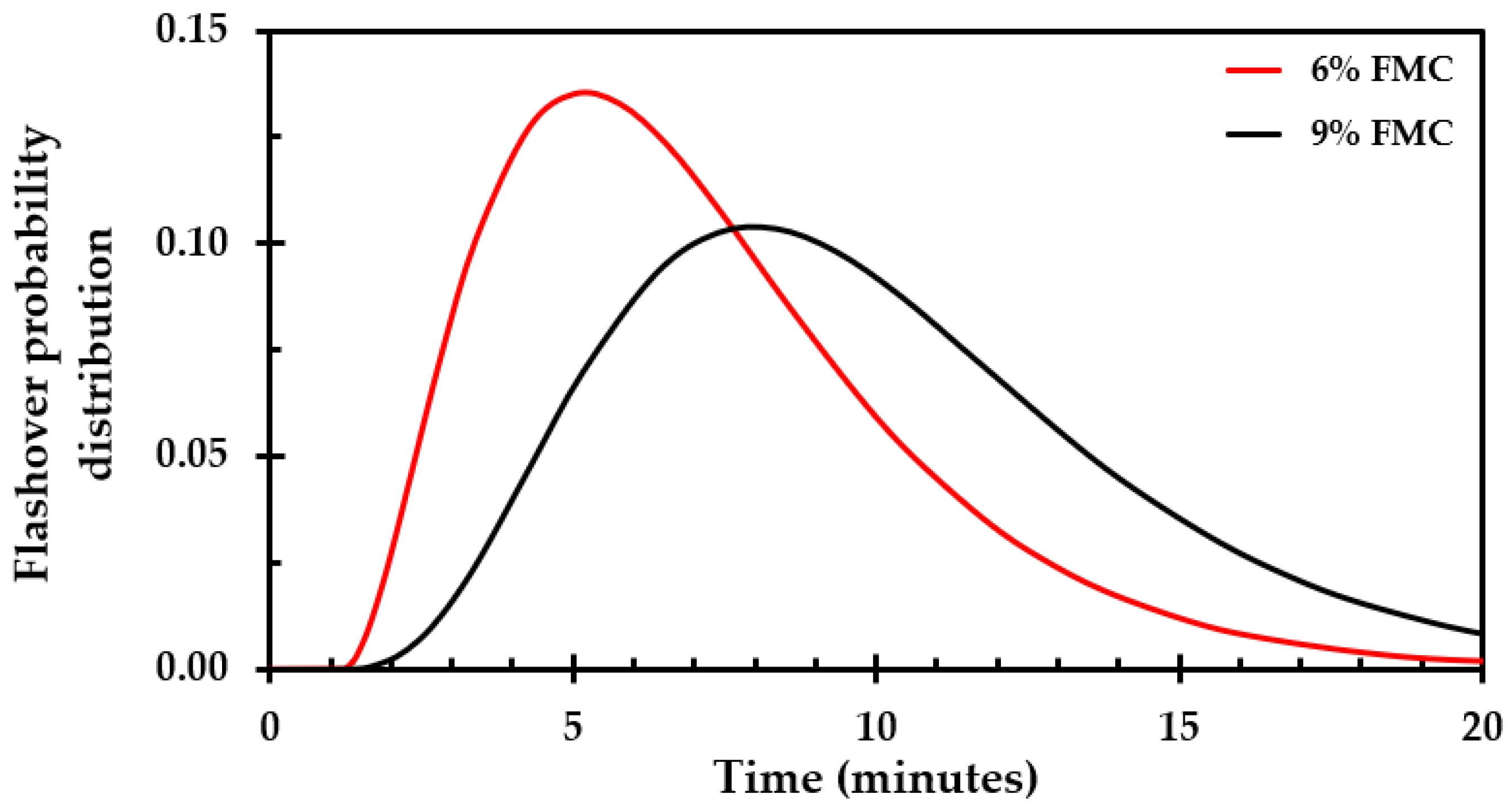

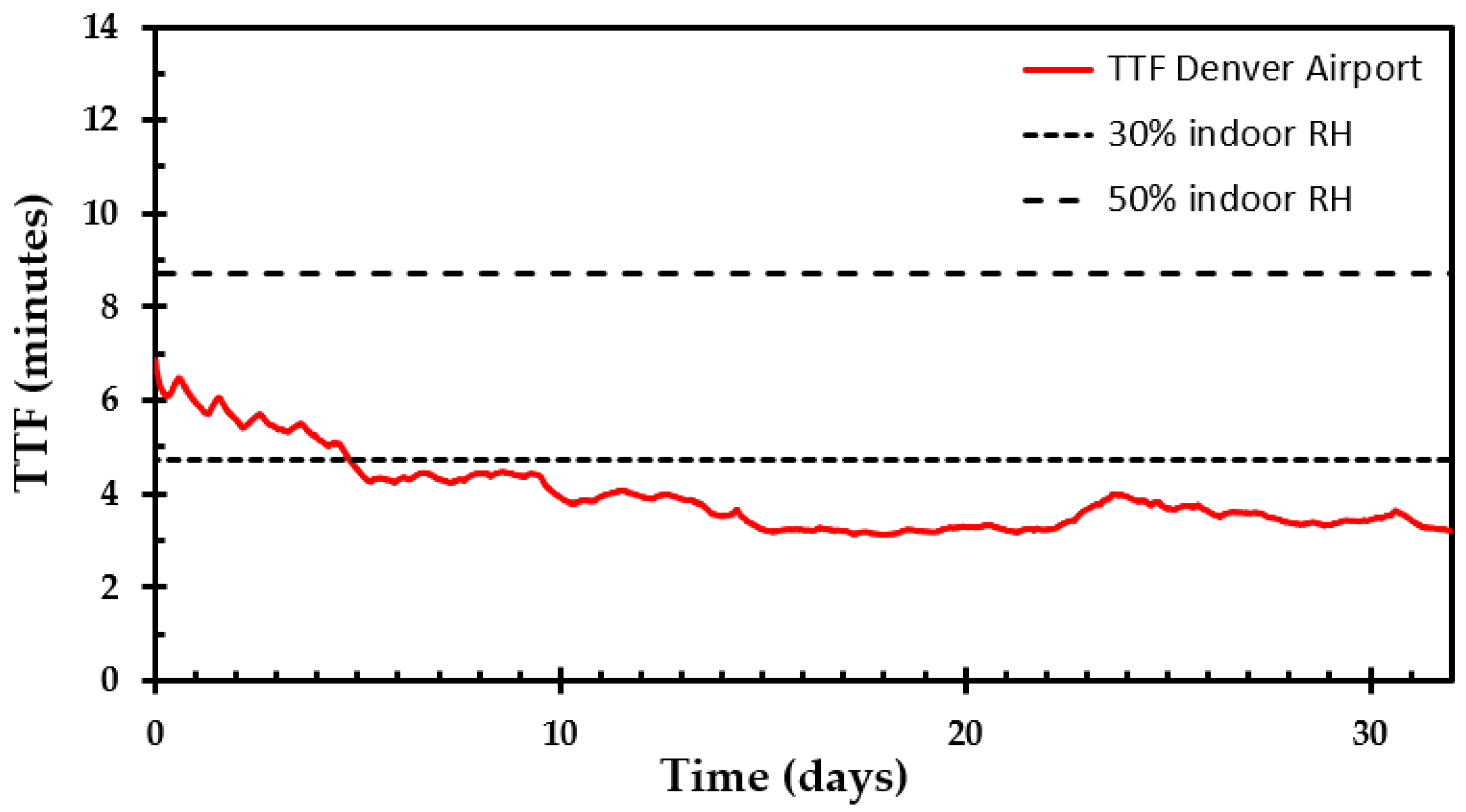

Many factors influence an enclosure fire, and any attempt to describe a possible fire scenario development would require a case-specific consideration. However, supporting the presented theory, it has been shown through experiments that for enclosure fires with indoor wooden panels the TTF is highly dependent on the FMC of the wall and ceiling panels [

10]. This has been shown for different sizes of compartments and HRRs. The most recent experiments performed within the DYNAMIC research project were one half-scale ISO-room size experiments involving 12 mm wooden pine panel cladding. The one half-scale ISO-rooms were conditioned in a climate chamber three rooms at a time and burned successively. The initial HRR was kept constant, and the only parameter intentionally varied was the FMC. The FMC values ranged from 10% to approximately 18% by dry weight. The time to flashover for the wooden compartments ranged from less than 4 min to more than 18 min for the low and high FMC values, respectively. An observation from this experiments is that when the FMC is high, preheating new fuel (especially wooden ceiling panels) takes much more time (energy), as previously described, causing the currently involved wood to char to depths where the fuel becomes thermally insulated and the production of pyrolysis products is significantly reduced. This causes the fire to decrease in size, and it takes time before it increases again in intensity, resulting in the large differences in observed TTF. The intensity increases after a time when the humidity of the wood panels was removed, and the wooden surfaces were sufficiently heated to produce pyrolysis products. In the case of dry wooden compartments, very thin layers of char (less than 0.5 mm) were observed for large areas of the compartment, typically the whole ceiling and upper walls. These results indicate that when the wooden panels are dry, energy is mostly consumed by heating and pyrolysis. The fire spreads across the wooden panels faster than thermally insulating char develops, causing a rapid temperature increase and full room involvement at a much earlier stage. This experimental work is reported for the first time in the present study.

From the presented theory and experimental observations, it is evident that the FMC is expected to highly influence fire development for enclosure fires involving wooden interior surfaces (ceiling and walls). Nonetheless, despite high FMC values, the initial fuel and fire spread may be fast enough to cause rapid fire growth and flashover. Hence, large variations in fire development will be observed despite the modelled FMC indicator.

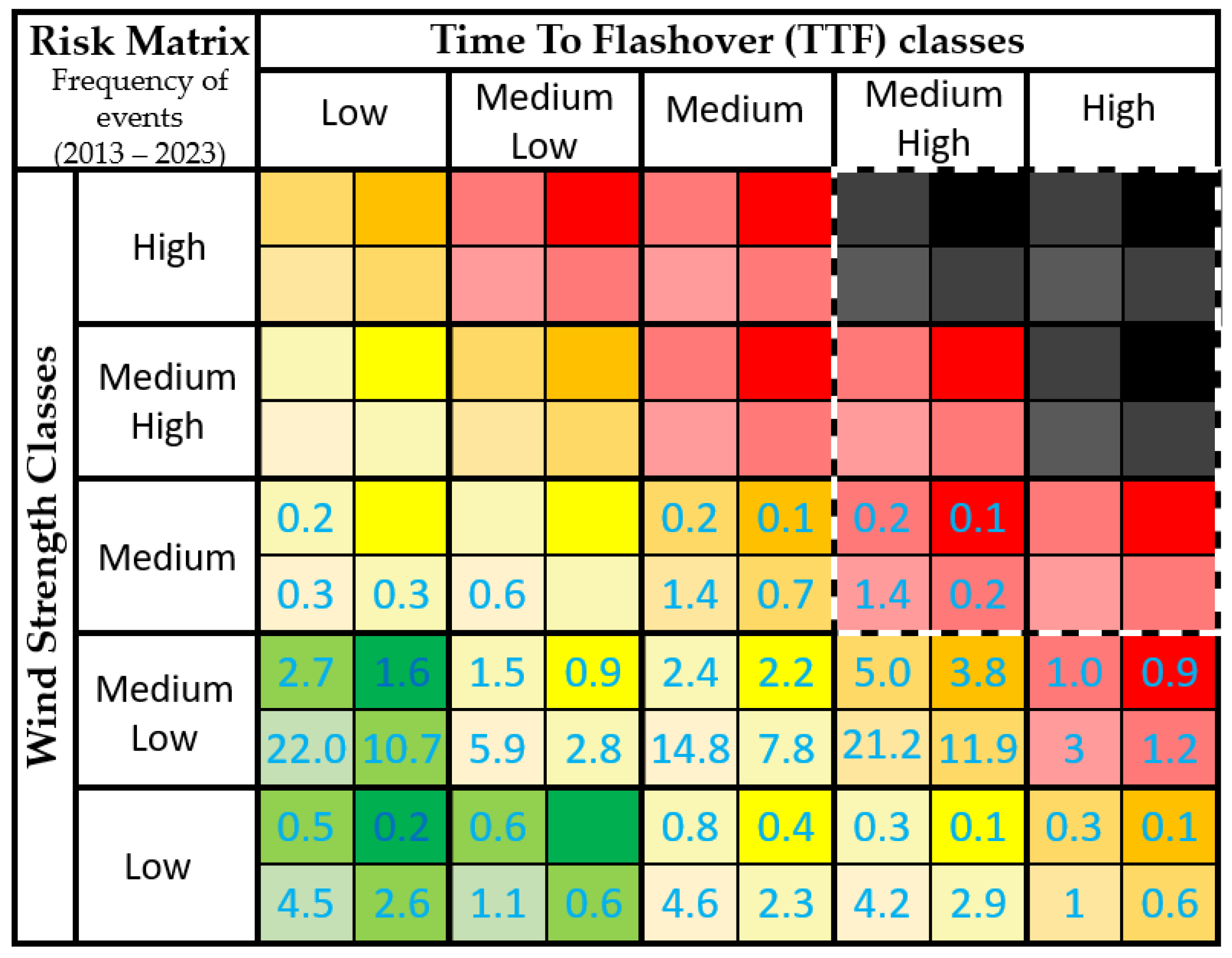

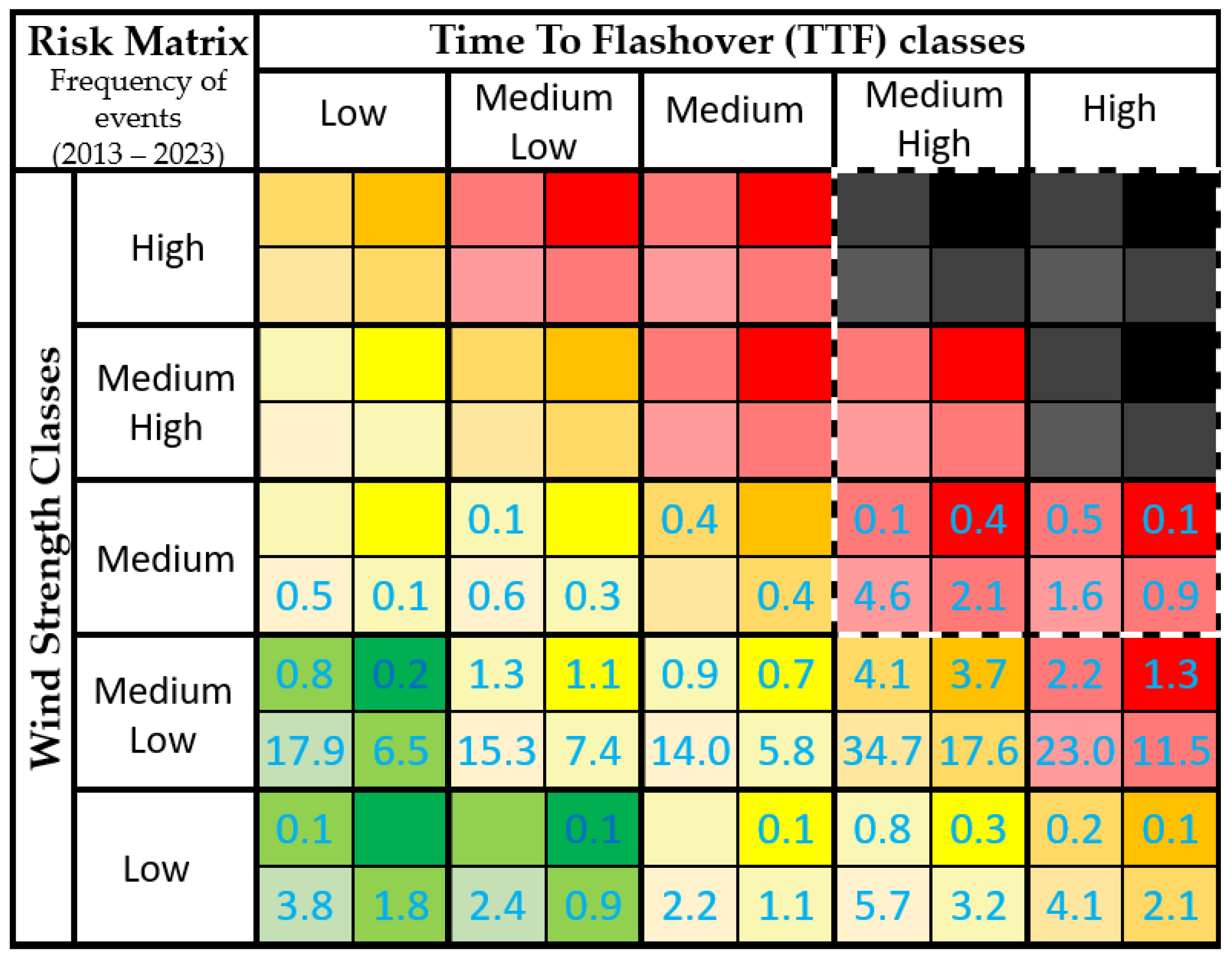

Figure 3 illustrates this through skewed normal distributions. The respective distributions illustrate the variation in observed TTF for the many different wooden homes; however, depending on the FMC level, different average TTF probabilities exist. It is these expected values that are being implicitly modelled when computing the wooden home fire risk indications. In similar fire scenarios where the only difference is the FMC value of the wooden panels, lower FMC values generally result in faster fire development towards flashover and more severe fire development post-flashover.

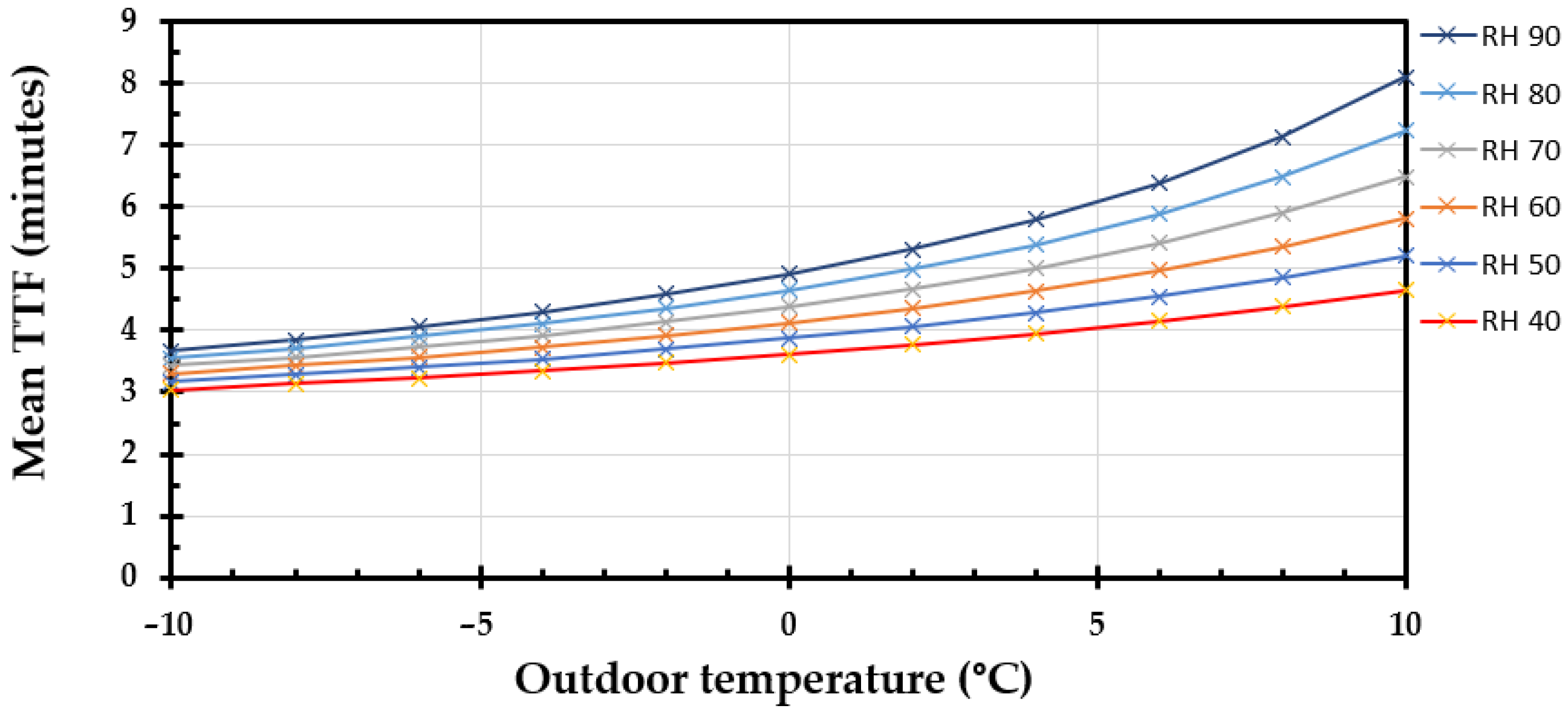

2.4. Modelling In-Home Fuel Moisture Content

Considering that the FMC is a reasonable WHFR indicator and may be used for indicating wooden home conflagration events, it needs to be modelled. From previous efforts, a model predicting indoor relative humidity (RH) and FMC of in-home wooden surfaces was developed and validated in [

11]. The indoor FMC was then correlated with the TTF according to the findings in [

10] and further validated in terms of producing reasonable output [

12]. The model uses outdoor RH and outdoor temperature to compute the indoor RH and FMC of ceilings and walls from first principle mathematics and physics. Previous model versions have been implemented as a cloud-based microservice [

12,

33], as well as in a mobile application using edge computing [

34]. The model does not need sophisticated tools to run and can simply be implemented and tested on a spreadsheet; however, it is the continuous (dynamic) operation of the model that requires a more advanced implementation. Using historical and predicted (forecasted) weather data, the indoor RH and FMC can be computed for the present and near future. Predictions are shown reliable for the upcoming 2–3 days [

33]. The uncertainty in the predictions depends highly on the uncertainty of the weather forecast, that is, forecasted versus occurring weather. Reliable weather data for Norway are supplied by the Norwegian Meteorological Institute and made available through the application programming interfaces (APIs) of FROST [

35] and MET [

36].

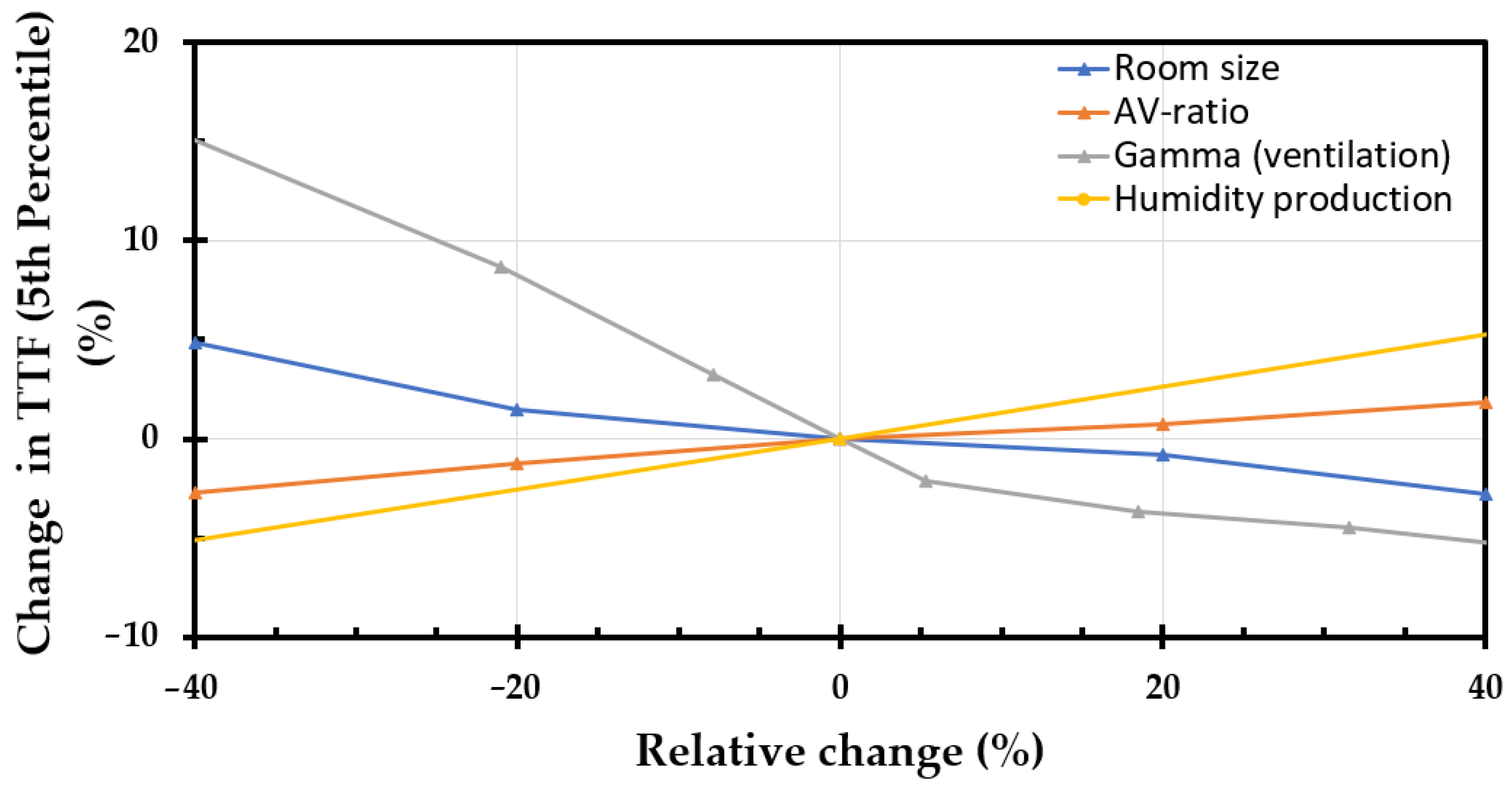

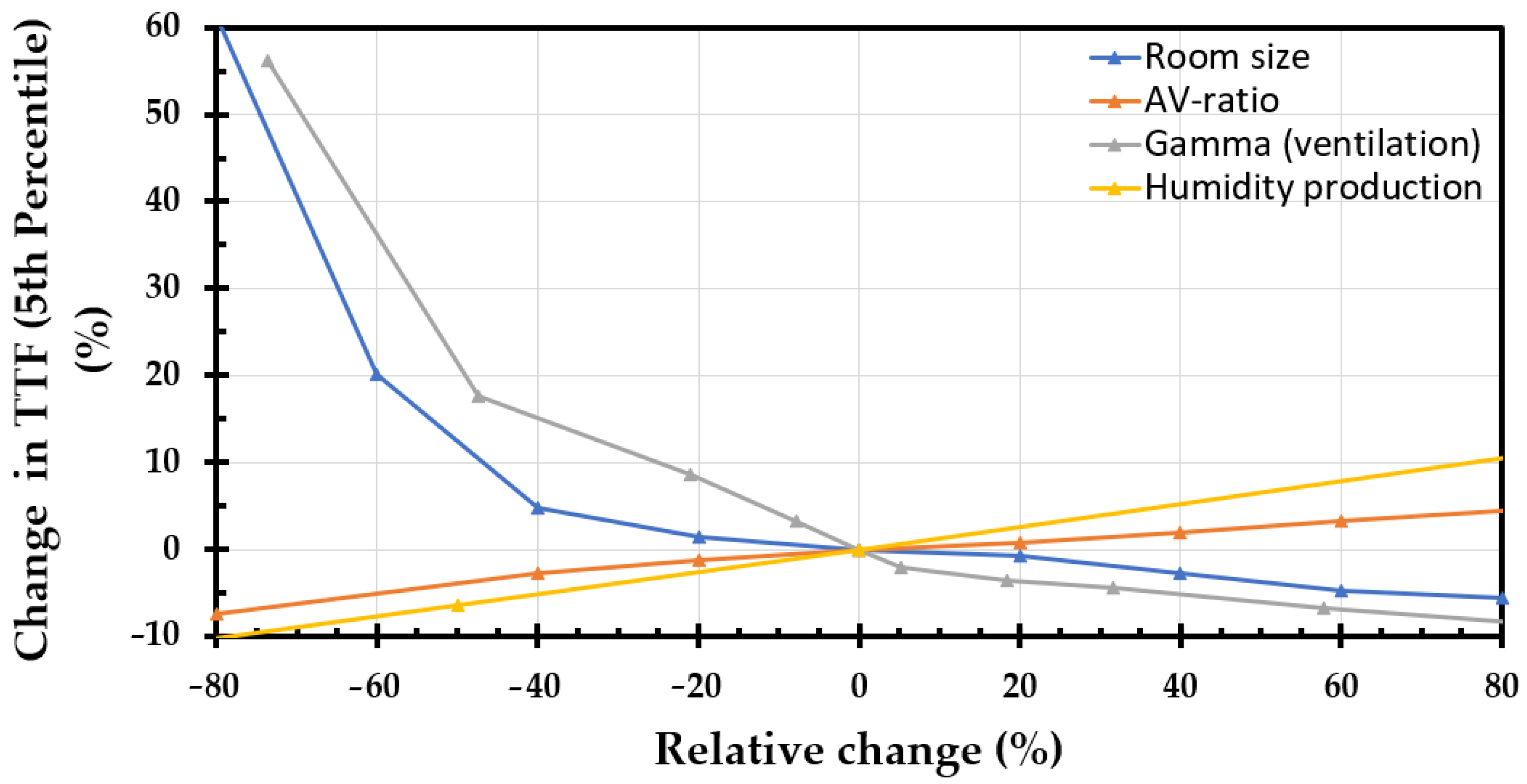

While the mentioned model has undergone essential validation, it lacks a justified generic approach to many Norwegian wooden homes. In order to quantify the general modelling parameters, the principle of the modelling and a short discussion on the sensitivity of key parameters are presented.

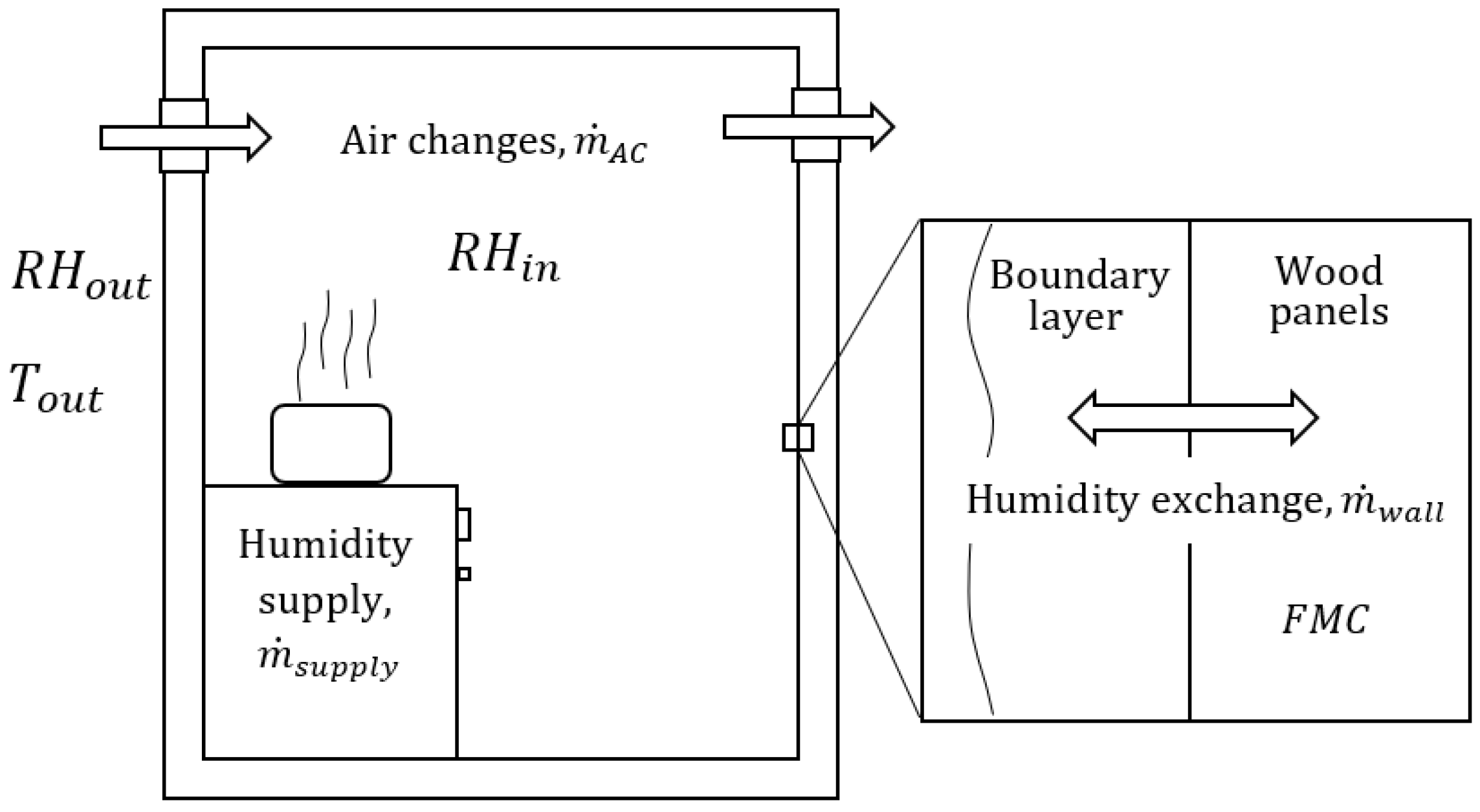

The final equation to solve in order to determine the indoor water concentration, and consequently the FMC [

11], is

where

C (

) is the water vapour concentration in the indoor air used to calculate the indoor RH,

(

) is the mass transfer of water vapour across wooden surfaces,

(

) is the mass transfer of water vapour through air changes induced by either a ventilation system or natural ventilation and leaks,

(

) is the water vapour production through everyday use such as cooking, showering, and respiring, and

(

) is the enclosure volume. A principal sketch of the terms in Equation (

4) is shown in

Figure 4. It can be seen that the water concentration of the bulk air within the enclosure changes as a function of (1) humidity exchange between wooden surfaces and bulk air, (2) air changes caused by ventilation, and (3) humidity supplied from in-home activities.

The depends on the area of indoor wooden surfaces available for humidity exchange. For old wooden homes, all interior surfaces may be covered by wood; however, for newer or refurbished homes wood is more likely to be only part of the room. The fraction of wooden surface area is considered through the AV ratio, which is the ratio of the wooden surface area available for vapour exchange to the room volume ratio. The primarily depends on the ventilation principle, herein taken as natural ventilation. For natural ventilation, variations occur due to pressure differences caused by wind or temperature differences, i.e., the stack effect. The quantity depends on the intended use of the considered enclosure. In the following, these terms are briefly considered with respect to the existing literature.

2.5. Model Input

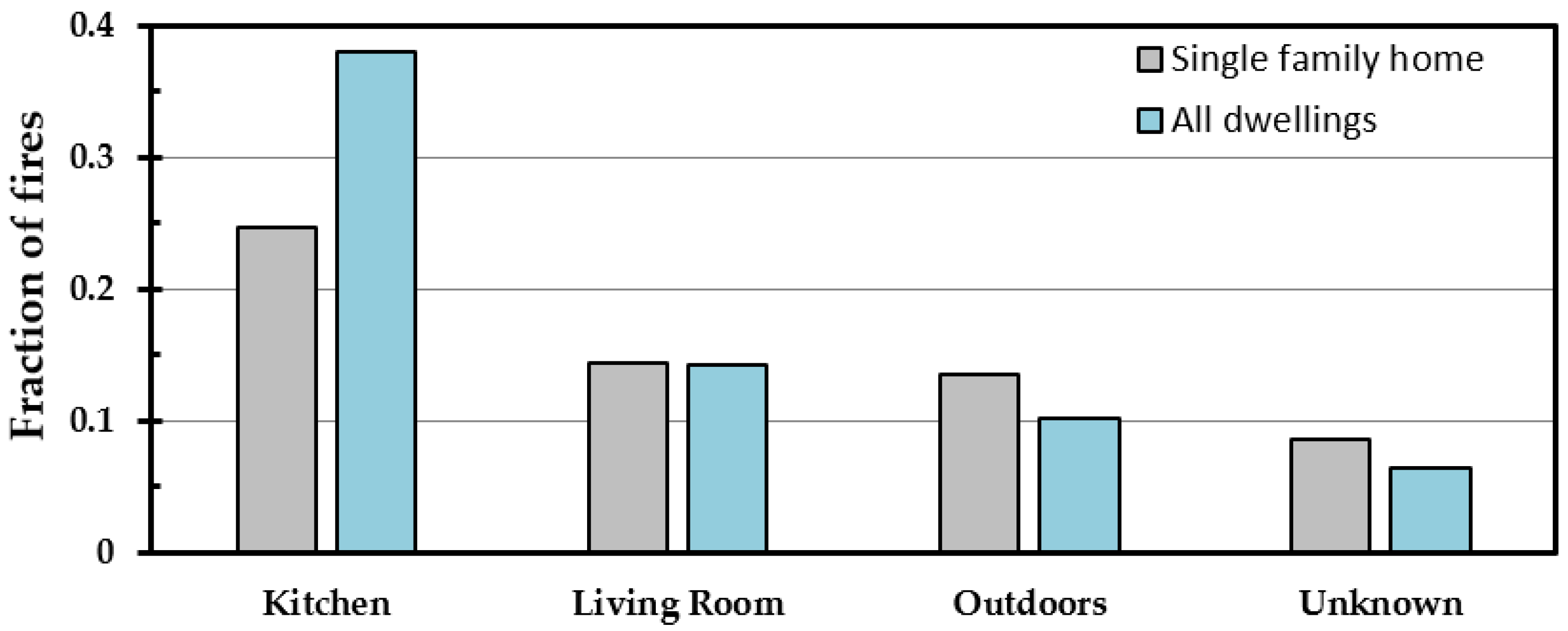

There are probably no generic wooden homes, at least not considering the modern building mass. Nonetheless, it may be argued that a generic home is more reasonable for modelling older wooden homes at heritage sites. However, for the modelling of indoor FMC the generic home is not needed per se; when modelling the risk indicator, the layout and exact content of the house are not very important, as the key influencing factors for the FMC described in Equation (

4) either account for potential effects, i.e., hygroscopic properties, or are independent of these specific house-related variables. Instead of a generic home, the model uses a generic wooden home enclosure to compute a representative FMC value. Statistics from Norway show that kitchens and living rooms are the enclosures of fire origin in about 40% of all single-home fires [

5]. Expanding these statistics to comprise dwellings, which might include apartments and multiple units (multiplex) houses, in which the latter may be wooden heritage townhouses, the share of fires in kitchens and living rooms increases to 50%. Compared to other compartments or areas of fire origin, kitchen and living room fires are highly representative, as can be seen from

Figure 5. Hence, for modelling the FMC it is reasonable to take these enclosures as the basis. Note that fires originating from outside the building envelope are the third largest reported place of fire origin. Hence, the modelling of FMC for external wooden panels is an important topic and a part of a future conflagration warning system combining interior and exterior fire risks; however, it is not addressed in the present study.

Concerning the modelling of the FMC, the key parameters from Equation (

4) and associated sub-terms are considered from statistics for a generic living room and kitchen.

2.5.1. Enclosure Base Area

When determining the area of a representative enclosure, it is important to consider the effects of the enclosure base area when modelling the FMC. An increased base area generally results in increased enclosure volume and increased surface area for humidity exchange. It may be assumed that the ratio between the humidity exchange area, i.e., wooden surfaces, and the enclosure volume is constant. Then, increasing the enclosure base area will result in reduced FMC values as the volume increases relative to internal humidity production. The opposite is true when decreasing the base area. Then, higher FMC values are achieved if the humidity production is kept at a constant level. The connection between these parameters is associated with a larger base area typically housing more inhabitants, causing larger humidity production. Therefore, these parameters must be seen in context.

The enclosure base area for the model is determined based on field studies and the literature. A general trend for dwellings is combining the kitchen and living room into one enclosure. This modern trend affects new as well as refurbished older homes in Norway. For old wooden houses, the kitchen is typically adjacent to the living room, though with different degrees of openness between the rooms. Hence, humidity production within the kitchen likely affects the living room, and vice versa. By taking this into account and considering the larger enclosures to generally provide a lower FMC, a general area for the kitchen and living room can be determined. According to more recent Norwegian guidelines [

37], the minimum combined kitchen and living room area for a four-room dwelling is 35 m

. However, field observations and expert opinion suggest a 40–60

range. Therefore, the present study assumes a value of 50

as quite representative. Combined with a standard room height of about 2.4 m, the compartment volume becomes 120

.

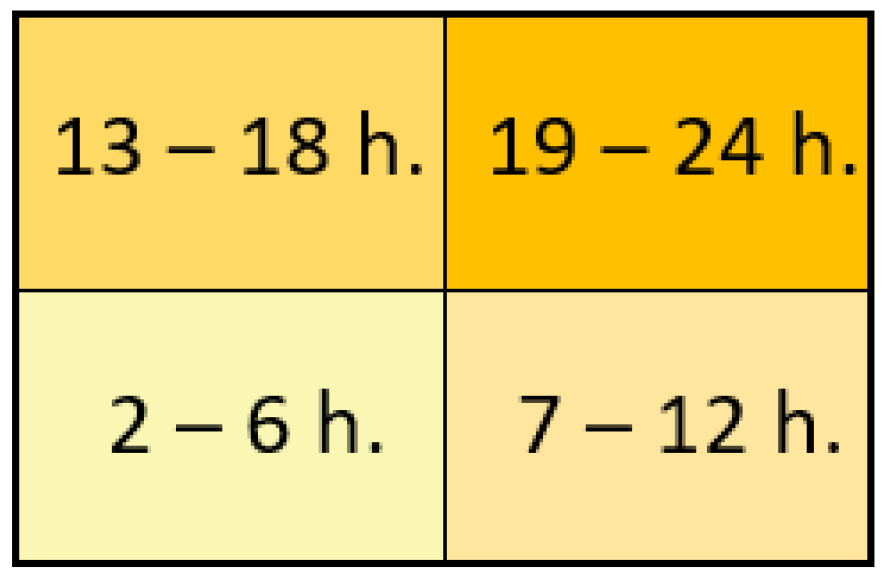

2.5.2. Humidity Production

As mentioned, humidity production must be seen in context with compartment size. If considering the suggested 50

combined living room and kitchen to house a family of five, the moisture supply from respiration and sweating during five hours is in the range of 1.2 kg (Distribution; father = 70 g/h, mother = 60 g/h, Children 1 and 2 = 40 g/h and Children 3 = 30 g/h) [

8]. Then, cooking and dishwashing for five persons adds another kilogram of moisture to the indoor air, adding up to at least 2 kg/day of humidity production. However, only a part of the humidity supplied to the indoor air reaches equilibrium with indoor materials, with a large portion being ventilated away before the temporarily increased humidity levels can reach a new equilibrium with the surroundings. Currently, the assumption has been that 50% of the supplied water vapour stays within the room while the remaining vapour becomes ventilated. Field measurements from old wooden homes combined with modelling efforts support a 1 kg/day humidity production distributed evenly throughout the hours of the day [

11]. This even humidity distribution allows for smoothing of the FMC development, avoiding unnecessary fluctuations.

2.5.3. Air-Volume Ratio

The humidity exchange area to the enclosure volume ratio, or AV ratio, is another important aspect of the generic enclosure. Increasing the wooden exchange area for a set enclosure base area prolongs the time until equilibrium is reached, as more mass is available as a humidity buffer. In turn, a smaller wooden exchange area results in more responsive modelling, as the wooden enclosure more rapidly adapts to outdoor conditions. This latter observation might be part of a conservative modelling approach taken to ensure that dry indoor periods are identified early. The AV ratio should stay above 0.4 to ensure that wooden panels cover at least an exchange area consistent with the enclosure roof. Based on refurbishments and the identified lag (if too large wooden areas are assumed), it is suggested to keep the AV ratio in the range of 0.4–0.6, with a recommended value of 0.5. The suggested value corresponds to at least the ceiling (most importantly) and about one wall being covered with wooden panels.