2.1. Experimental Design

In this study, a simulation calculation was carried out for the safety of fireproof insulation board for use in warehouses. An opening rate of 25% of the fireproof insulation board can effectively control the smoke layer height of vehicle fire in the lane to be no less than 4m, effectively controlling the spread of smoke in large quantities. The temperature and visibility at a height of 4.0 m from the ground can ensure the safety of personnel during evacuation and fire rescue. Through the abovementioned special fire protection design, the safety design goals of covering new green recyclable fireproof insulation board and creating quasi-evacuation safety areas can be achieved.

Ensuring the safe evacuation of personnel is an important safety goal in building fire protection design. Safe evacuation of personnel means that the entire building system (including the fire protection system) can provide sufficient time for all personnel in the building to evacuate to a safe location when a fire occurs in the building, the entire evacuation process should not be subject to fire hazards. If the time it takes for the users of the building to evacuate to the safety zone (RSET) is less than the time taken for the fire to develop beyond the human tolerance limit (ASET), it indicates that the requirements for the safety of personnel are met [

8]. That is, the criterion for ensuring safe evacuation is:

where REST: time required to evacuate; AEST: time when the intolerable condition of the human body begins; TS: safety margin.

The hazards of fire to people mainly come from the smoke generated by the fire, which mainly manifests in the thermal effect and toxicity of the smoke. In addition, the visibility of the smoke is also an important factor for evacuation. Therefore, when analyzing the impact of fire on evacuation, it is generally discussed in terms of temperature, concentration of toxic gases, and visibility.

Table 1 shows the criteria for determining the life safety of personnel in various countries [

9].

To predict the arrival time of danger, it is necessary to analyze the movement characteristics of the hot smoke generated by the fire in the building space under the action of the designed smoke prevention and exhaust system. This project uses the FDS field model to predict and analyze the movement of fire smoke. FDS (FirG Dynamics Simulator) is a CFD model of fluid flow during combustion developed by NIST (the National Institute of Standards and Technology). It is mainly used to analyze the movement of smoke and heat in fires [

10]. The calculation of the combustion heat release rate and the radiative heat transfer by the FDS program is more accurate, and the modeling is easier. At the same time, it is closer to perfection in terms of mesh division, wall heat conduction, combustion model, and initial condition setting.

Determination of fire scale:

(1) Passage fire: For when a fire occurs in the passageway of a warehouse, we referred to the management mode of other subterranean parking lots. Since the passageway of the warehouse is clean and tidy, as the personnel are staff and cleaning personnel, there is not a large amount of combustible substances, so the possibility of fire is small. This research selects the fire of a small number of accumulated items for simulation calculation. According to the fire experiment, it is unlikely that a fire started in a dustbin would exceed 400 kw, and the fire scale of a single small item is smaller, about 200 kw~300 kw. Considering the fire test and the fire scale controlled by the staff, we determined the maximum heat release rate of fire in a warehouse passage as 2 MW.

(2) Train fire: The materials used in modern subway trains are very different from those used in previous trains. They are basically made of non-combustible or flame-retardant materials, which can reduce the generation of toxic substances and greatly improve the overall fire resistance of trains.

According to train flashover test data from the Hong Kong Mass Transit Railway’s LAR line, its largest fires ranged from 5MW to 10MW, mainly due to the large number of seats included in its trains. The “Subway Design Fire Protection Standard”, metro design fire protection standard GB51298-2018 article 8.2.4, stipulates that the design scale of domestic subway trains in China country is usually 7.5 MW~10.5 MW. This research conservatively uses a fast T2 fire with a maximum heat release rate of 10.5MW to characterize subway train fires to analyze the flow of fire smoke and evaluate the safety of personnel evacuation [

11].

(3) Van fire on fireproof insulation board:Fire size, smoke generation, gas temperature and relevant parameters for different vehicle type were shown from

Table 2,

Table 3,

Table 4 and

Table 5. According to the daily management and process requirements of the parking lot, there may be situations such as small trucks being used for the transportation of materials and the parking of vehicles.

Based on the above literature, we conservatively selected a fire scale of 20 MW for the van, and selected 6 m × 2 m for the size of the van. Based on the above analysis, the fire types and scales of this project were determined as shown in

Table 5.

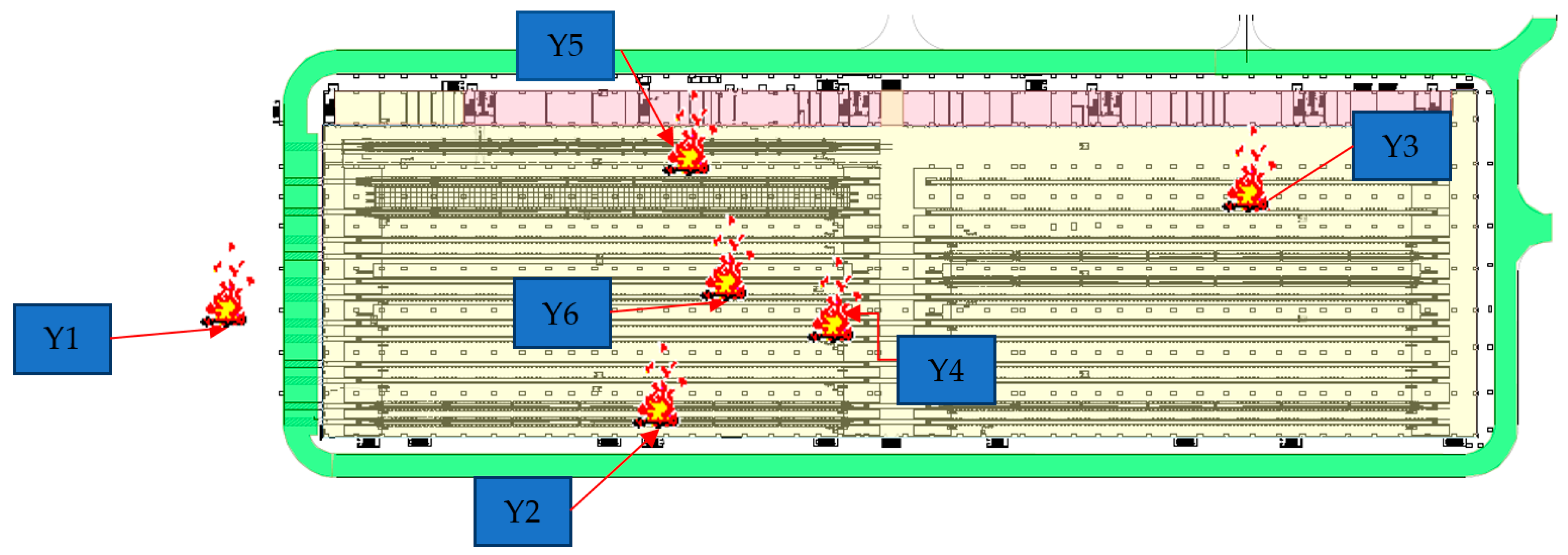

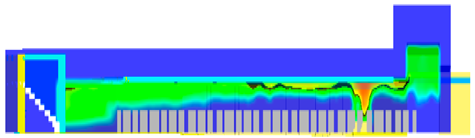

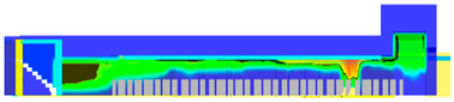

In this study, numerical simulation analysis was carried out on fire in different areas of a parking lot passageway, a train compartment and throat area, and the entry and exit sections of fireproof insulation board. The design’s fire situation in each area is summarized in the

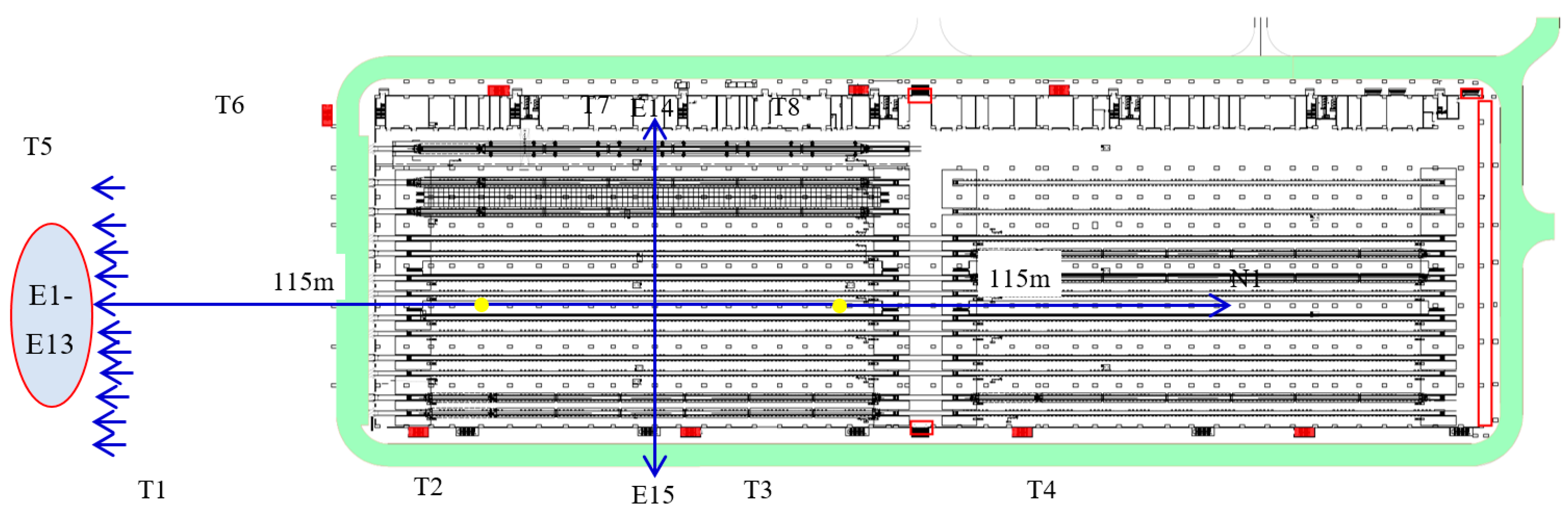

Table 6, location of fire scene is shown in

Figure 3 and

Figure 4:

There are generally three methods for calculating the evacuation action time: the field simulation test measurement method, the empirical formula method, and the computer simulation method. The method of on-site simulation test measurement is mainly used for scientific research and is rarely used in engineering applications due to the limitation of funds and test conditions; evacuation prediction is carried out by manual calculation, and some countries represented by Japan mainly use this method; the computer simulation method uses computer software to simulate the dynamic process of personnel evacuation to predict the process and time of personnel evacuation movement. At present, there are mainly network models. There are two simulation models, thenetwork model and the fine mesh model. The calculation of the evacuation action time of this project uses STEPS simulation software for calculation [

12]. The analysis tool used in the simulation’s analysis of personnel evacuation action time is Pathfinder personnel evacuation commercial software, which is a brand-new evacuation simulator that is different from traditional software based on fluid flow calculation [

13,

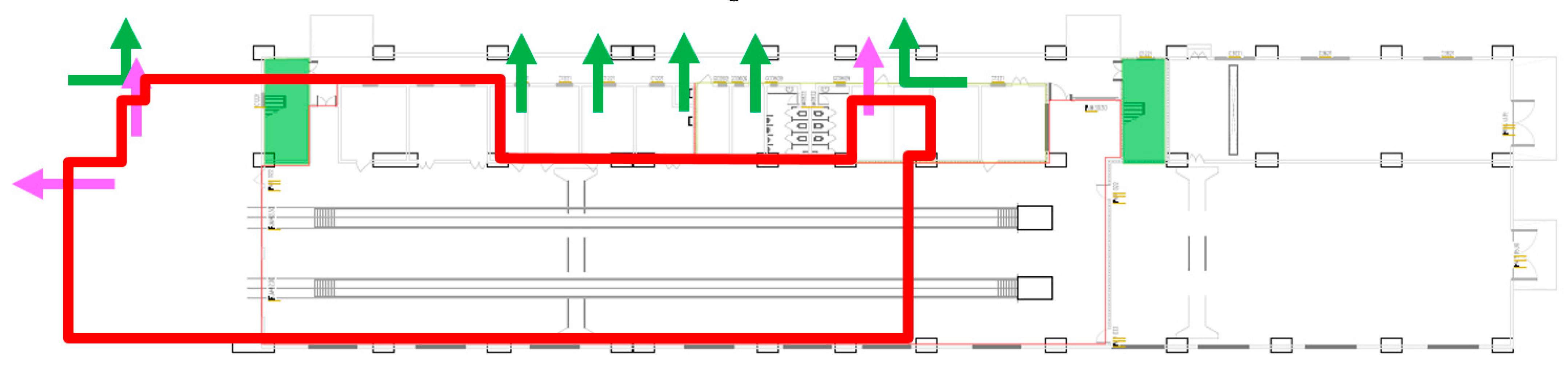

14]. Based on computer science in the field of graphic image technology, Pathfinder achieves accurate predictions of how each individual moves. The engineering garage is mainly used for water supply, refueling and general troubleshooting. There are few personnel. The personnel in the engineering garage are evacuated through the fireproof insulation board [

15,

16,

17]. They can be evacuated to the surrounding fireproof insulation board through the surrounding evacuation doors, and then evacuated to the outside of the cover, an outdoor environment as shown in

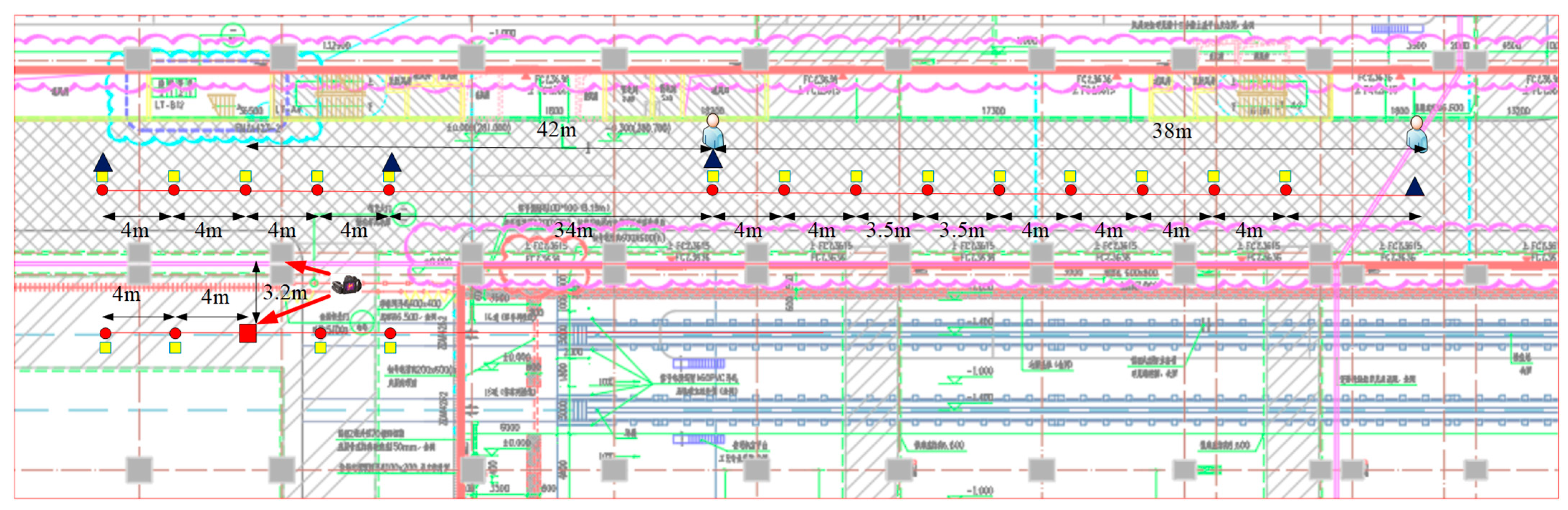

Figure 5. The distance from the evacuation door of the engineering garage to the fireproof insulation board should not be greater than 15 m.

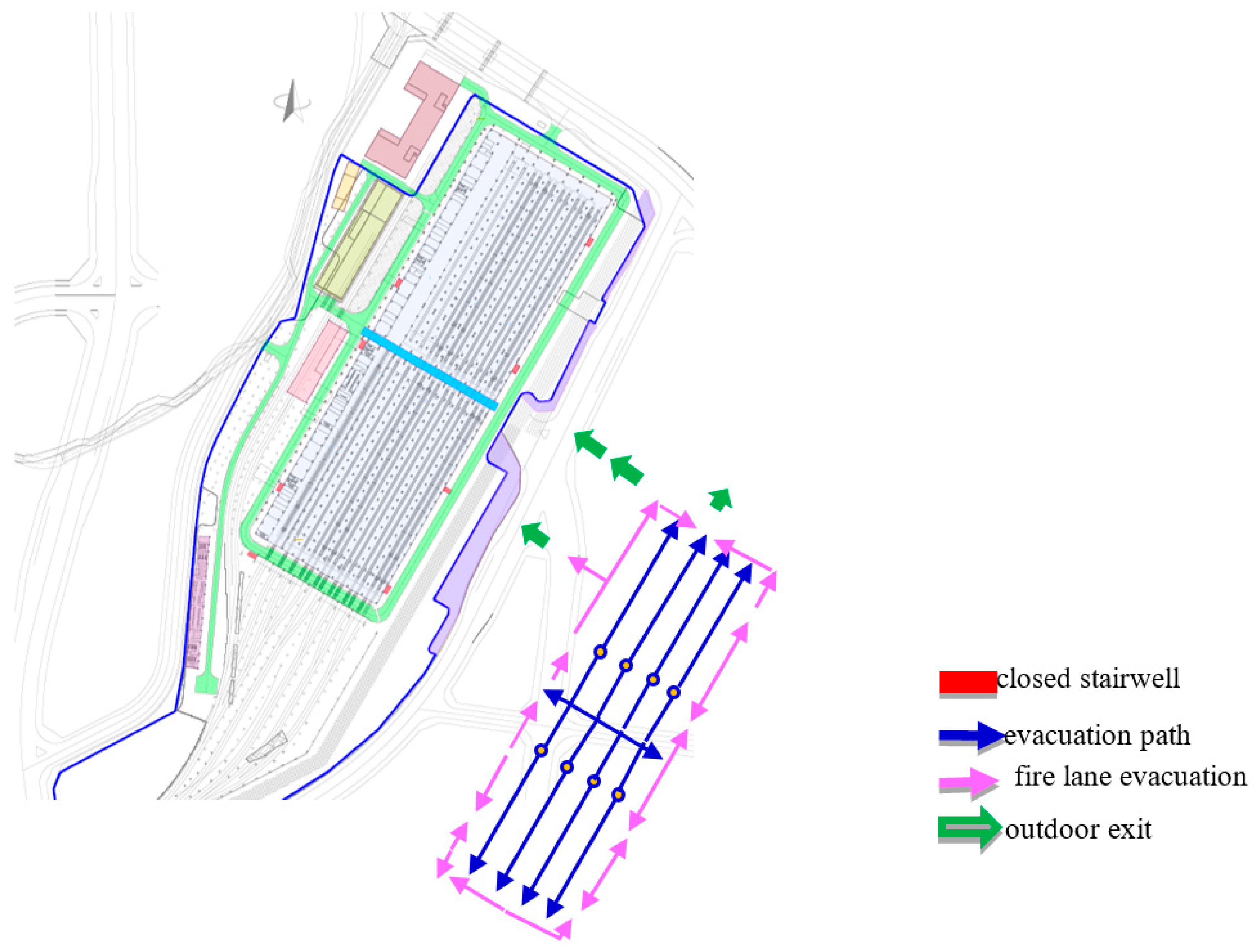

The personnel in the warehouse can be evacuated through the surrounding new green recyclable fireproof insulation board. Specific evacuation path: personnel are evacuated to the fireproof insulation board through the use of the evacuation door of the warehouse, and then pass through the closed stairwell set in fireproof insulation board or use the east side slope to set up the evacuation stairs to go directly outdoors, and the personnel on the north side go directly outdoors through the main entrance and exit of the municipal road as shown in

Figure 6. The interval between closed stairwells in the fireproof insulation board area should not be more than 120 m.

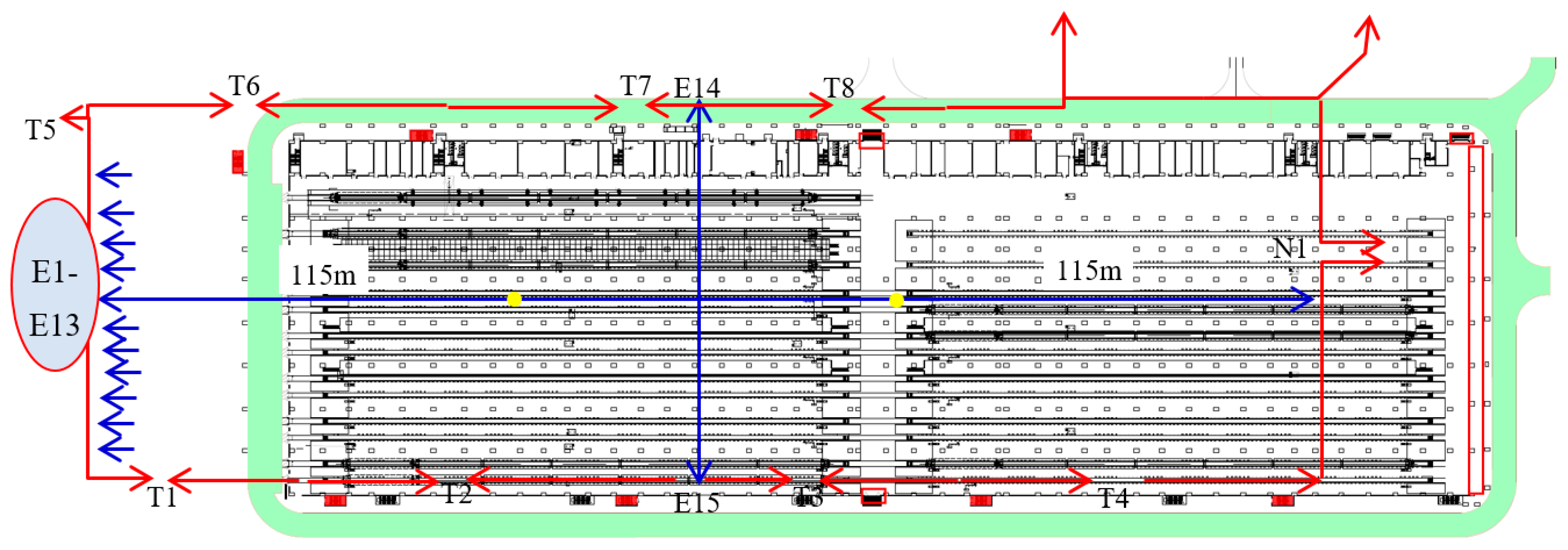

Due to the need for vehicle parking at the use library, the evacuation distance is long, and the longest evacuation distance in the use library is 115 m as shown in

Figure 7:

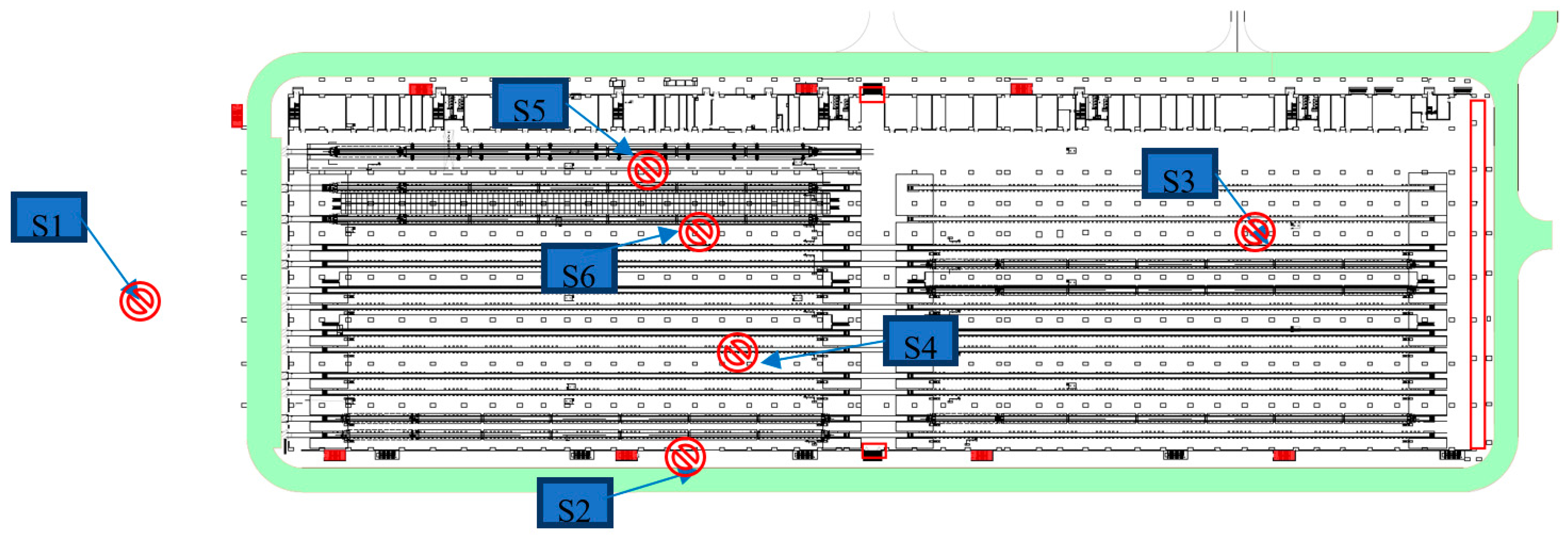

The evacuation exits of the operating warehouse are located around the building. The specific evacuation exit location, evacuation direction, and width statistics are shown in

Figure 8 and

Table 7.

The proportion of each personnel classification is based on the value suggested by Simulex [

18], and considering that the main functions of the building are vehicle maintenance and parking functions, the types and composition of personnel in this project are shown in

Table 8:

The maximum plane walking speed of each type of personnel is based on pathfinder Handbook and Simulex [

19,

20], and is reduced with reference to the characteristics of Chinese personnel. The determined values are shown in

Table 9:

The length of the evacuation movement time is related to parameters such as the length, width, number of personnel, and travel speed of the evacuation passage in the building. The speed of human travel is related to population density, age, and flexibility. When the density of people is less than 0.5 people/m

2, the traveling speed of the crowd on level ground can reach 70m/min without crowding, and the speed of descending the stairs can reach 51–63 m/min [

21,

22,

23]. On the contrary, when the population density is greater than 3.5 people/m

2, the crowd is very crowded and can hardly move. In addition, referring to the provisions of 5.5.16 of the “

Code for Fire Protection of Building Design” (GB50016-2014 (2018 edition)), the personnel flow per share on flat sloped ground is 43 people/min, and the personnel flow per share on stepped ground is 37 people/min. Thus, the flow of people per minute per meter’s widths (i.e., outflow coefficient) are 43/0.55 = 78 (people) and 37/0.55 = 67 (people), respectively [

24,

25,

26,

27]. The general principle of evacuation scene design is to find out the most unfavorable situation for the safe evacuation of personnel after a fire occurs. The personnel evacuation scenarios of this project are set as shown in

Table 10 and

Table 11.

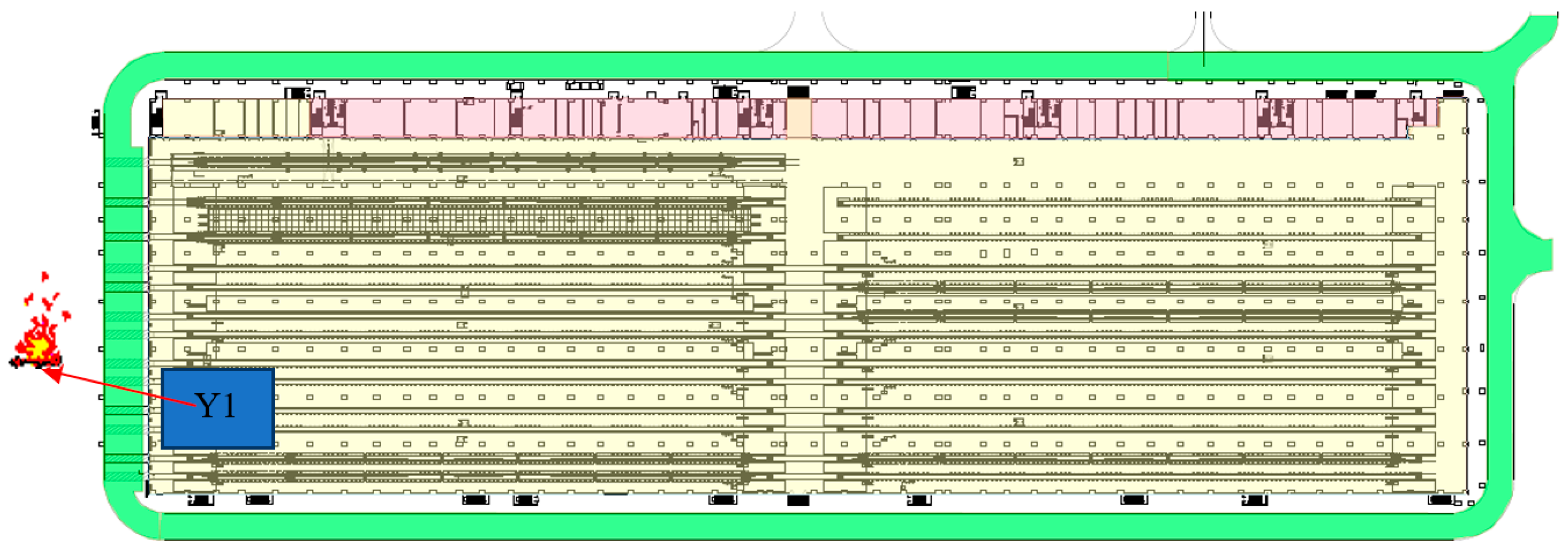

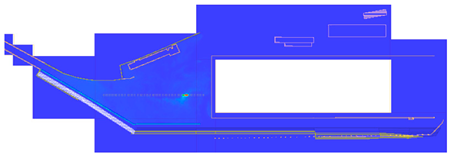

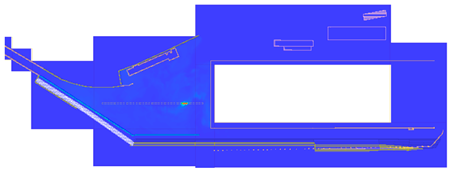

Figure 9 and

Figure 10 show the evacuation scenario diagram and fire scene location: