A Study of the Wear Mechanism of Composites Modified with Silicate Filler

Abstract

1. Introduction

2. Material and Methods

2.1. Materials

2.2. Manufacturing of PCM

2.3. Study Methods

3. Results and Discussion

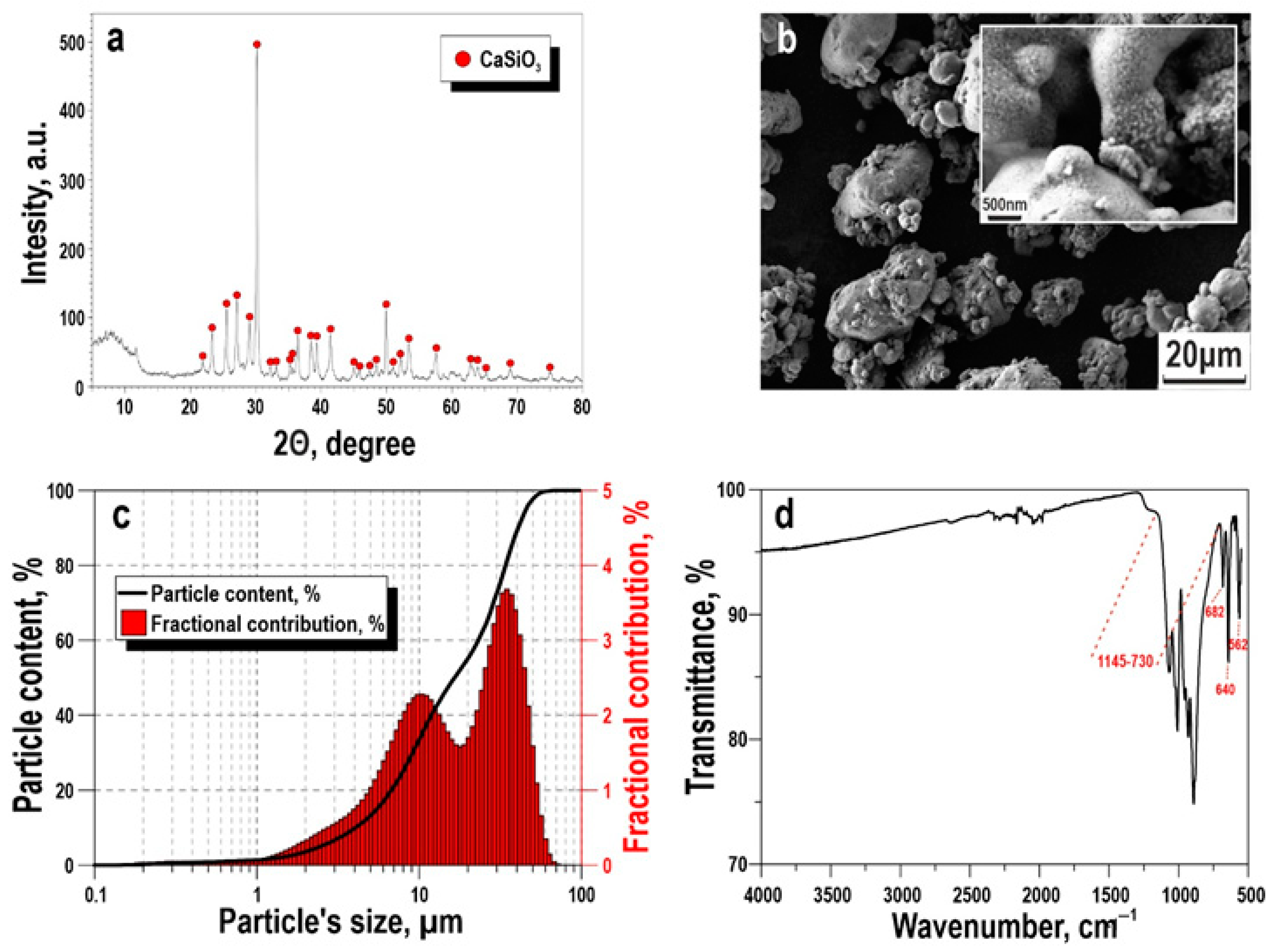

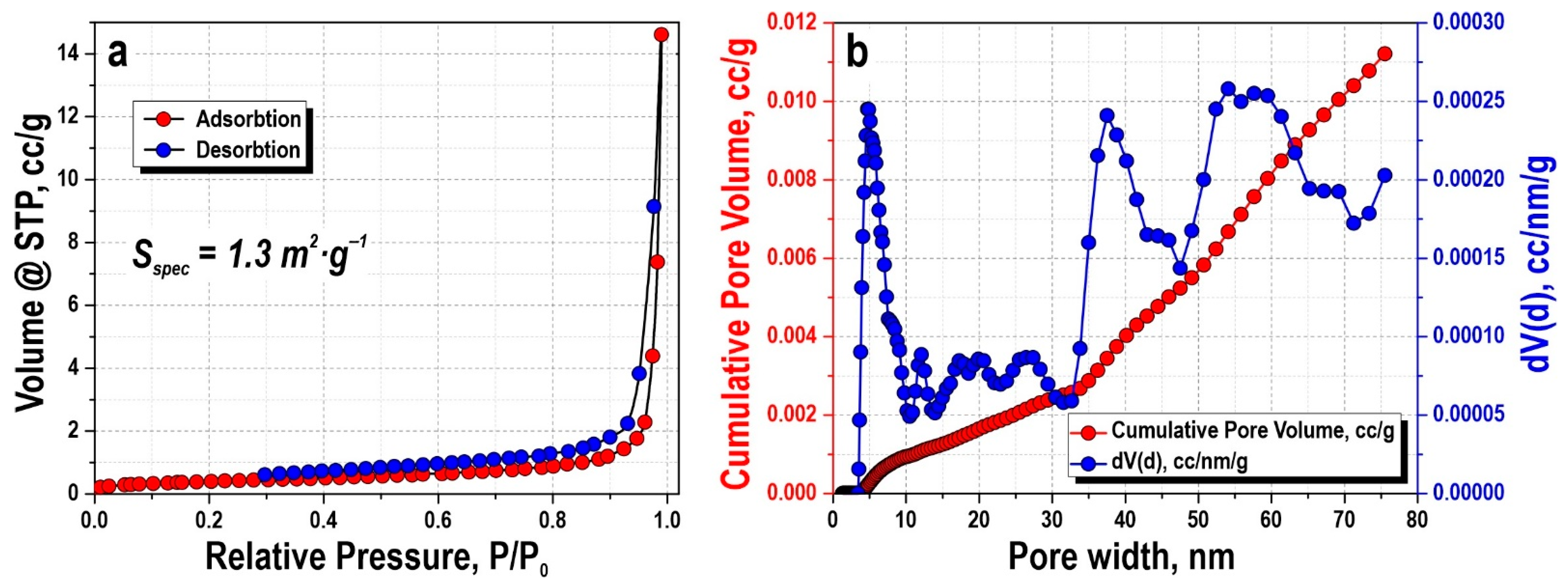

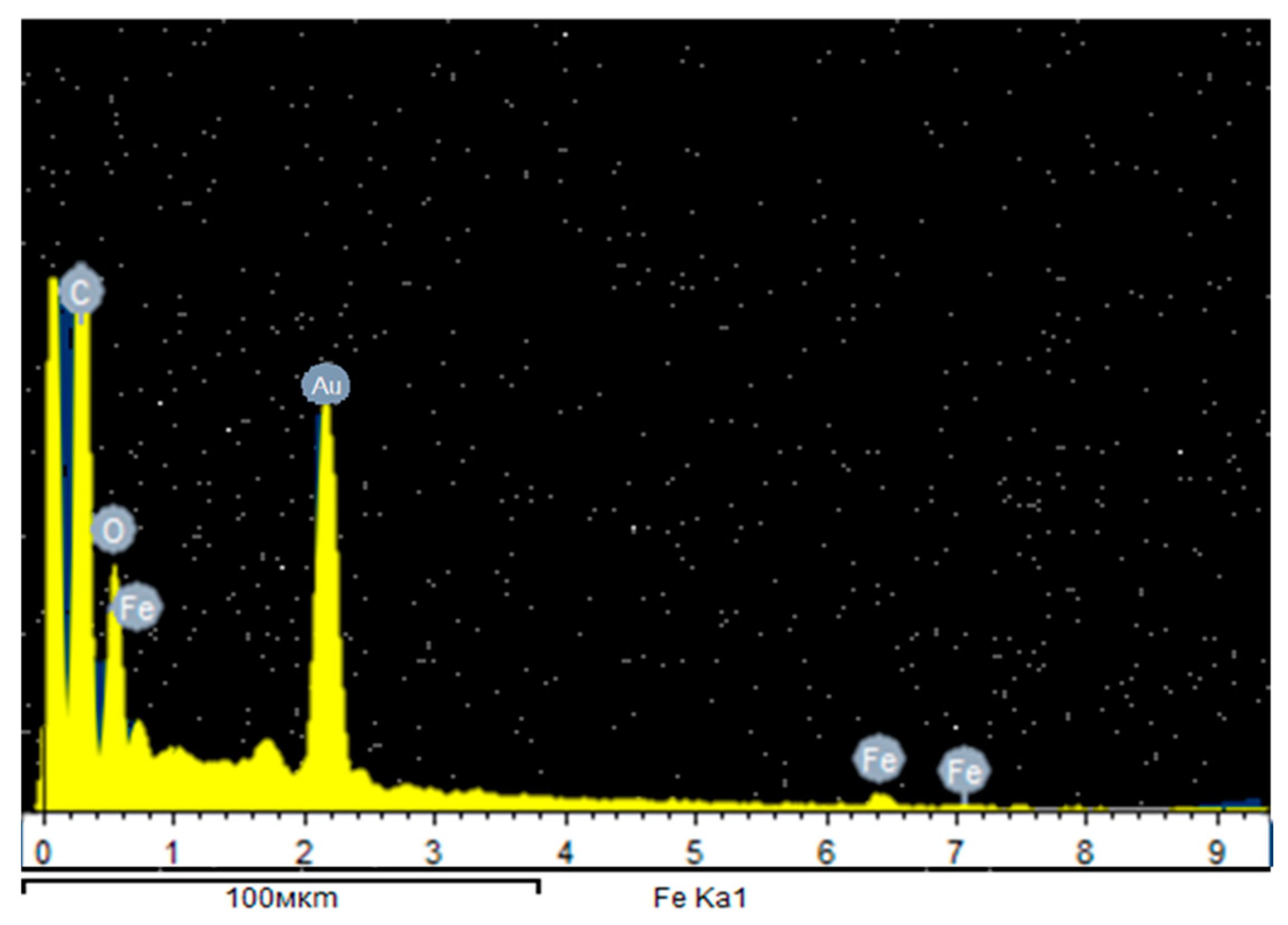

3.1. Characteristics of Wollastonite

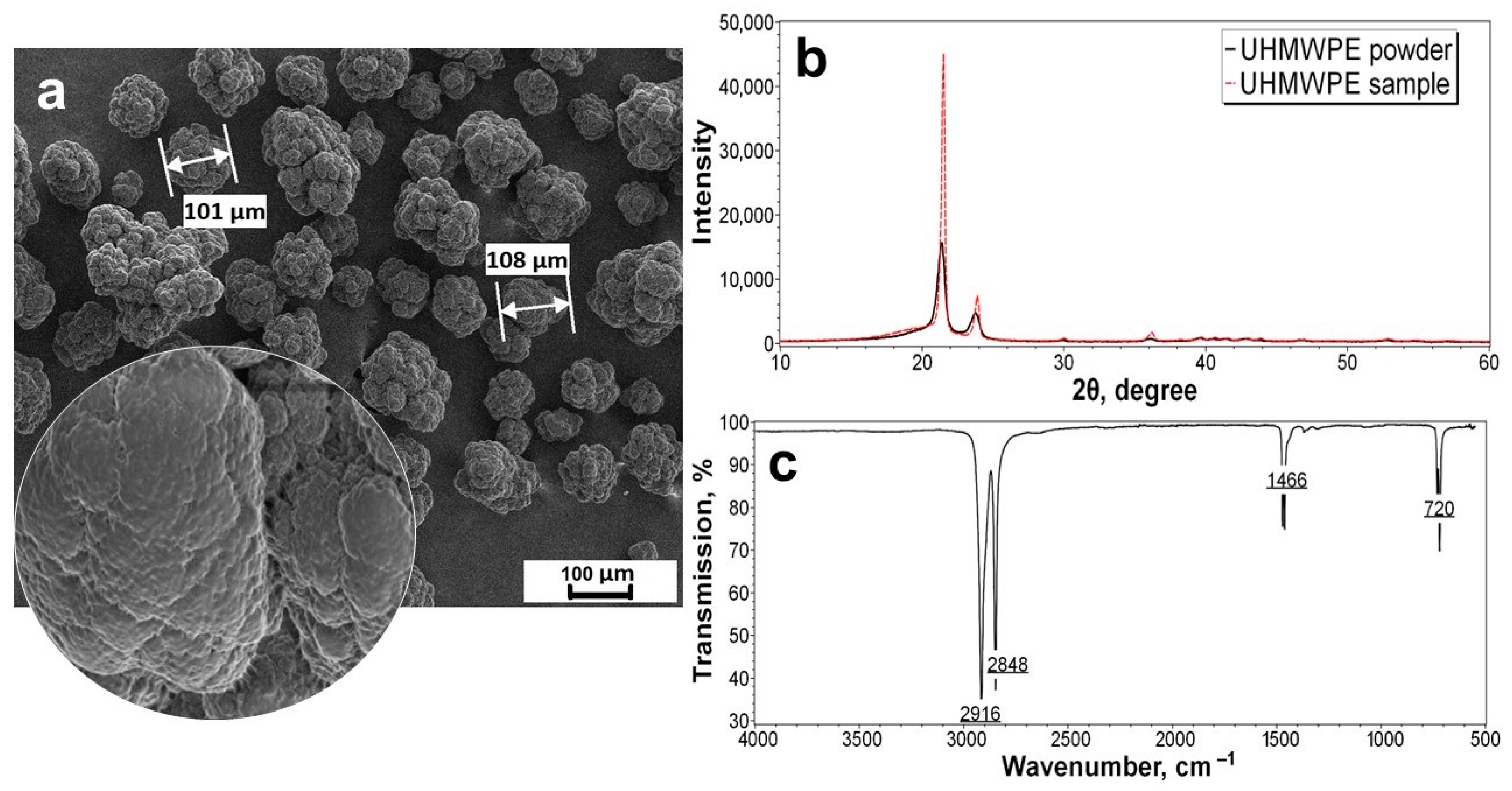

3.2. Characteristics of UHMWPE

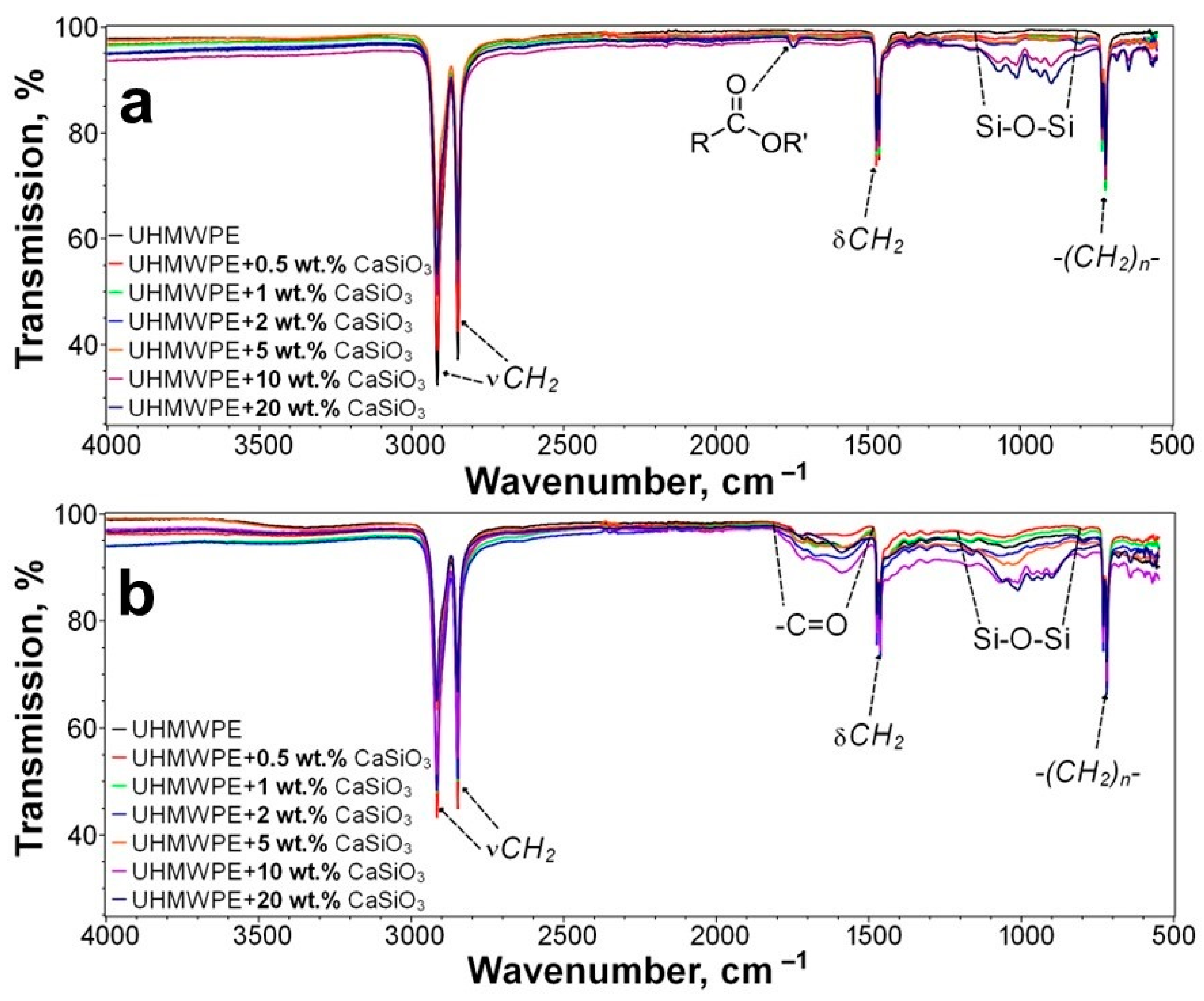

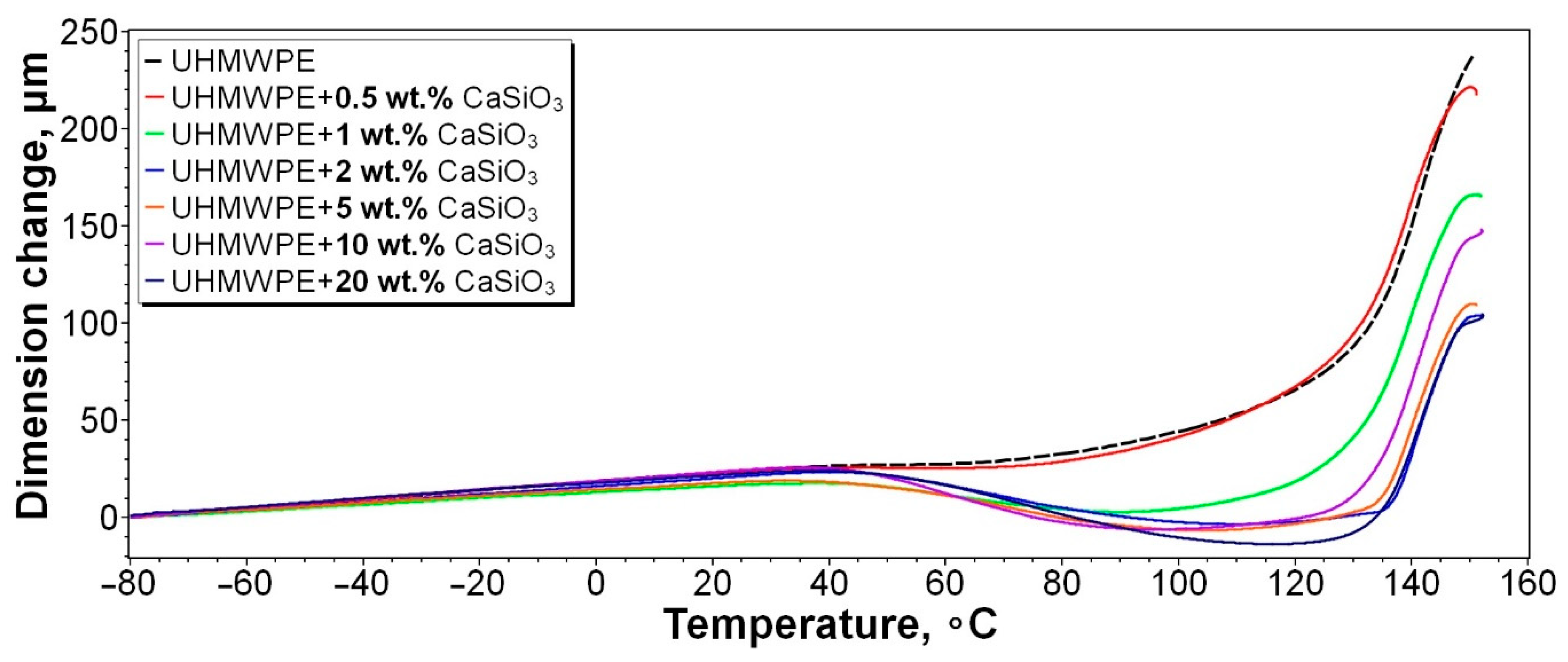

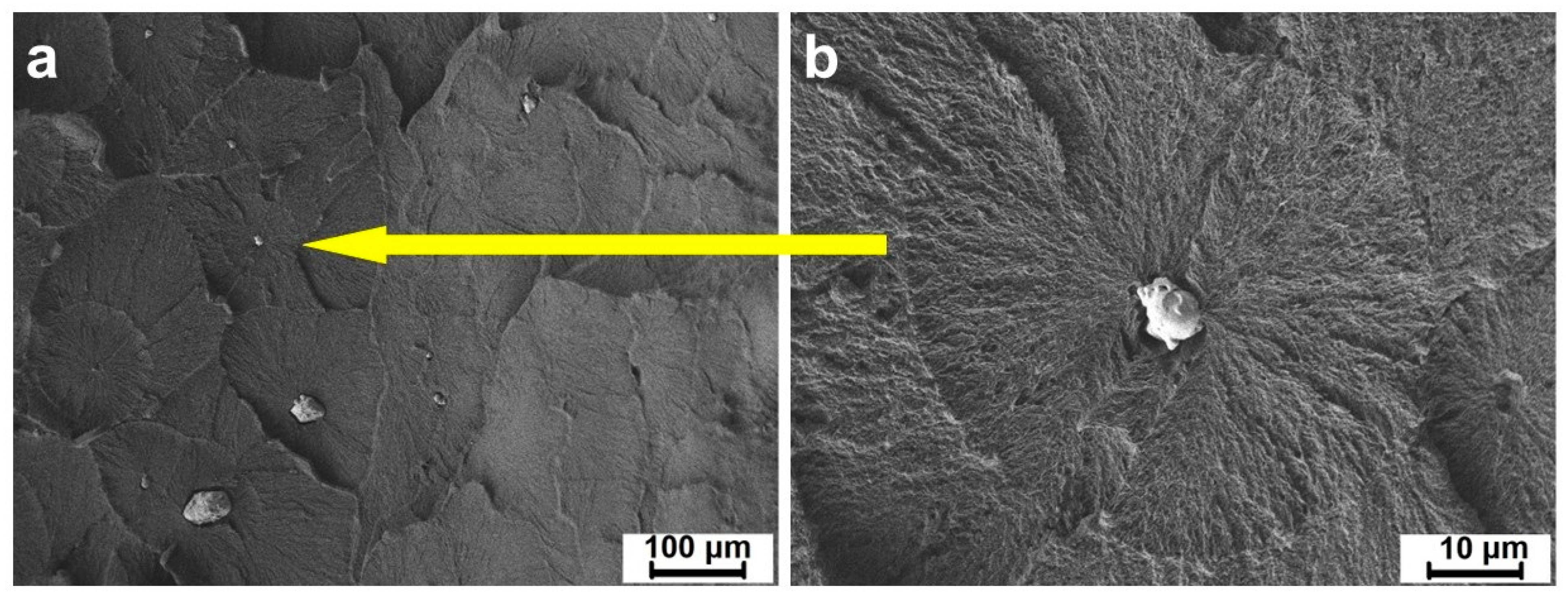

3.3. Characteristics of PCM

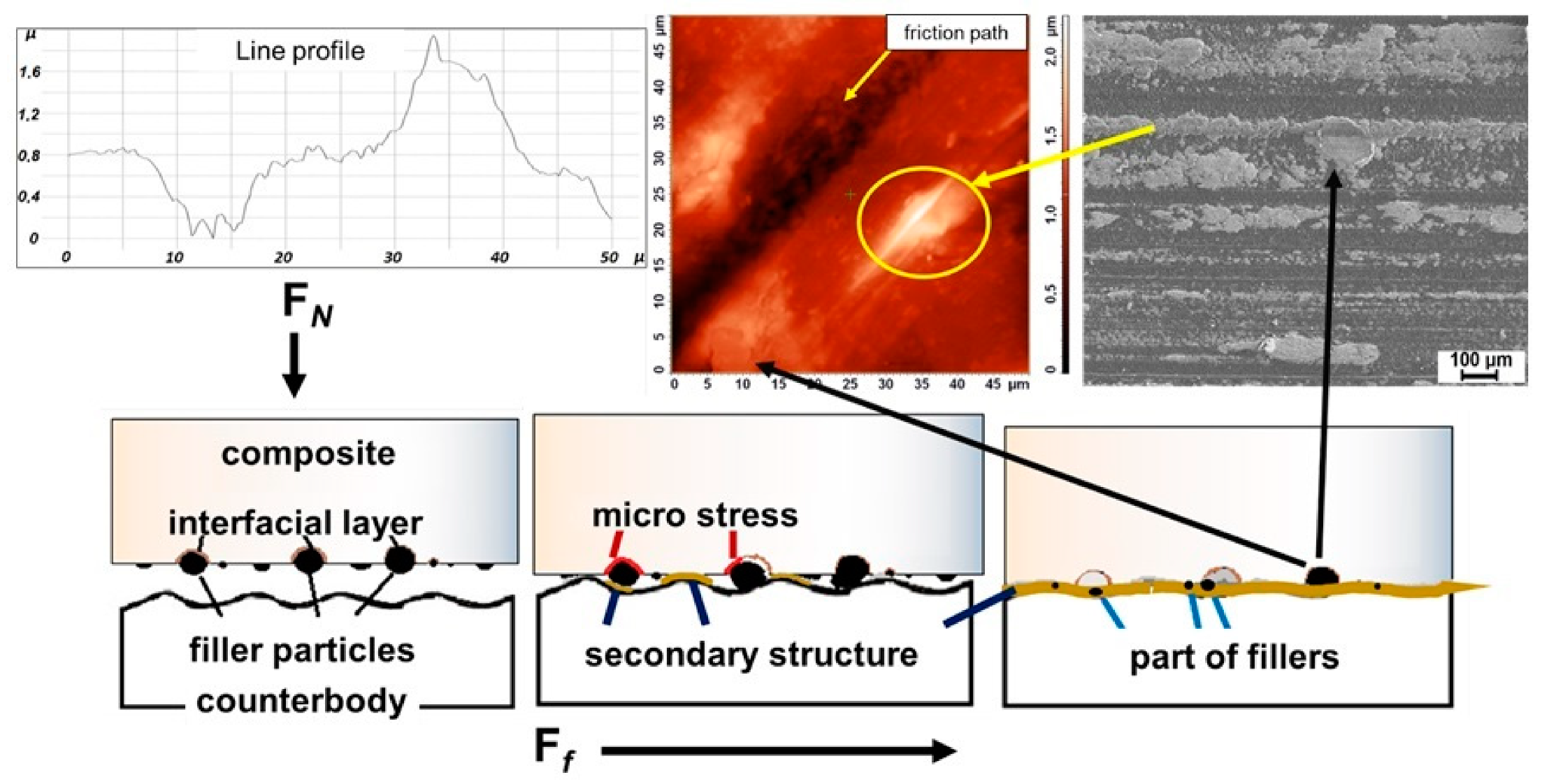

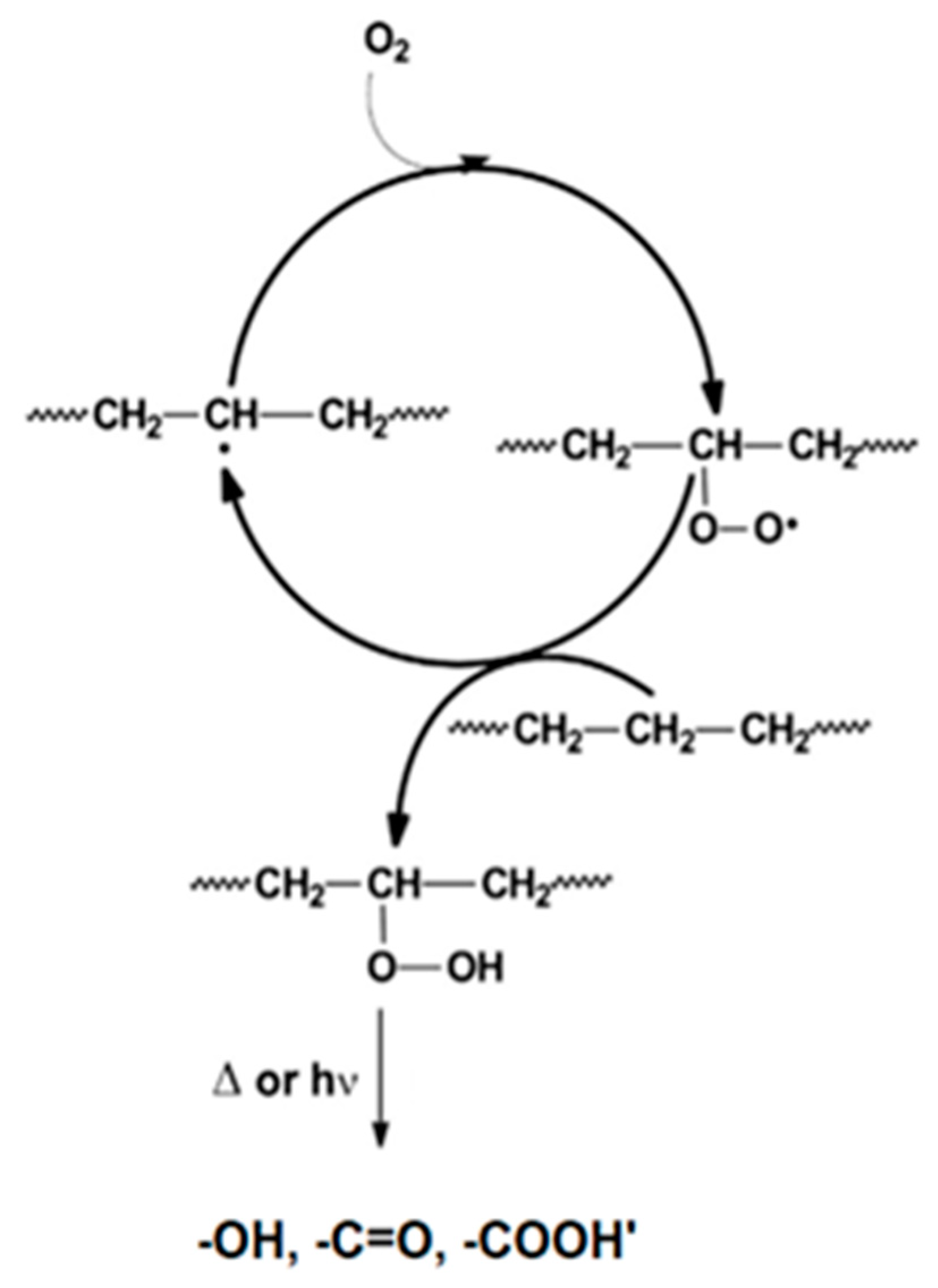

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kochurov, D.V. High-strength polymer composite materials. Int. Stud. Sci. Bull. 2018, 167. [Google Scholar]

- Starchak, E.E.; Gostev, S.S.; Ushakova, T.M.; Grinev, V.G.; Krasheninnikov, V.G.; Gorenberg, A.Y.; Novokshonova, L.A. Modification of properties of ultra-high molecular weight polyethylene by creating polymer-polymer compositions based on it in the process of synthesis. Technol. Mater. Extrem. Cond. (Predict. Res. Innov. Dev.) 2018, 188–194. [Google Scholar]

- Kryzhanovsky, V.K. Manufacture of Polymer Products; Profession: Saint Petersburg, Russia, 2008. [Google Scholar]

- Valueva, M.I.; Kolobkov, A.S.; Malakhovskiy, S.S. Ultra-high molecular weight polyethylene: Market, properties, directions of application (review). Proc. VIAM 2020, 3, 49–57. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, Y.; Wang, Q.; Ge, S. Biotribological behavior of ultra high molecular weight polyethylene composites containing bovine bone hydroxyapatite. J. China Univ. Min. Technol. 2008, 18, 606–612. [Google Scholar] [CrossRef]

- Benkocká, M.; Lupínková, S.; Knapová, T.; Kolářová, K.; Matoušek, J.; Slepička, P.; Švorčík, V.; Kolská, Z. Antimicrobial and photophysical properties of chemically grafted ultra-high-molecular-weight polyethylene. Mater. Sci. Eng. C 2019, 96, 479–486. [Google Scholar] [CrossRef]

- Galeski, A.; Bartczak, Z.; Vozniak, A.; Pawlak, A.; Walkenhorst, R. Morphology and Plastic Yielding of Ultrahigh Molecular Weight Polyethylene. Macromolecules 2020, 53, 6063–6077. [Google Scholar] [CrossRef]

- Panin, S.V.; Kornienko, L.A.; Alexenko, V.O.; Ivanova, L.R. Improvement of Wear Resistance of UHMWPE by Adding Solid Lubricating Fillers. Key Eng. Mater. 2016, 712, 155–160. [Google Scholar] [CrossRef]

- Panin, S.V.; Kornienko, L.A.; Buslovich, D.G.; Alexenko, V.O.; Ivanova, L.R. Influence of load and sliding velocity on wear resistance of solid-lubricant composites of ultra-high molecular weight polyethylene. AIP Conf. Proc. 2017, 1915, 30017. [Google Scholar]

- Danilova, S.N.; Vasilev, A.P.; Dyakonov, A.A.; Okhlopkova, A.A.; Sleptsova, S.A.; Yarusova, S.B.; Gerasimova, Y.S. Development of high-strength materials based on UHMWPE modified with 2-mercaptobenzothiazole. Aviat. Mater. Technol. 2020, 3, 10–18. [Google Scholar] [CrossRef]

- Okhlopkova, A.A.; Danilova, S.N.; Dyakonov, A.A.; Vasilev, A.P.; Tuisov, A.G.; Kychkin, A.K. Tribological Properties of Composites Based on a UHMWPE Modified Borpolymer. J. Frict. Wear 2022, 43, 27–34. [Google Scholar] [CrossRef]

- Wang, J.; Yan, F.; Xue, Q. Friction and Wear Behavior of Ultra-High Molecular Weight Polyethylene Sliding Against GCr15 Steel and Electroless Ni–P Alloy Coating Under the Lubrication of Seawater. Tribol. Lett. 2009, 35, 85–95. [Google Scholar] [CrossRef]

- Panin, S.V.; Huang, Q.; Alexenko, V.O.; Buslovich, D.G.; Kornienko, L.A.; Berto, F.; Bochkareva, S.A.; Panov, I.L.; Ryabova, N.V. Design of Wear-Resistant UHMWPE-Based Composites Loaded with Wollastonite Microfibers Treated with Various Silane Coupling Agents. Appl. Sci. 2020, 10, 4511. [Google Scholar] [CrossRef]

- Chan, J.X.; Wong, J.F.; Hassan, A.; Mohamad, Z.; Othman, N. Mechanical properties of wollastonite reinforced thermoplastic composites: A review. Polym. Compos. 2020, 41, 395–429. [Google Scholar] [CrossRef]

- Karle, A.H.; Tungikar, V.B. Optimization of wollastonite reinforced epoxy composites. Mater. Today Proc. 2021, 45, 5153–5157. [Google Scholar] [CrossRef]

- Guan, J.F.; Yang, H.Q.; Yu, Y.Q.; Chen, Y.; Yang, G.B.; Gao, H.M.; Zhang, L.Y. Reinforcement of natural rubber with quartz/sericite/wollastonite. Adv. Mater. Res. 2011, 239, 2953–2957. [Google Scholar] [CrossRef]

- Tong, J.; Ma, Y.; Arnell, R.D.D.; Ren, L. Free abrasive wear behavior of UHMWPE composites filled with wollastonite fibers. Compos. Part A Appl. Sci. Manuf. 2006, 37, 38–45. [Google Scholar] [CrossRef]

- Tong, J.; Ma, Y.; Jiang, M. Effects of the wollastonite fiber modification on the sliding wear behavior of the UHMWPE composites. Wear 2003, 255, 734–741. [Google Scholar] [CrossRef]

- Danilova, S.N.; Yarusova, S.B.; Kulchin, Y.N.; Zhevtun, I.G.; Buravlev, I.Y.; Okhlopkova, A.A.; Gordienko, P.S.; Subbotin, E.P. UHMWPE/CaSiO3 Nanocomposite: Mechanical and Tribological Properties. Polymers 2021, 13, 570. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Apanasevich, V.I.; Plekhova, N.G.; Buravlev, I.Y.; Zinoviev, S.V.; Mayorov, V.Y.; Fedorets, A.N.; Merkulov, E.B.; Shlyk, D.K.; et al. Synthetic nanostructured wollastonite: Composition, structure and “in vitro” biocompatibility investigation. Ceram. Int. 2021, 47, 22487–22496. [Google Scholar] [CrossRef]

- Amin, A.M.M.; El-Amir, A.A.M.; Karunakaran, G.; Kuznetsov, D.; Ewais, E.M.M. In-vitro evaluation of wollastonite nanopowder produced by a facile process using cheap precursors for biomedical applications. Ceram. Int. 2021, 47, 18684–18692. [Google Scholar] [CrossRef]

- Greish, Y.; Attia, N.; Mourad, A.H. Formation and biomimetic deposition of bone-like hydroxyapatite on wollastonite-gypsum composites. J. Bionic Eng. 2018, 15, 894–906. [Google Scholar] [CrossRef]

- Available online: https://www.celanese.com/ (accessed on 8 September 2022).

- Yarusova, S.B.; Gordienko, P.S.; Okhlopkova, A.A.; Zhevtun, I.G.; Dostovalov, D.V.; Buravlev, I.Y.; Danilova, S.N. Influence of synthesis conditions on the peculiarities of calcium silicate formation in various multicomponent systems. Chem. Technol. 2019, 20, 661–666. [Google Scholar]

- Lazarev, A.N. Oscillation Spectra and Structure of Silicates; Nauka: Saint Petersburg, Russia, 1968. [Google Scholar]

- Sitarz, M.; Handke, M.; Mozgawa, W. Calculations of silicooxygen ring vibration frequencies. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 1999, 55, 2831–2837. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Vadivel, H.S.; Bek, M.; Šebenik, U.; Perše, L.S.; Kádár, R.; Emami, N.; Kalin, M. Do the particle size, molecular weight, and processing of UHMWPE affect its thermomechanical and tribological performance? J. Mater. Res. Technol. 2021, 12, 1728–1737. [Google Scholar] [CrossRef]

- Rimell, J.T.; Marquis, P.M. Selective laser sintering of ultra high molecular weight polyethylene for clinical applications. J. Biomed. Mater. Res. 2000, 53, 414–420. [Google Scholar] [CrossRef]

- Michler, G.H.; Seydewitz, V.; Buschnakowski, M.; Myasnikowa, L.P.; Ivan’kova, E.M.; Marikhin, V.A.; Boiko, Y.M.; Goerlitz, S. Correlation among powder morphology, compactability, and mechanical properties of consolidated nascent UHMWPE. J. Appl. Polym. Sci. 2010, 118, 866–875. [Google Scholar] [CrossRef]

- Bracco, P.; Bellare, A.; Bistolfi, A.; Affatato, S. Ultra-High Molecular Weight Polyethylene: Influence of the Chemical, Physical and Mechanical Properties on the Wear Behavior. A Review. Materials 2017, 10, 791. [Google Scholar] [CrossRef]

- Barron, D.; Birkinshaw, C. Ultra-high molecular weight polyethylene—Evidence for a three-phase morphology. Polymer 2008, 49, 3111–3115. [Google Scholar] [CrossRef]

- Tarasevich, B.N. IR Spectra of Major Classes of Organic Compounds; MSU: Moscow, Russia, 2012. [Google Scholar]

- Wang, H.; Wang, Y.; Su, Q.; Wang, Y.; Sun, C.; Wang, A. Self-Lubricating Ultrahigh Molecular Weight Polyethylene Thin Films with Excellent Wear Resistance at Light Friction Loads on Glass and Silicon. J. Macromol. Sci. Part B 2019, 58, 317–329. [Google Scholar] [CrossRef]

- Badgayan, N.D.; Samanta, S.; Sahu, S.K.; Siva, S.B.V.; Sadasivuni, K.K.; Sahu, D.; Sreekanth, P.S.R. Tribological behaviour of 1D and 2D nanofiller based high densitypoly-ethylene hybrid nanocomposites: A run-in and steady state phase analysis. Wear 2017, 376–377, 1379–1390. [Google Scholar] [CrossRef]

- Luikov, A.V.; Shashkov, A.G.; Vasiliev, L.L.; Fraiman, Y.E. Thermal conductivity of porous systems. Int. J. Heat Mass Transf. 1968, 11, 117–140. [Google Scholar] [CrossRef]

- Rodiouchkina, M.; Lind, J.; Pelcastre, L.; Berglund, K.; Rudolphi, Å.K.; Hardell, J. Tribological behaviour and transfer layer development of self-lubricating polymer composite bearing materials under long duration dry sliding against stainless steel. Wear 2021, 484–485, 204027. [Google Scholar] [CrossRef]

- Sobieraj, M.C.; Rimnac, C.M. Ultra high molecular weight polyethylene: Mechanics, morphology, and clinical behavior. J. Mech. Behav. Biomed. Mater. 2009, 2, 433–443. [Google Scholar] [CrossRef] [PubMed]

- Colorado, H.A.; Yuan, W.; Guo, Z.; Juanri, J.; Yang, J.M. Poly-dicyclopentadiene-wollastonite composites toward structural applications. J. Compos. Mater. 2014, 48, 2023–2031. [Google Scholar] [CrossRef]

- Svab, I.; Musil, V.; Pustak, A.; Smit, I. Wollastonite-reinforced polypropylene composites modified with novel metallocene EPR copolymers. II. Mechanical properties and adhesion. Polym. Compos. 2009, 30, 1091. [Google Scholar] [CrossRef]

- Liang, J.Z. Impact and flexural properties of PP/CaSiO3 composites. Polym. Compos. 2018, 39, 398–404. [Google Scholar] [CrossRef]

- Tsioptsias, C.; Leontiadis, K.; Messaritakis, S.; Terzaki, A.; Xidas, P.; Mystikos, K.; Tzimpilis, E.; Tsivintzelis, I. Experimental investigation of polypropylene composite drawn fibers with talc, wollastonite, attapulgite and single-wall carbon nanotubes. Polymers 2022, 14, 260. [Google Scholar] [CrossRef]

- Leontiadis, K.; Tsioptsias, C.; Messaritakis, S.; Terzaki, A.; Xidas, P.; Mystikos, K.; Tzimpilis, E.; Tsivintzelis, I. Optimization of Thermal and Mechanical Properties of Polypropylene-Wollastonite Composite Drawn Fibers Based on Surface Response Analysis. Polymers 2022, 14, 924. [Google Scholar] [CrossRef]

- Wong, J.F.; Chan, J.X.; Hassan, A.B. Thermal and flammability properties of wollastonite-filled thermoplastic composites: A review. J. Mater. Sci. 2021, 56, 8911–8950. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Chuayjuljit, S.; Srasomsub, S.; Boonmahitthisud, A. Composites of poly (lactic acid)/poly (butylene adipate-co-terephthalate) blend with wood fiber and wollastonite: Physical properties, morphology, and biodegradability. J. Appl. Polym. Sci. 2019, 136, 47543. [Google Scholar] [CrossRef]

- Amin, A.S.; Oza, B.I. Study on effect of wollastonite on the thermal properties of nylon-6 and morphological analysis. Int. J. Recent Innov. Trends Comput. Commun. 2015, 3, 4650–4653. [Google Scholar] [CrossRef]

- Lapčík, L.; Maňas, D.; Lapčíková, B.; Vašina, M.; Staněk, M.; Čépe, K.; Vlček, J.; Waters, K.E.; Greenwood, R.W.; Rowson, N.A. Effect of filler particle shape on plastic-elastic mechanical behavior of high density poly (ethylene)/mica and poly (ethylene)/wollastonite composites. Compos. B Eng. 2018, 141, 92–99. [Google Scholar] [CrossRef]

- Ding, Q.; Zhang, Z.; Dai, X.; Li, M.; Mai, K. Crystalline morphology and mechanical properties of isotactic polypropylene composites filled by wollastonite with β-nucleating surface. Polym. Compos. 2014, 35, 1445–1452. [Google Scholar] [CrossRef]

- Sobhani, H.; Khorasani, M.M. Optimization of scratch resistance and mechanical properties in wollastonite-reinforced polypropylene copolymers. Polym. Adv. Technol. 2016, 27, 765–773. [Google Scholar] [CrossRef]

- Yabutsuka, T.; Takai, S. Impartation of hydroxyapatite formation ability to ultra-high molecular weight polyethylene by deposition of apatite nuclei. IET Nanobiotechnol. 2020, 14, 673–679. [Google Scholar] [CrossRef]

- Luyt, A.S.; Dramićanin, M.D.; Antić, Ž.; Djoković, V. Morphology, mechanical and thermal properties of composites of polypropylene and nanostructured wollastonite filler. Polym. Test. 2009, 28, 348–356. [Google Scholar] [CrossRef]

- Kalkan, Ş.O.; Yavaş, A.; Güler, S.; Kayalar, M.T.; Sütçü, M.; Gündüz, L. An experimental approach to a cementitious lightweight composite mortar using synthetic wollastonite. Constr. Build. Mater. 2022, 341, 127911. [Google Scholar] [CrossRef]

- Yarusova, S.B.; Gordienko, P.S.; Sharma, Y.C.; Perfilev, A.V.; Kozin, A.V. Industrial waste as raw material for producing synthetic wollastonite in Russia. Int. J. Environ. Sci. Dev. 2017, 8, 1–5. [Google Scholar] [CrossRef][Green Version]

- Zhang, G.; Chang, L.; Schlarb, A.K. The roles of nano-SiO2 particles on the tribological behavior of short carbon fiber reinforced PEEK. Compos. Sci. Technol. 2009, 69, 1029–1035. [Google Scholar] [CrossRef]

- Panin, S.V.; Kornienko, L.A.; Alexenko, V.O.; Buslovich, D.G.; Bochkareva, S.A.; Lyukshin, B.A. Increasing wear resistance of UHMWPE by loading enforcing carbon fibers: Effect of irreversible and elastic deformation, friction heating, and filler size. Materials 2020, 13, 338. [Google Scholar] [CrossRef] [PubMed]

- Petrovich, V.A.; Nikolaevna, L.N.; Aleksandrovich, N.L.; Alekseevna, O.A.; Afanasyevna, S.S.; Semenovna, S.T. Development and tribological properties of polymer composites. Tribol. Polym. Compos. 2021, 31–62. [Google Scholar] [CrossRef]

- Panin, S.V.; Kornienko, L.A.; Buslovich, D.G.; Dontsov, Y.V.; Lyukshin, B.A.; Bochkareva, S.A.; Alexenko, V.O.; Shilko, S.V. Quality of polymeric tribocompound powders and its influence on microstructure and mechanical/tribological behavior of 3D manufactured parts. In Structure and Properties of Additive Manufactured Polymer Components; Woodhead Publishing: Duxford, UK, 2020; pp. 221–252. [Google Scholar]

- Bolland, J.L. Kinetics of olefin oxidation. Q. Rev. Chem. Soc. 1949, 3, 1–21. [Google Scholar] [CrossRef]

- Costa, L.; Bracco, P. Mechanisms of cross-linking, oxidative degradation, and stabilization of UHMWPE. In UHMWPE Biomaterials Handbook; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 467–487. [Google Scholar] [CrossRef]

- Sleptsova, S.A.; Lazareva, N.N.; Fedoseeva, V.I.; Kapitonova, Y.V.; Okhlopkova, A.A. The influence of metal cations of mechanoactivated bentonite on tribochemical processes in PTFE. J. Frict. Wear 2018, 39, 469–475. [Google Scholar] [CrossRef]

- Harris, K.L.; Pitenis, A.A.; Sawyer, W.G.; Krick, B.A.; Blackman, G.S.; Kasprzak, D.J.; Junk, C.P. PTFE tribology and the role of mechanochemistry in the development of protective surface films. Macromolecules 2015, 48, 3739–3745. [Google Scholar] [CrossRef]

- Ye, J.; Burris, D.L.; Xie, T. A review of transfer films and their role in ultra-low-wear sliding of polymers. Lubricants 2016, 4, 4. [Google Scholar] [CrossRef]

- Cai, T.; Zhan, S.; Yang, T.; Li, Y.; Jia, D.; Tu, J.; Li, J.; Duan, H. Study on the tribological properties of UHMWPE modified by UV-induced grafting under seawater lubrication. Tribol. Int. 2022, 168, 10741. [Google Scholar] [CrossRef]

| Composite | f | L, mm | I, mg/h | K, 10−6 mm3/(N·m) | ρ, g/cm3 | |

|---|---|---|---|---|---|---|

| Resin Torque | Wollastonite, wt% | |||||

| UHMWPE | 0 | 0.38 ± 0.01 | 0.31 ± 0.02 | 0.12 ± 0.01 | 0.57 | 0.93 |

| 0.5 | 0.38 ± 0.01 | 0.21 ± 0.02 | 0.07 ± 0.03 | 0.33 | 0.94 | |

| 1 | 0.41 ± 0.02 | 0.12 ± 0.01 | 0.03 ± 0.02 | 0.14 | 0.94 | |

| 2 | 0.37 ± 0.01 | 0.09 ± 0.01 | 0.05 ± 0.02 | 0.23 | 0.95 | |

| 5 | 0.39 ± 0.01 | 0.13 ± 0.01 | 0.07 ± 0.02 | 0.32 | 0.96 | |

| 10 | 0.35 ± 0.02 | 0.10 ± 0.02 | 0.08 ± 0.01 | 0.36 | 0.99 | |

| 20 | 0.29 ± 0.02 | 0.15 ± 0.01 | 0.12 ± 0.01 | 0.52 | 1.03 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Danilova, S.N.; Yarusova, S.B.; Lazareva, N.N.; Buravlev, I.Y.; Shichalin, O.O.; Papynov, E.K.; Zhevtun, I.G.; Gordienko, P.S.; Okhlopkova, A.A. A Study of the Wear Mechanism of Composites Modified with Silicate Filler. Ceramics 2022, 5, 731-747. https://doi.org/10.3390/ceramics5040053

Danilova SN, Yarusova SB, Lazareva NN, Buravlev IY, Shichalin OO, Papynov EK, Zhevtun IG, Gordienko PS, Okhlopkova AA. A Study of the Wear Mechanism of Composites Modified with Silicate Filler. Ceramics. 2022; 5(4):731-747. https://doi.org/10.3390/ceramics5040053

Chicago/Turabian StyleDanilova, Sakhayana N., Sofia B. Yarusova, Nadezhda N. Lazareva, Igor Yu. Buravlev, Oleg O. Shichalin, Evgeniy K. Papynov, Ivan G. Zhevtun, Pavel S. Gordienko, and Aitalina A. Okhlopkova. 2022. "A Study of the Wear Mechanism of Composites Modified with Silicate Filler" Ceramics 5, no. 4: 731-747. https://doi.org/10.3390/ceramics5040053

APA StyleDanilova, S. N., Yarusova, S. B., Lazareva, N. N., Buravlev, I. Y., Shichalin, O. O., Papynov, E. K., Zhevtun, I. G., Gordienko, P. S., & Okhlopkova, A. A. (2022). A Study of the Wear Mechanism of Composites Modified with Silicate Filler. Ceramics, 5(4), 731-747. https://doi.org/10.3390/ceramics5040053