Recent Progress and Scientific Challenges in Wire-Arc Additive Manufacturing of Metallic Multi-Material Structures

Abstract

1. Introduction

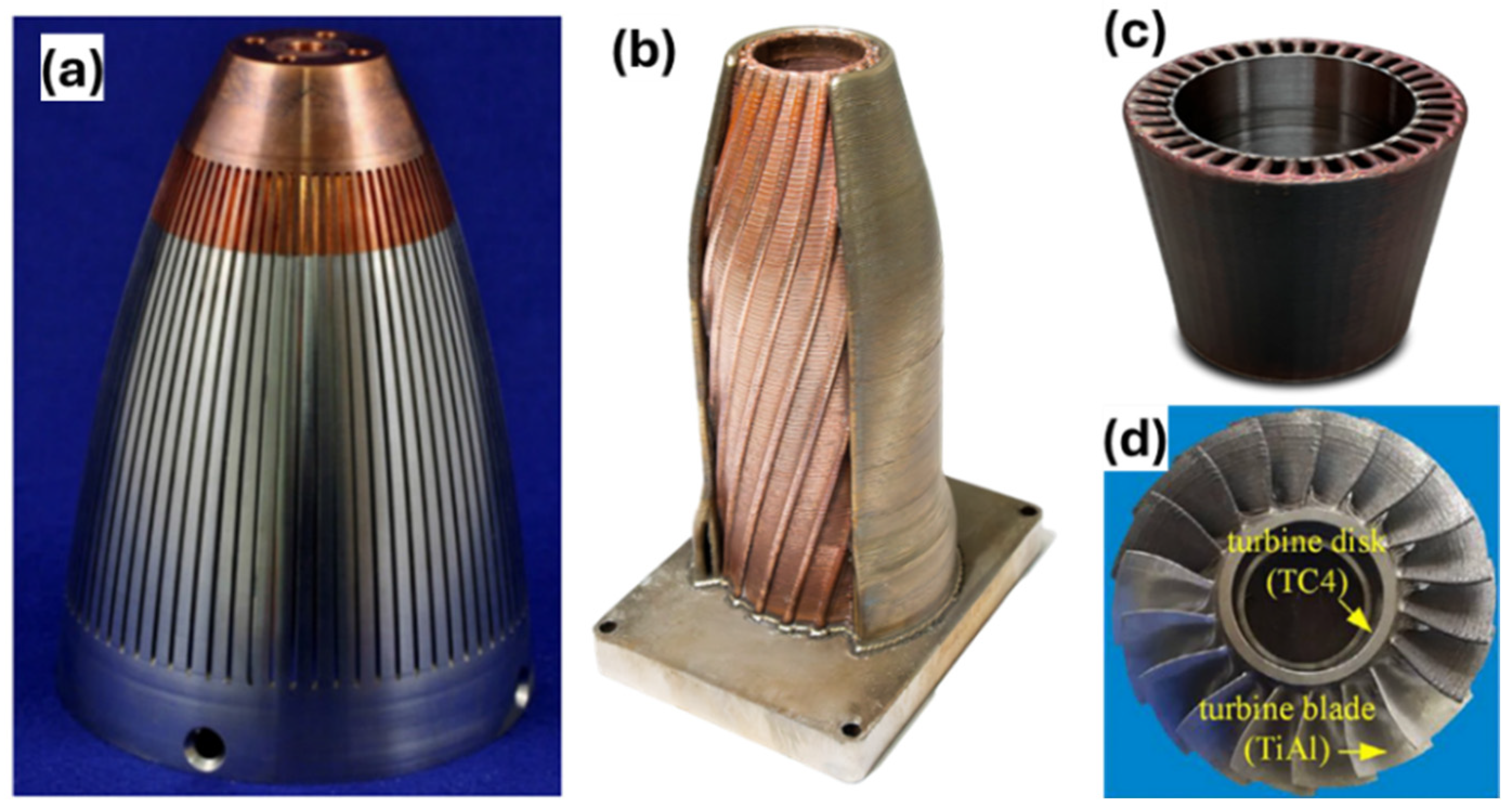

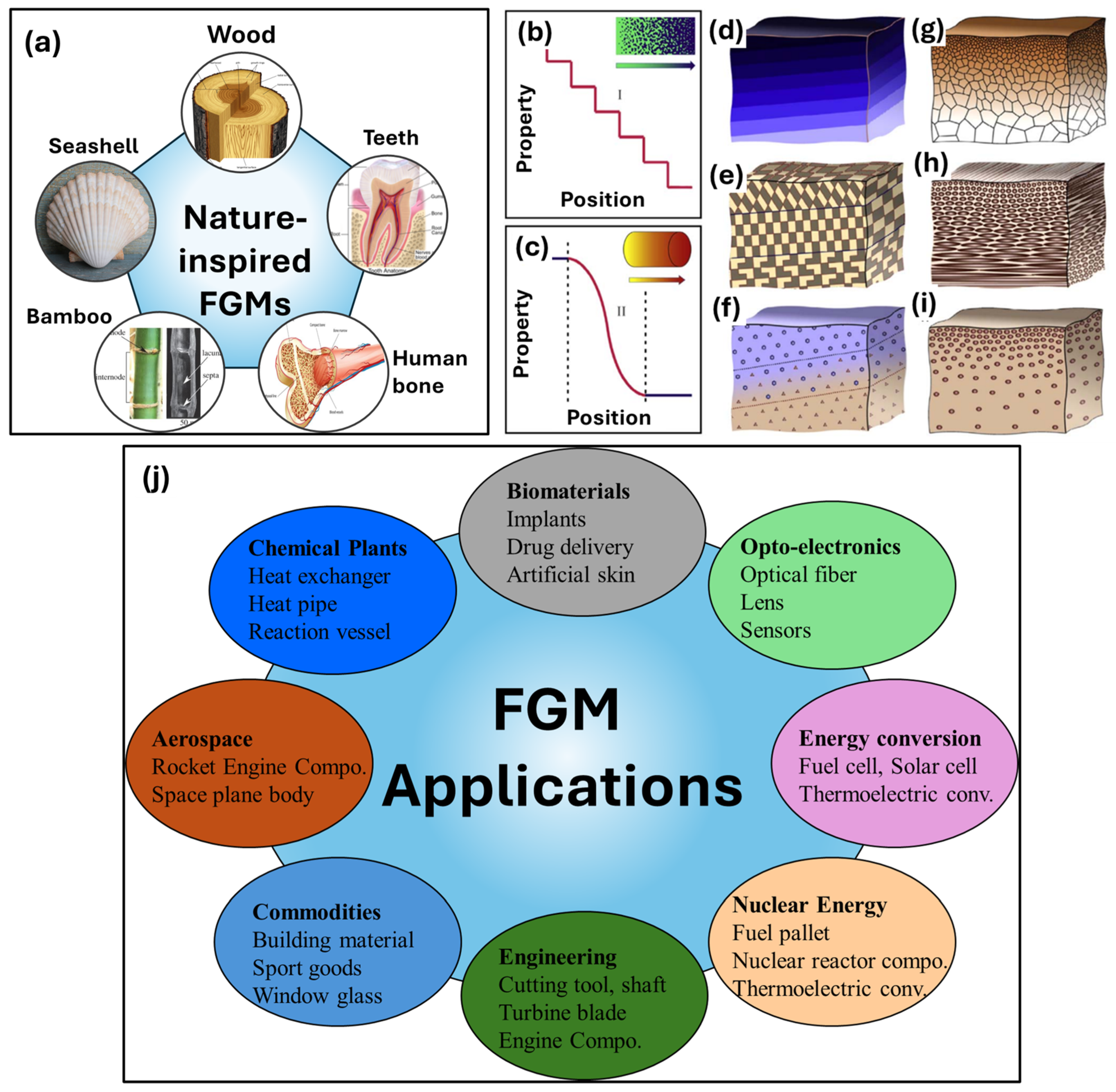

1.1. Multi-Material Structures

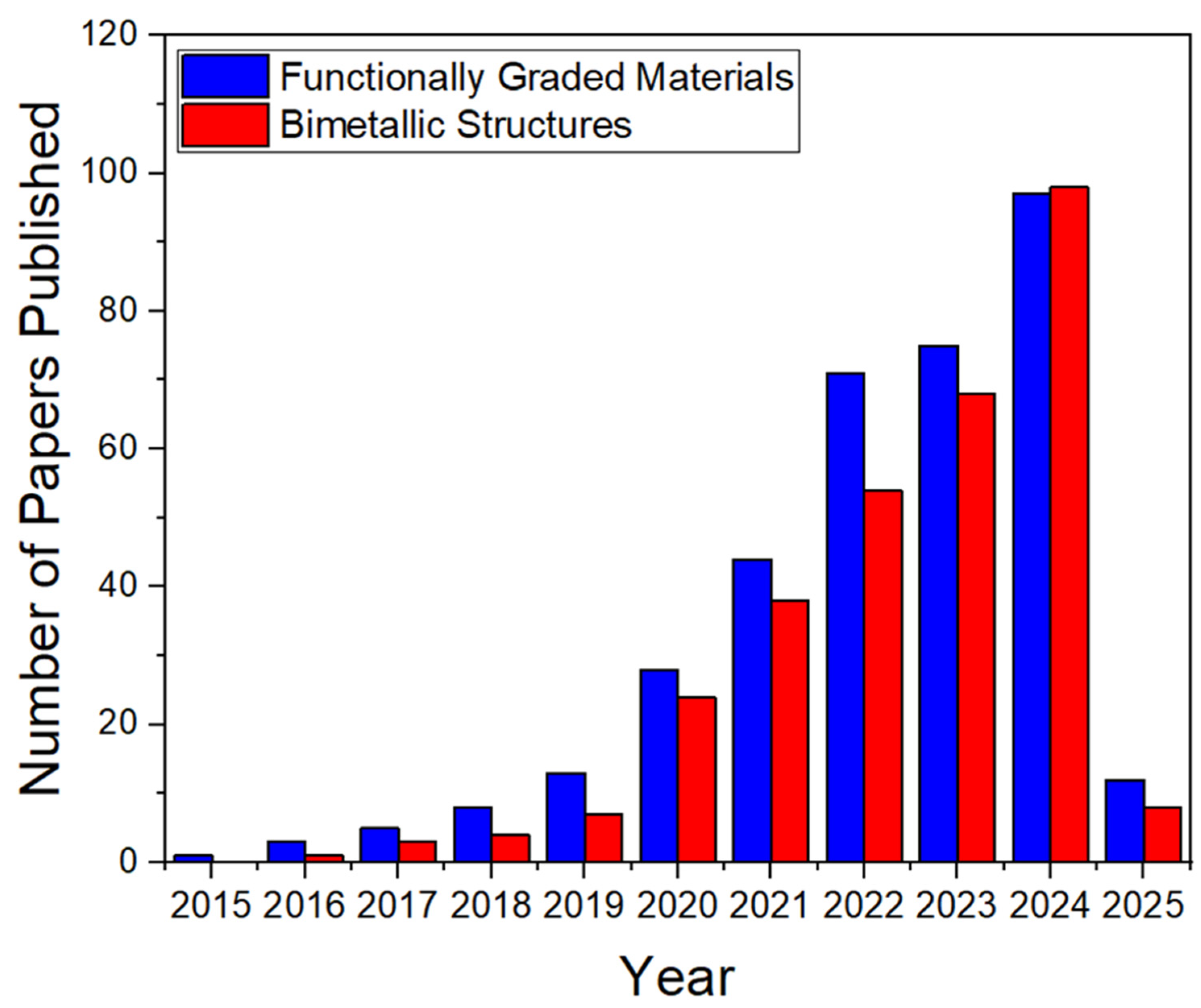

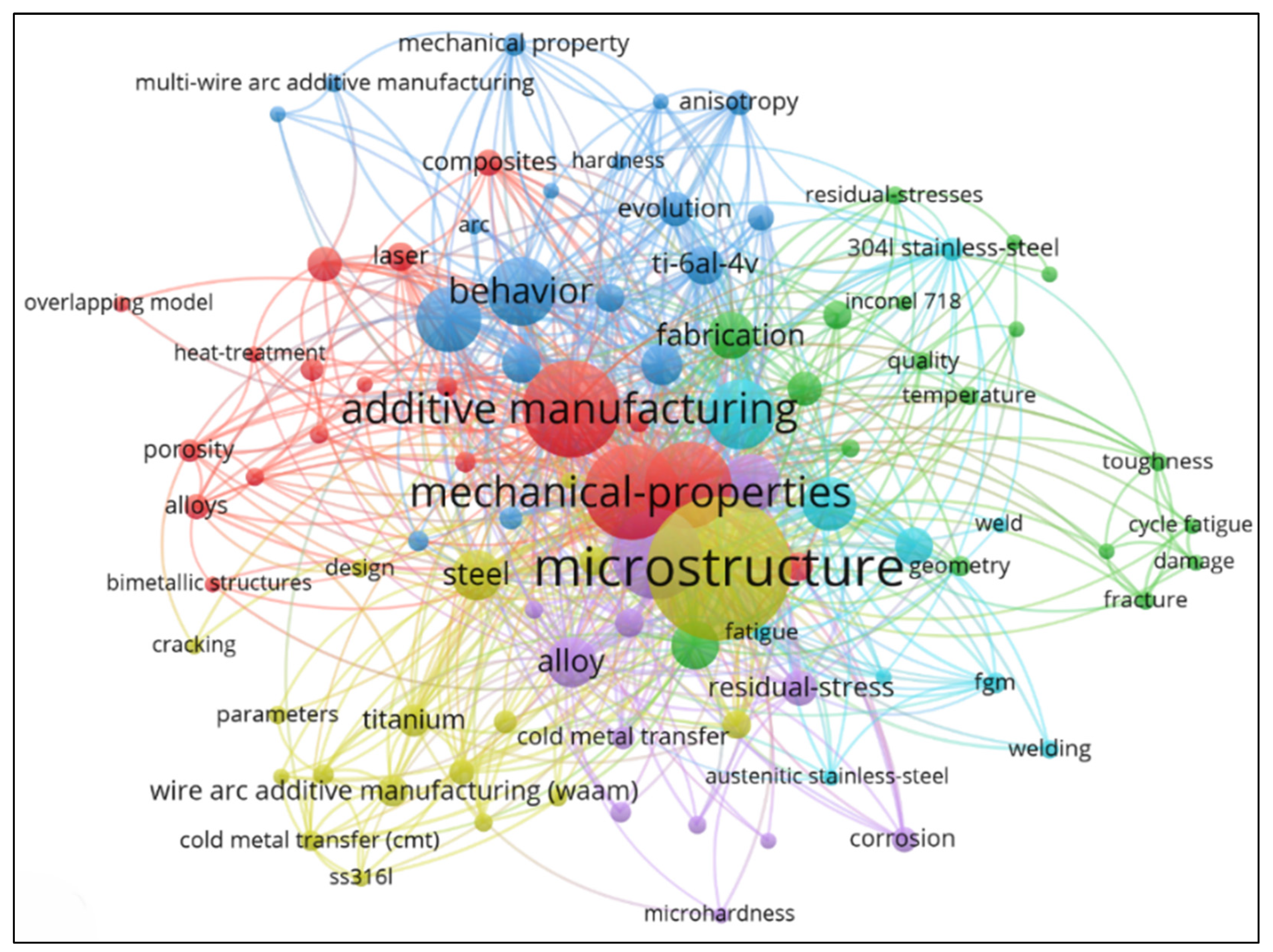

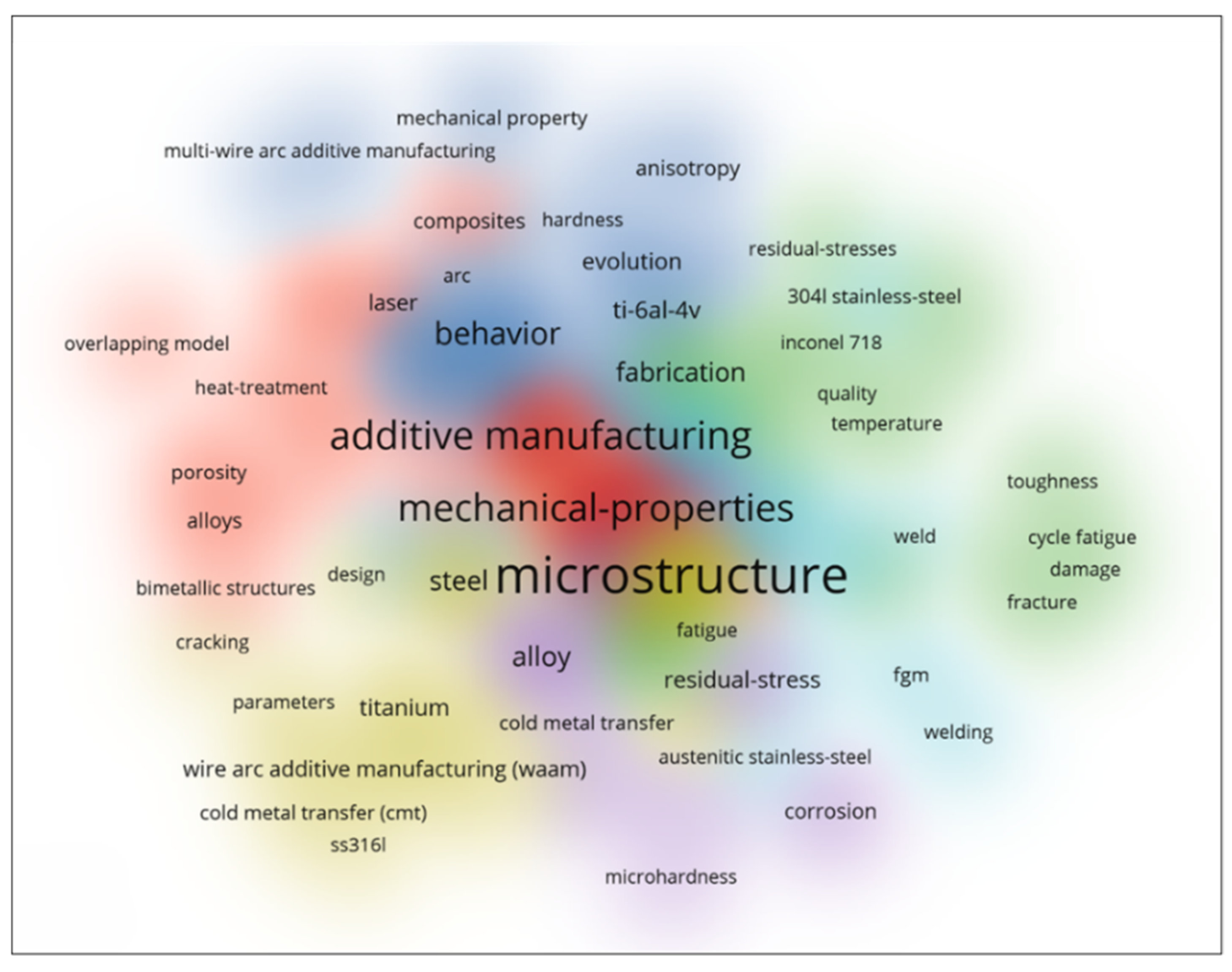

1.2. Bibliometric Analysis

2. Multi-Material Structure Fabrication

2.1. Conventional and Additive Manufacturing Methods

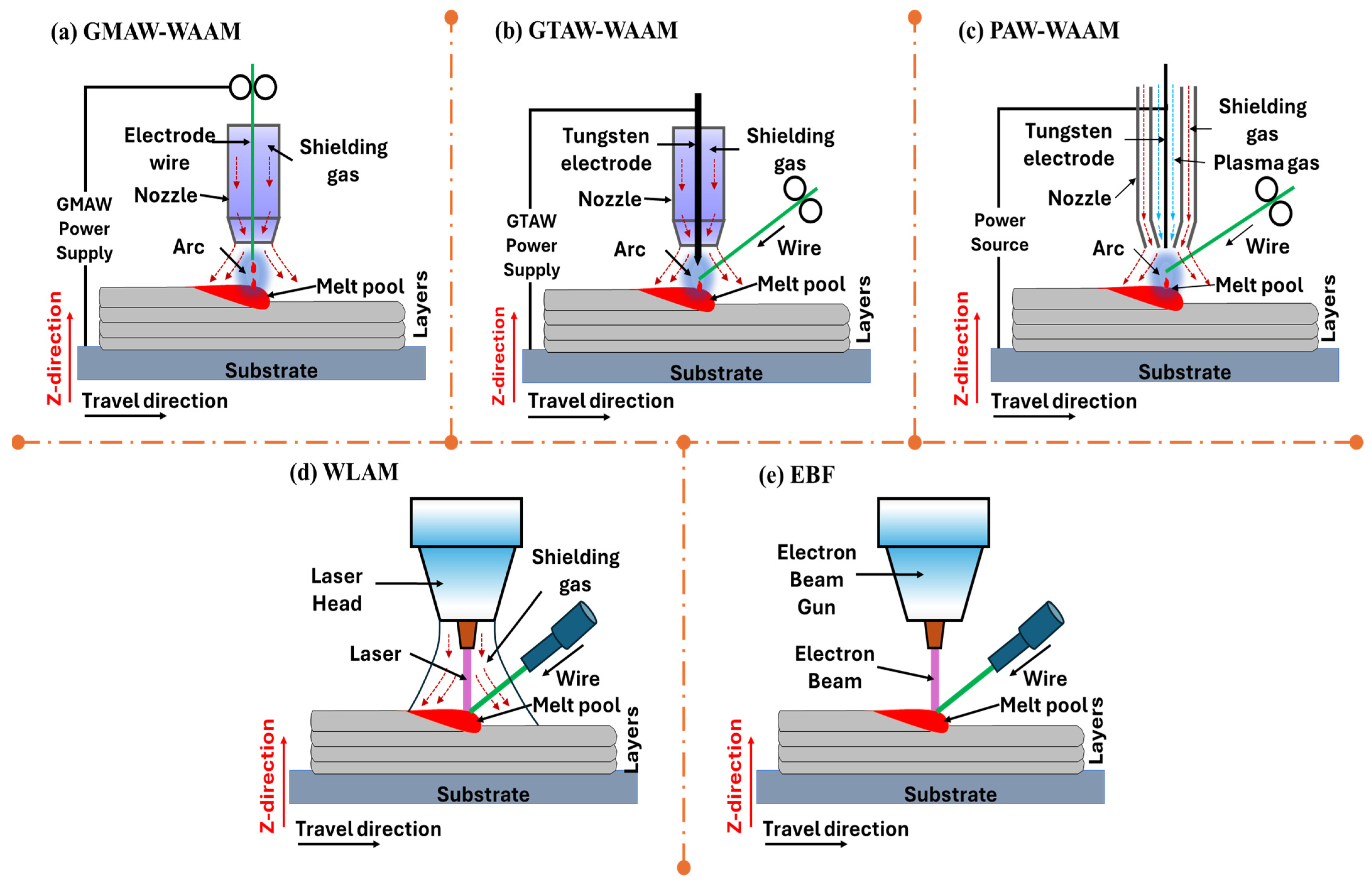

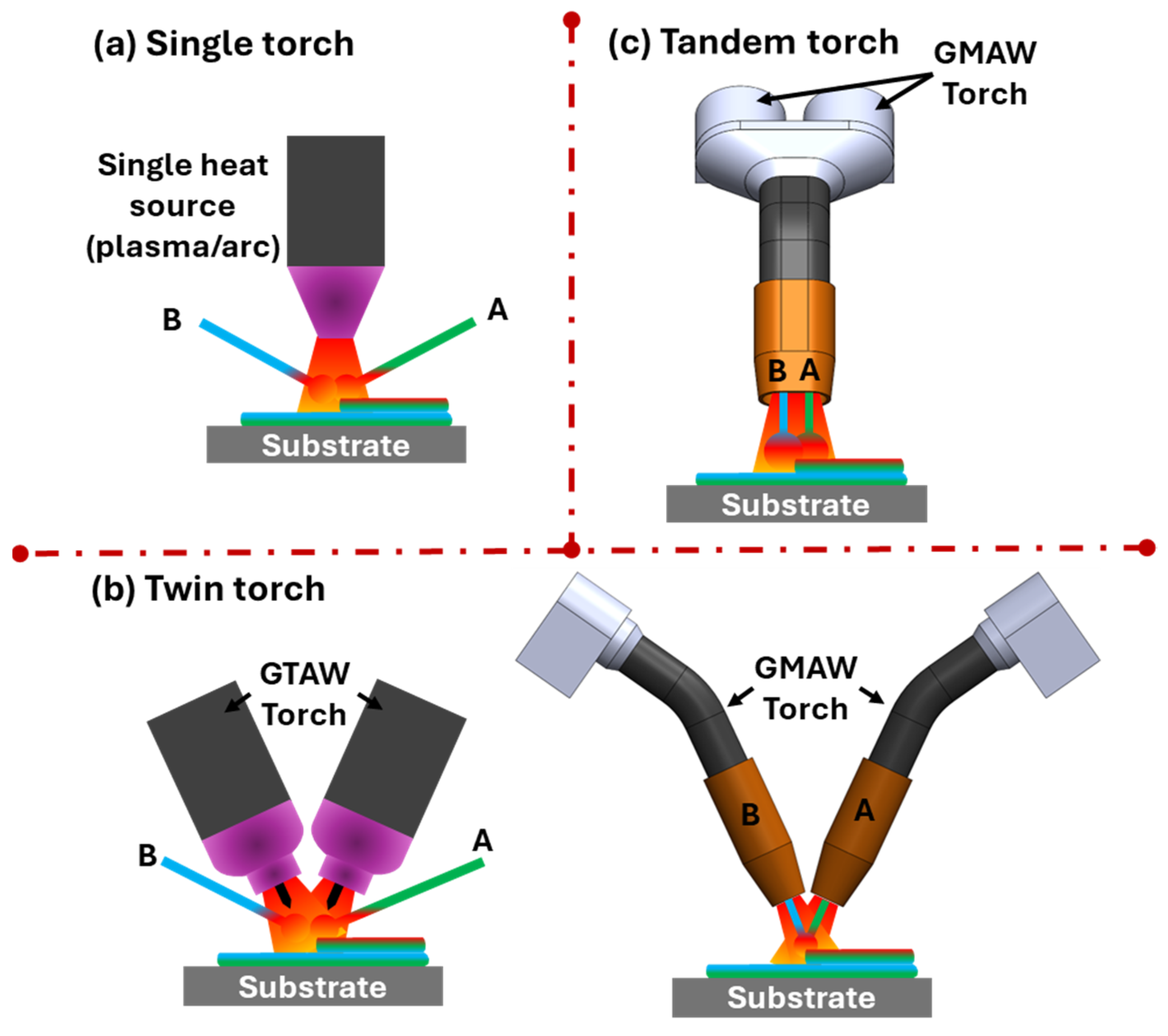

2.2. Wire DED Additive Manufacturing Processes

3. Recent Research Progress in the Wire-Arc Additive Manufacturing of Multi-Material Structures

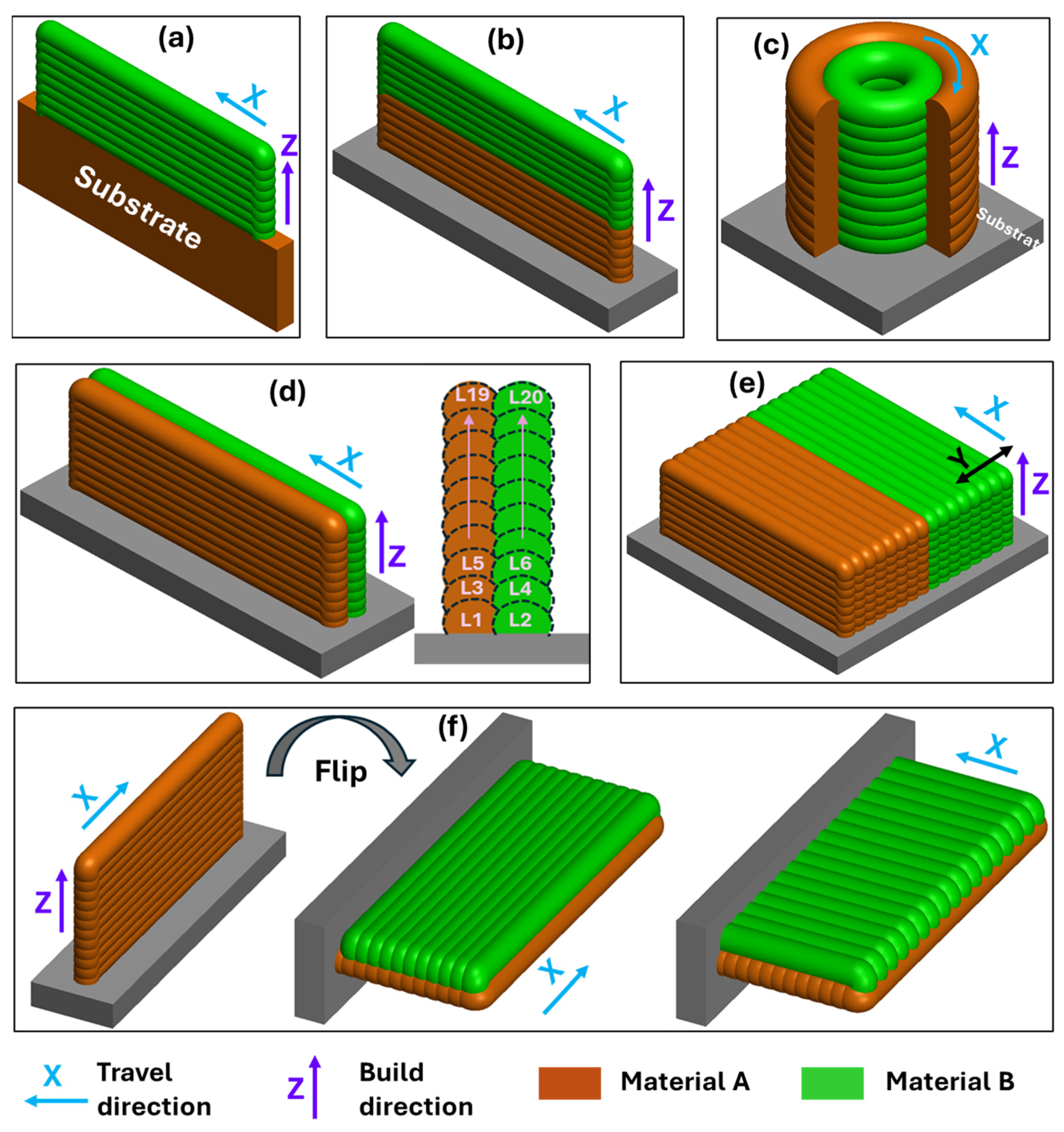

3.1. Bimetallic Structures: Deposition Strategies

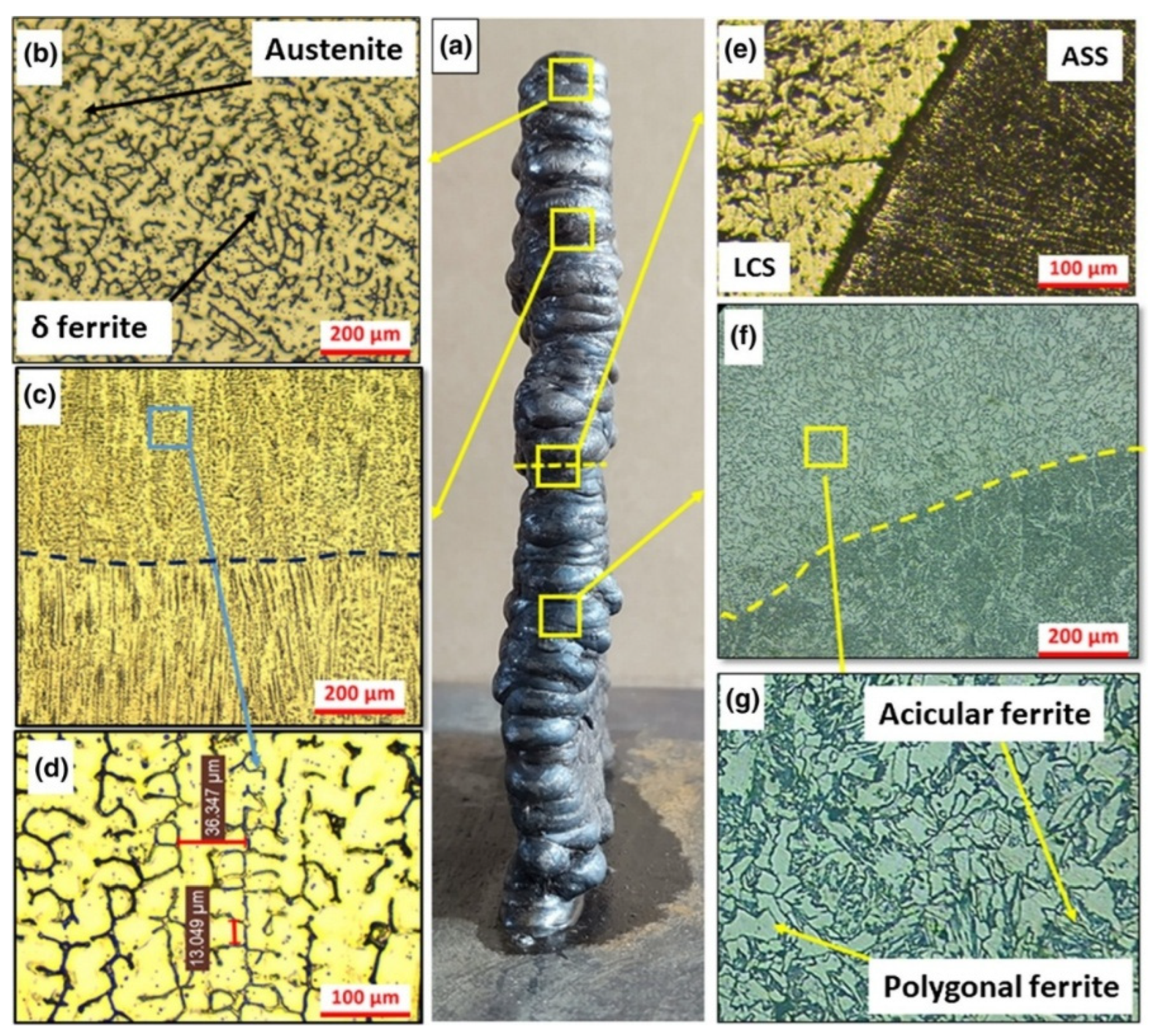

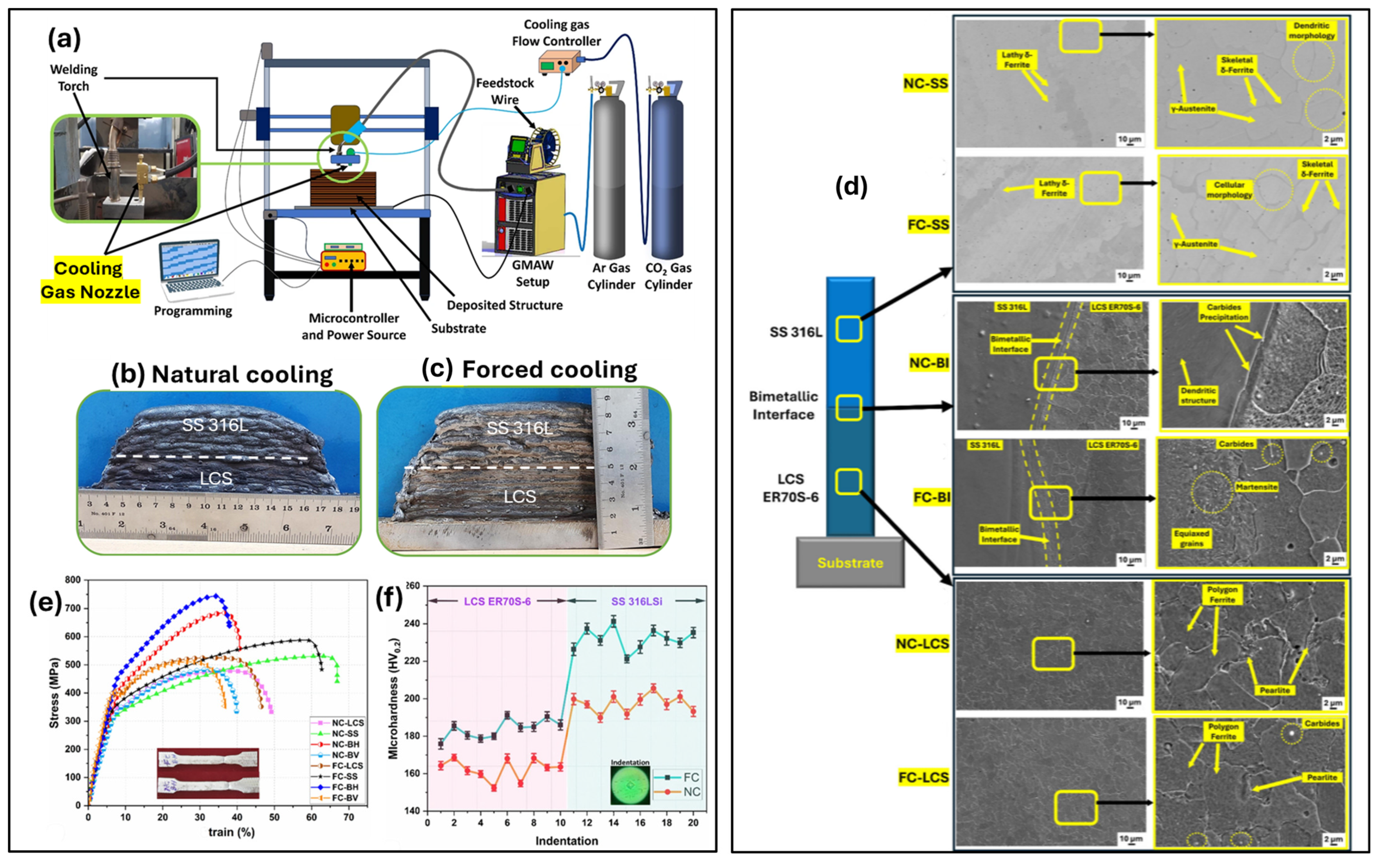

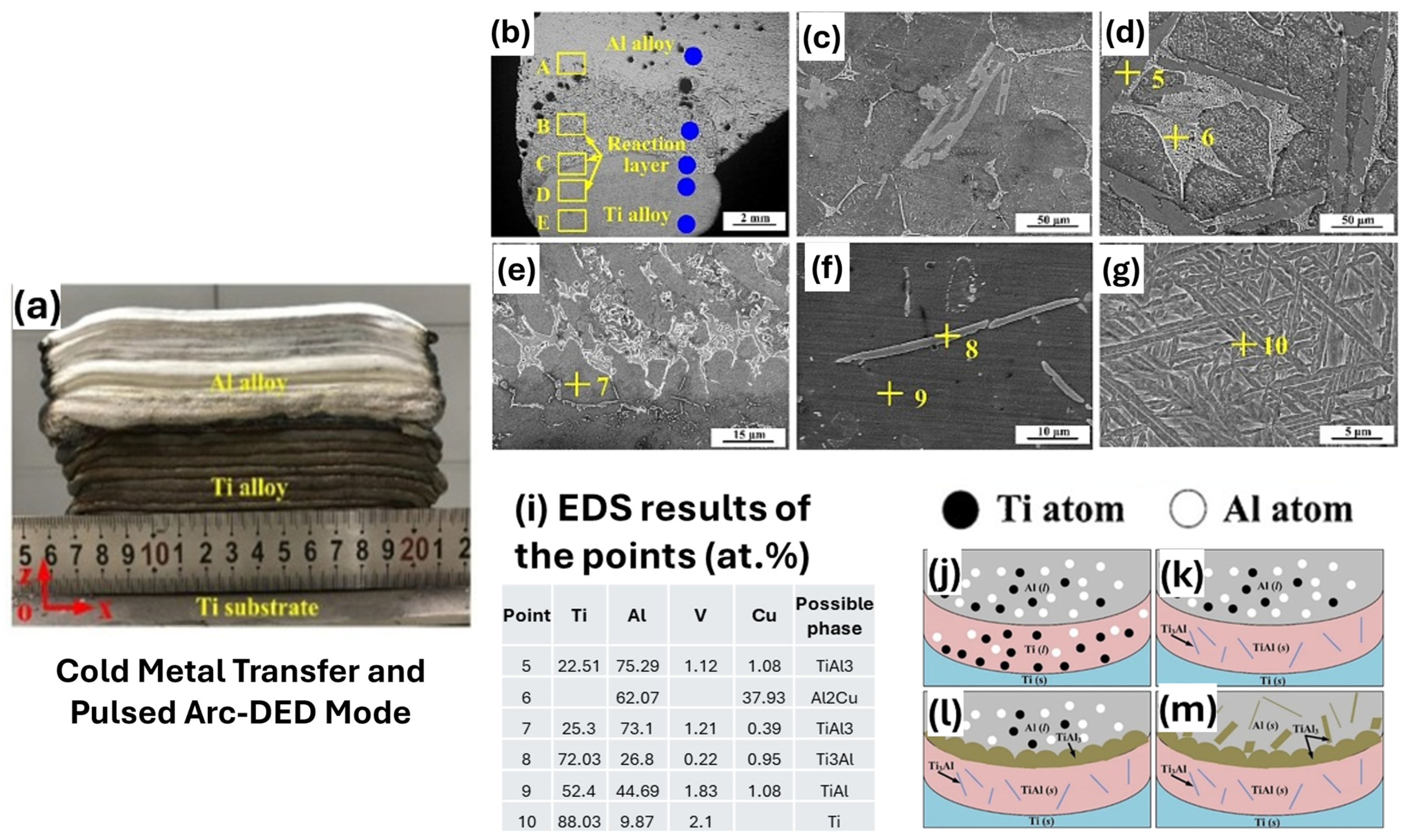

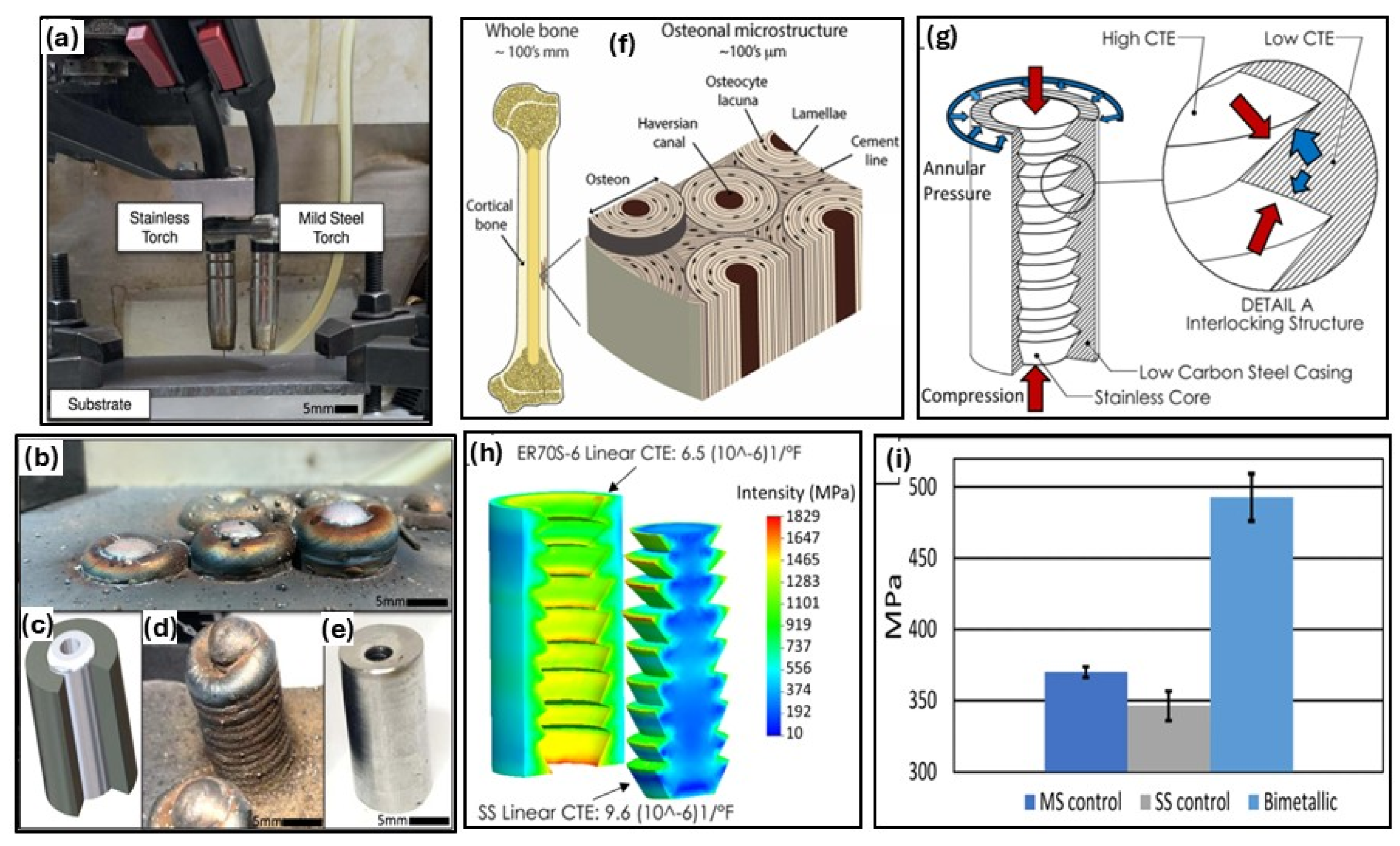

3.2. Bimetallic Structures: Fabrication and Characterization Studies

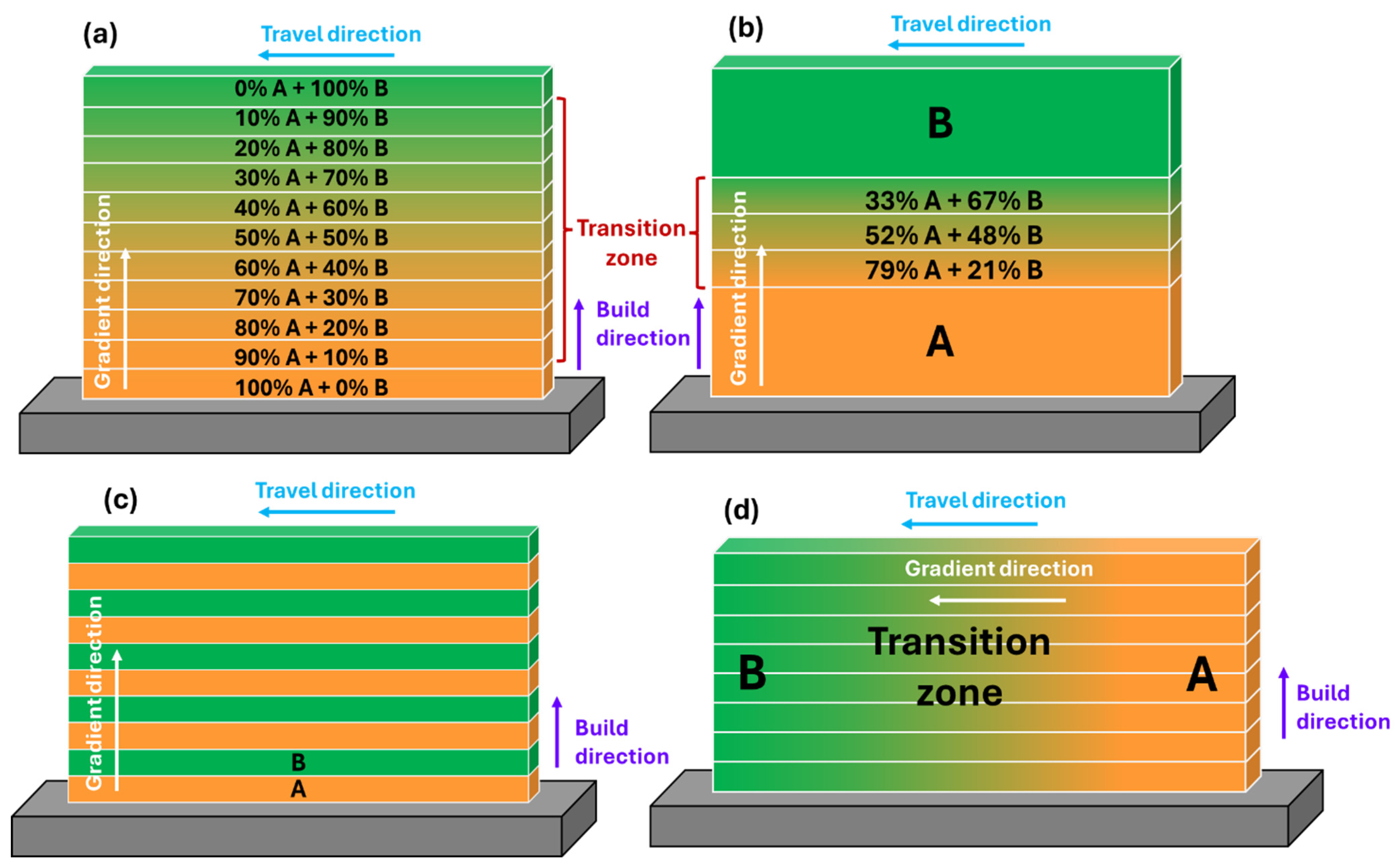

3.3. Functionally Graded Materials: Deposition Strategies, Wire Feeding Layout, Arrangement of Torches

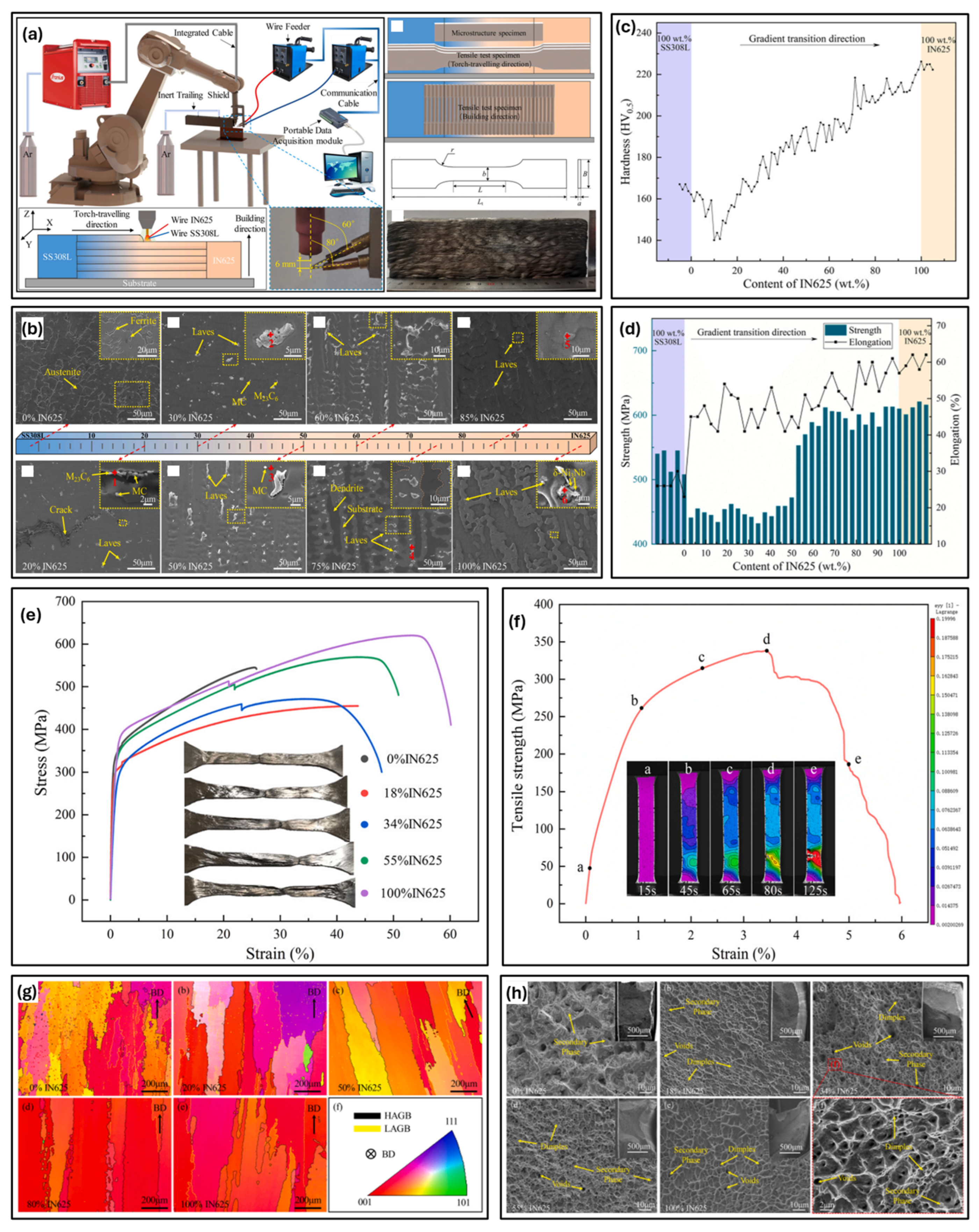

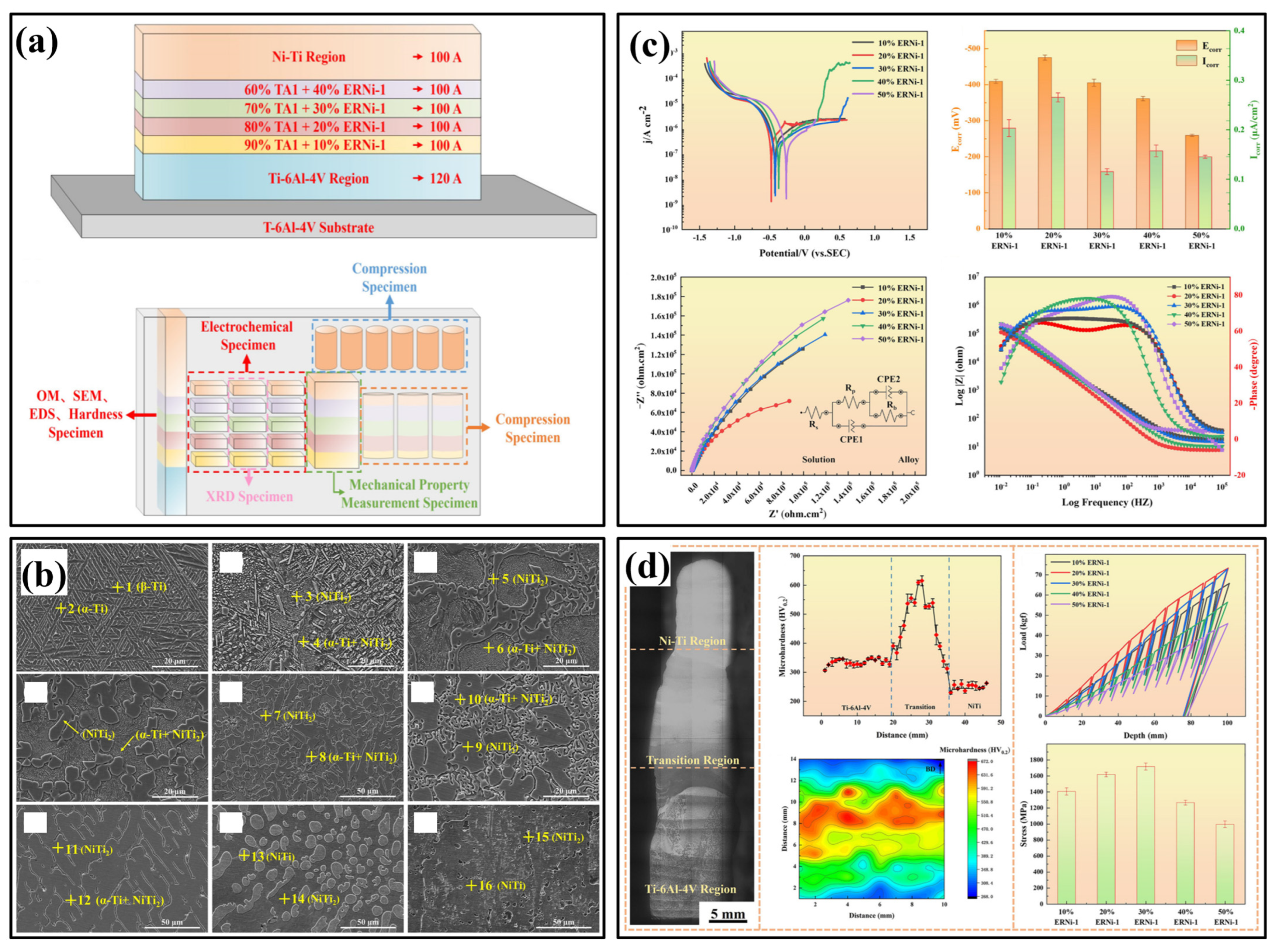

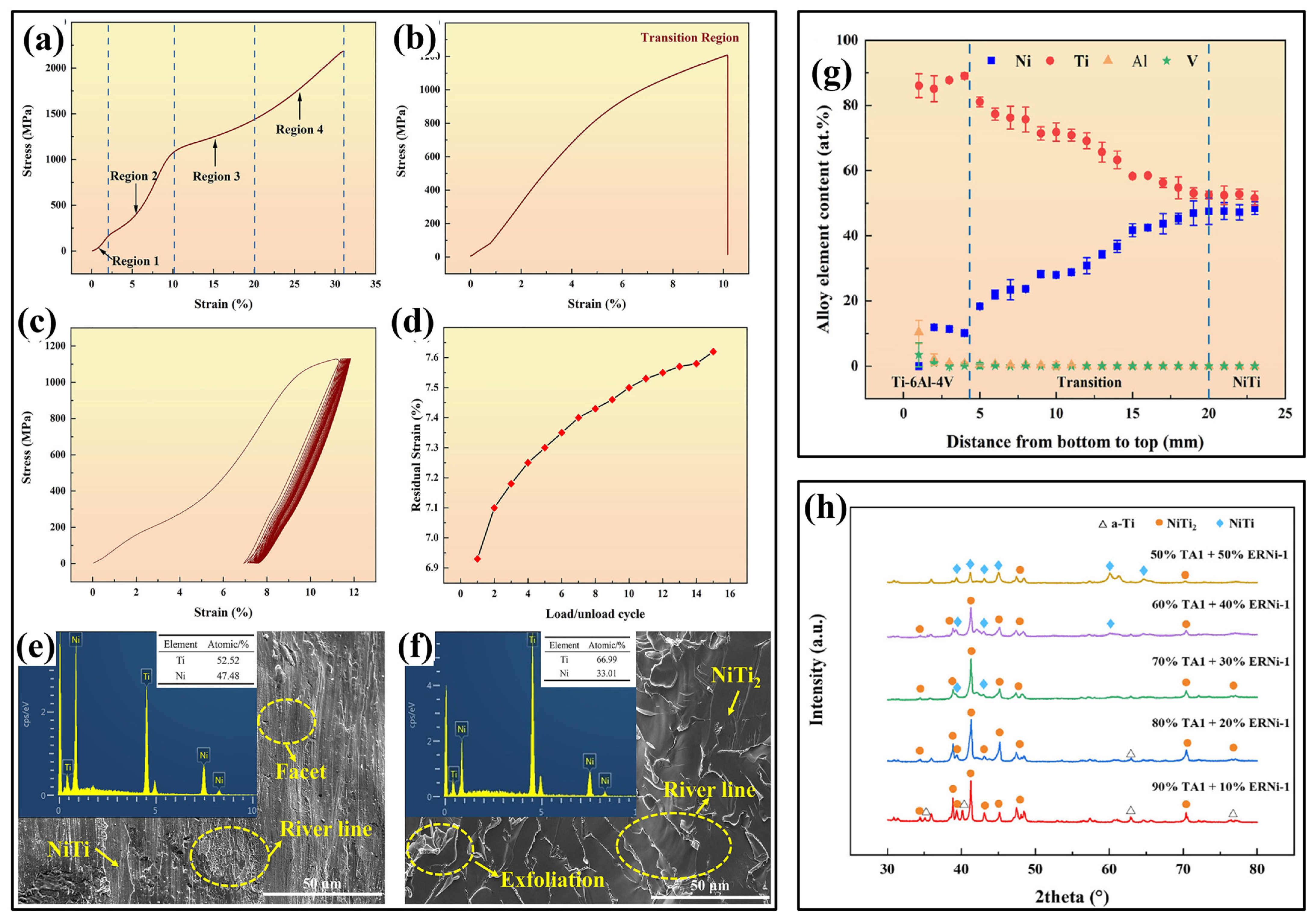

3.4. Functionally Graded Materials: Fabrication and Characterization Studies

4. Challenges

4.1. Porosity and Lack of Fusion

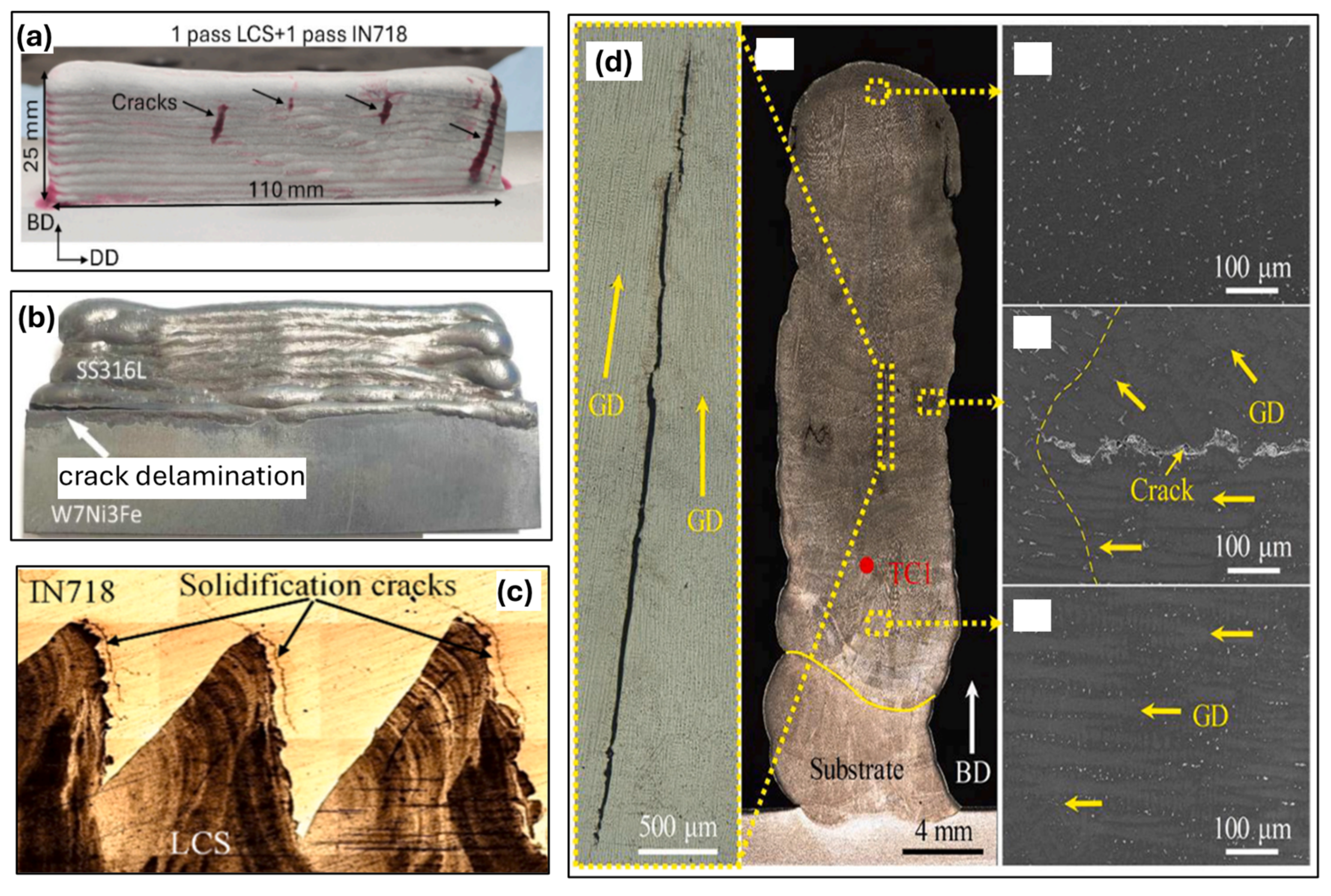

4.2. Residual Stress and Cracking

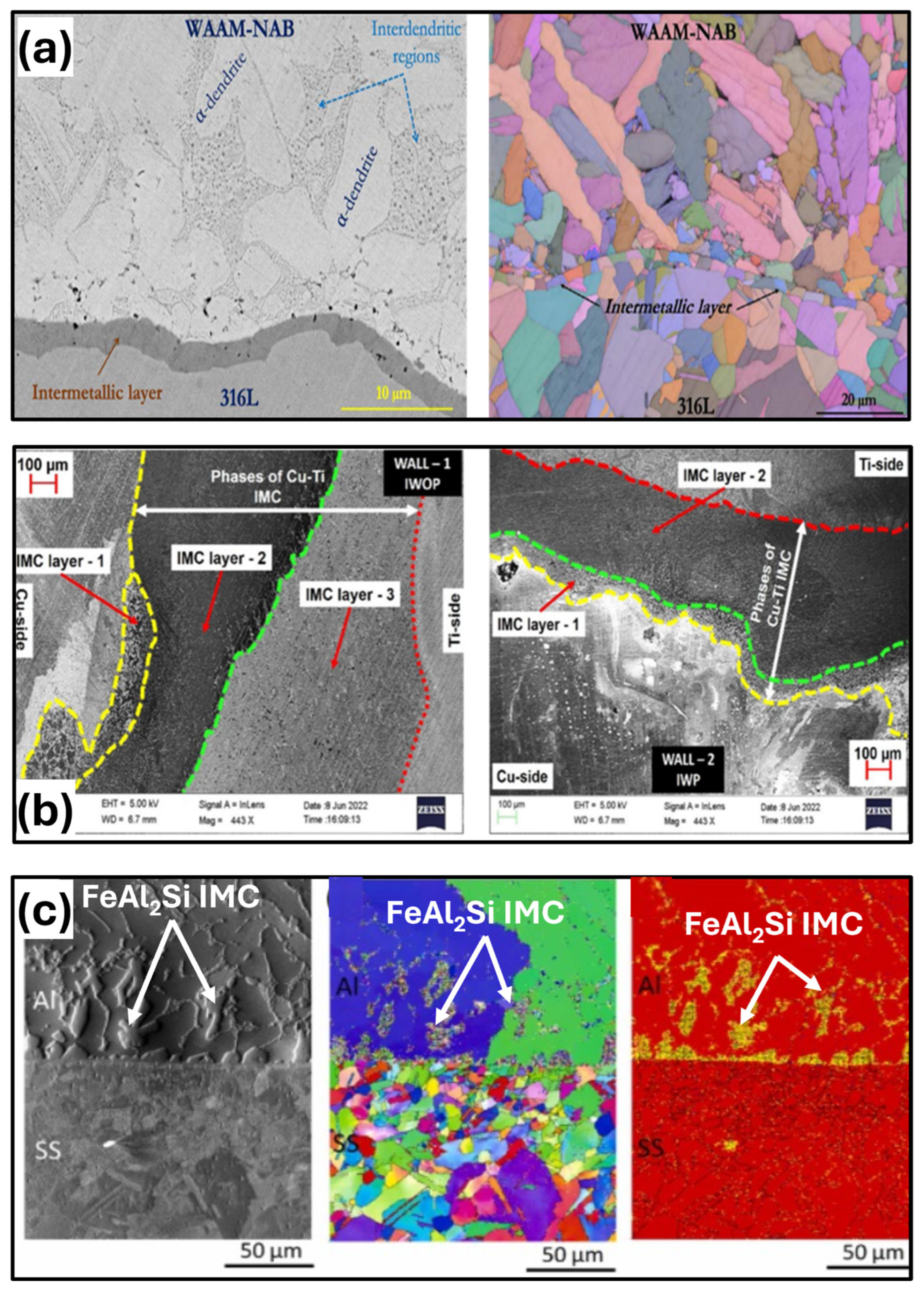

4.3. Material Compatibility Issues and Brittle Intermetallic (IMC) Phase Formation

4.4. Modeling and Simulation Challenges

4.5. Process Control and Automation

5. Future Directions

5.1. Development of Advanced Wire Feedstock Materials

- Designing novel wire compositions: Tailored feedstock materials with optimized elemental composition can mitigate issues related to phase segregation and metallurgical incompatibility.

- Development of functionally graded wires: Pre-alloyed or gradient-layered wire feedstock can provide controlled transitions between dissimilar materials, reducing sharp material property variations.

- Incorporation of nanoparticle reinforcements: Dispersion of nanoparticles in metal feedstock can enhance mechanical performance, improve wear resistance, and modify thermal conductivity properties.

5.2. In Situ Monitoring and Adaptive Process Control

- Real-time defect detection: Optical and infrared sensors, coupled with machine learning algorithms, can continuously monitor temperature gradients, porosity formation, and phase transformations.

- Closed-loop control systems: AI-driven process adjustments based on real-time data can optimize deposition parameters, reducing defects and ensuring metallurgical integrity.

- Advanced thermal management techniques: Utilizing localized heating or cooling mechanisms to control thermal cycling can minimize residual stress and prevent intermetallic brittleness.

5.3. Computational Modeling and Simulation Approaches

- CALPHAD-based thermodynamic modeling: Predicting phase formation and stability at multi-material interfaces can guide alloy selection and processing conditions.

- Finite Element Analysis for residual stress prediction: Computational simulations can help us understand stress distributions and optimize deposition strategies.

- Multiphysics simulation for heat and mass transfer: Combining computational fluid dynamics (CFD) with solidification modeling can provide insights into material flow and thermal history during the WAAM process.

5.4. Process Optimization for Enhanced Microstructure and Mechanical Properties

- Gradient optimization algorithms: Machine learning-based models can determine optimal composition transition profiles for functionally graded structures.

- Residual stress and distortion management: The high heating and cooling rates associated with DED processes, along with mismatch in thermal conductivity and thermal coefficient of expansion of materials used for multi-material structures, result in residual stresses, cracking, and distortion. Preheating and post-processing techniques, such as heat treatment, hot isostatic pressing (HIP) can assist in alleviating some of these issues. However, developing in-process control and mitigation approaches through optimal deposition path design, adaptive process parameters, and filler material selection is critical. This reduces the need for costly post-processing. Advanced multi-physics modeling of thermo-mechanical interactions is critical for understanding the fundamental causes of residual stress and distortions.

- Exploration of Multi-field Assisted wire-arc additive manufacturing: Existing studies have confirmed that arc additive manufacturing with the introduction of energy field-assisted technology can effectively suppress porosity defects and agglomeration of ceramic particles in the preparation of metal matrix composites [211]. Research on introduction of magnetic field, ultrasonic vibration (UV), laser, and deformation field in energy field-assisted WAAM needs to be explored and improved further to mitigate the microstructural defects and to enhance the mechanical properties of WAAMed multi-material structures.

5.5. Standardization

5.6. Expanding Application Scope and Industrial Adoption

- Renewable energy applications: WAAMed multi-material structures can enable the development of high-performance wind turbine components, hydrogen storage systems, and nuclear reactor components.

- Defense and space exploration: Functionally graded armor systems, propulsion components, and lightweight structural elements can benefit from WAAM’s scalability and material flexibility.

- Biomedical and healthcare innovations: Multi-material WAAM has the potential to produce customized implants, prosthetics, and bioactive scaffolds for tissue engineering.

6. Conclusions

- WAAM has emerged as a promising technique for producing bimetallic structures and functionally graded materials using various material combinations, including low carbon steel/stainless steel, stainless steel/maraging steel, steel/copper and copper alloys, steel/aluminum and aluminum alloys, steel/nickel alloys, steel/NAB, titanium/aluminum alloys, nickel/titanium alloys, and refractory alloy/steel or Inconel systems. Among these, materials such as low carbon steel, SS316L, Inconel 625, Inconel 718, and Ti-6Al-4V are most commonly used in WAAM-based multi-material fabrication.

- Studies have demonstrated that WAAM can produce BS and FGMs with defect-free interfaces, robust interfacial bonding, and tailorable mechanical properties, which is particularly advantageous for high tech engineering applications. However, their performance and integrity are significantly influenced by the mismatch in thermophysical properties (e.g., thermal conductivity, melting point), metallurgical characteristics (e.g., crystal structure), and elastic moduli between dissimilar materials. Addressing these issues is critical to achieving high-quality and durable structures for demanding applications.

- Despite the many advantages of WAAM, several challenges remain unresolved. Common defects such as cracks, delamination, intermetallic formation, residual stresses, and porosity must be carefully mitigated. In-depth studies are still needed to understand the fundamental mechanisms of defect formation and to develop effective post-processing strategies. Mitigating these problems requires precise control of process parameters, use of interlayers, thermodynamic modeling (e.g., CALPHAD), and advanced real-time process monitoring and automation for reliable, defect-free builds.

- To unlock the full potential of WAAM for multi-material fabrication, future research should focus on the development of advanced wire materials, integration of in situ monitoring systems, and optimization of process parameters. Additionally, the use of computational modeling, multi-physics simulation, and artificial intelligence (AI) or machine learning (ML) techniques will be essential for predicting microstructure and mechanical properties and enhancing quality, repeatability, and scalability of multi-material structures The establishment of comprehensive global standards will be indispensable for the widespread industrial adoption of multi-material WAAM in sectors such as renewable energy, defense, and biomedical engineering.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wei, C.; Zhang, Z.; Cheng, D.; Sun, Z.; Zhu, M.; Li, L. An overview of laser-based multiple metallic material additive manufacturing: From macro- to micro-scales. Int. J. Extrem. Manuf. 2020, 3, 012003. [Google Scholar] [CrossRef]

- Wang, D.; Liu, L.; Deng, G.; Deng, C.; Bai, Y.; Yang, Y.; Wu, W.; Chen, J.; Liu, Y.; Wang, Y.; et al. Recent progress on additive manufacturing of multi-material structures with laser powder bed fusion. Virtual Phys. Prototyp. 2022, 17, 329–365. [Google Scholar] [CrossRef]

- Wits, W.W.; Amsterdam, E. Graded structures by multi-material mixing in laser powder bed fusion. CIRP Ann. 2021, 70, 159–162. [Google Scholar] [CrossRef]

- Chen, P.-Y.; Novitskaya, E.; Lopez, M.I.; Sun, C.-Y.; McKittrick, J. Toward a better understanding of mineral microstructure in bony tissues. Bioinspired Biomim. Nanobiomater. 2014, 3, 71–84. [Google Scholar] [CrossRef]

- Katti, K.S.; Katti, D.R.; Mohanty, B. Biomimetic Lessons Learnt from Nacre. In Biomimetics Learning from Nature; IntechOpen Limited: London, UK, 2010; ISBN 978-953-307-025-4. [Google Scholar] [CrossRef]

- Cui, Y.; Li, J.; Yim, S.; Yamanaka, K.; Aoyagi, K.; Wang, H.; Chiba, A. Multi-material additive manufacturing of steel/Al alloy by controlling the liquid/solid interface in laser beam powder bed fusion. Addit. Manuf. 2024, 96, 104529. [Google Scholar] [CrossRef]

- Tisza, M.; Czinege, I. Comparative study of the application of steels and aluminium in lightweight production of automotive parts. Int. J. Lightweight Mater. Manuf. 2018, 1, 229–238. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2008, 1, 30–42. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Ma, R.; Xu, G.; Wang, W.; Liu, J. Laser additive manufacturing of bimetallic structure from Ti-6Al-4V to Ti-48Al-2Cr-2Nb via vanadium interlayer. Mater. Lett. 2020, 263, 127210. [Google Scholar] [CrossRef]

- Gradl, P.R.; Protz, C.S. Technology advancements for channel wall nozzle manufacturing in liquid rocket engines. Acta Astronaut. 2020, 174, 148–158. [Google Scholar] [CrossRef]

- Feng, Z. Managed by UT-Battelle for the Department of Energy Multi-Material Joining Challenges and Opportunities; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2012.

- Nazir, A.; Gokcekaya, O.; Billah, K.M.M.; Ertugrul, O.; Jiang, J.; Sun, J.; Hussain, S. Multi-material additive manufacturing: A systematic review of design, properties, applications, challenges, and 3D printing of materials and cellular metamaterials. Mater. Des. 2023, 226, 111661. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Zhang, Y.; Onuike, B. Additive manufacturing of bimetallic structures. Virtual Phys. Prototyp. 2022, 17, 256–294. [Google Scholar] [CrossRef]

- Ghanavati, R.; Naffakh-Moosavy, H. Additive manufacturing of functionally graded metallic materials: A review of experimental and numerical studies. J. Mater. Res. Technol. 2021, 13, 1628–1664. [Google Scholar] [CrossRef]

- Sanjeeviprakash, K.; Kannan, A.R.; Shanmugam, N.S. Additive manufacturing of metal-based functionally graded materials: Overview, recent advancements and challenges. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 1–35. [Google Scholar] [CrossRef]

- Reichardt, A.; Shapiro, A.A.; Otis, R.; Dillon, R.P.; Borgonia, J.P.; McEnerney, B.W.; Hosemann, P.; Beese, A.M. Advances in additive manufacturing of metal-based functionally graded materials. Int. Mater. Rev. 2021, 66, 1–29. [Google Scholar] [CrossRef]

- Feenstra, D.; Banerjee, R.; Fraser, H.; Huang, A.; Molotnikov, A.; Birbilis, N. Critical review of the state of the art in multi-material fabrication via directed energy deposition. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100924. [Google Scholar] [CrossRef]

- Meltio. 2025. Available online: https://meltio3d.com/applications/ (accessed on 20 June 2025).

- Zhang, B.; Jaiswal, P.; Rai, R.; Nelaturi, S. Additive Manufacturing of Functionally Graded Material Objects: A Review. J. Comput. Inf. Sci. Eng. 2018, 18, 138209. [Google Scholar] [CrossRef]

- Yan, L.; Chen, Y.; Liou, F. Additive manufacturing of functionally graded metallic materials using laser metal deposition. Addit. Manuf. 2020, 31, 100901. [Google Scholar] [CrossRef]

- Owoputi, A.O.; Inambao, F.L.; Ebhota, W.S. A Review of Functionally Graded Materials: Fabrication Processes and Applications. Int. J. Appl. Eng. Res. 2018, 13, 16141–16151. [Google Scholar]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on additive manufacturing of multi-material parts: Progress and challenges. J. Manuf. Mater. Process. 2022, 6, 4. [Google Scholar] [CrossRef]

- Dhanola, A.; Prasad, D.S. A comprehensive review of wire arc additive manufacturing for metallic functionally graded materials. Eng. Res. Express 2024, 6, 042501. [Google Scholar] [CrossRef]

- Scheinpflug, J.; Pfeiffenberger, M.; Damerau, A.; Schwarz, F.; Textor, M.; Lang, A.; Schulze, F. Journey into bone models: A review. Genes 2018, 9, 247. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Z.; Hao, L.; Huang, L.; Xin, C.; Wang, Y.; Bilotti, E.; Essa, K.; Zhang, H.; Li, Z.; et al. A Review on Functionally Graded Materials and Structures via Additive Manufacturing: From Multi--Scale Design to Versatile Functional Properties. Adv. Mater. Technol. 2020, 5, 1900981. [Google Scholar] [CrossRef]

- Mannan, S.; Knox, J.P.; Basu, S. Correlations between axial stiffness and microstructure of a species of bamboo. R. Soc. Open Sci. 2017, 4, 160412. [Google Scholar] [CrossRef] [PubMed]

- MedlinePlus Medical Encyclopedia Image, Tooth Anatomy. Available online: https://medlineplus.gov/ency/imagepages/1121.htm (accessed on 9 January 2025).

- Teacher, M.; Velu, R. Additive Manufacturing of Functionally Graded Materials: A Comprehensive Review. Int. J. Precis. Eng. Manuf. 2023, 25, 165–197. [Google Scholar] [CrossRef]

- Liu, Z.; Meyers, M.A.; Zhang, Z.; Ritchie, R.O. Functional gradients and heterogeneities in biological materials: Design principles, functions, and bioinspired applications. Prog. Mater. Sci. 2017, 88, 467–498. [Google Scholar] [CrossRef]

- Silva, R.F.; Coelho, P.G.; Gustavo, C.V.; Almeida, C.J.; Farias, F.W.C.; Duarte, V.R.; Xavier, J.; Esteves, M.B.; Conde, F.M.; Cunha, F.G.; et al. Functionally Graded Materials and Structures: Unified Approach by Optimal Design, Metal Additive Manufacturing, and Image-Based Characterization. Materials 2024, 17, 4545. [Google Scholar] [CrossRef]

- Alkunte, S.; Fidan, I.; Naikwadi, V.; Gudavasov, S.; Ali, M.A.; Mahmudov, M.; Hasanov, S.; Cheepu, M. Advancements and Challenges in Additively Manufactured Functionally Graded Materials: A Comprehensive Review. J. Manuf. Mater. Process. 2024, 8, 23. [Google Scholar] [CrossRef]

- Saleh, B.; Jiang, J.; Fathi, R.; Al-Hababi, T.; Xu, Q.; Wang, L.; Song, D.; Ma, A. 30 Years of functionally graded materials: An overview of manufacturing methods, Applications and Future Challenges. Compos. Part B Eng. 2020, 201, 108376. [Google Scholar] [CrossRef]

- Hamrani, A.; Bouarab, F.Z.; Agarwal, A.; Ju, K.; Akbarzadeh, H. Advancements and applications of multiple wire processes in additive manufacturing: A comprehensive systematic review. Virtual Phys. Prototyp. 2023, 18, e2273303. [Google Scholar] [CrossRef]

- Verma, A.; Kapil, A.; Klobčar, D.; Sharma, A. A Review on Multiplicity in Multi-Material Additive Manufacturing: Process, Capability, Scale, and Structure. Materials 2023, 16, 5246. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, H.; Sun, D.; Liu, W. Fabrication of Multi-Material Components by Wire Arc Additive Manufacturing. Coatings 2022, 12, 1683. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Kusekar, S.K.; Pirani, M.; Birajdar, V.D.; Borkar, T.; Farahani, S. Toward the Progression of Sustainable Structural Batteries: State-of-the-Art Review. SAE Int. J. Sustain. Transp. Energy Environ. Policy 2025, 5. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Tian, X.; Zhao, Z.; Wang, H.; Liu, X.; Song, X. Progresses on the additive manufacturing of functionally graded metallic materials. J. Alloys Compd. 2023, 960, 170687. [Google Scholar] [CrossRef]

- Wei, C.; Li, L. Recent progress and scientific challenges in multi-material additive manufacturing via laser-based powder bed fusion. Virtual Phys. Prototyp. 2021, 16, 347–371. [Google Scholar] [CrossRef]

- Jiang, W.; Guan, F.; Li, G.; Jiang, H.; Zhu, J.; Fan, Z. Processing of Al/Cu bimetal via a novel compound casting method. Mater. Manuf. Process. 2019, 34, 1016–1025. [Google Scholar] [CrossRef]

- Rogachev, S.O.; Andreev, V.A.; Yusupov, V.S.; Bondareva, S.A.; Khatkevich, V.M.; Nikolaev, E.V. Effect of Rotary Forging on Microstructure Evolution and Mechanical Properties of Aluminum Alloy/Copper Bimetallic Material. Met. Mater. Int. 2022, 28, 1038–1046. [Google Scholar] [CrossRef]

- Sun, Z.; Karppi, R. The application of electron beam welding for the joining of dissimilar metals: An overview. J. Mater. Process. Technol. 1996, 59, 257–267. [Google Scholar] [CrossRef]

- Chen, H.-C.; Pinkerton, A.J.; Li, L. Fibre laser welding of dissimilar alloys of Ti-6Al-4V and Inconel 718 for aerospace applications. Int. J. Adv. Manuf. Technol. 2011, 52, 977–987. [Google Scholar] [CrossRef]

- Chu, Q.; Zhang, M.; Li, J.; Yan, C. Experimental and numerical investigation of microstructure and mechanical behavior of titanium/steel interfaces prepared by explosive welding. Mater. Sci. Eng. A 2017, 689, 323–331. [Google Scholar] [CrossRef]

- Razzaq, S.; Pan, Z.; Li, H.; Ringer, S.; Liao, X. Joining dissimilar metals by additive manufacturing: A review. J. Mater. Res. Technol. 2024, 31, 2820–2845. [Google Scholar] [CrossRef]

- Fazel-Najafabadi, M.; Kashani-Bozorg, S.; Zarei-Hanzaki, A. Joining of CP-Ti to 304 stainless steel using friction stir welding technique. Mater. Des. 2010, 31, 4800–4807. [Google Scholar] [CrossRef]

- Celik, S.; Cakir, R. Effect of Friction Stir Welding Parameters on the Mechanical and Microstructure Properties of the Al-Cu Butt Joint. Metals 2016, 6, 133. [Google Scholar] [CrossRef]

- Feng, J.; Songbai, X.; Wei, D. Reliability studies of Cu/Al joints brazed with Zn–Al–Ce filler metals. Mater. Des. 2012, 42, 156–163. [Google Scholar] [CrossRef]

- Hong, I.-T.; Koo, C.-H. Microstructural evolution and shear strength of brazing C103 and Ti–6Al–4V using Ti–20Cu–20Ni–20Zr (wt.%) filler metal. Int. J. Refract. Met. Hard Mater. 2006, 24, 247–252. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, G.; Jin, H.; Shi, Z.; Qiao, G. Intermetallic phase formation in diffusion-bonded Cu/Al laminates. J. Mater. Sci. 2011, 46, 2467–2473. [Google Scholar] [CrossRef]

- Elrefaey, A.; Tillmann, W. Solid state diffusion bonding of titanium to steel using a copper base alloy as interlayer. J. Mech. Work. Technol. 2009, 209, 2746–2752. [Google Scholar] [CrossRef]

- Zakipour, S.; Halvaee, A.; Amadeh, A.A.; Samavatian, M.; Khodabandeh, A. An investigation on microstructure evolution and mechanical properties during transient liquid phase bonding of stainless steel 316L to Ti–6Al–4V. J. Alloys Compd. 2015, 626, 269–276. [Google Scholar] [CrossRef]

- Norouzi, E.; Atapour, M.; Shamanian, M.; Allafchian, A. Effect of bonding temperature on the microstructure and mechanical properties of Ti-6Al-4V to AISI 304 transient liquid phase bonded joint. Mater. Des. 2016, 99, 543–551. [Google Scholar] [CrossRef]

- Martinsen, K.; Hu, S.; Carlson, B. Joining of dissimilar materials. CIRP Ann. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Naebe, M.; Shirvanimoghaddam, K. Functionally graded materials: A review of fabrication and properties. Appl. Mater. Today 2016, 5, 223–245. [Google Scholar] [CrossRef]

- Bergmann, C.P.; Modupe, R.; Esther, M.; Akinlabi, T. Topics in Mining, Metallurgy and Materials Engineering Series Editor: Functionally Graded Materials. Available online: http://www.springer.com/series/11054 (accessed on 22 May 2025).

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Kieback, B.; Neubrand, A.; Riedel, H. Processing techniques for functionally graded materials. Mater. Sci. Eng. A 2003, 362, 81–106. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2017; Additive Manufacturing—General Principles—Terminology. ASTM International/International Organization for Standardization: Geneva, Switzerland, 2017.

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in metal additive manufacturing: A review of common processes, industrial applications, and current challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Sampaio, R.; Pragana, J.; Bragança, I.; Silva, C.; Nielsen, C.; Martins, P. Modelling of wire-arc additive manufacturing—A review. Adv. Ind. Manuf. Eng. 2023, 6, 100121. [Google Scholar] [CrossRef]

- Özel, T.; Shokri, H.; Loizeau, R. A Review on Wire-Fed Directed Energy Deposition Based Metal Additive Manufacturing. J. Manuf. Mater. Process. 2023, 7, 45. [Google Scholar] [CrossRef]

- Costello, S.C.; Cunningham, C.R.; Xu, F.; Shokrani, A.; Dhokia, V.; Newman, S.T. The state-of-the-art of wire arc directed energy deposition (WA-DED) as an additive manufacturing process for large metallic component manufacture. Int. J. Comput. Integr. Manuf. 2023, 36, 469–510. [Google Scholar] [CrossRef]

- Abuabiah, M.; Mbodj, N.G.; Shaqour, B.; Herzallah, L.; Juaidi, A.; Abdallah, R.; Plapper, P. Advancements in Laser Wire-Feed Metal Additive Manufacturing: A Brief Review. Materials 2023, 16, 2030. [Google Scholar] [CrossRef]

- Osipovich, K.; Kalashnikov, K.; Chumaevskii, A.; Gurianov, D.; Kalashnikova, T.; Vorontsov, A.; Zykova, A.; Utyaganova, V.; Panfilov, A.; Nikolaeva, A.; et al. Wire-Feed Electron Beam Additive Manufacturing: A Review. Metals 2023, 13, 279. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A Review of the Recent Developments and Challenges in Wire Arc Additive Manufacturing (WAAM) Process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Moschinger, M.; Vauderwange, T.; Enzinger, N. Plasma wire arc additive manufacturing and its influence on high-carbon steel substrate properties. Weld. World 2024, 68, 1999–2011. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Tiwari, A.; Dongre, M. Wire arc additive manufacturing of metals: A review on processes, materials and their behaviour. Mater. Chem. Phys. 2023, 294, 126988. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Jadhav, S.; Karim, A.; Kim, D.B. Bimetallic structure of TZM and NbZr1 fabricated by wire-based directed energy deposition. Mater. Lett. 2024, 356, 135605. [Google Scholar] [CrossRef]

- Jadhav, S.; Tanvir, G.; Karim, A.; Islam, S.; Noh, S.D.; Kim, D.B. Microstructures and mechanical behaviour of bimetallic structures of tungsten alloy (90WNiFe) and nickel alloy (In625) fabricated by wire-arc directed energy deposition. Virtual Phys. Prototyp. 2024, 19, e2370957. [Google Scholar] [CrossRef]

- Karim, A.; Jadhav, S.; Kannan, R.; Pierce, D.; Lee, Y.; Nandwana, P.; Kim, D.B. Investigating stainless steel/aluminum bimetallic structures fabricated by cold metal transfer (CMT)-based wire-arc directed energy deposition. Addit. Manuf. 2024, 81, 104015. [Google Scholar] [CrossRef]

- Karim, A.; Islam, S.; Tanvir, G.; Jadhav, S.; Kim, Y.-M.; Jeon, Y.; Kim, D.B. Wire-arc directed energy deposition of steel onto tungsten substrate: Fabricability and mechanical performance of synergistic structures. Virtual Phys. Prototyp. 2025, 20, e2443578. [Google Scholar] [CrossRef]

- Jadhav, S.; Bajestani, M.S.; Islam, S.; Karim, A.; Kim, C.J.; Lee, H.-J.; Cho, Y.T.; Kim, D.B. Materials characterization of Ti6Al4V to NbZr1 bimetallic structure fabricated by wire arc additive manufacturing. Mater. Today Commun. 2023, 36, 106934. [Google Scholar] [CrossRef]

- Kannan, R.; Pierce, D.; Nayir, S.; Ahsan, R.U.; Kim, D.; Unocic, K.; Lee, Y.; Jadhav, S.; Karim, A.; Nandwana, P. Wire directed energy deposition of steel-aluminum structures using cold metal transfer process. J. Mater. Res. Technol. 2024, 29, 4537–4546. [Google Scholar] [CrossRef]

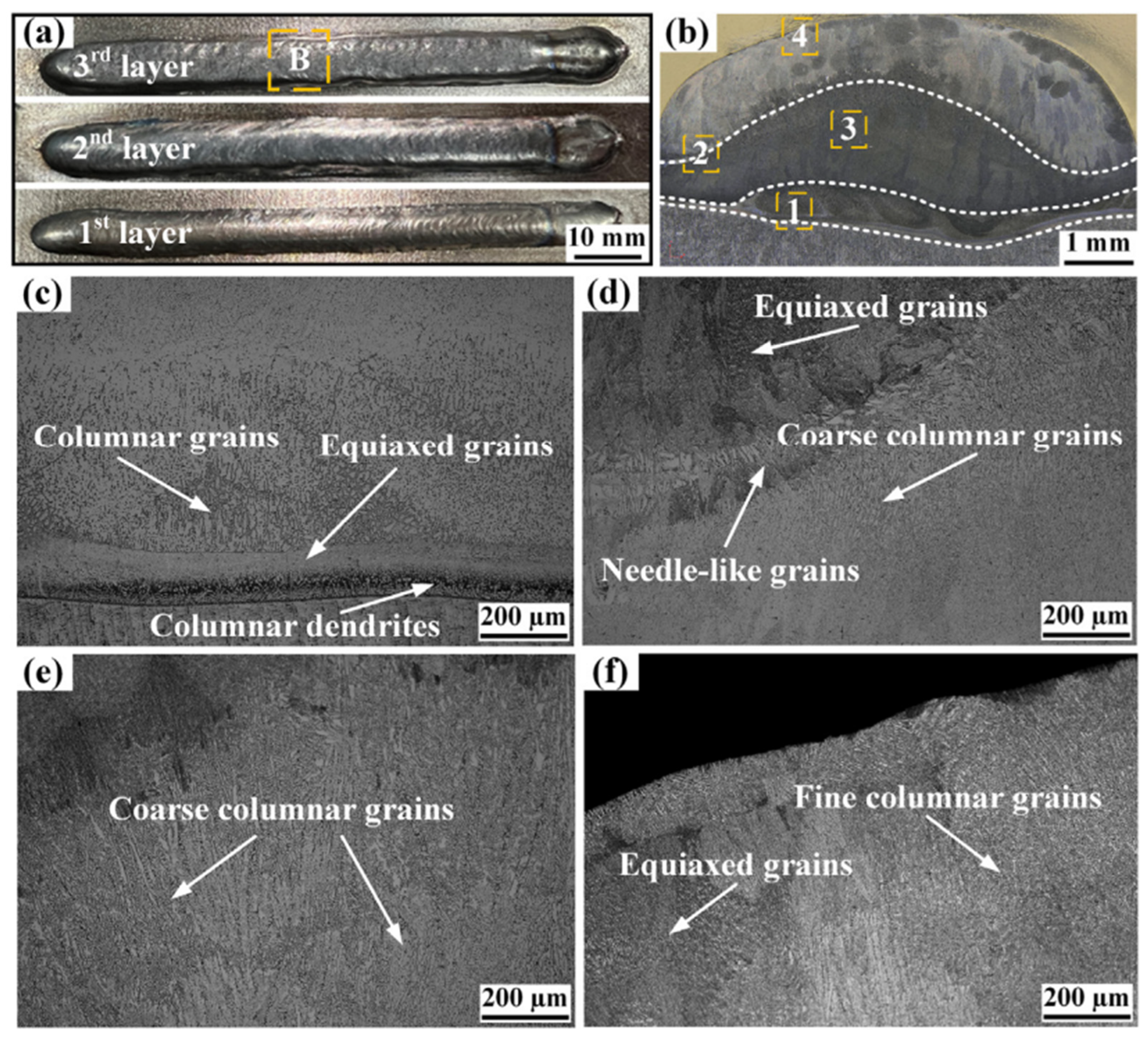

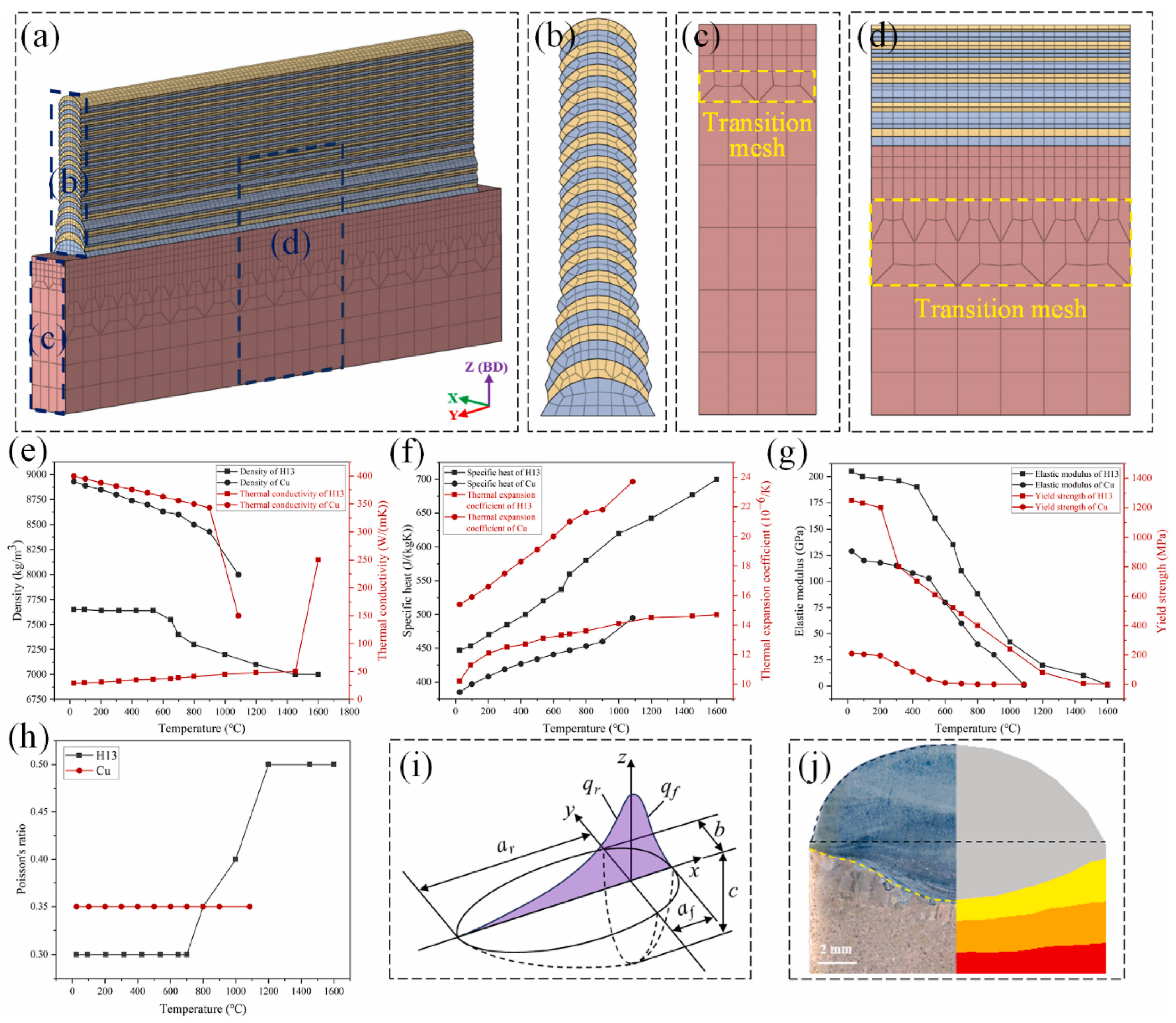

- Du, X.; Wei, Y.; Guo, K.; Long, J.; Liu, X.; Zhao, W.; Liu, R. Interface microstructure and evolution mechanism of wire arc additively manufactured H13 steel-copper hybrid components. J. Mater. Res. Technol. 2025, 35, 4929–4944. [Google Scholar] [CrossRef]

- Zhang, W.; Lei, Y.; Meng, W.; Ma, Q.; Yin, X.; Guo, L. Effect of Deposition Sequence on Microstructure and Properties of 316L and Inconel 625 Bimetallic Structure by Wire Arc Additive Manufacturing. J. Mater. Eng. Perform. 2021, 30, 8972–8983. [Google Scholar] [CrossRef]

- Xu, N.; Shen, J.; Hu, S.; Tian, Y.; Bi, J. Bimetallic structure of Ti6Al4V and Al6.21Cu fabricated by cold metal transfer additive manufacturing via Nb interlayer added by TIG. Mater. Lett. 2021, 302, 130397. [Google Scholar] [CrossRef]

- Munusamy, S.; Jerald, J. Effect of build orientation on the microstructure and mechanical properties of wire arc additive manufactured grade 91 steel/monel 400 bimetallic components. Vacuum 2024, 227, 113429. [Google Scholar] [CrossRef]

- Tian, Y.; Shen, J.; Hu, S.; Gou, J.; Cui, Y. Effects of cold metal transfer mode on the reaction layer of wire and arc additive-manufactured Ti-6Al-4V/Al-6.25Cu dissimilar alloys. J. Mater. Sci. Technol. 2021, 74, 35–45. [Google Scholar] [CrossRef]

- Raut, L.P.; Taiwade, R.V. Microstructure and Mechanical Properties of Wire Arc Additively Manufactured Bimetallic Structure of Austenitic Stainless Steel and Low Carbon Steel. J. Mater. Eng. Perform. 2022, 31, 8531–8541. [Google Scholar] [CrossRef]

- Squires, L.; Roberts, E.; Bandyopadhyay, A. Radial bimetallic structures via wire arc directed energy deposition-based additive manufacturing. Nat. Commun. 2023, 14, 3544. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, Z.; Pan, Z.; Carpenter, K.; Wang, T.; Ding, D.; Van Duin, S.; Li, H. Enhanced interface strength in steel-nickel bimetallic component fabricated using wire arc additive manufacturing with interweaving deposition strategy. J. Mater. Sci. Technol. 2020, 52, 226–234. [Google Scholar] [CrossRef]

- Marefat, F.; Kapil, A.; Banaee, S.A.; Van Rymenant, P.; Sharma, A. Evaluating shielding gas-filler wire interaction in bi-metallic wire arc additive manufacturing (WAAM) of creep resistant steel-stainless steel for improved process stability and build quality. J. Manuf. Process. 2023, 88, 110–124. [Google Scholar] [CrossRef]

- Ozaner, O.C.; Klobčar, D.; Sharma, A. Machining Strategy Determination for Single- and Multi-Material Wire and Arc Additive Manufactured Thin-Walled Parts. Materials 2023, 16, 2055. [Google Scholar] [CrossRef] [PubMed]

- Suárez, A.; Panfilo, A.; Aldalur, E.; Veiga, F.; Gomez, P. Microstructure and mechanical properties of mild steel-stainless steel bimetallic structures built using Wire Arc Additive Manufacturing. CIRP J. Manuf. Sci. Technol. 2022, 38, 769–773. [Google Scholar] [CrossRef]

- Marefat, F.; De Pauw, J.; Kapil, A.; Chernovol, N.; Van Rymenant, P.; Sharma, A. Design strategies for bi-metallic additive manufacturing in the context of wire and arc directed energy deposition. Mater. Des. 2022, 215, 110496. [Google Scholar] [CrossRef]

- Pattanayak, S.; Sahoo, S.K.; Sahoo, A.K. An approach to tunable advanced high-strength steel fabrication through multi-wire arc additive manufacturing (M-WAAM). J. Manuf. Process. 2025, 133, 705–722. [Google Scholar] [CrossRef]

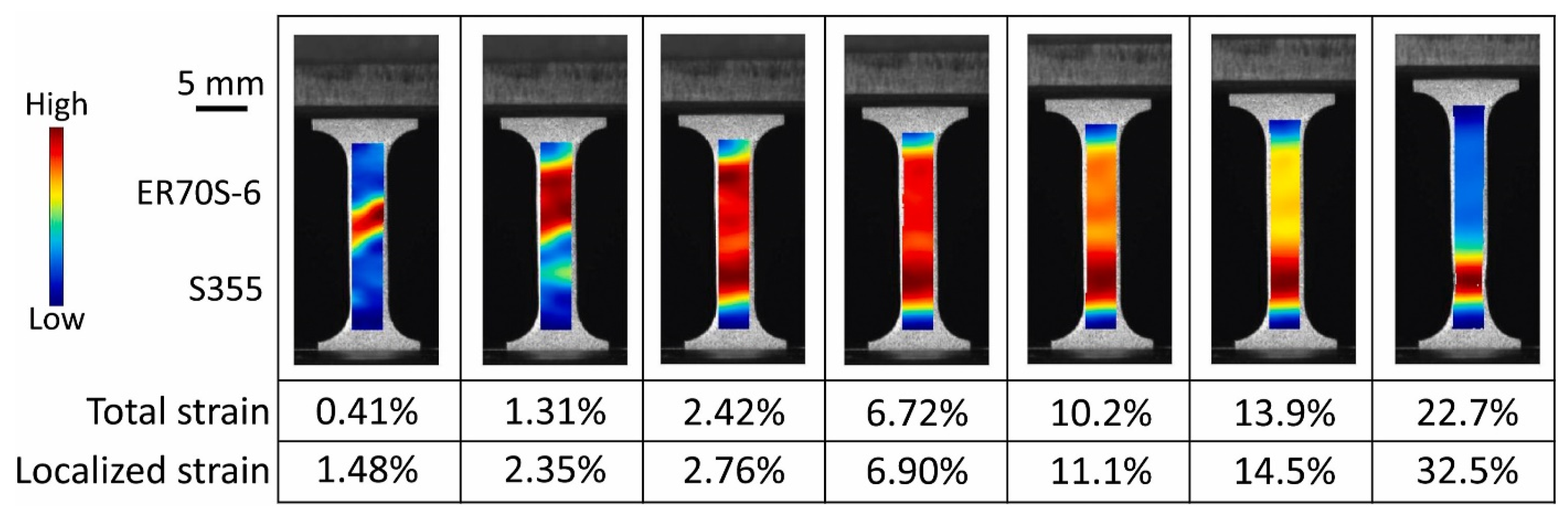

- Zhai, W.; Guo, Y.; Aishwarya; Canturri, C.; Shandro, R.; Zhou, W. Wire arc additive manufacturing of ER70S-6/S355 bimetal component. Mater. Sci. Eng. A 2024, 900, 146498. [Google Scholar] [CrossRef]

- Yadav, A.; Srivastava, M.; Jain, P.K. Design and fabrication of wire arc additive manufacturing setup and enhanced tailored properties of dissimilar steel additively deposited by WAAM process. Structures 2025, 72, 108228. [Google Scholar] [CrossRef]

- Kumar, A.; Maji, K.; Samanta, A. Fabrication and characterization of austenite-ferrite stainless steel bimetals by twin wire arc additive manufacturing. J. Adhes. Sci. Technol. 2024, 39, 708–733. [Google Scholar] [CrossRef]

- Thirugnanasambandam, A.; Subramaniyan, M.K.; Elumalai, V. Fabrication of Bimetallic Structure (SS 316L/SS 308L) via Wire + Arc Additive Manufacturing: A Detailed Characterization of Interface. J. Mater. Eng. Perform. 2025, 34, 16297–16308. [Google Scholar] [CrossRef]

- Singh, S.; Jinoop, A.; Palani, I.; Paul, C.; Tomar, K.; Prashanth, K. Microstructure and mechanical properties of NiTi-SS bimetallic structures built using Wire Arc Additive Manufacturing. Mater. Lett. 2021, 303, 130499. [Google Scholar] [CrossRef]

- Aslam, M.; Sahoo, C.K. Development of hard and wear-resistant SiC-AISI304 stainless steel clad layer on low carbon steel by GMAW process. Mater. Today Commun. 2023, 36, 106444. [Google Scholar] [CrossRef]

- Gürol, U.; Turgut, B.; Güleçyüz, N.; DİLİBAL, S.; Koçak, M. Development of Multi-Material Components Via Robotic Wire Arc additive Manufacturing. Int. J. 3D Print. Technol. Digit. Ind. 2021, 5, 721–729. [Google Scholar] [CrossRef]

- Badoniya, P.; Srivastava, M.; Jain, P.K. Microstructural Characteristics and Mechanical Performance of WAAM Fabricated LCS–SS 316L Bimetallic Structure Under Forced Cooling. J. Mater. Eng. Perform. 2025, 1–15. [Google Scholar] [CrossRef]

- Tyagi, S.; Balla, S.K.; Manjaiah, M.; Aranas, C. Microstructure and mechanical properties of stainless steel 316L-Inconel 625 bimetallic structure fabricated by laser wire direct energy deposition. J. Mater. Res. Technol. 2024, 33, 8361–8371. [Google Scholar] [CrossRef]

- Ahsan, R.; Fan, X.; Seo, G.-J.; Ji, C.; Noakes, M.; Nycz, A.; Liaw, P.K.; Kim, D.B. Microstructures and mechanical behavior of the bimetallic additively-manufactured structure (BAMS) of austenitic stainless steel and Inconel 625. J. Mater. Sci. Technol. 2021, 74, 176–188. [Google Scholar] [CrossRef]

- Wu, B.; Shi, H.; Liu, J.; Zhang, B.; Zhou, T.; Pan, Z.; Li, H. Selective crack propagation in steel-nickel component printed by wire arc directed energy deposition. Mater. Des. 2024, 237, 112541. [Google Scholar] [CrossRef]

- Kumar, A.; Maji, K. Microstructure and Chemical Composition Analysis of Double Wire Arc Additive Manufactured Bimetallic Structure. J. Mater. Eng. Perform. 2021, 30, 5413–5425. [Google Scholar] [CrossRef]

- Sridar, S.; Klecka, M.A.; Xiong, W. Interfacial characteristics of P91 steel—Inconel 740H bimetallic structure fabricated using wire-arc additive manufacturing. J. Mech. Work. Technol. 2022, 300, 117396. [Google Scholar] [CrossRef]

- Hwang, Y.-H.; Lee, C.-M.; Kim, D.-H. The Effects of the Variable-Pressure Rolling of a Wire Arc Additively Manufactured Inconel625-SS308L Bimetallic Structure. Appl. Sci. 2023, 13, 10187. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Y.; Du, M.; Zhang, S.; Lei, L. Experimental Characterization and Microstructural Evaluation of Silicon Bronze-Alloy Steel Bimetallic Structures by Additive Manufacturing. Met. Mater. Trans. A 2021, 52, 4664–4674. [Google Scholar] [CrossRef]

- Liu, J.; Miao, Y.; Wang, Z.; Zhao, Y.; Wu, Y.; Li, C. Improved interfacial strength in bimetallic additive manufacturing of aluminum bronze/steel by controlling interface melting. J. Manuf. Process. 2024, 121, 333–342. [Google Scholar] [CrossRef]

- Mishra, A.; Paul, A.R.; Mukherjee, M.; Singh, R.K. Bimetallic Structure of Ti6Al4V/IN718 with CuSi Interlayer for Wire-Arc Directed Energy Deposition Process. Met. Mater. Int. 2023, 29, 2331–2344. [Google Scholar] [CrossRef]

- Cai, X.; Wang, Z.; Dong, L.; Yang, M.; Zhou, J.; Xue, F. Advanced mechanical properties of nickel--aluminum bronze/steel composite structure prepared by wire--arc additive manufacturing. Mater. Des. 2022, 221, 110969. [Google Scholar] [CrossRef]

- Singh, S.; Demidova, E.; Resnina, N.; Belyaev, S.; Iyamperumal, P.A.; Paul, C.P.; Prashanth, K.G. NiTi–Cu Bimetallic Structure Fabrication through Wire Arc Additive Manufacturing. Materials 2024, 17, 1006. [Google Scholar] [CrossRef]

- Tomar, B.; Shiva, S. Microstructure evolution in steel/copper graded deposition prepared using wire arc additive manufacturing. Mater. Lett. 2022, 328, 133217. [Google Scholar] [CrossRef]

- Chen, L.; Oliveira, J.P.; Yan, X.; Pang, B.; Ke, W.; Shen, J.; Teshome, F.B.; Schell, N.; Zhou, N.; Peng, B.; et al. Microstructure and Phase Transformation Behavior of NiTiCu Shape Memory Alloys Produced Using Twin-Wire Arc Additive Manufacturing. Addit. Manuf. Front. 2024, 3, 200132. [Google Scholar] [CrossRef]

- Munusamy, S.; Jerald, J. Impact of Laser Shock Peening on Mechanical Properties of Wire Arc Additive Manufactured Grade 91 Steel and Monel-400 Bimetallic Components. Met. Mater. Int. 2024, 31, 36–48. [Google Scholar] [CrossRef]

- Tian, Y.; Shen, J.; Hu, S.; Chen, X.; Cai, Y.; Han, J. Effect of deposition layer on microstructure of Ti–Al bimetallic structures fabricated by wire and arc additive manufacturing. Sci. Technol. Weld. Join. 2022, 27, 22–32. [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, X.; Chen, L.; Jiang, X.; Liao, H. Deformation Characteristics and Mechanical Properties of Ti/Al Bimetallic Composite Materials Fabricated by Wire Plus Arc Additive Manufacturing. J. Wuhan Univ. Technol. Sci. Ed. 2023, 38, 885–892. [Google Scholar] [CrossRef]

- Ozlati, A.; Movahedi, M.; Ramezani, H. Wire arc additive manufacturing of stainless steel/aluminum bi-metal using roll-bonded transition joint. Manuf. Lett. 2025, 43, 6–11. [Google Scholar] [CrossRef]

- Liu, J.; Miao, Y.; Wang, Z.; Zhao, Y.; Wu, Y.; Li, C. Effect of heat treatment on microstructure and properties of additively manufactured aluminum bronze-steel bimetallic structures. Mater. Charact. 2024, 207, 113462. [Google Scholar] [CrossRef]

- Tanvir, G.; Karim, A.; Jadhav, S.; Islam, S.; Kim, Y.-M.; Ryu, H.J.; Kim, D.B. Effect of hot isostatic pressing on porosity of wire-arc directed energy deposited TZM/NbZr1 bimetallic structure. Virtual Phys. Prototyp. 2024, 19, e2404989. [Google Scholar] [CrossRef]

- Hauser, T.; Reisch, R.T.; Seebauer, S.; Parasar, A.; Kamps, T.; Casati, R.; Volpp, J.; Kaplan, A.F. Multi-Material Wire Arc Additive Manufacturing of low and high alloyed aluminium alloys with in-situ material analysis. J. Manuf. Process. 2021, 69, 378–390. [Google Scholar] [CrossRef]

- Azar, A.S.; Lekatou, A.; Sunding, M.F.; Graff, J.S.; Tzima, N.; Diplas, S. Corrosion performance and degradation mechanism of a bi-metallic aluminum structure processed by wire-arc additive manufacturing. NPJ Mater. Degrad. 2021, 5, 1–15. [Google Scholar] [CrossRef]

- Han, S.; Zhang, Z.; Liu, Z.; Zhang, H.; Xue, D. Investigation of the microstructure and mechanical performance of bimetal components fabricated using CMT-based wire arc additive manufacturing. Mater. Res. Express 2020, 7, 116525. [Google Scholar] [CrossRef]

- Motwani, A.; Kumar, A.; Puri, Y.; Lautre, N.K. Mechanical characteristics and microstructural investigation of CMT deposited bimetallic SS316LSi-IN625 thin wall for WAAM. Weld. World 2023, 67, 967–980. [Google Scholar] [CrossRef]

- Mahmoudiniya, M.; Thorr, A.-S.; Petrov, R.H.; Hermans, M.J.; Kestens, L.A. Wire arc additive manufacturing of Ni Fe alloy/ductile cast iron bimetallic structure; phase transformations, microstructure and crystallographic texture. Mater. Charact. 2025, 220, 114650. [Google Scholar] [CrossRef]

- He, T.; Yu, S.; Runzhen, Y.; Bo, Z. Oscillating wire arc additive manufacture of rocket motor bimetallic conical shell. Int. J. Adv. Manuf. Technol. 2022, 119, 6601–6612. [Google Scholar] [CrossRef]

- Tomar, B.; Shiva, S. Analysis of AISI 316L-Ti Graded Deposition Fabricated by Wire and Arc Additive Manufacturing. Trans. Indian Inst. Met. 2024, 77, 279–285. [Google Scholar] [CrossRef]

- Abe, T.; Sasahara, H. Dissimilar metal deposition with a stainless steel and nickel-based alloy using wire and arc-based additive manufacturing. Precis. Eng. 2016, 45, 387–395. [Google Scholar] [CrossRef]

- Gürol, U.; Turgut, B.; Kumek, H.; Dilibal, S.; Koçak, M. Fabrication and Characterization of Wire Arc Additively Manufactured Ferritic-Austenitic Bimetallic Structure. Met. Mater. Int. 2024, 30, 1342–1355. [Google Scholar] [CrossRef]

- Gürol, U.; DİLİBAL, S.; Turgut, B.; Baykal, H.; Kümek, H.; Koçak, M. Manufacturing and characterizaton of waam-based bimetallic cutting tool. Int. J. 3D Print. Technol. Digit. Ind. 2022, 6, 548–555. [Google Scholar] [CrossRef]

- Dharmendra, C.; Shakerin, S.; Ram, G.J.; Mohammadi, M. Wire-arc additive manufacturing of nickel aluminum bronze/stainless steel hybrid parts—Interfacial characterization, prospects, and problems. Materialia 2020, 13, 100834. [Google Scholar] [CrossRef]

- Rani, K.U.; Kumar, R.; Mahapatra, M.M.; Mulik, R.S.; Świerczyńska, A.; Fydrych, D.; Pandey, C. Wire Arc Additive Manufactured Mild Steel and Austenitic Stainless Steel Components: Microstructure, Mechanical Properties and Residual Stresses. Materials 2022, 15, 7094. [Google Scholar] [CrossRef]

- Kannan, A.R.; Kumar, S.M.; Pramod, R.; Kumar, N.P.; Shanmugam, N.S.; Palguna, Y. Microstructure and mechanical properties of wire arc additive manufactured bi-metallic structure. Sci. Technol. Weld. Join. 2020, 26, 47–57. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Wang, L.; Su, L.; Carpenter, K.; Wang, J.; Wang, R.; Li, H. In-situ dual wire arc additive manufacturing of NiTi-coating on Ti6Al4V alloys: Microstructure characterization and mechanical properties. Surf. Coat. Technol. 2020, 386, 125439. [Google Scholar] [CrossRef]

- Liu, K.; Yan, Z.; Pan, R.; Wang, X.; Wang, F.; Chen, S. Interfacial bonding and microstructural evolution in Inconel-copper bimetallic structures fabricated by directed energy deposition-arc. Mater. Sci. Eng. A 2024, 898, 146381. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, X.; Shen, X.; Tan, Z. Microstructure and corrosion resistance in bimetal materials of Q345 and 308 steel wire-arc additive manufacturing. Crystals 2021, 11, 1401. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, W.; Xu, J.; Zhu, J.; Ma, Z.; Shi, J.; Zhou, Q. Fabrication of TC4 and Ti48Al bimetals by plasma arc additive manufacturing: Microstructure and mechanical properties. J. Mater. Res. Technol. 2024, 32, 2482–2494. [Google Scholar] [CrossRef]

- Segovia-Guerrero, L.; Baladés, N.; Attard, B.; De Nicolás, M.; Scotti, A.; Zammit, A.; Sales, D.L. Multi-material stainless steel fabrication using plasma wire arc additive manufacturing. J. Mater. Res. Technol. 2024, 30, 3996–4002. [Google Scholar] [CrossRef]

- Yadav, A.; Srivastava, M.; Jain, P.K.; Rathee, S. Functional behaviour of novel multi-layered deposition via twin wire arc additive manufacturing: Microstructure evolution and wear tailoring characteristics. Structures 2024, 67, 106901. [Google Scholar] [CrossRef]

- Han, J.; Lu, L.; Xin, Y.; Chen, X.; Zhang, G.; Cai, Y.; Tian, Y. Microstructure and mechanical properties of a novel functionally graded material from Ti6Al4V to Inconel 625 fabricated by dual wire + arc additive manufacturing. J. Alloys Compd. 2022, 903, 163981. [Google Scholar] [CrossRef]

- Lu, L.; Tian, Y.; Cai, Y.; Xin, Y.; Chen, X.; Zhang, G.; Han, J. Microstructure and mechanical properties of a functionally graded material from TA1 to Inconel 625 fabricated by dual wire + arc additive manufacturing. Mater. Lett. 2021, 298, 130010. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.; Yang, X.; Wang, D.; Hu, W.; Di, X.; Zhang, J. In-situ heat treatment (IHT) wire arc additive manufacturing of Inconel625-HSLA steel functionally graded material. Mater. Lett. 2023, 330, 133326. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.; Ba, L.; Di, X. Transition Strategy Optimization of Inconel625-HSLA Steel Functionally Graded Material Fabricated by Wire Arc Additive Manufacturing. Met. Mater. Int. 2023, 29, 767–776. [Google Scholar] [CrossRef]

- Jeong, T.-W.; Cho, Y.T.; Lee, C.-M.; Kim, D.-H. Effects of ultrasonic treatment on mechanical properties and microstructure of stainless steel 308L and Inconel 718 functionally graded materials fabricated via double-wire arc additive manufacturing. Mater. Sci. Eng. A 2024, 896, 146298. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Xu, T.; Li, Z.; Liu, C. Research on the microstructure and mechanical properties of functional gradient materials of TC4/TC11 titanium alloys for wire arc additive manufacturing with different transitional forms. J. Manuf. Process. 2024, 131, 245–255. [Google Scholar] [CrossRef]

- Xin, D.; Yao, X.; Zhang, J.; Chen, X. Fabrication of functionally graded material of 304L stainless steel and Inconel625 by twin-wire plasma arc additive manufacturing. J. Mater. Res. Technol. 2023, 23, 4135–4147. [Google Scholar] [CrossRef]

- Ayan, Y.; Kahraman, N. Fabrication and characterization of functionally graded material (FGM) structure containing two dissimilar steels (ER70S-6 and 308LSi) by wire arc additive manufacturing (WAAM). Mater. Today Commun. 2022, 33, 104457. [Google Scholar] [CrossRef]

- Yadav, A.; Srivastava, M.; Jain, P.K.; Rathee, S. Functionally graded deposition of dissimilar steel (316LSi and ER70S-6) fabricated through twin-wire arc additive manufacturing. Mater. Lett. 2024, 354, 135395. [Google Scholar] [CrossRef]

- Li, T.; Wang, Z.; Hu, S.; Yang, Z.; Wang, Y. Hot cracking during the fabrication of Inconel 625/stainless steel 308 L functionally graded material by dual-wire arc additive manufacturing. J. Manuf. Process. 2022, 82, 461–473. [Google Scholar] [CrossRef]

- Li, T.; Wang, Z.; Yang, Z.; Shu, X.; Xu, J.; Wang, Y.; Hu, S. Fabrication and characterization of stainless steel 308 L/Inconel 625 functionally graded material with continuous change in composition by dual-wire arc additive manufacturing. J. Alloys Compd. 2022, 915, 165398. [Google Scholar] [CrossRef]

- Li, T.; Wang, Z.; Yang, Z.; Wang, Y.; Hu, S. Effect of Different Wire Feeding Strategies on the Preparation of Functionally Graded Materials by Dual-Wire Arc Additive Manufacturing. Met. Mater. Trans. B 2023, 54, 43–49. [Google Scholar] [CrossRef]

- Pütz, R.D.; Pratesa, Y.; Oster, L.; Sharma, R.; Reisgen, U.; Zander, D. Microstructure and Corrosion Behavior of Functionally Graded Wire Arc Additive Manufactured Steel Combinations. Steel Res. Int. 2021, 92, 2100387. [Google Scholar] [CrossRef]

- Li, T.; Wang, Z.; Yang, Z.; Wang, Y. Strengthening the functionally graded material of stainless steel 308L and Inconel 625 by local Nb alloying. Mater. Lett. 2023, 331, 133499. [Google Scholar] [CrossRef]

- Reisgen, U.; Sharma, R.; Oster, L. Plasma Multiwire technology with alternating wire feed for tailor-made material properties in wire and arc additive manufacturing. Metals 2019, 9, 745. [Google Scholar] [CrossRef]

- Zhu, Q.; Yu, X.; Yao, P.; Yue, Y.; Kang, G. Study on Optimization Strategy for the Composition Transition Gradient in SS 316L/Inconel 625 Functionally Graded Materials. Materials 2024, 17, 2910. [Google Scholar] [CrossRef]

- Yadav, A.; Srivastava, M.; Jain, P.K.; Rathee, S. Microstructure and tribological behaviour of dissimilar steel functional structure developed via arc-based DED process. Tribol. Int. 2024, 197, 109782. [Google Scholar] [CrossRef]

- Tirupataiah, K.; Kiran, D.V.; Venkaiah, N. Iron aluminide FGM thin wall fabrication using CMT-based twin wire arc additive manufacturing process. Mater. Lett. 2023, 349, 134836. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Banaee, S.A.; Sharma, M.; Kapil, A.; Sharma, A. IN718-LCS bi-metallic deposition by wire arc additive manufacturing: Issues, mitigation strategies, and interfacial behavior. J. Manuf. Process. 2025, 140, 204–223. [Google Scholar] [CrossRef]

- Khan, A.U.; Sadhya, S.; Kumar, A.B.; Chatterjee, S.; Madhukar, Y.K. Investigation on dual wire TIG Arc additive manufacturing of IN625 and SS316L FGM for continuous gradient and sandwich structures. Thin-Walled Struct. 2024, 200, 111881. [Google Scholar] [CrossRef]

- Shen, C.; Pan, Z.; Cuiuri, D.; Roberts, J.; Li, H. Fabrication of Fe-FeAl Functionally Graded Material Using the Wire-Arc Additive Manufacturing Process. Met. Mater. Trans. B 2016, 47, 763–772. [Google Scholar] [CrossRef]

- Huang, J.; Liu, G.; Yu, X.; Guan, Z.; Yu, S.; Fan, D. Characterization of nickel-titanium alloy graded materials using double wire alternating current cross arc additive manufacturing. J. Alloys Compd. 2022, 910, 164912. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Ma, Y.; Lu, Y.; Shen, C.; Cuiuri, D.; Li, H. Characterization of wire arc additively manufactured titanium aluminide functionally graded material: Microstructure, mechanical properties and oxidation behaviour. Mater. Sci. Eng. A 2018, 734, 110–119. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Xu, T.; Liu, C. Different compositions of TC4/TC11 functional gradient materials interface by wire arc additive manufacturing. Sci. China Technol. Sci. 2024, 67, 3777–3782. [Google Scholar] [CrossRef]

- Yu, X.; Xue, J.; Shen, Q.; Zheng, Z.; Ou, N.; Wu, W. Dual-Wire Plasma Arc Additively Manufactured SS 316L-Inconel 625 Functionally Graded Material: Microstructure Evolution and Mechanical Properties. J. Mater. Eng. Perform. 2023, 32, 1412–1422. [Google Scholar] [CrossRef]

- Miao, Y.; Li, C.; Zhao, Y.; Wu, Y.; Liu, J.; Wang, Z.; Zhang, B. Material properties of gradient copper--nickel alloy fabricated by wire arc additive manufacturing based on bypass-current PAW. J. Manuf. Process. 2022, 83, 637–649. [Google Scholar] [CrossRef]

- Huang, J.; Liu, G.; Yu, X.; Wu, H.; Huang, Y.; Yu, S.; Fan, D. Microstructure regulation of titanium alloy functionally gradient materials fabricated by alternating current assisted wire arc additive manufacturing. Mater. Des. 2022, 218, 110731. [Google Scholar] [CrossRef]

- Shen, C.; Liss, K.-D.; Reid, M.; Pan, Z.; Hua, X.; Li, F.; Mou, G.; Huang, Y.; Dong, B.; Luo, D.; et al. Effect of the post-production heat treatment on phase evolution in the Fe3Ni–FeNi functionally graded material: An in-situ neutron diffraction study. Intermetallics 2021, 129, 107032. [Google Scholar] [CrossRef]

- Jiang, P.; Nie, M.; Teng, J.; Wang, X.; Liu, C.; Zhang, Z. Multi-wire arc additive manufacturing of TC4/Nb bionic layered heterogeneous alloy: Microstructure evolution and mechanical properties. Mater. Sci. Eng. A 2023, 874, 145076. [Google Scholar] [CrossRef]

- Xiang, R.; Huang, J.; Yu, X.; Zhao, H.; Song, X.; Fan, D. The effect of Ni/Ti atomic ratios on residual stress and deformation in WAAM of dissimilar filler wire NiTi alloys. J. Mater. Res. Technol. 2025, 35, 1813–1828. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Bairrão, N.; Farias, F.W.C.; Shamsolhodaei, A.; Shen, J.; Zhou, N.; Maawad, E.; Schell, N.; Santos, T.G.; Oliveira, J. Steel-copper functionally graded material produced by twin-wire and arc additive manufacturing (T-WAAM). Mater. Des. 2022, 213, 110270. [Google Scholar] [CrossRef]

- Li, Z.; Chang, B.; Cui, Y.; Zhang, H.; Liang, Z.; Liu, C.; Wang, L.; Du, D.; Chang, S. Effect of twin-wire feeding methods on the in-situ synthesis of electron beam fabricated Ti-Al-Nb intermetallics. Mater. Des. 2022, 215, 110509. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, J.; Zhu, X.; Lu, X.; Ling, X. A functionally graded material from stainless steel 304 to Fe–40Al fabricated by dual wire arc additive manufacturing. J. Mater. Res. Technol. 2024, 28, 3566–3572. [Google Scholar] [CrossRef]

- Tomar, B.; Shiva, S. Microstructural and mechanical properties examination of SS316L-Cu functionally graded material fabricated by wire arc additive manufacturing. CIRP J. Manuf. Sci. Technol. 2024, 50, 26–39. [Google Scholar] [CrossRef]

- Ju, Y.; Li, C.; Yang, X.; Ba, L.; Wang, Y.; Di, X. Recent progress on additive manufacturing of steel-based functionally graded materials. Mater. Today Commun. 2024, 40, 109953. [Google Scholar] [CrossRef]

- Adinarayanappa, S.M.; Simhambhatla, S. Twin-wire welding based additive manufacturing (TWAM): Manufacture of functionally gradient objects. Rapid Prototyp. J. 2017, 23, 858–868. [Google Scholar] [CrossRef]

- Yi, H.; Jia, L.; Ding, J.; Li, H. Achieving material diversity in wire arc additive manufacturing: Leaping from alloys to composites via wire innovation. Int. J. Mach. Tools Manuf. 2024, 194, 104103. [Google Scholar] [CrossRef]

- Senthil, T.S.; Babu, S.R.; Puviyarasan, M. Mechanical, microstructural and fracture studies on inconel 825–SS316L functionally graded wall fabricated by wire arc additive manufacturing. Sci. Rep. 2023, 13, 1–14. [Google Scholar] [CrossRef]

- Kumar, S.M.; Kannan, A.R.; Kumar, N.P.; Pramod, R.; Shanmugam, N.S.; Vishnu, A.S.; Channabasavanna, S.G. Microstructural Features and Mechanical Integrity of Wire Arc Additive Manufactured SS321/Inconel 625 Functionally Gradient Material. J. Mater. Eng. Perform. 2021, 30, 5692–5703. [Google Scholar] [CrossRef]

- Amiri, V.; Naffakh-Moosavy, H. Wire arc additive manufacturing of functionally graded carbon steel—Stainless steel 316L—Inconel 625: Microstructural characterization and mechanical behavior. J. Adv. Join. Process. 2024, 9, 100194. [Google Scholar] [CrossRef]

- Singh, M.; Singh, R.K.R.; Gupta, D. Metallurgical and mechanical properties of trimetallic functionally graded material fabricated by wire arc additive manufacturing. J. Alloys Compd. 2024, 1004, 175725. [Google Scholar] [CrossRef]

- Kannan, A.R.; Kumar, S.M.; Kumar, N.P.; Shanmugam, N.S.; Vishnu, A.; Palguna, Y. Process-microstructural features for tailoring fatigue strength of wire arc additive manufactured functionally graded material of SS904L and Hastelloy C-276. Mater. Lett. 2020, 274, 127968. [Google Scholar] [CrossRef]

- Muthu, S.; Prabu, S.S.; Sujai, S.; Sebastian, J.; Liyakat, N.A. Microstructure and mechanical properties of functionally graded materials alloy 82/AISI 304L by employing WAAM. Mater. Today Commun. 2025, 42, 111399. [Google Scholar] [CrossRef]

- Senthil, T.; Babu, S.R.; Puviyarasan, M.; Dhinakaran, V. Mechanical and microstructural characterization of functionally graded Inconel 825—SS316L fabricated using wire arc additive manufacturing. J. Mater. Res. Technol. 2021, 15, 661–669. [Google Scholar] [CrossRef]

- Sainath, K.; Prabagaran, S.; Soundararajan, R. A Comparison Study on Detailed Strengthening mechanism analysis on micro structure and mechanical properties of 3 phases FGM Material with vibrational behavior analysis is fabricated using WAAM process and traditional method. J. Alloys Compd. 2024, 1003, 175543. [Google Scholar] [CrossRef]

- Senthil, T.; Puviyarasan, M.; Babu, S.R.; Prabhu, T.R. Pitting corrosion studies on functionally graded Inconel 825-SS316L wall manufactured by wire arc additive manufacturing. Eng. Res. Express 2022, 4, 035013. [Google Scholar] [CrossRef]

- Veeman, D.; Alruqi, M.; Subramaniyan, M.K.; Nallathambhi, S.S.; Browne, M.A.; Kamaraj, A. Fabrication of functionally graded material via gas tungsten arc welding based wire feeding additive manufacturing: Mechanical and microstructural characterization. Mater. Lett. 2022, 324, 132786. [Google Scholar] [CrossRef]

- Chen, X.; Han, J.; Wang, J.; Cai, Y.; Zhang, G.; Lu, L.; Xin, Y.; Tian, Y. A functionally graded material from TC4 to 316L stainless steel fabricated by double-wire + arc additive manufacturing. Mater. Lett. 2021, 300, 130141. [Google Scholar] [CrossRef]

- Han, J.; Meng, M.; Liu, H.; Jiang, Z.; Zhao, X.; Xu, Y.; Tian, Y.; Zhang, X. Microstructure and mechanical properties of Ti-6Al-4V/Ni-Ti functionally graded material fabricated by multi-wire arc additive manufacturing. Sci. Technol. Weld. Join. 2024, 29, 232–241. [Google Scholar] [CrossRef]

- Marinelli, G.; Martina, F.; Lewtas, H.; Hancock, D.; Ganguly, S.; Williams, S. Functionally graded structures of refractory metals by wire arc additive manufacturing. Sci. Technol. Weld. Join. 2019, 24, 495–503. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Hari, S.; Amirthalingam, M. Functionally graded materials for marine risers by additive manufacturing for high-temperature applications: Experimental investigations. Structures 2022, 35, 931–938. [Google Scholar] [CrossRef]

- Wang, Y.; Konovalov, S.; Chen, X.; Singh, R.A.; Jayalakshmi, S. Research on plasma arc additive manufacturing of Inconel 625 Ni–Cu functionally graded materials. Mater. Sci. Eng. A 2022, 853, 143796. [Google Scholar] [CrossRef]

- Shen, C.; Hua, X.; Reid, M.; Liss, K.-D.; Mou, G.; Pan, Z.; Huang, Y.; Li, H. Thermal induced phase evolution of Fe–Fe3Ni functionally graded material fabricated using the wire-arc additive manufacturing process: An in-situ neutron diffraction study. J. Alloys Compd. 2020, 826, 154097. [Google Scholar] [CrossRef]

- Singh, M.; Singh, R.K.R.; Gupta, D. Investigation of Frictional Deformation on Mechanical and Metallurgical Properties of Ni-based Functionally Graded Materials Developed by Wire and Arc Additive Manufacturing. J. Mater. Eng. Perform. 2024, 34, 1112–1122. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Bocklund, B.; Reichardt, A.; Otis, R.; Borgonia, J.P.; Dillon, R.P.; Shapiro, A.A.; McEnerney, B.W.; Hosemann, P.; Liu, Z.-K.; et al. Analysis of formation and growth of the σ phase in additively manufactured functionally graded materials. J. Alloys Compd. 2020, 814, 151729. [Google Scholar] [CrossRef]

- Chen, X.; Kong, F.; Fu, Y.; Zhao, X.; Li, R.; Wang, G.; Zhang, H. A review on wire-arc additive manufacturing: Typical defects, detection approaches, and multisensor data fusion-based model. Int. J. Adv. Manuf. Technol. 2021, 117, 707–727. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, C.; Pan, T.; Flood, A.; Zhang, Y.; Li, L.; Liou, F. Additive manufacturing of copper—H13 tool steel bi-metallic structures via Ni-based multi-interlayer. Addit. Manuf. 2020, 36, 101474. [Google Scholar] [CrossRef]

- Osipovich, K.; Vorontsov, A.; Chumaevskii, A.; Gurianov, D.; Shamarin, N.; Savchenko, N.; Kolubaev, E. Characterization of a bimetallic multilayered composite “stainless steel/copper” fabricated with wire-feed electron beam additive manufacturing. Metals 2021, 11, 1151. [Google Scholar] [CrossRef]

- Ghanavati, R.; Naffakh-Moosavy, H.; Moradi, M.; Gadalińska, E.; Saboori, A. Residual stresses and distortion in additively-manufactured SS316L-IN718 multi-material by laser-directed energy deposition: A validated numerical-statistical approach. J. Manuf. Process. 2023, 108, 292–309. [Google Scholar] [CrossRef]

- Dharmendra, C.; Shakerin, S.; Mohammadi, M. Metallurgical Assessment of Additive Manufactured Nickel Aluminum Bronze-316L Stainless Steel Bimetallic Structure: Effect of Deposit Geometry on the Interfacial Characteristics and Cracking. J. Mater. Eng. Perform. 2021, 30, 8746–8762. [Google Scholar] [CrossRef]

- Hauser, T.; Reisch, R.T.; Breese, P.P.; Lutz, B.S.; Pantano, M.; Nalam, Y.; Bela, K.; Kamps, T.; Volpp, J.; Kaplan, A.F.H. Porosity in wire arc additive manufacturing of aluminium alloys. Addit. Manuf. 2021, 41, 101993. [Google Scholar] [CrossRef]

- Zhang, W.; Yi, H.; He, H.; Cao, H. Content effects of in-situ synthesis TiC for grain refinement, porosity suppression and performance enhancement in wire arc additive manufactured Al-Cu alloy. J. Mech. Work. Technol. 2025, 340, 118875. [Google Scholar] [CrossRef]

- Treutler, K.; Wesling, V. The current state of research of wire arc additive manufacturing (Waam): A review. Appl. Sci. 2021, 11, 8619. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zhang, W.; DebRoy, T. An improved prediction of residual stresses and distortion in additive manufacturing. Comput. Mater. Sci. 2017, 126, 360–372. [Google Scholar] [CrossRef]

- Ahmad, B.; Zhang, X.; Guo, H.; Fitzpatrick, M.E.; Neto, L.M.S.C.; Williams, S. Influence of Deposition Strategies on Residual Stress in Wire + Arc Additive Manufactured Titanium Ti-6Al-4V. Metals 2022, 12, 253. [Google Scholar] [CrossRef]

- Wu, Q.; Mukherjee, T.; De, A.; DebRoy, T. Residual stresses in wire-arc additive manufacturing—Hierarchy of influential variables. Addit. Manuf. 2020, 35, 101355. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, H.; Shang, S.L.; Liu, Z.K.; Beese, A.M. Effect of heat treatment on functionally graded 304L stainless steel to Inconel 625 fabricated by directed energy deposition. Materialia 2024, 34, 102067. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, B.-G.; Chen, G.-Q.; Feng, J.-C.; Tang, Q. Electron beam welding of Ti-15-3 titanium alloy to 304 stainless steel with copper interlayer sheet. Trans. Nonferrous Met. Soc. China 2010, 20, 1829–1834. [Google Scholar] [CrossRef]

- Alkunte, S.; Gupta, M.; Rajeshirke, M.; More, N.; Cheepu, M.; Gupta, A.; Lakal, N.; Shingare, K.; Alifui-Segbaya, F.; Fidan, I. Functionally Graded Metamaterials: Fabrication Techniques, Modeling, and Applications—A Review. Processes 2024, 12, 2252. [Google Scholar] [CrossRef]

- Mattera, G.; Nele, L.; Paolella, D. Monitoring and control the Wire Arc Additive Manufacturing process using artificial intelligence techniques: A review. J. Intell. Manuf. 2024, 35, 467–497. [Google Scholar] [CrossRef]

- Chen, Z.; Yuan, L.; Pan, Z.; Zhu, H.; Ma, N.; Ding, D.; Li, H. A comprehensive review and future perspectives of simulation approaches in wire arc additive manufacturing (WAAM). Int. J. Extrem. Manuf. 2025, 7, 022016. [Google Scholar] [CrossRef]

- Yi, H.; Lang, T.; Si, J.; Chi, Y.; Cao, H.; Huang, Y. High-performance manufacturing of metal components via multi-field assisted wire-arc directed energy deposition. J. Manuf. Process. 2025, 143, 234–276. [Google Scholar] [CrossRef]

- Chen, Z.; Han, C.; Gao, M.; Kandukuri, S.Y.; Zhou, K. A review on qualification and certification for metal additive manufacturing. Virtual Phys. Prototyp. 2022, 17, 382–405. [Google Scholar] [CrossRef]

| Feature | Bimetallic Structures | Functionally Graded Materials |

|---|---|---|

| Interface | Sharp transition | Smooth transition |

| Stress Distribution | High at the interface | Smooth, gradual |

| Property tailoring | Limited | Highly customizable |

| Processing complexity | Low weld/join | High—requires AM/control |

| Structural integrity | Interfacial failure risk | Better bonding |

| Design Freedom | Limited to two layers | Multi-gradient possible |

| Feature | Advantages | Limitations |

|---|---|---|

| Deposition Rate | High deposition rate suitable for large-scale production | Less suitable for fine-featured or intricate geometries |

| Material Utilization | Low buy-to-fly ratio; minimal material wastage | May require post-processing for surface finish |

| Heat Input Control | Better control overheat input compared to powder-based AM | Thermal cycles can induce residual stresses |

| Component Size Capability | Capable of producing large structural components | Limited resolution and dimensional accuracy |

| Cost-Effectiveness | More economically feasible for large metal parts and structures | Equipment and skill requirements may be high |

| Multi-Material Fabrication | Successfully demonstrated for BS and FGMs | Interface control and metallurgical bonding challenges |

| Material System | AM System | Processing Parameters | Key Findings | Ref. |

|---|---|---|---|---|

| SS316L/Inconel 625 | GMAW-WAAM (CMT) | Wire diameter: 1.2 mm, Current: 200 A (SS316L), 148 A (In625); Voltage: 13.1 V (SS316L), 14.5 V (In625); Feed rate: 6.5 m/min; Travel speed: 600 mm/min | Smooth compositional transition at the interface Microhardness: 240 HV (Interface), UTS/% Elongation: 600 MPa/40% | [103] |

| SS316L/Inconel 625 | GMAW-WAAM (CMT) | Wire diameter: 1.2 mm, Current: 85–160 A, Voltage: 16.4–20.0 V (auto-adjusted), Wire Feed Speed: 2.9–5.7 m/min, Travel Speed: 200 mm/min | The interface well bonded with no defects, has plenty of Laves phases rich in Nb, Mo Microhardness: 240 HV (Interface) UTS/% Elongation: 406–444 MPa/23–38% | [82] |

| ER70S-6/SS316L | GMAW-WAAM (CMT) | Wire Feed Speed: ER70S-6—2 m/min (fixed) and 316L SS—0 to 1.5 m/min, Voltage: 18.5 V, Travel speed: 200 mm/min; Gas: Ar @ 20 L/min; Stand-off: 6 mm | Microstructures comprise ferrite, bainite and martensite phases with the evolution of δ-ferrite Microhardness ER70S-6: 220 HV UTS/% Elongation: 1089–1231 MPa/17–22% | [93] |

| Al-5Mg alloy (AA5083)/Al-6061-T6 plate | GMAW-WAAM (CMT) | Voltage: 15.3 V, Current: 177 A, Wire Feed Rate: 8 m/min, Travel Speed: 360 mm/min | Presence of relatively coarse IMCs Al (Fe, Mn)Si UTS: 220–250 MPa Corrosion Behavior, Surface Chemistry, Topography | [122] |

| TC4 (Ti-6Al-4V)/ER5356 (Al–5Mg) | GMAW-WAAM (CMT) | Wire Diameter: TC4 (Ti-6Al-4V)—Ø 1.2 mm; ER5356 (Al–5Mg)—Ø 1.2 mm; Wire Feed Speed: TC4—9.1 m/min; ER5356—5.9 m/min. | Presence Pores and Ti/Al intermetallic compounds Hardness: TC4—384.9 HV, ER5356—84.38 HV UTS/% Elongation: 250–1314 MPa/4.1–8.8% | [117] |

| Low Carbon Steel (LCS)/SS 316L stainless steel | GMAW-WAAM (CMT) | Wire Diameter: 1.2 mm; Voltage: 12.8–15 V; Wire Feed Speed (WFS): 4.5–7.5 m/min; Travel Speed (TS): 200–400 mm/min; Interpass Temperature: ~100 °C; Heat Input: ~14.9–41.3 kJ/mm | Interface sound and free from defects Microhardness: LCS Side: ~180–200 HV, SS316L Side: ~220–250 HV, Interface (CTZ): Up to 463 HV Interfacial shear strength: 140 MPa | [92] |

| Ti-6Al-4V/Al-6.25Cu | GMAW-WAAM (CMT) | Wire Diameter: 1.2 mm, Feed speed: 7.2 m/min (Ti wire), 4.0 m/min (Al wire); Travel speed: 0.3 m/min, Wire extension: 12 mm, | TiAl3, TiAl, and Ti3Al IMCs observed EDS Morphology, phase composition, intermetallic formation) | [116] |

| Ti-6Al-4V/Al-6.25Cu | GMAW-WAAM (CMT) | Wire Diameter: 1.2 mm, Wire Feed Speed (WFS): Ti: 7.2 m/min, Al: 4.0 m/min; Travel Speed: 300 mm/min, Torch Distance (CTWD): 12 mm | TiAl3 IMCs in DC-CMT mode TiAl and Ti3Al IMCs in CMT+P mode Hardness: Lower, smoother hardness gradient (~370 HV) | [85] |

| ER80S-G and MF6–55GP/Q235 low carbon steel | GMAW-WAAM (CMT) | Wire Diameter: 1.2 mm, Current: 82 A, Voltage: 12.6 V, Travel Speed: 300 mm/min, Wire Feed Speed: 5 m/min, Interpass Temperature: 130 °C | No defects at interface Microhardness: MF6–55GP: Increases from 500 HV (transition zone) to peak 800 HV at 8th layer UTS: 447.79 MPa, has better stability, wear resistance | [123] |

| SS316L/ER70S-6 (Low Carbon Steel) | GMAW-WAAM (CMT) | Wire Diameter: 1.0 mm, Current: SS316L—70 A, ER70S-6—80 A; Voltage: SS316L—17.8 V, ER70S-6—18.9 V; Travel Speed: 540 mm/min | Microhardness: SS316L~210 HV, ER70S-6~245 HV, Transition Region: Smooth gradient from 210 to 245 HV across layers, Machinability, Wear Properties | [90] |

| ER316LSi/ERNiCrMo-3 (Inconel 625) | GMAW-WAAM (CMT) | Wire Diameter: 1.2 mm, Current: SS316LSi—150 A, IN625—120 A; Voltage: 12.8 V; Travel Speed: 360 mm/min; Wire Feed Speed: SS316LSi—5.5 m/min, IN625—4.2 m/min; Interlayer Dwell Temperature: 80–100 °C. | Epitaxial grain growth in the build direction Microhardness: SS316LSi~160–190 HV, IN625~220–245 HV UTS: IN625~761 MPa, SS316LSi~502 MPa, IN625/SS316LSi BS~507 MPa. | [124] |

| Ni-Fe alloy/ductile cast iron | GMAW-WAAM (CMT) | current: 220 A, voltage: 20.1 V, Welding speed: 1000 mm/min, Shield gas flow rate: 14–16 L/min, Layer thickness: 2.5 mm, Hatching distance: 3.25 mm, Wire diameter: 1.2 mm, Wire feeding speed: 7 m/min, Deposition rate: 3900 gr/h | Cracks, pores at interface and deposited layers Peak hardness in partially melted zone. UTS/YS/% elongation: 400 MPa/230 MPa/24.0% | [125] |

| Inconel625/SS308L | GMAW-WAAM (CMT) | SS308L: Voltage: 17.2 V, Current: 115 A, Feed rate: 4.3 m/min, Travel speed: 420 mm/min. Inconel625: Voltage: 14.5 V, Current: 160 A, Feed rate: 6.6 m/min, Travel speed:420 mm/min | Microhardness: SS308L~139–188 HV, Inconel625~187–222 HV, UTS/YS/% elongation: 564 MPa/377 MPa/38% | [107] |

| HS600/HS950 | GMAW-WAAM (CMT) | Deposition Current: 135–145 A, Deposition Voltage: 20–22 V, Swing Speed: 60 mm/min, Robot Forward Speed: 60 mm/min | HS600: YS(Rp0.2) ~534 MPa, UTS(Rm) ~874 MPa, Elongation ~32%, Impact Toughness at −20 °C (AK): 115 J HS950: YS (Rp0.2) ~652 MPa, UTS (Rm) ~961 MPa, Elongation ~19%, Impact Toughness at −20 °C (AK): 87 J | [126] |

| ER70S-G/SS316LSi | GMAW-WAAM (CMT) | ER70S-G: Current: 110 A:Voltage: 12.5 V, Torch Speed: 114 mm/min, Wire Feed Speed: 2.9 m/min, Shielding Gas: 98% Ar, 2% O2, Shielding Gas Flow Rate: 15 L/min, Interpass Temperature: 200 °C, SS316LSi: Current: 90 A, Voltage: 11.9 V, Torch Speed: 96 mm/min, Wire Feed Speed: 2.3 m/min, Shielding Gas: 98% Ar, 2% O2, Shielding Gas Flow Rate: 15 L/min, Interpass Temperature: 200 °C, | ASS revealed vermicular d-ferrite, while LCS revealed an acicular, polygonal ferrite morphology YS: 306.54 ± 1.59 MPa, UTS: 493.11 ± 15.17 MPa Elongation: 22.70 ± 2.38% Microhardness: 212 HV | [86] |

| AISI 316L/Ti | GMAW-WAAM (CMT) | Travel Speed: 350 mm/min, Wire Feed Rate: 3.1 m/min, Current: 125 A for Stainless Steel (SS) 135 A for Titanium (Ti), Voltage: 13.5 V for SS, 13.8 V for Ti, Arc Length: 3.8 mm, Wire-Feed Angle: 90°, Dwell Time Between Each Layer: 60 s for SS, 90 s for Ti, Shielding Gas: Pure Argon, Gas Flow Rate: 18 L/min | Interface microstructure consists of Fe–Ti IMCs of cellular dendritic shapes, their boundaries were wetted by Cr–Ti IMCs. Peak Microhardness ~967 ± 12 HV at the interface | [127] |

| NiTi/SS316L | GMAW-WAAM | Wire Diameter: 1.2 mm, Feed rate: SS—5.5 m/min, NiTi—5.0 m/min, Voltage: SS—16.5 V, Preheating: 400 °C | TiCr2, TiNi3, FeNi IMCs at interface Microhardness: 400 HV (Interface) Ultimate strength (Compression): 570 MPa | [98] |

| Nickel Aluminum Bronze (NAB)/SS316L | GMAW-WAAM | Wire: AWS A5.7 ERCuNiAl, Current: 60 A, Voltage: 8.7, Swing Amplitude: 10 mm, Frequency: 2.0 Hz, Travel Speed: 100 mm/min, Line Energy: 48.9 J/cm, Energy Density: 1174.5 J/cm2. | ~1.3 μm Fe3Al-rich IMC layer between NAB, steel UTS/% Elongation: 721.8 MPa/24.3% | [111] |

| ER70S-6 Mild Steel/ER308L stainless steel | GMAW-WAAM | Wire diameter: ER70S-6 Mild Steel—Ø 1.2 mm, ER308L Stainless Steel—Ø 1.2 mm; Mild Steel: 15.1 V, 168 in/min; SS308L: 21 V, 349 in/min; Travel speed: Mild Steel—250 mm/min, SS308L—330 mm/min; | Residual stresses at interface Microhardness: SS308L ~249 HV, Mild Steel ~277 HV Ultimate strength (Compression): 493 MPa FEM residual stress modeling | [87] |

| ER70S-6/ER316L | GMAW-WAAM | Wire diameter: 1.0 mm, Voltage: 14.6 V (ER70S-6), 15.3 V (ER316L), Current: 132 A (ER70S-6), 150 A (ER316L); Travel speed: 500 mm/min; Torch angle: 90°. | Defect free interface, high hardness at interface due to Fe, C migrations Microhardness: ER70S-6: ~180 HV, ER316L: ~225–240 HV; | [100] |

| YS308L/Ni6082 | GMAW-WAAM | Wire diameter: 1.2 mm, Current: 140 A, Voltage: YS308L—20.6 V, Ni6082—24.2 V; Feed: 200 mm/min, Cross-feed: 6 mm | No defects at interface, Hardness—YS308L: ~200 HV, Ni6082: ~160 HV, UTS: ~530–600 MPa | [128] |

| ER50–6 low-alloy steel/HS211 silicon bronze (Cu-Ni interlayer) | GMAW-WAAM | Wire diameter: 1.2 mm, Current: Steel and Interlayer—200 A, HS211—230 A; Voltage: Steel and Interlayer—22 V, HS211—25 V; Travel Speed: 300 mm/min; Interlayer Dwell Time: ~100 °C maintained between layers. | Microhardness: Silicon Bronze-110–120 HV, Steel-170–180 HV, UTS: 207.5 MPa (no interlayer), 345.2 MPa (with Cu-Ni interlayer) | [108] |

| SS316L (ER316L)/Low Carbon Steel (LCS) (E70C-6M) | GMAW-WAAM | Wire diameter: 1.2 mm, Current: SS316L—150 A, LCS—150 A; Voltage: SS316L—15 V, LCS—18 V; Travel Speed: 420 mm/min for both; Electrode-to-Workpiece Distance: 15 mm (stick-out); Interlayer Dwell Time: 180 s | Martensitic microstructure, carbide precipitation at interface Microhardness: Interface-240–390 HV, UTS: Interface-Horizontal~948 MPa, Interface-Vertical~511 MPa. | [129] |

| SS316L/SS308L | GMAW-WAAM | Wire diameter: 1.2 mm, Current: 150 A, Voltage: 19.5 V, Travel Speed: 180 mm/min, Wire Feed Speed: 5.5 m/min, Electrode-to-Workpiece Distance: 8 mm, Interlayer Dwell Time: 120 s. | Interface exhibited dendritic structure, no defects Microhardness: BMS Interface~234.33 HV UTS: BMS~605.1 MPa > UTS of SS316L | [97] |

| ER 316LSi/MSG 6 GZ-60 | GMAW-WAAM | Wire Diameter: 1.2 mm, Current: ER 316LSi—110 A, MSG 6 GZ-60—100 A; Voltage: ER 316LSi—15 V, MSG 6 GZ-60—18 V; Travel Speed: 400 mm/min, Interlayer Dwell Time: 120 s per layer. | Excellent bonding at interface, no defects Microhardness: ER316LSi ~187 HV, MSG6GZ 563~625 HV, Interface ~360 HV | [130] |

| Nickel aluminum bronze (NAB)/316L SS | GMAW-WAAM | Voltage of 12.5 V with 114 Amp current, 6.5 m/min wire-feed rate, 480 mm/min travel speed (i.e., heat input of ~170 J/mm) | Fe-Al based intermetallic layers (2 µm) formation, Metallurgical bond with 2 μm inter-diffusion region Microhardness: WAAM NAB~260 HV | [131] |

| AISI316L stainless steel/AA5183 aluminum | GMAW-WAAM | Steel Deposition: Heat input: 2074 J/mm (24 V, 180 A, 100 mm/min). Aluminum Deposition: Low heat-input (LH): 384 J/mm (20 V, 120 A, 300 mm/min). Medium heat-input (MH): 576 J/mm (20 V, 120 A, 200 mm/min). High heat-input (HH): 1152 J/mm (20 V, 120 A, 100 mm/min). Layer height: 2 mm. Total layers: 15 per side | Wall with Low heat input showed no defects or Fe-Al IMC at interface UTS: LH sample ~42 MPa, ~21% elongation, MH sample ~17 MPa, ~4.7% elongation | [118] |

| Mild Steel/304 SS | GMAW-WAAM | Mild Steel: Arc Voltage (V): 13–17, Welding Current (A): 100–130, Travel Speed (mm/min): 300–480, Wire Diameter (mm): 1.2, Shielding Gas Type: Argon, Shielding Gas Flow Rate (L/min): 14, 304SS: Arc Voltage (V): 19, Welding Current (A): 160, Travel Speed (mm/min): 300–480, Wire Diameter (mm): 1.2, Shielding Gas Type: Argon, Shielding Gas Flow Rate (L/min): 14 | Interface reveals two discrete zones of mild steel, SS304 deposits without any weld defects Microhardness: MS ~160–180 HV, SS ~240–260 HV, Transition zone~240–280 HV Residual stress: 50–80 MPa (Comp.), 90 MPa (Longitudinal) | [132] |

| NiTi/Cu | GMAW-WAAM | NiTi: Wire Feed Rate: 15 m/min, Argon Gas Flow Rate: 5 L/min, Voltage: 20 V, St-off Distance: 16.5 mm, wire diameter: 1.2 mm Cu: Wire Feed Rate: 20 m/min, Argon Gas Flow Rate: 5 L/min, Voltage: 20 V, Stand-off Distance: 20 mm | Interface was characterized by Ti(Ni,Cu)2, Cu, Ti2 (Ni,Cu)3 precipitates, Ni-rich NiTi precipitates Average Hardness at Joint and base Material: 485 HV Compressive strength: 650 MPa | [112] |

| SS904L/Hastelloy C-276 | GMAW-WAAM | Welding current: 160 Amps, Welding voltage: 16.40 Volts, Welding speed: 250 mm/min, Wire feed speed: 5.23 m/min, Deposition rate: 1.18 kg/h, Heat input: 0.56 kJ/mm, Average layer height: ~2.72 mm, contact tip to layer angle: 90° | Directionally elongated, columnar, equi-axed dendrites in BS 0° Orientation: Avg. UTS:634.38 ± 7.86 MPa, Elongation: 45.37 ± 1.26%, 90° Orientation: Avg. UTS: 680.73 ± 6.45 MPa, Elongation: 37.87 ± 1.71%, Microhardness: 227 ± 6 HV | [133] |

| Austenite stainless steel (SS304L)/Ferrite stainless steel (SS430L). | GMAW-WAAM | For 304L: Voltage: 27 V, Wire Feed Speed: 3 m/min, Travel Speed: 7 mm/min, Gas Flow Rate: 200 L/min, For 430L: Gas Flow Rate: 15 L/min, Combination C2 For 304L:Wire Feed Speed: 5 m/min, For 430L: Wire Feed Speed: 5 m/min, Combination C3 For 304L: Wire Feed Speed: 7 m/min, For 430L:Wire Feed Speed: 3 m/min | At interface austenite and ferrite phases with higher amounts of Ni-content with no defects UTS: 500–600 MPa, YS: 290–320 MPa, % Elongation: 22–65% Microhardness: 180–225 HV | [96] |

| H13 steel/copper | GMAW-WAAM | H13: Wire Diameter 1.6 mm, Current: 1st layer 360 A, above 1st layer 300 A; Voltage: 1st layer 38 V, above 1st layer 32 V; Wire feeding speed: 1st layer 7.3 m/min, above 1st layer 5.2 m/min; Travel speed: 1st layer 180 mm/min, 2nd–7th layer 240–480 mm/min, above 7th layer 60 mm/min. | Interface with Fe-rich/Cu-rich islands, pores Microhardness: 568.3 ± 22.6 HV interface UTS: 221 MPa, YS: 110 MPa, % Elongation: 29% | [81] |

| SS316L/IN718 alloy | GMAW-WAAM | Current 152 A, Voltage 20 V, wire feed speed 5 m/min, travel speed 250 mm/min, Interpass temperature 150 °C. | Cracks, cellular dendrites, columnar dendrites, equiaxed grains at interface. Top side UTS: 670.5 MPa, % Elongation: 24.1 Bottom side UTS: 659.4 MPa, % Elongation: 23.8% | [104] |

| AISI 304L/Low Carbon Steel (LCS) | GMAW-WAAM + Surface Cladding | Wire diameter: 1.2 mm, Voltage: 24–30 V, CWFR: 5–6 m/min, Welding speed: 180 mm/min, Argon flow: 15 L/min, Layers: 3-pass, CTWD: 18 mm | CrSi2, Mn3Ni2Si, Fe2C, Fe5C2, Cr7C3 IMC at interface Microhardness: 450–504 HV Abrasive, Adhesive Wear Testing: COF: 0.8 vs. 0.48 for uncoated LCS | [99] |

| ER70S-6 steel/ERNi-1 (Ni-3.5 wt%Ti) | GTAW-WAAM | Wire diameter: 1.2 mm, Current: 140 A, Voltage: 13 V, Travel Speed: 820 mm/min, Wire Feed Speed: 1 m/min, Torch Angle: 60°, Shielding Gas: Argon, Gas Flow Rate: 10 L/min, Dwell Time: 1 min | Interlocking interface Microhardness: Steel-170–210 HV, nickel—140–150 HV, Interface-160 HV UTS: Steel-573 MPa, nickel-455 MPa Interface-634 MPa | [88] |

| Pure Titanium (TA2) and Pure Nickel/Ti6Al4V | GTAW-WAAM | Wire diameter: Pure Ti (Ø 1.2 mm), Pure Ni (Ø 0.9 mm); Current: 50 A, 60 A, 70 A; Travel Speed: 95 mm/min, Wire Feed Speed: Ti—0.416 m/min; Ni—238 mm/min, Substrate Preheat Temperature: 300 °C, | Crack free coating with NiTi2, NiTi phases at interface Microhardness: Max. 818 HV, Wear Resistance: 0.112 mm3 wear volume, lowest friction coefficient (~0.374). | [134] |

| Inconel625/Pure Copper | GTAW-WAAM | Wire diameter: 1.2 mm, Current: Inconel—180 A, Copper—160 A; Voltage: Inconel—14.5 V, Copper—14 V; Travel Speed: 400 mm/min (Inconel), 350 mm/min (Copper); Wire Feed Speed: Inconel—5 m/min, Copper—4.5 m/min; | No new phases at interface Microhardness: Inconel625 ~220–250 HV, Copper ~75–85 HV, Transition zone ~120–160 HV, Shear Strength at Interface: ~82.3 MPa | [135] |

| Q345steel/308 stainless steel | GTAW-WAAM | Wire Diameter: Q345—1.2 mm, 308—1.0 mm; Current: 150 A, Wire Feed Speed: Q345—1 m/min, 308—1 m/min, Dual-wire Sample 3—80 (Q345) + 100 (308), Sample 4—100 + 100; | Interface with good metallurgical bonding, no defects Microhardness: Q345 ~227 HV, 308 SS ~238 HV Corrosion Resistance (in 3.5% NaCl solution) | [136] |

| NiTi/Cu | GTAW-WAAM | Base current (A) 100, UHFP current (A) 60, UHFP frequency (kHz) 20, UHFP duty cycle (%) 50, Arc length 3 mm, Torch travel speed 300 mm/min, NiTi wire feed speed 2.2 m/min, Cu wire feed speed 0.240 m/min, Deposited time interval (min) 1 | Microstructure showed columnar, equiaxed, needle-like grains, Microhardness: Gradually increased from the first to the third layer, UTS: 232 ± 11 MPa, Fracture Strain: 3.72% ± 0.7%, | [114] |

| SS316LSi/ER70S—6 | GTAW-WAAM | SS316LSi: Voltage: 14 V, Average Current: 140 A, Torch Speed: 327 mm/min, Wire Feed Rate: 4 m/min. ER70S-6: Voltage: 18 V, Average Current: 110 A, Torch Speed: 330 mm/min, Wire Feed Rate: 4.8 m/min | Interface exhibits impressive mechanical bonding UTS/YS/Elongation: 560.28 ± 8 MPa/333.70 ± 5.5 MPa/33.51 ± 3%, Microhardness: ER70S-6 ~189 HV, Interface ~258 HV, SS316LSi ~176 HV | [95] |

| Ti6Al4V/NbZr1 | GTAW-WAAM | Current: 180, 200, 220 A, WFS-1.5 m/min, TS-200 mm/min Wire dia.-0.95 mm, Shielding gas flow rate-15 L/min | Solid solutions of (βTi, Nb) and (α + β Ti, Nb) at interface, No IMCs, cracks, pores Hardness: 99–339 HV, UTS: 367–543 MPa | [79] |

| TZM/NbZr1 | GTAW-WAAM | Current: 200 A, WFS-1.5 m/min, TS-200 mm/min Wire dia.-0.95 mm, Shielding gas flow rate-15 L/min | Non-uniformly distributed pores of various sizes at interface, Mo diffused into NbZr1, No IMCs Hardness: 160–253 HV, UTS: 158–393 MPa | [75] |

| 90WNiFe/In625 | GMAW—(CMT) + GTAW-WAAM | GTAW-Current: 180, 200, 220 A, WFS-2 m/min, TS-200 mm/min, Wire dia.-1.2 mm, CMT-106 A, WFS-2 m/min, TS-200 mm/min, Shielding gas flow rate-15 L/min | Diffusion of Cr, Ni, Mo, Nb from In625 into the γ-(Ni, Fe, W) binding matrix of the 90WNiFe Hardness: 282–313 HV (interface), UTS: 618 MPa, Elongation: 49% | [76] |

| Ti6Al4V/Al6.21Cu (ER2319) with Nb | GMAW- (CMT) + GTAW-WAAM | Wire diameter: 1.2 mm, TIG-welded at 80 A, Ti6Al4V: 8 m/min, Al6.21Cu: 4 m/min, Travel speed: 300 mm/min, Nb foil (0.3 mm thick) | Nb remained largely unmixed, acting as a diffusion barrier to suppress Ti–Al IMCs UTS/% Elongation: 120.9 MPa/1.14% With Nb interlayer UTS/% Elongation: 94.5 MPa/0.34% Without Nb interlayer | [83] |

| ER70S-6/SS 316L | GMAW + GTAW WAAM | Superimpose Wall—GTAW (SS 316L): WFR 3.5 m/min, TS 350 mm/min, Current 250 A, Voltage 14.5 V; GMAW (ER70S-6): WFR 3.5 m/min, TS 350 mm/min, Current 120 A, Voltage not specified. | Microhardness: ER70 ~380 HV, SS316L-190 HV UTS: 869 MPa (overlapped), 628 MPa (Sandwich)YS: 584 MPa (overlapped), 389 MPa (Sandwich) Elongation: 20% (overlapped), 36% (Sandwich) | [91] |