Effects of Compaction Thickness on Density, Integrity, and Microstructure of Green Parts in Binder Jetting Additive Manufacturing of Silicon Carbide

Abstract

1. Introduction

2. Experimental Method

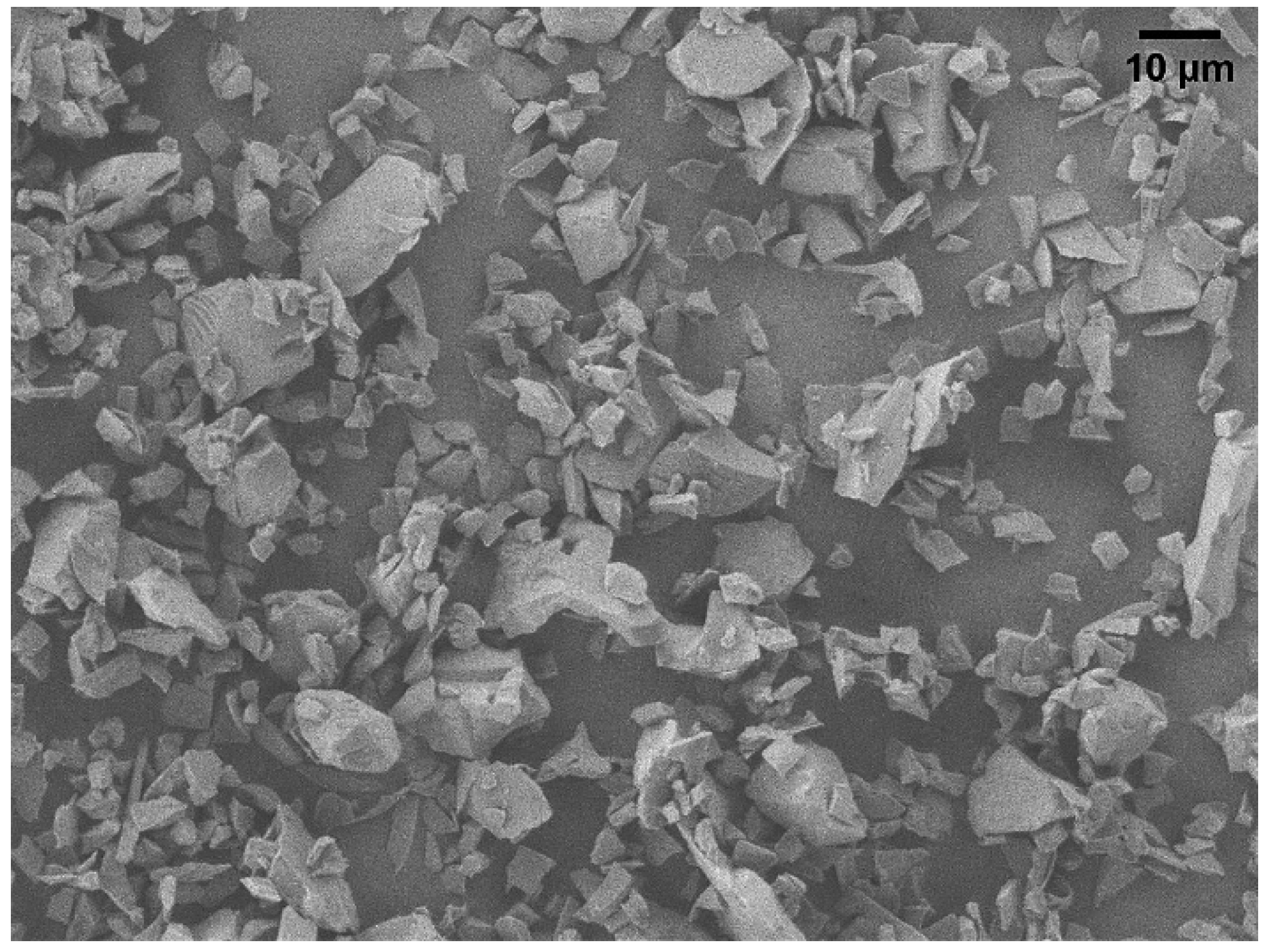

2.1. Feedstock Powder

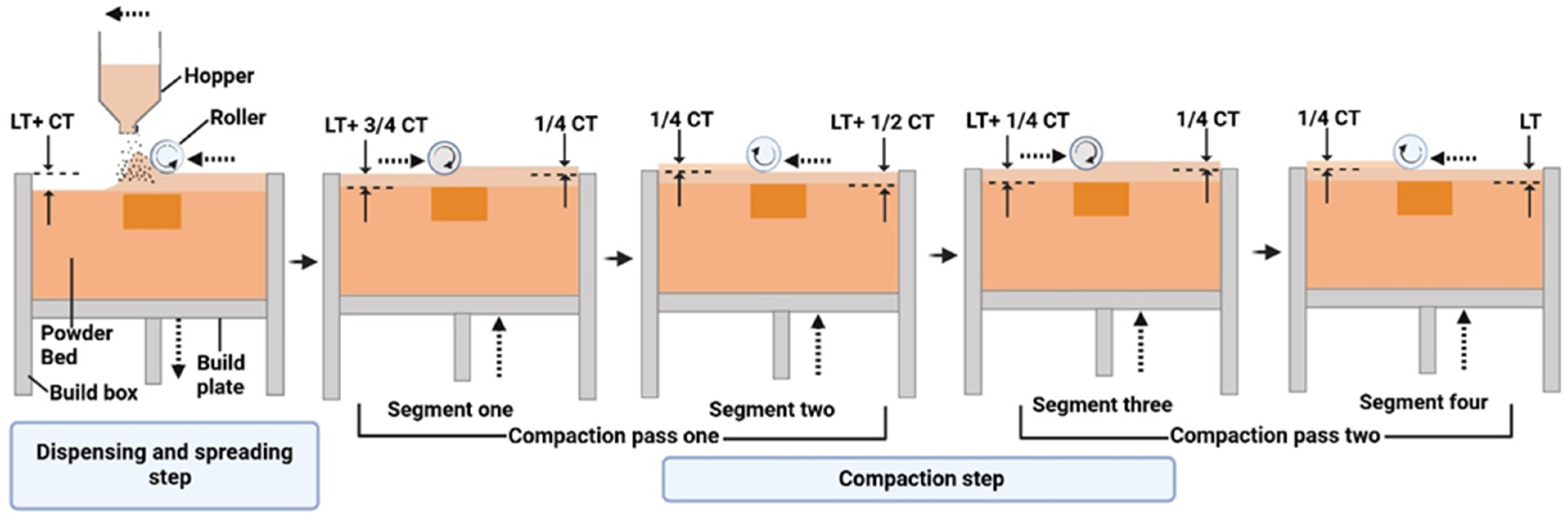

2.2. Binder Jetting of Green Parts

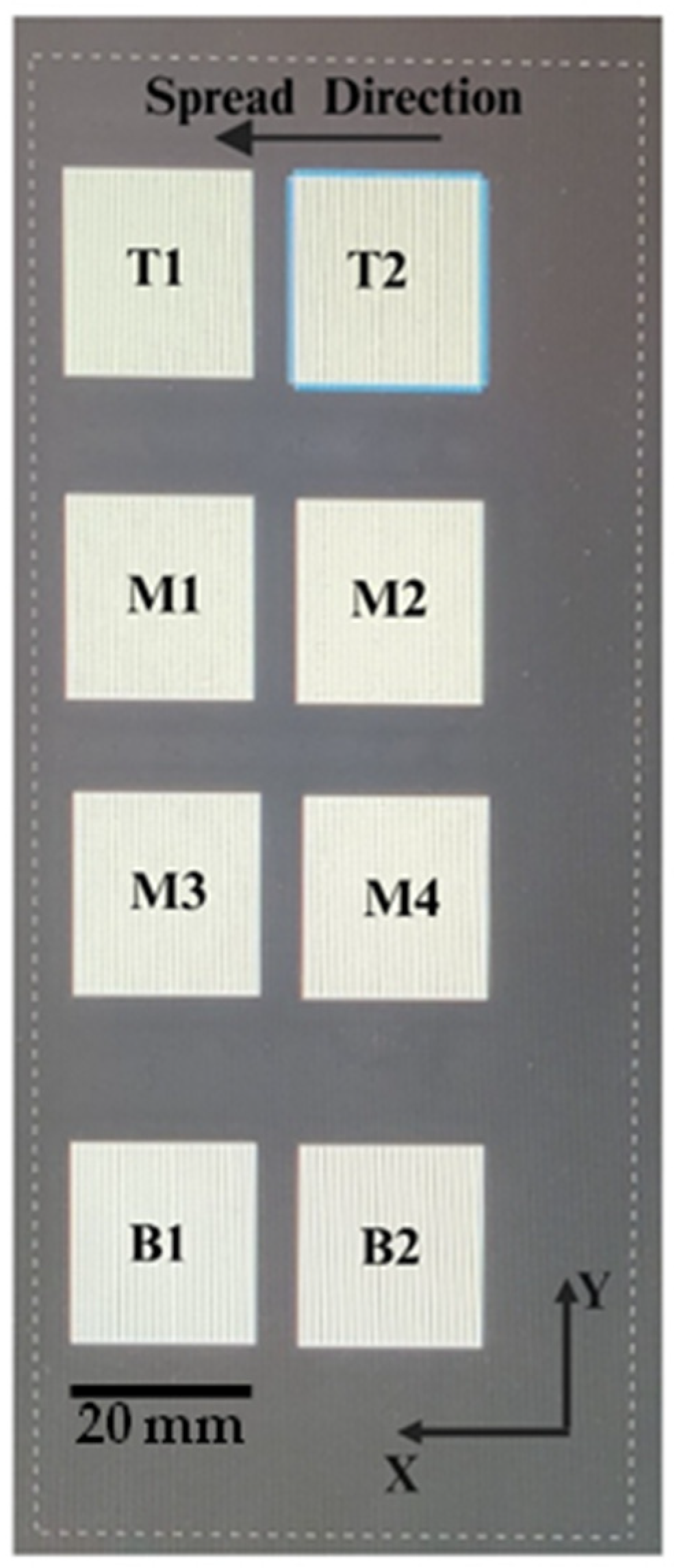

2.3. Design of Experiments

2.4. Measurement of Density of Green Parts

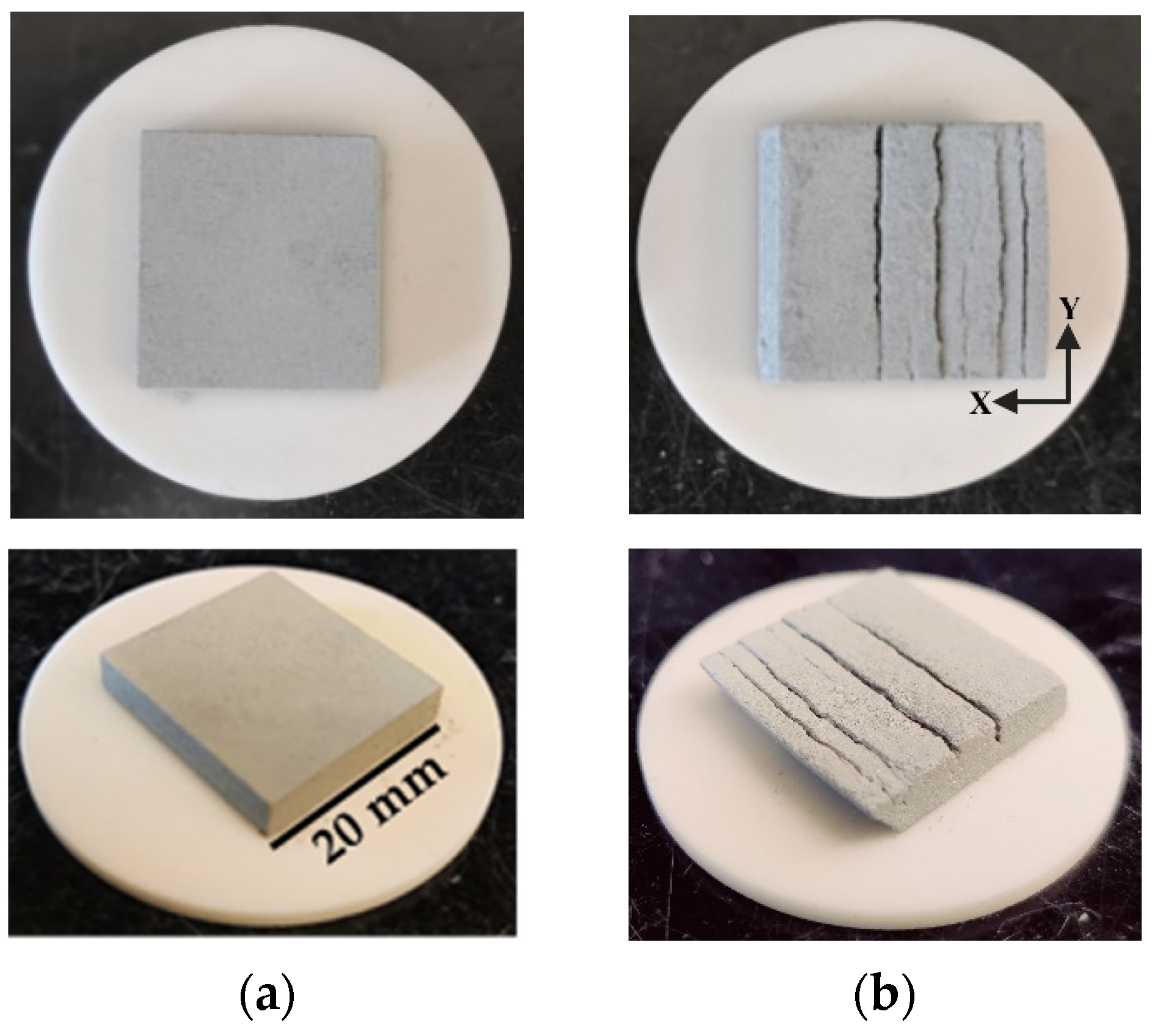

2.5. Evaluation of Integrity of Green Parts

2.6. Characterization of Microstructure of Green Parts

3. Results and Discussion

3.1. Results

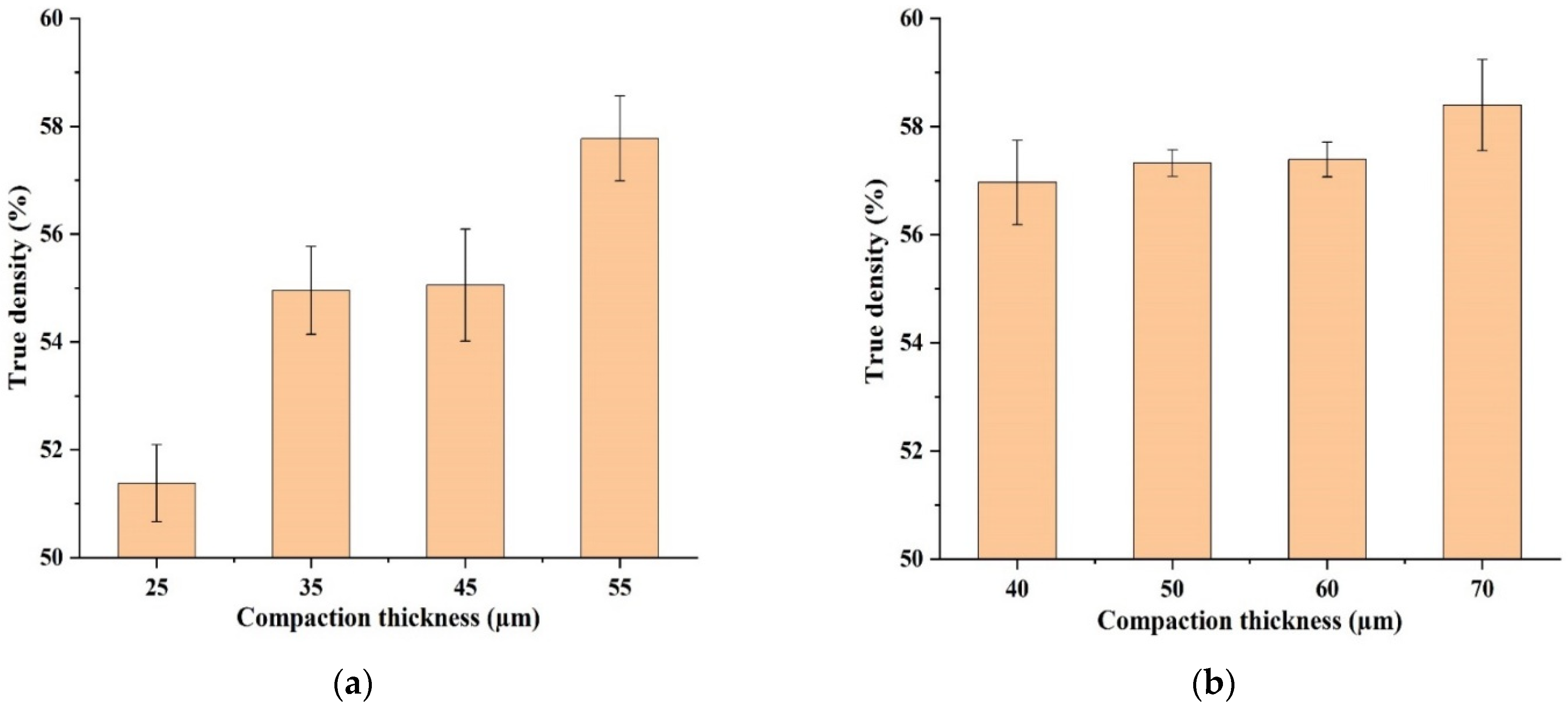

3.1.1. Effects of Compaction Thickness on Density of Green Parts

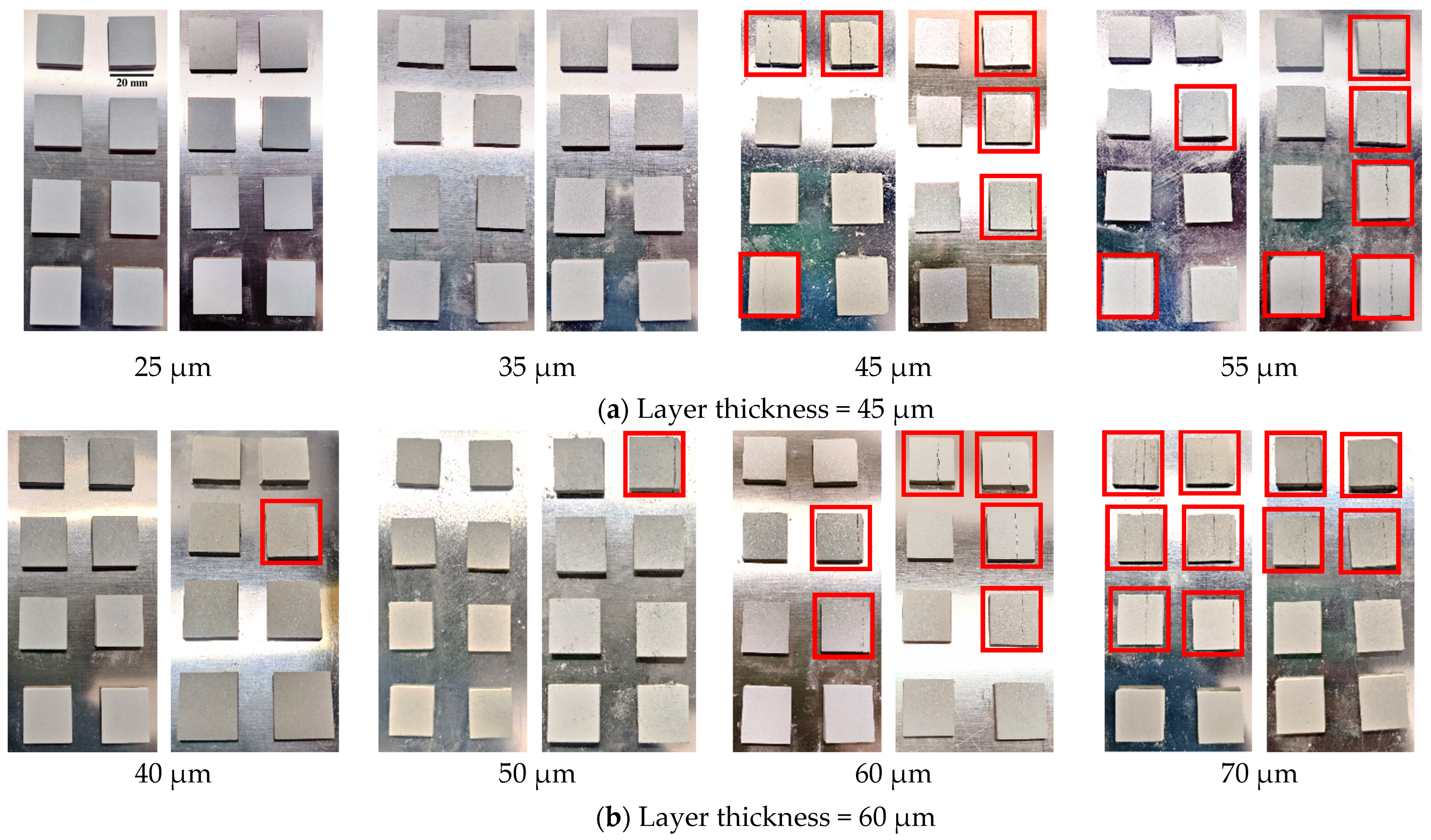

3.1.2. Effects of Compaction Thickness on Integrity of Green Parts

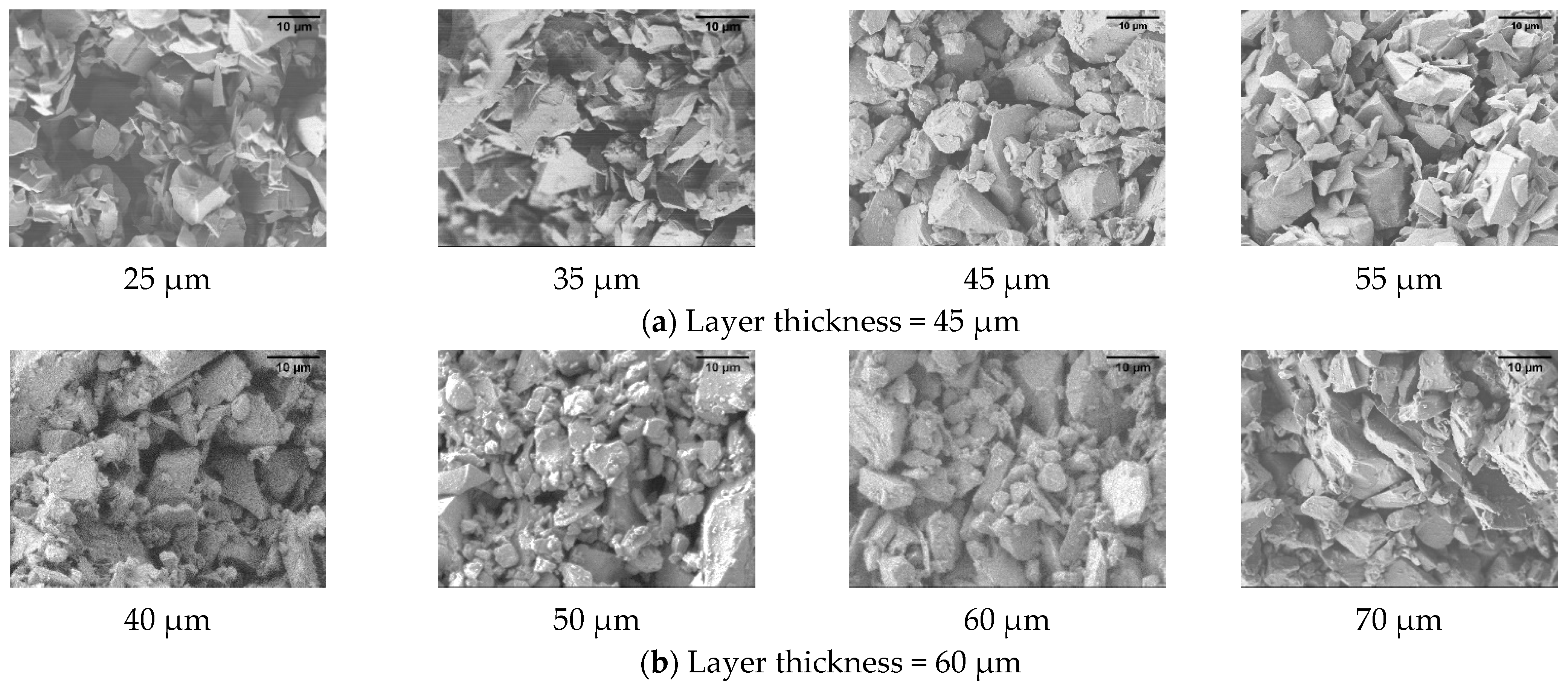

3.1.3. Effects of Compaction Thickness on Microstructure of Green Parts

3.2. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boretti, A.; Castelletto, S. A perspective on 3D printing of silicon carbide. J. Eur. Ceram. Soc. 2024, 44, 1351–1360. [Google Scholar] [CrossRef]

- Eom, J.-H.; Kim, Y.-W.; Raju, S. Processing and properties of macroporous silicon carbide ceramics: A review. J. Asian Ceram. Soc. 2013, 1, 220–242. [Google Scholar] [CrossRef]

- Polozov, I.; Razumov, N.; Masaylo, D.; Silin, A.; Lebedeva, Y.; Popovich, A. Fabrication of silicon carbide fiber-reinforced silicon carbide matrix composites using binder jetting additive manufacturing from irregularly-shaped and spherical powders. Materials 2020, 13, 1766. [Google Scholar] [CrossRef]

- Steibel, J. Ceramic matrix composites taking flight at GE Aviation. Am. Ceram. Soc. Bull 2019, 98, 30–33. [Google Scholar]

- Zhu, D. Aerospace Ceramic Materials: Thermal, Environmental Barrier Coatings and SiC/SiC Ceramic Matrix Composites for Turbine Engine Applications; Glenn Research Center: Brook Park, OH, USA, 2018. [Google Scholar]

- Wang, X.; Gao, X.; Zhang, Z.; Cheng, L.; Ma, H.; Yang, W. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: A focused review. J. Eur. Ceram. Soc. 2021, 41, 4671–4688. [Google Scholar] [CrossRef]

- Chatterjee, S.; Cholkar, A.; Kinahan, D.; Brabazon, D. Fabrication of Periodic Textures at Micron Level on Silicone Membrane Using Femtosecond Laser. In Proceedings of the TMS Annual Meeting & Exhibition, Orlando, FL, USA, 3–7 March 2024; pp. 1551–1562. [Google Scholar]

- Mahato, V.; Chatterjee, S.; Nyabadza, A.; Caputo, A.; Brabazon, D. Layer porosity in powder-bed fusion prediction using regression machine learning models and time-series features. Int. J. AI Mater. Des. 2024, 1, 33–49. [Google Scholar] [CrossRef]

- Banerjee, A.; Mondal, A.K.; Haldar, B.; Chatterje, S.; Alsaleh, N.A. Synthesis and characterisation of Fe38Al26Cu16Ni13Cr6 high entropy alloy processed through combined cable wire arc additive manufacturing (WAAM) process. Int. J. Adv. Manuf. Technol. 2024, 135, 5553–5573. [Google Scholar] [CrossRef]

- Khan, F.; Arman, M.S.; Sanders, J.; Pasha, M.M.; Rahman, A.M.; Pei, Z.; Dong, T. Binder Jetting 3D Printing Utilizing Waste Algae Powder: A Feasibility Study. Intell. Sustain. Manuf. 2024, 1, 10016. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Pasha, M.M.; Arman, M.S.; Khan, F.; Pei, Z.; Kachur, S. Effects of Layer Thickness and Compaction Thickness on Green Part Density in Binder Jetting Additive Manufacturing of Silicon Carbide: Designed Experiments. J. Manuf. Mater. Process. 2024, 8, 148. [Google Scholar] [CrossRef]

- Enneti, R.K.; Prough, K.C. Effect of binder saturation and powder layer thickness on the green strength of the binder jet 3D printing (BJ3DP) WC-12% Co powders. Int. J. Refract. Met. Hard Mater. 2019, 84, 104991. [Google Scholar] [CrossRef]

- Pasha, M.M.; Pei, Z.; Arman, M.S.; Gasdaska, C.J.; Kao, Y.-T. Effects of Mixing Speed and Mixing Time on Powder Segregation During Powder Mixing for Binder Jetting Additive Manufacturing: An Experimental Study. J. Manuf. Mater. Process. 2025, 9, 117. [Google Scholar] [CrossRef]

- Khan, F.; Sanders, J.; Arman, M.S.; Pasha, M.M.; Kachur, S.; Pei, Z. Fabrication of SiC–Aluminum Composites via Binder Jetting 3D Printing and Infiltration: A Feasibility Study. J. Compos. Sci. 2025, 9, 111. [Google Scholar] [CrossRef]

- Miyanaji, H.; Rahman, K.M.; Da, M.; Williams, C.B. Effect of fine powder particles on quality of binder jetting parts. Addit. Manuf. 2020, 36, 101587. [Google Scholar] [CrossRef]

- Jimenez, E.M.; Ding, D.; Su, L.; Joshi, A.R.; Singh, A.; Reeja-Jayan, B.; Beuth, J. Parametric analysis to quantify process input influence on the printed densities of binder jetted alumina ceramics. Addit. Manuf. 2019, 30, 100864. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Z.; Chen, L.; Zhu, D.; Fu, Z. Optimization of printing parameters to achieve high-density 316L stainless steel manufactured by binder jet 3D printing. J. Mater. Eng. Perform. 2023, 32, 3602–3616. [Google Scholar] [CrossRef]

- Mostafaei, A.; De Vecchis, P.R.; Kimes, K.A.; Elhassid, D.; Chmielus, M. Effect of binder saturation and drying time on microstructure and resulting properties of sinter-HIP binder-jet 3D-printed WC-Co composites. Addit. Manuf. 2021, 46, 102128. [Google Scholar] [CrossRef]

- Crane, N.B. Impact of part thickness and drying conditions on saturation limits in binder jet additive manufacturing. Addit. Manuf. 2020, 33, 101127. [Google Scholar] [CrossRef]

- Moghadasi, M.; Miao, G.; Li, M.; Pei, Z.; Ma, C. Combining powder bed compaction and nanopowders to improve density in ceramic binder jetting additive manufacturing. Ceram. Int. 2021, 47, 35348–35355. [Google Scholar] [CrossRef]

- Du, W.; Li, M.; Pei, Z.; Ma, C. Roller-compaction-assisted binder jetting with different granulated zirconia powders. Manuf. Lett. 2023, 35, 576–582. [Google Scholar] [CrossRef]

- Cramer, C.L.; Elliott, A.M.; Lara-Curzio, E.; Flores-Betancourt, A.; Lance, M.J.; Han, L.; Blacker, J.; Trofimov, A.A.; Wang, H.; Cakmak, E. Properties of SiC-Si made via binder jet 3D printing of SiC powder, carbon addition, and silicon melt infiltration. J. Am. Ceram. Soc. 2021, 104, 5467–5478. [Google Scholar] [CrossRef]

- She, Y.; Tang, J.; Wang, C.; Wang, Z.; Huang, Z.; Yang, Y. Preparation of high-density green body based on binder jetting 3d printing using spheroidized SiC powder. Ceram. Int. 2024, 50, 32412–32419. [Google Scholar] [CrossRef]

- Terrani, K.; Jolly, B.; Trammell, M. 3D printing of high-purity silicon carbide. J. Am. Ceram. Soc. 2020, 103, 1575–1581. [Google Scholar] [CrossRef]

- Elsergany, R.N.; Vreeman, G.; Sun, C.C. An approach for predicting the true density of powders based on in-die compression data. Int. J. Pharm. 2023, 637, 122875. [Google Scholar] [CrossRef]

- Li, M.; Wei, X.; Pei, Z.; Ma, C. Binder jetting additive manufacturing: Observations of compaction-induced powder bed surface defects. Manuf. Lett. 2021, 28, 50–53. [Google Scholar] [CrossRef]

- Dorula, M.; Khademitab, M.; Jamalkhani, M.; Mostafaei, A. Location dependency of green density and dimension variation in binder jetted parts. Int. J. Adv. Manuf. Technol. 2024, 132, 2853–2861. [Google Scholar] [CrossRef]

| Material | Particle Size | Particle Shape | Variable | Reference |

|---|---|---|---|---|

| Tungsten carbide–12% cobalt powder | 18.8–39.5 µm | Spherical | Binder saturation, layer thickness | [13] |

| Tungsten carbide–cobalt (WC-Co) powder | 1–63 µm | Spherical | Binder saturation, drying time | [19] |

| Copper powder | 3.2–7.5 µm | Spherical | Ultrasonic intensity, roller traverse speed | [16] |

| Stainless steel (316, 420) powder | 9.8–35, 25.5–63.2 µm | N/A | Layer thickness, binder saturation | [20] |

| Stainless steel powder | 24–50 µm | Spherical | Layer thickness, binder saturation, roller traverse speed | [18] |

| Alumina powder | 20–40 µm | Prismatic | Layer thickness, recoat speed, binder saturation, drying time | [17] |

| Alumina nano powder | 100 nm | Irregular | Layer thickness, compaction thickness | [21] |

| Zirconia powder | 25–90 µm | Spherical | Compaction thickness | [22] |

| SiC powder | 3–14 µm | N/A | Layer thickness, compaction thickness | [12] |

| Printing Variable | Value |

|---|---|

| Ultrasonic intensity (%) | 100 |

| Roller traverse speed during spreading (mm/s) | 15 |

| Roller traverse speed during compaction (mm/s) | 5 |

| Roller rotation speed during spreading (rpm) | 300 |

| Binder saturation (%) | 60 |

| Binder set time (s) | 30 |

| Bed temperature (°C) | 50 |

| Drying time (s) | 15 |

| Packing rate (%) | 50 |

| Experimental Condition | Layer Thickness (µm) | Compaction Thickness (µm) |

|---|---|---|

| 1 | 45 | 25 |

| 2 | 45 | 35 |

| 3 | 45 | 45 |

| 4 | 45 | 55 |

| 5 | 60 | 40 |

| 6 | 60 | 50 |

| 7 | 60 | 60 |

| 8 | 60 | 70 |

| Layer Thickness (µm) | Compaction Thickness (µm) | Replicate 1 Green Part Density (g/cm3) | Replicate 2 Green Part Density (g/cm3) | Average Green Part Density (g/cm3) | Standard Deviation (g/cm3) | Green Part Density (%) |

|---|---|---|---|---|---|---|

| 45 | 25 | 1.67 | 1.63 | 1.65 | 0.023 | 51.38 |

| 45 | 35 | 1.78 | 1.75 | 1.76 | 0.026 | 54.96 |

| 45 | 45 | 1.79 | 1.74 | 1.77 | 0.033 | 55.06 |

| 45 | 55 | 1.87 | 1.84 | 1.85 | 0.025 | 57.77 |

| 60 | 40 | 1.85 | 1.81 | 1.83 | 0.025 | 56.97 |

| 60 | 50 | 1.83 | 1.85 | 1.84 | 0.008 | 57.33 |

| 60 | 60 | 1.85 | 1.83 | 1.84 | 0.010 | 57.39 |

| 60 | 70 | 1.86 | 1.89 | 1.87 | 0.027 | 58.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasha, M.M.; Arman, M.S.; Pei, Z.; Khan, F.; Sanders, J.; Kachur, S. Effects of Compaction Thickness on Density, Integrity, and Microstructure of Green Parts in Binder Jetting Additive Manufacturing of Silicon Carbide. J. Manuf. Mater. Process. 2025, 9, 136. https://doi.org/10.3390/jmmp9040136

Pasha MM, Arman MS, Pei Z, Khan F, Sanders J, Kachur S. Effects of Compaction Thickness on Density, Integrity, and Microstructure of Green Parts in Binder Jetting Additive Manufacturing of Silicon Carbide. Journal of Manufacturing and Materials Processing. 2025; 9(4):136. https://doi.org/10.3390/jmmp9040136

Chicago/Turabian StylePasha, Mostafa Meraj, Md Shakil Arman, Zhijian Pei, Fahim Khan, Jackson Sanders, and Stephen Kachur. 2025. "Effects of Compaction Thickness on Density, Integrity, and Microstructure of Green Parts in Binder Jetting Additive Manufacturing of Silicon Carbide" Journal of Manufacturing and Materials Processing 9, no. 4: 136. https://doi.org/10.3390/jmmp9040136

APA StylePasha, M. M., Arman, M. S., Pei, Z., Khan, F., Sanders, J., & Kachur, S. (2025). Effects of Compaction Thickness on Density, Integrity, and Microstructure of Green Parts in Binder Jetting Additive Manufacturing of Silicon Carbide. Journal of Manufacturing and Materials Processing, 9(4), 136. https://doi.org/10.3390/jmmp9040136