Prediction of Residual Stresses During the Hot Forging Process of Spherical Shells Based on Microstructural Evolution

Abstract

1. Introduction

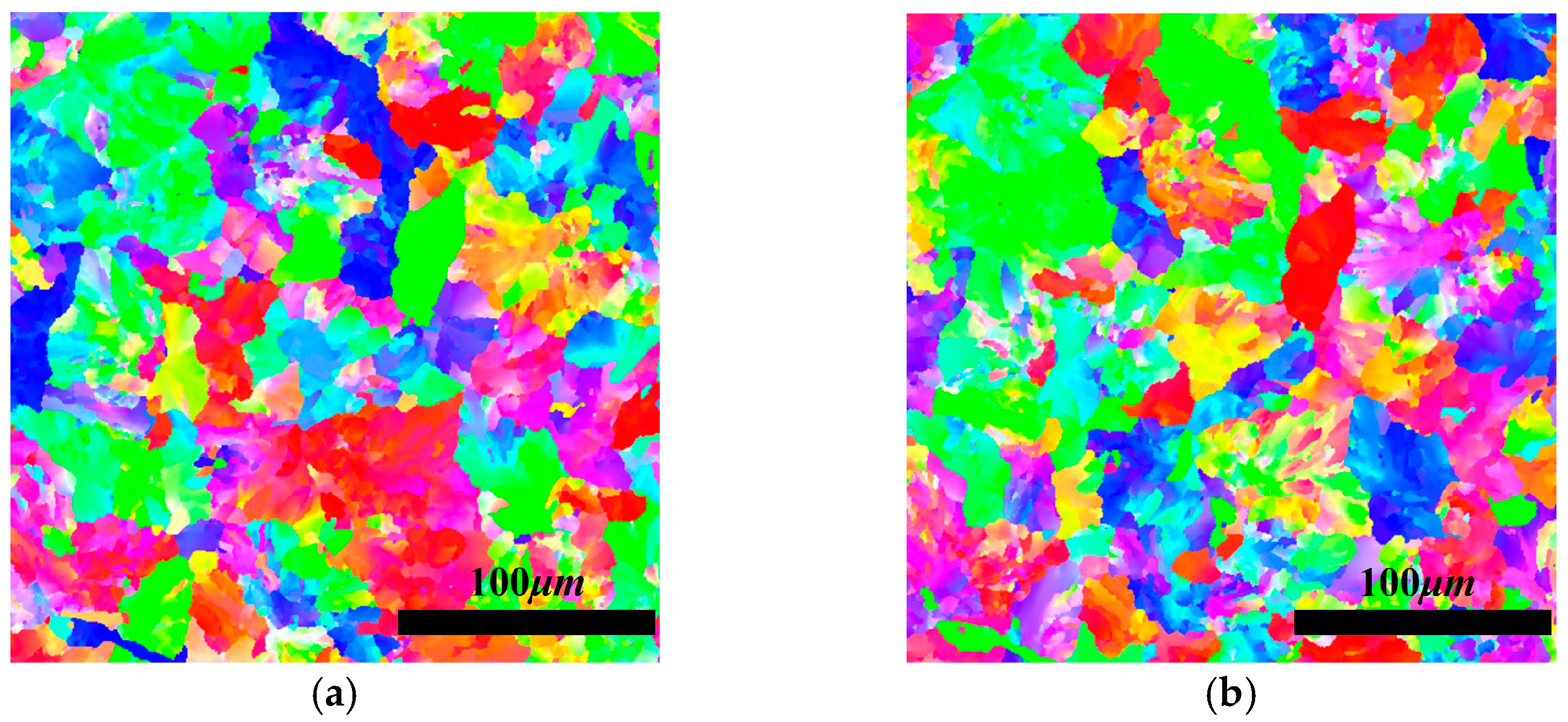

2. Experimental Procedure

3. Unified Viscoplastic Constitutive Model

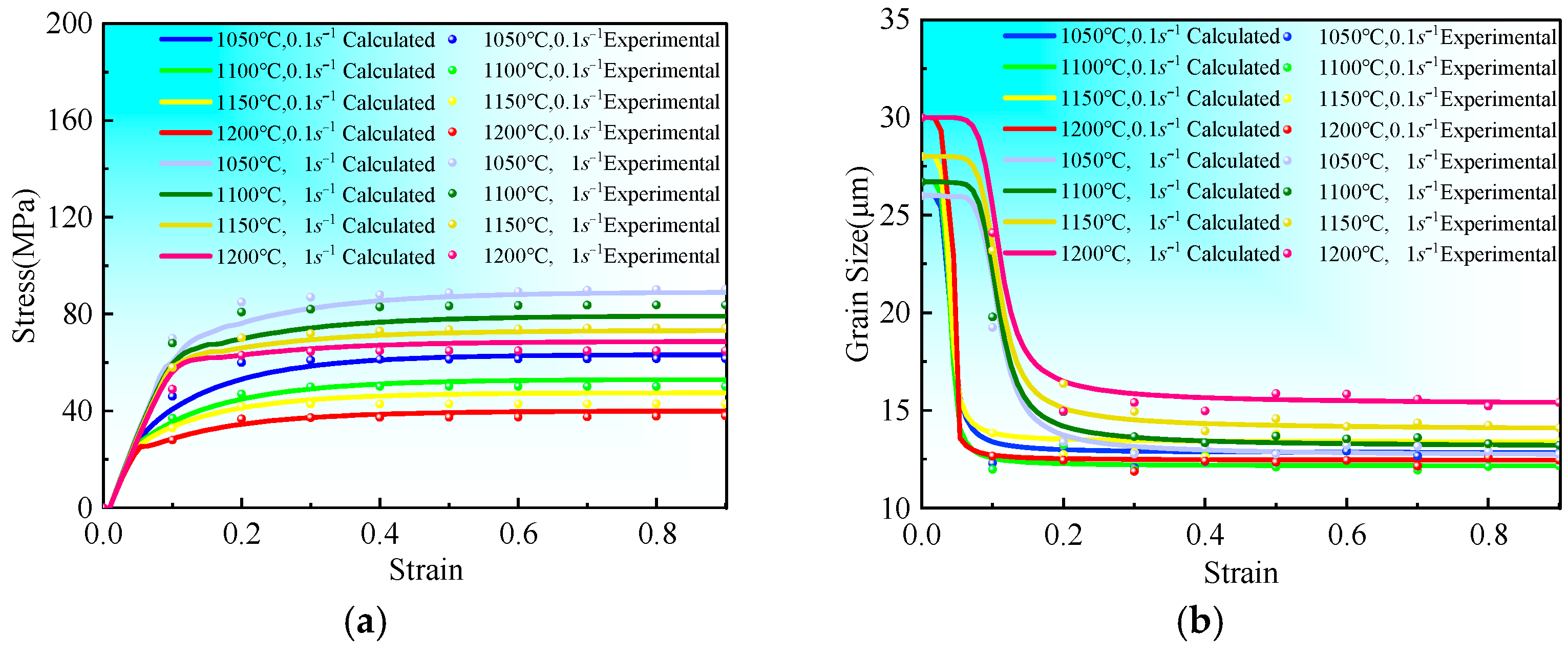

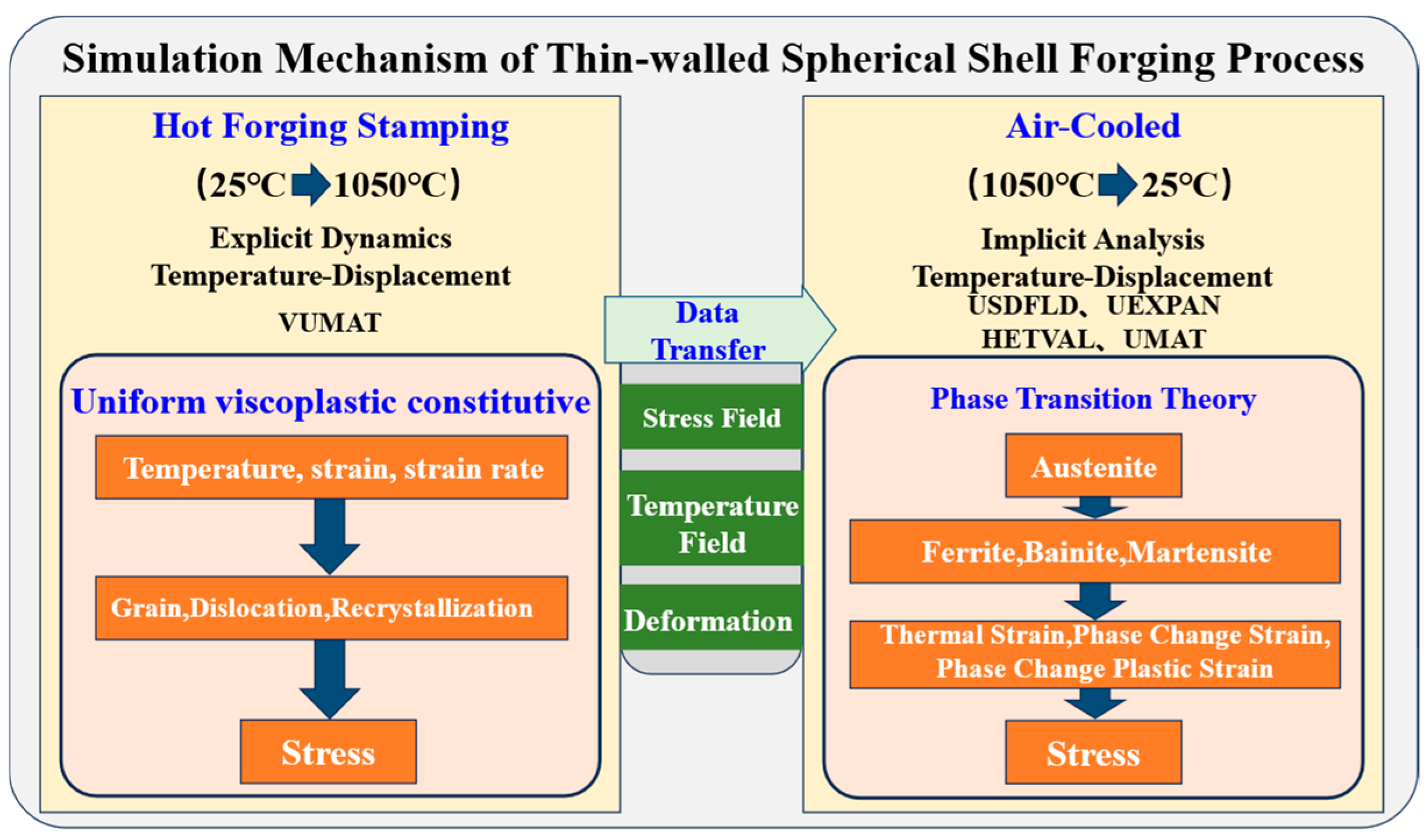

3.1. The Establishment of the Unified Viscoplastic Constitutive Model

3.2. Multi-Parameter Optimization of the Viscoplastic Constitutive Equation Based on a Genetic Algorithm

4. Thermoplastic Constitutive Model of Phase Transformation

4.1. Phase Transition Field

4.2. Strain Field

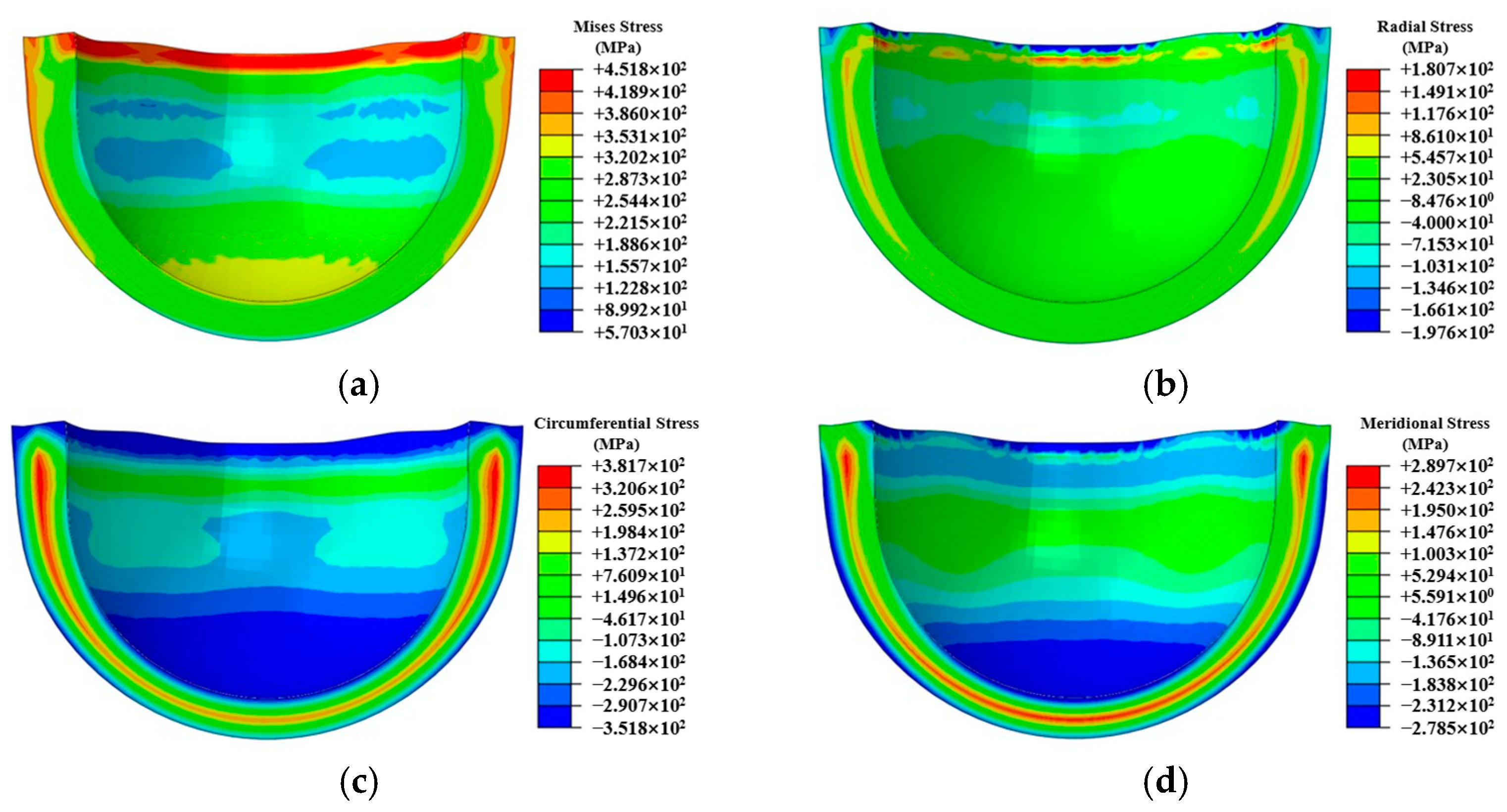

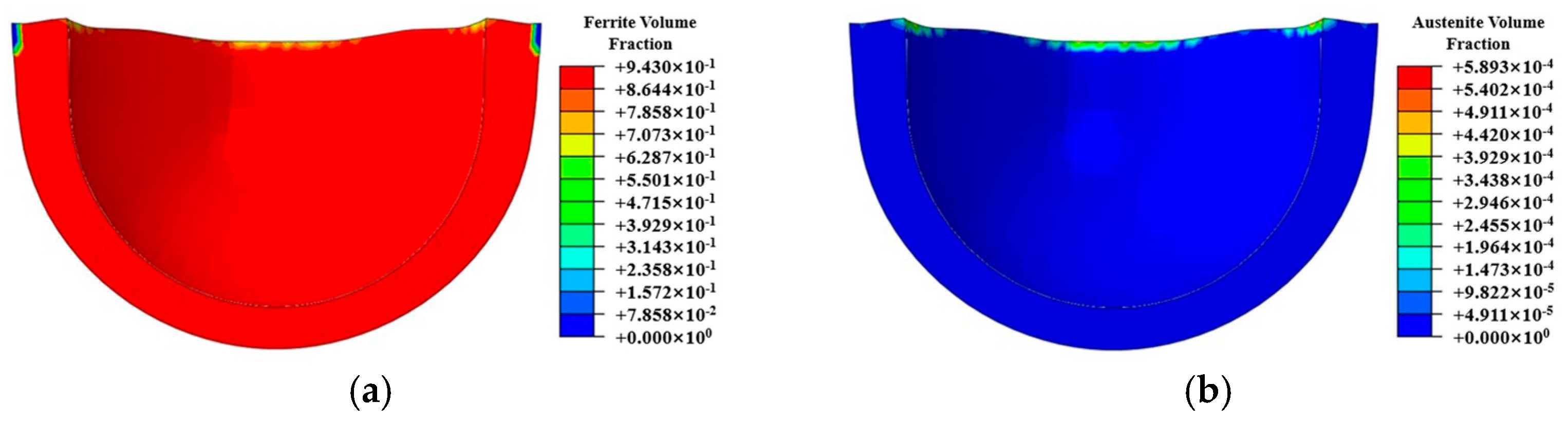

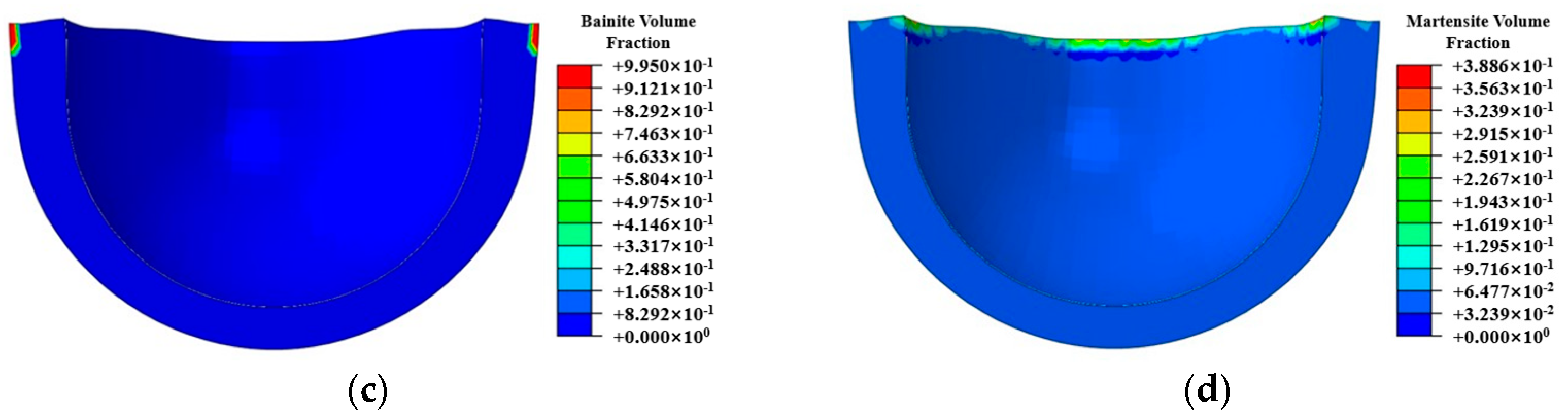

5. Distribution Law of Residual Stress in Thermal Forging of Thin-Walled Spherical Shells and Experimental Verification

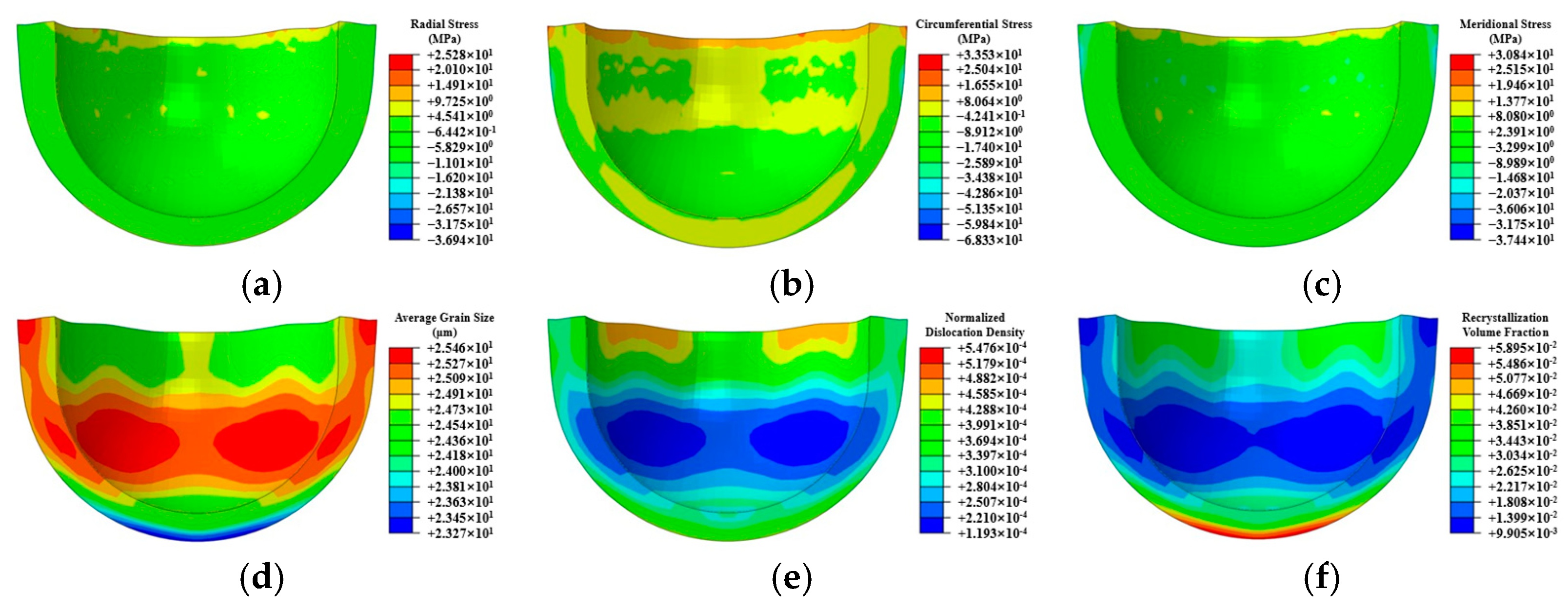

5.1. Numerical Simulation of Residual Stress Evolution During the Hot Forging Process

5.2. Measurement of Residual Stress Using Ultrasonic Method

6. Conclusions

- (1)

- Through systematic high-temperature dynamic compression experiments, this study develops a unified viscoplastic constitutive model specifically tailored for medium-carbon steel. The proposed model effectively captures the intricate coupling mechanisms between microstructural evolution and stress–strain response across a wide range of thermomechanical processing conditions (temperature: 1050–1150 °C; strain rate: 0.1–1 s ⁻1). The model’s formulation incorporates key metallurgical phenomena, including dynamic recovery and recrystallization processes, enabling accurate prediction of material behavior under complex thermo-mechanical loading scenarios.

- (2)

- A unified viscoplastic constitutive model was employed to numerically simulate the behavior of thin-walled spherical shells during the hot forging and stamping process. The study revealed the distribution patterns of grain size, dislocations, and recrystallization under high-temperature transient conditions. Corresponding processing techniques were developed to ensure that components achieve a uniform grain distribution.

- (3)

- Leveraging the time–temperature–transformation (TTT) diagram for undercooled austenite in medium-carbon steel (ISO C45E [1]), a comprehensive kinetic model was developed to characterize phase transformation behavior during air cooling processes. This model incorporates temperature-dependent transformation kinetics and accounts for the cooling rate effects within the range of 0.5–5 °C/s. Through coupled thermo-metallurgical-mechanical finite element simulations, the research successfully predicted the spatial distribution of phase constituents (ferrite, pearlite, and bainite fractions) and the corresponding residual stress fields in thin-walled spherical shells upon reaching room temperature (25 ± 2 °C). The simulation results demonstrated a strong correlation with experimental measurements, within 16.5% error in residual stress magnitude.

- (4)

- Experimental validation through residual stress measurements (utilizing an ultrasonic measurement technique with a measurement accuracy of ±40 MPa) demonstrates that the implemented data transfer methodology effectively preserves the continuity of stress fields, temperature histories, and deformation states between successive manufacturing stages. This approach enables precise prediction of residual stress evolution throughout multi-step manufacturing processes, with particular accuracy in tracking stress redistribution during critical transitions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ISV | Internal State Variables |

References

- Nina, S.; Ivan, S.; Yuri, P. Low-cycle deformation of steel C45E under rigid loading. Procedia Struct. Integr. 2022, 39, 157–160. [Google Scholar]

- Petkar, P.M.; Gaitonde, V.N.; Karnik, S.R.; Kulkarni, V.N.; Raju, T.K.G.; Davim, J.P. Analysis of Forming Behavior in Cold Forging of AISI 1010 Steel Using Artificial Neural Network. Metals 2020, 10, 1431. [Google Scholar] [CrossRef]

- Cheng, W.L.; Bai, Y.; Ma, S.C.; Wang, L.; Wang, H.; Yu, H. Hot deformation behavior and workability characteristic of a fine-grained Mg-8Sn-2Zn-2Al alloy with processing map. J. Mat. Sci. Technol. 2019, 35, 1198–1209. [Google Scholar] [CrossRef]

- Davim, J.P. Materials Forming and Machining; Woodhead Publishing: Sawston, UK, 2015; Available online: https://www.sciencedirect.com/book/9780857094834/materials-forming-and-machining (accessed on 26 August 2024).

- Zhang, F.; Liu, Z.; Wang, Y.; Mao, P.; Kuang, X.; Zhang, Z.; Ju, Y.; Xu, X. The modified temperature term on Johnson-Cook constitutive model of AZ31 magnesium alloy with {0002} texture. J. Magnes. Alloys 2020, 8, 172–183. [Google Scholar] [CrossRef]

- Xia, X.S.; Chen, Q.; Zhang, K.; Zhao, Z.; Ma, M.; Li, X.; Li, Y. Hot deformation behavior and processing map of coarse-grained Mg-Gd-Y-Nd-Zr alloy. Mater. Sci. Eng. A 2013, 587, 283–290. [Google Scholar] [CrossRef]

- Xiao, W.C.; Wang, B.Y.; Wu, Y.; Yang, X. Constitutive modeling of flow behavior and microstructure evolution of AA7075 in hot tensile deformation. Mater. Sci. Eng. A 2018, 712, 704–713. [Google Scholar] [CrossRef]

- Huo, Y.M.; Bai, Q.; Wang, B.Y.; Lin, J.; Zhou, J. A new application of unified constitutive equations for cross wedge rolling of a high-speed railway axle steel. J. Mater. Process. Technol. 2015, 223, 274–283. [Google Scholar] [CrossRef]

- Alabort, E.; Putman, D.; Reed, R.C. Superplasticity in Ti-6Al-4V: Characterisation, modelling and applications. Acta Mater. 2015, 95, 428–442. [Google Scholar] [CrossRef]

- Cai, Y.; Sun, C.Y.; Wang, W.R.; Li, Y.L.; Wan, L.; Qian, L.Y. An isothermal forming process with multi-stage variable speed for magnesium compo-nentassisted by sensitivity analysis. Mater. Sci. Eng. A 2018, 729, 9–20. [Google Scholar] [CrossRef]

- Su, Z.X.; Sun, C.Y.; Wang, M.J.; Qian, L.; Li, X. Modeling of microstructure evolution of AZ80 magnesium alloy during hot working process using a unified internal state variable method. J. Magnes. Alloys 2021, 10, 281–294. [Google Scholar] [CrossRef]

- Yang, X.; Li, Z.C.; Chen, S.N.; Wang, B.; Wang, B.; Tian, Y.; Wang, J. Establishment and application of an internal-variable-based constitutive model for the superplastic deformation of Inconel 718 alloy. Mater. Sci. Eng. A 2024, 896, 146297. [Google Scholar] [CrossRef]

- Pan, J.Q.; Zhang, W.C.; Yang, J.L.; Wang, S.; Wu, Y.; Li, H. Prediction of microstructure evolution of ZK6l alloy during hot spinning by internal state variable method. Trans. Nonferrous Met. Soc. 2024, 35, 126–142. [Google Scholar] [CrossRef]

- Dixit, U.S.; Joshi, S.N.; Davim, J.P. Incorporation of material behavior in modeling of metal forming and machining processes: A review. Mater. Des. 2011, 32, 3655–3670. [Google Scholar] [CrossRef]

- Zhu, B.; Zhang, Y.S.; Li, J.; Wang, H.; Ye, Z.C. Simulation research of hot stamping and phase transition of automotive high strength steel. Mater. Res. Innov. 2011, 15, 426–430. [Google Scholar] [CrossRef]

- Zhong, H.L.; Wang, Z.; Gan, J.; Wang, X.; Yang, Y.; He, J.; Wei, T.; Qin, X. Hot Numerical simulation of martensitic transformation plasticity of 42CrMo steel based on spot continual induction hardening model. Surf. Coat. Technol. 2020, 385, 125428. [Google Scholar] [CrossRef]

- Wang, M.M.; Han, L.Z.; Gu, J.F. Microstructure and kinetics of tempering of Mn-Mo-Ni nuclear power forging steel. Int. Heat Treat. Surf. Eng. 2013, 7, 159–163. [Google Scholar] [CrossRef]

- Li, C.W.; Han, L.Z.; Luo, X.M.; Liu, Q.D.; Gu, J.F. Effect of tempering temperature on the microstructure and mechanical properties of a reactor pressure vessel steel. J. Nucl. Mater. 2016, 477, 246–256. [Google Scholar] [CrossRef]

- Lin, J.; Dean, T.A. Modelling of microstructure evolution in hot forming using unified constitutive equations. J. Mater. Process. Tech. 2005, 167, 354–362. [Google Scholar] [CrossRef]

- Yang, L.; Wang, B.Y.; Liu, G.; Zhao, H.; Zhou, J. Hot Tensile Behavior and Self-consistent Constitutive Modeling of TA15 Titanium Alloy Sheets. J. Mater. Eng. Perform. 2015, 24, 4647–4655. [Google Scholar] [CrossRef]

- Wang, X.L.; Meng, Q.S.; Wang, Z.; Gan, J.; Yang, Y.; Qin, X.; Gao, K.; Zhong, H.; Cheng, M.; Gan, X. Prediction of the surface characteristic of 42CrMo after spot continual induction hardening based on a novel co-simulation method. Surf. Coat. Tech. 2019, 357, 252–266. [Google Scholar] [CrossRef]

- Mahmoud, Y.; Mounir, K.; Fakhreddine, D. Simulation of the thermomechanical and metallurgical behavior of steels by using ABAQUS software. Comput. Mater. Sci. 2013, 68, 297–306. [Google Scholar]

| Element | C | Si | Mn | Cr | Ni |

|---|---|---|---|---|---|

| Weight % | 0.42~0.50 | 0.20~0.26 | 0.55~0.63 | 0.20~0.25 | 0.25~0.30 |

| Strain | Strain Rate: 0.1 s−1 | Strain Rate: 1 s−1 | ||||||

|---|---|---|---|---|---|---|---|---|

| Temperature | 1050 °C | 1100 °C | 1150 °C | 1200 °C | 1050 °C | 1100 °C | 1150 °C | 1200 °C |

| 0 | 26 | 26.7 | 28 | 30 | 26 | 26.7 | 28 | 30 |

| 0.2 | 13.0 | 13.2 | 12.7 | 12.5 | 13.4 | 14.9 | 16.4 | 14.9 |

| 0.4 | 12.4 | 12.7 | 12.6 | 12.4 | 13.0 | 13.3 | 13.9 | 14.9 |

| 0.6 | 12.9 | 12.4 | 12.4 | 12.4 | 13.2 | 13.5 | 14.2 | 15.8 |

| 0.8 | 12.9 | 12.1 | 12.2 | 12.6 | 12.9 | 13.3 | 14.2 | 15.2 |

| = 8.31 J/mol/K (Universal gas constant); T: Absolute temperature (K) | |

| Material Constant | Optimal Value | Material Constant | Optimal Value | Material Constant | Optimal Value |

|---|---|---|---|---|---|

| 0.00978 | 2.62774 | 6.4186 × 104 | |||

| 2.10595 | 2.4804 × 102 | 7.1194 × 108 | |||

| 0.09196 | 0.00288 | 9.631 × 105 | |||

| 0.17491 | 0.74583 | 7.0607 × 102 | |||

| 9.5626 × 106 | 0.90535 | 2.71903 | |||

| 26 | 9.79059 | 56.93149 | |||

| 1.89809 | 3.6648 × 104 | 3.63979 | |||

| 1.7918 × 102 | 8.85911 | 3.2934 × 102 | |||

| 9.7320 × 10−21 | 9.8460 × 10−15 | 9.2481 × 103 | |||

| 7.38631 | 0.12982 | 9.8947 | |||

| 7.22927 |

| Temperature (K) | Coefficients of Thermal Expansion (1/K) | Thermal Conductivity (N/(sK)) | Specific Heat (N/mm2/K) |

|---|---|---|---|

| 373 | 1.16 × 10−5 | 43.53 | 4.80 × 108 |

| 473 | 1.32 × 10−5 | 40.44 | 4.98 × 108 |

| 573 | 1.48 × 10−5 | 38.13 | 5.24 × 108 |

| 673 | 1.64 × 10−5 | 36.02 | 5.60 × 108 |

| 773 | 1.76 × 10−5 | 34.16 | 6.15 × 108 |

| 873 | 1.92 × 10−5 | 31.98 | 7.00 × 108 |

| 973 | 2.12 × 10−5 | 28.66 | 8.54 × 108 |

| 1073 | 2.24 × 10−5 | 26.49 | 8.06 × 108 |

| 1173 | 2.36 × 10−5 | 25.92 | 6.37 × 108 |

| 1273 | 2.52 × 10−5 | 24.02 | 6.02 × 108 |

| 1373 | 2.64 × 10−5 | 24.02 | 6.02 × 108 |

| 1473 | 2.72 × 10−5 | 24.02 | 6.02 × 108 |

| 1573 | 2.72 × 10−5 | 24.02 | 6.05 × 108 |

| Phase | ρc (J/m3/°C) | Temperature (°C) |

|---|---|---|

| Austenite | 4.29 × 106 4.019 × 106 + 4.034 × 10−1T2 + 2.015 × 104T0.5 | ~200 200~900 |

| Ferrite | 3.42 × 106 + 1.347 × 10−1T2.5 − 3.745×10−3T3 + 2.698 × 10−2T0.5 | 19~900 |

| Bainite | 3.487 × 106 + 1.404 × 103T + 5.715 × 103T0.5 | 19~600 |

| Martensite | 3.41 × 106 + 3.215 × 10−3T3 + 2.919 × 104T0.5 | 19~400 |

| Phase | λ (W/m/°C) | Temperature (°C) |

|---|---|---|

| Austenite | 18 10.41 + 2.51 × 10−8T2.5 + 4.653×10−1T0.5 | ~200 200~900 |

| Ferrite | 44.01 − 3.863 × 10−5T2 − 3.001×10−7T2.5 | 19~900 |

| Bainite | 44.04 − 4.871 × 10−4T1.5 − 1.794×10−8T3 | 19~600 |

| Martensite | 44.05 − 5.019 × 10−4T1.5 − 1.611×10−8T3 | 19~400 |

| Phase Transformation | ΔH (J/m3) |

|---|---|

| Austenite to ferrite | 1.082 × 102 − 0.162(T + 273) + 1.118 × 10−4(T + 273)2 − 3 × 10−8(T + 273)3 − 3.501 × 104(T + 273)−1 |

| Austenite to bainite | 1.56 × 109 − 1.5 × 106T |

| Austenite to martensite | 6.4 × 108 |

| σy (Pa) | Temperature Range |

|---|---|

| −4.942 × 10−8T3 + 1.014 × 10−4T2 − 4.610 × 10−1T + 4.057 × 102 | 25~900 °C |

| Phase | α (1/°C) |

|---|---|

| Austenite | 2.20 × 10−5 |

| Ferrite | 1.57 × 10−5 |

| Bainite | 2.20 × 10−5 |

| Martensite | 1.15 × 10−5 |

| Phase Transformation | ξ = ΔV/3V (%) |

|---|---|

| Ferrite to austenite | −0.126 |

| Austenite to martensite | 0.342 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Li, J.; Wei, Z.; Fang, Y.; Li, H.; Huang, M. Prediction of Residual Stresses During the Hot Forging Process of Spherical Shells Based on Microstructural Evolution. J. Manuf. Mater. Process. 2025, 9, 86. https://doi.org/10.3390/jmmp9030086

Wu Y, Li J, Wei Z, Fang Y, Li H, Huang M. Prediction of Residual Stresses During the Hot Forging Process of Spherical Shells Based on Microstructural Evolution. Journal of Manufacturing and Materials Processing. 2025; 9(3):86. https://doi.org/10.3390/jmmp9030086

Chicago/Turabian StyleWu, Yupeng, Jiasheng Li, Zhaocheng Wei, Yuxin Fang, Hongxia Li, and Ming Huang. 2025. "Prediction of Residual Stresses During the Hot Forging Process of Spherical Shells Based on Microstructural Evolution" Journal of Manufacturing and Materials Processing 9, no. 3: 86. https://doi.org/10.3390/jmmp9030086

APA StyleWu, Y., Li, J., Wei, Z., Fang, Y., Li, H., & Huang, M. (2025). Prediction of Residual Stresses During the Hot Forging Process of Spherical Shells Based on Microstructural Evolution. Journal of Manufacturing and Materials Processing, 9(3), 86. https://doi.org/10.3390/jmmp9030086