Effects of Electron Beam Hardening Parameters on the Residual Stresses and Microstructures in C45 Steel Cylindrical Specimens

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

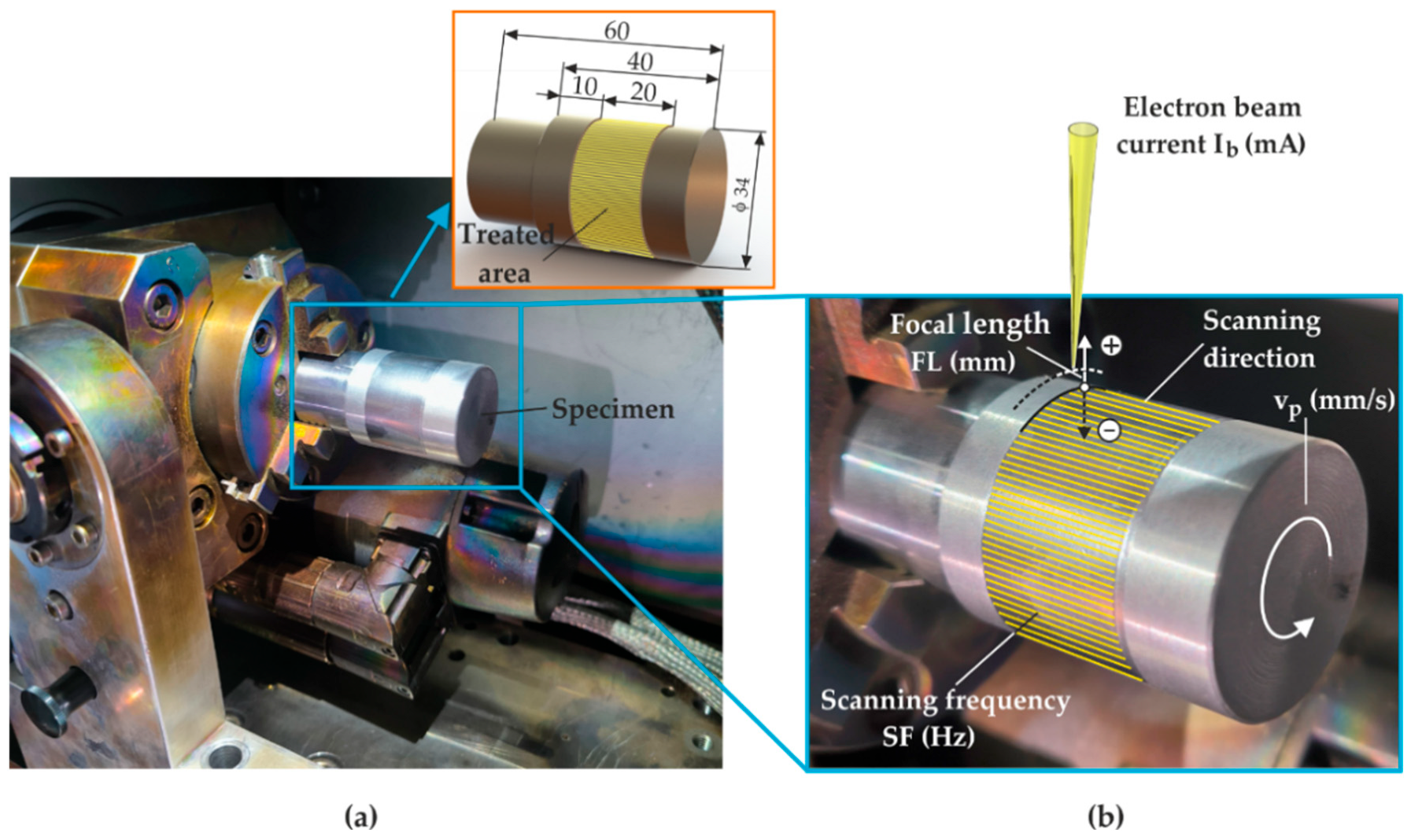

2.3. EBH Implementation

2.4. SI Characteristics Measurement

3. Results

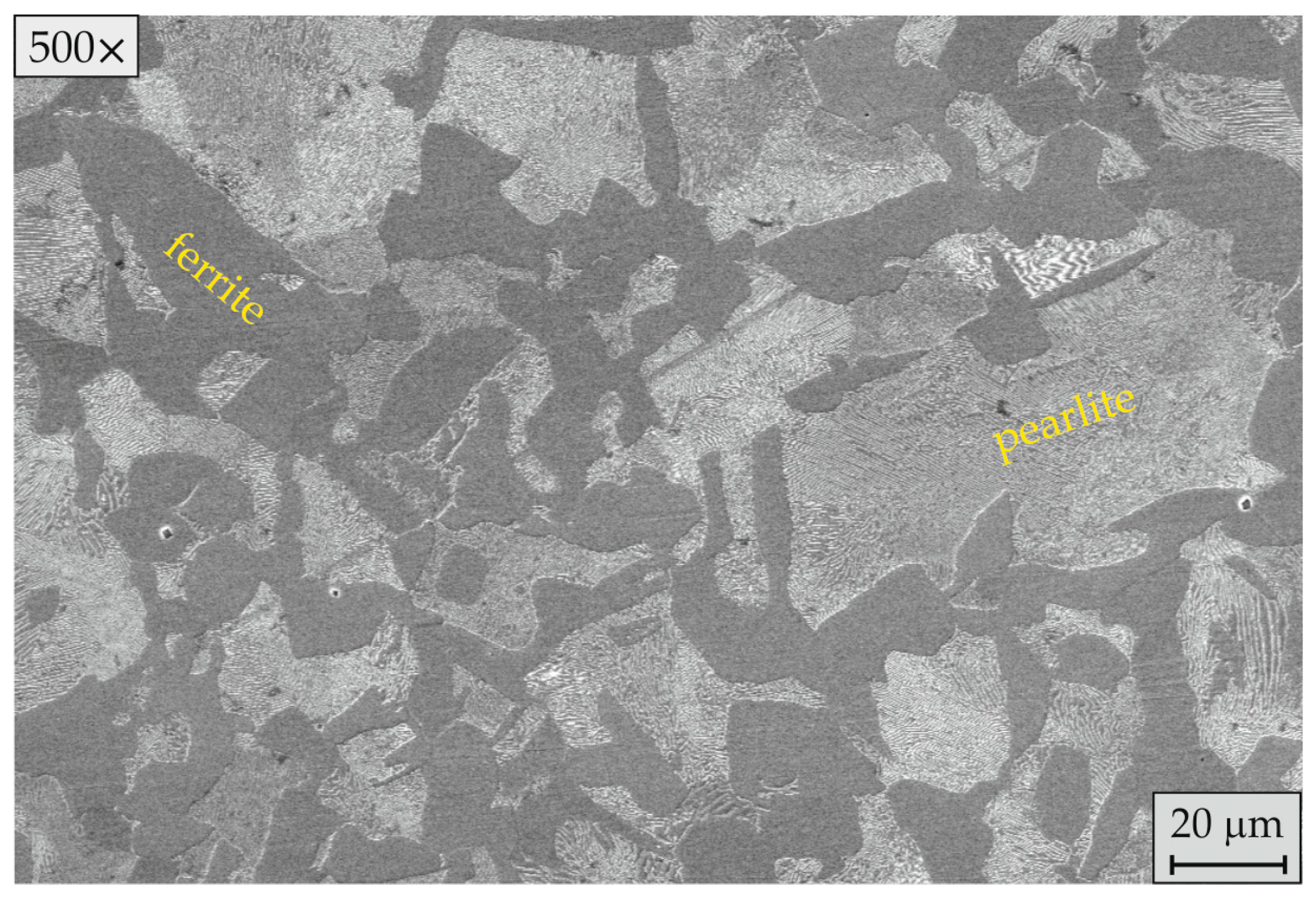

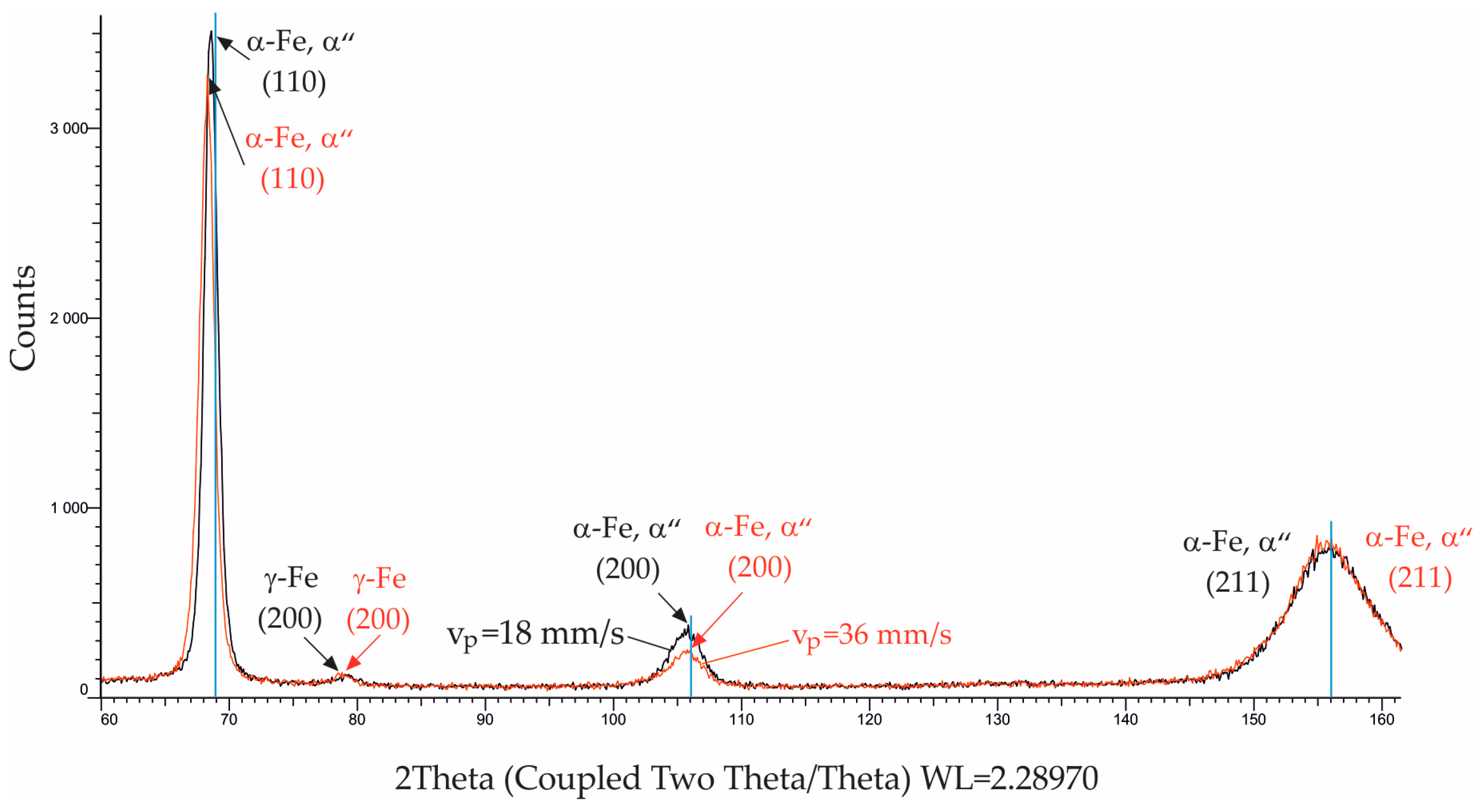

3.1. Material Measurements

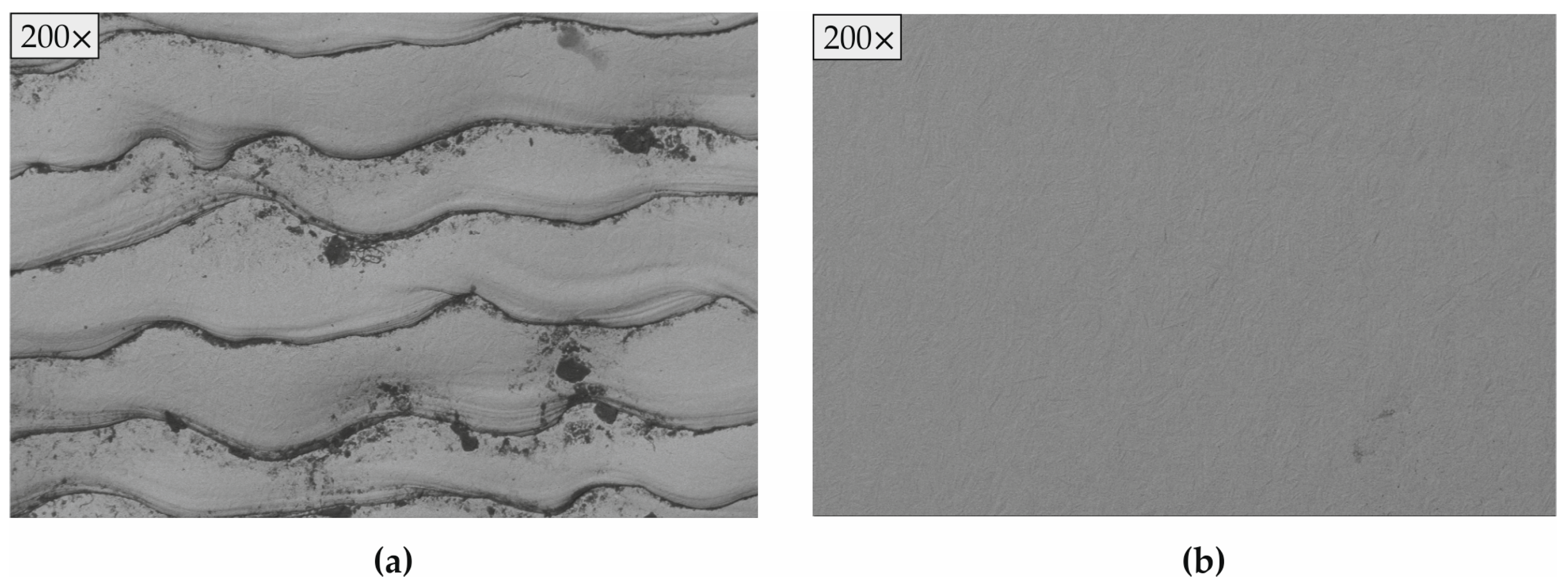

3.2. Roughness Parameter Evolution

3.3. Residual Stress

3.3.1. Effect of Electron Beam Current on RS

3.3.2. Effect of Workpiece Peripheral Velocity on RS

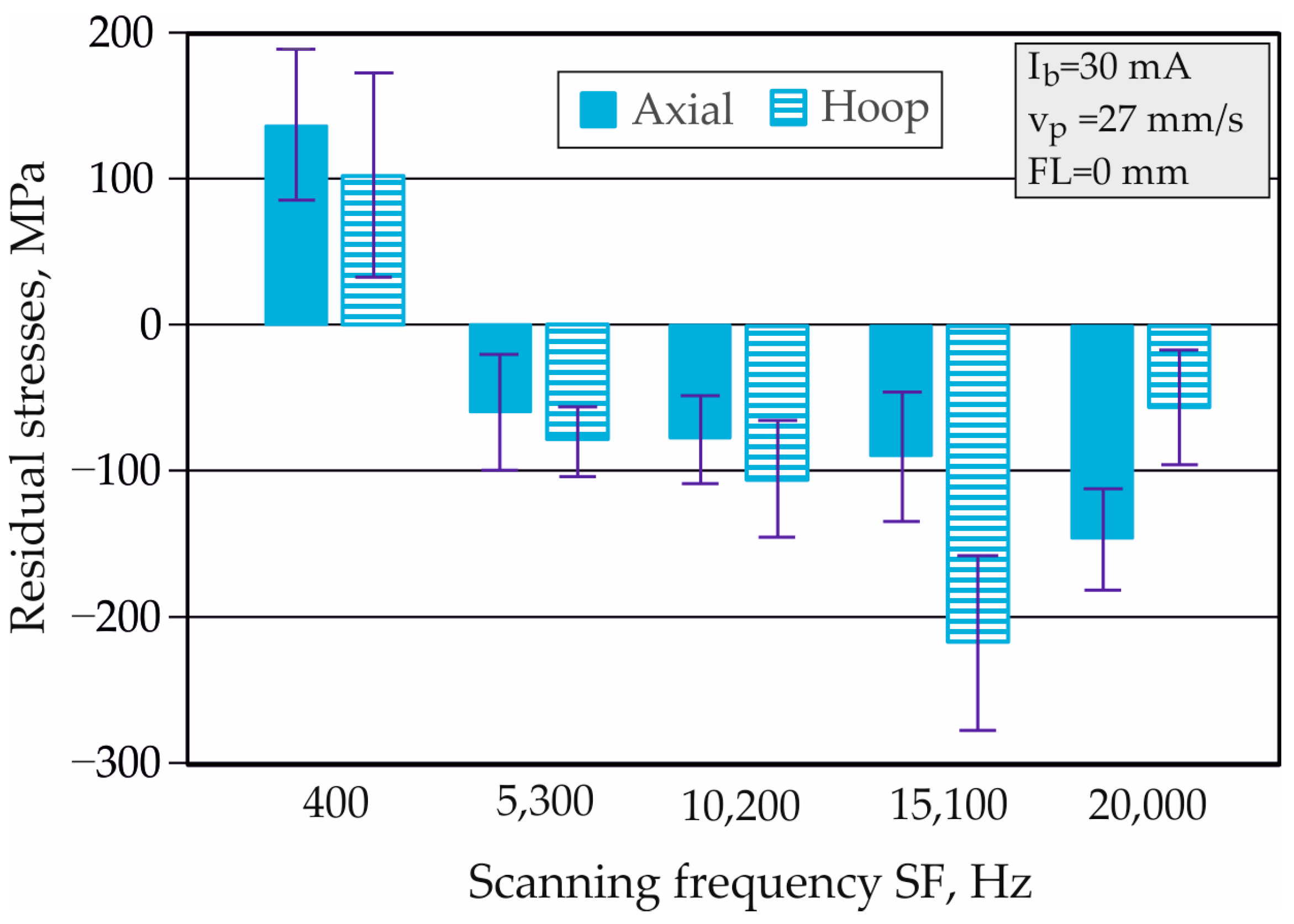

3.3.3. Effect of SF on RS

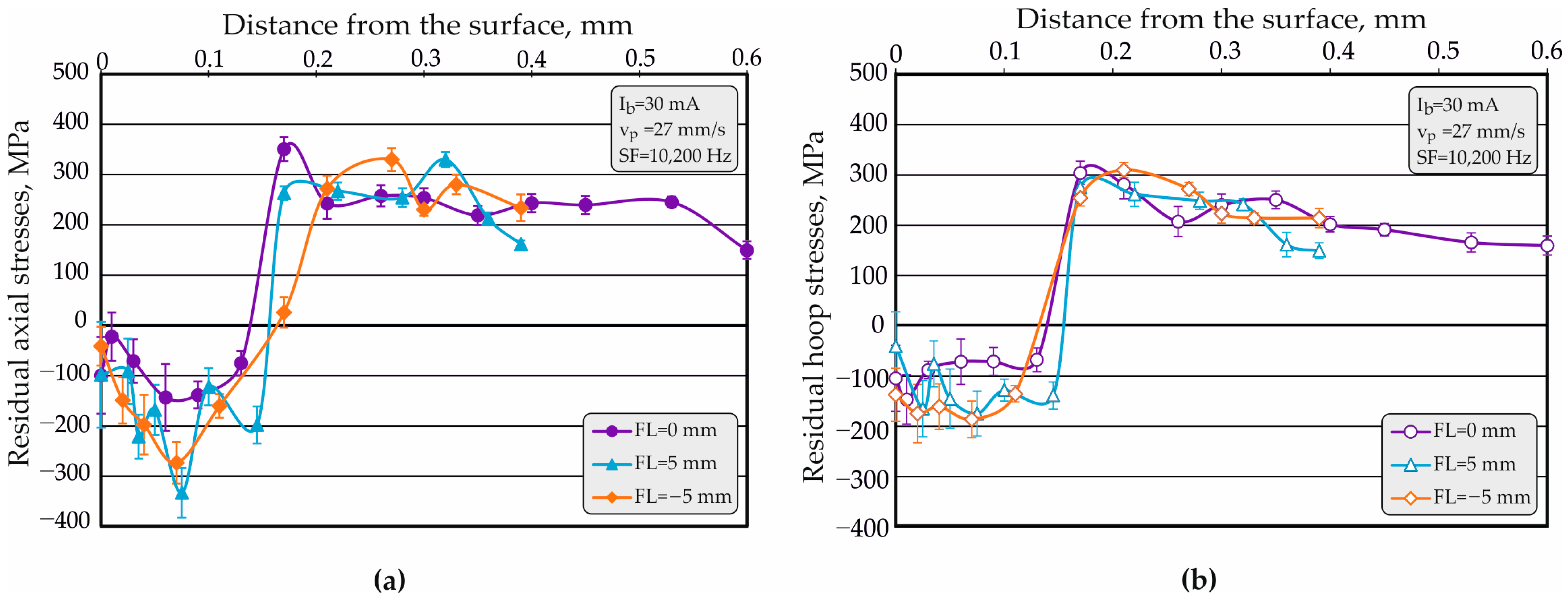

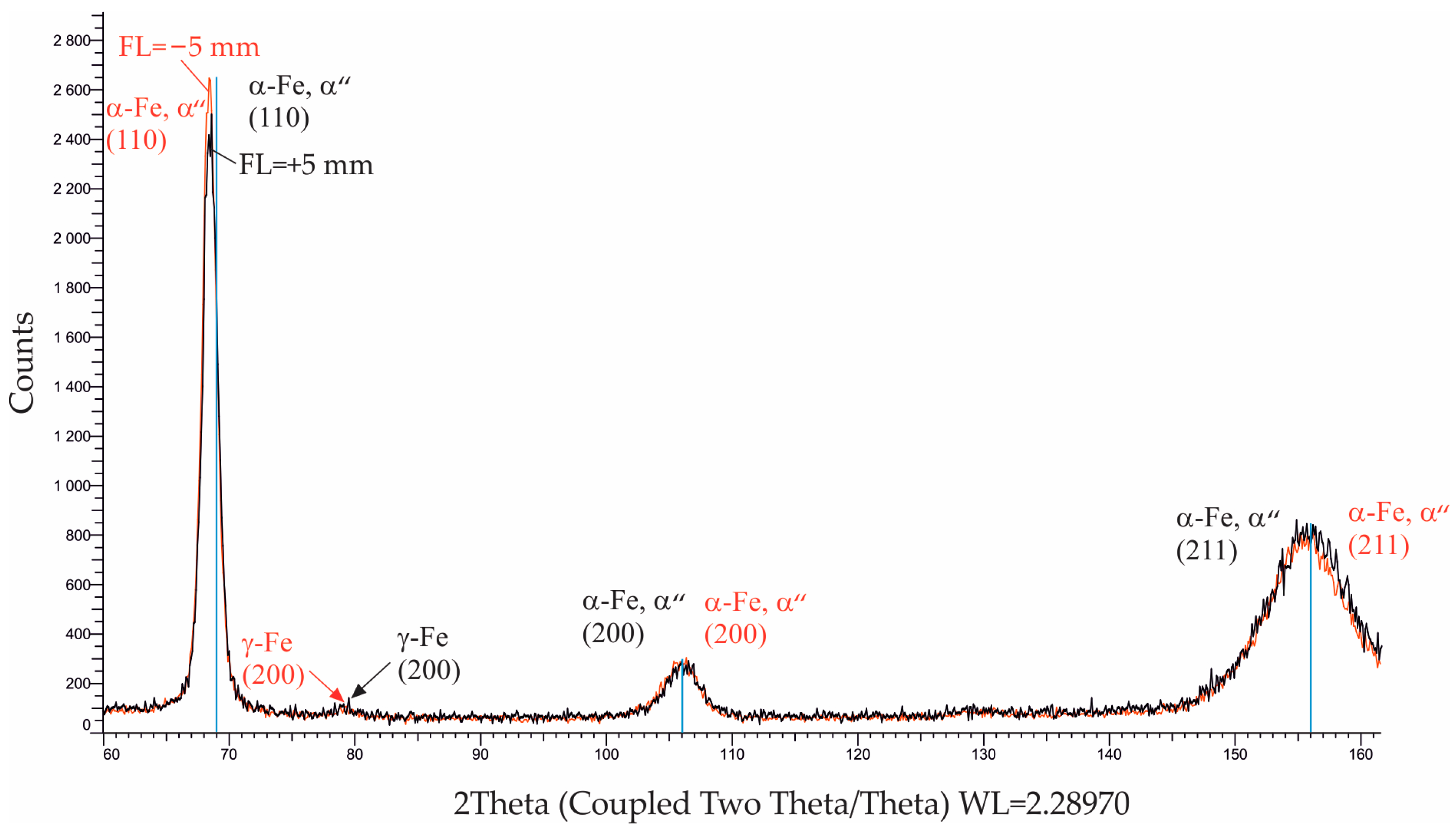

3.3.4. Effect of FL on RS

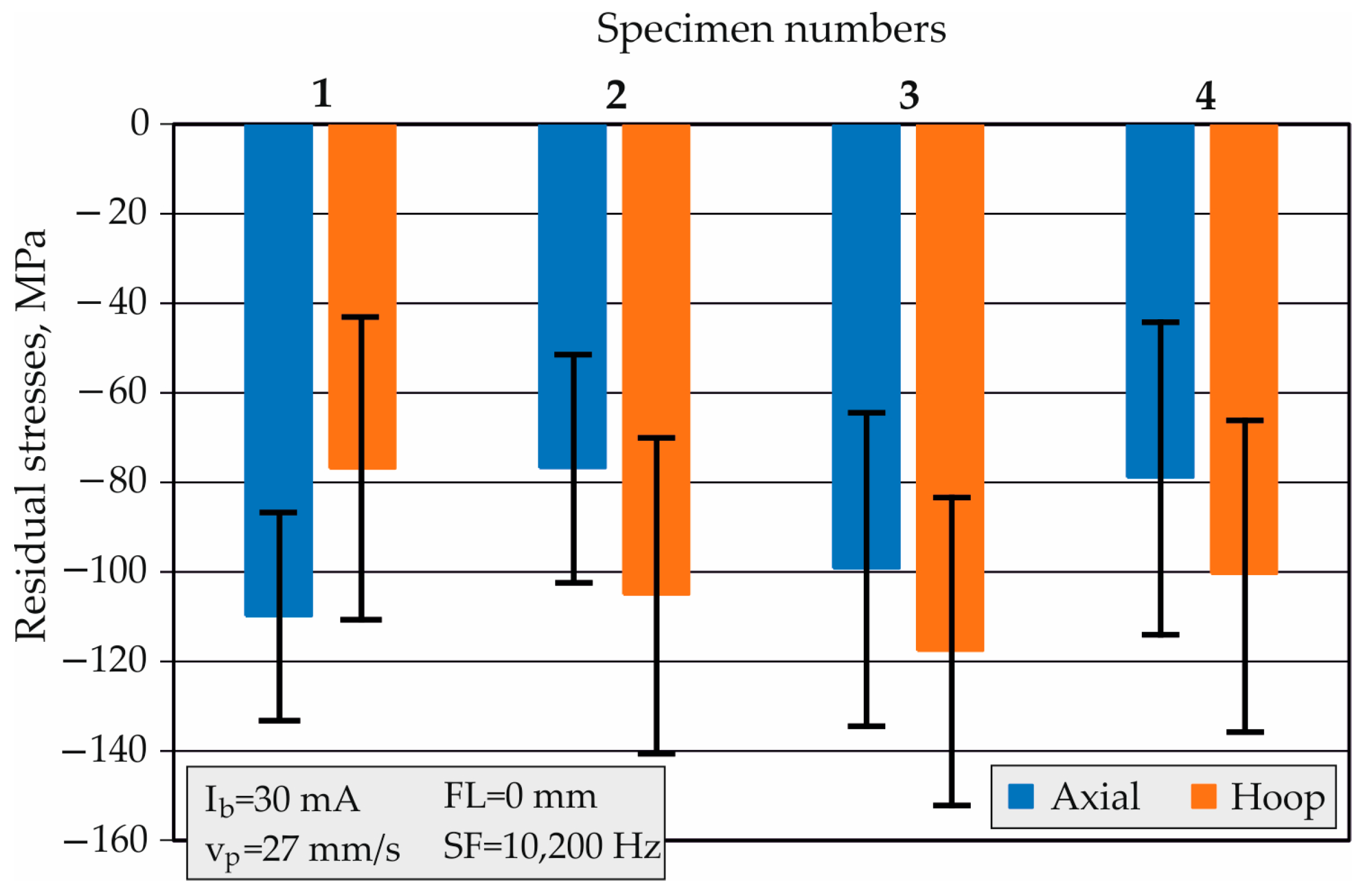

3.3.5. Experimental Study of the Repeatability of RS

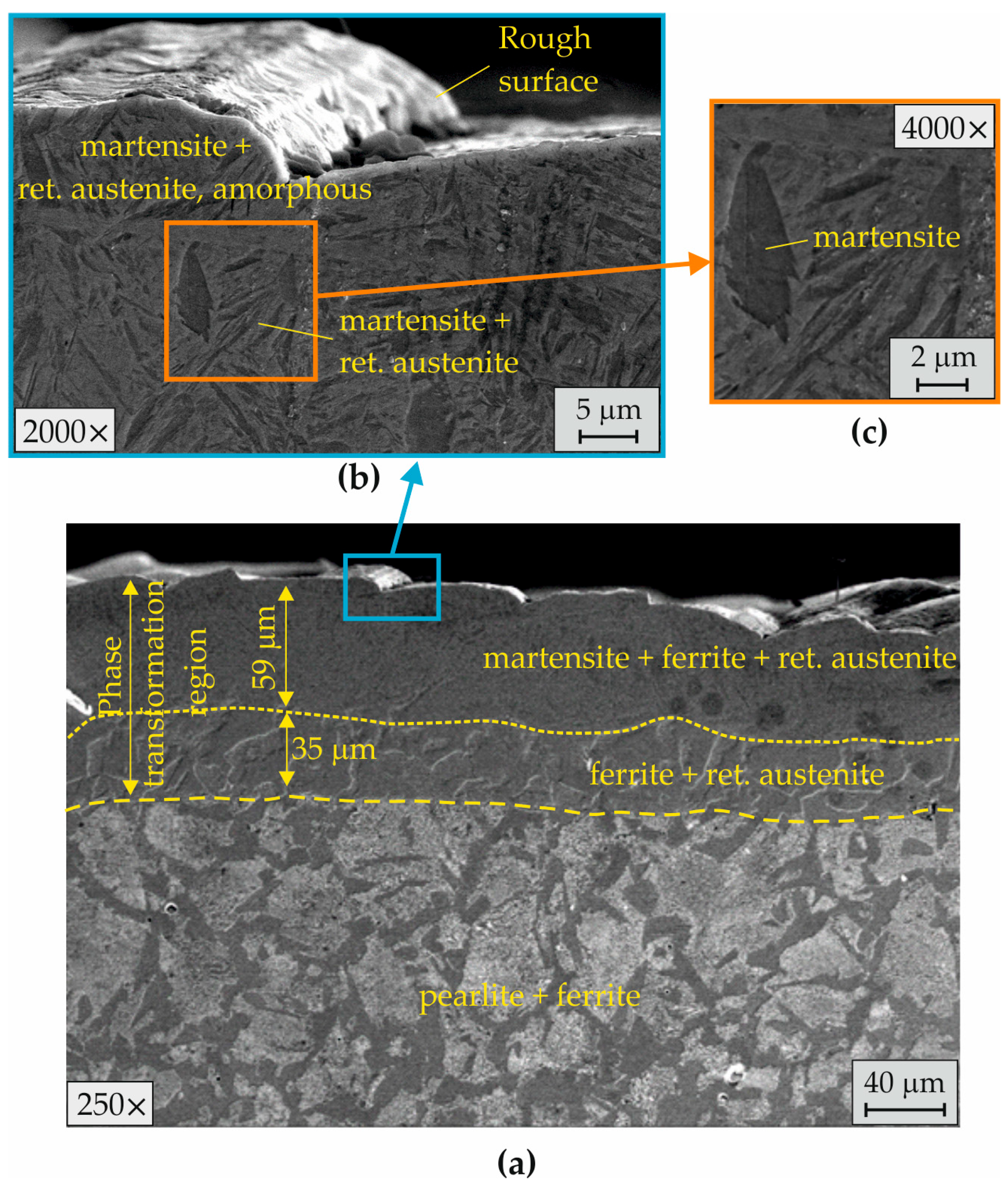

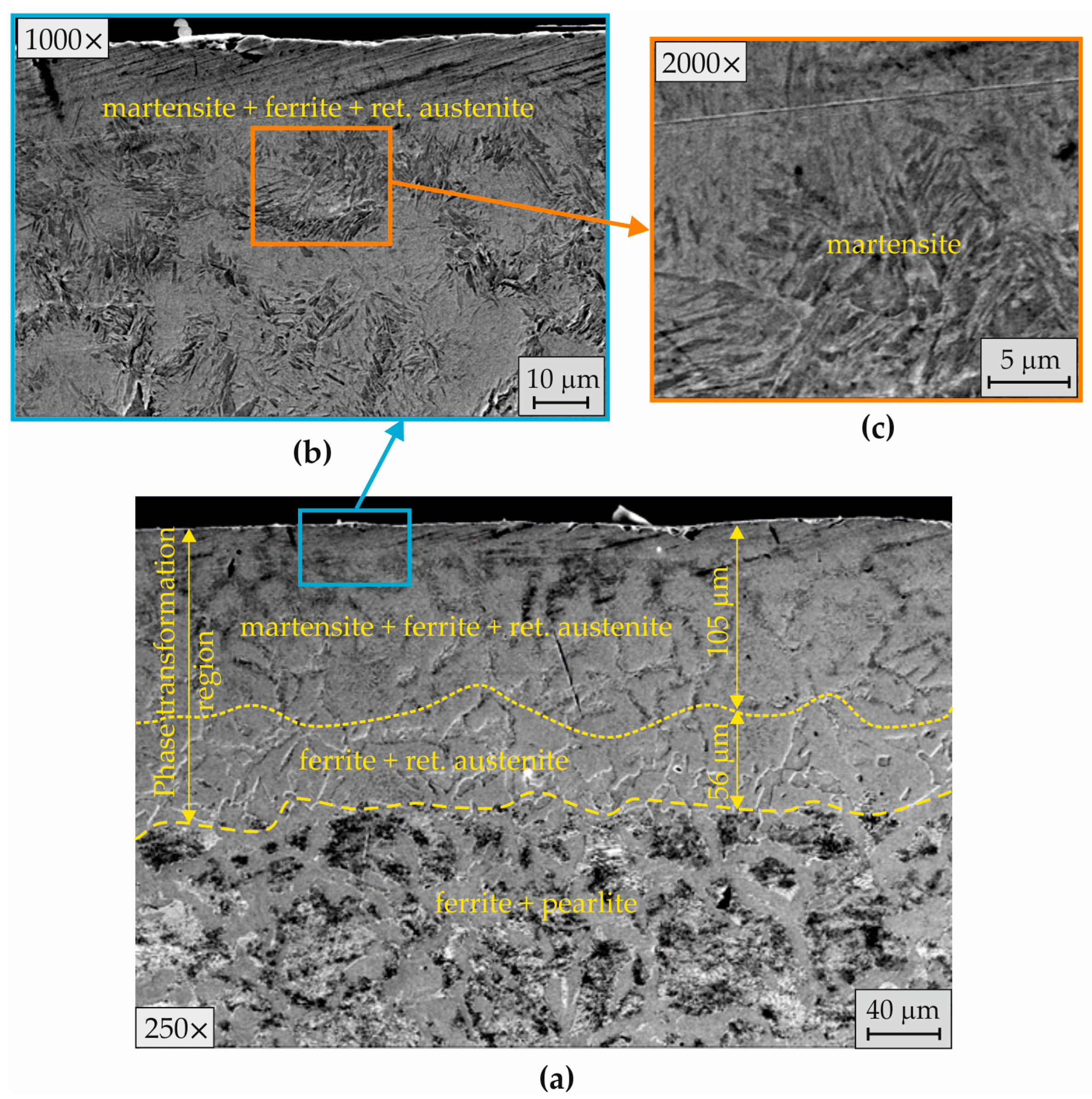

3.4. Microstructure

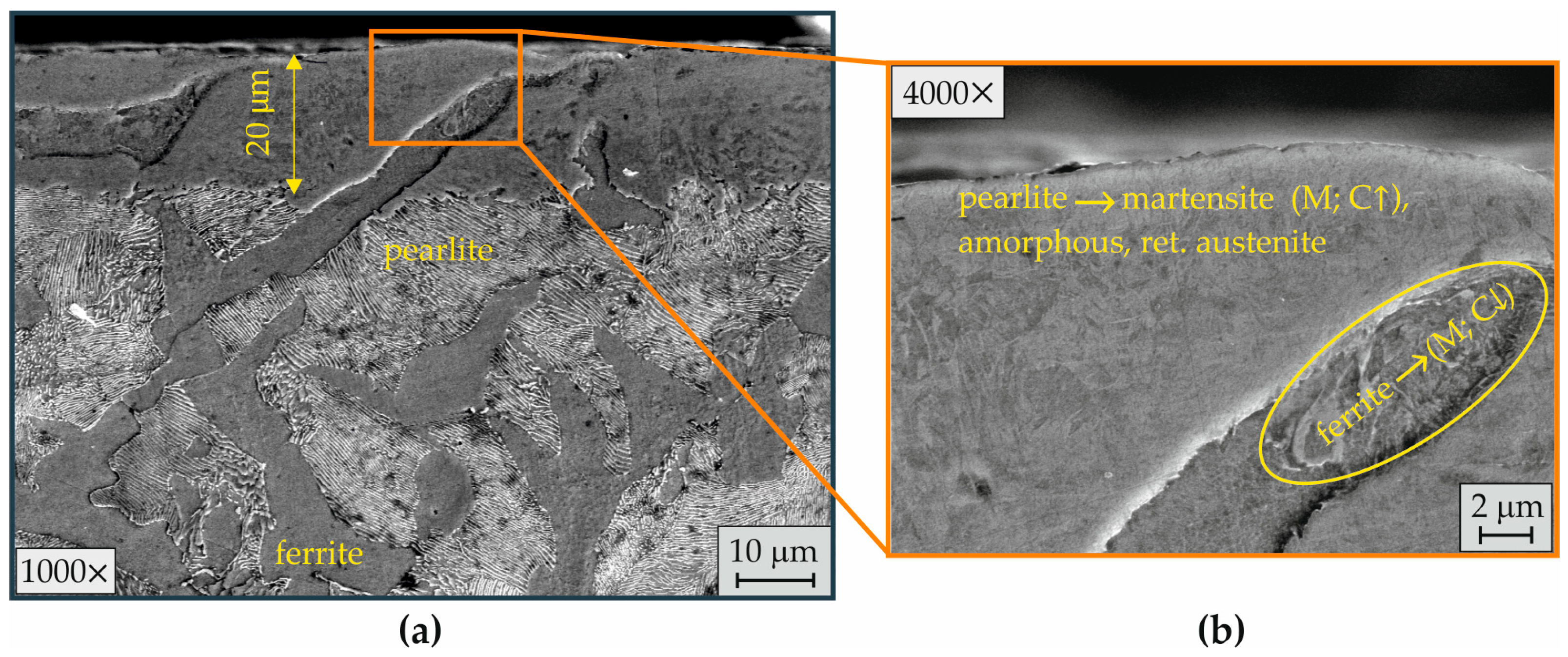

3.4.1. Effect of Electron Beam Current on Microstructure

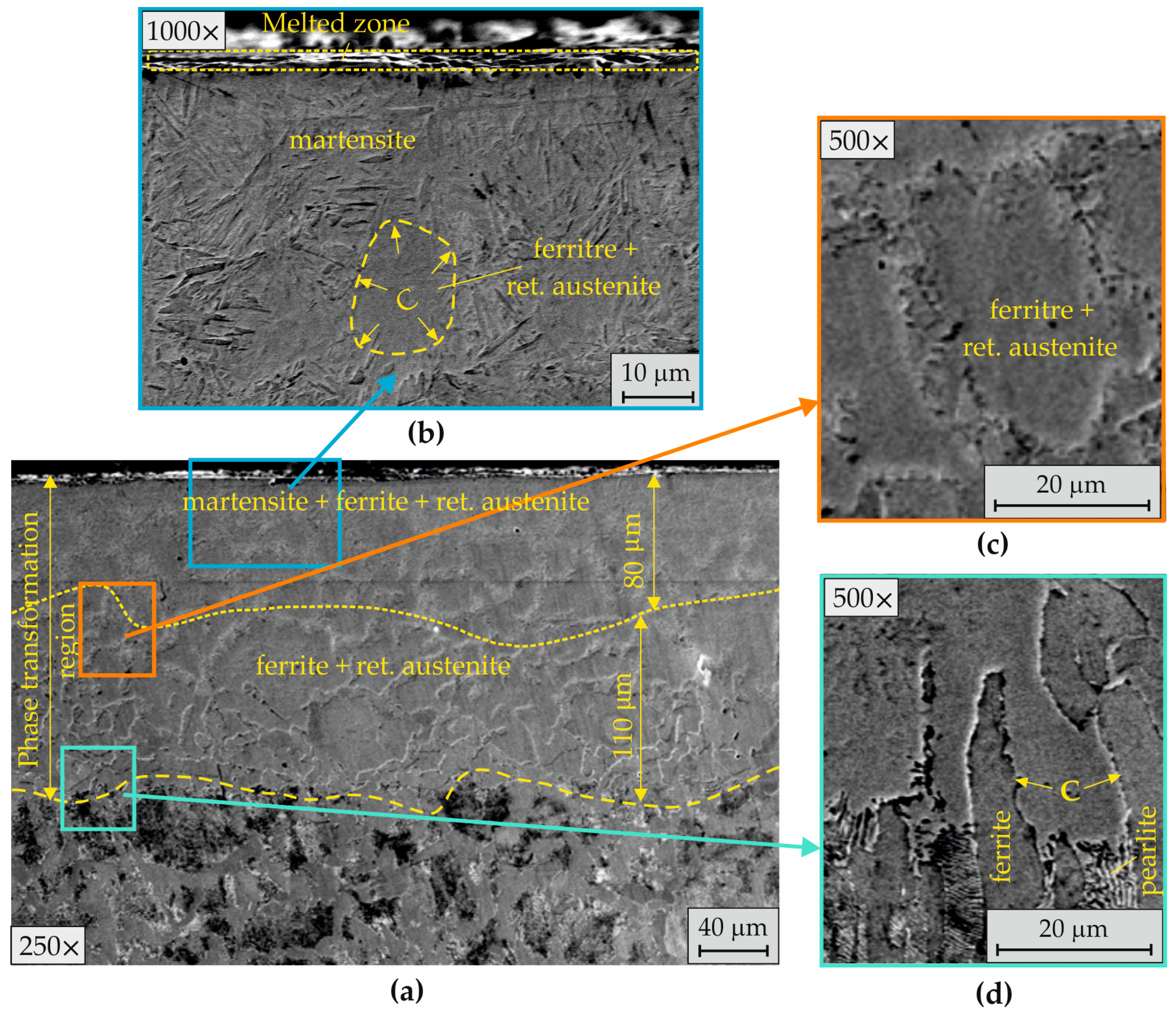

3.4.2. Effect of Workpiece Peripheral Velocity on Microstructure

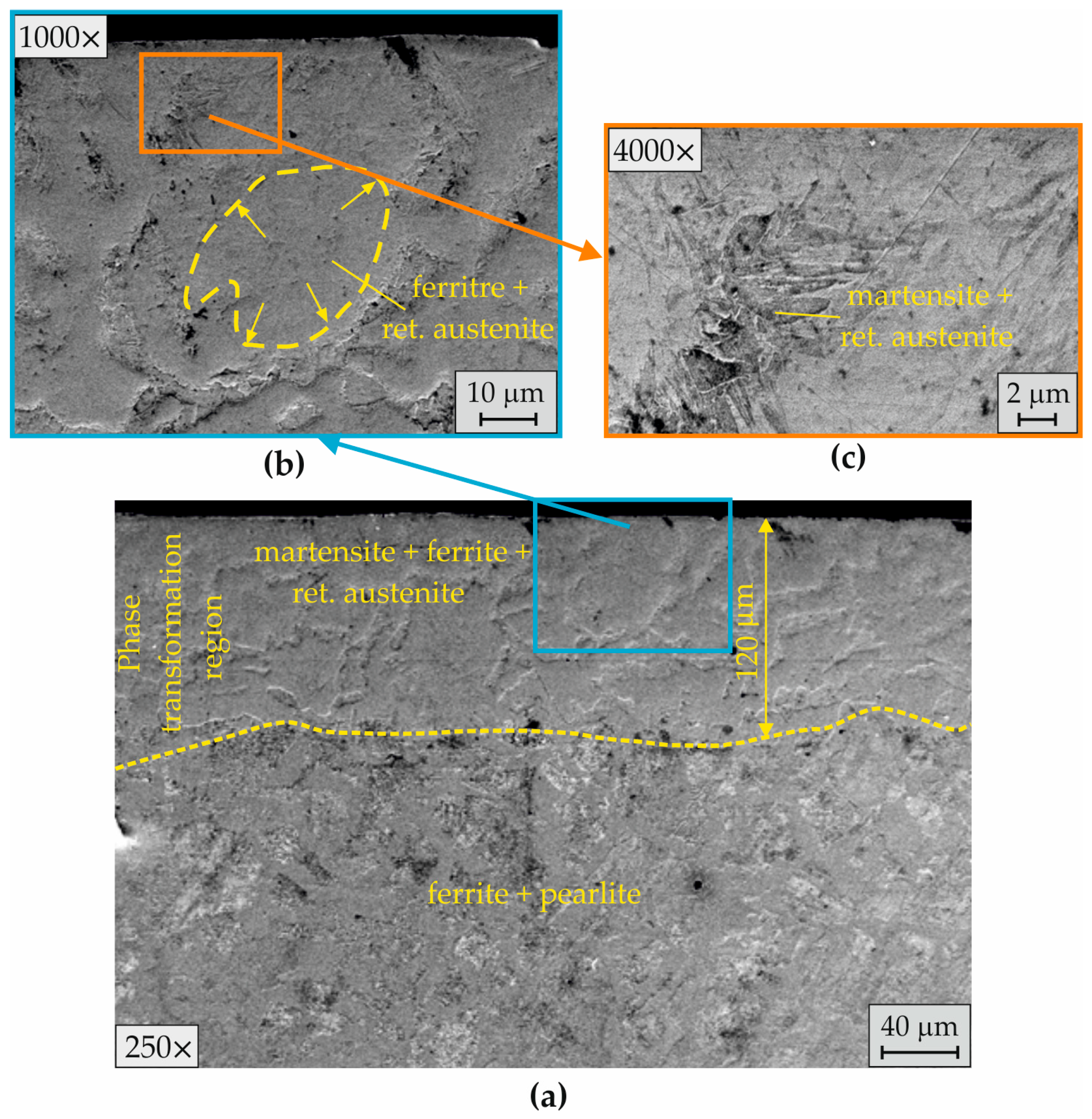

3.4.3. Effect of SF on Microstructure

3.4.4. Effect of FL on Microstructure

4. Discussion

5. Conclusions

- The X-ray diffraction results for the surface axial and hoop RSs and the distribution of the two types of RS demonstrate the potential of the novel EBH for the formation of useful compressive RSs due to martensitic transformation in the SL.

- The SEM images of the surface microstructure confirmed the transition from a hard, surface zone with complete phase pretransformation, which contained martensite, a second zone with partial pretransformation, to the ferrite and pearlite structure in the core. The resulting gradient microstructure provided strengthened SLs and preserved bulk properties such as toughness and ductility; therefore, it is particularly suitable for rotating machine elements such as shafts and axles.

- The electron beam current in the range intensified the martensitic transformation, which favoured the formation of compressive surface axial and hoop RSs and a compressive zone at a depth reaching 0.2 mm. The EBH implemented with the parameters , , , and favoured the formation of needle-like martensite and amorphous grains in the SL; this microstructure provided the maximum axial and hoop RSs of and , respectively.

- The EBH implementation with the lowest peripheral speed of led to a deeper phase transformation region, which correlated with the measured maximum compressive axial and hoop RSs of and , respectively, and a compressive zone at a depth of approximately 0.3 mm for both types of RS.

- The highest maximized the generated heat over a unit area for the same time and minimized the overlapping effect in the circumferential direction, which provided the most homogeneous surface and smooth surface morphology. Consequently, the depth of the phase transformation region was significantly increased, the compressive axial and hoop RSs were maximized, and the compressive zone depth increased to approximately 0.25 mm.

- The EBH implementation with opposite FLs () provided similar thermal conditions, which caused similar modified surface zones containing low-carbon martensite and a smaller amount of retained austenite, practically identical phase analyses, and similar RS profiles with a pronounced compressive zone.

- The following limitations were established with respect to the suitable operating parameter ranges: (1) the electron beam current of was insufficient to enable martensitic transformation; (2) caused uneven heating and solidification, a characteristic markedly rough surface morphology, and tensile axial and hoop surface RS; (3) the positive FLs in the interval caused tensile surface axial and hoop RSs. After excluding these parameter values, the suitable ranges of the operating parameters were , and . The specified ranges are the basis for conducting a planned experiment on the novel EBH process, which will reflect the interactions between operating parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviations | |

| EBH | Electron beam hardening |

| Focal length | |

| LBH | Laser beam hardening |

| Power density | |

| RSs | Residual Stresses |

| Scanning frequency | |

| SI | Surface integrity |

| SL | Surface layer |

| List of Symbols | |

| Electron beam area | |

| Electron beam diameter | |

| Electron beam current | |

| Irradiation power | |

| Arithmetic average of roughness profile after EBH | |

| Arithmetic average of roughness profile after turning | |

| Workpiece peripheral velocity | |

References

- Astakhov, V. Surface integrity–definition and importance in functional performance. In Surface Integrity in Machining; Springer: London, UK, 2010; pp. 1–35. [Google Scholar]

- Dwivedi, D. Characterization of Engineered Surfaces. In Surface Engineering: Enhancing Life of Tribological Components; Springer: New Delhi, India, 2018; pp. 171–215. [Google Scholar]

- Maximov, J.; Duncheva, G. The correlation between surface integrity and operating behaviour of slide burnished components—A review and prospects. Appl. Sci. 2023, 13, 3313. [Google Scholar] [CrossRef]

- Fischer, A.; Berthold, S.; Niendorf, T. On the Influence of Surface Hardening Treatments on Microstructure Evolution and Residual Stress in Microalloyed Medium Carbon Steel. J. Mater. Eng. Perform. 2020, 29, 3040–3054. [Google Scholar] [CrossRef]

- Lesyk, D.; Mordyuk, B.; Alnusirat, W.; Martinez, S.; Dzhemelinskyi, V.; Goncharuk, O.; Kondrashev, P.; Klyuchnikov, Y.; Lamikiz, A. Ultrasonic surface finishing of AISI 1045 steel hardened by laser heat treatment with fibre laser and scanning optics: Layered-structure-induced hardening and enhanced surface morphology. Prog. Phys. Met./Usp. Fiz. Met. 2024, 25, 822–867. [Google Scholar]

- Kikuchi, S.; Minamizawa, K.; Arakawa, J.; Akebono, H.; Takesue, S.; Hayakawa, M. Combined effect of surface morphology and residual stress induced by fine particle and shot peening on the fatigue limit for carburized steels. Int. J. Fatigue 2023, 168, 107441. [Google Scholar] [CrossRef]

- Duncheva, G.; Maximov, J. Cold working technologies for increasing the fatigue life of metal structural components with fastener holes—Review and perspectives. Int. J. Adv. Manuf. Technol. 2025, 136, 2909–2943. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Z.; Wang, B.; Thrush, S.; Barber, G.; Qiu, F. Microstructures, compressive residual stress, friction behavior, and wear mechanism of quenched and tempered shot peened medium carbon steel. Wear 2022, 488, 204131. [Google Scholar] [CrossRef]

- Dwivedi, P.; Rai, A.; Ganesh, P.; Ranganathan, K.; Bindra, S.; Dutta, K. Effect of laser shock peening on microstructure and micro-texture evolution in high-strength low-alloy steel upon electrochemical interaction. J. Mater. Eng. Perform. 2024, 33, 5206–5222. [Google Scholar] [CrossRef]

- Velázquez-Corral, E.; Llumà, J.; Jerez-Mesa, R.; Wagner, V.; Dessein, G.; Travieso-Rodriguez, J. Fatigue enhancement and hardening effect through ultrasonic vibration-assisted ball-burnishing process on AISI 1045 steel. Fatigue Fract. Eng. Mater. Struct. 2024, 47, 203–219. [Google Scholar] [CrossRef]

- Zhao, Y.; Gong, B.; Liu, Y.; Zhang, W.; Deng, C. Fatigue behaviors of ultrasonic surface rolling processed AISI 1045: The role of residual stress and gradient microstructure. Int. J. Fatigue 2024, 178, 107993. [Google Scholar] [CrossRef]

- Qin, T.; Ao, N.; Ren, X.; Zhao, X.; Wu, S. Determination of optimal ultrasonic surface rolling parameters to enhance the fatigue strength of railway axle EA4T steel. Eng. Fract. Mech. 2022, 275, 108831. [Google Scholar] [CrossRef]

- Balusamy, T.; Sathyaraj, P.; Ravichandran, K.; Narayanan, T. Influence of surface mechanical attrition treatment parameters on the residual stress of EN8 steel. J. Mater. Eng. Perform. 2024, 33, 7679–7688. [Google Scholar] [CrossRef]

- Noronha, D.; Sharma, S.; Parkala, R.; Shankar, G.; Kumar, N.; Doddapaneni, S. Deep rolling techniques: A comprehensive review of process parameters and impacts on the material properties of commercial steels. Metals 2024, 14, 667. [Google Scholar] [CrossRef]

- de Oliveira, D.; Martins, A.; dos Santos, A.; de Castro MagalhŃes, F.; AbrŃo, A. Influence of the hydrostatic ball burnishing on surface quality and ultra-microhardness. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 74. [Google Scholar] [CrossRef]

- Maximov, J.; Duncheva, G. Effects of diamond burnishing on surface integrity, fatigue, wear, and corrosion of metal components—Review and perspectives. Int. J. Adv. Manuf. Technol. 2025, 139, 4233–4267. [Google Scholar] [CrossRef]

- Maximov, J.; Duncheva, G.; Ichkova, M.; Anastasov, K. Optimal Diamond Burnishing of Chromium–Nickel Austenitic Stainless Steels Based on the Finishing Process–Surface Integrity–Operating Behavior Correlations. Metals 2025, 15, 574. [Google Scholar] [CrossRef]

- Hurey, I.; Gurey, V.; Bartoszuk, M.; Hurey, T. Formation of residual stresses during discontinuous friction treatment. J. Eng. Sci. 2021, 8, C38–C44. [Google Scholar] [CrossRef]

- Minamizawa, K.; Arakawa, J.; Akebono, H.; Nambu, K.; Nakamura, Y.; Hayakawa, M.; Kikuchi, S. Fatigue limit estimation for carburized steels with surface compressive residual stress considering residual stress relaxation. Int. J. Fatigue 2022, 160, 106846. [Google Scholar] [CrossRef]

- Taweejun, N.; Praditja, T.; Bootchai, S.; Kanchanomai, C. Effect of multi-cycle nitrocarburizing on the microstructure and surface hardness of low-carbon steel. Met. Sci. Heat Treat. 2021, 63, 380–387. [Google Scholar] [CrossRef]

- Hoja, S.; Baustert, R.; Hasselbruch, H.; Steinbacher, M.; Fechte-Heinen, R. Investigation of combined surface treatments and coatings to increase the wear behavior of heat treatable steels. Surf. Coat. Technol. 2023, 472, 129929. [Google Scholar] [CrossRef]

- Marichamy, S.; Dhinakaran, V.; Stalin, B.; Ravichandran, M.; Balasubramanian, M.; Chairman, C. Taguchi optimization and flame hardening experimental investigation on eglin steel. IOP Conf. Ser. Mater. Sci. Eng. 2020, 988, 012099. [Google Scholar] [CrossRef]

- Thamilarasan, J.; Karunagaran, N.; Nanthakumar, P. Optimization of oxy-acetylene flame hardening parameters to analysis the surface structure of low carbon steel. Mater. Today Proc. 2021, 46, 4169–4173. [Google Scholar] [CrossRef]

- Stević, Z.; Dimitrijević, S.; Stević, M.; Stolić, P.; Petrović, S.; Radivojević, M.; Radovanović, I. The design of a system for the induction hardening of steels using simulation parameters. Appl. Sci. 2023, 13, 11432. [Google Scholar] [CrossRef]

- Holmberg, J.; Steuwer, A.; Stormvinter, A.; Kristoffersen, H.; Haakanen, M.; Berglund, J. Residual stress state in an induction hardened steel bar determined by synchrotron-and neutron diffraction compared to results from lab-XRD. Mater. Sci. Eng. 2016, 667, 199–207. [Google Scholar] [CrossRef]

- Qin, T.; Hu, F.; Xu, P.; Zhang, H.; Zhou, L.; Ao, N.; Su, Y.; Shobu, T.; Wu, S. Gradient residual stress and fatigue life prediction of induction hardened carbon steel S38C axles: Experiment and simulation. Int. J. Fatigue 2024, 185, 108336. [Google Scholar] [CrossRef]

- Muthukumaran, G.; Babu, P. Laser transformation hardening of various steel grades using different laser types. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 103. [Google Scholar] [CrossRef]

- Wang, J.; Xia, J.; Liu, Z.; Xu, L.; Liu, J.; Xiao, Y.; Gao, J.; Ru, H.; Jiao, J. A comprehensive review of metal laser hardening: Mechanism, process, and applications. Int. J. Adv. Manuf. Technol. 2024, 134, 5087–5115. [Google Scholar] [CrossRef]

- Łach, Ł. Recent advances in laser surface hardening: Techniques, modeling approaches, and industrial applications. Crystals 2024, 14, 726. [Google Scholar] [CrossRef]

- Valkov, S.; Ormanova, M.; Petrov, P. Electron-beam surface treatment of metals and alloys: Techniques and trends. Metals 2020, 10, 1219. [Google Scholar] [CrossRef]

- Kiefer, D.; Schüssler, P.; Mühl, F.; Gibmeier, J. Experimental and simulative studies on residual stress formation for laser-beam surface hardening. HTM J. Heat Treat. Mater. 2019, 74, 23–35. [Google Scholar] [CrossRef]

- Cvetkovski, K.; Ahlström, J.; Karlsson, B. Influence of short heat pulses on properties of martensite in medium carbon steels. Mater. Sci. Eng. 2013, 561, 321–328. [Google Scholar] [CrossRef]

- Muthukumaran, G.; Babu, P. Analysis of residual stress distribution and corrosion in laser surface hardened low alloy steel with a flat top-hat laser beam, using a high-power diode laser. Arab. J. Sci. Eng. 2022, 47, 8785–8803. [Google Scholar] [CrossRef]

- Lu, Y.; Ehle, L.; Richter, S.; Radel, T. Influence of multi-pass laser hardening of normalized AISI 4140 on the grain size. Surf. Coat. Technol. 2021, 421, 127434. [Google Scholar] [CrossRef]

- Preußner, J.; Oeser, S.; Pfeiffer, W.; Temmler, A.; Willenborg, E. Microstructure and residual stresses of laser remelted surfaces of a hot work tool steel. Int. J. Mater. Res. 2014, 105, 328–336. [Google Scholar] [CrossRef]

- Jong-Do, K.I.M.; Myeong-Hoon, L.E.E.; Su-Jin, L.E.E.; Woon-Ju, K.A.N.G. Laser transformation hardening on rod-shaped carbon steel by Gaussian beam. Trans. Nonferrous Met. Soc. China 2009, 19, 941–945. [Google Scholar] [CrossRef]

- Guarino, S.; Barletta, M.; Afilal, A. High Power Diode Laser (HPDL) surface hardening of low carbon steel: Fatigue life improvement analysis. J. Manuf. Process. 2017, 28, 266–271. [Google Scholar] [CrossRef]

- Ponticelli, G.; Guarino, S.; Giannini, O. An optimal genetic algorithm for fatigue life control of medium carbon steel in laser hardening process. Appl. Sci. 2020, 10, 1401. [Google Scholar] [CrossRef]

- Čapek, J.; Trojan, K.; Kec, J.; Ganev, N.; Černý, I.; Mužík, T. Residual Stresses and the Microstructure of Modeled Laser-Hardened Railway Axle Seats under Fatigue. Metals 2024, 14, 290. [Google Scholar] [CrossRef]

- Śliwiński, P.; Węglowski, M.; Kwieciński, K.; Wieczorek, A. Electron beam surface hardening. Biul. Inst. Spaw. 2022, 66, 7–20. [Google Scholar] [CrossRef]

- Matlák, J.; Dlouhý, I. Properties of electron beam hardened layers made by different beam deflection. Manuf. Technol. 2018, 18, 279–284. [Google Scholar] [CrossRef]

- Fu, Y.; Hu, J.; Shen, X.; Wang, Y.; Zhao, W. Surface hardening of 30CrMnSiA steel using continuous electron beam. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2017, 410, 207–214. [Google Scholar] [CrossRef]

- Choo, S.; Lee, S.; Golkovski, M. Effects of accelerated electron beam irradiation on surface hardening and fatigue properties in an AISI 4140 steel used for automotive crankshaft. Mater. Sci. Eng. 2000, 293, 56–70. [Google Scholar] [CrossRef]

- Śliwiński, P.; Węglowski, M.; Wieczorek, A.; Skołek, E. Electron beam hardening of nanobainitic steel. Surf. Eng. 2024, 40, 276–283. [Google Scholar] [CrossRef]

- Petrov, P. Optimization of carbon steel electron-beam hardening. J. Phys. Conf. Ser. 2010, 223, 12–29. [Google Scholar] [CrossRef]

- Fu, Y.; Hu, J.; Zhang, X.; Huo, W.; Cao, X.; Zhao, W. Surface modification of AISI 1045 steel by pseudospark based pulsed electron beam. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2018, 434, 88–92. [Google Scholar] [CrossRef]

- Anchev, A.; Stoyanov, B.; Atanasova, M.; Argirov, Y.; Petkov, B. Improving in microhardness of C45 steel obtained via electron beam hardening using a one factor-at-a-time technique. Int. J. Innov. Res. Sci. Stud. 2025, 8, 1255–1270. [Google Scholar] [CrossRef]

- DIFFRAC.DQUANT V1.5; Quantitative Analysis from Calibration to Reporting. Bruker AXS GmbH: Karlsrue, Germany, 2018.

- Falodun, O.; Oke, S.; Bodunrin, M. A comprehensive review of residual stresses in carbon steel welding: Formation mechanisms, mitigation strategies, and advanced post-weld heat treatment techniques. Int. J. Adv. Manuf. Technol. 2025, 136, 4107–4140. [Google Scholar] [CrossRef]

- Guan, Q.F.; Zou, H.; Zou, G.; Wu, A.M.; Hao, S.Z.; Zou, J.X.; Qin, Y.; Dong, C.; Zhang, Q.Y. Surface nanostructure and amorphous state of a low carbon steel induced by high-current pulsed electron beam. Surf. Coat. Technol. 2005, 196, 145–149. [Google Scholar] [CrossRef]

| Governing Factor | Magnitude | ||||||

|---|---|---|---|---|---|---|---|

| Electron beam current | 12 | 16.5 | 21 | 25.5 | 30 | 34.5 | |

| Workpiece peripheral velocity | 18 | 22 | 27 | 31 | 36 | 53 | |

| Scanning frequency | 400 | 5300 | 10,200 | 15,100 | 20,000 | - | |

| Focal length | +20 | +15 | +10 | +5 | 0 | −5 | −10 |

| Measuring Device | Bruker D8 Advance Diffractometer |

|---|---|

| X-ray tube | Long focus Cr–Kα |

| Crystallographic plane | Fe(α)—(211) |

| Diffraction angle (2θ) | 156.08° (152–160°) |

| Measuring method | Offset coupled TwoTheta/Theta (sin2ψ method) |

| Scan mode | Continuous PSD fast |

| X-ray detector | SSD160-2 (1D scanning) |

| Collimator spot size | Standard ϕ 1.0 mm |

| Measurement time for single scan | Approx. 30 s |

| Elastic constant s1 | −1.271 × 10−6 |

| Elastic constant 1/2s2 | 5.811 × 10−6 |

| Voltage | 30 kV |

| Current | 40 mA |

| Step size | 0.5° |

| Time for step | 1 s |

| One-Factor-at-a-Time Experiment | Magnitudes | |||||||

|---|---|---|---|---|---|---|---|---|

| Variation in the parameter; Constant parameters: | 12 | 16.5 | 21 | 25.5 | 30 | 34.5 | - | |

| 1.069 | 1.197 | 1.096 | 1.188 | 1.058 | 1.193 | - | ||

| , | 1.041 | 1.071 | 0.794 | 0.912 | 0.483 | 0.258 | - | |

| Variation in the parameter; Constant parameters: | 18 | 22 | 27 | 31 | 36 | 53 | - | |

| 1.637 | 1.260 | 1.180 | 1.640 | 1.292 | 1.55 | - | ||

| , | 0.192 | 0.901 | 0.422 | 0.584 | 0.610 | 1.294 | - | |

| Variation in the parameter; Constant parameters: | 400 * | 5300 | 10,200 | 15,100 | 20,000 | - | - | |

| 1.080 * | 1.350 | 1.139 | 1.100 | 1.030 | - | - | ||

| , | 5.735 * | 0.757 | 0.509 | 0.294 | 0.298 | - | - | |

| Variation in the parameter; Constant parameters: | +20 | +15 | +10 | +5 | 0 | −5 | −10 | |

| 1.125 | 1.260 | 1.235 | 1.150 | 1.255 | 1.188 | 1.220 | ||

| , | 0.593 | 0.788 | 0.418 | 0.547 | 0.798 | 0.455 | 0.516 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duncheva, G.; Dunchev, V.; Atanasova, M.; Todorov, V.; Argirov, Y.; Ivanova, M.; Petkov, B. Effects of Electron Beam Hardening Parameters on the Residual Stresses and Microstructures in C45 Steel Cylindrical Specimens. J. Manuf. Mater. Process. 2025, 9, 388. https://doi.org/10.3390/jmmp9120388

Duncheva G, Dunchev V, Atanasova M, Todorov V, Argirov Y, Ivanova M, Petkov B. Effects of Electron Beam Hardening Parameters on the Residual Stresses and Microstructures in C45 Steel Cylindrical Specimens. Journal of Manufacturing and Materials Processing. 2025; 9(12):388. https://doi.org/10.3390/jmmp9120388

Chicago/Turabian StyleDuncheva, Galya, Vladimir Dunchev, Milka Atanasova, Vladimir Todorov, Yaroslav Argirov, Marieta Ivanova, and Boris Petkov. 2025. "Effects of Electron Beam Hardening Parameters on the Residual Stresses and Microstructures in C45 Steel Cylindrical Specimens" Journal of Manufacturing and Materials Processing 9, no. 12: 388. https://doi.org/10.3390/jmmp9120388

APA StyleDuncheva, G., Dunchev, V., Atanasova, M., Todorov, V., Argirov, Y., Ivanova, M., & Petkov, B. (2025). Effects of Electron Beam Hardening Parameters on the Residual Stresses and Microstructures in C45 Steel Cylindrical Specimens. Journal of Manufacturing and Materials Processing, 9(12), 388. https://doi.org/10.3390/jmmp9120388