Build Orientation-Driven Anisotropic Fracture Behaviour in Polymer Parts Fabricated by Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

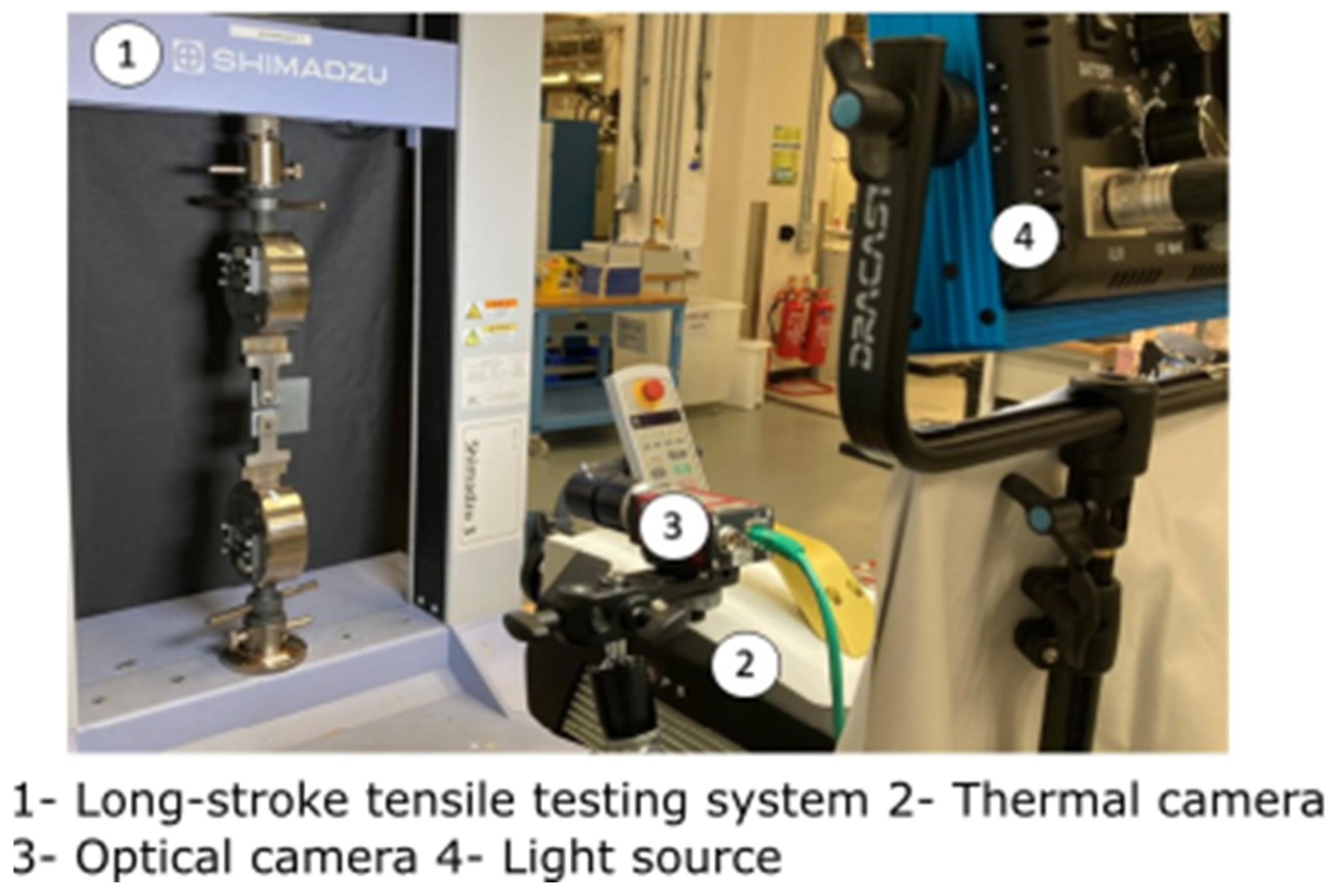

2.1. Experimental Setup

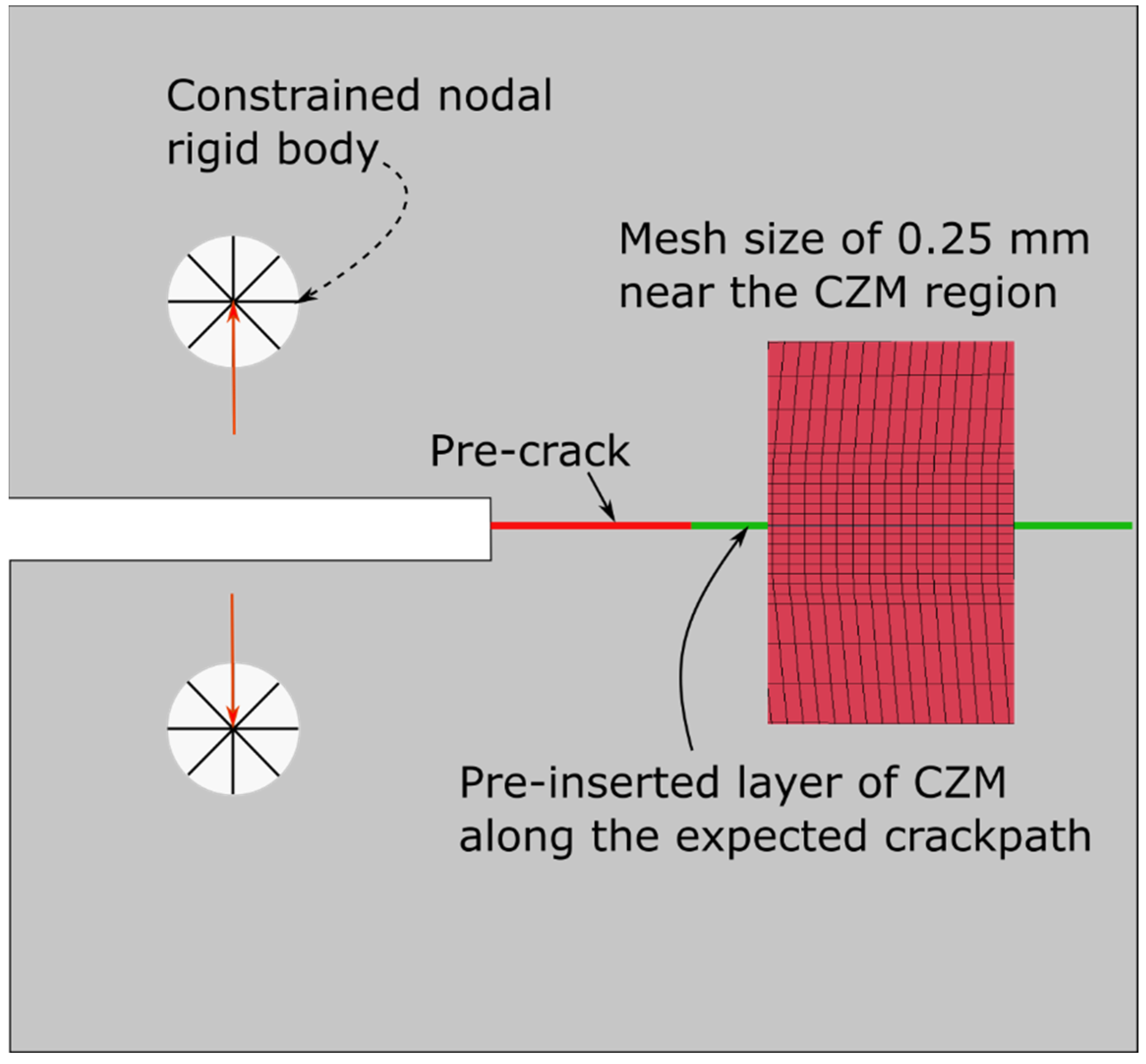

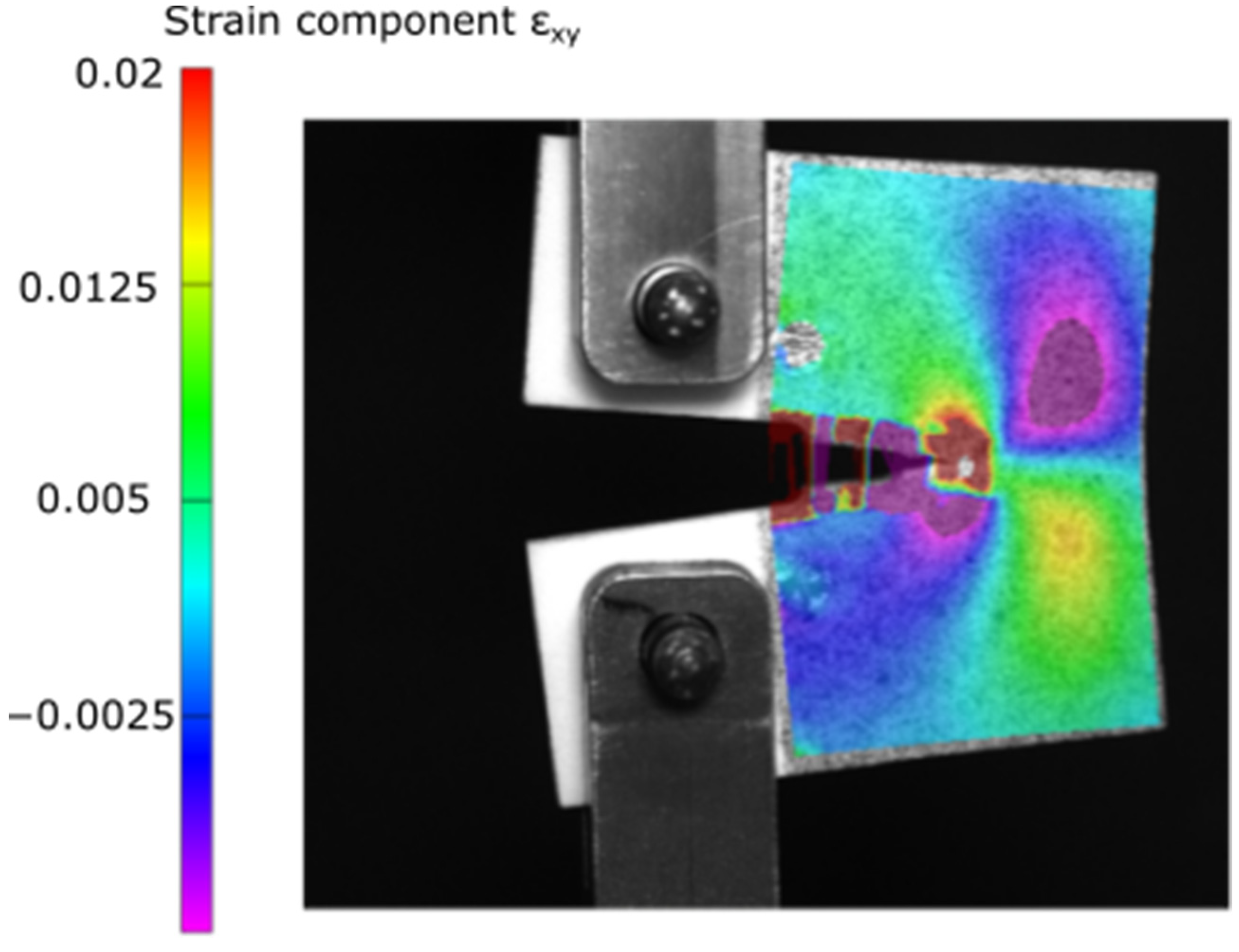

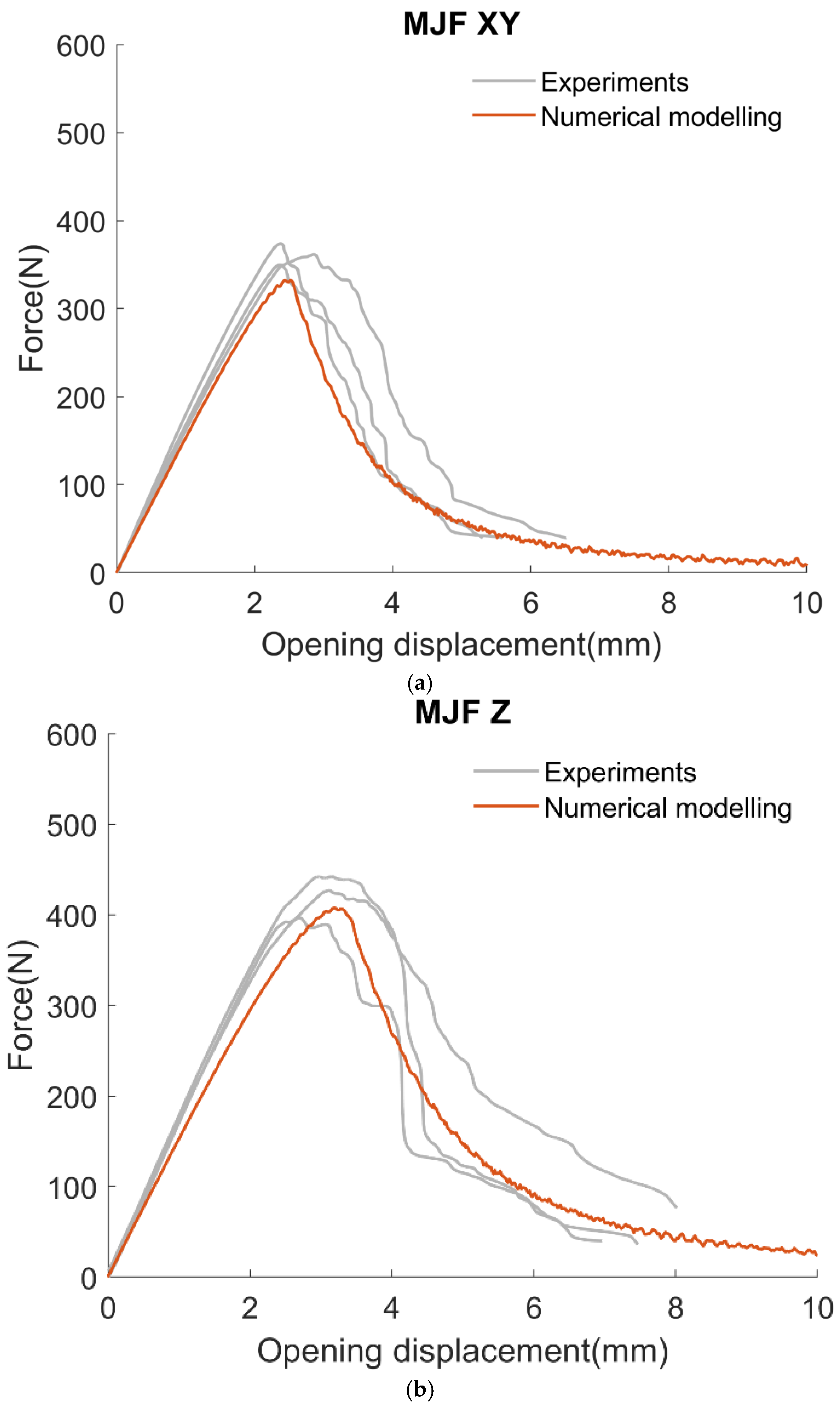

2.2. Numerical Model

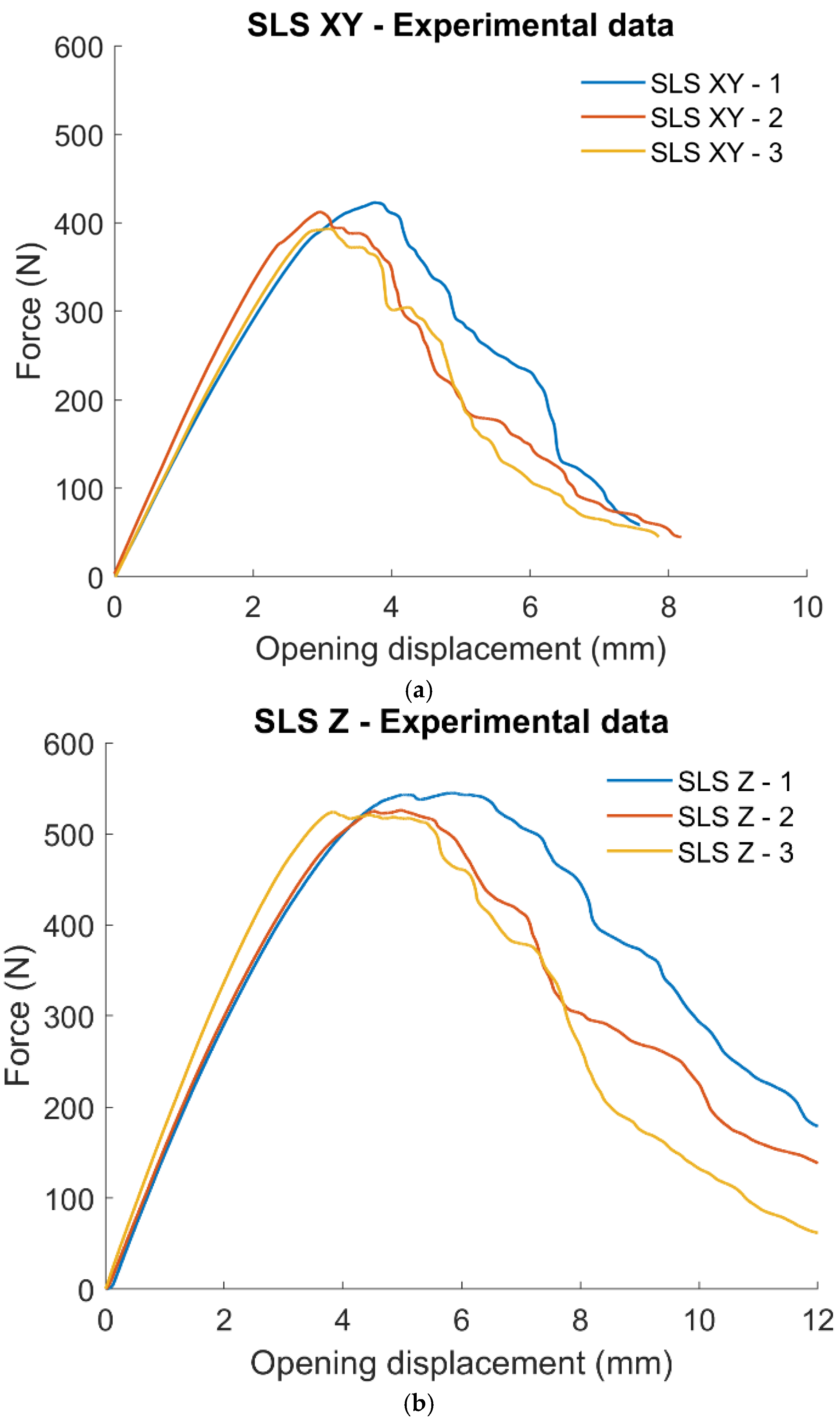

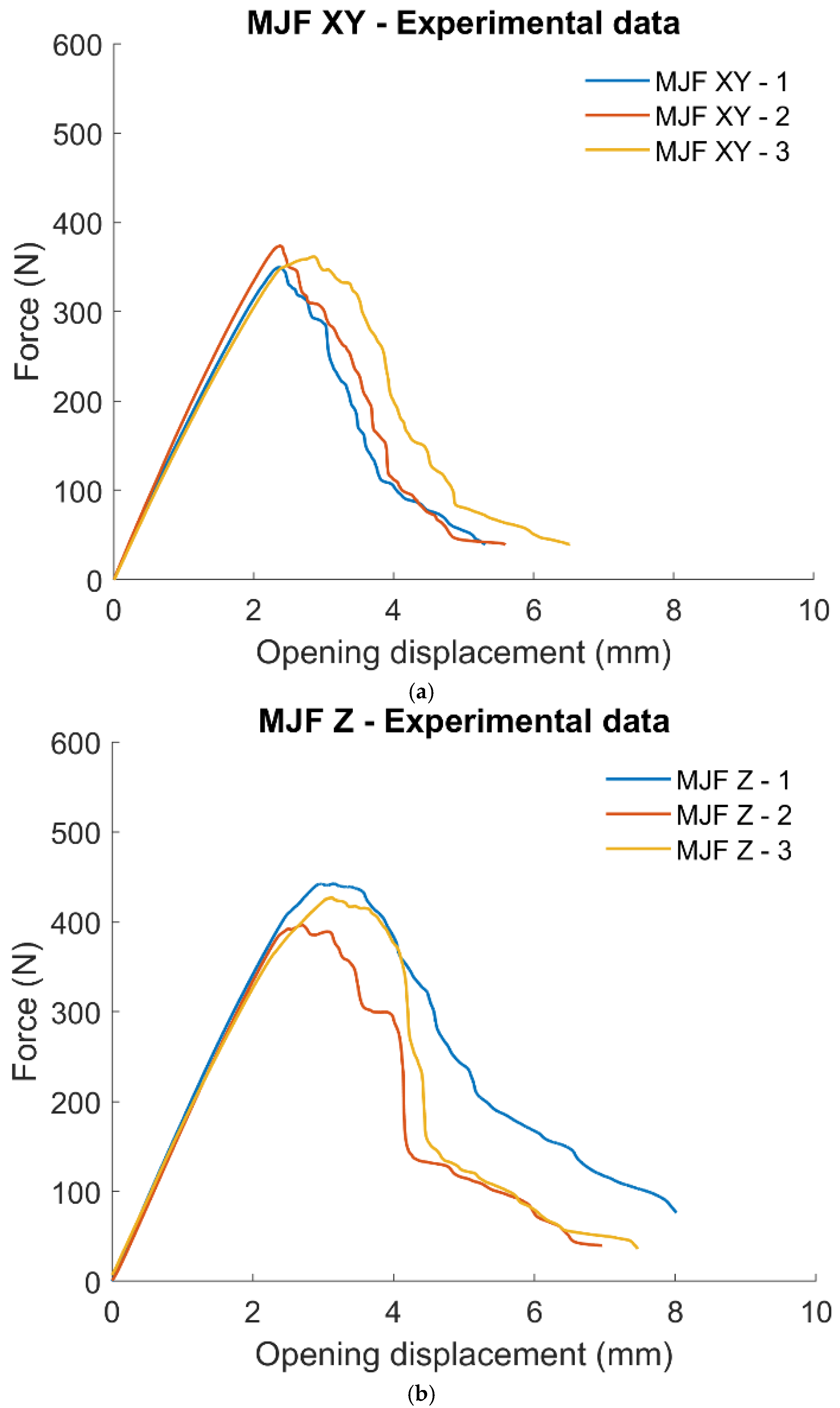

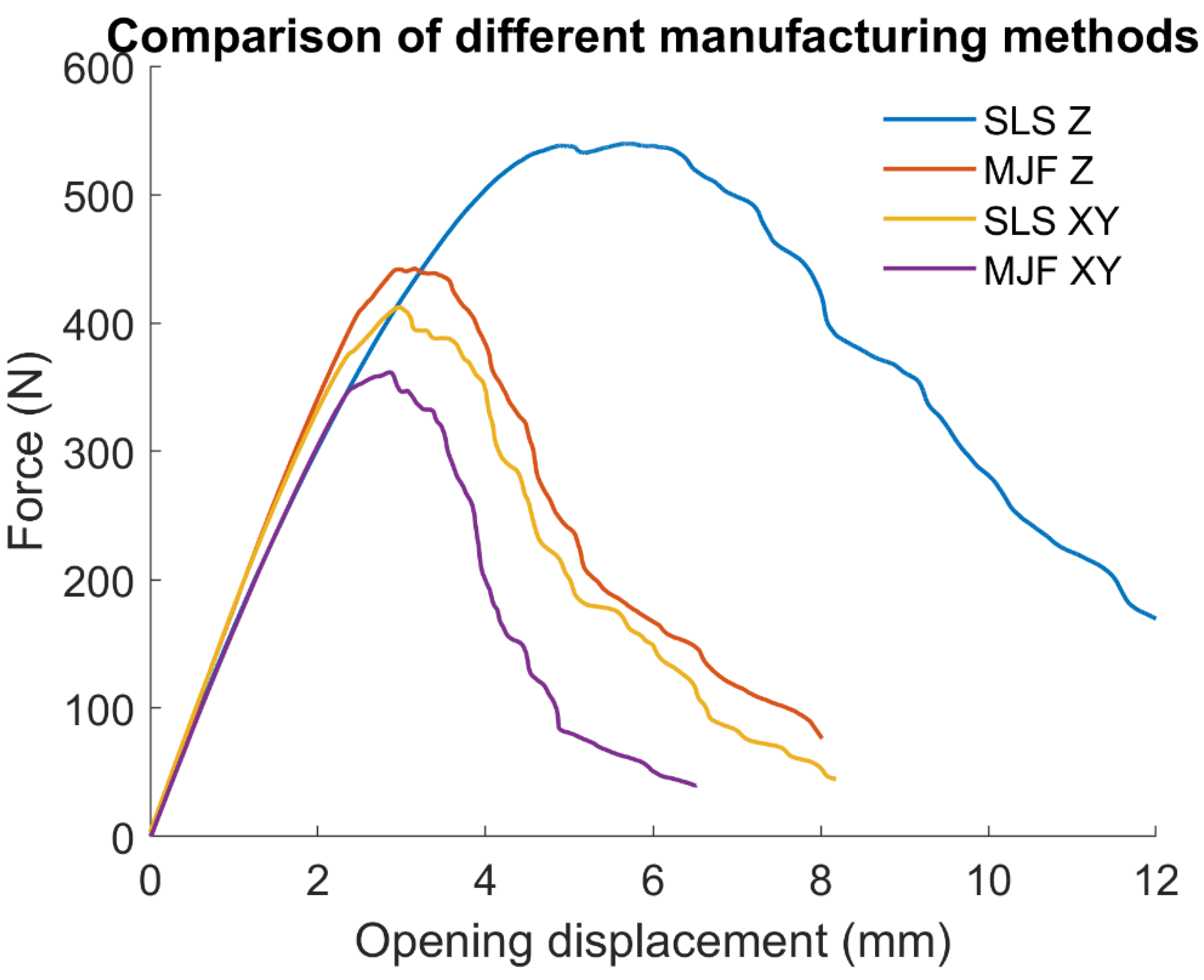

3. Results

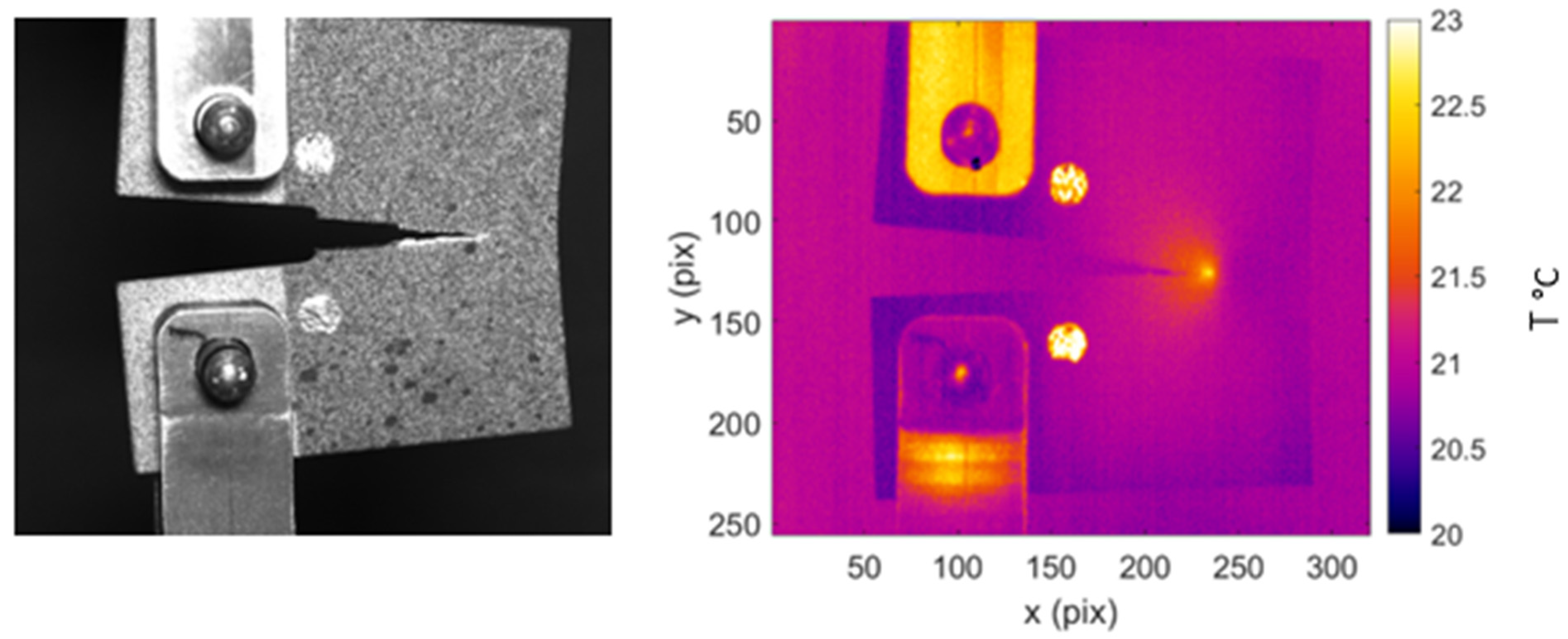

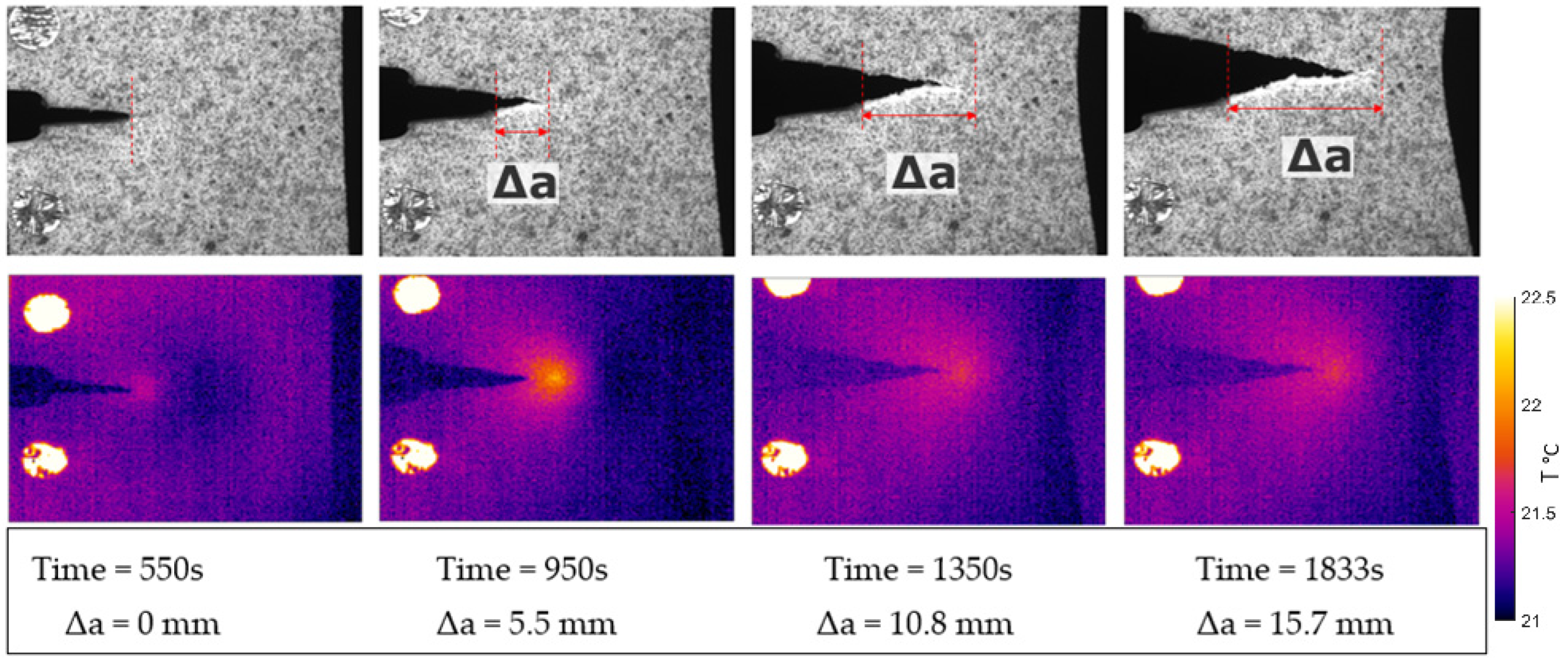

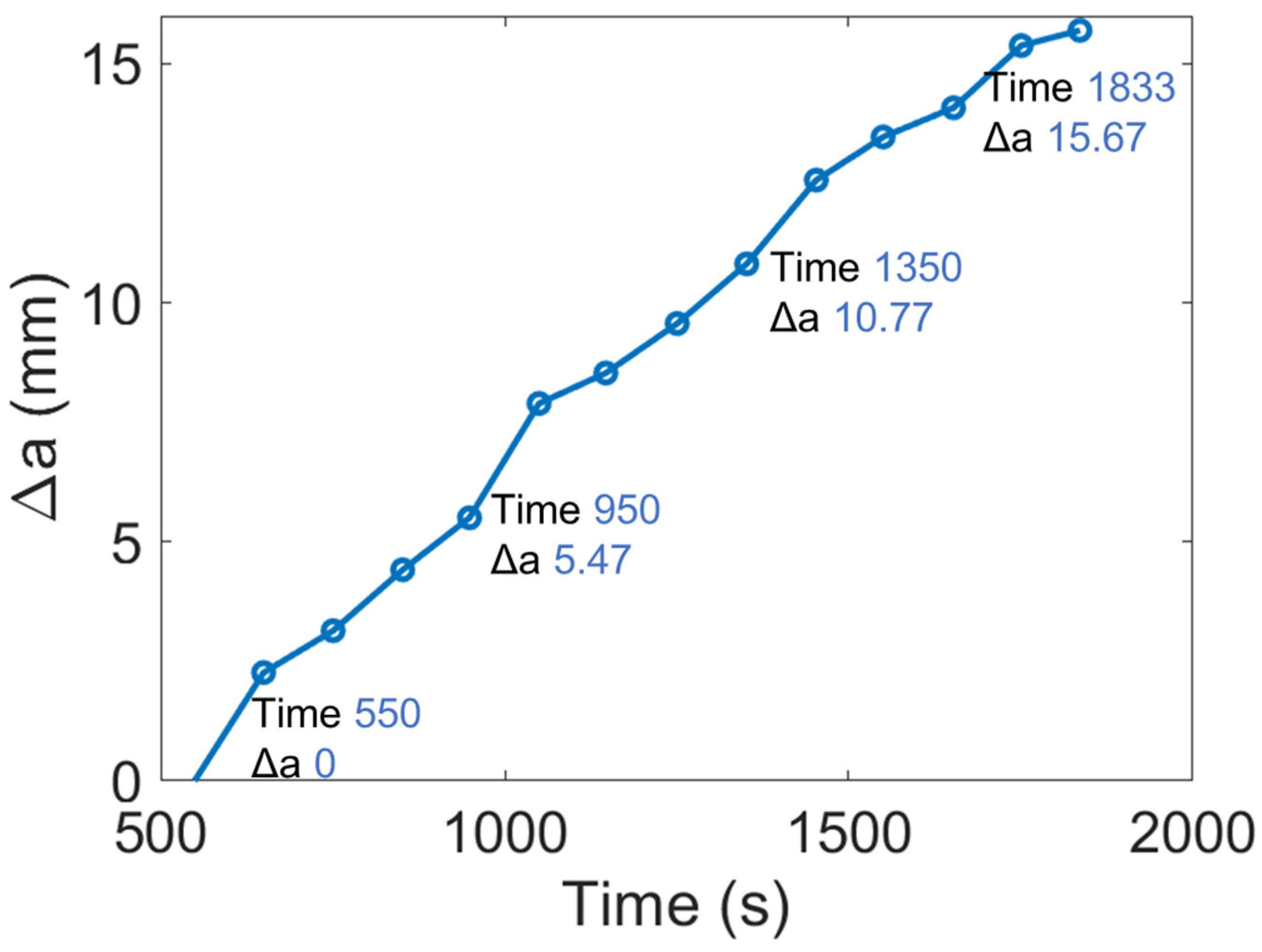

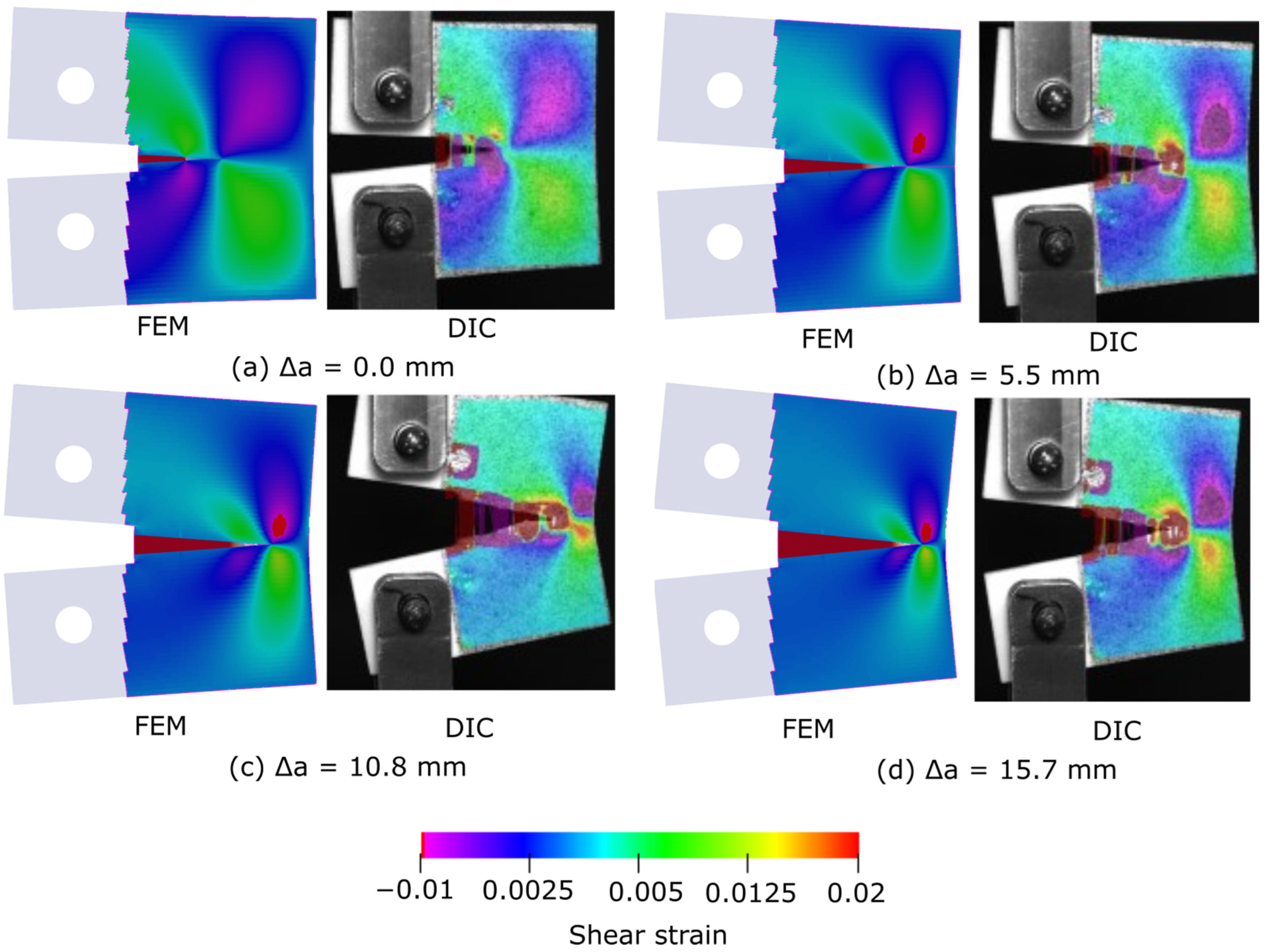

3.1. Crack Length Measurement

3.2. Data Reduction

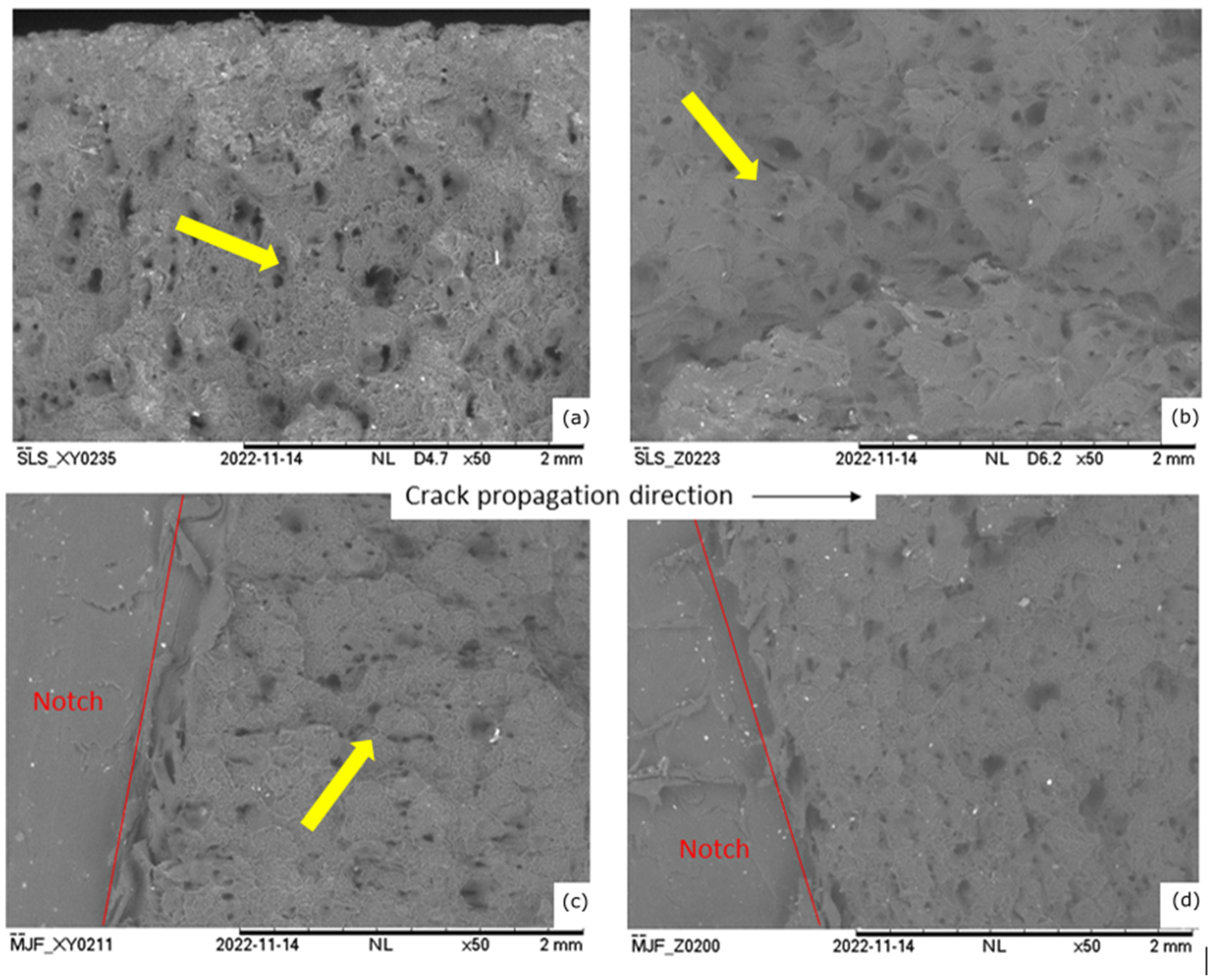

3.3. Fracture Morphology

4. Conclusions

- The layer-based manufacturing process leads to significant differences in fracture toughness among additively manufactured samples, resulting in anisotropic properties across various size scales;

- Comparative analyses of SLS and MJF technologies revealed distinct trends in mechanical strength, build-orientation effects, and fracture properties. In the present work, SLS with build orientation in the Z direction was observed to give maximal load-carrying capability and fracture energy dissipation;

- The finite-element approach with cohesive elements enabled the analysis of crack initiation, propagation, and coalescence, providing valuable insights into fracture mechanics and aiding in the design of more resilient polymer structures. The elastic stiffness, peak load, and the failure propagation were predicted in good agreement to the experiments.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chyr, G.; DeSimone, J.M. Review of high-performance sustainable polymers in additive manufacturing. Green Chem. 2022, 25, 453–466. [Google Scholar] [CrossRef]

- Shanthar, R.; Chen, K.; Abeykoon, C. Powder-based additive manufacturing: A critical review of materials, methods, opportunities and challenges. Adv. Eng. Mater. 2023, 25, 2300375. [Google Scholar] [CrossRef]

- O’Connor, H.J.; Dickson, A.N.; Dowling, D.P. Evaluation of the mechanical performance of polymer parts fabricated using a production scale multi jet fusion printing process. Addit. Manuf. 2018, 22, 381–387. [Google Scholar] [CrossRef]

- Brighenti, R.; Cosma, M.P.; Marsavina, L.; Spagnoli, A.; Terzano, M. Laser-based additively manufactured polymers: A review on processes and mechanical models. J. Mater. Sci. 2021, 56, 961–998. [Google Scholar] [CrossRef]

- Picard, M.; Mohanty, A.K.; Misra, M. Recent Advances in Additive Manufacturing of Engineering Thermoplastics: Challenges and Opportunities; Royal Society of Chemistry: London, UK, 2020; Volume 10. [Google Scholar] [CrossRef]

- Cai, C.; Tey, W.S.; Chen, J.; Zhu, W.; Liu, X.; Liu, T.; Zhao, L.; Zhou, K. Comparative study on 3D printing of polyamide 12 by selective laser sintering and multi jet fusion. J. Mater. Process. Technol. 2021, 288, 116882. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Hui, Z.; Chen, K.; Du, H.; Zeng, J.; Zhou, K. Long-term ageing effect on mechanical properties of polyamide 12 printed by Multi-Jet-Fusion. Int. J. Mech. Sci. 2023, 256, 108513. [Google Scholar] [CrossRef]

- Zarringhalam, H.; Hopkinson, N.; Kamperman, N.F.; de Vlieger, J.J. Effects of processing on microstructure and properties of SLS Nylon 12. Mater. Sci. Eng. A 2006, 435–436, 172–180. [Google Scholar] [CrossRef]

- Stoia, D.I.; Marsavina, L.; Linul, E. Correlations between process parameters and outcome properties of laser-sintered polyamide. Polymers 2019, 11, 1850. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Y.; Wu, D.; Ananth, K.P.; Bai, J. The process and performance comparison of polyamide 12 manufactured by multi jet fusion and selective laser sintering. J. Manuf. Process. 2019, 47, 419–426. [Google Scholar] [CrossRef]

- Xu, Y.; Quino, G.; Ramakrishnan, K.R.; Pellegrino, A. Effects of build orientation and strain rate on the tensile-shear behaviour of polyamide-12 manufactured via laser powder bed fusion. Mater. Des. 2023, 232, 112162. [Google Scholar] [CrossRef]

- Yao, B.; Li, Z.; Zhu, F. Effect of powder recycling on anisotropic tensile properties of selective laser sintered PA2200 polyamide. Eur. Polym. J. 2020, 141, 110093. [Google Scholar] [CrossRef]

- Sharafi, S.; Santare, M.H.; Gerdes, J.; Advani, S.G. A review of factors that influence the fracture toughness of extrusion-based additively manufactured polymer and polymer composites. Addit. Manuf. 2021, 38, 101830. [Google Scholar] [CrossRef]

- Hitt, D.J.; Haworth, B.; Hopkinson, N. Fracture mechanics approach to compare laser sintered parts and injection mouldings of nylon-12. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1663–1672. [Google Scholar] [CrossRef]

- Martínez, M.; Cano, A.J.; Salazar, A.; Rodríguez, J. On the failure assessment diagram methodology in polyamide 12. Eng. Fract. Mech. 2022, 269, 108558. [Google Scholar] [CrossRef]

- Cano, A.J.; Salazar, A.; Rodríguez, J. Effect of temperature on the fracture behavior of polyamide 12 and glass-filled polyamide 12 processed by selective laser sintering. Eng. Fract. Mech. 2018, 203, 66–80. [Google Scholar] [CrossRef]

- Brugo, T.; Palazzetti, R.; Ciric-Kostic, S.; Yan, X.T.; Minak, G.; Zucchelli, A. Fracture mechanics of laser sintered cracked polyamide for a new method to induce cracks by additive manufacturing. Polym. Test. 2016, 50, 301–308. [Google Scholar] [CrossRef]

- Linul, E.; Marsavina, L.; Stoia, D.I. Mode I and II fracture toughness investigation of Laser-Sintered Polyamide. Theor. Appl. Fract. Mech. 2020, 106, 102497. [Google Scholar] [CrossRef]

- Lingua, A.; Piccirelli, N.; Therriault, D.; Lévesque, M. In-situ full-field measurements for 3D printed polymers during mode I interface failure. Eng. Fract. Mech. 2022, 269, 108483. [Google Scholar] [CrossRef]

- Zhang, G.; Ghorbani, J.; Zheng, X.; Heathman, N.; Pan, D.; Wang, Q.; Zhao, K.; Tehrani, M.; Xu, L.R. Anisotropic and elastoplastic mode-I fracture toughnesses of three additively manufactured polymers fabricated via material extrusion and powder bed fusion. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 4776–4782. [Google Scholar] [CrossRef]

- Stoia, D.I.; Linul, E.; Marsavina, L. Mixed-mode I/II fracture properties of selectively laser sintered polyamide. Theor. Appl. Fract. Mech. 2022, 121, 103527. [Google Scholar] [CrossRef]

- Rosso, S.; Meneghello, R.; Biasetto, L.; Grigolato, L.; Concheri, G.; Savio, G. In-depth comparison of polyamide 12 parts manufactured by Multi Jet Fusion and Selective Laser Sintering. Addit. Manuf. 2020, 36, 101713. [Google Scholar] [CrossRef]

- Calignano, F.; Giuffrida, F.; Galati, M. Effect of the build orientation on the mechanical performance of polymeric parts produced by multi jet fusion and selective laser sintering. J. Manuf. Process. 2021, 65, 271–282. [Google Scholar] [CrossRef]

- Tasch, D.; Schagerl, M.; Wazel, B.; Wallner, G. Impact behavior and fractography of additively manufactured polymers: Laser sintering, multijet fusion, and hot lithography. Addit. Manuf. 2019, 29, 100816. [Google Scholar] [CrossRef]

- Pinho, S.T.; Robinson, P.; Iannucci, L. Fracture toughness of the tensile and compressive fibre failure modes in laminated composites. Compos. Sci. Technol. 2006, 66, 2069–2079. [Google Scholar] [CrossRef]

- Jiang, W.; Hallett, S.R.; Green, B.G.; Wisnom, M.R. A concise interface constitutive law for analysis of delamination and splitting in composite materials and its application to scaled notched tensile specimens. Int. J. Numer. Methods Eng. 2007, 69, 1982–1995. [Google Scholar] [CrossRef]

- Selvaraj, J.; Kawashita, L.F.; Hallett, S.R. Mesh independent modelling of tensile failure in laminates using mixed-time integration in explicit analysis. Eng. Fract. Mech. 2022, 259, 108113. [Google Scholar] [CrossRef]

- Peng, K.; Lee, M.; Pandelidi, C.; Kajtaz, M. Build orientation effects on mechanical properties and porosity of polyamide-11 fabricated via multi jet fusion. Addit. Manuf. 2020, 36, 101533. [Google Scholar] [CrossRef]

- Flodberg, G.; Pettersson, H.; Yang, L. Pore analysis and mechanical performance of selective laser sintered objects. Addit. Manuf. 2018, 24, 307–315. [Google Scholar] [CrossRef]

- Sillani, F.; Kleijnen, R.G.; Vetterli, M.; Schmid, M.; Wegener, K. Selective laser sintering and multi jet fusion: Process-induced modification of the raw materials and analyses of parts performance. Addit. Manuf. 2019, 27, 32–41. [Google Scholar] [CrossRef]

- Araújo, L.C.; Gabriel, H.G.; Eduardo, B.; Avila, J.A.; Jardini, L.; Seno, R.; Lopes, S.N. Effects of build orientation and heat treatments on the tensile and fracture toughness properties of additively manufactured AlSi10Mg. Int. J. Mech. Sci. 2022, 213, 106868. [Google Scholar] [CrossRef]

| Printing Type | Density (kg/m3) | Elastic Modulus (MPa) | Poisson’s Ratio |

|---|---|---|---|

| SLS | 990 | 1760 | 0.35 |

| MJF | 930 | 1420 | 0.33 |

| Printing Type | Penalty Stiffness (N/mm3) | Stress at Softening Initiation (MPa) | Fracture Toughness (KJ/m2) |

|---|---|---|---|

| SLS XY | 105 | 43.61 | 11.01 |

| SLS Z | 105 | 43.61 | 27.59 |

| MJF XY | 105 | 40.10 | 4.59 |

| MJF Z | 105 | 40.10 | 7.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramakrishnan, K.R.; Selvaraj, J. Build Orientation-Driven Anisotropic Fracture Behaviour in Polymer Parts Fabricated by Powder Bed Fusion. J. Manuf. Mater. Process. 2024, 8, 263. https://doi.org/10.3390/jmmp8060263

Ramakrishnan KR, Selvaraj J. Build Orientation-Driven Anisotropic Fracture Behaviour in Polymer Parts Fabricated by Powder Bed Fusion. Journal of Manufacturing and Materials Processing. 2024; 8(6):263. https://doi.org/10.3390/jmmp8060263

Chicago/Turabian StyleRamakrishnan, Karthik Ram, and Jagan Selvaraj. 2024. "Build Orientation-Driven Anisotropic Fracture Behaviour in Polymer Parts Fabricated by Powder Bed Fusion" Journal of Manufacturing and Materials Processing 8, no. 6: 263. https://doi.org/10.3390/jmmp8060263

APA StyleRamakrishnan, K. R., & Selvaraj, J. (2024). Build Orientation-Driven Anisotropic Fracture Behaviour in Polymer Parts Fabricated by Powder Bed Fusion. Journal of Manufacturing and Materials Processing, 8(6), 263. https://doi.org/10.3390/jmmp8060263