Experimental Methodology to Identify Optimal Friction Stir Welding Parameters Based on Temperature Measurement

Abstract

1. Introduction

2. State of the Art

| Author | Year | Method | Material | Tmin < Tm < Tmax | References |

|---|---|---|---|---|---|

| D. Ambrosio | 2022 | TC-Tool | AA-6082-T6 | 477 < Tm (°C) < Ts | [8] |

| AA-5083-H111 | |||||

| AA-7075-T6 | |||||

| A. Wright | 2021 | TC-Tool | AA-6111 | Tm = 450 °C | [30] |

| D. Ambrosio | 2020 | TC-Workpiece | AA-7075-T6 | Tmin = 350 °C | [21] |

| IR Camera | |||||

| S. Verma | 2020 | TC-Workpiece | AA-7039 | 283 < Tm (°C) < 390 | [26] |

| T. Wu | 2019 | TC-Tool | 2A14-T6 | [31] | |

| TC-Workpiece | |||||

| G. Sorger | 2018 | TC-Workpiece | HSS | 650 < Tm (°C) < 900 | [32] |

| A. C. F. Silva | 2016 | TC-Workpiece | AA-6082-T6 | Tmax = 500 °C | [27] |

| TWT | |||||

| TC-Tool | |||||

| A. Fehrenbacher | 2013 | TC-Tool-Shoulder | AA-6061 | 515 < Tm (°C) < Ts | [33] |

| AA-5083 H111 | 518 < Tm (°C) < Ts | ||||

| TC-Tool-Pin | AA-6061 | 460 < Tm (°C) < Ts | |||

| AA-5083 H111 | 479 < Tm (°C) < Ts | ||||

| J. De Backer | 2013 | TWT | AA-6082-T6 | Tmax = 432 °C | [34,35] |

| C. Hamilton | 2010 | IR Camera | SSA038-T6 | Tmax = 400 °C | [36] |

| P. Upadhyay | 2010 | TC-Tool | AA-7050 | Tmax = 350 °C | [37] |

| T7451 | |||||

| P. L. Threadgill | 2009 | TC-Workpiece | AA-6061 T6 | Tmax = 500 °C | [38] |

| F. Gratecap | 2008 | TC-Workpiece | AA-2017 T4 | 0.7 Tmelt < Tm (K) < 0.8 Tmelt | [39] |

| Yuh J. Chao | 2003 | TC-Workpiece | AA-2195 | 0.8 Tmelt < Tm (°C) < 0.9 Tmelt | [40] |

| L.E. Murr | 1998 | AA-6061 | Tmax = 425 °C | [41] | |

| M.W. Mahoney | 1998 | TC-Workpiece | AA-7075 T651 | Tmax < Tmelt | [42] |

| W. Tang | 1998 | TC-Tool | AA-6061 T6 | Tmax = 450 °C | [43] |

| C.G. Rhodes | 1997 | TC-Workpiece | AA-7075 T651 | 400 < Tm (°C) < 480 | [44] |

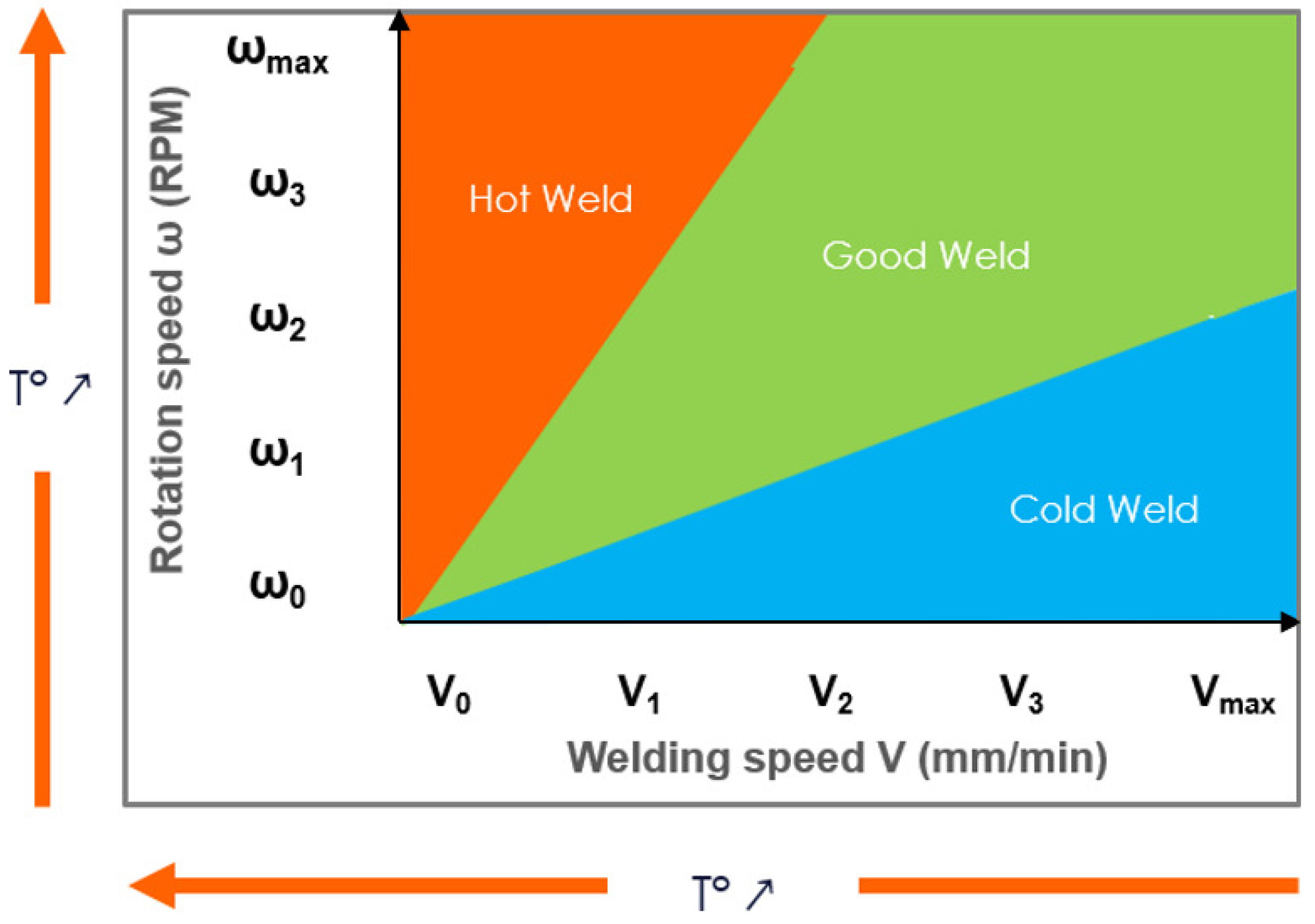

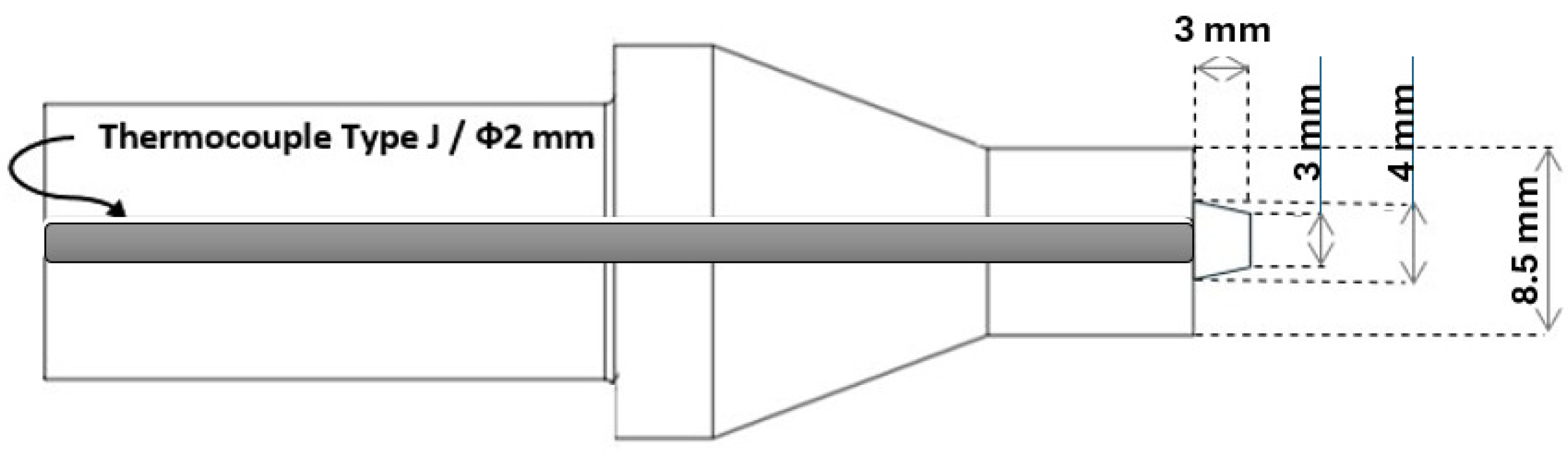

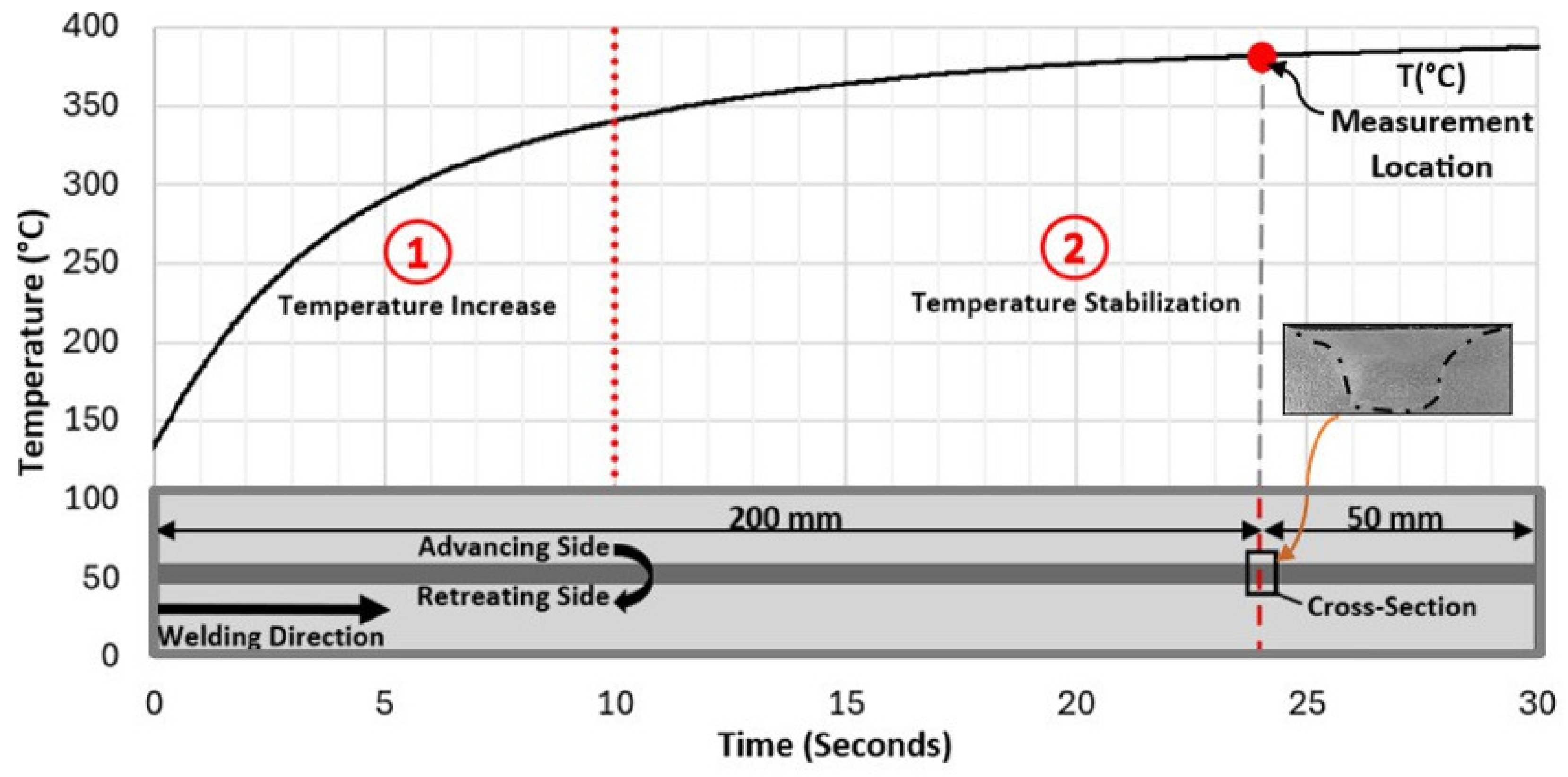

3. Experimental Approach

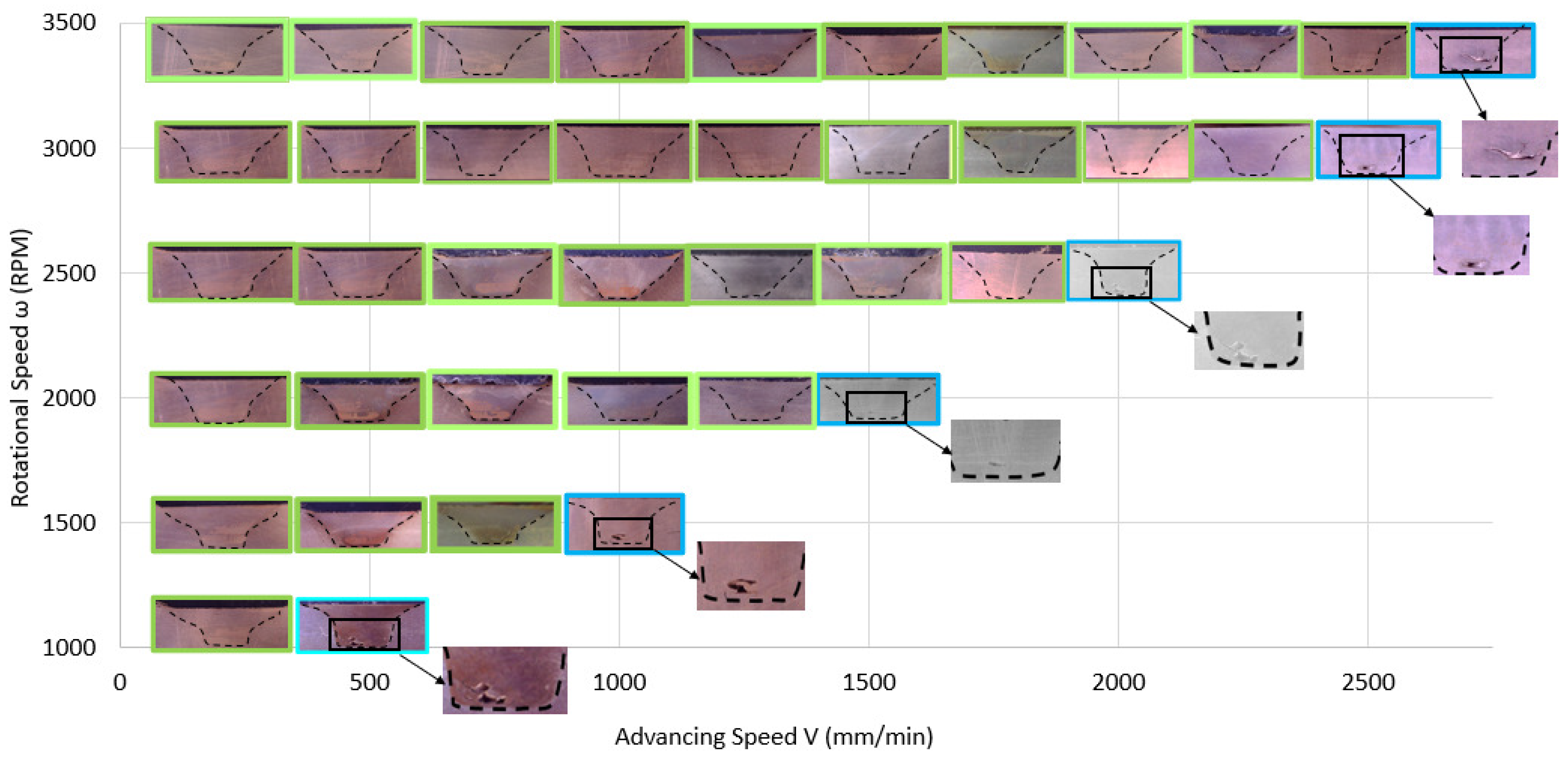

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Welding. US5460317A, 24 October 1995. [Google Scholar]

- Mishra, R.S. Friction Stir Welding of High Strength 7XXX Aluminum Alloys; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Ericsson, M.; Sandström, R. Influence of welding speed on the fatigue of friction stir welds, and comparison with MIG and TIG. Int. J. Fatigue 2003, 25, 1379–1387. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, X.; Fang, H. Mechanical properties of friction stir welding and metal inert gas welding of Al-Zn aluminum alloy joints. Int. J. Adv. Manuf. Technol. 2017, 91, 3025–3031. [Google Scholar] [CrossRef]

- Paik, J.K. Mechanical properties of friction stir welded aluminum alloys 5083 and 5383. Int. J. Nav. Archit. Ocean Eng. 2009, 1, 39–49. [Google Scholar] [CrossRef]

- Leitão, C.; Louro, R.; Rodrigues, D.M. Analysis of high temperature plastic behaviour and its relation with weldability in friction stir welding for aluminium alloys AA5083-H111 and AA6082-T6. Mater. Des. 2012, 37, 402–409. [Google Scholar] [CrossRef]

- Song, M.; Kovacevic, R. Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int. J. Mach. Tools Manuf. 2003, 43, 605–615. [Google Scholar] [CrossRef]

- Ambrosio, D. A semi-empirical model for peak temperature estimation in friction stir welding of aluminium alloys. Sci. Technol. Weld. Join. 2022, 527, 491–500. [Google Scholar] [CrossRef]

- Sadeghi, B.; Sadeghian, B.; Taherizadeh, A.; Laska, A.; Cavaliere, P.; Gopinathan, A. Effect of Porosity on the Thermo-Mechanical Behavior of Friction-Stir-Welded Spark-Plasma-Sintered Aluminum Matrix Composites with Bimodal Micro- and Nano-Sized Reinforcing Al2O3 Particles. Metals 2022, 12, 1660. [Google Scholar] [CrossRef]

- El-Moayed, M.H.; Shash, A.Y.; Rabou, M.A.; El-Sherbiny, M.G. Thermal-induced Residual Stresses and Distortions in Friction Stir Welds—A Literature Review. J. Weld. Join. 2021, 39, 409–418. [Google Scholar] [CrossRef]

- Boldsaikhan, E.; Corwin, E.; Logar, A.; McGough, J.; Arbegast, W. Detecting Wormholes in Friction Stir Welds from Welding Feedback Data. 42nd Midwest Instr. Comput. Symp. 2009. Available online: https://api.semanticscholar.org/CorpusID:201826216 (accessed on 1 April 2024).

- Wang, W.; Meng, X.; Dong, W.; Xie, Y.; Ma, X.; Mao, D.; Zhang, Z.; Huang, Y. In-Situ rolling friction stir welding of aluminum alloys towards corrosion resistance. Corros. Sci. 2024, 230, 111920. [Google Scholar] [CrossRef]

- ISO 25239; Friction stir welding — Aluminium. International Organization for Standardization: 2020.

- Albannai, A.I. Review The Common Defects In Friction Stir Welding. Int. J. Sci. Technol. Res. 2020, 19, 318–329. [Google Scholar]

- Pratap, V.; Kumar, S.; Ranjan, A.; Kuriachen, B. Recent research progress in solid state friction-stir welding of aluminium—Magnesium alloys: A critical review. Integr. Med. Res. 2020, 9, 6217–6256. [Google Scholar]

- Mehta, K.P.; Badheka, V.J. A Review on Dissimilar Friction Stir Welding of Copper to Aluminum: Process, Properties, and Variants A Review on Dissimilar Friction Stir Welding of Copper to Aluminum: Process, Properties, and Variants. LMMP 2016, 31, 233–254. [Google Scholar] [CrossRef]

- Adriana, M.; Obregon, T. Effect of Process Parameters on Temperature Distribution, Microstructure, and Mechanical Properties of Self-Reacting Friction Stir Welded Aluminum Alloy 6061-T651; ETD Collection for University of Texas, El Paso, AAI1498322; University of Texas at El Paso: El Paso, TX, USA, 2011. [Google Scholar]

- Xue, P.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al–Cu joints. Int. J. Mater. Sci. Eng. 2011, 528, 4683–4689. [Google Scholar] [CrossRef]

- Golezani, A.S.; Barenji, R.; Heidarzadeh, A.; Pouraliakbar, H. Elucidating of tool rotational speed in friction stir welding of 7020-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2015, 81, 1155–1164. [Google Scholar] [CrossRef]

- Shojaeefard, M.; Khalkhali, A.; Akbari, M.; Tahani, M. Application of Taguchi optimization technique in determining aluminum to brass friction stir welding parameters. Mater. Des. 2013, 52, 587–592. [Google Scholar] [CrossRef]

- Ambrosio, D. Influence of welding parameters on the microstructure, thermal fields and defect formation in AA7075-T6 friction stir welds. Weld. World 2020, 64, 773–784. [Google Scholar] [CrossRef]

- Tabasi, M.; Farahani, M.; Givi, M.K.B.; Farzami, M.; Moharami, A. Dissimilar friction stir welding of 7075 aluminum alloy to AZ31 magnesium alloy using SiC nanoparticles. Int. J. Adv. Manuf. Technol. 2016, 86, 705–715. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Els-botes, A.; Mcgrath, P.J. Effect of Travel speed on Joint properties of Dissimilar Metal Friction Stir Welds. In Proceedings of the Second International Conference on Advances in Engineering and Technology, Phuket, Thailand, 4–5 June 2016. [Google Scholar]

- Sato, Y.; Urata, M.; Kokawa, H. Parameters Controlling Microstructure and Hardness during Friction-Stir Welding of Precipitation-Hardenable Aluminum Alloy 6063. Metall. Mater. Trans. A 2002, 33, 625–635. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Ilio, A.D. Forces and temperature variation during friction stir welding of aluminum alloy AA6082-T6. Int. J. Adv. Manuf. Technol. 2018, 99, 337–346. [Google Scholar] [CrossRef]

- Verma, S. Effect of process parameters on temperature and force distribution during friction stir welding of armor- marine grade aluminum alloy. J. Eng. Manuf. 2021, 235, 144–154. [Google Scholar] [CrossRef]

- Silva, A.C.F.; Backer, J.D.; Bolmsjö, G. Temperature measurements during friction stir welding. Int. J. Adv. Manuf. Technol. 2017, 88, 2899–2908. [Google Scholar] [CrossRef]

- Silva-magalhães, A.; Backer, J.D.; Martin, J.; Bolmsjö, G. In-situ temperature measurement in friction stir welding of thick section aluminium alloys. J. Manuf. Process. 2019, 39, 12–17. [Google Scholar] [CrossRef]

- Cederqvist, L. Friction Stir Welding of Copper Canisters Using Power and Temperature Control. Ph.D. Thesis, LUND University, Lund, Sweden, 2011. [Google Scholar]

- Wright, A.; Munro, T.R.; Hovanski, Y. Evaluating Temperature Control in Friction Stir Welding for Industrial Applications. J. Manuf. Mater. Process. 2021, 5, 124. [Google Scholar] [CrossRef]

- Wu, T.; Zhao, F.; Luo, H.; Wang, H.; Li, Y. Temperature Monitoring and Material Flow Characteristics of Friction Stir Welded 2A14-t6 Aerospace Aluminum Alloy. Materials 2019, 12, 3387. [Google Scholar] [CrossRef] [PubMed]

- Sorger, G.; Sarikka, T.; Vilaça, P. Effect of processing temperatures on the properties of a high-strength steel welded by FSW. Weld. World 2018, 62, 1173–1185. [Google Scholar] [CrossRef]

- Fehrenbacher, A.; Duffie, N.A.; Ferrier, N.J.; Pfefferkorn, F.E.; Zinn, M.R. Effects of tool workpiece interface temperature on weld quality and quality improvements through temperature control in friction stir welding. Int. J. Adv. Manuf. Technol. 2014, 71, 165–179. [Google Scholar] [CrossRef]

- de Backer, J.; Bolmsjo, G. Thermoelectric method for temperature measurement in friction stir welding. Sci. Technol. Weld. Join. 2013, 18, 558–565. [Google Scholar] [CrossRef]

- Backer, J.D.; Bolmsjö, G.; Christiansson, A.K. Temperature control of robotic friction stir welding using the thermoelectric effect. Int. J. Adv. Manuf. Technol. 2014, 70, 605–615. [Google Scholar] [CrossRef]

- Hamilton, C.; Sommers, A.; Dymek, S. A thermal model of friction stir welding applied to Sc-modified Al-Zn-Mg-Cu alloy extrusions. Int. J. Mach. Tools Manuf. 2009, 49, 230–238. [Google Scholar] [CrossRef]

- Upadhyay, P.; Reynolds, A.P. Effects of thermal boundary conditions in friction stir welded AA7050-T7 sheets. Mater. Sci. Eng. A 2010, 527, 1537–1543. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Gratecap, F.; Racineux, G.; Marya, S. A simple methodology to define conical tool geometry and welding parameters in friction stir welding. Int. J. Mater. Form. 2008, 1, 143–158. [Google Scholar] [CrossRef]

- Chao, W.T.Y.J.; Qi, X. Heat Transfer in Friction Stir Welding—Experimental and Numerical Studies. Int. J. Manuf. Sci. Eng. 2003, 125, 138–145. [Google Scholar] [CrossRef]

- Murr, L.E.; Liu, G.; McClure, J.C. A TEM study of precipitation and related microstructures in friction-stir-welded 6061 aluminium. Int. J. Mat. Sci. 1998, 3, 1243–1251. [Google Scholar] [CrossRef]

- Mahoney, M.W.; Rhodes, C.G.; Flintoff, J.G.; Spurling, R.A.; Bingel, W.H. Properties of Friction-Stir-Welded 7075 T651 Aluminum. Metall. Mater. Trans. A 1998, 29, 1955–1964. [Google Scholar] [CrossRef]

- Tang, W. Heat Input and Temperature Distribution in Friction Stir Welding. J. Manuf. Mater. Process. 1998, 7, 163–172. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C. Effects of Friction Stir Welding on Microstructure of 7075 Aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Gratecap, F.; Racineux, G.; Poitou, A. Choix et optimisation de l’outil et des paramètres de soudage en FSW. In Proceedings of the CFM 2007—18ème Congrès Français de Mécanique, Grenoble, France, 27–31 August 2007. [Google Scholar]

- Okamura, H. Visualization of material flow in an autogenous friction stir weld. J. Jpn. Weld. Soc. 2000, 69, 565–571. [Google Scholar] [CrossRef]

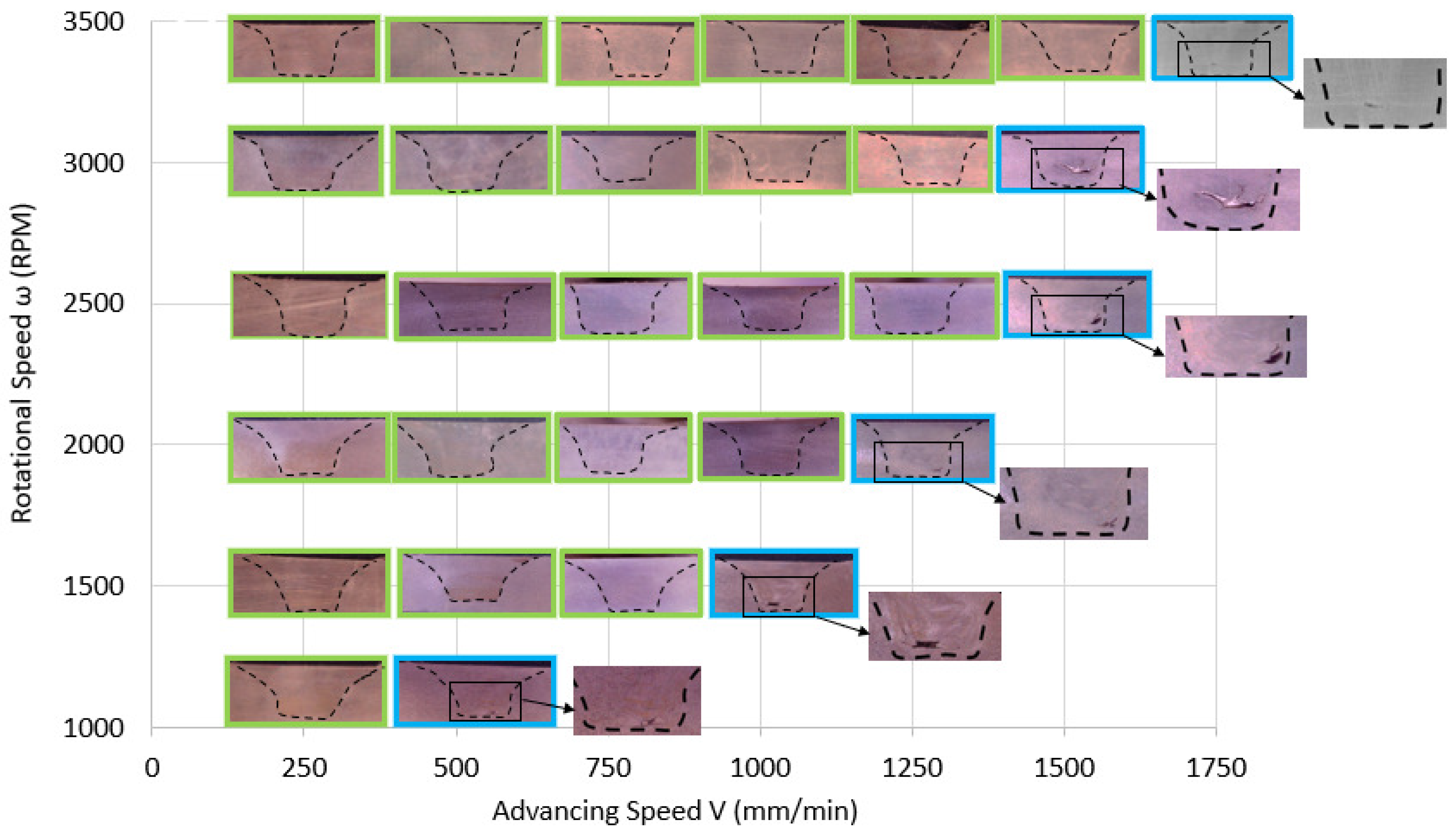

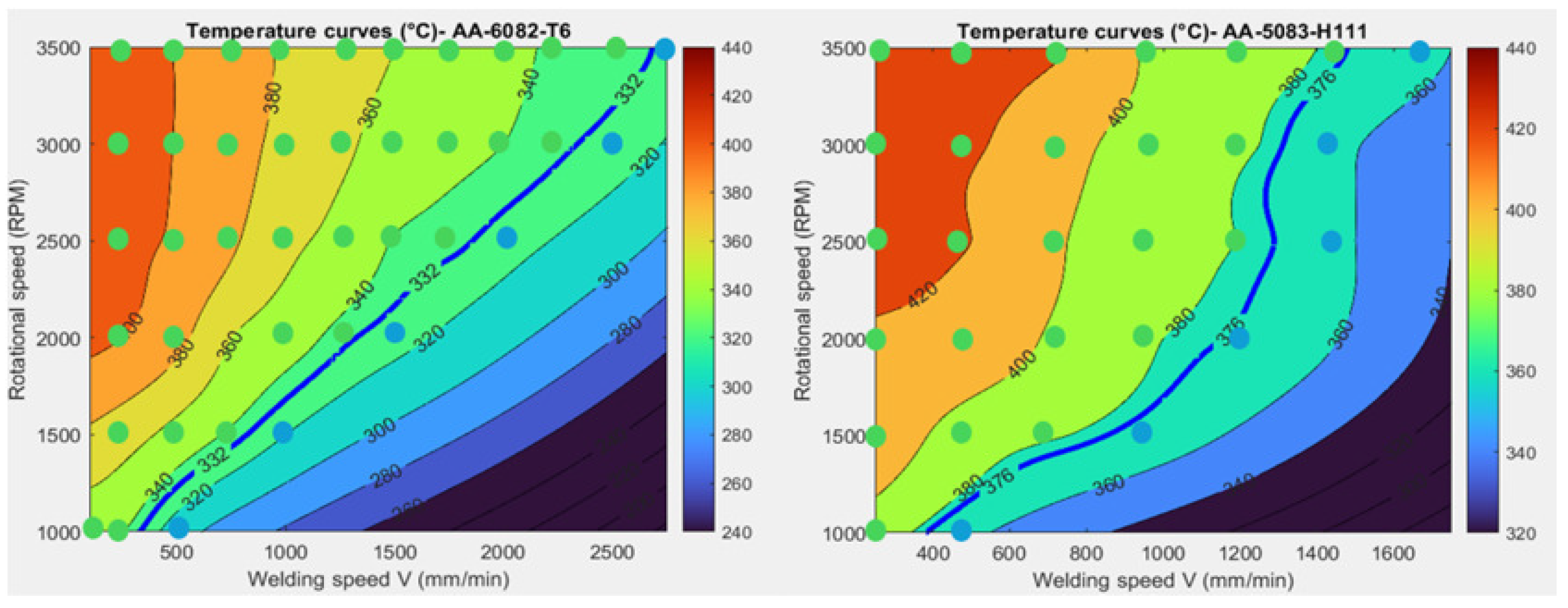

| Material AA | Advancing Speed (mm/min) | Rotational Speed (RPM) |

|---|---|---|

| 6082-T6 | 100:250:2750 | 1000:500:3500 |

| 5083-H111 | 250:250:1750 | 1000:500:3500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abboud, M.; Dubourg, L.; Racineux, G.; Kerbrat, O. Experimental Methodology to Identify Optimal Friction Stir Welding Parameters Based on Temperature Measurement. J. Manuf. Mater. Process. 2024, 8, 137. https://doi.org/10.3390/jmmp8040137

Abboud M, Dubourg L, Racineux G, Kerbrat O. Experimental Methodology to Identify Optimal Friction Stir Welding Parameters Based on Temperature Measurement. Journal of Manufacturing and Materials Processing. 2024; 8(4):137. https://doi.org/10.3390/jmmp8040137

Chicago/Turabian StyleAbboud, Moura, Laurent Dubourg, Guillaume Racineux, and Olivier Kerbrat. 2024. "Experimental Methodology to Identify Optimal Friction Stir Welding Parameters Based on Temperature Measurement" Journal of Manufacturing and Materials Processing 8, no. 4: 137. https://doi.org/10.3390/jmmp8040137

APA StyleAbboud, M., Dubourg, L., Racineux, G., & Kerbrat, O. (2024). Experimental Methodology to Identify Optimal Friction Stir Welding Parameters Based on Temperature Measurement. Journal of Manufacturing and Materials Processing, 8(4), 137. https://doi.org/10.3390/jmmp8040137