Dissimilar Probeless Friction Stir Spot Welding of Aluminum Alloy and USIBOR®1500-AS Steel Thin Plates

Abstract

1. Introduction

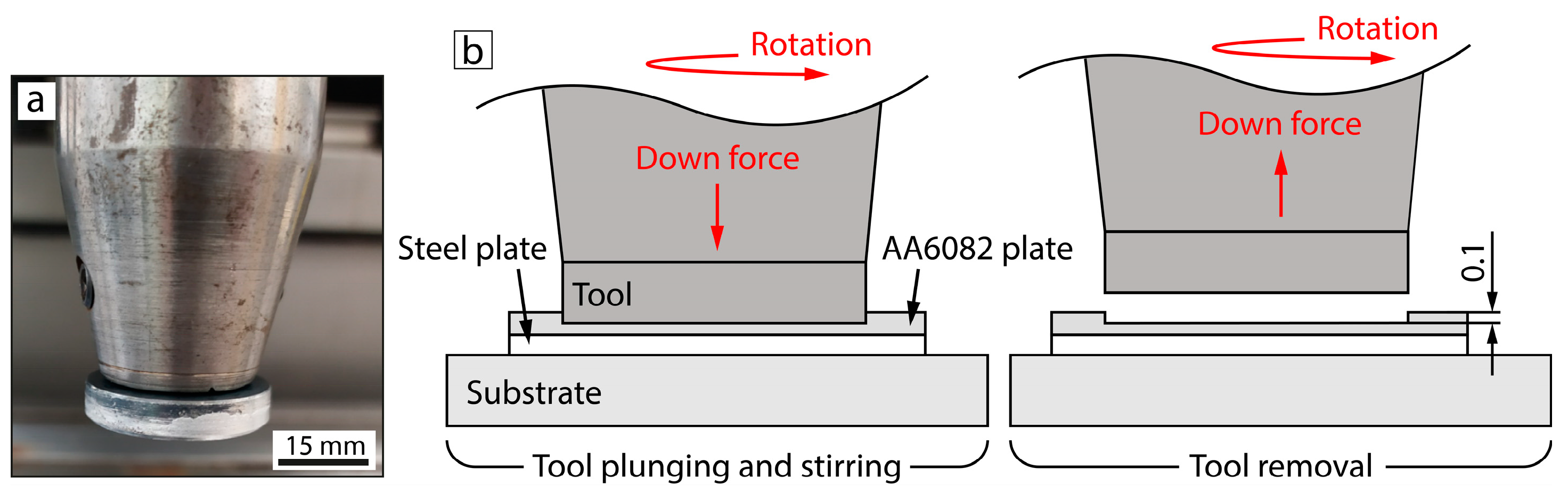

2. Materials and Methods

3. Results and Discission

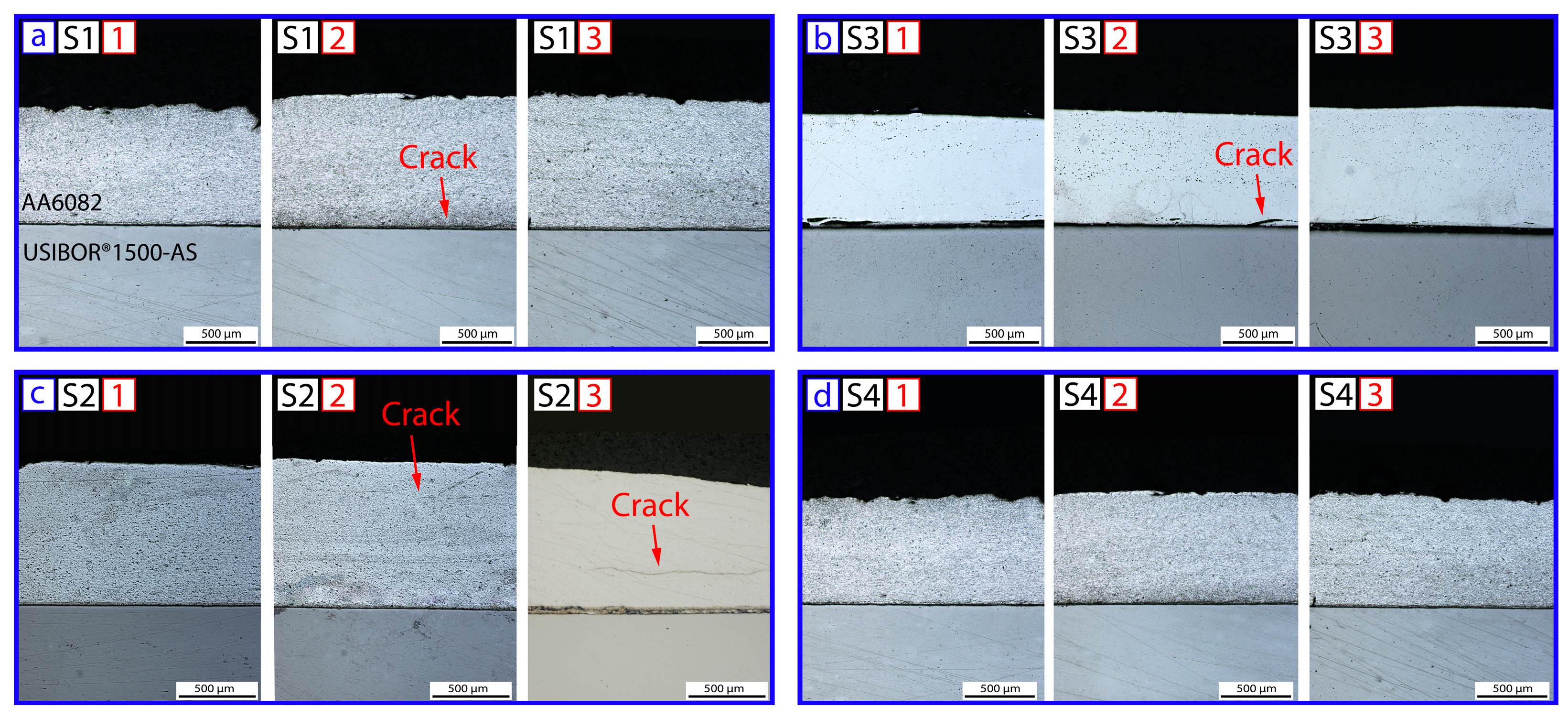

3.1. Weld Appearance and Macrostructure

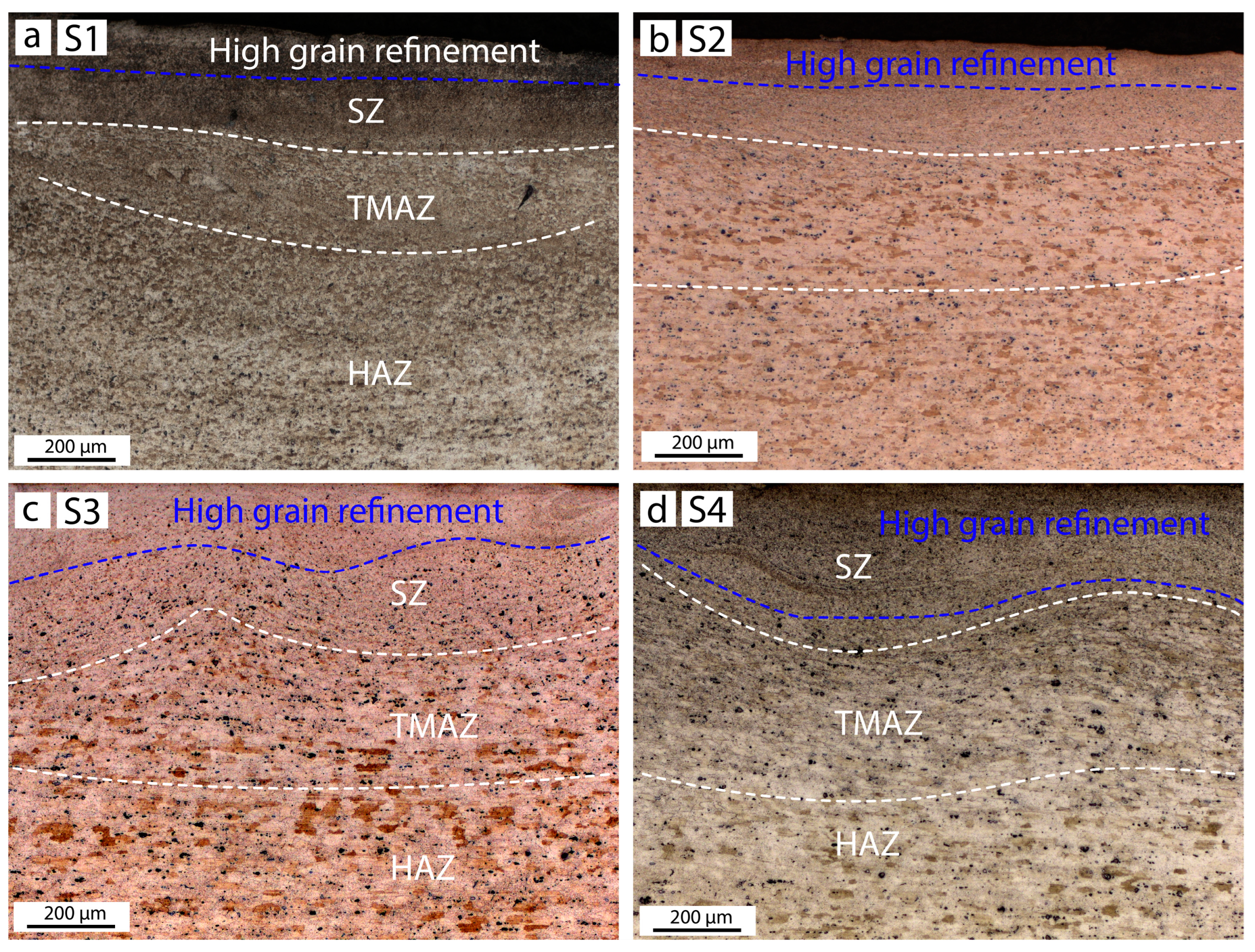

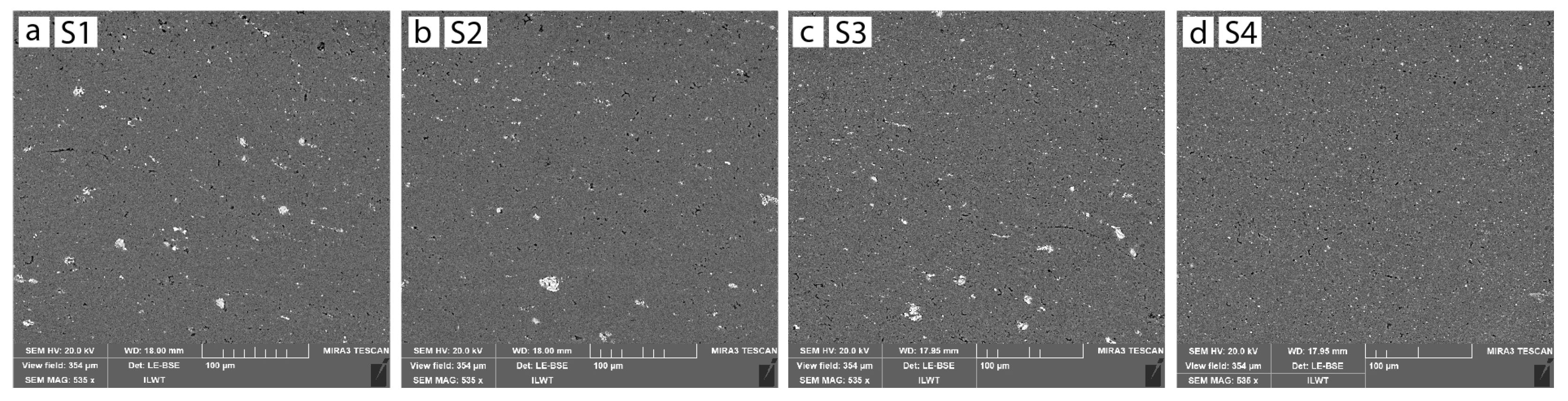

3.2. Microstructure of the Upper Plate

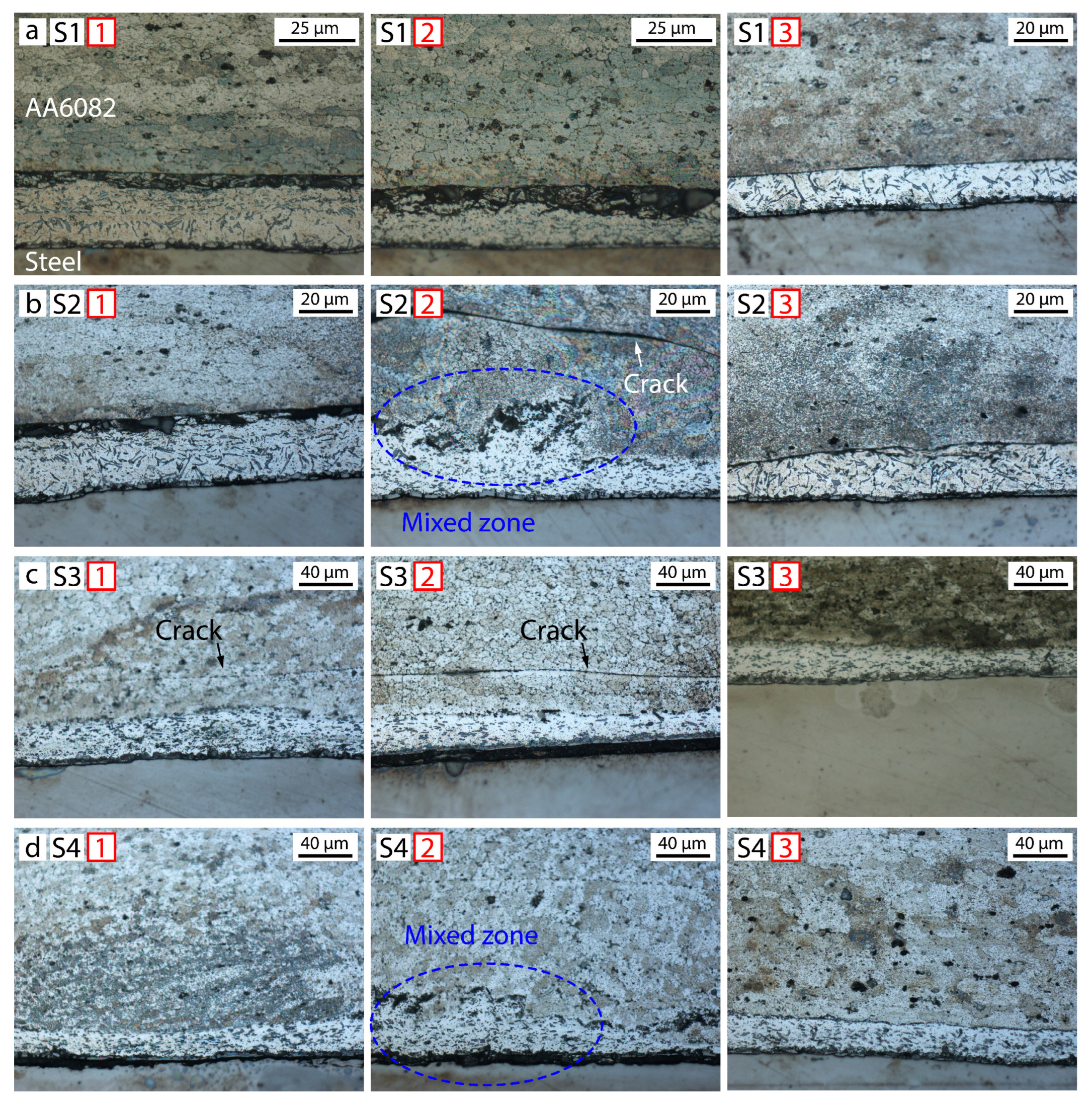

3.3. Microstructure of the Joining Interface

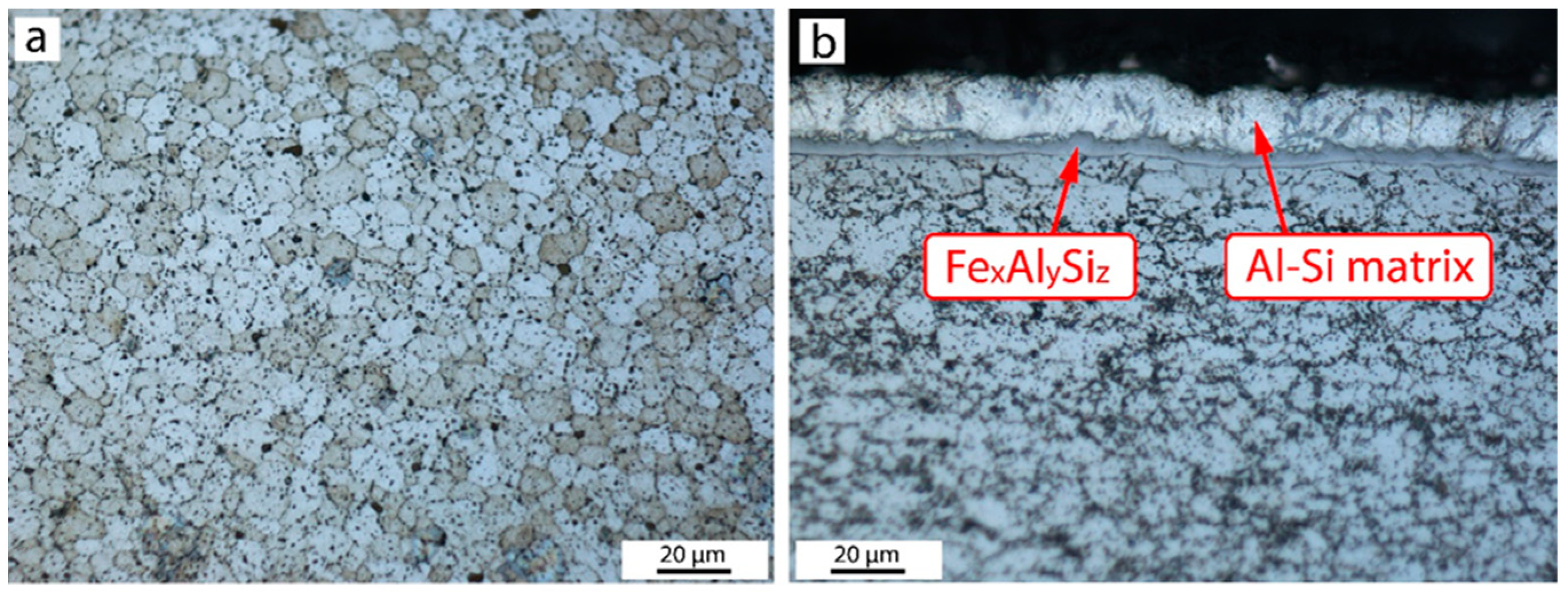

3.3.1. Al-Si Matrix

3.3.2. Joining Interface between the Aluminum and the Al-Si Coating

3.3.3. Interface between the Steel and the Al-Si Coating

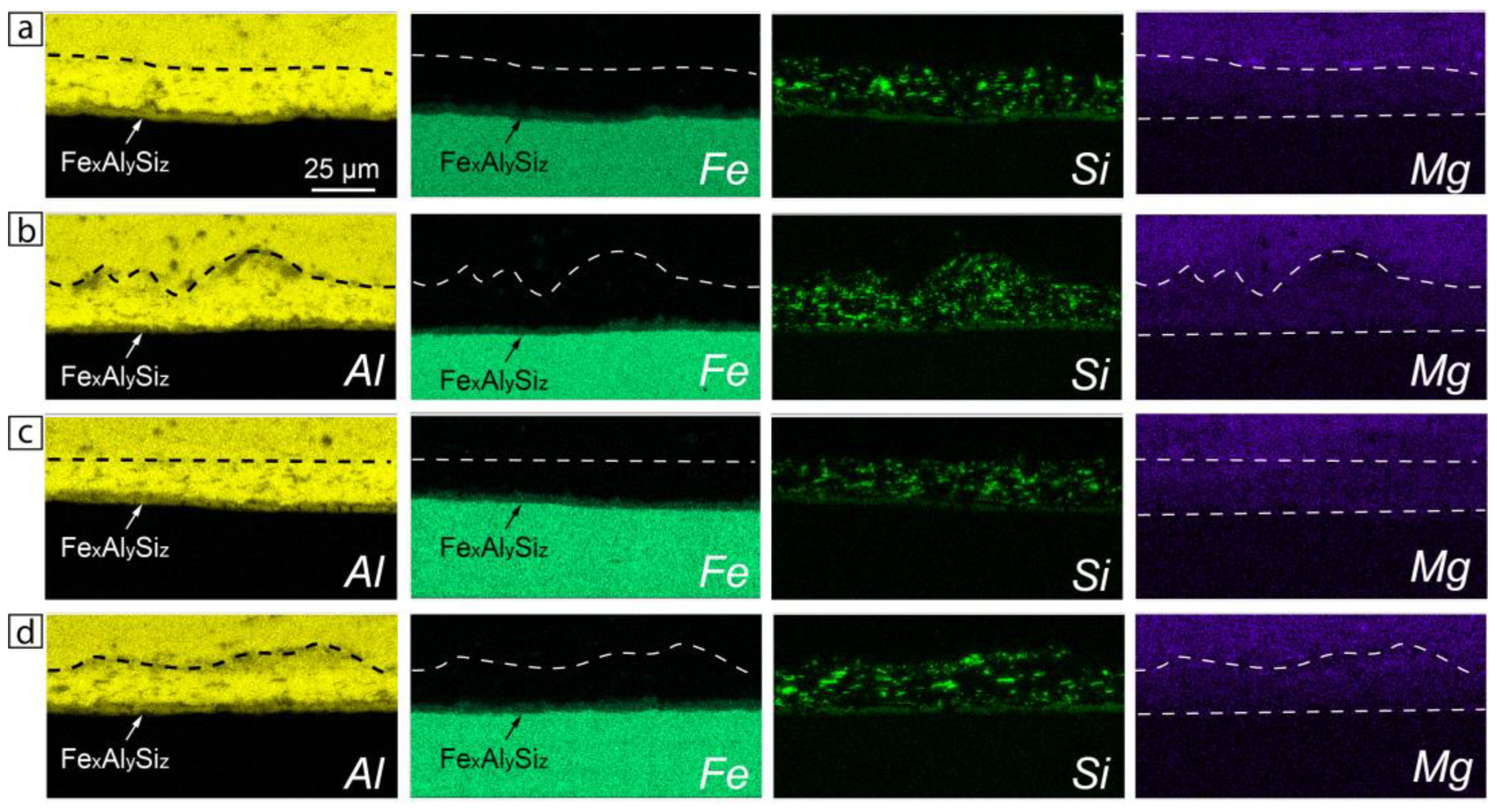

3.4. Elemental Distribution across the Joining Line

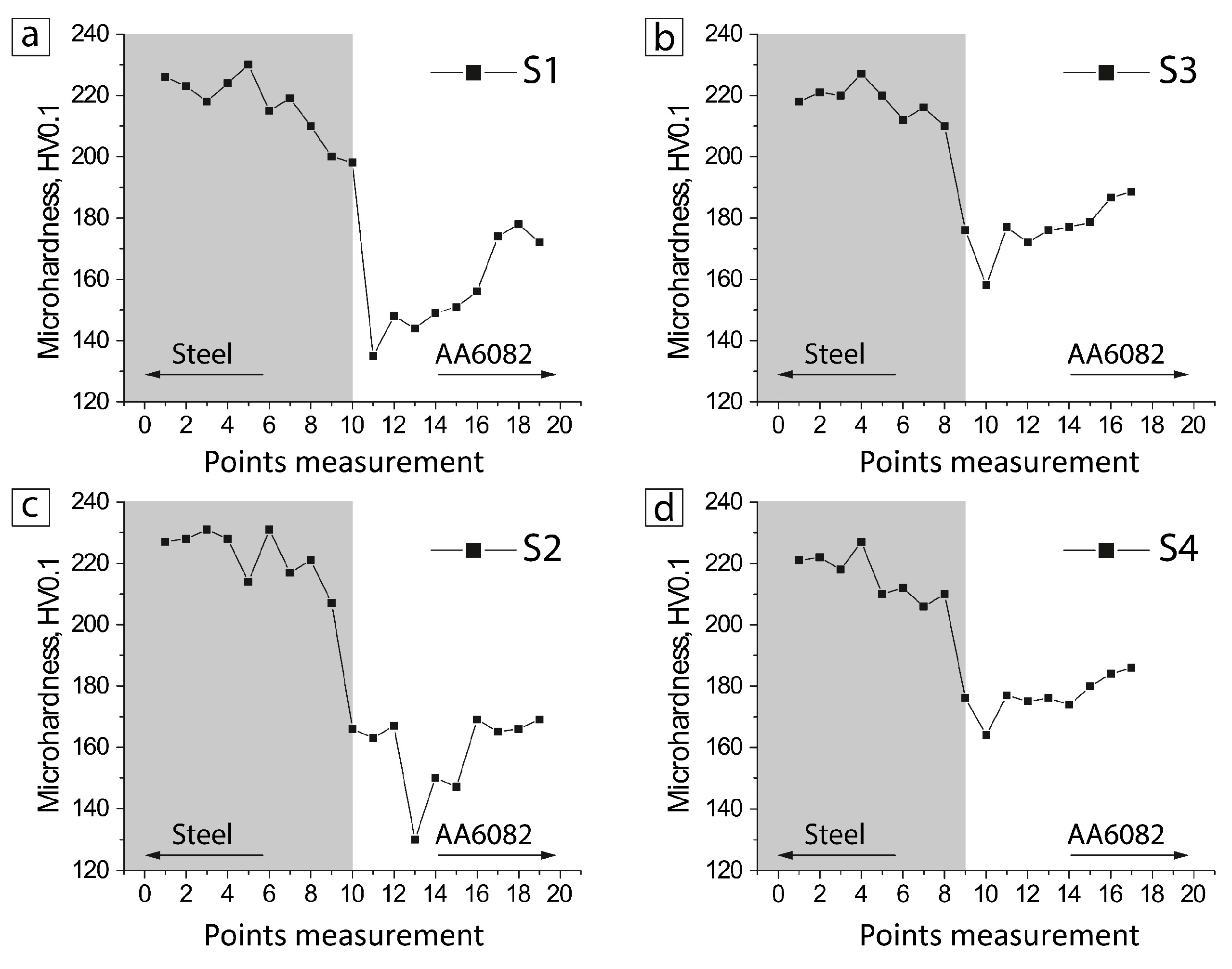

3.5. Microhardness of the Joining Interface

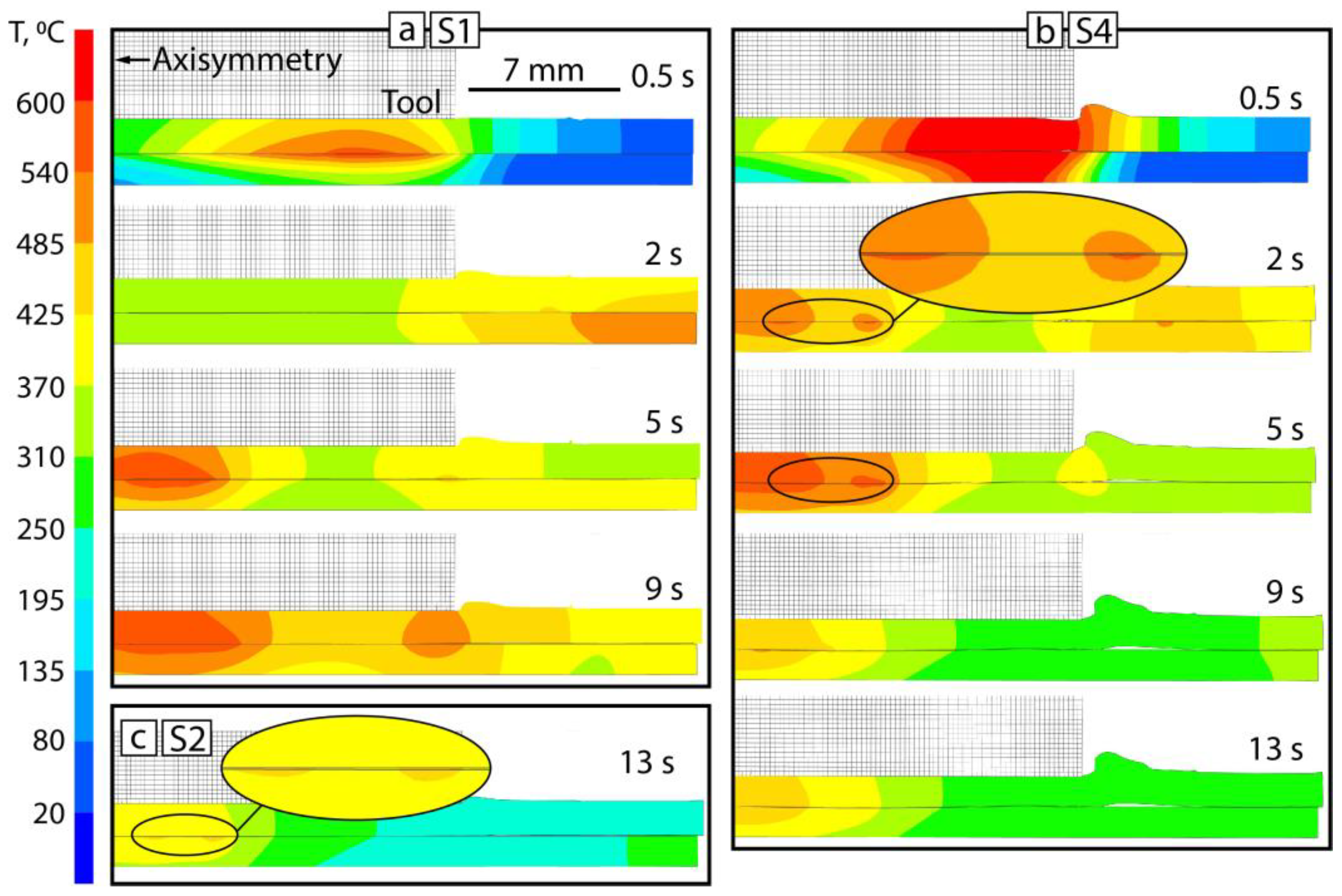

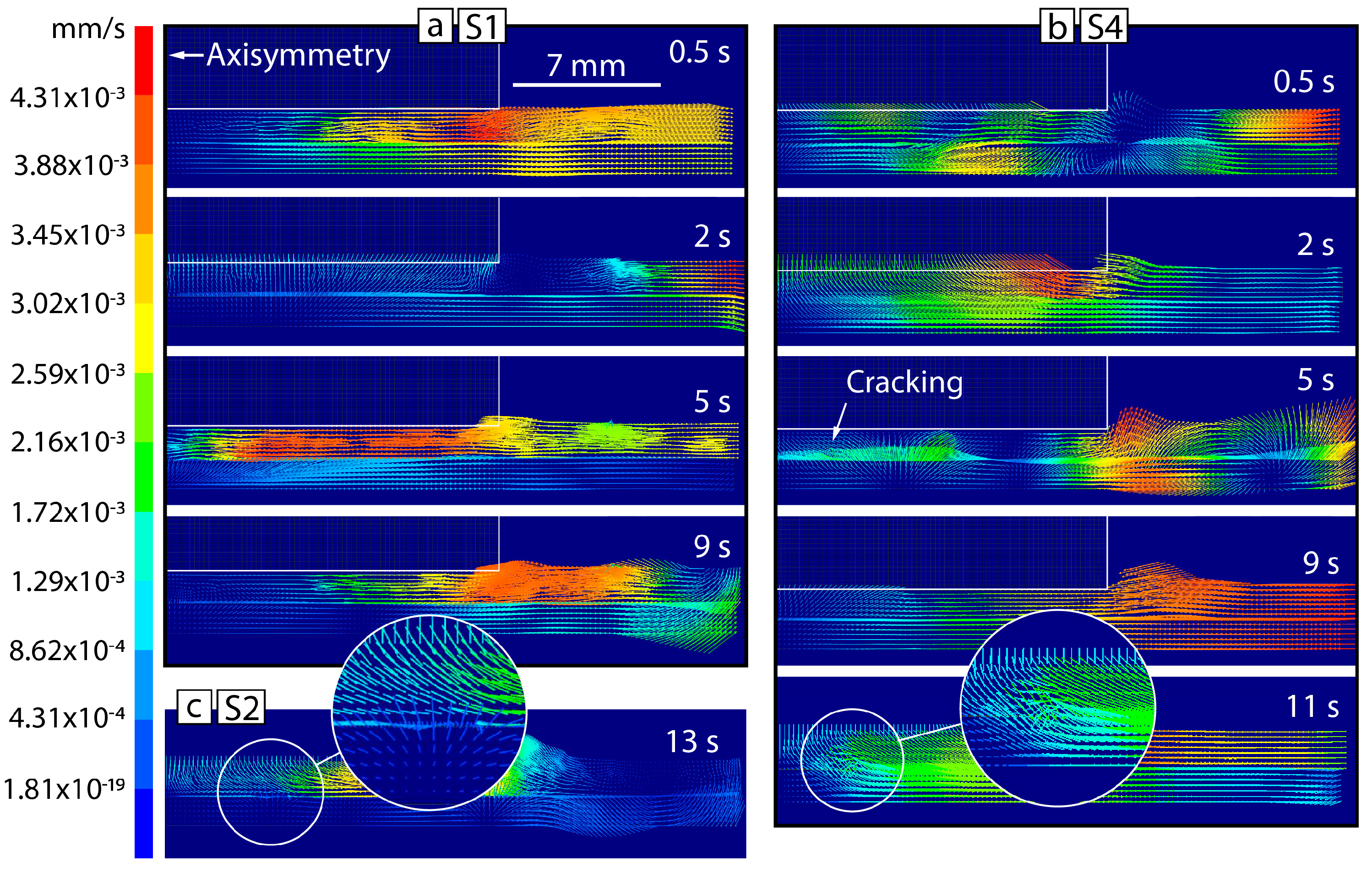

3.6. Temperature Field and Material Flow Simulation

4. Conclusions

- The adoption of an Al-Si coating on the UHSS steel promoted the interfacial bonding between the aluminum plate and the coated steel under a higher rotational speed of 1500 rpm, preventing oxidative coating wear. In the samples obtained at 1000 rpm, interfacial bonding was barely observed due to the presence of surface oxides.

- Thermo-mechanical deformation occurred solely within the upper aluminum plate. The amount of heat input was mostly influenced by the rotational speed, resulting in a wider grain refinement area within the aluminum plate.

- A dwell time of 15 s at rotational speeds of both 1000 rpm and 1500 rpm was responsible for a partial temperature concentration, which represents the formation of a mixed area between the aluminum plate and Al-Si coating.

- Coupling the numerical results on the temperature and material flow, employing both dwell times of 10 s and 15 s and a rotational speed of 1000 rpm created cracks in the upper aluminum plate due to insufficient material plastitization. The formation of cracks also occurred at a rotational speed of 1500 rpm with a shorter dwell time of 10 s owing to less intensity of the material flow being concentrated at the center of the weld spot at 5 s of P-FSSW process. In contrast, an extended dwell time under 1500 rpm promoted a more vigorous material flow at 11 s through the process, effectively eliminating the incidence of cracking.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Czerwinski, F. Current trends in automotive lightweighting strategies and materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef]

- Yang, J.; Oliveira, J.P.; Li, Y.; Tan, C.; Gao, C.; Zhao, Y.; Yu, Z. Laser techniques for dissimilar joining of aluminum alloys to steels: A critical review. J. Mater. Process. Technol. 2022, 301, 117443. [Google Scholar] [CrossRef]

- Fan, D.W.; De Cooman, B.C. State-of-the-Knowledge on Coating Systems for Hot Stamped Parts. Steel Res. Int. 2012, 83, 412–433. [Google Scholar] [CrossRef]

- Kucera, V.; Cabibbo, M.; Prusa, F.; Fojt, J.; Petr-Soini, J.; Pilvousek, T.; Kolarikova, M.; Vojtech, D. Phase Composition of Al-Si Coating from the Initial State to the Hot-Stamped Condition. Materials 2021, 14, 1125. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.; Yang, J.; Xu, J.; Jiang, J.; Zhang, H.; Oliveira, J.P.; Lv, X.; Xue, J.; Li, Z. Interfacial microstructure and strengthening mechanism of dissimilar laser al/steel joint via a porous high entropy alloy coating. J. Mater. Res. Technol. 2023, 23, 3997–4011. [Google Scholar] [CrossRef]

- Fedorov, V.; Uhlig, T.; Wagner, G. Joining of aluminum and stainless steel using AlSi10 brazing filler: Microstructure and mechanical properties. AIP Conf. Proc. 2017, 1, 1858. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, D.; Han, L.; Liu, D. Interfacial microstructure and mechanical property of resistance spot welded joint of high strength steel and aluminium alloy with 4047 AlSi12 interlayer. Mater. Des. 2014, 57, 186–194. [Google Scholar] [CrossRef]

- Zheng, M.; Zhang, H.; Gao, Y.; Zhao, Y.; Tan, C.; Song, X.; Yang, J. Influence of porous high entropy alloy coating on wetting behavior and interfacial microstructure of Al-Si alloy on steel substrate. J. Alloys Compd. 2022, 912, 165154. [Google Scholar] [CrossRef]

- Dheerendra, K.D. Dissimilar Metal Joining; Springer Nature Singapore Pte Ltd.: Singapore, 2023. [Google Scholar] [CrossRef]

- Tarasov, S.; Rubtsov, V.; Kolubaev, E. A proposed diffusion-controlled wear mechanism of alloy steel friction stir welding (FSW) tools used on an aluminum alloy. Wear 2014, 318, 130–134. [Google Scholar] [CrossRef]

- Sahlot, P.; Arora, A. Numerical model for prediction of tool wear and worn-out pin profile during friction stir welding. Wear 2018, 408, 96–107. [Google Scholar] [CrossRef]

- Li, S.; Chen, Y.; Kang, J.; Amirkhiz, B.S.; Nadeau, F. Friction stir lap welding of aluminum alloy to advanced high strength steel using a cold-spray deposition as an interlayer. Mater. Lett. 2019, 239, 212–215. [Google Scholar] [CrossRef]

- Schilling, C.; Dos Santos, J. Method and Device for Joining at Least Two Adjoining Work Pieces by Friction Welding. Google Patents US20020179682A1, 5 December 2002. [Google Scholar]

- Silva, B.H.; Zepon, G.; Bolfarini, C.; Dos Santos, J.F. Refill friction stir spot welding of AA6082-T6 alloy: Hook defect formation and its influence on the mechanical properties and fracture behavior. Mater. Sci. Eng. 2020, 773, 138724. [Google Scholar] [CrossRef]

- Tozaki, Y.; Uematsu, Y.; Tokaji, K. A newly developed tool without probe for friction stir spot welding and its performance. J. Mater. Process. Technol. 2010, 210, 844–851. [Google Scholar] [CrossRef]

- Li, W.; Li, J.; Zhang, Z.; Gao, D.; Wang, W.; Dong, C. Improving mechanical properties of pinless friction stir spot welded joints by eliminating hook defect. Mater. Des. 2014, 62, 247–254. [Google Scholar] [CrossRef]

- Lee, W.B.; Schmuecker, M.; Mercardo, U.A.; Biallas, G.; Jung, S.B. Interfacial reaction in steel–aluminum joints made by friction stir welding. Scr. Mater. 2006, 55, 355–358. [Google Scholar] [CrossRef]

- Da Silva, A.A.M.; Aldanondo, E.; Alvarez, P.; Arrurti, E.; Echeverría, A. Friction stir spot welding of AA 1050 Al alloy and hot stamped boron steel (22MnB5). Sci. Technol. Weld. Join. 2010, 15, 682–687. [Google Scholar] [CrossRef]

- Shen, Z.; Ding, Y.; Chen, J.; Shalch Amirkhiz, B.; Wen, J.Z.; Fu, L.; Gerlich, A.P. Interfacial bonding mechanism in Al/coated steel dissimilar refill friction stir spot welds. J. Mater. Sci. Technol. 2019, 35, 1027–1038. [Google Scholar] [CrossRef]

- Watanabe, M.; Feng, K.; Nakamura, Y.; Kumai, Y. Growth manner of intermetallic compound layer produced at welding interface of friction stir spot welded aluminum/steel lap joint. Mater. Trans. 2011, 52, 953–959. [Google Scholar] [CrossRef]

- Ishak, I.; Uematsu, Y.; Kakiuchi, T.; Tozaki, Y.; Mizutani, Y. Fatigue behaviour of dissimilar Al alloy/galvanised steel friction stir spot welds fabricated by scroll grooved tool without probe. Sci. Technol. Weld. Join. 2015, 20, 670–678. [Google Scholar] [CrossRef]

- Contuzzi, N.; Rashkovets, M.; Casalino, G. Numerical and experimental investigation of probeless friction stir spot welding of a multilayer aluminium alloy compound. Sci. Technol. Weld. Join. 2023, 1, 653–661. [Google Scholar] [CrossRef]

- Simufact Forming Manual Guide. 2021. Available online: https://nexus.hexagon.com/documentationcenter/bundle/Simufact_Forming_2021_Basics/resource/Simufact_Forming_2021_Basics.pdf (accessed on 30 December 2023).

- Chu, Q.; Yang, X.; Li, W. Microstructure and mechanical behaviour of pinless friction stir spot welded AA2198 joints. Sci. Technol. Weld. Join. 2016, 21, 164–170. [Google Scholar] [CrossRef]

- Oladimeji, O.O.; Taban, E.; Kaluc, E. Understanding the role of welding parameters and tool profile on the morphology and properties of expelled flash of spot welds. Mater. Des. 2016, 108, 518–528. [Google Scholar] [CrossRef]

- Rashkovets, M.; Contuzzi, N.; Casalino, G. Modeling of probeless friction stir spot welding of AA2024/AISI304 steel lap joint. Materials 2022, 15, 8205. [Google Scholar] [CrossRef]

- Reilly, A.; Shercliff, H.; Chen, Y.; Prangnel, P. Modelling and visualisation of material flow in friction stir spot welding. J. Mater. Process. Technol. 2015, 225, 473–484. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enomoto, M.; Jogan, S. Microstructural evolution of 6063 aluminum during friction-stir welding. Metall. Mater. Trans. A Phys. 1999, 30, 2429–2437. [Google Scholar] [CrossRef]

- Buckley, D.H. Surface films and metallurgy related to lubrication and wear. Prog. Surf. Sci. 1982, 12, 1–153. [Google Scholar] [CrossRef]

| Alloy | Al | Cu | Mg | Mn | Si | Fe | Cr | Zn | Ti | C |

|---|---|---|---|---|---|---|---|---|---|---|

| AA 6082–T6 | Bal. | ≤0.1 | 0.6–1.2 | 0.4–1.0 | 0.7–1.3 | ≤0.5 | ≤0.25 | ≤0.2 | ≤0.1 | - |

| USIBOR®1500-AS | ≤0.1 | ≤0.2 | - | ≤1.4 | ≤0.4 | Bal. | ≤0.35 | - | ≤0.05 | ≤0.25 |

| Al-Si coating | Bal. | - | - | - | 10 | - | - | - | - | - |

| Sample | Rotational Speed, rpm | Down Force, N | Dwell Time, s |

|---|---|---|---|

| S1 | 1000 | 7350 | 10 |

| S2 | 1000 | 15 | |

| S3 | 1500 | 10 | |

| S4 | 1500 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashkovets, M.; Palmieri, M.E.; Contuzzi, N.; Tricarico, L.; Casalino, G. Dissimilar Probeless Friction Stir Spot Welding of Aluminum Alloy and USIBOR®1500-AS Steel Thin Plates. J. Manuf. Mater. Process. 2024, 8, 55. https://doi.org/10.3390/jmmp8020055

Rashkovets M, Palmieri ME, Contuzzi N, Tricarico L, Casalino G. Dissimilar Probeless Friction Stir Spot Welding of Aluminum Alloy and USIBOR®1500-AS Steel Thin Plates. Journal of Manufacturing and Materials Processing. 2024; 8(2):55. https://doi.org/10.3390/jmmp8020055

Chicago/Turabian StyleRashkovets, Mariia, Maria Emanuela Palmieri, Nicola Contuzzi, Luigi Tricarico, and Giuseppe Casalino. 2024. "Dissimilar Probeless Friction Stir Spot Welding of Aluminum Alloy and USIBOR®1500-AS Steel Thin Plates" Journal of Manufacturing and Materials Processing 8, no. 2: 55. https://doi.org/10.3390/jmmp8020055

APA StyleRashkovets, M., Palmieri, M. E., Contuzzi, N., Tricarico, L., & Casalino, G. (2024). Dissimilar Probeless Friction Stir Spot Welding of Aluminum Alloy and USIBOR®1500-AS Steel Thin Plates. Journal of Manufacturing and Materials Processing, 8(2), 55. https://doi.org/10.3390/jmmp8020055