Quality Analysis of Weld-Line Defects in Carbon Fibre Reinforced Sheet Moulding Compounds by Automated Eddy Current Scanning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Manufacturing

2.2. NDT Tests and Microstructural Analysis

2.2.1. Robot-Based EC Measurement

2.2.2. Micro CT and Radiography

2.3. Process Simulation

2.4. Mechanical Testing with 3D DIC

3. Results

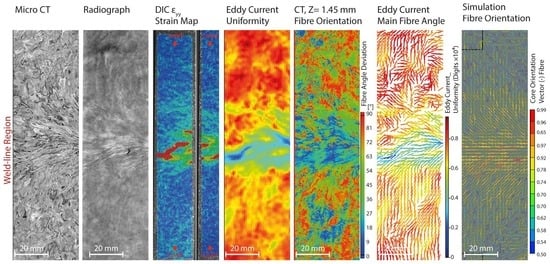

3.1. Effect of Different Flow Patterns on Microstructure

3.2. Mechanical Properties and Comparing DIC/EC

3.3. Microstructure Analysis Using Micro-CT

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fereshteh-Saniee, N.; Reynolds, N.; Kelly, C.A.; Wilson, P.R.; Jenkins, M.J.; Kendall, K.N. Introducing cryomilling for reliable determination of resin content and degree of cure in structural carbon fibre reinforced thermoset composites. Compos. Part A Appl. Sci. Manuf. 2018, 107, 197–204. [Google Scholar] [CrossRef] [Green Version]

- Gupta, J.; Reynolds, N.; Chiciudean, T.; Kendall, K. A comparative study between epoxy and vinyl ester CF-SMC for high volume automotive composite crash structures. Compos. Struct. 2020, 244, 112299. [Google Scholar] [CrossRef]

- Centea, T.; Hubert, P. Measuring the impregnation of an out-of-autoclave prepreg by micro-CT. Compos. Sci. Technol. 2011, 71, 593–599. [Google Scholar] [CrossRef]

- Qian, C.; Harper, L.; Turner, T.; Warrior, N. Notched behaviour of discontinuous carbon fibre composites: Comparison with quasi-isotropic non-crimp fabric. Compos. Part A Appl. Sci. Manuf. 2011, 42, 293–302. [Google Scholar] [CrossRef]

- Selezneva, M.; Lessard, L. Characterization of mechanical properties of randomly oriented strand thermoplastic composites. J. Compos. Mater. 2016, 50, 2833–2851. [Google Scholar] [CrossRef]

- Visweswaraiah, S.B.; Selezneva, M.; Lessard, L.; Hubert, P. Mechanical characterisation and modelling of randomly oriented strand architecture and their hybrids—A general review. J. Reinf. Plast. Compos. 2018, 37, 548–580. [Google Scholar] [CrossRef]

- Feraboli, P.; Cleveland, T.; Ciccu, M.; Stickler, P.; DeOto, L. Defect and damage analysis of advanced discontinuous carbon/epoxy composite materials. Compos. Part A Appl. Sci. Manuf. 2010, 41, 888–901. [Google Scholar] [CrossRef]

- Favaloro, A.J.; Tseng, H.-C.; Pipes, R.B. A new anisotropic viscous constitutive model for composites molding simulation. Compos. Part A Appl. Sci. Manuf. 2018, 115, 112–122. [Google Scholar] [CrossRef]

- Chookaew, W.; Mingbunjurdsuk, J.; Jittham, P.; Ranong, N.N.; Patcharaphun, S. An Investigation of Weldline Strength in Injection Molded Rubber Parts. In Energy Procedia, Proceedings of the 10th Eco-Energy and Materials Science and Engineering Symposium, Ubon-Ratchathani, Thailand, 5–8 December 2012; Yupapin, P., PivsaArt, S., Ohgaki, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 767–774. [Google Scholar]

- Chrysostomou, A.; Hashemi, S. Mechanical properties of injection moulded styrene maleic anhydride (SMA) Part II Influence of short glass fibres and weldlines. J. Mater. Sci. 1998, 33, 4491–4501. [Google Scholar] [CrossRef]

- Debondue, E.; Fournier, J.-E.; Lacrampe, M.-F.; Krawczak, P. Weld-line sensitivity of injected amorphous polymers. J. Appl. Polym. Sci. 2004, 93, 644–650. [Google Scholar] [CrossRef]

- Fellahi, S.; Meddad, A.; Fisa, B.; Favis, B.D. Weldlines in injection-molded parts: A review. Adv. Polym. Technol. 1995, 14, 169–195. [Google Scholar] [CrossRef]

- Hashemi, S. Thermal effects on weld and unweld tensile properties of injection moulded short glass fibre reinforced ABS composites. Express Polym. Lett. 2007, 1, 688–697. [Google Scholar] [CrossRef]

- Baradi, M.B.; Cruz, C.; Riedel, T.; Régnier, G. Mechanical and microstructural characterization of flowing weld lines in injection-molded short fiber-reinforced PBT. Polym. Test. 2019, 74, 152–162. [Google Scholar] [CrossRef] [Green Version]

- Quintana, M.C.; Frontini, P. Weld line strength factors in a reinforced injection molded part: Relationship with predicted fiber orientation. J. Reinf. Plast. Compos. 2019, 39, 219–230. [Google Scholar] [CrossRef]

- Leblanc, D.; Landry, B.; Levy, A.; Hubert, P.; Roy, S.; Yousefpour, A.; Quinlan, E. Study of Processing Conditions on the Forming of Ribbed Features Using Randomly Oriented Strands Thermoplastic Composites. J. Am. Helicopter Soc. 2015, 60, 1–9. [Google Scholar] [CrossRef]

- Martulli, L.; Creemers, T.; Schöberl, E.; Hale, N.; Kerschbaum, M.; Lomov, S.V.; Swolfs, Y. A thick-walled sheet moulding compound automotive component: Manufacturing and performance. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105688. [Google Scholar] [CrossRef]

- Martulli, L.; Kerschbaum, M.; Lomov, S.V.; Swolfs, Y. Weld lines in tow-based sheet moulding compounds tensile properties: Morphological detrimental factors. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106109. [Google Scholar] [CrossRef]

- Teuwsen, J.; Hohn, S.K.; Osswald, T.A. Direct Fiber Simulation of a Compression Molded Ribbed Structure Made of a Sheet Molding Compound with Randomly Oriented Carbon/Epoxy Prepreg Strands—A Comparison of Predicted Fiber Orientations with Computed Tomography Analyses. J. Compos. Sci. 2020, 4, 164. [Google Scholar] [CrossRef]

- Auld, B.A.; Moulder, J.C. Review of Advances in Quantitative Eddy Current Nondestructive Evaluation. J. Nondestruct. Eval. 1999, 18, 3–36. [Google Scholar] [CrossRef]

- Bardl, G.; Nocke, A.; Hübner, M.; Gereke, T.; Pooch, M.; Schulze, M.; Heuer, H.; Schiller, M.; Kupke, R.; Klein, M.; et al. Analysis of the 3D draping behavior of carbon fiber non-crimp fabrics with eddy current technique. Compos. Part B Eng. 2018, 132, 49–60. [Google Scholar] [CrossRef]

- Berger, D.; Lanza, G. Development and Application of Eddy Current Sensor Arrays for Process Integrated Inspection of Carbon Fibre Preforms. Sensors 2017, 18, 4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheng, J.; Ji, H.; Qiu, J.; Takagi, T.; Uchimoto, T.; Hu, N. Role of interlaminar interface on bulk conductivity and electrical anisotropy of CFRP laminates measured by eddy current method. NDT E Int. 2014, 68, 1–12. [Google Scholar] [CrossRef]

- Heuer, H.; Schulze, M.; Pooch, M.; Gäbler, S.; Nocke, A.; Bardl, G.; Cherif, C.; Klein, M.; Kupke, R.; Vetter, R.; et al. Review on quality assurance along the CFRP value chain—Non-destructive testing of fabrics, preforms and CFRP by HF radio wave techniques. Compos. Part B Eng. 2015, 77, 494–501. [Google Scholar] [CrossRef]

- Hughes, R.R.; Drinkwater, B.W.; Smith, R.A. Characterisation of carbon fibre-reinforced polymer composites through radon-transform analysis of complex eddy-current data. Compos. Part B Eng. 2018, 148, 252–259. [Google Scholar] [CrossRef]

- Schulze, M.H.; Heuer, H.; Küttner, M.; Meyendorf, N. High-resolution eddy current sensor system for quality assessment of carbon fiber materials. Microsyst. Technol. 2010, 16, 791–797. [Google Scholar] [CrossRef]

- Bardl, G.; Nocke, A.; Cherif, C.; Pooch, M.; Schulze, M.; Heuer, H.; Schiller, M.; Kupke, R.; Klein, M. Automated detection of yarn orientation in 3D-draped carbon fiber fabrics and preforms from eddy current data. Compos. Part B Eng. 2016, 96, 312–324. [Google Scholar] [CrossRef]

- Khan, A.M.; Bardl, G.; Nocke, A.; Cherif, C. Quality analysis of 2D and 3D-draped carbon preforms by eddy current scanning. Compos. Part B Eng. 2019, 176, 107110. [Google Scholar] [CrossRef]

- Suragus GmbH. Available online: https://www.suragus.com/en/products/carbon-fiber-testing/portable-devices/portable-handheld-for-carbon-fiber-testing/ (accessed on 15 October 2019).

- Feraboli, P.; Peitso, E.; Cleveland, T.; Stickler, P.B. Modulus Measurement for Prepreg-based Discontinuous Carbon Fiber/Epoxy Systems. J. Compos. Mater. 2009, 43, 1947–1965. [Google Scholar] [CrossRef]

- Evans, A.; Qian, C.; Turner, T.; Harper, L.; Warrior, N. Flow characteristics of carbon fibre moulding compounds. Compos. Part A Appl. Sci. Manuf. 2016, 90, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Feraboli, P.; Peitso, E.; Cleveland, T.; Stickler, P.B.; Halpin, J.C. Notched behavior of prepreg-based discontinuous carbon fiber/epoxy systems. Compos. Part A Appl. Sci. Manuf. 2009, 40, 289–299. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Robot scanning speed | 30 mm/s |

| Robot positioning accuracy (ISO 9283) | ±0.1 mm |

| Sensor type | SURAGUS 48 |

| -Coil diameter -Shape of coil -Coil configuration | 3 mm Helical Half-transmission |

| Sample rate | 100 Hz |

| Eddy current frequency | 6 MHz |

| Average Distance between data points | 0.25 mm |

| Tescan Unitom XL Parameters | Radiographs | 3D Micro-CT Scans | ||||||

|---|---|---|---|---|---|---|---|---|

| Flow | Butt | 50 mm Flow | 50 mm Butt | 25 mm Flow and Butt | 50 mm Flow | 50 mm Butt | 25 mm Flow and Butt | |

| Sample size (mm) | 250 × 250 | 250 × 250 | 50 × 250 | 50 × 250 | 2 × (25 × 250) | 50 × 250 | 50 × 250 | 2 × (25 × 250) |

| Field of view (mm) | 297 × 262 | 297 × 262 | 49 × 49 | 49 × 49 | 54 × 54 | 13 × 187 | 13 × 192 | 74 × 74 |

| Image stacking | 2 × 2 | 2 × 2 | 1 × 6 | 1 × 6 | 1 × 1 | 1 × 5 | 1 × 5 | 1 × 1 |

| No. sub-scans | 4 | 4 | 6 | 6 | 1 | 5 | 5 | 1 |

| Detector size (pixels) | 2856 × 2856 | 2856 × 2856 | 2856 × 2856 | 2856 × 2856 | 2856 × 2856 | 1920 × 1896 | 1920 × 1896 | 2856 × 2856 |

| Image size (pixels) | 5034 × 5712 | 5034 × 5712 | 2856 × 2856 | 2856 × 2856 | 2856 × 2856 | 1920 × 7181 | 1920 × 7112 | 2856 × 2856 |

| Resolution (μm) | 52 | 52 | 17 | 18 | 19 | 26 | 27 | 26 |

| Voltage (kV) | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Power (W) | 15 | 15 | 15 | 15 | 15 | 30 | 30 | 30 |

| Grey range (×1000) | 29–52 | 33–52 | 29–52 | 33–52 | 29–52 | 10–52 | 10–52 | 10–52 |

| Sensor | GOM 12 M with Titanar 100 mm Lens |

|---|---|

| Image window | 4000 pixel × 3000 pixel |

| Measurement area | 150 mm × 100 mm |

| Calibration plate used | CP20 90 × 72 |

| Facet size | 19 pixels (16 pixels step size) |

| Depth of field | 39 mm |

| Frame rate | 1 Hz |

| εx (%) | dx (mm) | dy (mm) | |||

|---|---|---|---|---|---|

| Mean Bias | Mean Precision | Mean Bias | Mean Precision | Mean Bias | Mean Precision |

| −0.0005 | 0.0195 | 0.0034 | 0.0005 | −0.0002 | 0.0006 |

| Configuration | Tensile Strength (MPa) | Apparent Modulus (GPa) | Max Global εy (%) | Max Local εy (%) |

|---|---|---|---|---|

| Mono (M2) | 90.4 ± 0.1 | 16.5 ± 0.1 | 0.569 ± 0.001 | 6.208 ± 0.001 |

| Butt (B2) | 40.5 ± 0.1 | * 17.2 ± 0.1 | 0.242 ± 0.001 | 3.425 ± 0.001 |

| Flow (F2) | 12.3 ± 0.1 | * 16.3 ± 0.1 | 0.073 ± 0.001 | 1.732 ± 0.001 |

| Flow Joint | Micro-CT | Simulation | EC (2D Measurement) |

|---|---|---|---|

| Area 1: 40 mm above the WL | |||

| Area 2: ±20 mm around the WL | |||

| Area 3: 40 mm below the WL |

| Adjacent Joint | Micro-CT | Simulation | EC 2D Measurement (Mean Vector Vx = sin2α, Vy = cos2α) |

|---|---|---|---|

| Area 1: 40 mm above the WL | |||

| Area 2: ±20 mm around the WL | |||

| Area 3: 40 mm below the WL |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fereshteh-Saniee, N.; Reynolds, N.; Norman, D.; Qian, C.; Armstrong, D.J.; Smith, P.; Kupke, R.; Williams, M.A.; Kendall, K. Quality Analysis of Weld-Line Defects in Carbon Fibre Reinforced Sheet Moulding Compounds by Automated Eddy Current Scanning. J. Manuf. Mater. Process. 2022, 6, 151. https://doi.org/10.3390/jmmp6060151

Fereshteh-Saniee N, Reynolds N, Norman D, Qian C, Armstrong DJ, Smith P, Kupke R, Williams MA, Kendall K. Quality Analysis of Weld-Line Defects in Carbon Fibre Reinforced Sheet Moulding Compounds by Automated Eddy Current Scanning. Journal of Manufacturing and Materials Processing. 2022; 6(6):151. https://doi.org/10.3390/jmmp6060151

Chicago/Turabian StyleFereshteh-Saniee, Nessa, Neil Reynolds, Danielle Norman, Connie Qian, David J. Armstrong, Paul Smith, Richard Kupke, Mark A. Williams, and Kenneth Kendall. 2022. "Quality Analysis of Weld-Line Defects in Carbon Fibre Reinforced Sheet Moulding Compounds by Automated Eddy Current Scanning" Journal of Manufacturing and Materials Processing 6, no. 6: 151. https://doi.org/10.3390/jmmp6060151

APA StyleFereshteh-Saniee, N., Reynolds, N., Norman, D., Qian, C., Armstrong, D. J., Smith, P., Kupke, R., Williams, M. A., & Kendall, K. (2022). Quality Analysis of Weld-Line Defects in Carbon Fibre Reinforced Sheet Moulding Compounds by Automated Eddy Current Scanning. Journal of Manufacturing and Materials Processing, 6(6), 151. https://doi.org/10.3390/jmmp6060151