Irregular Shape Effect of Brass and Copper Filler on the Properties of Metal Epoxy Composite (MEC) for Rapid Tooling Application

Abstract

1. Introduction

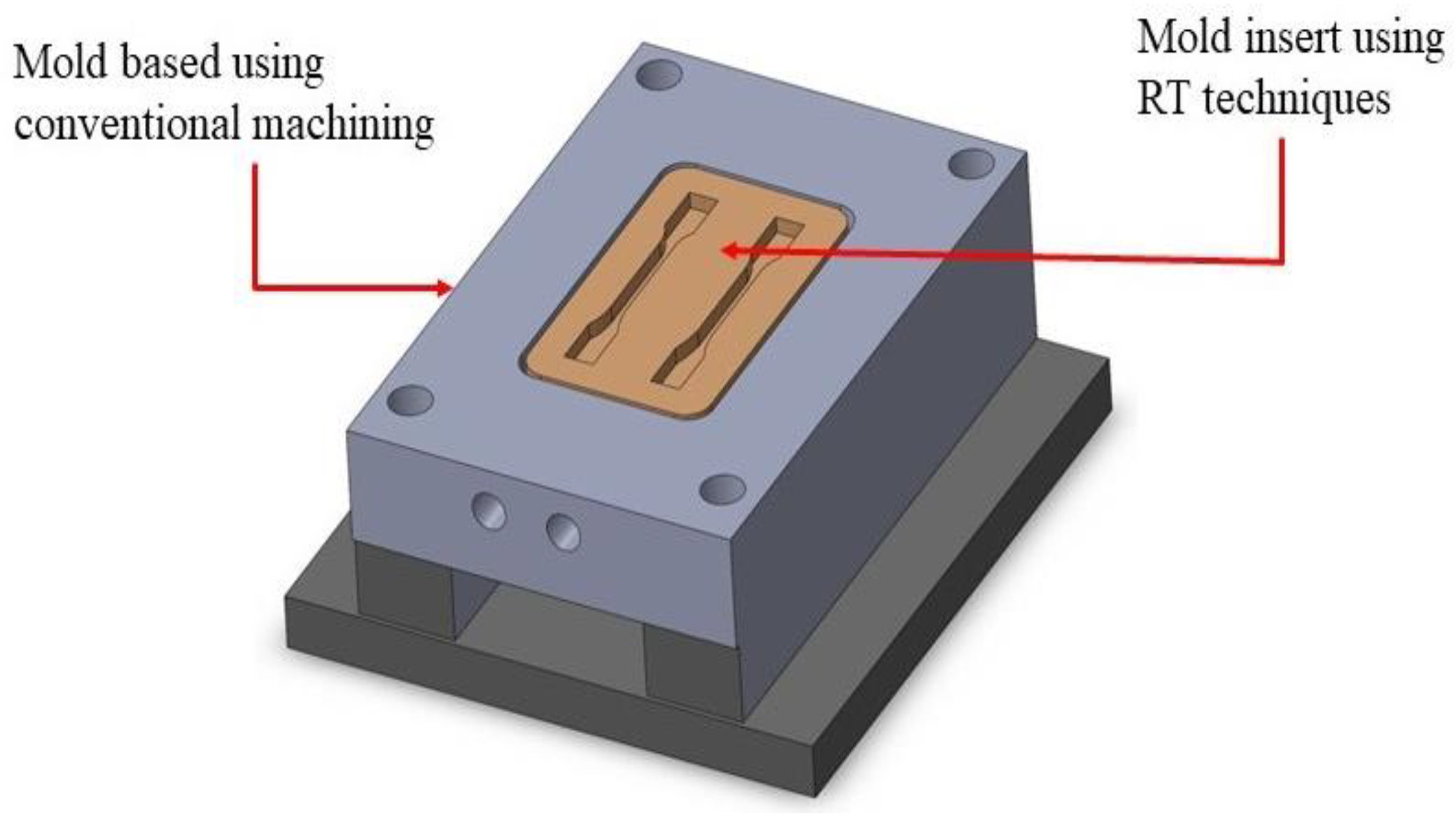

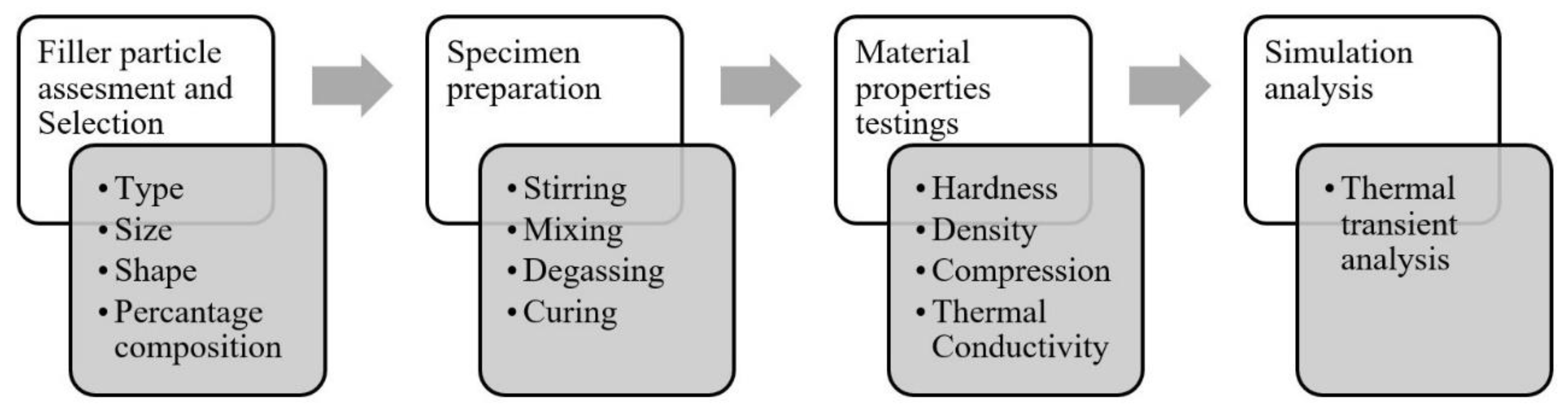

2. Methodology

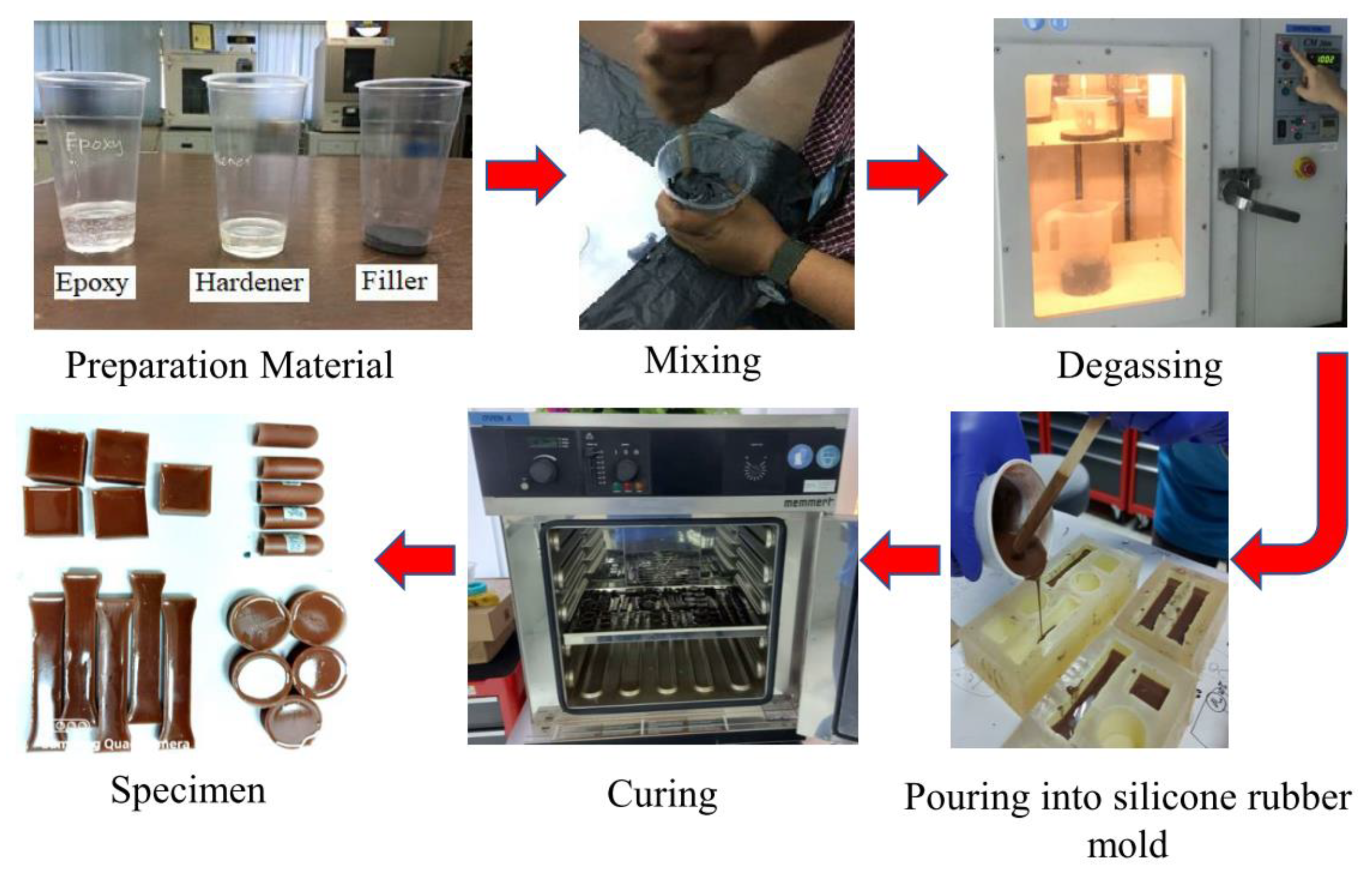

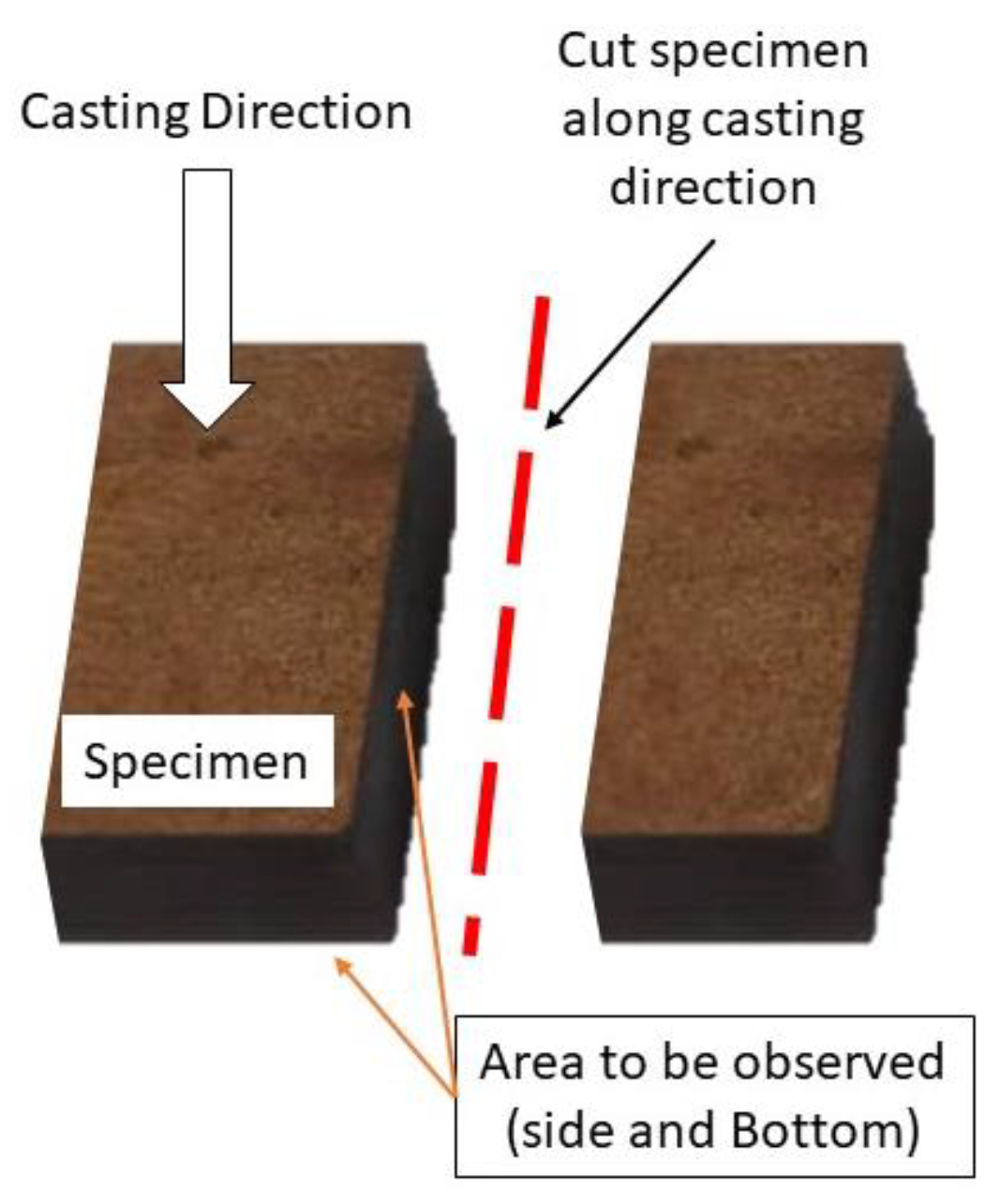

2.1. Specimen Preparation

2.2. Experimental Set-Up

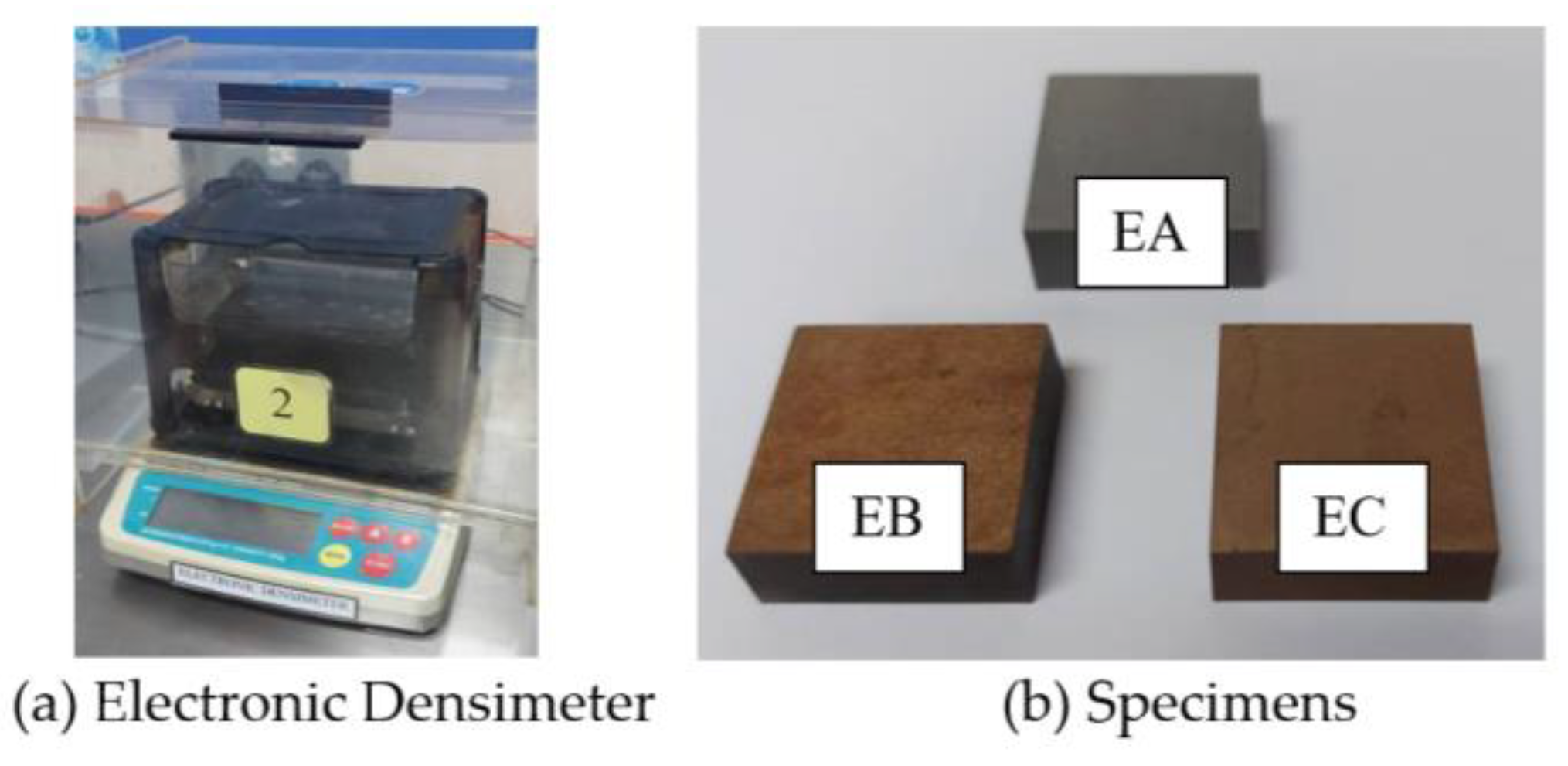

2.2.1. Density Test

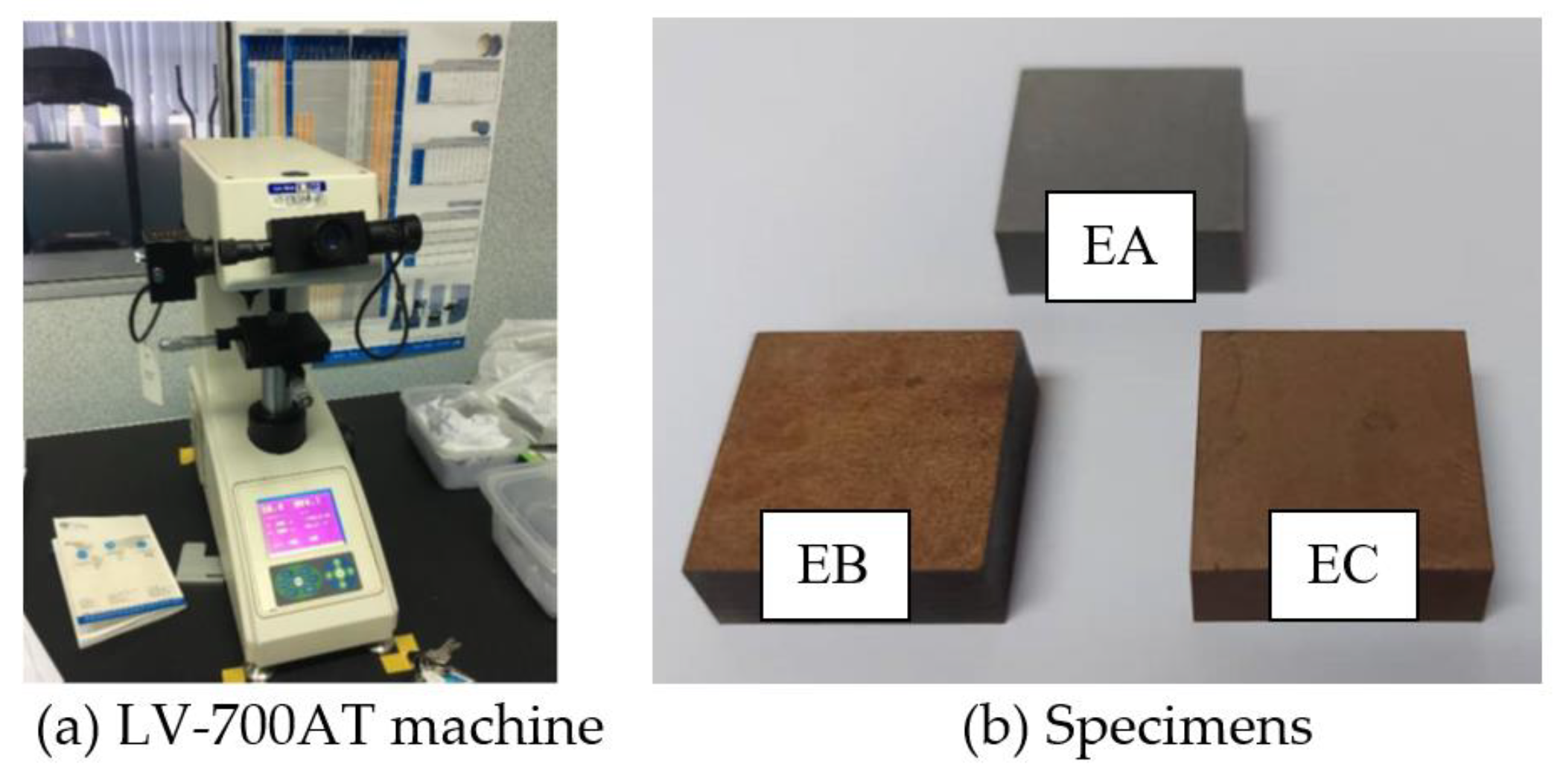

2.2.2. Hardness Test

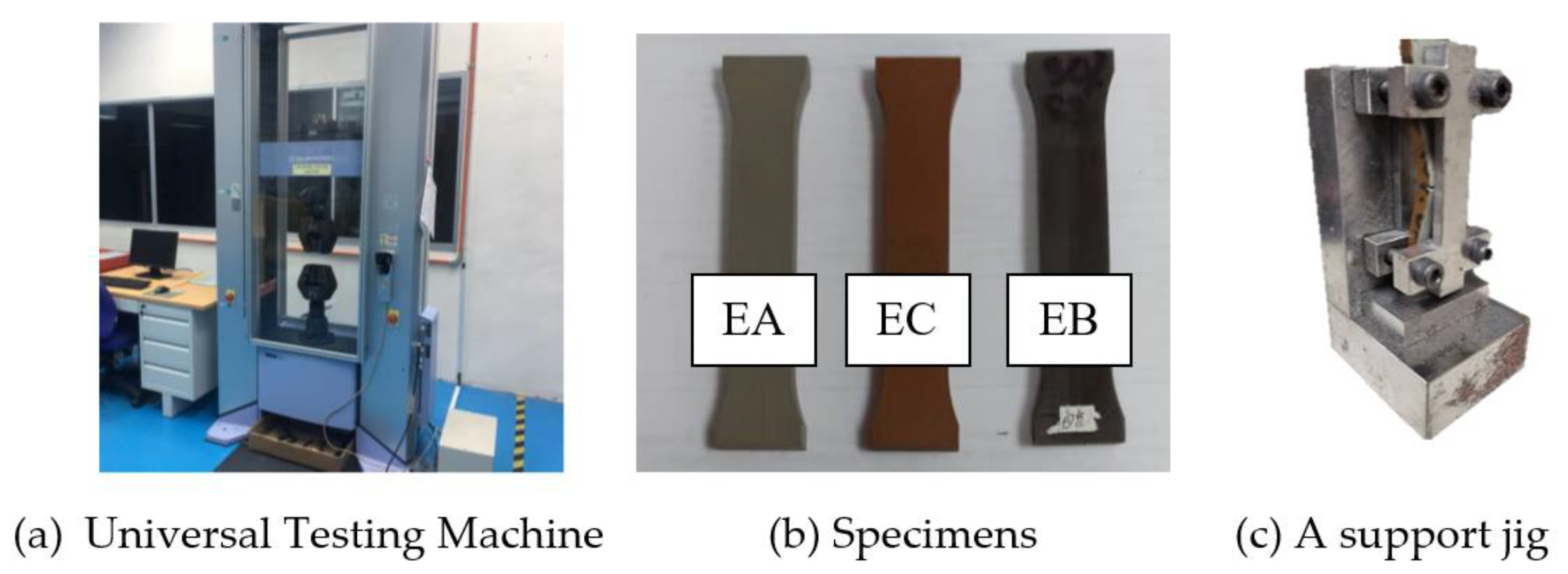

2.2.3. Compressive Strength Test

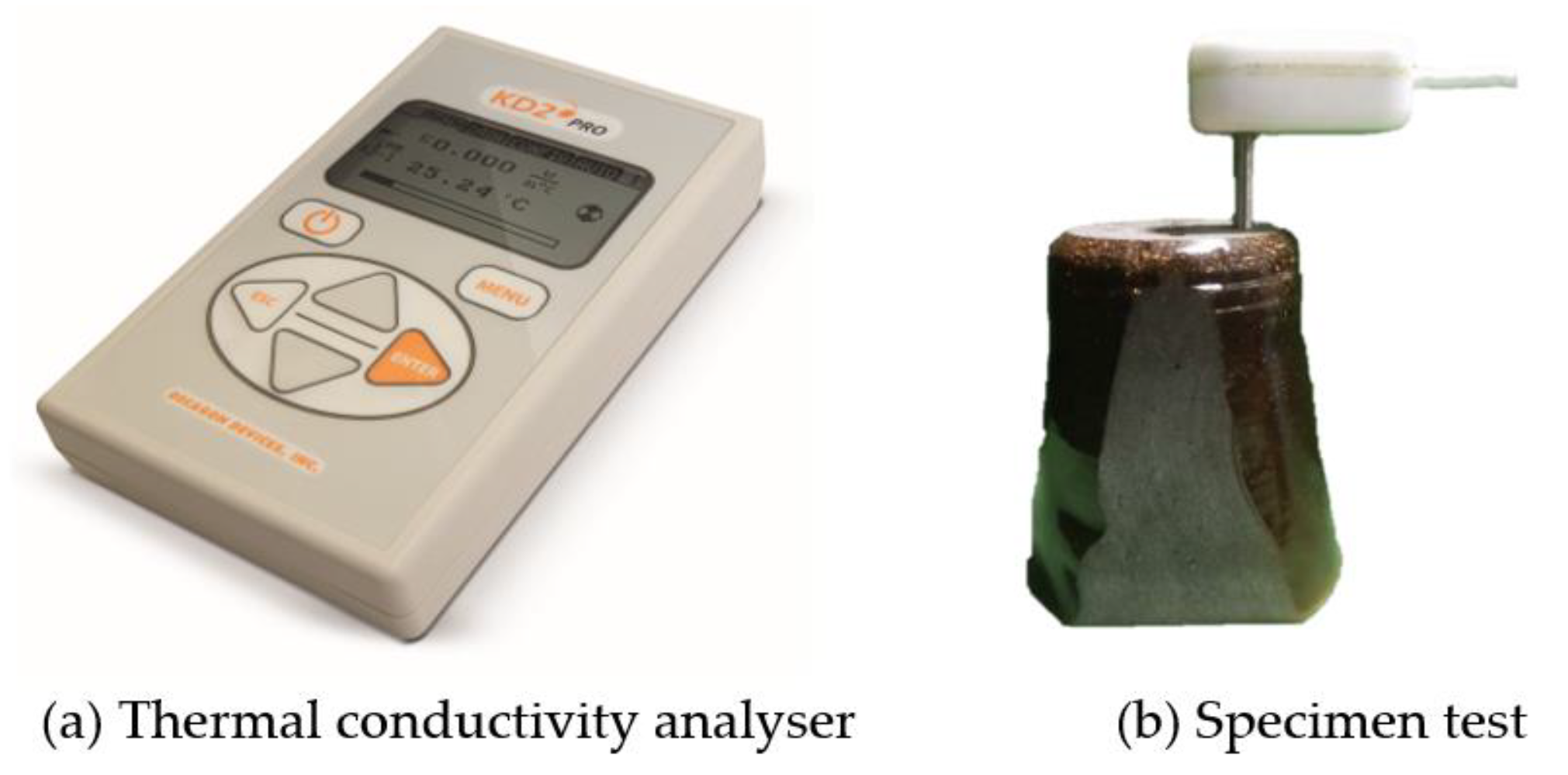

2.2.4. Thermal Conductivity Test

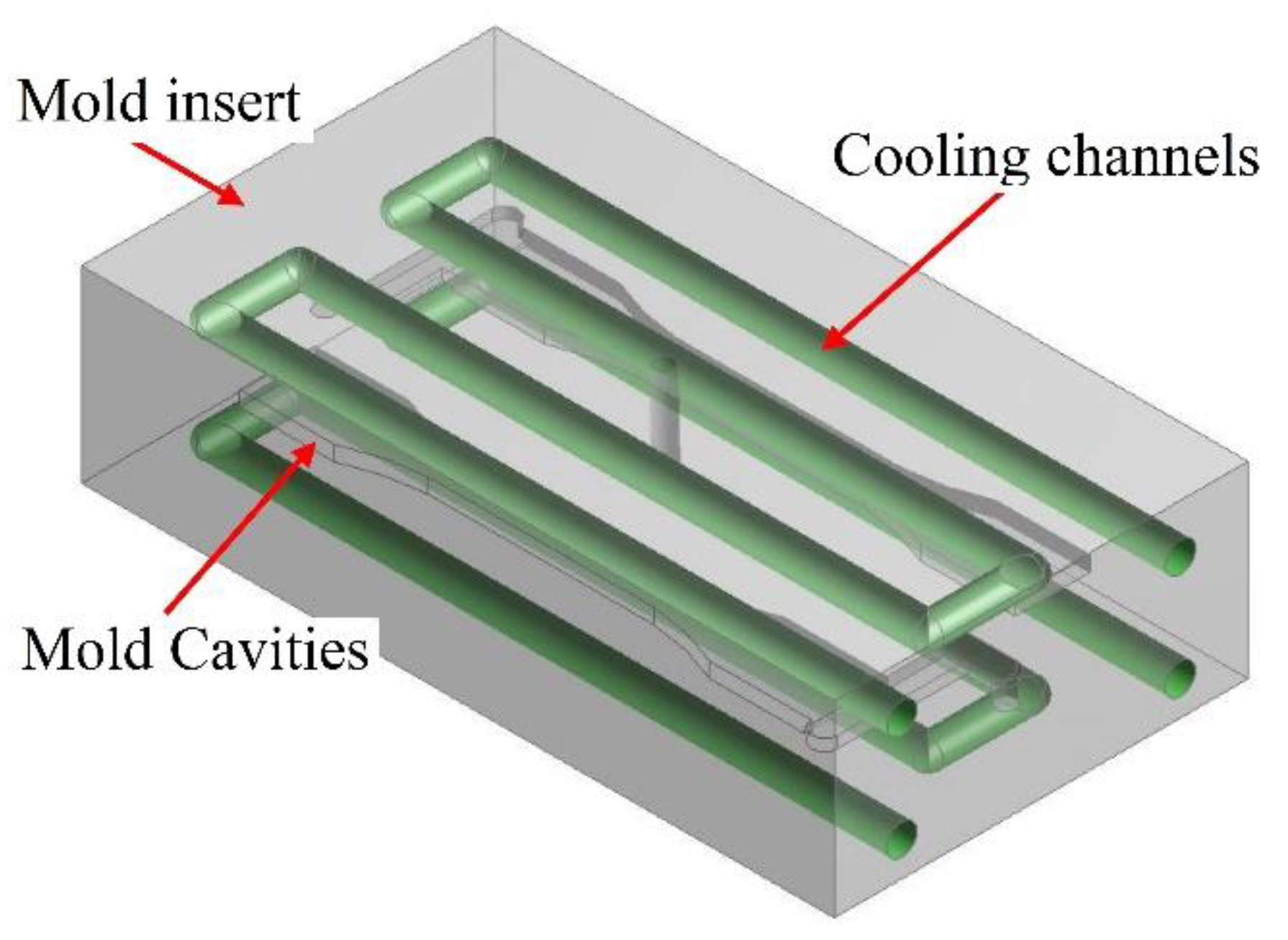

2.2.5. Set-Up for Thermal Transient Analysis of Cooling Time

3. Result of Material Properties Testing of EA, EB, and EC

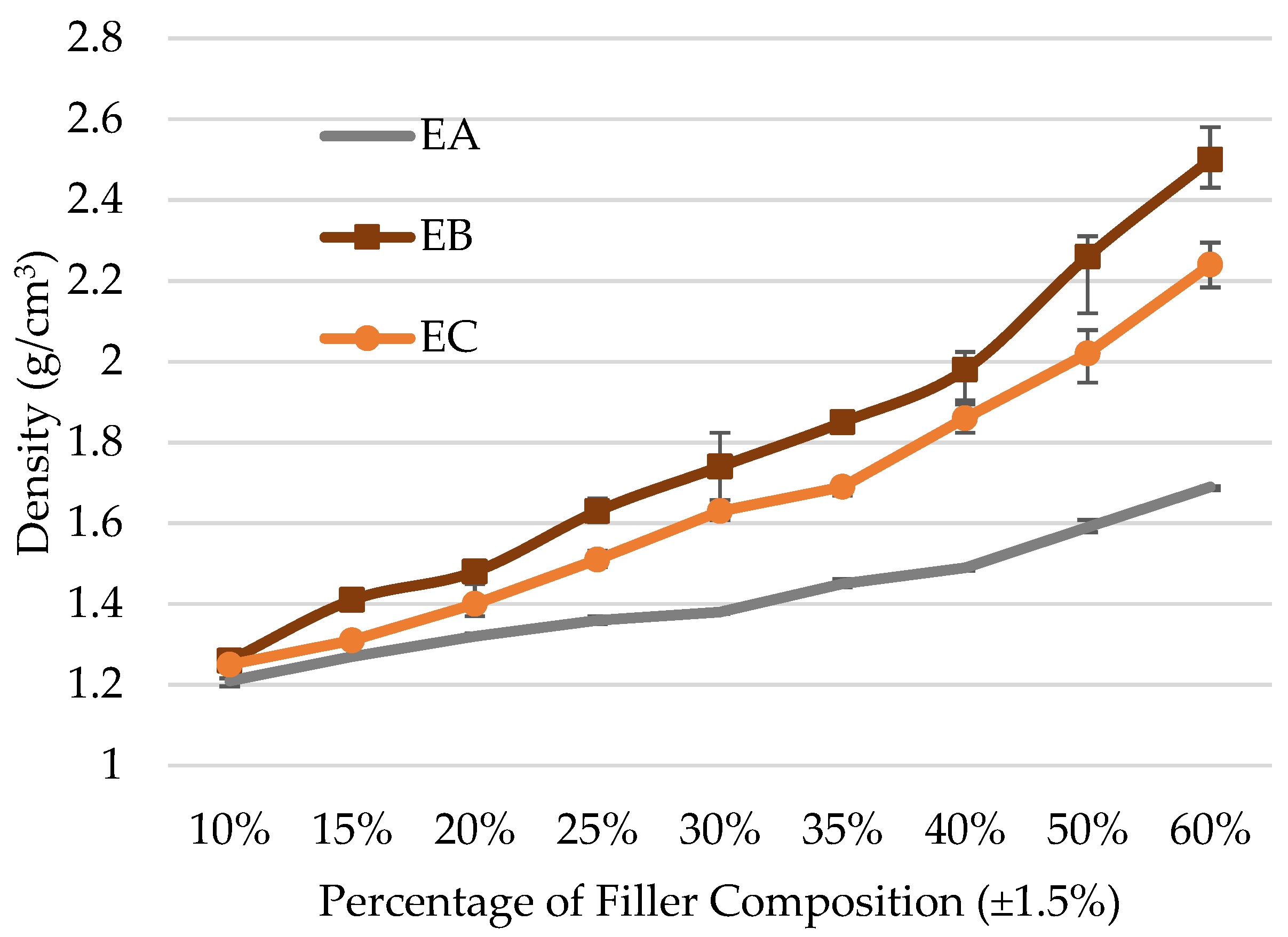

3.1. Density Test Result

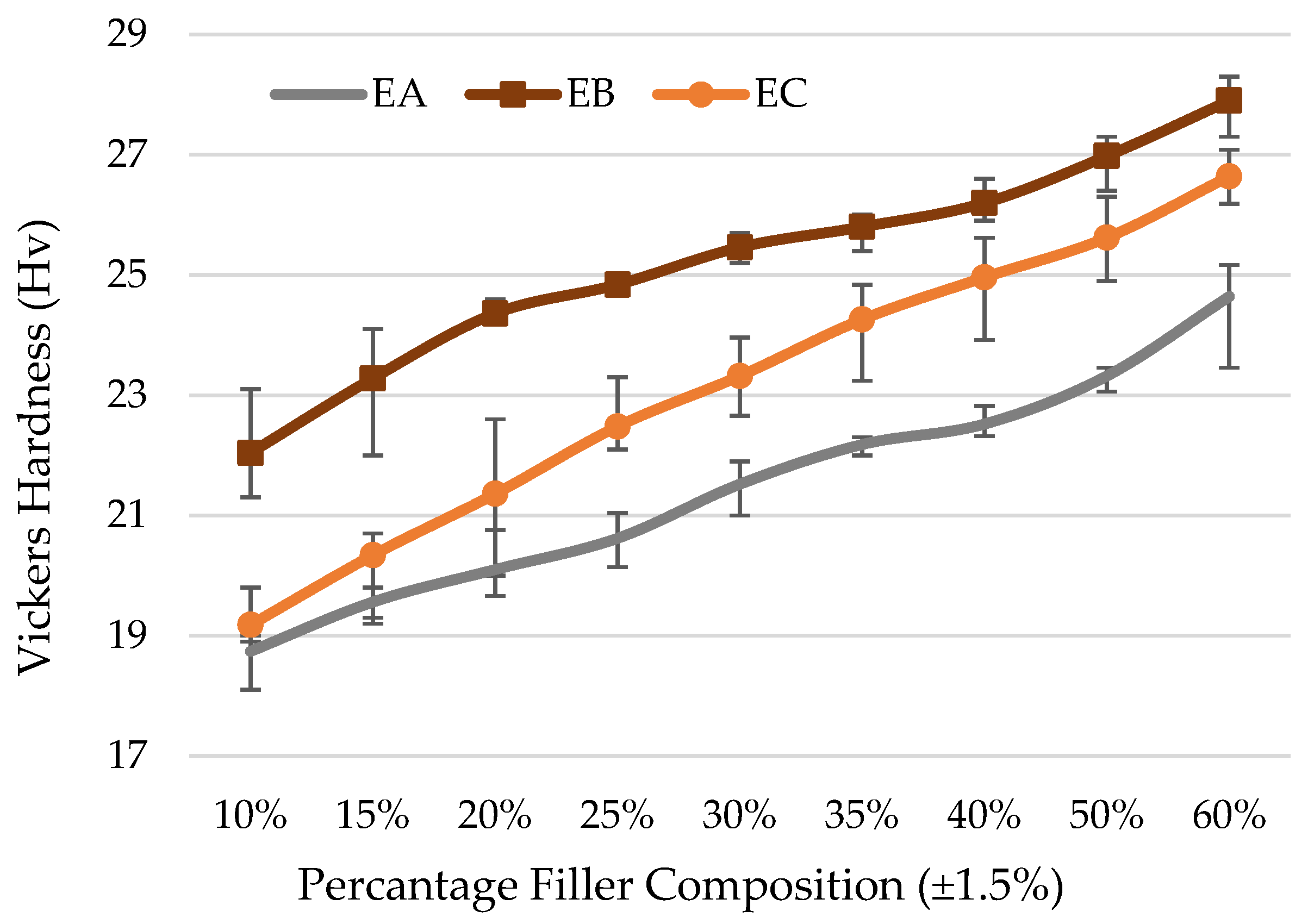

3.2. Hardness Test Results

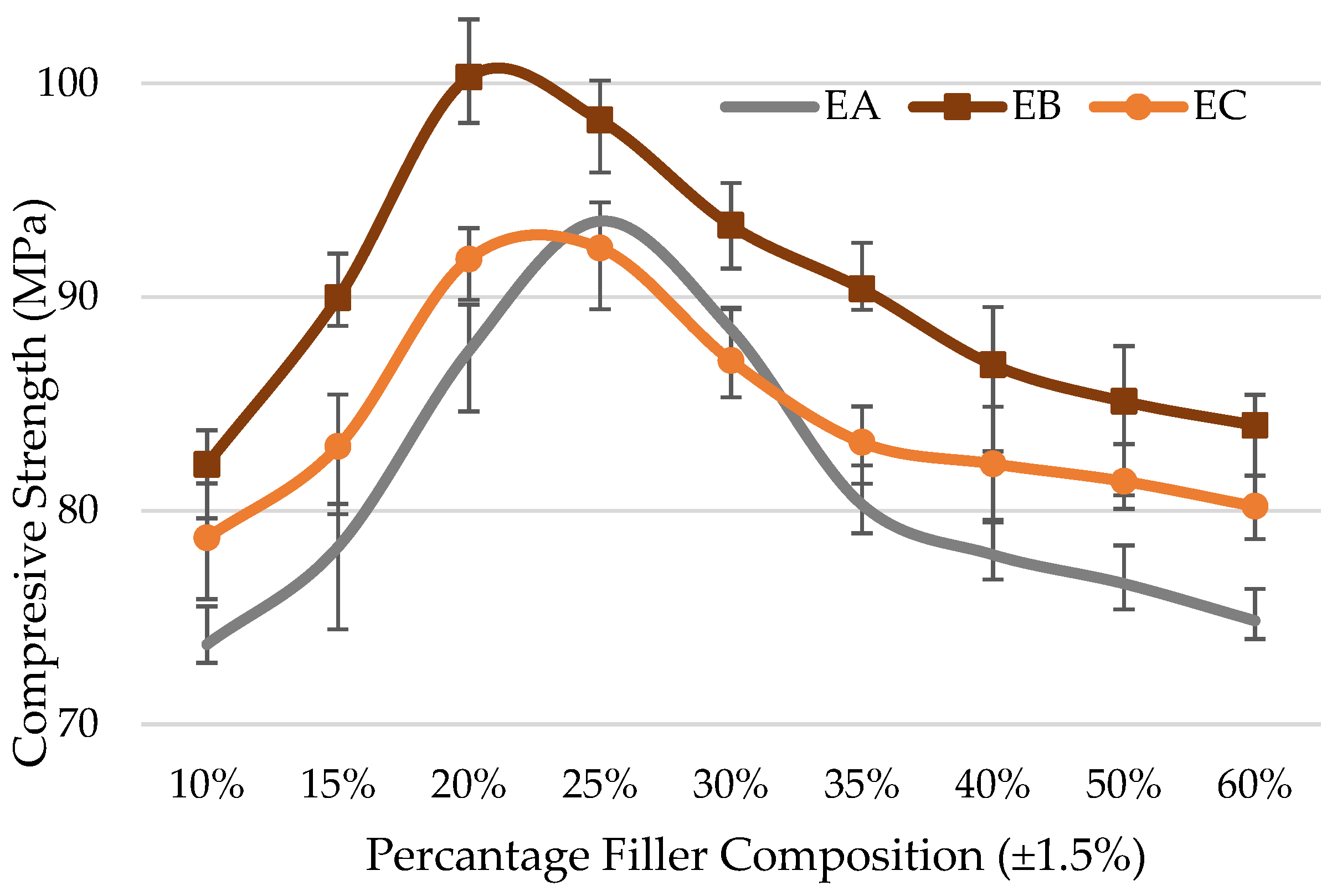

3.3. Compressive Strength Test Results

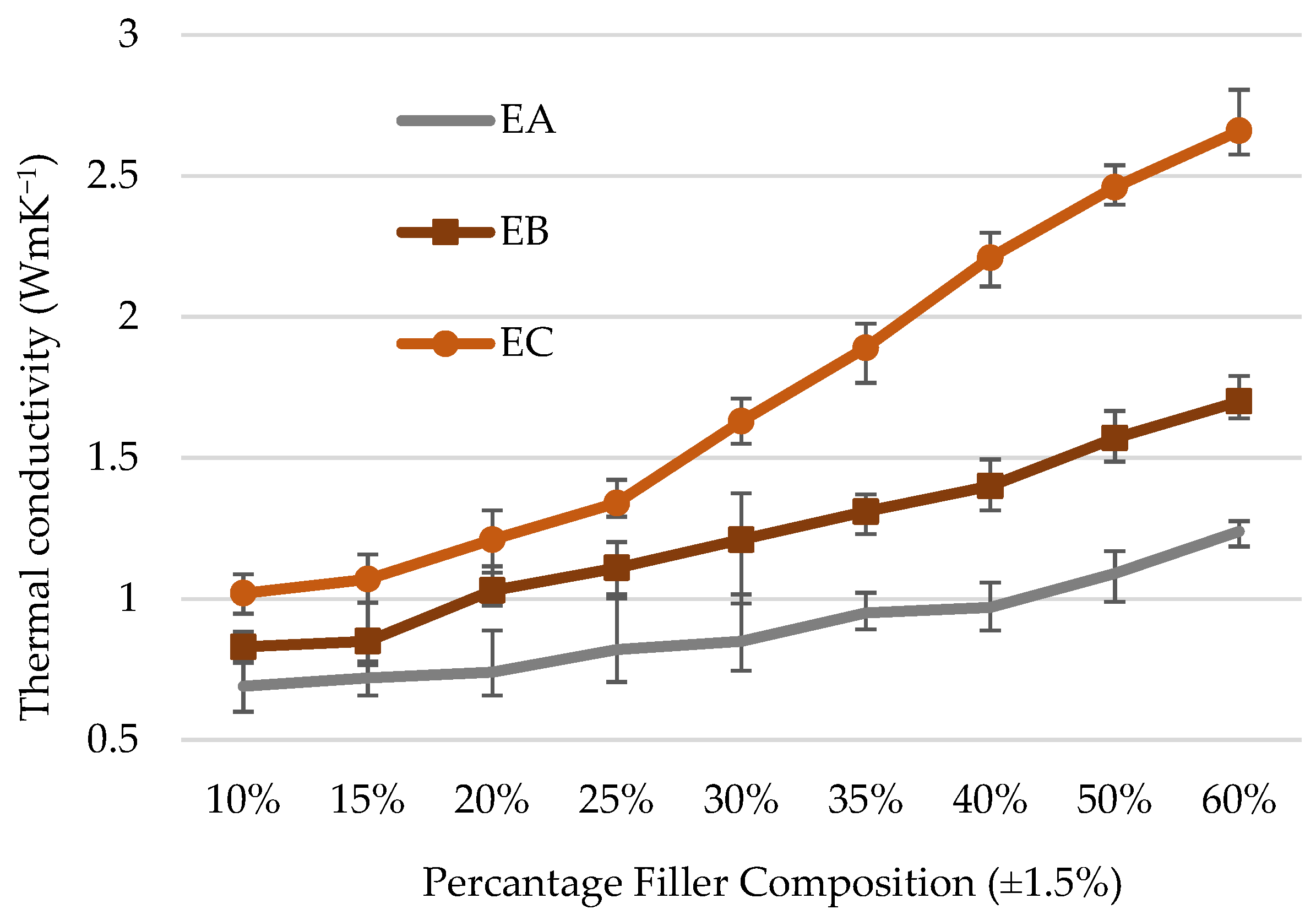

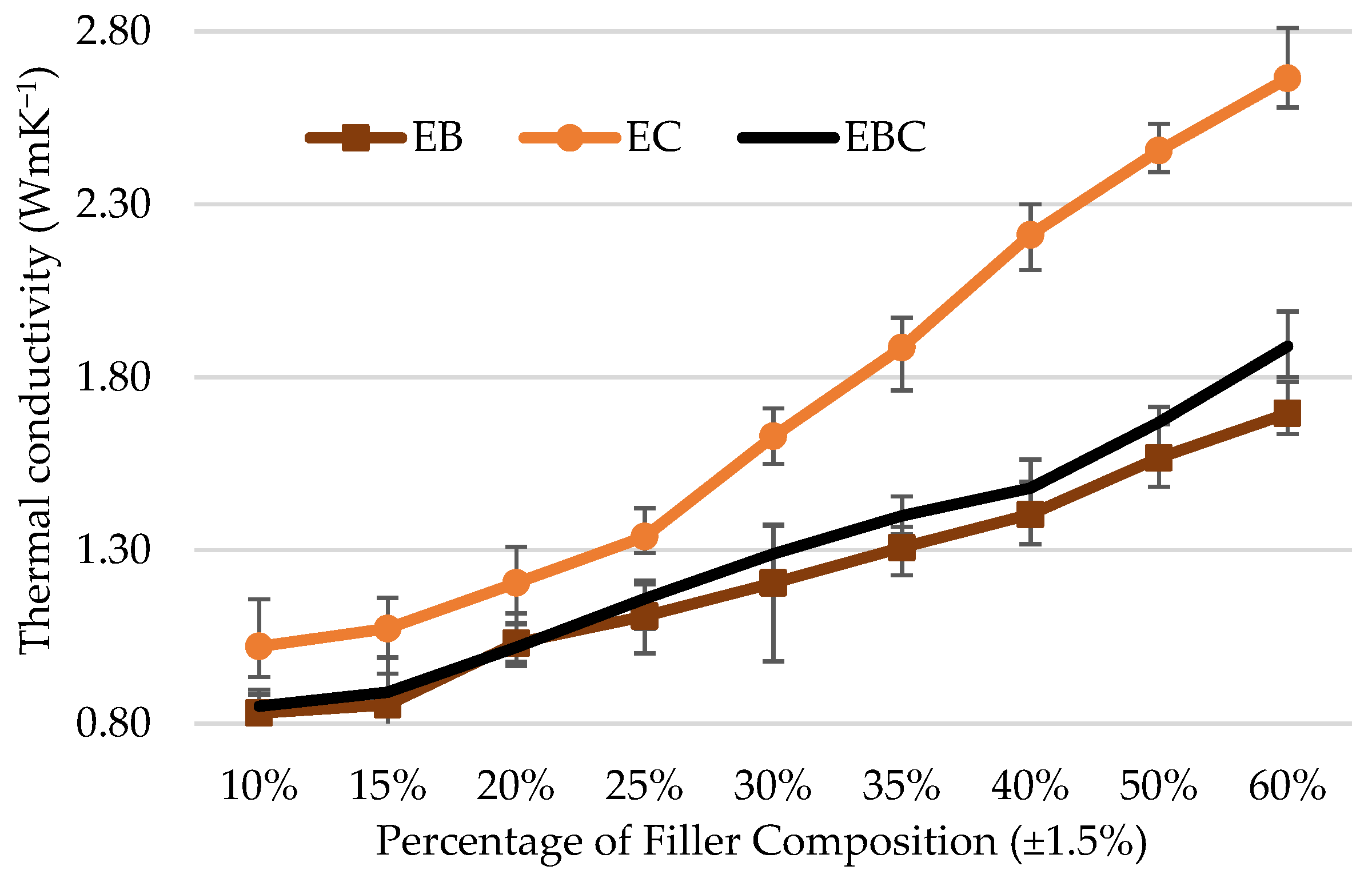

3.4. Thermal Conductivity Test Results

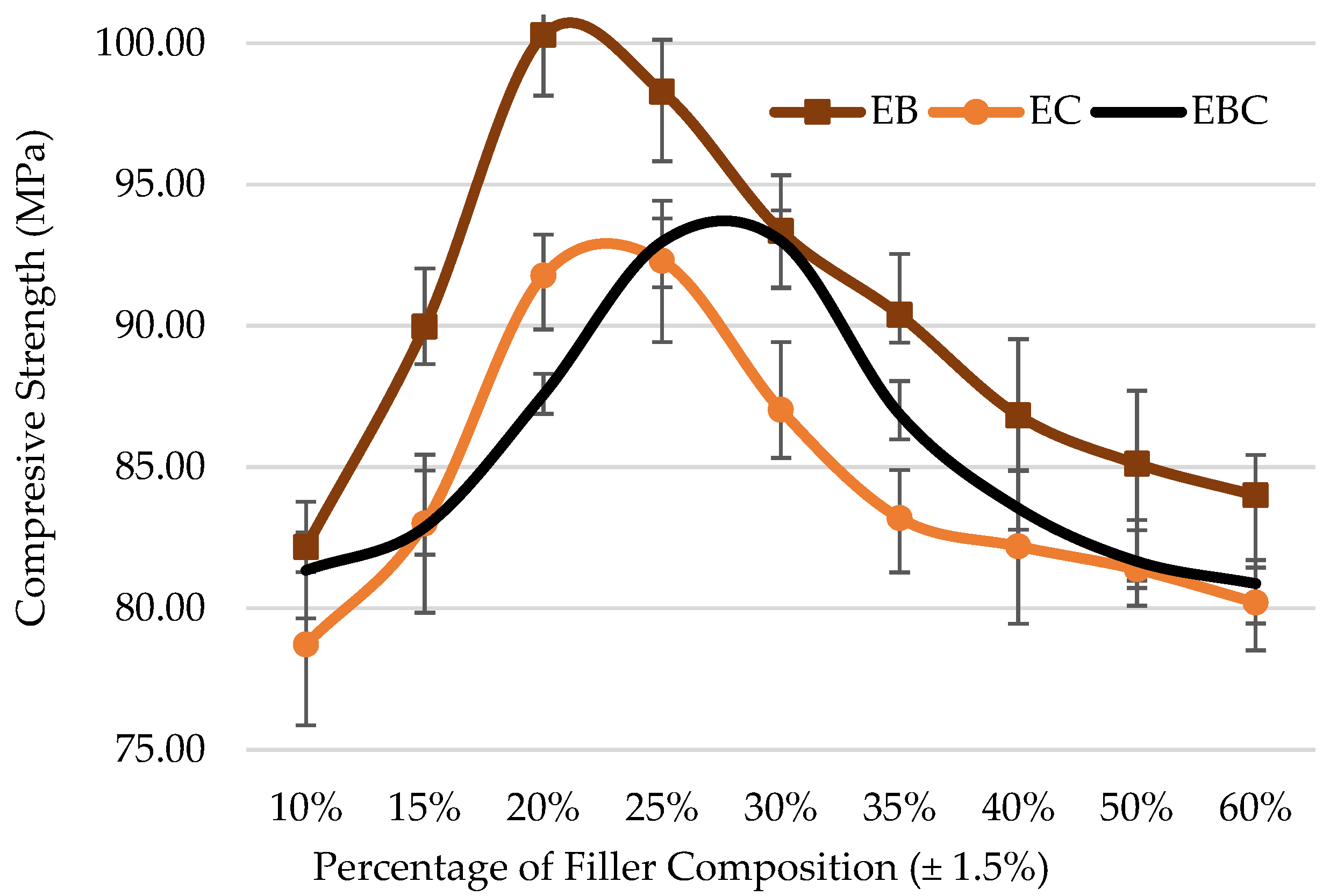

3.5. EBC Filler Testing for Compressive Strength and Thermal Conductivity

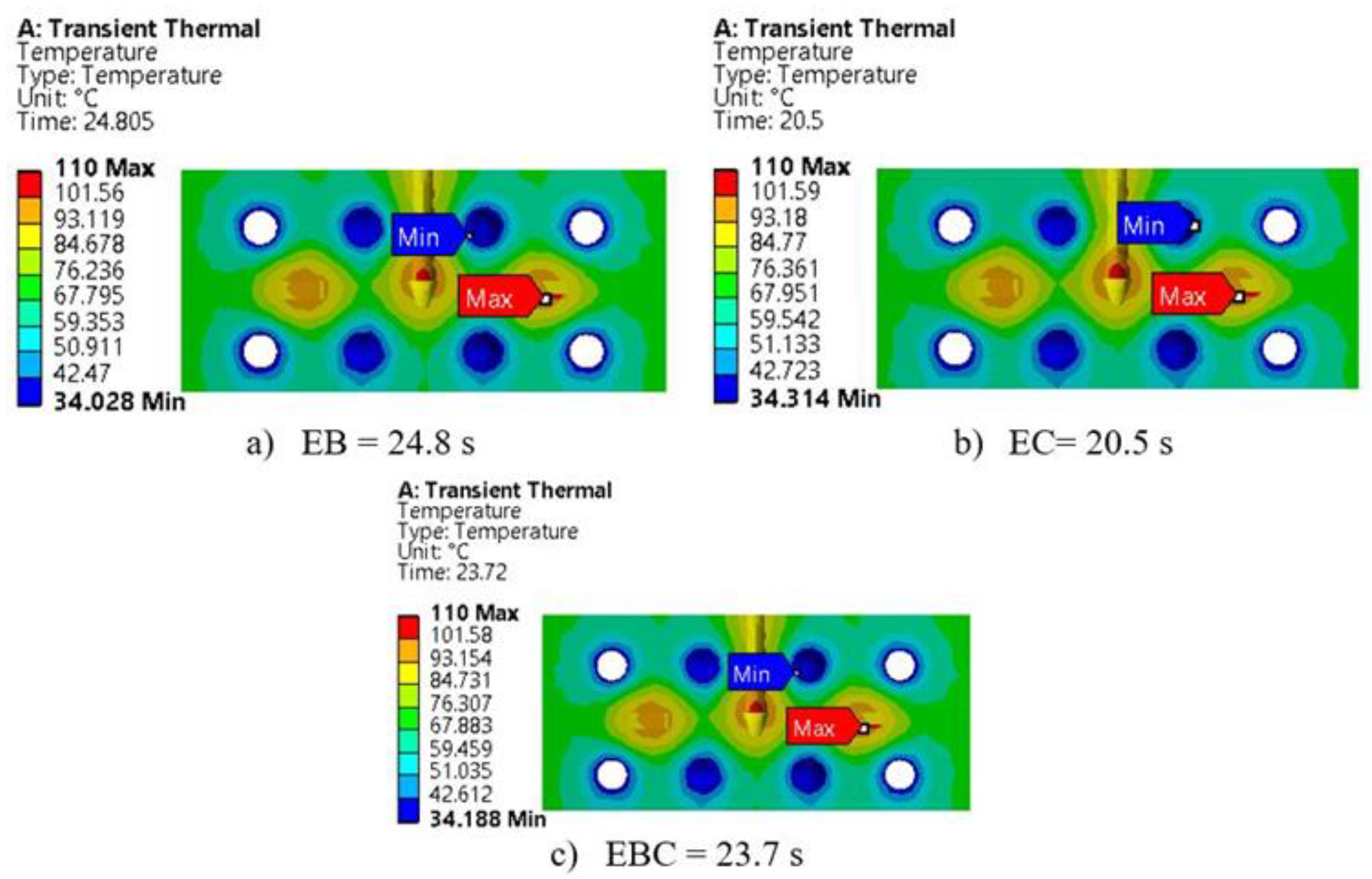

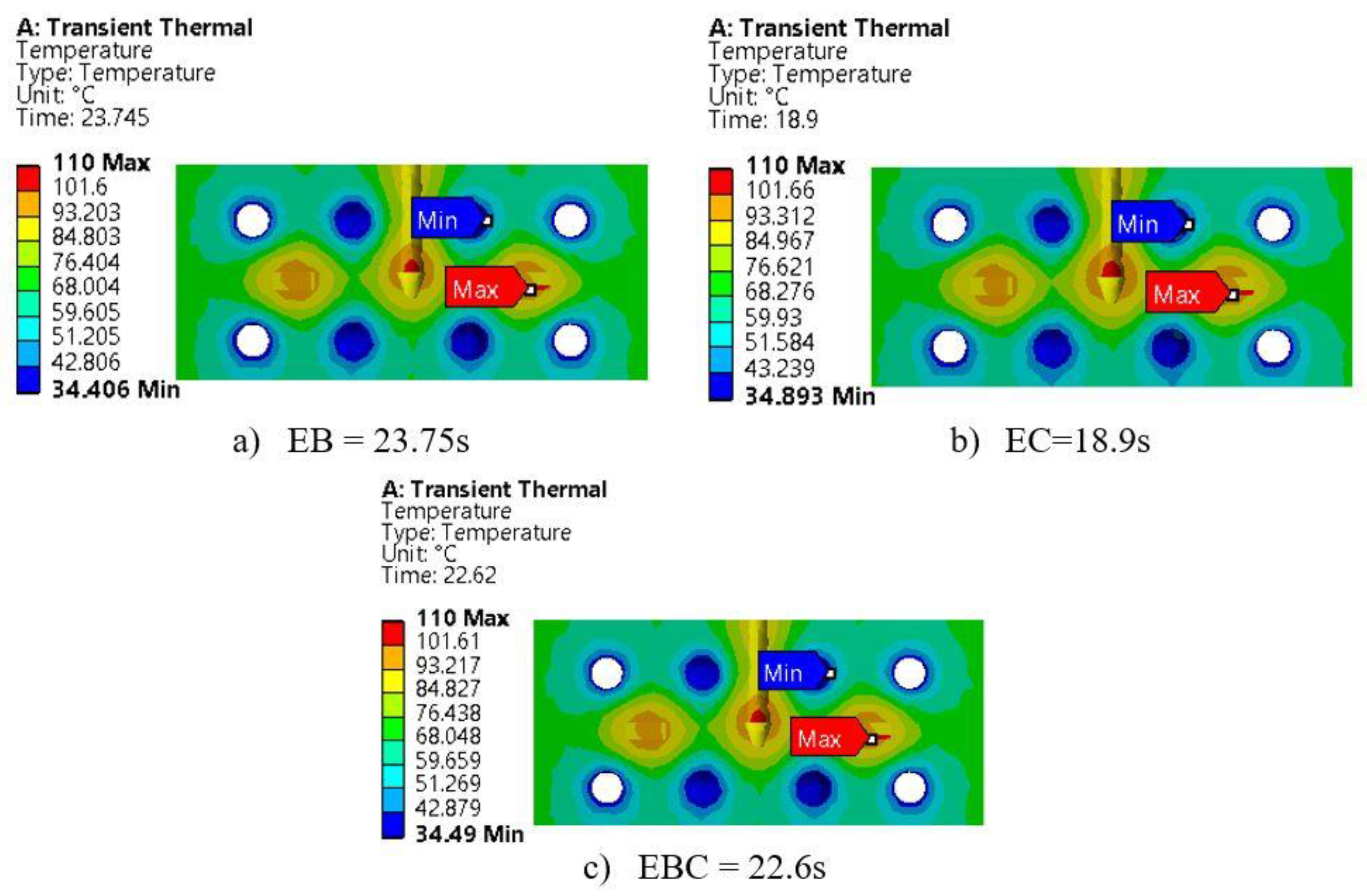

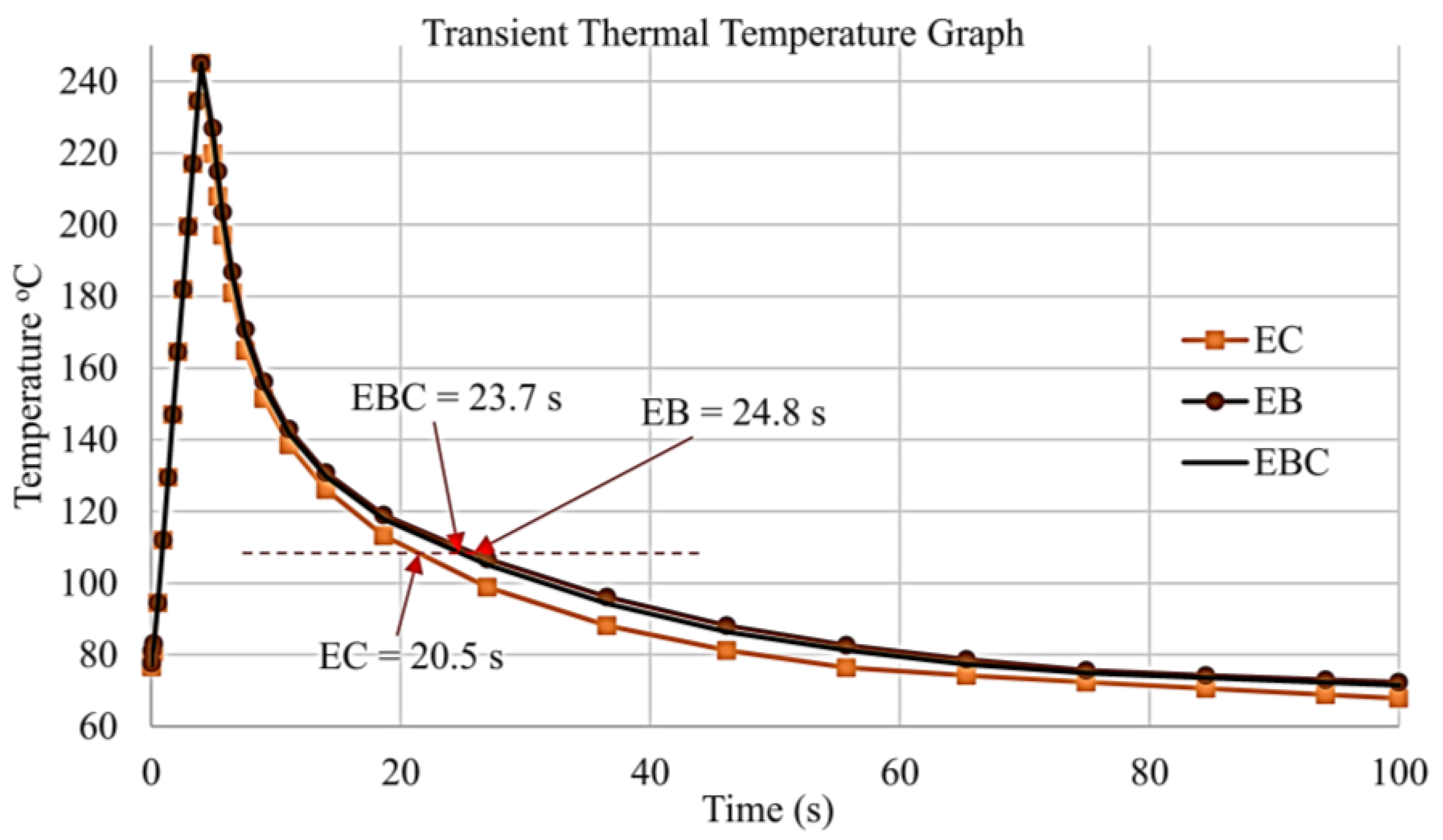

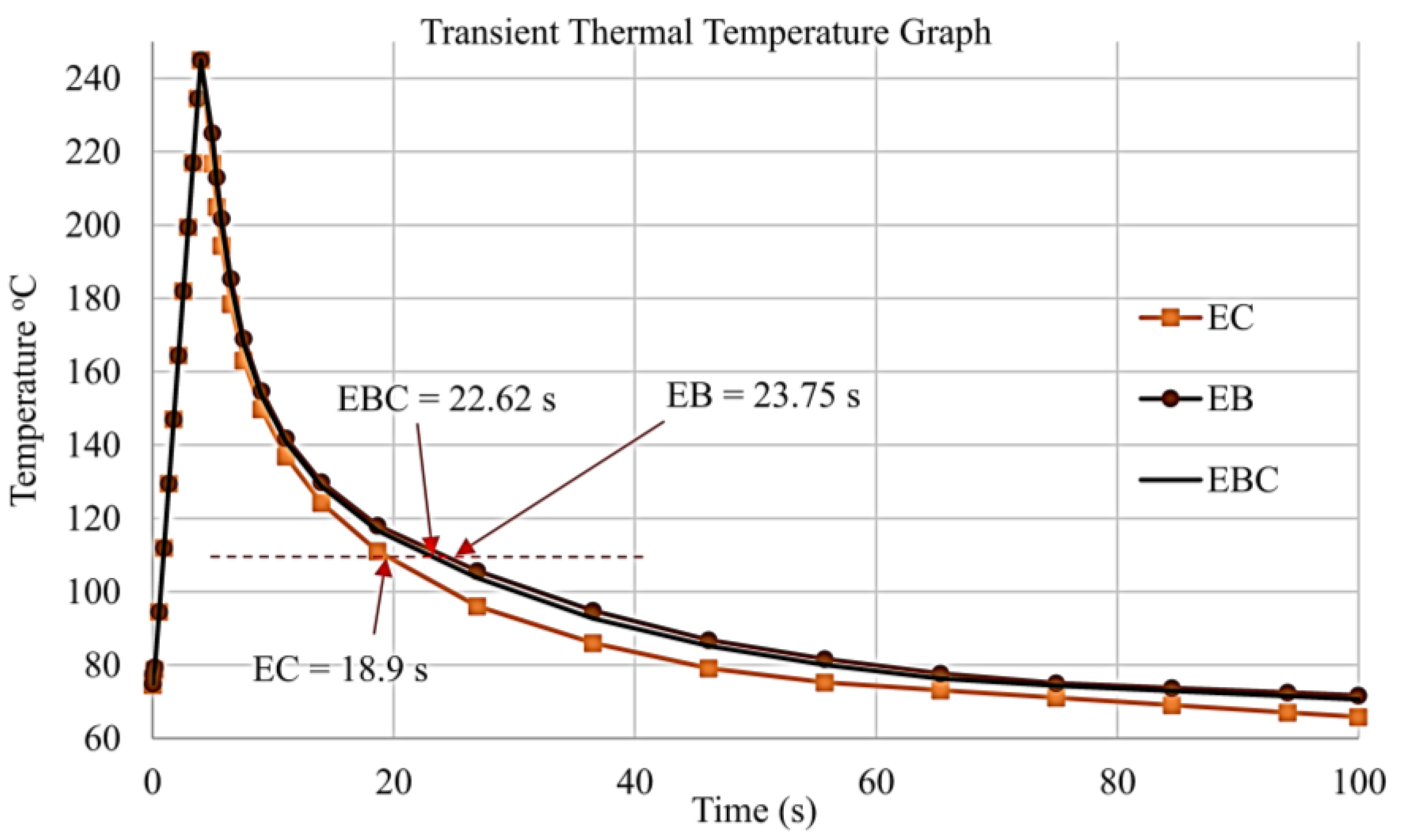

4. Thermal Transient Analysis Results for Cooling Time for EB, EC and EBC

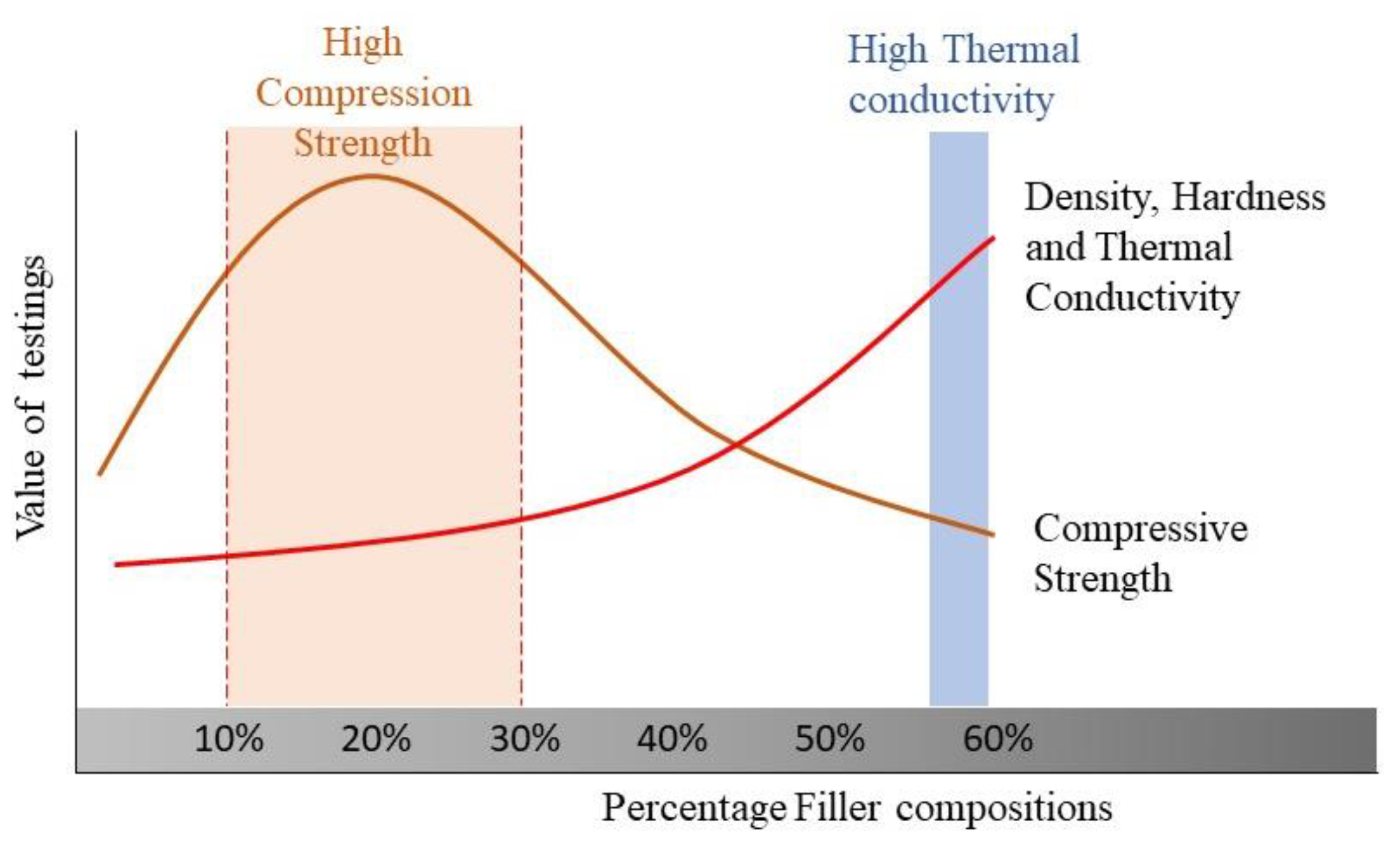

5. MEC Material Selection as Mold Insert

- The presence of EC and EB fillers affect the properties of epoxy, resulting in the improvement of MEC material properties. The thermal conductivity test, which measures how well a mold insert performs against cooling time, particularly favors EC fillers, while EB fillers tend to improve the compressive strength of the material.

- EBC provides a minimal increase in cooling efficiency when compared to EB. This combination also increases the percentage of filler composition higher than EC and EB at the highest compressive strength, which promotes the increase in thermal conductivity of MEC material.

- Based on data generated from ANSYS simulation software, EC showed the best cooling time value in both conditions at high compressive strength and at high thermal conductivity. EC outperformed the EB and the EBC by up to 17.4% and 13.5%, respectively, in terms of cooling efficiency. Meanwhile, in the case of high thermal conductivity, EC increased the cooling efficiency by up to 20.3% compared with EB and 16.5% compared with EBC. The results show that the EC filler has the best cooling time among the MEC materials for mold inserts because the copper filler increases thermal conductivity, , as indicated by the short cooling time. EC gives the best cooling time under high compressive strength and at high thermal conductivity.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rajaguru, J.C.; Duke, M.B.; Au, C. Development of rapid tooling by rapid prototyping technology and electroless nickel plating for low-volume production of plastic parts. Int. J. Adv. Manuf. Technol. 2015, 78, 31–40. [Google Scholar] [CrossRef]

- Equbal, A.; Sood, A.K.; Shamim, M. Rapid tooling: A major shift in tooling practice. Manuf. Ind. Eng. 2015, 14, 1–9. [Google Scholar] [CrossRef]

- Pontes, A.J.; Queirós, M.P.; Martinho, P.G.; Bártolo, P.J.; Pouzada, A.S. Experimental assessment of hybrid mould performance. Int. J. Adv. Manuf. Technol. 2010, 50, 441–448. [Google Scholar] [CrossRef]

- Altaf, K.; Rani, A.M.A.; Ahmad, F.; Baharom, M.; Raghavan, V.R. Determining the effects of thermal conductivity on epoxy molds using profiled cooling channels with metal inserts. J. Mech. Sci. Technol. 2016, 30, 4901–4907. [Google Scholar] [CrossRef]

- Mendible, G.A.; Rulander, J.A.; Johnston, S.P. Comparative study of rapid and conventional tooling for plastics injection molding. Rapid Prototyp. J. 2017, 23, 344–352. [Google Scholar] [CrossRef]

- Khushairi, M.T.M.; Sharif, S.; Jamaludin, K.R.; Razak, Z.; Shah, Z.N.; Suhaimi, M.A.; Shayfull, Z. Development of Metal Filled Epoxy Inserts for Injection Moulding Process. In Proceedings of the Green Design and Manufacture: Advanced and Emerging Applications, Ho Chi Minh, Vietnam, 29–30 April 2018; Volume 020084. [Google Scholar]

- Kuo, C.-C.; Chen, W.-H.; Liu, X.-Z.; Liao, Y.-L.; Chen, W.-J.; Huang, B.-Y.; Tsai, R.-L. Development of a low-cost wax injection mold with high cooling efficiency. Int. J. Adv. Manuf. Technol. 2017, 93, 2081–2088. [Google Scholar] [CrossRef]

- Kazmer, D.O. Injection Mold Design Engineering, 2nd ed.; Hamilton, C., Ed.; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2016; ISBN 978-1-56990-570-8. [Google Scholar]

- Elangovan, K.; Kumar, K.K.I.; Kothandaraman, B. Effect of glass microspheres and aluminium filler in the properties of epoxy and modified epoxy matrix composite for rapid tooling applications. Int. J. Plast. Technol. 2009, 13, 38–46. [Google Scholar] [CrossRef]

- Cheah, C.; Chua, C.; Lee, C.; Lim, S.; Eu, K.; Lin, L. Rapid Sheet Metal Manufacturing. Part 2: Direct Rapid Tooling. Int. J. Adv. Manuf. Technol. 2002, 19, 510–515. [Google Scholar] [CrossRef]

- Hopkinson, N.; Dickens, P. A comparison between stereolithography and aluminium injection moulding tooling. Rapid Prototyp. J. 2000, 6, 253–258. [Google Scholar] [CrossRef]

- Freitas, A.; Soares, R.; Martinho, P.G.; Pouzada, A.S. Rapid Prototyping and Tooling in the Manufacture of Mould Elements for Large Parts. In High Value Manufacturing: Advanced Research in Virtual and Rapid Prototyping: Proceedings of the 6th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 1–5 October 2013; CRC Press: Boca Raton, FL, USA, 2013; pp. 327–332. [Google Scholar]

- Shinde, M.S.; Ashtankar, K.M.; Kuthe, A.M.; Dahake, S.W.; Mawale, M.B. Direct rapid manufacturing of molds with conformal cooling channels. Rapid Prototyp. J. 2018, 24, 1347–1364. [Google Scholar] [CrossRef]

- Vasconcelos, P.V.; Lino, F.J.; Baptista, A.M.; Neto, R.J. Tribological behaviour of epoxy based composites for rapid tooling. Wear 2006, 260, 30–39. [Google Scholar] [CrossRef]

- Ma, S.; Gibson, I.; Balaji, G.; Hu, Q. Development of epoxy matrix composites for rapid tooling applications. J. Mater. Process. Technol. 2007, 192–193, 75–82. [Google Scholar] [CrossRef]

- Srivastava, V.K.; Verma, A. Mechanical Behaviour of Copper and Aluminium Particles Reinforced Epoxy Resin Composites. Am. J. Mater. Sci. 2015, 5, 84–89. [Google Scholar] [CrossRef]

- Senthilkumar, N.; Kalaichelvan, K.; Elangovan, K. Mechanical behaviour of aluminum particulate epoxy composite—Experimental study and numerical simulation. Int. J. Mech. Mater. Eng. 2012, 7, 214–221. [Google Scholar]

- Khushairi, M.T.M.; Sharif, S.; Ani, J.S.M. Parameter Design for Hardness of Metal Filled Epoxy Matrix. Adv. Mater. Res. 2015, 1125, 152–156. [Google Scholar] [CrossRef]

- Barros, T.P.D.S.; Cavalcante, D.G.D.L.; de Oliveira, D.F.; Caluête, R.E.; de Lima, S.J.G. Study of the surface properties of the epoxy/quasicrystal composite. J. Mater. Res. Technol. 2019, 8, 590–598. [Google Scholar] [CrossRef]

- Jin, F.-L.; Li, X.; Park, S.-J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Fernandes, A.D.C.; Souza, A.F.D.; Howarth, J.L.L. Mechanical and dimensional characterisation of polypropylene injection moulded parts in epoxy resin/aluminium inserts for rapid tooling. Int. J. Mater. Prod. Technol. 2016, 52, 37–52. [Google Scholar] [CrossRef]

- Khushairi, M.T.M.; Sharif, S.; Jamaludin, K.R.; Mohruni, A.S. Effects of Metal Fillers on Properties of Epoxy for Rapid Tooling Inserts. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 1155. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Xu, J.-Y.; Zhu, Y.-J.; Lee, C.-H. Effects of Different Mold Materials and Coolant Media on the Cooling Performance of Epoxy-Based Injection Molds. Polymers 2022, 14, 280. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Wu, J.-Q. Development of a low-cost epoxy resin mold with high cooling efficiency. Int. J. Adv. Manuf. Technol. 2021, 113, 2065–2086. [Google Scholar] [CrossRef]

- El-Masry, M.M.; Imam, N. A comparative study between Ag-CuO/ epoxy and Mg-CuO/ epoxy hybrid nanocomposites: Impressive electrical, mechanical and thermal properties. J. Mater. Res. Technol. 2022, 18, 1784–1801. [Google Scholar] [CrossRef]

- Hamidon, M.H.; Sultan, M.T.; Ariffin, A.H.; Shah, A.U. Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: A review. J. Mater. Res. Technol. 2019, 8, 3327–3337. [Google Scholar] [CrossRef]

- Gao, X.; Yang, W.; Cheng, L.; Ding, Y.; Zhan, J.; Tan, J. Epoxy resin composite containing nanocarbon-coated glass fiber and cloth for electromagnetic interference shielding. J. Mater. Res. Technol. 2021, 13, 1759–1766. [Google Scholar] [CrossRef]

- Singh, M.K.; Gautam, R.K. Structural, Mechanical, and Electrical Behavior of Ceramic-Reinforced Copper Metal Matrix Hybrid Composites. J. Mater. Eng. Perform. 2019, 28, 886–899. [Google Scholar] [CrossRef]

- Tekce, H.S.; Kumlutas, D.; Tavman, I.H. Effect of Particle Shape on Thermal Conductivity of Copper Reinforced Polymer Composites. J. Reinf. Plast. Compos. 2007, 26, 113–121. [Google Scholar] [CrossRef]

- ALWA ALWA HT RESIN:High Temperature Resin. Available online: https://www.alwa.de/en/products/high-temperature-resin/ (accessed on 2 January 2019).

- RenCast CW 47; (Switzerland) GmbH. 2014. Available online: https://www.obo-werke.de/fileadmin/templates/downloads/technische_datenblaetter/en/rencast-cw-47-hy-33.pdf (accessed on 23 January 2022).

- Altaf, K. Novel Techniques for Reducing Cooling Time in Polymer Injection Moulds using Rapid Tooling Technologies. Ph.D. Dissertation, Universiti Teknologi Petronas, Seri Iskandar, Malaysia, 2011. [Google Scholar]

- Khushairi, M.T.M.; Sharif, S.; Ani, J.S.M. Evaluation of Mechanical Properties of Filled Epoxy Composite for Improving Mould Performance—A Review. Appl. Mech. Mater. 2015, 735, 13–18. [Google Scholar] [CrossRef]

- Compound, E.C.; Neukadur vg alu. 1–2. Available online: https://www.altropol.de/wp-content/uploads/2016/09/E_VG_Alu.pdf (accessed on 23 January 2022).

- Pamphlet, T. TECHNICAL PAMPHLET RECKLI®; Epoxy WST: Perth, Australia. Available online: https://www.reckli.com/en/service/downloads (accessed on 23 January 2022).

- Gibson, I. Micro Prototyping and Fabrication in Manufacturing. In Handbook of Manufacturing Engineering and Technology; Springer: London, UK, 2013; pp. 1–14. ISBN 9781447149767. [Google Scholar]

- Segal, J.; Campbell, R. A review of research into the effects of rapid tooling on part properties. Rapid Prototyp. J. 2001, 7, 90–99. [Google Scholar] [CrossRef]

- Rahmati, S.; Dickens, P. Rapid tooling analysis of Stereolithography injection mould tooling. Int. J. Mach. Tools Manuf. 2007, 47, 740–747. [Google Scholar] [CrossRef]

- Martinho, P.G.; Bártolo, P.J.; Pouzada, A.S. Hybrid moulds: Effect of the moulding blocks on the morphology and dimensional properties. Rapid Prototyp. J. 2009, 15, 71–82. [Google Scholar] [CrossRef]

- Pouzada, A.S. Hybrid moulds: A case of integration of alternative materials and rapid prototyping for tooling. Virtual Phys. Prototyp. 2009, 4, 195–202. [Google Scholar] [CrossRef]

- Ferreira, J. Manufacturing core-boxes for foundry with rapid tooling technology. J. Mater. Process. Technol. 2004, 155–156, 1118–1123. [Google Scholar] [CrossRef]

- Vaezi, M.; Safaeian, D.; Chua, C. Gas turbine blade manufacturing by use of epoxy resin tooling and silicone rubber molding techniques. Rapid Prototyp. J. 2011, 17, 107–115. [Google Scholar] [CrossRef]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. Modeling and Optimization of the Injection-Molding Process: A Review. Adv. Polym. Technol. 2016, 37, 429–449. [Google Scholar] [CrossRef]

- Moradi, S.; Calventus, Y.; Roman, F.; John, M. Hutchinson Achieving High Thermal Conductivity in Epoxy Composites: Effect of Boron Nitride Particle Size and Matrix-Filler Interface. Polimers 2019, 11, 1156. [Google Scholar] [CrossRef]

- Liu, C.; Chen, M.; Zhou, D.; Wu, D.; Yu, W. Effect of Filler Shape on the Thermal Conductivity of Thermal Functional Composites. J. Nanomater. 2017, 2017, 6375135. [Google Scholar] [CrossRef]

- Lee, J.; Yun, T.S.; Choi, S.-U. The Effect of Particle Size on Thermal Conduction in Granular Mixtures. Materials 2015, 8, 3975–3991. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhai, Z.; Drummer, D. Thermal Conductivity of Aluminosilicate- and Aluminum Oxide-Filled Thermosets for Injection Molding: Effect of Filler Content, Filler Size and Filler Geometry. Polymers 2018, 10, 457. [Google Scholar] [CrossRef]

- Miracon Two Components Heat Resistance Epoxy Lamination System; 2020. Available online: https://www.miracon.com.my/epoxy-tooling-system/ (accessed on 12 February 2022).

- Bin Hussin, R.; Bin Sharif, S.; Rahim, S.Z.B.A.; Bin Suhaimi, M.A.; Khushairi, M.T.B.M.; El-Hadj, A.A.; Bin Shuaib, N.A. The potential of metal epoxy composite (MEC) as hybrid mold inserts in rapid tooling application: A review. Rapid Prototyp. J. 2021, 27, 1069–1100. [Google Scholar] [CrossRef]

- Zhao, S.; Schadler, L.S.; Duncan, R.; Hillborg, H.; Auletta, T. Mechanisms leading to improved mechanical performance in nanoscale alumina filled epoxy. Compos. Sci. Technol. 2008, 68, 2965–2975. [Google Scholar] [CrossRef]

- Sarkar, P.; Modak, N.; Sahoo, P. Mechanical and Tribological Characteristics of Aluminium Powder filled Glass Epoxy Composites. Mater. Today Proc. 2018, 5, 5496–5505. [Google Scholar] [CrossRef]

- Kumar, T.S.; Shivashankar, G.; Dhotey, K.; Singh, J. Experimental study wear rate of glass fibre reinforced epoxy polymer composites filled with aluminium powder. Mater. Today Proc. 2017, 4, 10764–10768. [Google Scholar] [CrossRef]

- Martin, M.; Hanagud, S.; Thadhani, N. Mechanical behavior of nickel+aluminum powder-reinforced epoxy composites. Mater. Sci. Eng. A 2007, 443, 209–218. [Google Scholar] [CrossRef]

- Liang, M.; Wong, K. Study of Mechanical and Thermal Performances of Epoxy Resin Filled with Micro Particles and Nanoparticles. Energy Procedia 2017, 110, 156–161. [Google Scholar] [CrossRef]

- ASTM D792-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. ASTM: West Conshohocken, PA, USA, 2017; Volume 5.

- Kalpakjian, S.; Schmid, S.R. Manufacturing Engineering and Technology, 8th ed.; Pearson: London, UK, 2020. [Google Scholar]

- ASTM D 695; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM: West Conshohocken, PA, USA, 2016; Volume 3.

- ISO 3167; ISO 3167 Plastics—Multipurpose Test Specimens. ISO: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/65105.html (accessed on 25 March 2022).

- Bhagyashekar, M.S.; Rao, K.; Rao, R.; Bhagyashekar, M.S.; Rao, K.; Rao, R. Studies on Rheological and Physical Properties of Metallic and Non-metallic Particulate Filled Epoxy Composites. J. Reinf. Plast. Compos. 2008, 28, 2869–2878. [Google Scholar] [CrossRef]

- Yemam, D.M.; Kim, B.-J.; Moon, J.-Y.; Yi, C. Mechanical Properties of Epoxy Resin Mortar with Sand Washing Waste as Filler. Materials 2017, 10, 246. [Google Scholar] [CrossRef]

- Tomori, T.; Melkote, S.; Kotnis, M. Injection mold performance of machined ceramic filled epoxy tooling boards. J. Mater. Process. Technol. 2004, 145, 126–133. [Google Scholar] [CrossRef]

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Mai, V.-D.; Lee, D.-I.; Park, J.-H.; Lee, D.-S. Rheological Properties and Thermal Conductivity of Epoxy Resins Filled with a Mixture of Alumina and Boron Nitride. Polymers 2019, 11, 597. [Google Scholar] [CrossRef]

| Filler | Shape | Particle Size (mm) | Metal Contents (%) |

|---|---|---|---|

| Aluminum | Spherical | 40–65 µm | 99 |

| Brass | Irregular | 10–100 µm | 95 |

| Copper | Irregular | 10–100 µm | 99 |

| No. | Type of Fillers | Mixing Composition (grams) | Total (100%) | |||||

|---|---|---|---|---|---|---|---|---|

| Metal Fillers (± 1.5%) | Epoxy Resin | Hardener | ||||||

| 1. | (EA, EB or EC) | 10% | 7.0 g | 60% | 42.0 g | 30% | 21.0 g | 70 g |

| 2. | 15% | 10.5 g | 56.7% | 39.7 g | 28.3% | 19.8 g | 70 g | |

| 3. | 20% | 14.0 g | 53.3% | 37.3 g | 26.7% | 18.7 g | 70 g | |

| 4. | 25% | 17.5 g | 50% | 35.0 g | 25% | 17.5 g | 70 g | |

| 5. | 30% | 21.0 g | 46.7% | 32.7 g | 23.3% | 16.3 g | 70 g | |

| 6. | 35% | 24.5 g | 43.3% | 30.3 g | 21.7% | 15.2 g | 70 g | |

| 7. | 40% | 28.0 g | 40% | 28.0 g | 20% | 14.0 g | 70 g | |

| 8. | 50% | 35.0 g | 33.3% | 23.3 g | 16.7% | 11.7 g | 70 g | |

| 9. | 60% | 42.0 g | 26.7% | 18.7 g | 13.3% | 9.3 g | 70 g | |

| Property | Unit | EB | EC | EBC |

|---|---|---|---|---|

| Percentage composition | % | 20 (±1.5%) | 25 (±1.5%) | 30 (±1.5%) |

| Density, | g/cm3 | 1.48 (+0.02/−0.03) | 1.51 (+0.02/−0.02) | 1.70 (+0.08/−0.07) |

| Specific Heat, | J/kg·K | 1300 | 1300 | 1300 |

| Thermal Conductivity, | W/m·C | 1.03 (+0.09/−0.05) | 1.34 (+0.08/−0.05) | 1.29 (+0.08/−0.06) |

| Compression | MPa | 100.3 (+2.71/−2.14) | 92.30 (+2.13/−2.88) | 93.01 (+1.08/−1.65) |

| Coeff. of Thermal Expansion, CTE | 1/C | 3.5 to 5.0·10−6 | ||

| Property | Unit | EB | EC | EBC |

|---|---|---|---|---|

| Percentage composition | % | 60 (±1.5%) | 60 (±1.5%) | 60 (±1.5%) |

| Density, | g/cm3 | 2.50 (+0.08/−0.07) | 2.24 (+0.05/−0.06) | 2.42 (+0.00/−0.01) |

| Specific Heat, | J/kg·K | 1300 | 1300 | 1300 |

| Thermal Conductivity, | W/m·C | 1.70 (+0.09/−0.06) | 2.66 (+0.15/−0.08) | 1.89 (+0.10/−0.09) |

| Compression | MPa | 84.00 (+1.43/−3.91) | 80.20 (+1.51/−1.69) | 80.87 (+0.57/−1.41) |

| Coeff. of Thermal Expansion, CTE | 1/C | 3.5 to 5.0·10−6 | ||

| No | Parameter | Setting |

|---|---|---|

| i | Step | 2 (step 1 = 4 s, step 2 = 100 s) |

| ii | Mold temperature (initial condition) | 70 °C |

| iii | Water Temperature | 35 °C |

| iv | Convection coefficient (cooling channel) | (a) 5098 W/m2 °C |

| v | Ejection Temperature | 110 °C |

| vi | Melt Temperature | (b) 245 °C |

| vii | Diameter of cooling channel | (c) 0.08 m |

| Filler Type | Percentage Filler Composition (±1.5%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 15% | 20% | 25% | 30% | 35% | 40% | 50% | 60% | ||

| EA | Average | 1.21 | 1.27 | 1.32 | 1.36 | 1.38 | 1.45 | 1.49 | 1.59 | 1.69 |

| + | 0.01 | 0.00 | 0.01 | 0.01 | 0.01 | 0.01 | 0.00 | 0.02 | 0.00 | |

| − | 0.01 | 0.00 | 0.00 | 0.01 | 0.00 | 0.01 | 0.01 | 0.01 | 0.01 | |

| EB | Average | 1.26 | 1.41 | 1.48 | 1.63 | 1.74 | 1.85 | 1.98 | 2.26 | 2.50 |

| + | 0.01 | 0.02 | 0.02 | 0.03 | 0.08 | 0.01 | 0.04 | 0.05 | 0.08 | |

| − | 0.00 | 0.01 | 0.03 | 0.03 | 0.12 | 0.02 | 0.08 | 0.14 | 0.07 | |

| EC | Average | 1.25 | 1.31 | 1.40 | 1.51 | 1.63 | 1.69 | 1.86 | 2.02 | 2.24 |

| + | 0.02 | 0.01 | 0.05 | 0.02 | 0.03 | 0.02 | 0.03 | 0.06 | 0.05 | |

| − | 0.01 | 0.01 | 0.03 | 0.02 | 0.02 | 0.02 | 0.04 | 0.07 | 0.06 | |

| Filler Type | Percentage Filler Composition (±1.5%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 15% | 20% | 25% | 30% | 35% | 40% | 50% | 60% | ||

| EA | Average | 18.74 | 19.56 | 20.34 | 21.08 | 21.62 | 22.18 | 22.70 | 23.46 | 24.48 |

| + | 0.26 | 0.24 | 0.66 | 0.42 | 0.38 | 0.12 | 0.30 | 0.14 | 0.53 | |

| − | 0.64 | 0.26 | 0.44 | 0.48 | 0.52 | 0.18 | 0.20 | 0.26 | 1.18 | |

| EB | Average | 22.04 | 23.28 | 24.36 | 24.84 | 25.46 | 25.80 | 26.30 | 26.98 | 27.90 |

| + | 1.06 | 0.82 | 0.24 | 0.16 | 0.24 | 0.20 | 0.40 | 0.32 | 0.40 | |

| − | 0.74 | 1.28 | 0.16 | 0.14 | 0.26 | 0.40 | 0.30 | 0.58 | 0.60 | |

| EC | Average | 19.18 | 20.34 | 21.36 | 22.08 | 22.96 | 23.52 | 23.94 | 24.72 | 25.36 |

| + | 0.62 | 0.36 | 1.24 | 0.82 | 0.64 | 0.58 | 0.66 | 0.68 | 0.44 | |

| − | 0.28 | 1.14 | 1.36 | 0.38 | 0.66 | 1.02 | 1.04 | 0.72 | 0.46 | |

| Filler Type | Percentage Filler Composition (±1.5%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 15% | 20% | 25% | 30% | 35% | 40% | 50% | 60% | ||

| EA | Average | 73.75 | 78.30 | 87.49 | 93.56 | 88.50 | 80.29 | 77.94 | 76.59 | 74.85 |

| + | 1.77 | 2.02 | 2.16 | 0.87 | 1.00 | 1.84 | 1.64 | 1.78 | 1.49 | |

| − | 0.87 | 3.85 | 2.84 | 1.00 | 1.49 | 1.35 | 1.16 | 1.21 | 0.86 | |

| EB | Average | 82.17 | 89.97 | 100.29 | 98.28 | 93.35 | 90.38 | 86.83 | 85.11 | 84.00 |

| + | 1.60 | 2.06 | 2.71 | 1.85 | 1.98 | 2.16 | 2.70 | 2.59 | 1.43 | |

| − | 2.53 | 1.33 | 2.14 | 2.45 | 2.02 | 0.98 | 4.05 | 4.39 | 3.91 | |

| EC | Average | 78.72 | 83.00 | 91.77 | 92.30 | 87.02 | 83.19 | 82.19 | 81.37 | 80.20 |

| + | 2.56 | 2.44 | 1.46 | 2.13 | 2.40 | 1.70 | 2.68 | 1.75 | 1.45 | |

| − | 2.86 | 3.16 | 1.90 | 2.88 | 1.70 | 1.92 | 2.74 | 1.28 | 1.52 | |

| Filler Type | Percentage Filler Composition (±1.5%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 15% | 20% | 25% | 30% | 35% | 40% | 50% | 60% | ||

| EA | Average | 0.69 | 0.72 | 0.74 | 0.82 | 0.85 | 0.95 | 0.97 | 1.09 | 1.24 |

| + | 0.10 | 0.06 | 0.15 | 0.20 | 0.17 | 0.07 | 0.09 | 0.08 | 0.04 | |

| − | 0.09 | 0.06 | 0.08 | 0.11 | 0.10 | 0.06 | 0.08 | 0.10 | 0.05 | |

| EB | Average | 0.83 | 0.85 | 1.03 | 1.11 | 1.21 | 1.31 | 1.40 | 1.57 | 1.70 |

| + | 0.05 | 0.14 | 0.09 | 0.09 | 0.16 | 0.06 | 0.09 | 0.10 | 0.09 | |

| − | 0.06 | 0.08 | 0.05 | 0.11 | 0.23 | 0.08 | 0.09 | 0.08 | 0.06 | |

| EC | Average | 1.02 | 1.07 | 1.21 | 1.34 | 1.63 | 1.89 | 2.21 | 2.46 | 2.66 |

| + | 0.07 | 0.09 | 0.10 | 0.08 | 0.08 | 0.09 | 0.09 | 0.08 | 0.15 | |

| − | 0.07 | 0.08 | 0.12 | 0.05 | 0.08 | 0.12 | 0.10 | 0.06 | 0.08 | |

| Filler Type | Percentage Filler Composition (±1.5%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 15% | 20% | 25% | 30% | 35% | 40% | 50% | 60% | ||

| EBC | Average | 81.34 | 82.87 | 87.56 | 92.98 | 93.01 | 86.87 | 83.54 | 81.66 | 80.87 |

| + | 1.33 | 2.00 | 0.74 | 0.82 | 1.08 | 1.17 | 1.35 | 1.11 | 0.57 | |

| − | 2.40 | 0.98 | 0.68 | 1.62 | 1.65 | 0.89 | 1.21 | 0.67 | 1.41 | |

| EB | Average | 82.17 | 89.97 | 100.29 | 98.28 | 93.35 | 90.38 | 86.83 | 85.11 | 84.00 |

| + | 1.60 | 2.06 | 2.71 | 1.85 | 1.98 | 2.16 | 2.70 | 2.59 | 1.43 | |

| − | 2.53 | 1.33 | 2.14 | 2.45 | 2.02 | 0.98 | 4.05 | 4.39 | 3.91 | |

| EC | Average | 78.72 | 83.00 | 91.77 | 92.30 | 87.02 | 83.19 | 82.19 | 81.37 | 80.20 |

| + | 2.56 | 2.44 | 1.46 | 2.13 | 2.40 | 1.70 | 2.68 | 1.75 | 1.51 | |

| − | 2.86 | 3.16 | 1.90 | 2.88 | 1.70 | 1.92 | 2.74 | 1.28 | 1.69 | |

| Filler Type | Percentage Filler Composition (±1.5%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 15% | 20% | 25% | 30% | 35% | 40% | 50% | 60% | ||

| EBC | Average | 0.85 | 0.89 | 1.02 | 1.16 | 1.29 | 1.40 | 1.48 | 1.67 | 1.89 |

| + | 0.05 | 0.05 | 0.07 | 0.05 | 0.08 | 0.06 | 0.08 | 0.04 | 0.10 | |

| − | 0.06 | 0.05 | 0.05 | 0.09 | 0.06 | 0.05 | 0.05 | 0.09 | 0.09 | |

| EB | Average | 0.83 | 0.85 | 1.03 | 1.11 | 1.21 | 1.31 | 1.40 | 1.57 | 1.70 |

| + | 0.05 | 0.14 | 0.09 | 0.09 | 0.16 | 0.06 | 0.09 | 0.10 | 0.09 | |

| − | 0.07 | 0.08 | 0.05 | 0.11 | 0.23 | 0.08 | 0.09 | 0.08 | 0.06 | |

| EC | Average | 0.05 | 1.07 | 1.21 | 1.34 | 1.63 | 1.89 | 2.21 | 2.46 | 2.66 |

| + | 0.14 | 0.09 | 0.10 | 0.08 | 0.08 | 0.09 | 0.09 | 0.08 | 0.15 | |

| − | 0.09 | 0.08 | 0.12 | 0.05 | 0.08 | 0.12 | 0.10 | 0.06 | 0.08 | |

| MEC Material | High Compressive Strength | High Thermal Conductivity | ||

|---|---|---|---|---|

| Cooling Time | % Composition (±1.5%) | Cooling Time | % Composition (±1.5%) | |

| EB | 24.8 s | 20 | 23.75 s | 60 |

| EC | 20.5 s | 25 | 18.9 s | 60 |

| EBC | 23.7 s | 30 | 22.62 s | 60 |

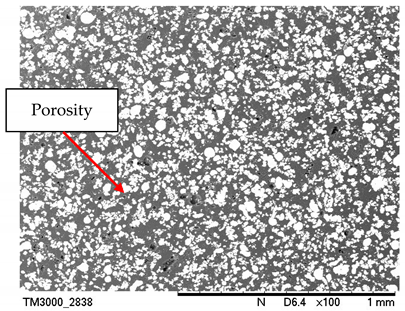

| Experiment Test | Density | 2.24 g/cm3 |

| Hardness | 25.36 Hv | |

| Compressive Strength | 80.20 MPa | |

| Thermal Conductivity | 2.66 WmK−1 | |

| Simulation Test | Cooling time | 18.9 s |

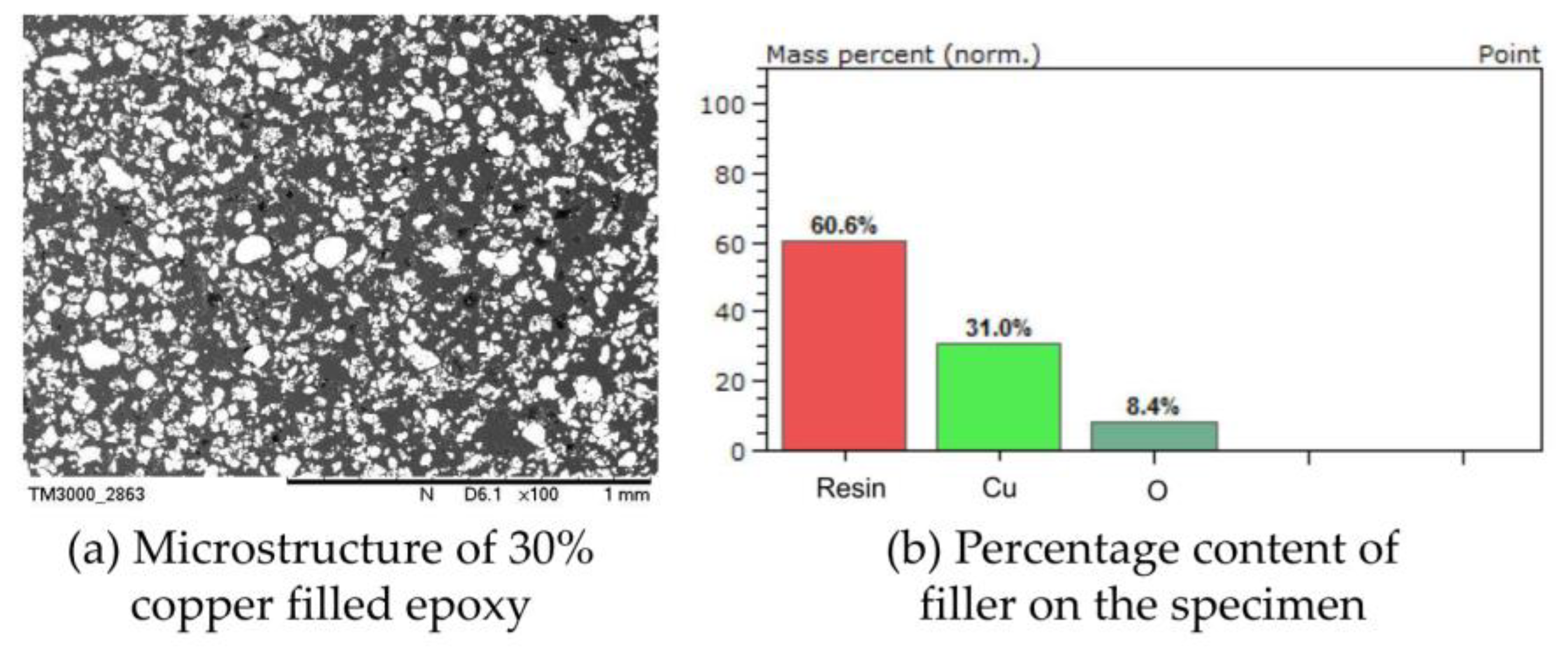

| Microstructural Image (filler distribution) |  | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussin, R.; Sharif, S.; Abd Rahim, S.Z.; Rennie, A.; Suhaimi, M.A.; Abdellah, A.E.-h.; Shuaib, N.A.; Mohd Khushairi, M.T.; Titu, A.M. Irregular Shape Effect of Brass and Copper Filler on the Properties of Metal Epoxy Composite (MEC) for Rapid Tooling Application. J. Manuf. Mater. Process. 2022, 6, 134. https://doi.org/10.3390/jmmp6060134

Hussin R, Sharif S, Abd Rahim SZ, Rennie A, Suhaimi MA, Abdellah AE-h, Shuaib NA, Mohd Khushairi MT, Titu AM. Irregular Shape Effect of Brass and Copper Filler on the Properties of Metal Epoxy Composite (MEC) for Rapid Tooling Application. Journal of Manufacturing and Materials Processing. 2022; 6(6):134. https://doi.org/10.3390/jmmp6060134

Chicago/Turabian StyleHussin, Radhwan, Safian Sharif, Shayfull Zamree Abd Rahim, Allan Rennie, Mohd Azlan Suhaimi, Abdellah El-hadj Abdellah, Norshah Afizi Shuaib, Mohd Tanwyn Mohd Khushairi, and Aurel Mihail Titu. 2022. "Irregular Shape Effect of Brass and Copper Filler on the Properties of Metal Epoxy Composite (MEC) for Rapid Tooling Application" Journal of Manufacturing and Materials Processing 6, no. 6: 134. https://doi.org/10.3390/jmmp6060134

APA StyleHussin, R., Sharif, S., Abd Rahim, S. Z., Rennie, A., Suhaimi, M. A., Abdellah, A. E.-h., Shuaib, N. A., Mohd Khushairi, M. T., & Titu, A. M. (2022). Irregular Shape Effect of Brass and Copper Filler on the Properties of Metal Epoxy Composite (MEC) for Rapid Tooling Application. Journal of Manufacturing and Materials Processing, 6(6), 134. https://doi.org/10.3390/jmmp6060134