Photocatalytic Materials Obtained from E-Waste Recycling: Review, Techniques, Critique, and Update

Abstract

:1. Introduction

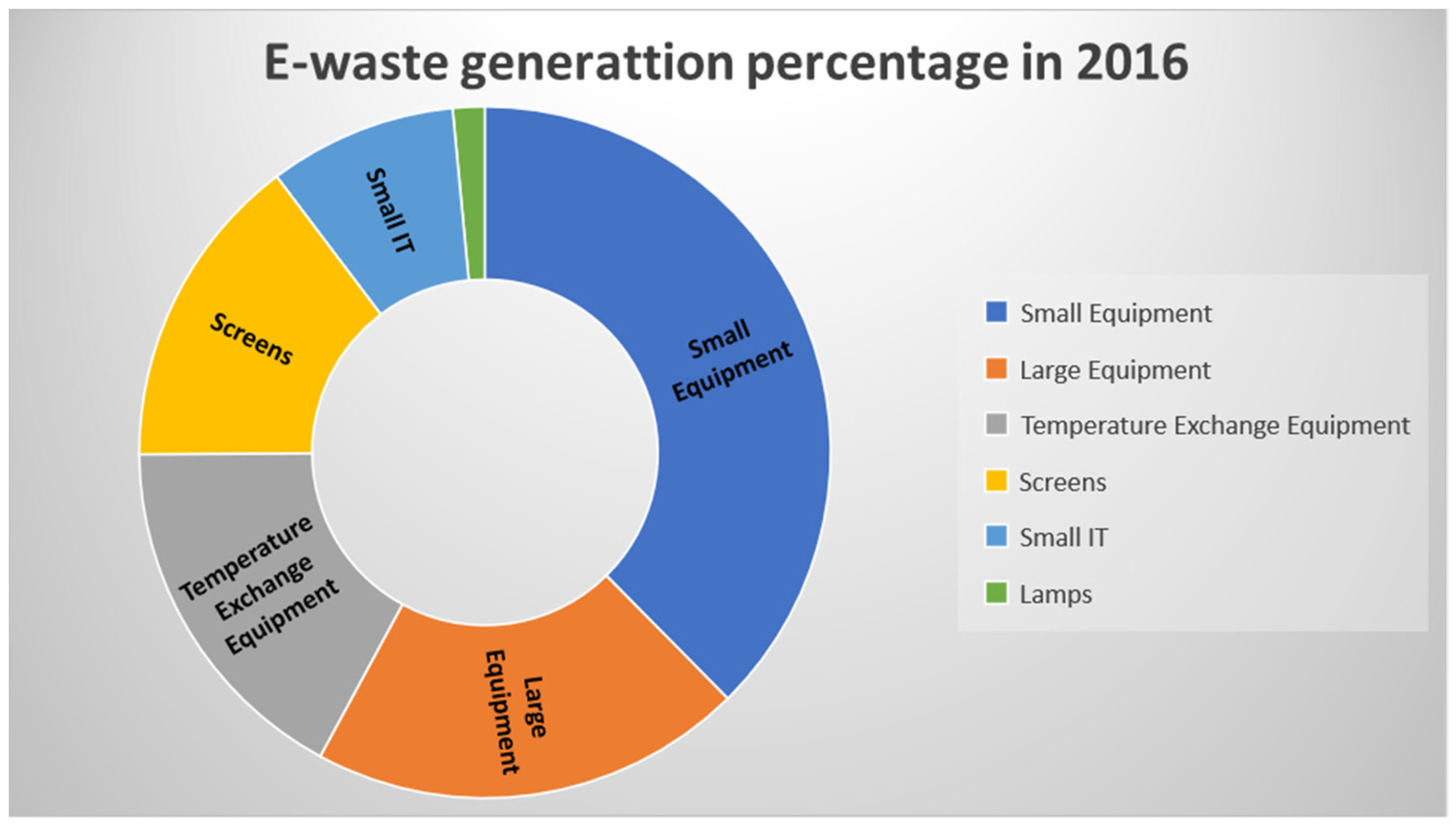

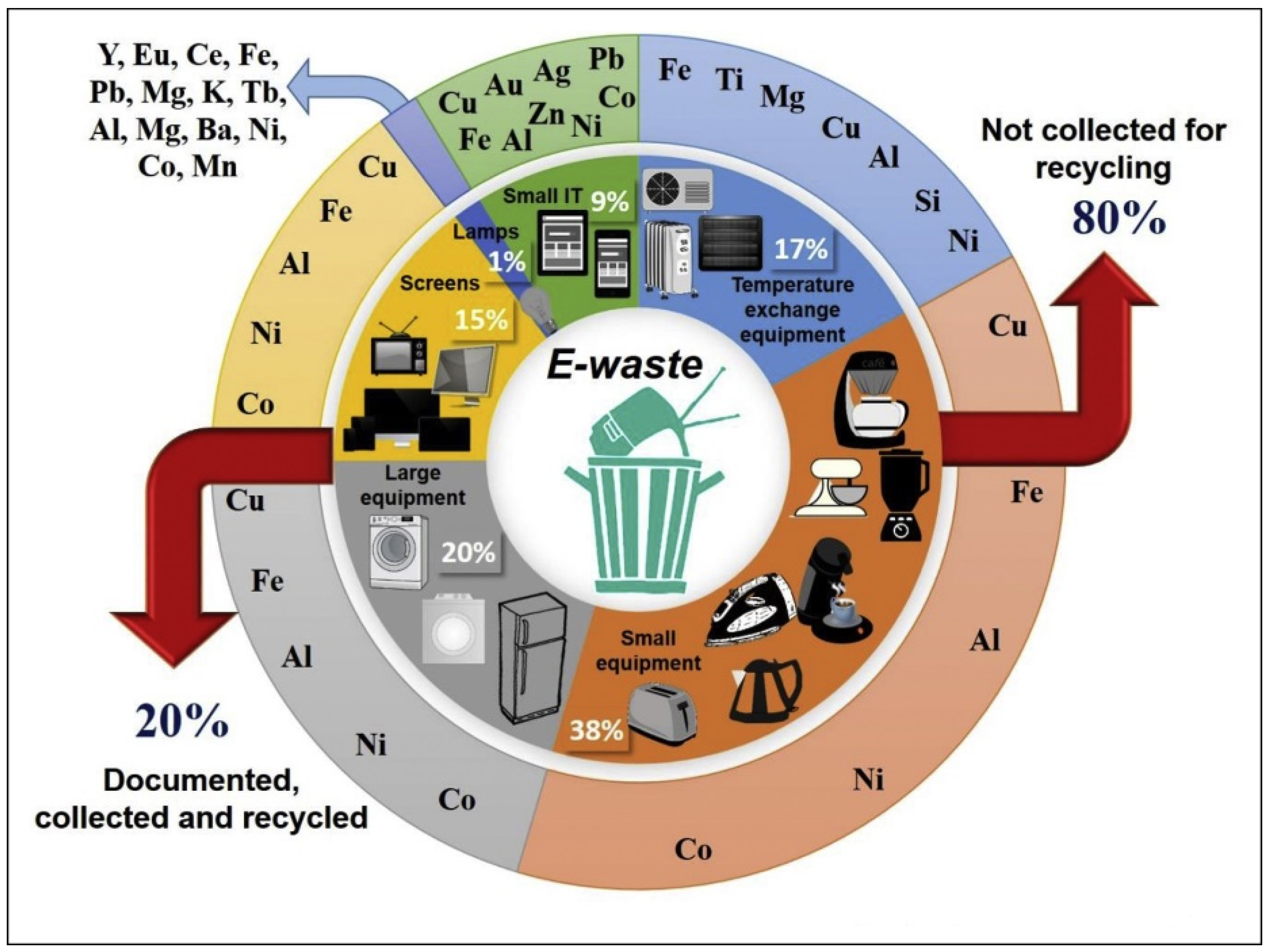

1.1. Global Status of E-Waste

1.2. Importance of the Study and Aims

1.3. Photocatalytic Materials from E-Waste

2. Methodology

3. Results and Discussion

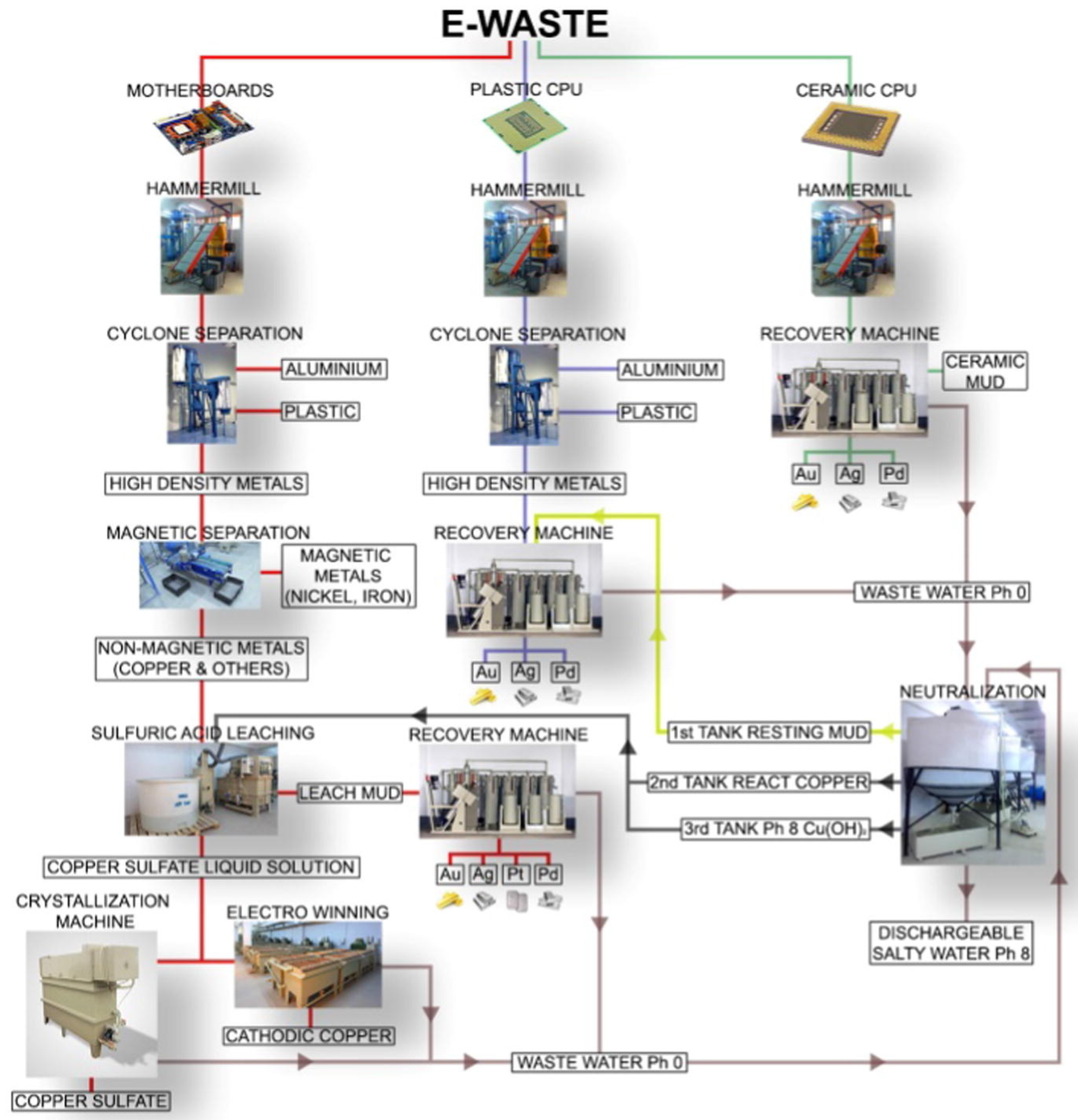

3.1. Strategies of Metal Oxide Recovery

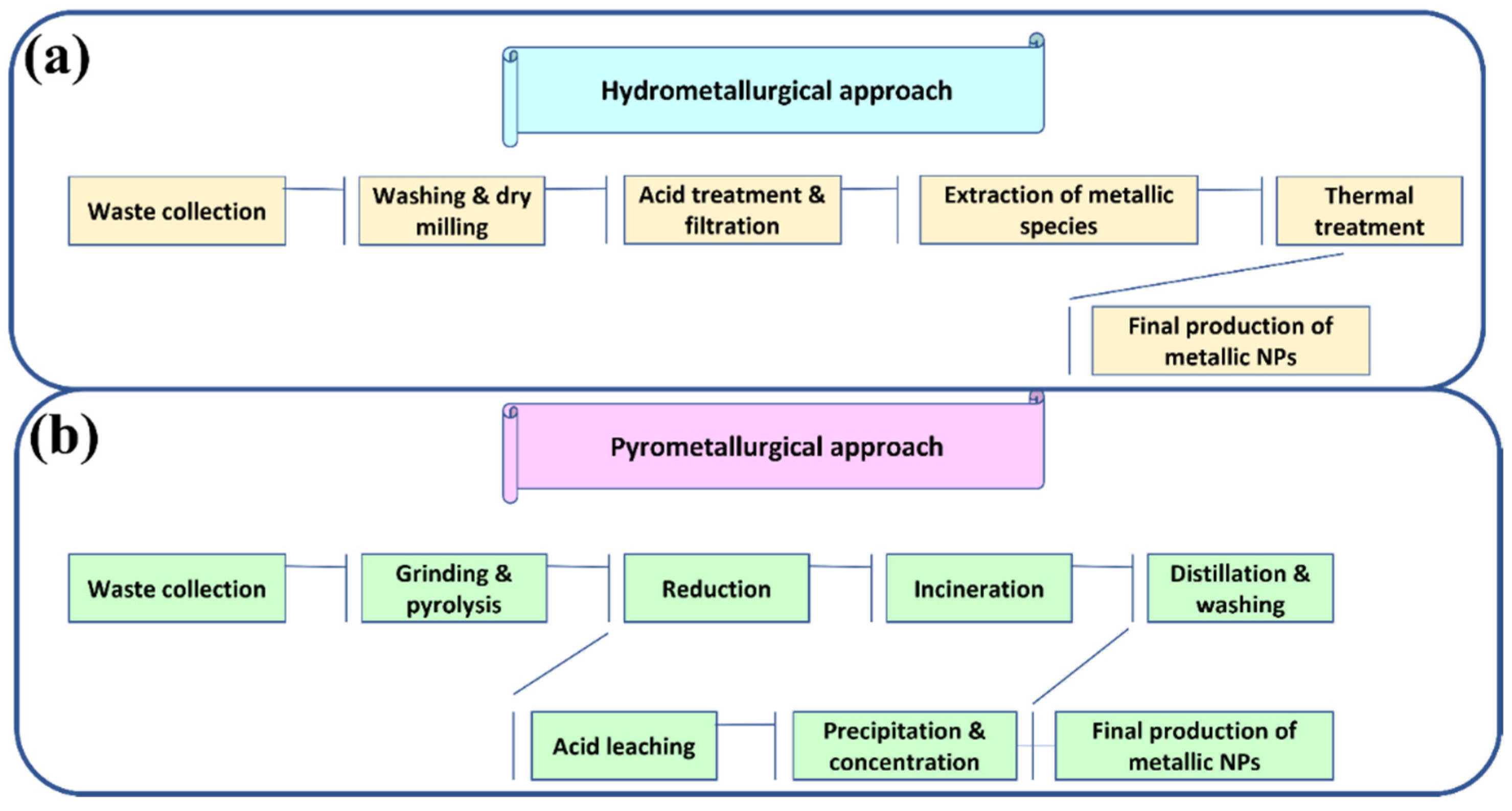

3.1.1. Hydrometallurgical Approaches

3.1.2. Pyrometallurgical Approaches

3.1.3. Biotechnological Approaches

3.2. Photocatalytic Materials from E-Waste

3.2.1. TiO2-Based Materials

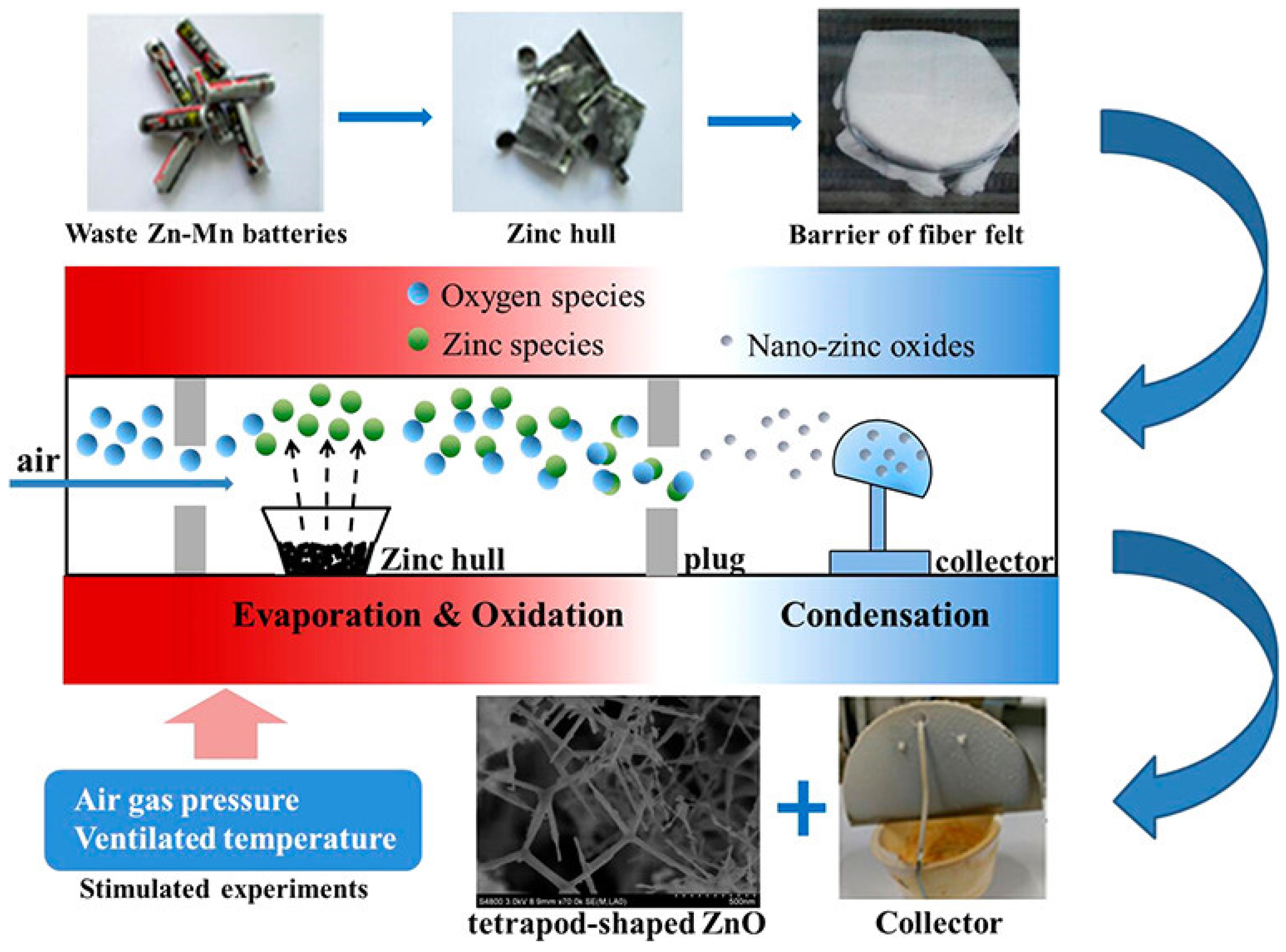

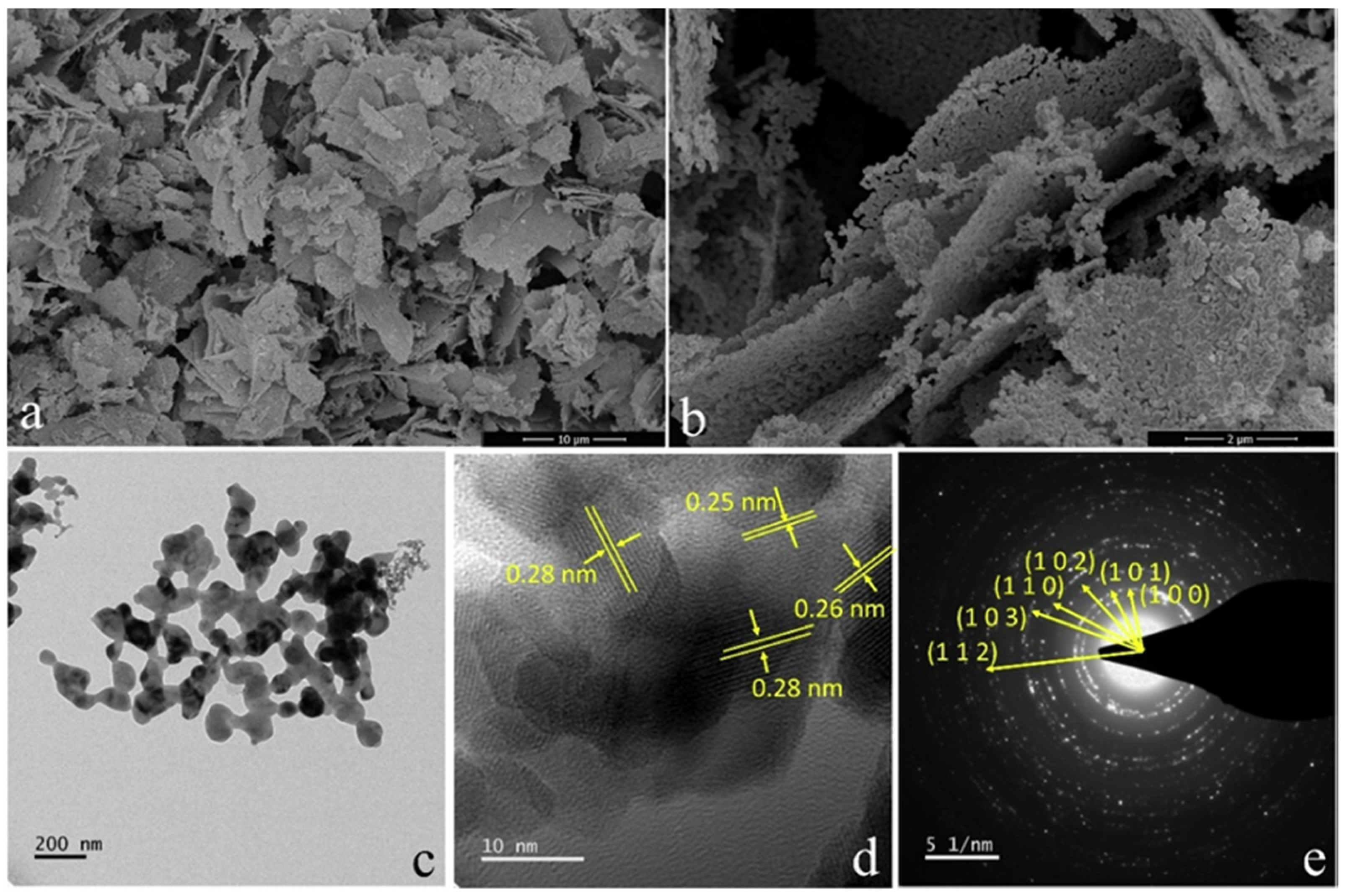

3.2.2. ZnO-Based Materials

3.2.3. Sulfide-Based Materials

3.2.4. Ferrite-Based Materials

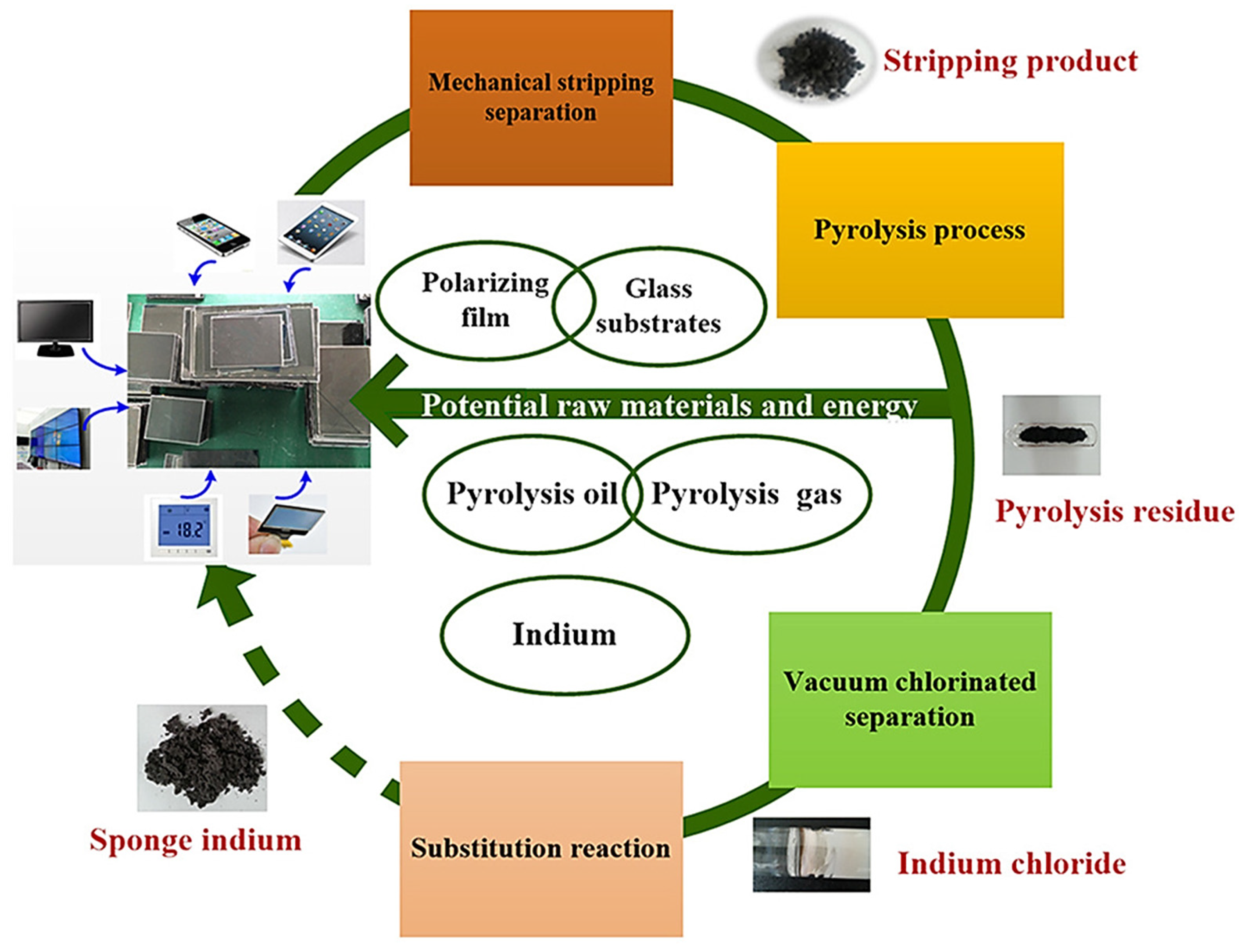

3.2.5. Indium Tin Oxide Materials

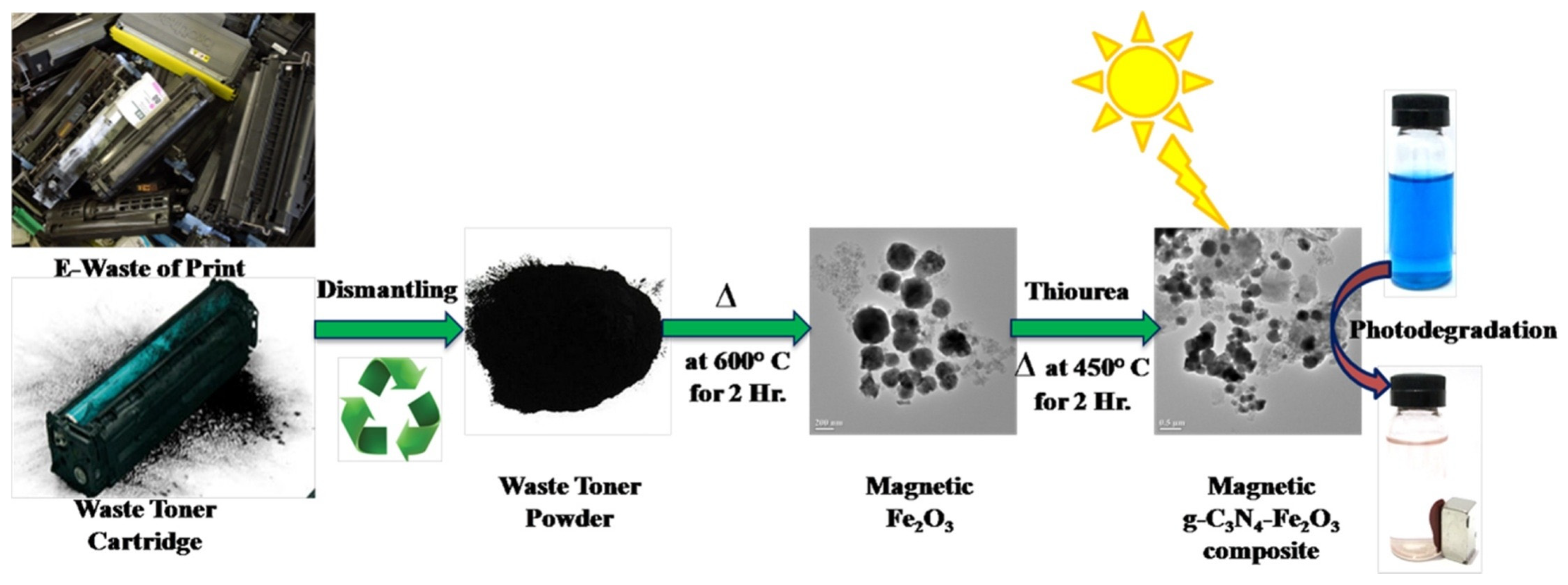

3.2.6. Other Photocatalytic Materials from E-Waste

3.3. Insights and Critiques

4. Conclusions, Recommendations, and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Gollakota, A.R.K.; Gautam, S.; Shu, C.-M. Inconsistencies of e-waste management in developing nations—Facts and plausible solutions. J. Environ. Manag. 2020, 261, 110234. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Zhang, L. Metallurgical recovery of metals from electronic waste: A review. J. Hazard. Mater. 2008, 158, 228–256. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Cao, H.; Xiao, Y.; Sietsma, J.; Jin, W.; Agterhuis, H.; Yang, Y. Toward sustainability for recovery of critical metals from electronic waste: The hydrochemistry processes. ACS Sustain. Chem. Eng. 2017, 5, 21–40. [Google Scholar] [CrossRef]

- Heacock, M.; Kelly, C.B.; Asante, K.A.; Birnbaum, L.S.; Bergman, Å.L.; Bruné, M.-N.; Buka, I.; Carpenter, D.O.; Chen, A.; Huo, X.; et al. E-waste and harm to vulnerable populations: A growing global problem. Environ. Health Perspect. 2016, 124, 550–555. [Google Scholar] [CrossRef] [PubMed]

- Balde, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global E-Waste Monitor 2017: Quantities, Flows and Resources; United Nations University (UNU): Bonn, Germany; International Telecommunication Union (ITU): Geneva, Switzerland; International Solid Waste Association (ISWA): Vienna, Austria, 2017. [Google Scholar] [CrossRef]

- Rodríguez-Padrón, D.; Alothman, Z.A.; Osman, S.M.; Luque, R. Recycling electronic waste: Prospects in green catalysts design. Curr. Opin. Green Sustain. Chem. 2020, 25, 100357. [Google Scholar] [CrossRef]

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows, and the Circular Economy Potential, United Nations University/United Nations Institute for Training and Research, International Telecommunication Union, and International Solid Waste Association. 2020. Available online: https://collections.unu.edu/view/UNU:7737#.YPMJtX3T63c.mendeley (accessed on 17 July 2021).

- Tiseo, I. Electronic Waste Generated Worldwide From 2010 to 2019, Statista. 2021. Available online: https://www.statista.com/statistics/499891/projection-ewaste-generation-worldwide/ (accessed on 10 April 2022).

- Cui, J.; Roven, H.J. Electronic waste. In Waste; Elsevier: Amsterdam, The Netherlands, 2011; pp. 281–296. [Google Scholar] [CrossRef]

- Seif El-Nasr, R.; Abdelbasir, S.M.; Kamel, A.H.; Hassan, S.S.M. Environmentally friendly synthesis of copper nanoparticles from waste printed circuit boards. Sep. Purif. Technol. 2020, 230, 115860. [Google Scholar] [CrossRef]

- Thakur, P.; Kumar, S. Metallurgical processes unveil the unexplored “sleeping mines” e-waste: A review. Environ. Sci. Pollut. Res. 2020, 27, 32359–32370. [Google Scholar] [CrossRef]

- Herrmann, J.-M.; Duchamp, C.; Karkmaz, M.; Hoai, B.T.; Lachheb, H.; Puzenat, E.; Guillard, C. Environmental green chemistry as defined by photocatalysis. J. Hazard. Mater. 2007, 146, 624–629. [Google Scholar] [CrossRef]

- Ravelli, D.; Dondi, D.; Fagnoni, M.; Albini, A. Photocatalysis. A multi-faceted concept for green chemistry. Chem. Soc. Rev. 2009, 38, 1999. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, Y.-L.; Lou, X.; Zhou, T.; Wang, Z.; Fang, C.; Guan, J.; Chen, S.; Xu, X.; Zhang, R.-Q. Efficient degradation of industrial pollutants with sulfur (IV) mediated by LiCoO2 cathode powders of spent lithium ion batteries: A “treating waste with waste” strategy. J. Hazard. Mater. 2020, 399, 123090. [Google Scholar] [CrossRef]

- Naushad, M.; Rajendran, S.; Lichtfouse, E. Green Photocatalysts; Naushad, M., Rajendran, S., Lichtfouse, E., Eds.; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Fu, J.; Zhang, H.; Zhang, A.; Jiang, G. E-waste recycling in China: A challenging field. Environ. Sci. Technol. 2018, 52, 6727–6728. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.-Y.; Schoenung, J. Electronic waste recycling: A review of U.S. infrastructure and technology options. Resour. Conserv. Recycl. 2005, 45, 368–400. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Attarilar, S.; Shaeri, M.H.; Gode, C.; Armoon, H.; Djavanroodi, F. An investigation into the effect of alloying elements on corrosion behavior of severely deformed Cu-Sn alloys by equal channel angular pressing. Arch. Civ. Mech. Eng. 2019, 19, 842–850. [Google Scholar] [CrossRef]

- Laursen, S.; Poudyal, S. Photo- and electro-catalysis. In Novel Materials for Carbon Dioxide Mitigation Technology; Elsevier: Amsterdam, The Netherlands, 2015; pp. 233–268. [Google Scholar] [CrossRef]

- Kaya, M. Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Xu, Z. Novel approach for in situ recovery of lithium carbonate from spent lithium ion batteries using vacuum metallurgy. Environ. Sci. Technol. 2017, 51, 11960–11966. [Google Scholar] [CrossRef]

- Natarajan, G.; Ting, Y.-P. Pretreatment of e-waste and mutation of alkali-tolerant cyanogenic bacteria promote gold biorecovery. Bioresour. Technol. 2014, 152, 80–85. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, Z.; Zhang, F.-S. Direct extraction of palladium and silver from waste printed circuit boards powder by supercritical fluids oxidation-extraction process. J. Hazard. Mater. 2016, 318, 216–223. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, M.; Wen, J.; Wan, Y.; Zhao, Q.; Cao, X.; Ding, Y.; Wang, Z.L.; Li, H.; Bian, Z. Selective recovery of precious metals through photocatalysis. Nat. Sustain. 2021, 4, 618–626. [Google Scholar] [CrossRef]

- Niu, B.; Xu, Z. Innovating e-waste recycling: From waste multi-layer ceramic capacitors to Nb Pb codoped and ag-Pd-Sn-Ni loaded BaTiO3 nano-photocatalyst through one-step ball milling process. Sustain. Mater. Technol. 2019, 21, e00101. [Google Scholar] [CrossRef]

- Guo, J.; Guo, J.; Xu, Z. Recycling of non-metallic fractions from waste printed circuit boards: A review. J. Hazard. Mater. 2009, 168, 567–590. [Google Scholar] [CrossRef]

- Zhou, Y.; Qiu, K. A new technology for recycling materials from waste printed circuit boards. J. Hazard. Mater. 2010, 175, 823–828. [Google Scholar] [CrossRef] [PubMed]

- Veit, H.M.; Diehl, T.R.; Salami, A.P.; Rodrigues, J.S.; Bernardes, A.M.; Tenório, J.A.S. Utilization of magnetic and electrostatic separation in the recycling of printed circuit boards scrap. Waste Manag. 2005, 25, 67–74. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Chen, Y.; Wang, L.Y.; Qian, G.Y.; Zhou, M.; Zhou, J. A new technology for separation and recovery of materials from waste printed circuit boards by dissolving bromine epoxy resins using ionic liquid. J. Hazard. Mater. 2012, 239, 270–278. [Google Scholar] [CrossRef]

- Quan, C.; Li, A.; Gao, N.; Dan, Z. Characterization of products recycling from PCB waste pyrolysis. J. Anal. Appl. Pyrolysis 2010, 89, 102–106. [Google Scholar] [CrossRef]

- Bernardes, A.; Espinosa, D.C.; Tenório, J.A. Recycling of batteries: A review of current processes and technologies. J. Power Sources 2004, 130, 291–298. [Google Scholar] [CrossRef]

- Espinosa, D.C.R.; Bernardes, A.M.; Tenório, J.A.S. An overview on the current processes for the recycling of batteries. J. Power Sources 2004, 135, 311–319. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Gode, C. Severely deformed copper by equal channel angular pressing. Prog. Nat. Sci. Mater. Int. 2017, 27, 244–250. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Shaeri, M.H.; Gode, C.; Armoon, H.; Shamsborhan, M. The synergistic effect of dilute alloying and nanostructuring of copper on the improvement of mechanical and tribological response. Compos. Part B Eng. 2019, 164, 508–516. [Google Scholar] [CrossRef]

- Kim, Y.; Matsuda, M.; Shibayama, A.; Fujita, T. Recovery of LiCoO2 from wasted lithium ion batteries by using mineral processing technology. Resour. Process. 2004, 51, 3–7. [Google Scholar] [CrossRef] [Green Version]

- Huang, B.; Pan, Z.; Su, X.; An, L. Recycling of lithium-ion batteries: Recent advances and perspectives. J. Power Sources 2018, 399, 274–286. [Google Scholar] [CrossRef]

- Ordoñez, J.; Gago, E.J.; Girard, A. Processes and technologies for the recycling and recovery of spent lithium-ion batteries. Renew. Sustain. Energy Rev. 2016, 60, 195–205. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Djavanroodi, F.; Tiji, S.; Gholipour, H.; Gode, C. Experimental investigation of the equal channel forward extrusion process. Metals 2015, 5, 471–483. [Google Scholar] [CrossRef] [Green Version]

- Deep, A.; Kumar, K.; Kumar, P.; Kumar, P.; Sharma, A.L.; Gupta, B.; Bharadwaj, L.M. Recovery of Pure ZnO nanoparticles from spent Zn-MnO 2 alkaline batteries. Environ. Sci. Technol. 2011, 45, 10551–10556. [Google Scholar] [CrossRef]

- Deep, A.; Sharma, A.L.; Mohanta, G.C.; Kumar, P.; Kim, K.-H. A facile chemical route for recovery of high quality zinc oxide nanoparticles from spent alkaline batteries. Waste Manag. 2016, 51, 190–195. [Google Scholar] [CrossRef]

- Guo, Y.; Li, F.; Zhu, H.; Li, G.; Huang, J.; He, W. Leaching lithium from the anode electrode materials of spent lithium-ion batteries by hydrochloric acid (HCl). Waste Manag. 2016, 51, 227–233. [Google Scholar] [CrossRef]

- Mantuano, D.P.; Dorella, G.; Elias, R.C.A.; Mansur, M.B. Analysis of a hydrometallurgical route to recover base metals from spent rechargeable batteries by liquid–liquid extraction with Cyanex 272. J. Power Sources 2006, 159, 1510–1518. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, S.; Li, S.; Chen, M.; Chen, H.; Liu, B. Bioleaching waste printed circuit boards by Acidithiobacillus ferrooxidans and its kinetics aspect. J. Biotechnol. 2014, 173, 24–30. [Google Scholar] [CrossRef] [PubMed]

- Van Yken, J.; Cheng, K.Y.; Boxall, N.J.; Nikoloski, A.N.; Moheimani, N.; Valix, M.; Sahajwalla, V.; Kaksonen, A.H. Potential of metals leaching from printed circuit boards with biological and chemical lixiviants. Hydrometallurgy 2020, 196, 105433. [Google Scholar] [CrossRef]

- Chu, H.; Qian, C.; Tian, B.; Qi, S.; Wang, J.; Xin, B. Pyrometallurgy coupling bioleaching for recycling of waste printed circuit boards. Resour. Conserv. Recycl. 2022, 178, 106018. [Google Scholar] [CrossRef]

- Cayumil, R.; Ikram-Ul-Haq, M.; Khanna, R.; Saini, R.; Mukherjee, P.; Mishra, B.; Sahajwalla, V. High temperature investigations on optimising the recovery of copper from waste printed circuit boards. Waste Manag. 2018, 73, 556–565. [Google Scholar] [CrossRef]

- Yao, L.; Xi, Y.; Xi, G.; Feng, Y. Synthesis of cobalt ferrite with enhanced magnetostriction properties by the sol−gel−hydrothermal route using spent Li-ion battery. J. Alloys Compd. 2016, 680, 73–79. [Google Scholar] [CrossRef]

- Long, L.; Sun, S.; Zhong, S.; Dai, W.; Liu, J.; Song, W. Using vacuum pyrolysis and mechanical processing for recycling waste printed circuit boards. J. Hazard. Mater. 2010, 177, 626–632. [Google Scholar] [CrossRef] [PubMed]

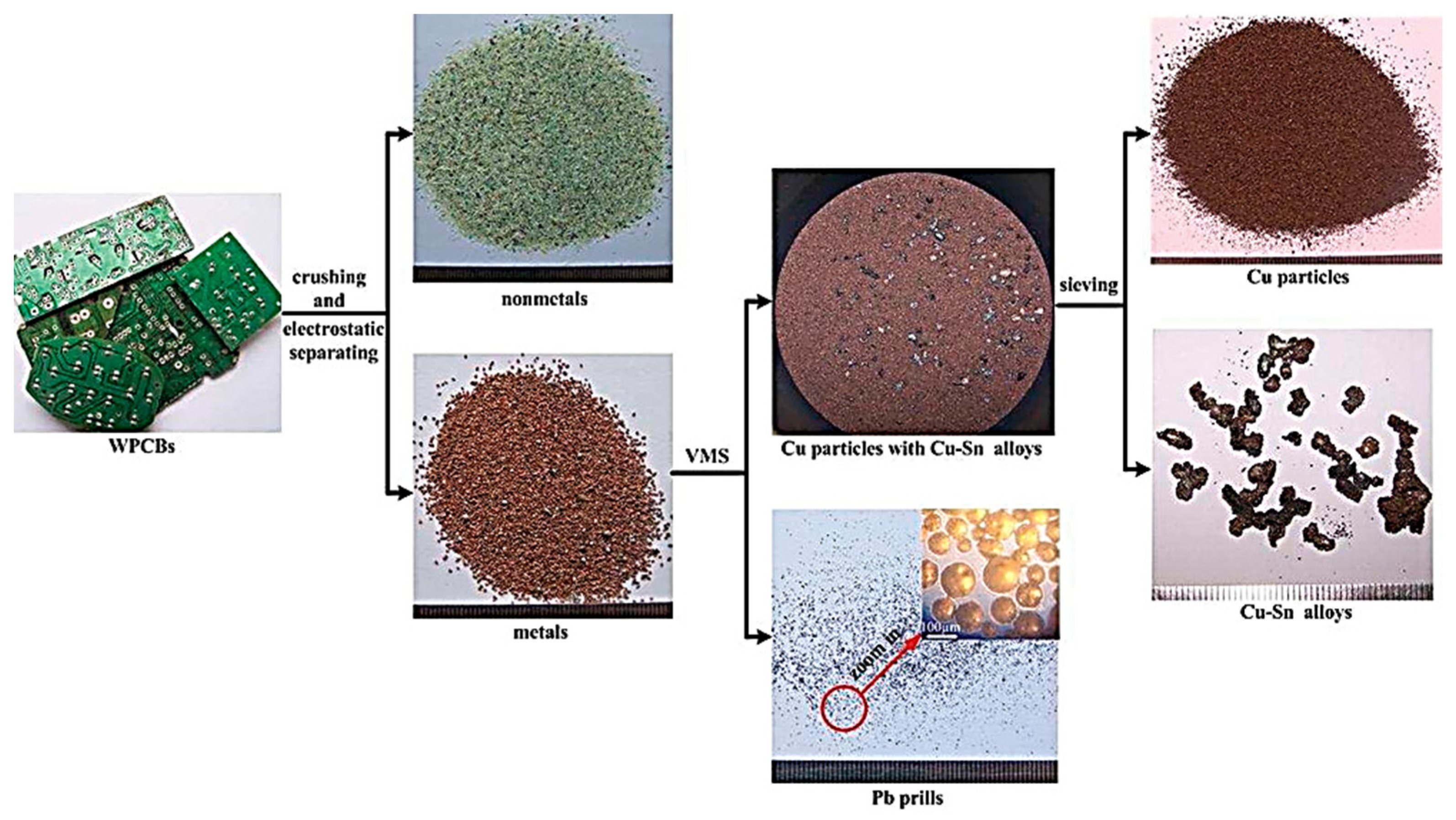

- Zhan, L.; Xu, Z. Separating and recovering Pb from copper-rich particles of crushed waste printed circuit boards by evaporation and condensation. Environ. Sci. Technol. 2011, 45, 5359–5365. [Google Scholar] [CrossRef]

- Buzatu, T.; Popescu, G.; Birloaga, I.; Săceanu, S. Study concerning the recovery of zinc and manganese from spent batteries by hydrometallurgical processes. Waste Manag. 2013, 33, 699–705. [Google Scholar] [CrossRef] [PubMed]

- Ashiq, A.; Kulkarni, J.; Vithanage, M. Hydrometallurgical recovery of metals from e-waste. In Electronic Waste Management and Treatment Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 225–246. [Google Scholar] [CrossRef]

- Khaliq, A.; Rhamdhani, M.; Brooks, G.; Masood, S. Metal extraction processes for electronic waste and existing industrial routes: A review and Australian perspective. Resources 2014, 3, 152–179. [Google Scholar] [CrossRef] [Green Version]

- Djavanroodi, F.; Ebrahimi, M.; Nayfeh, J.F. Tribological and mechanical investigation of multi-directional forged nickel. Sci. Rep. 2019, 9, 241. [Google Scholar] [CrossRef]

- Sadegh Safarzadeh, M.; Bafghi, M.S.; Moradkhani, D.; Ojaghi Ilkhchi, M. A review on hydrometallurgical extraction and recovery of cadmium from various resources. Miner. Eng. 2007, 20, 211–220. [Google Scholar] [CrossRef]

- Meng, L.; Zhong, Y.; Guo, L.; Wang, Z.; Chen, K.; Guo, Z. High-temperature centrifugal separation of Cu from waste printed circuit boards. J. Clean. Prod. 2018, 199, 831–839. [Google Scholar] [CrossRef]

- da Silva, M.S.B.; de Melo, R.A.C.; Lopes-Moriyama, A.L.; Souza, C.P. Electrochemical extraction of tin and copper from acid leachate of printed circuit boards using copper electrodes. J. Environ. Manag. 2019, 246, 410–417. [Google Scholar] [CrossRef]

- Abdelbasir, S.M.; Hassan, S.S.M.; Kamel, A.H.; El-Nasr, R.S. Status of electronic waste recycling techniques: A review. Environ. Sci. Pollut. Res. 2018, 25, 16533–16547. [Google Scholar] [CrossRef]

- Rene, E.R.; Sethurajan, M.; Kumar Ponnusamy, V.; Kumar, G.; Bao Dung, T.N.; Brindhadevi, K.; Pugazhendhi, A. Electronic waste generation, recycling and resource recovery: Technological perspectives and trends. J. Hazard. Mater. 2021, 416, 125664. [Google Scholar] [CrossRef] [PubMed]

- Hsu, E.; Barmak, K.; West, A.C.; Park, A.-H.A. Advancements in the treatment and processing of electronic waste with sustainability: A review of metal extraction and recovery technologies. Green Chem. 2019, 21, 919–936. [Google Scholar] [CrossRef]

- Vats, M.C.; Singh, S.K. Assessment of gold and silver in assorted mobile phone printed circuit boards (PCBs). Waste Manag. 2015, 45, 280–288. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, S.; Li, B.; Pan, D.; Wu, Y.; Zuo, T. Recovery of waste printed circuit boards through pyrometallurgical processing: A review. Resour. Conserv. Recycl. 2017, 126, 209–218. [Google Scholar] [CrossRef]

- Faraji, F.; Golmohammadzadeh, R.; Pickles, C.A. Potential and current practices of recycling waste printed circuit boards: A review of the recent progress in pyrometallurgy. J. Environ. Manag. 2022, 316, 115242. [Google Scholar] [CrossRef] [PubMed]

- Windisch-Kern, S.; Holzer, A.; Ponak, C.; Raupenstrauch, H. Pyrometallurgical lithium-ion-battery recycling: Approach to limiting lithium slagging with the InduRed reactor concept. Processes 2021, 9, 84. [Google Scholar] [CrossRef]

- Yin, H.; Xing, P. Pyrometallurgical routes for the recycling of spent lithium-ion batteries. In Recycling of Spent Lithium-Ion Batteries: Processing Methods and Environmental Impacts; Springer International Publishing: Cham, Switzerland, 2019; pp. 57–83. [Google Scholar] [CrossRef]

- Holzer, A.; Windisch-Kern, S.; Ponak, C.; Raupenstrauch, H. A novel pyrometallurgical recycling process for lithium-ion batteries and its application to the recycling of LCO and LFP. Metals 2021, 11, 149. [Google Scholar] [CrossRef]

- De Oliveira, C.R.; Bernardes, A.M.; Gerbase, A.E. Collection and recycling of electronic scrap: A worldwide overview and comparison with the Brazilian situation. Waste Manag. 2012, 32, 1592–1610. [Google Scholar] [CrossRef]

- Zhan, L.; Xu, Z. Application of vacuum metallurgy to separate pure metal from mixed metallic particles of crushed waste printed circuit board scraps. Environ. Sci. Technol. 2008, 42, 7676–7681. [Google Scholar] [CrossRef]

- Huang, K.; Li, J.; Xu, Z. A novel process for recovering valuable metals from waste nickel−cadmium batteries. Environ. Sci. Technol. 2009, 43, 8974–8978. [Google Scholar] [CrossRef]

- Muñoz, A.J.; Espínola, F.; Ruiz, E. Biosorption of Ag(I) from aqueous solutions by Klebsiella sp. 3S1. J. Hazard. Mater. 2017, 329, 166–177. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, S.; Lee, J. Biometallurgical recovery of metals from waste electrical and electronic equipment: A review. ChemBioEng Rev. 2014, 1, 148–169. [Google Scholar] [CrossRef]

- Olson, G.J.; Brierley, J.A.; Brierley, C.L. Bioleaching review part B. Appl. Microbiol. Biotechnol. 2003, 63, 249–257. [Google Scholar] [CrossRef] [PubMed]

- Nancharaiah, Y.V.; Mohan, S.V.; Lens, P.N.L. Biological and bioelectrochemical recovery of critical and scarce metals. Trends Biotechnol. 2016, 34, 137–155. [Google Scholar] [CrossRef] [PubMed]

- Pathak, A.; Dastidar, M.G.; Sreekrishnan, T.R. Bioleaching of heavy metals from sewage sludge: A review. J. Environ. Manag. 2009, 90, 2343–2353. [Google Scholar] [CrossRef]

- Işıldar, A.; van Hullebusch, E.D.; Lenz, M.; Du Laing, G.; Marra, A.; Cesaro, A.; Panda, S.; Akcil, A.; Kucuker, M.A.; Kuchta, K. Biotechnological strategies for the recovery of valuable and critical raw materials from waste electrical and electronic equipment (WEEE)—A review. J. Hazard. Mater. 2019, 362, 467–481. [Google Scholar] [CrossRef]

- Islam, A.; Swaraz, A.M.; Teo, S.H.; Taufiq-Yap, Y.H.; Vo, D.-V.N.; Ibrahim, M.L.; Abdulkreem-Alsultan, G.; Rashid, U.; Awual, M.R. Advances in physiochemical and biotechnological approaches for sustainable metal recovery from e-waste: A critical review. J. Clean. Prod. 2021, 323, 129015. [Google Scholar] [CrossRef]

- Brandl, H.; Bosshard, R.; Wegmann, M. Computer-munching microbes: Metal leaching from electronic scrap by bacteria and fungi. Hydrometallurgy 2001, 59, 319–326. [Google Scholar] [CrossRef]

- Choi, M.-S.; Cho, K.-S.; Kim, D.-S.; Kim, D.-J. Microbial recovery of copper from printed circuit boards of waste computer by Acidithiobacillus ferrooxidans. J. Environ. Sci. Health Part A 2004, 39, 2973–2982. [Google Scholar] [CrossRef]

- Vestola, E.A.; Kuusenaho, M.K.; Närhi, H.M.; Tuovinen, O.H.; Puhakka, J.A.; Plumb, J.J.; Kaksonen, A.H. Acid bioleaching of solid waste materials from copper, steel and recycling industries. Hydrometallurgy 2010, 103, 74–79. [Google Scholar] [CrossRef]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; van Gerven, T.; Yang, Y.; Walton, A.; Buchert, M. Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22. [Google Scholar] [CrossRef]

- Yang, T.; Xu, Z.; Wen, J.; Yang, L. Factors influencing bioleaching copper from waste printed circuit boards by Acidithiobacillus ferrooxidans. Hydrometallurgy 2009, 97, 29–32. [Google Scholar] [CrossRef]

- Bas, A.D.; Deveci, H.; Yazici, E.Y. Bioleaching of copper from low grade scrap TV circuit boards using mesophilic bacteria. Hydrometallurgy 2013, 138, 65–70. [Google Scholar] [CrossRef]

- Brandl, H.; Faramarzi, M.A. Microbe-metal-interactions for the biotechnological treatment of metal-containing solid waste. China Particuology 2006, 4, 93–97. [Google Scholar] [CrossRef]

- Tran, C.D.; Lee, J.-C.; Pandey, B.D.; Jeong, J.; Yoo, K.; Huynh, T.H. Bacterial cyanide generation in the presence of metal ions (Na+, Mg2+, Fe2+, Pb2+) and gold bioleaching from waste PCBs. J. Chem. Eng. Jpn. 2011, 44, 692–700. [Google Scholar] [CrossRef]

- Kita, Y.; Nishikawa, H.; Takemoto, T. Effects of cyanide and dissolved oxygen concentration on biological Au recovery. J. Biotechnol. 2006, 124, 545–551. [Google Scholar] [CrossRef]

- Tay, S.B.; Natarajan, G.; Bin, A.; Rahim, M.N.; Tan, H.T.; Chung, M.C.M.; Ting, Y.P.; Yew, W.S. Enhancing gold recovery from electronic waste via lixiviant metabolic engineering in Chromobacterium violaceum. Sci. Rep. 2013, 3, 2236. [Google Scholar] [CrossRef] [Green Version]

- Ilyas, S.; Ruan, C.; Bhatti, H.N.; Ghauri, M.A.; Anwar, M.A. Column bioleaching of metals from electronic scrap. Hydrometallurgy 2010, 101, 135–140. [Google Scholar] [CrossRef]

- Ilyas, S.; Lee, J.; Chi, R. Bioleaching of metals from electronic scrap and its potential for commercial exploitation. Hydrometallurgy 2013, 131, 138–143. [Google Scholar] [CrossRef]

- Ilyas, S.; Anwar, M.A.; Niazi, S.B.; Afzal Ghauri, M. Bioleaching of metals from electronic scrap by moderately thermophilic acidophilic bacteria. Hydrometallurgy 2007, 88, 180–188. [Google Scholar] [CrossRef]

- Ilyas, S.; Lee, J. Fungal leaching of metals from electronic scrap. Min. Met. Explor. 2013, 30, 151–156. [Google Scholar] [CrossRef]

- Hasija, V.; Kumar, A.; Sudhaik, A.; Raizada, P.; Singh, P.; van Le, Q.; Le, T.T.; Nguyen, V.-H. Step-scheme heterojunction photocatalysts for solar energy, water splitting, CO2 conversion, and bacterial inactivation: A review. Environ. Chem. Lett. 2021, 19, 2941–2966. [Google Scholar] [CrossRef]

- Rodríguez-Padrón, D.; Luque, R.; Muñoz-Batista, M.J. Waste-derived materials: Opportunities in photocatalysis. Top. Curr. Chem. 2020, 378, 3. [Google Scholar] [CrossRef]

- Li, H.; Tu, W.; Zhou, Y.; Zou, Z. Z-scheme photocatalytic systems for promoting photocatalytic performance: Recent progress and future challenges. Adv. Sci. 2016, 3, 1500389. [Google Scholar] [CrossRef] [Green Version]

- Qi, K.; Cheng, B.; Yu, J.; Ho, W. A review on TiO2-based Z-scheme photocatalysts. Chin. J. Catal. 2017, 38, 1936–1955. [Google Scholar] [CrossRef]

- Xu, Q.; Zhang, L.; Cheng, B.; Fan, J.; Yu, J. S-scheme heterojunction photocatalyst. Chem 2020, 6, 1543–1559. [Google Scholar] [CrossRef]

- Solano, R.A.; Herrera, A.P.; Maestre, D.; Cremades, A. Cremades, Fe-TiO2 nanoparticles synthesized by green chemistry for potential application in waste water photocatalytic treatment. J. Nanotechnol. 2019, 2019, 1–11. [Google Scholar] [CrossRef] [Green Version]

- JFulekar, J.; Dutta, D.P.; Pathak, B.; Fulekar, M.H. Novel microbial and root mediated green synthesis of TiO2 nanoparticles and its application in wastewater remediation. J. Chem. Technol. Biotechnol. 2018, 93, 736–743. [Google Scholar] [CrossRef]

- Shimi, A.K.; Ahmed, H.M.; Wahab, M.; Katheria, S.; Wabaidur, S.M.; Eldesoky, G.E.; Islam, M.A.; Rane, K.P. Synthesis and applications of green synthesized TiO2 nanoparticles for photocatalytic dye degradation and antibacterial activity. J. Nanomater. 2022, 2022, 1–9. [Google Scholar] [CrossRef]

- Maurya, I.C.; Singh, S.; Senapati, S.; Srivastava, P.; Bahadur, L. Green synthesis of TiO2 nanoparticles using Bixa orellana seed extract and its application for solar cells. Sol. Energy 2019, 194, 952–958. [Google Scholar] [CrossRef]

- Nakata, K.; Fujishima, A. TiO2 photocatalysis: Design and applications. J. Photochem. Photobiol. C Photochem. Rev. 2012, 13, 169–189. [Google Scholar] [CrossRef]

- Guo, Q.; Zhou, C.; Ma, Z.; Yang, X. Fundamentals of TiO2 photocatalysis: Concepts, mechanisms, and challenges. Adv. Mater. 2019, 31, 1901997. [Google Scholar] [CrossRef] [PubMed]

- Ong, C.B.; Ng, L.Y.; Mohammad, A.W. A review of ZnO nanoparticles as solar photocatalysts: Synthesis, mechanisms and applications. Renew. Sustain. Energy Rev. 2018, 81, 536–551. [Google Scholar] [CrossRef]

- Fu, J.; Yu, J.; Jiang, C.; Cheng, B. g-C3N4-Based heterostructured photocatalysts. Adv. Energy Mater. 2018, 8, 1701503. [Google Scholar] [CrossRef]

- Taoda, H. Development of TiO2 photocatalysts suitable for practical use and their applications in environmental cleanup. Res. Chem. Intermed. 2008, 34, 417–426. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Park, S.-J. TiO2 photocatalyst for water treatment applications. J. Ind. Eng. Chem. 2013, 19, 1761–1769. [Google Scholar] [CrossRef]

- Zheng, H.; Okabe, T.H. Recovery of titanium metal scrap by utilizing chloride wastes. J. Alloys Compd. 2008, 461, 459–466. [Google Scholar] [CrossRef]

- Sahin, M.; Akcil, A.; Erust, C.; Altynbek, S.; Gahan, C.S.; Tuncuk, A. A potential alternative for precious metal recovery from e-waste: Iodine leaching. Sep. Sci. Technol. 2015, 2015, 150629132750004. [Google Scholar] [CrossRef]

- Rodríguez-Padrón, D.; Puente-Santiago, A.R.; Balu, A.M.; Muñoz-Batista, M.J.; Luque, R. Environmental catalysis: Present and future. ChemCatChem 2019, 11, 18–38. [Google Scholar] [CrossRef]

- Muñoz-Batista, M.J.; Meira, D.M.; Colón, G.; Kubacka, A.; Fernández-García, M. Phase-contact engineering in mono- and bimetallic Cu-Ni Co-catalysts for hydrogen photocatalytic materials. Angew. Chem. Int. Ed. 2018, 57, 1199–1203. [Google Scholar] [CrossRef]

- Kappadan, S.; Gebreab, T.W.; Thomas, S.; Kalarikkal, N. Tetragonal BaTiO3 nanoparticles: An efficient photocatalyst for the degradation of organic pollutants. Mater. Sci. Semicond. Process. 2016, 51, 42–47. [Google Scholar] [CrossRef]

- Tymińska, N.; Wu, G.; Dupuis, M. Water oxidation on oxygen-deficient barium titanate: A first-principles study. J. Phys. Chem. C 2017, 121, 8378–8389. [Google Scholar] [CrossRef]

- Niu, B.; Xu, Z. From e-waste to Nb-Pb Co-doped and Pd-loaded TiO2 /BaTiO3 heterostructure: Highly efficient photocatalytic performance. ChemSusChem 2019, 12, 2819–2828. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Yu, J.C.; Cheng, B.; Zhao, X. Photocatalytic activity and characterization of the sol-gel derived Pb-doped TiO2 thin films. J. Sol-Gel Sci. Technol. 2002, 24, 39–48. [Google Scholar] [CrossRef]

- Morris, D.; Dou, Y.; Rebane, J.; Mitchell, C.E.J.; Egdell, R.G.; Law, D.S.L.; Vittadini, A.; Casarin, M. Photoemission and STM study of the electronic structure of Nb-doped TiO2. Phys. Rev. B 2000, 61, 13445–13457. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Wu, Y.; Zuo, T. Green recovery of titanium and effective regeneration of TiO2 photocatalysts from spent selective catalytic reduction catalysts. ACS Sustain. Chem. Eng. 2018, 6, 3091–3101. [Google Scholar] [CrossRef]

- WYang, W.; Yu, Y.; Starr, M.B.; Yin, X.; Li, Z.; Kvit, A.; Wang, S.; Zhao, P.; Wang, X. Ferroelectric polarization-enhanced photoelectrochemical water splitting in TiO2–BaTiO3 core–shell nanowire photoanodes. Nano Lett. 2015, 15, 7574–7580. [Google Scholar] [CrossRef]

- Li, Q.; Li, R.; Zong, L.; He, J.; Wang, X.; Yang, J. Photoelectrochemical and photocatalytic properties of Ag-loaded BaTiO3/TiO2 heterostructure nanotube arrays. J. Hydrogen Energy 2013, 38, 12977–12983. [Google Scholar] [CrossRef]

- Niu, B.; Shanshan, E.; Cao, Y.; Xiao, J.; Zhan, L.; Xu, Z. Utilizing e-waste for construction of magnetic and core–shell Z-scheme photocatalysts: An effective approach to e-waste recycling. Environ. Sci. Technol. 2021, 55, 1279–1289. [Google Scholar] [CrossRef]

- MAli, M.A.; Idris, M.R.; Quayum, M.E. Fabrication of ZnO nanoparticles by solution-combustion method for the photocatalytic degradation of organic dye. J. Nanostructure Chem. 2013, 3, 36. [Google Scholar] [CrossRef] [Green Version]

- Ullah, R.; Dutta, J. Photocatalytic degradation of organic dyes with manganese-doped ZnO nanoparticles. J. Hazard. Mater. 2008, 156, 194–200. [Google Scholar] [CrossRef] [PubMed]

- Elsayed, M.H.; Elmorsi, T.M.; Abuelela, A.M.; Hassan, A.E.; Alhakemy, A.Z.; Bakr, M.F.; Chou, H.-H. Direct sunlight-active Na-doped ZnO photocatalyst for the mineralization of organic pollutants at different pH mediums. J. Taiwan Inst. Chem. Eng. 2020, 115, 187–197. [Google Scholar] [CrossRef]

- Guo, X.; Zhong, J.; Song, Y.; Tian, Q. Substance flow analysis of zinc in China. Resour. Conserv. Recycl. 2010, 54, 171–177. [Google Scholar] [CrossRef]

- Goktas, S.; Goktas, A. A comparative study on recent progress in efficient ZnO based nanocomposite and heterojunction photocatalysts: A review. J. Alloys Compd. 2021, 863, 158734. [Google Scholar] [CrossRef]

- El-Maghrabi, H.H.; Nada, A.A.; Soliman, F.S.; Raynaud, P.; Moustafa, Y.M.; Ali, G.A.M.; Bekheet, M.F. Recovery of metal oxide nanomaterials from electronic waste materials. In Waste Recycling Technologies for Nanomaterials Manufacturing; Springer: Berlin/Heidelberg, Germany, 2021; pp. 203–227. [Google Scholar] [CrossRef]

- Zhan, L.; Li, O.; Wang, Z.; Xie, B. Recycling zinc and preparing high-value-added nanozinc oxide from waste zinc–manganese batteries by high-temperature evaporation-separation and oxygen control oxidation. ACS Sustain. Chem. Eng. 2018, 6, 12104–12109. [Google Scholar] [CrossRef]

- Zhan, L.; Li, O.; Xu, Z. Preparing nano-zinc oxide with high-added-value from waste zinc manganese battery by vacuum evaporation and oxygen-control oxidation. J. Clean. Prod. 2019, 251, 119691. [Google Scholar] [CrossRef]

- Maroufi, S.; Nekouei, R.K.; Assefi, M.; Sahajwalla, V. Waste-cleaning waste: Synthesis of ZnO porous nano-sheets from batteries for dye degradation. Environ. Sci. Pollut. Res. 2018, 25, 28594–28600. [Google Scholar] [CrossRef]

- Nayak, P.; Kumar, S.; Sinha, I.; Singh, K.K. ZnO/CuO nanocomposites from recycled printed circuit board: Preparation and photocatalytic properties. Environ. Sci. Pollut. Res. 2019, 26, 16279–16288. [Google Scholar] [CrossRef]

- Charitidis, C.A.; Georgiou, P.; Koklioti, M.A.; Trompeta, A.-F.; Markakis, V. Manufacturing nanomaterials: From research to industry. Manuf. Rev. 2014, 1, 11. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Xu, Z. Application of supercritical water to decompose brominated epoxy resin and environmental friendly recovery of metals from waste memory module. Environ. Sci. Technol. 2015, 49, 1761–1767. [Google Scholar] [CrossRef]

- Lee, S.L.; Chang, C.-J. Recent progress on metal sulfide composite nanomaterials for photocatalytic hydrogen production. Catalysts 2019, 9, 457. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Ou, X.; Xiang, Q.; Carabineiro, S.A.C.; Fan, J.; Lv, K. Research progress in metal sulfides for photocatalysis: From activity to stability. Chemosphere 2022, 303, 135085. [Google Scholar] [CrossRef]

- Hsu, M.-H.; Chang, C.-J.; Weng, H.-T. Efficient H2 production using Ag2S-coupled ZnO@ZnS core–shell nanorods decorated metal wire mesh as an immobilized hierarchical photocatalyst. ACS Sustain. Chem. Eng. 2016, 4, 1381–1391. [Google Scholar] [CrossRef]

- Hao, H.; Lang, X. Metal sulfide photocatalysis: Visible-light-induced organic transformations. ChemCatChem 2019, 11, 1378–1393. [Google Scholar] [CrossRef]

- Halfyard, J.; Hawboldt, K. Separation of elemental sulfur from hydrometallurgical residue: A review. Hydrometallurgy 2011, 109, 80–89. [Google Scholar] [CrossRef]

- Pant, D.; Joshi, D.; Upreti, M.K.; Kotnala, R.K. Chemical and biological extraction of metals present in e waste: A hybrid technology. Waste Manag. 2012, 32, 979–990. [Google Scholar] [CrossRef] [PubMed]

- Pham, V.A.; Ting, Y.P. Gold bioleaching of electronic waste by cyanogenic bacteria and its enhancement with bio-oxidation. Adv. Mater. Res. 2009, 71, 661–664. [Google Scholar] [CrossRef]

- Suzuki, I. Microbial leaching of metals from sulfide minerals. Biotechnol. Adv. 2001, 19, 119–132. [Google Scholar] [CrossRef]

- Xu, Y.; Huang, S.; Xie, M.; Li, Y.; Jing, L.; Xu, H.; Zhang, Q.; Li, H. Core–shell magnetic Ag/AgCl@Fe2O3 photocatalysts with enhanced photoactivity for eliminating bisphenol A and microbial contamination. New J. Chem. 2016, 40, 3413–3422. [Google Scholar] [CrossRef]

- Yang, J.; Chen, H.; Gao, J.; Yan, T.; Zhou, F.; Cui, S.; Bi, W. Synthesis of Fe3O4 /g-C3N4 nanocomposites and their application in the photodegradation of 2,4,6-trichlorophenol under visible light. Mater. Lett. 2016, 164, 183–189. [Google Scholar] [CrossRef]

- Zhang, D.; Pu, X.; Du, K.; Yu, Y.M.; Shim, J.J.; Cai, P.; Kim, S.I.; Seo, H.J. Combustion synthesis of magnetic Ag/NiFe2O4 composites with enhanced visible-light photocatalytic properties. Sep. Purif. Technol. 2014, 137, 82–85. [Google Scholar] [CrossRef]

- Li, J.; Liu, Z.; Zhu, Z. Enhanced photocatalytic activity in ZnFe2O4–ZnO–Ag3PO4 hollow nanospheres through the cascadal electron transfer with magnetical separation. J. Alloys Compd. 2015, 636, 229–233. [Google Scholar] [CrossRef]

- Attarilar, S.; Djavanroodi, F.; Ebrahimi, M.; Al-Fadhalah, K.J.; Wang, L.; Mozafari, M. Hierarchical microstructure tailoring of pure titanium for enhancing cellular response at tissue-implant interface. J. Biomed. Nanotechnol. 2021, 17, 115–130. [Google Scholar] [CrossRef] [PubMed]

- Dutta, V.; Sharma, S.; Raizada, P.; Hosseini-Bandegharaei, A.; Gupta, V.K.; Singh, P. Review on augmentation in photocatalytic activity of CoFe2O4 via heterojunction formation for photocatalysis of organic pollutants in water. J. Saudi Chem. Soc. 2019, 23, 1119–1136. [Google Scholar] [CrossRef]

- Xi, G.; Li, Y.; Liu, Y. Study on preparation of manganese–zinc ferrites using spent Zn–Mn batteries. Mater. Lett. 2004, 58, 1164–1167. [Google Scholar] [CrossRef]

- Morais, V.S.; Barrada, R.V.; Moura, M.N.; Almeida, J.R.; Moreira, T.F.M.; Gonçalves, G.R.; Ferreira, S.A.D.; Lelis, M.F.F.; Freitas, M.B.J.G. Synthesis of manganese ferrite from spent Zn–MnO2 batteries and its application as a catalyst in heterogeneous photo-Fenton processes. J. Environ. Chem. Eng. 2020, 8, 103716. [Google Scholar] [CrossRef]

- Peng, C.; Bai, B.; Chen, Y. Study on the preparation of Mn–Zn soft magnetic ferrite powders from waste Zn–Mn dry batteries. Waste Manag. 2008, 28, 326–332. [Google Scholar] [CrossRef]

- Mylarappa, M.; Venkata Lakshmi, V.; Vishnu Mahesh, K.R.; Nagaswarupa, H.P.; Raghavendra, N. Recovery of Mn-Zn ferrite from waste batteries and development of rGO/Mn-Zn ferrite nanocomposite for water purification. Mater. Today Proc. 2019, 9, 256–265. [Google Scholar] [CrossRef]

- Habibi, M.H.; Talebian, N.; Choi, J.-H. Characterization and photocatalytic activity of nanostructured indium tin oxide thin-film electrode for azo-dye degradation. Thin Solid Films 2006, 515, 1461–1469. [Google Scholar] [CrossRef]

- Yu, Z.; Perera, I.R.; Daeneke, T.; Makuta, S.; Tachibana, Y.; Jasieniak, J.J.; Mishra, A.; Bäuerle, P.; Spiccia, L.; Bach, U. Indium tin oxide as a semiconductor material in efficient p-type dye-sensitized solar cells. NPG Asia Mater. 2016, 8, e305. [Google Scholar] [CrossRef]

- Betz, U.; Kharrazi Olsson, M.; Marthy, J.; Escolá, M.F.; Atamny, F. Thin films engineering of indium tin oxide: Large area flat panel displays application. Surf. Coat. Technol. 2006, 200, 5751–5759. [Google Scholar] [CrossRef]

- Luff, B.J.; Wilkinson, J.S.; Perrone, G. Indium tin oxide overlayered waveguides for sensor applications. Appl. Opt. 1997, 36, 7066. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- KInoue, K.; Nishiura, M.; Kawakita, H.; Ohto, K.; Harada, H. Recovery of indium from spent panel of liquid crystal display panels. Kagaku Kogaku Ronbunshu 2008, 34, 282–286. [Google Scholar] [CrossRef]

- Zhang, K.; Wu, Y.; Wang, W.; Li, B.; Zhang, Y.; Zuo, T. Recycling indium from waste LCDs: A review. Resour. Conserv. Recycl. 2015, 104, 276–290. [Google Scholar] [CrossRef]

- Wang, S.; He, Y.; Zhang, T.; Zhang, G. Recovery of valuable components from waste LCD panel through a dry physical method. Waste Manag. 2017, 64, 255–262. [Google Scholar] [CrossRef]

- Li, J.; Gao, S.; Duan, H.; Liu, L. Recovery of valuable materials from waste liquid crystal display panel. Waste Manag. 2009, 29, 2033–2039. [Google Scholar] [CrossRef]

- Hsieh, S.-J.; Chen, C.-C.; Say, W.C. Process for recovery of indium from ITO scraps and metallurgic microstructures. Mater. Sci. Eng. B 2009, 158, 82–87. [Google Scholar] [CrossRef]

- Park, K.-S.; Sato, W.; Grause, G.; Kameda, T.; Yoshioka, T. Recovery of indium from In2O3 and liquid crystal display powder via a chloride volatilization process using polyvinyl chloride. Thermochim. Acta 2009, 493, 105–108. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, B.; Chen, Y.; Xu, Z. Energy and valuable resource recovery from waste liquid crystal display panels by an environment-friendly technological process: Pyrolysis of liquid crystals and preparation of indium product. J. Clean. Prod. 2017, 162, 141–152. [Google Scholar] [CrossRef]

- Molaei, M.J. Carbon quantum dots and their biomedical and therapeutic applications: A review. RSC Adv. 2019, 9, 6460–6481. [Google Scholar] [CrossRef]

- Zhang, Z.; Zheng, T.; Li, X.; Xu, J.; Zeng, H. Progress of carbon quantum dots in photocatalysis applications. Part. Part. Syst. Charact. 2016, 33, 457–472. [Google Scholar] [CrossRef]

- Wang, R.; Lu, K.-Q.; Tang, Z.-R.; Xu, Y.-J. Recent progress in carbon quantum dots: Synthesis, properties and applications in photocatalysis. J. Mater. Chem. A 2017, 5, 3717–3734. [Google Scholar] [CrossRef]

- Abbas, A.; Mariana, L.T.; Phan, A.N. Biomass-waste derived graphene quantum dots and their applications. Carbon 2018, 140, 77–99. [Google Scholar] [CrossRef] [Green Version]

- PDevi, P.; Hipp, K.N.; Thakur, A.; Lai, R.Y. Waste to wealth translation of e-waste to plasmonic nanostructures for surface-enhanced Raman scattering. Appl. Nanosci. 2020, 10, 1615–1623. [Google Scholar] [CrossRef]

- Babar, S.; Gavade, N.; Shinde, H.; Gore, A.; Mahajan, P.; Lee, K.H.; Bhuse, V.; Garadkar, K. An innovative transformation of waste toner powder into magnetic g-C3N4-Fe2O3 photocatalyst: Sustainable e-waste management. J. Environ. Chem. Eng. 2019, 7, 103041. [Google Scholar] [CrossRef]

- Babar, S.; Gavade, N.; Shinde, H.; Mahajan, P.; Lee, K.H.; Mane, N.; Deshmukh, A.; Garadkar, K.; Bhuse, V. Evolution of waste iron rust into magnetically separable g-C3N4 –Fe2O3 photocatalyst: An efficient and economical waste management approach. ACS Appl. Nano Mater. 2018, 1, 4682–4694. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, J.; Zhang, M.; Wang, X. Polycondensation of thiourea into carbon nitride semiconductors as visible light photocatalysts. J. Mater. Chem. 2012, 22, 8083. [Google Scholar] [CrossRef]

- Shanmugam, M.; Alsalme, A.; Alghamdi, A.; Jayavel, R. Enhanced photocatalytic performance of the graphene-V2O5 nanocomposite in the degradation of methylene blue dye under direct sunlight. ACS Appl. Mater. Interfaces 2015, 7, 14905–14911. [Google Scholar] [CrossRef]

- Mohan, H.; Lim, J.-M.; Lee, S.-W.; Jang, J.S.; Park, Y.-J.; Seralathan, K.-K.; Oh, B.-T. Enhanced visible light photocatalysis with e-waste-based V2O5/zinc–ferrite: BTEX degradation and mechanism. J. Chem. Technol. Biotechnol. 2020, 95, 2842–2852. [Google Scholar] [CrossRef]

- Nekouei, R.K.; Pahlevani, F.; Mayyas, M.; Maroufi, S.; Sahajwalla, V. Direct transformation of waste printed circuit boards into high surface area t-SnO2 for photocatalytic dye degradation. J. Environ. Chem. Eng. 2019, 7, 103133. [Google Scholar] [CrossRef]

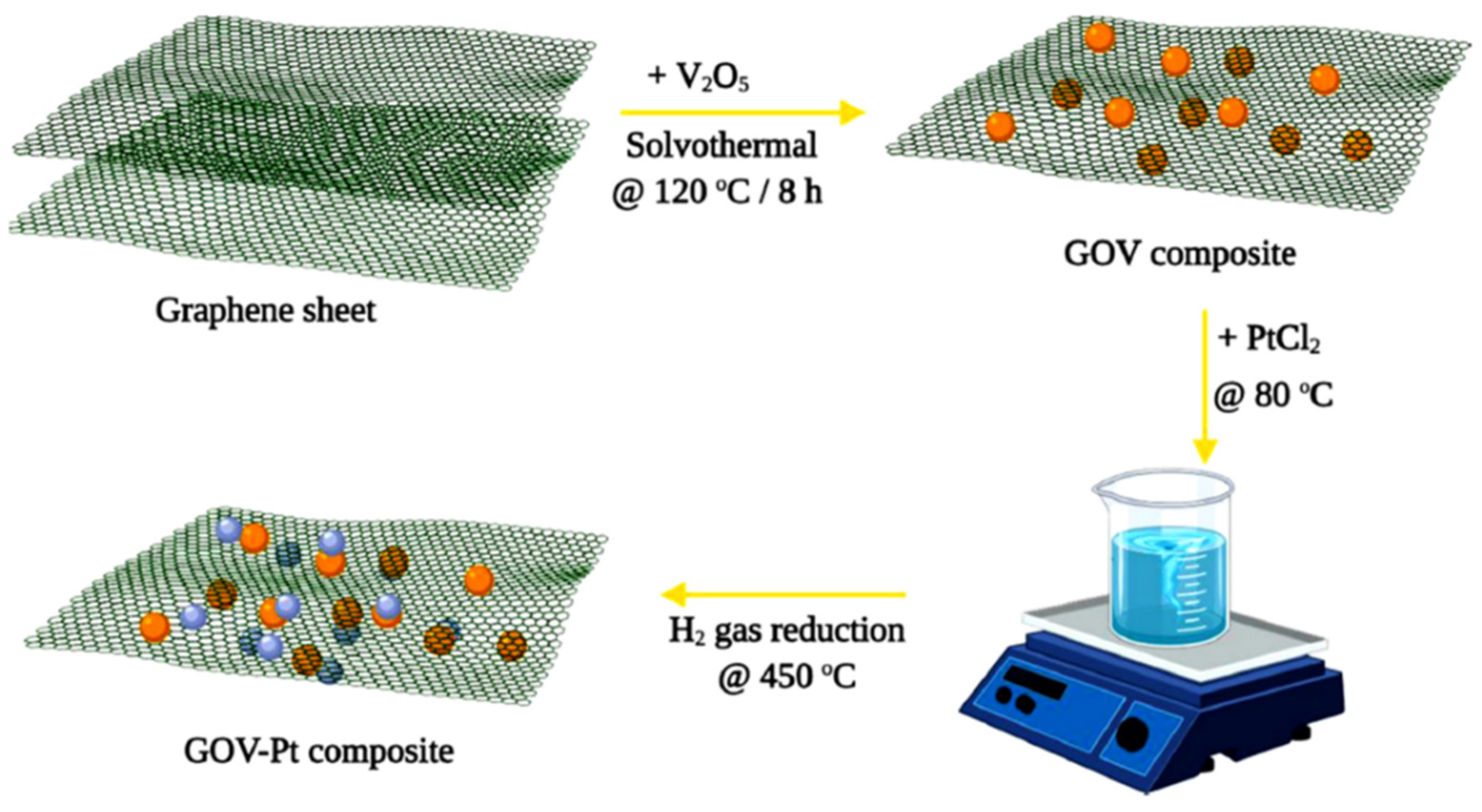

- Mohan, H.; Ramalingam, V.; Lim, J.-M.; Lee, S.-W.; Kim, J.; Lee, J.-H.; Park, Y.-J.; Seralathan, K.-K.; Oh, B.-T. E-waste based graphene oxide/V2O5/Pt ternary composite: Enhanced visible light driven photocatalyst for anti-microbial and anti-cancer activity. Colloids Surf. A Physicochem. Eng. Asp. 2020, 607, 125469. [Google Scholar] [CrossRef]

- HMohan, H.; Selvaraj, D.; Kuppusamy, S.; Venkatachalam, J.; Park, Y.; Seralathan, K.; Oh, B. E-waste based V2O5 /RGO/Pt nanocomposite for photocatalytic degradation of oxytetracycline. Environ. Prog. Sustain. Energy 2019, 38, 13123. [Google Scholar] [CrossRef]

- Liou, T.-H.; Lai, B.-C. Utilization of e-waste as a silica source for the synthesis of the catalyst support MCM-48 and highly enhanced photocatalytic activity of supported titania nanoparticles. Appl. Catal. B Environ. 2012, 115, 138–148. [Google Scholar] [CrossRef]

- Cao, Y.; Niu, B.; Sun, H.; Xu, Z. Synthesizing a high value-added composite photocatalyst using waste capacitors combined with PANI by a mechanical chemistry method. Sustain. Energy Fuels 2021, 5, 2916–2926. [Google Scholar] [CrossRef]

- Polyakov, E.G.; Sibilev, A.S. Recycling rare-earth-metal wastes by pyrometallurgical methods. Metallurgist 2015, 59, 368–373. [Google Scholar] [CrossRef]

- Zhou, M.; Li, B.; Li, J.; Xu, Z. Pyrometallurgical technology in the recycling of a spent lithium ion battery: Evolution and the challenge. ACS ES&T Eng. 2021, 1, 1369–1382. [Google Scholar] [CrossRef]

- Yao, Y.; Zhu, M.; Zhao, Z.; Tong, B.; Fan, Y.; Hua, Z. Hydrometallurgical processes for recycling spent lithium-ion batteries: A critical review. ACS Sustain. Chem. Eng. 2018, 6, 13611–13627. [Google Scholar] [CrossRef]

- Jain, N.; Sharma, D.K. Biohydrometallurgy for nonsulfidic minerals—A review. Geomicrobiol. J. 2004, 21, 135–144. [Google Scholar] [CrossRef]

- Li, Z.; Diaz, L.A.; Yang, Z.; Jin, H.; Lister, T.E.; Vahidi, E.; Zhao, F. Comparative life cycle analysis for value recovery of precious metals and rare earth elements from electronic waste. Resour. Conserv. Recycl. 2019, 149, 20–30. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, S.; Liu, B.; Zheng, H.; Chang, C.; Ekberg, C. Recovery of precious metals from electronic waste and spent catalysts: A review. Resour. Conserv. Recycl. 2019, 141, 284–298. [Google Scholar] [CrossRef]

- Masilela, M.; Ndlovu, S. Extraction of Ag and Au from chloride electronic waste leach solutions using ionic liquids. J. Environ. Chem. Eng. 2019, 7, 102810. [Google Scholar] [CrossRef]

- Kim, E.; Kim, M.; Lee, J.; Pandey, B.D. Selective recovery of gold from waste mobile phone PCBs by hydrometallurgical process. J. Hazard. Mater. 2011, 198, 206–215. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, S. Bioleaching of electronic waste using extreme acidophiles. In Electronic Waste Management and Treatment Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 153–174. [Google Scholar] [CrossRef]

- Bizzo, W.; Figueiredo, R.; de Andrade, V. Characterization of printed circuit boards for metal and energy recovery after milling and mechanical separation. Materials 2014, 7, 4555–4566. [Google Scholar] [CrossRef] [PubMed]

- Mmereki, D.; Li, B.; Baldwin, A.; Hong, L. The generation, composition, collection, treatment and disposal system, and impact of e-waste. In E-Waste in Transition—From Pollution to Resource; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Xu, Z. A review of current progress of supercritical fluid technologies for e-waste treatment. J. Clean. Prod. 2019, 227, 794–809. [Google Scholar] [CrossRef]

- Fayaz, S.M.; Abdoli, M.A.; Baghdadi, M.; Karbasi, A. Ag removal from e-waste using supercritical fluid: Improving efficiency and selectivity. Int. J. Environ. Stud. 2021, 78, 459–473. [Google Scholar] [CrossRef]

- Preetam, A.; Mishra, S.; Naik, S.N.; Pant, K.K.; Kumar, V. A sustainable approach for material and metal recovery from e-waste using subcritical to supercritical methanol. Waste Manag. 2022, 145, 29–37. [Google Scholar] [CrossRef]

| E-Waste | Recovered Material | Method | Recovery Rate (%) | Ref. |

|---|---|---|---|---|

| spent Zn-MnO2 alkaline batteries | ZnO | liquid–liquid extraction | 98 | [39] |

| spent alkaline batteries | ZnO | one-pot chemistry | Up to 98 | [40] |

| lithium-ion batteries | lithium | acid leaching | 99.4 | [41] |

| spent rechargeable batteries | Co, Mn, Cd | hydrometallurgical, liquid–liquid extraction | 100 | [42] |

| spent rechargeable batteries | Al | hydrometallurgical, liquid–liquid extraction | 67 | [42] |

| spent rechargeable batteries | Cu, Ni | hydrometallurgical, liquid–liquid extraction | 95 | [42] |

| PCBs | Al, Zn, Cu | biohydrometallurgy | 77, 86, 97 | [43] |

| PCBs | Cu, Al, Ni, Zn | biohydrometallurgy | 86.2, 100, 100, 100 | [44] |

| PCBs | Cu, Ni | pyrometallurgy coupling bioleaching | 49, 100 | [45] |

| PCBs | Cu | high temperature pyrolysis | 91.7 | [46] |

| spent Li-ion battery | cobalt ferrite | sol−gel−hydrothermal | - | [47] |

| PCBs | Cu | vacuum pyrolysis | 53–100 | [48] |

| PCBs | Cu, Pb, Sn | crushing and electrostatic separation | - | [49] |

| E-Waste | Microorganisms | Leaching Efficiency (Metal) (%) | Technique | Ref. |

|---|---|---|---|---|

| Mesophilic bacteria Autotrophs | ||||

| PCBs, scraps, e-wastes | A. ferrooxidans + A. thiooxidans | 90 (Al, Cu, Ni, Zn) | Rotary shaker, flasks | [76] |

| A. ferrooxidans | 37 (Cu) | Shake flasks | [77] | |

| Acidithiobacillus sp. + Leptospirillum sp. | 100 (Cu, Ni) | Erlenmeyer shake flasks | [78] | |

| Acidithiobacillus sp. Gallionella sp. + Leptospirillum sp. | 95 (Cu) | Shake flasks | [79] | |

| A. ferrooxidans | 98 (Cu) | Erlenmeyer shake flasks | [80] | |

| TV circuit boards | A. ferrooxidans + L. ferrooxidans + A. thiooxidans | 89 (Cu) | Erlenmeyer shake flasks | [81] |

| Heterotrophs | ||||

| PCBs, scraps, e-wastes | C. violaceum, P. fluorescens, P. plecoglossicida | 68.5 (Au) | Shake flasks | [82] |

| Waste mobile phone PCBs | C. violaceum | 13 (Au); 37 (Cu) | Shake flasks | [83] |

| C. violaceum | 11.31 (Au) | Shake flasks | [83] | |

| C. violaceum | insignificant (Au) | Conical shake flask | [84] | |

| C. violaceum | 20–30 (Au) | Shake flasks | [85] | |

| Moderately thermophilic bacteria | ||||

| Electronic scrap | S. thermosulfidooxidans + Thermoplasma acidophilum | 86 (Cu); 74 (Ni); 80 (Zn); 64 (Al) | Column bioleaching | [86] |

| S. thermosulfidooxidans + Sulfobacillus acidiphilus | 78 (Cu); 78 (Ni); 74 (Zn); 85 (Al) | Shake flasks and lab-scale column reactor | [87] | |

| S. thermosulfidooxidans + acidophilic heterotrophic bacteria | 89 (Cu); 81 (Ni); 83 (Zn); 79 (Al) | Shake flasks | [88] | |

| Fungi | ||||

| PCBs, scraps, e-wastes | A. niger + P. simplicissimum | 100 (Al, Cu, Zn, Ni) | Rotary shaker, flasks | [76] |

| Electronic scrap | P. chrysogenum | 97–98 (Cu) | One-step leaching with combined growth and leaching phases | [89] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahadoran, A.; De Lile, J.R.; Masudy-Panah, S.; Sadeghi, B.; Li, J.; Sabzalian, M.H.; Ramakrishna, S.; Liu, Q.; Cavaliere, P.; Gopinathan, A. Photocatalytic Materials Obtained from E-Waste Recycling: Review, Techniques, Critique, and Update. J. Manuf. Mater. Process. 2022, 6, 69. https://doi.org/10.3390/jmmp6040069

Bahadoran A, De Lile JR, Masudy-Panah S, Sadeghi B, Li J, Sabzalian MH, Ramakrishna S, Liu Q, Cavaliere P, Gopinathan A. Photocatalytic Materials Obtained from E-Waste Recycling: Review, Techniques, Critique, and Update. Journal of Manufacturing and Materials Processing. 2022; 6(4):69. https://doi.org/10.3390/jmmp6040069

Chicago/Turabian StyleBahadoran, Ashkan, Jeffrey Roshan De Lile, Saeid Masudy-Panah, Behzad Sadeghi, Jiaxin Li, Mohammad Hosein Sabzalian, Seeram Ramakrishna, Qinglei Liu, Pasquale Cavaliere, and Arun Gopinathan. 2022. "Photocatalytic Materials Obtained from E-Waste Recycling: Review, Techniques, Critique, and Update" Journal of Manufacturing and Materials Processing 6, no. 4: 69. https://doi.org/10.3390/jmmp6040069

APA StyleBahadoran, A., De Lile, J. R., Masudy-Panah, S., Sadeghi, B., Li, J., Sabzalian, M. H., Ramakrishna, S., Liu, Q., Cavaliere, P., & Gopinathan, A. (2022). Photocatalytic Materials Obtained from E-Waste Recycling: Review, Techniques, Critique, and Update. Journal of Manufacturing and Materials Processing, 6(4), 69. https://doi.org/10.3390/jmmp6040069