Remote Data Acquisition Using UAVs and Custom Sensor Node Technology

Abstract

1. Introduction

2. Materials and Methods

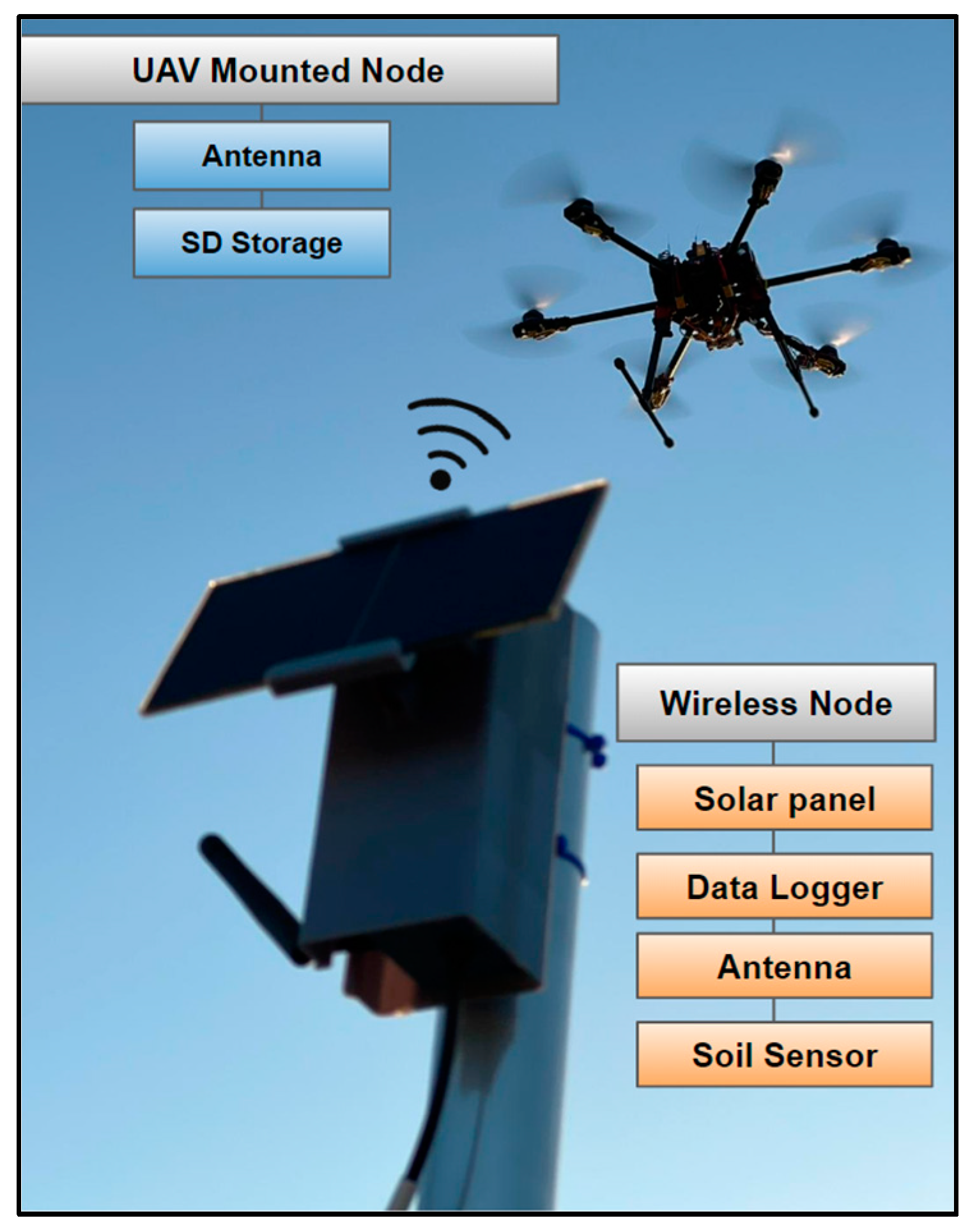

2.1. System Overview

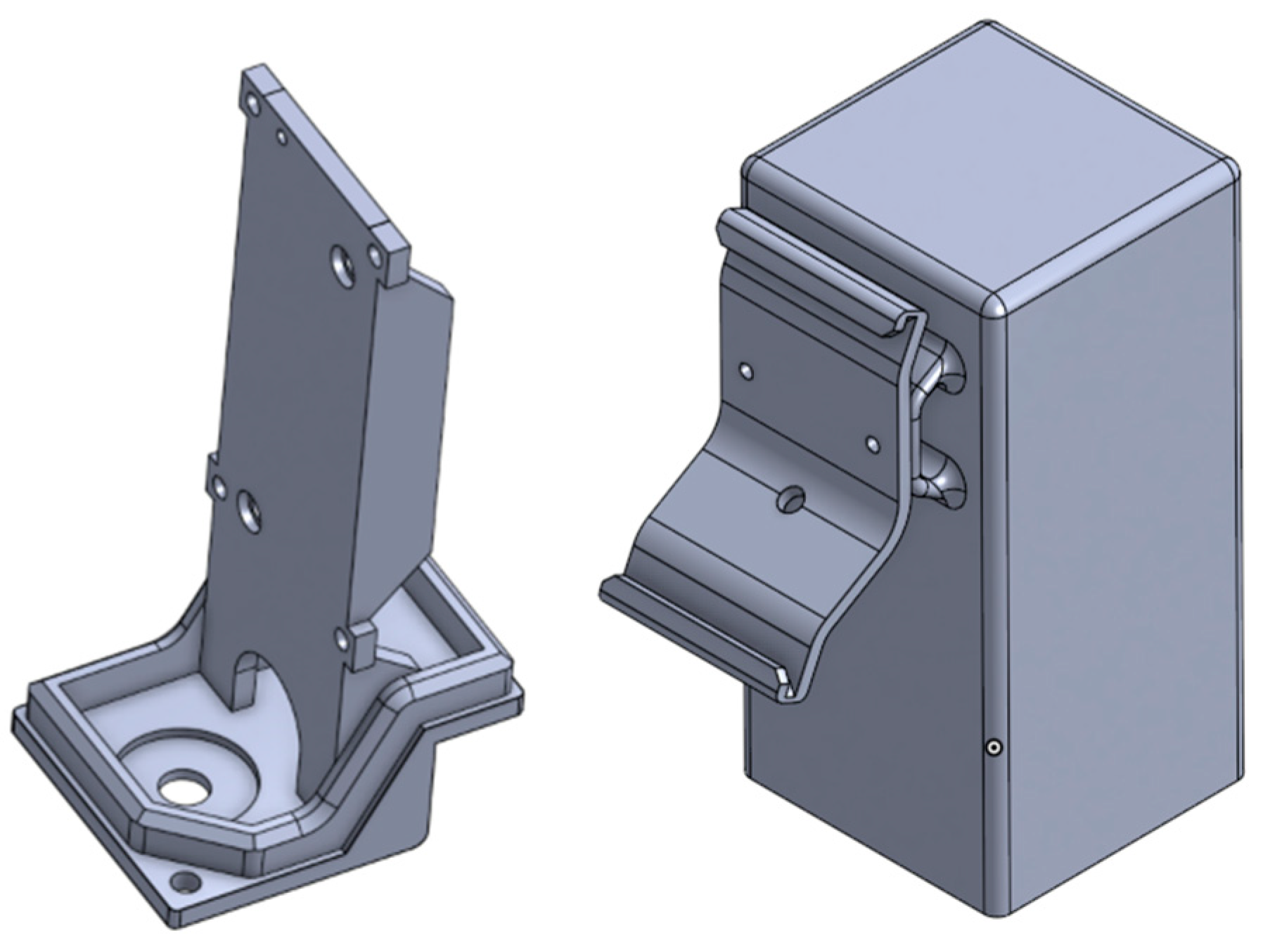

2.2. Sensor Node Design

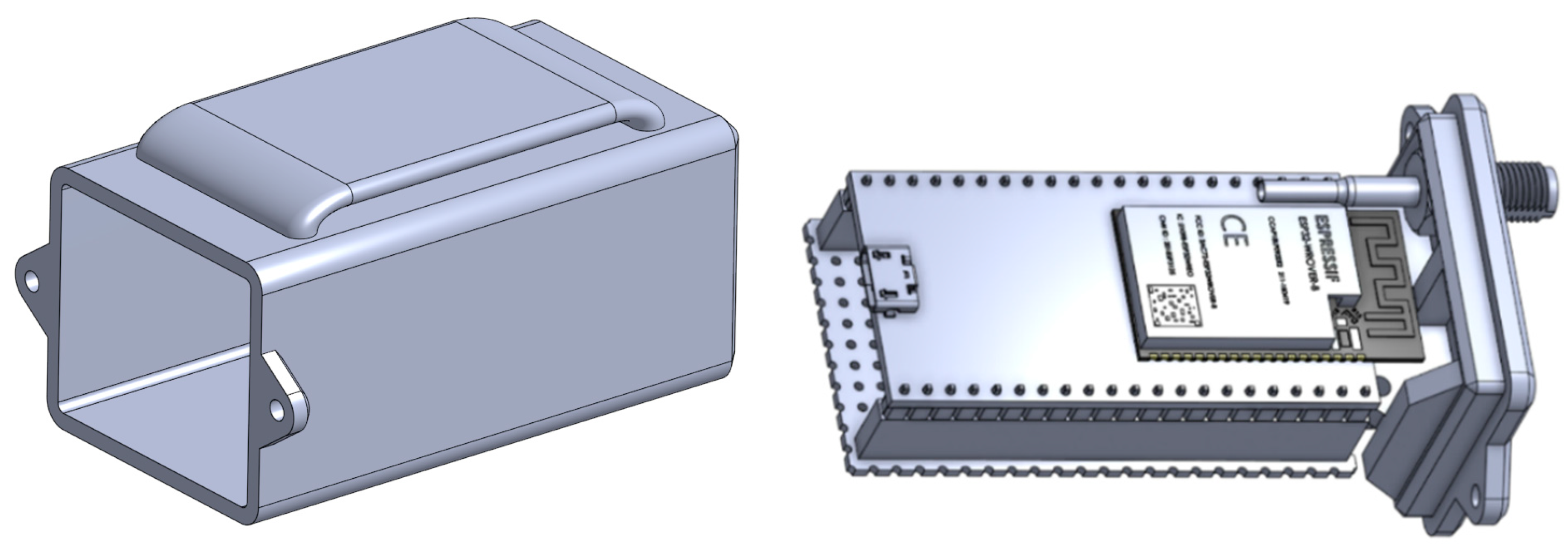

2.3. Drone Node Design

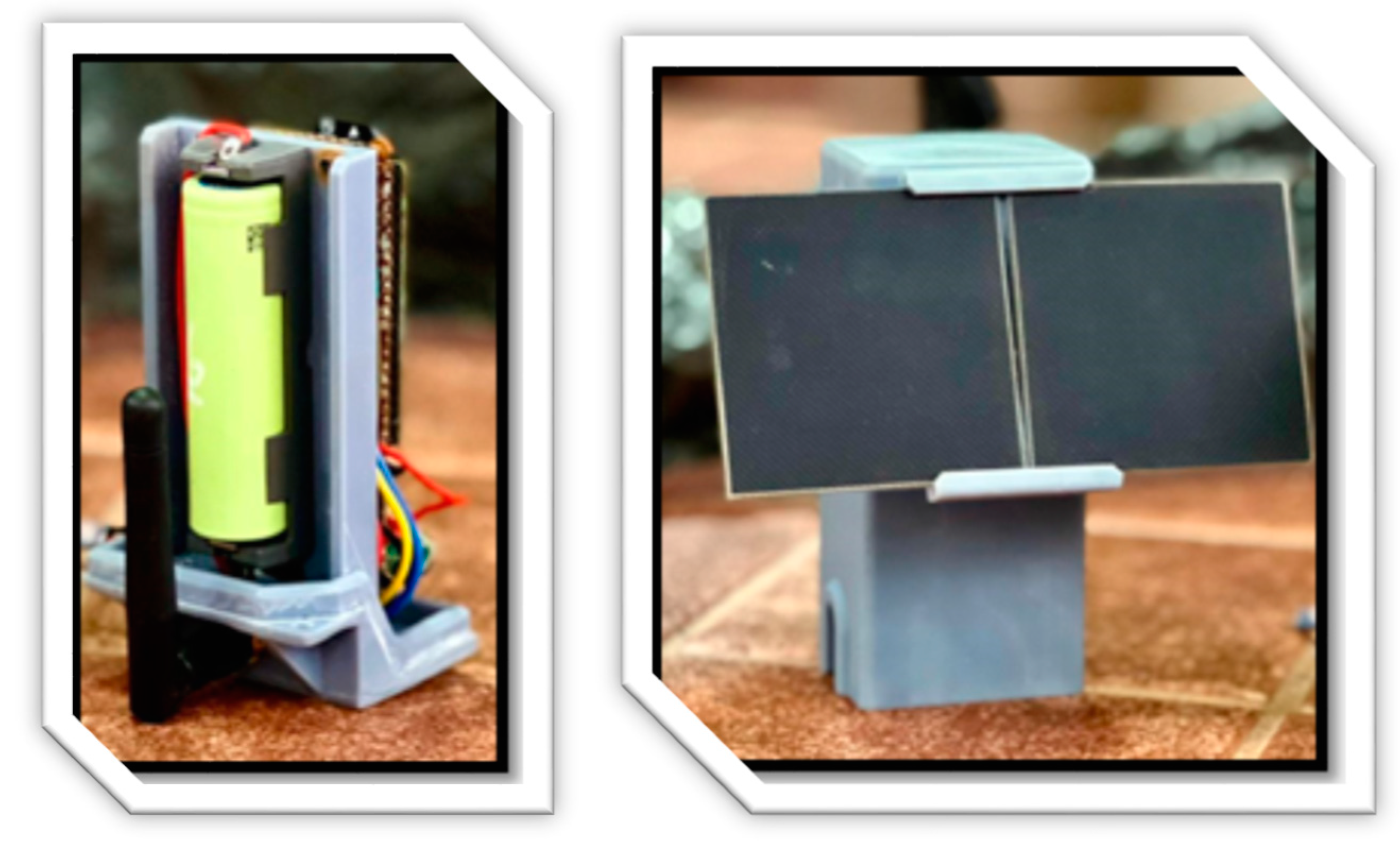

2.4. Design of Internal Components

- Microcontroller;

- Battery;

- Solar panels;

- Datalogger;

- External antenna;

- TEROS soil sensor.

- Microcontroller: An ESP32 acts as the controller for the entire system. This component was chosen due to its low-cost, low-power operation and versatility. It is often described as a “system on a chip” because of the integration of all or most components that can be found in a computer or other electronic system. The device comes integrated with Wi-Fi and Bluetooth modes. The microcontroller capabilities include an inbuilt uFL connector to allow signal processing in tandem with the external antenna. The I/O pins of the microcontroller are positioned to be broken out to the pin headers on both sides of the component. This allows for easy interfacing between the pin headers and the wire connections. The microcontroller capabilities also include the use of different “sleep modes”, which are power-saving modes that can be initiated and stopped with some simple coding. When in these sleep modes, all power that is unnecessary is cut. All information is stored in RAM, which continues to receive enough power to operate properly. The ESP32 communicates using an IEEE 802.11 b/g/n-compliant wireless communication protocol and transmits at a frequency of 2.4 GHz. The output power from the Wi-Fi module is 100 mW, which means no specific regulations due to the power output of the transmission being so low;

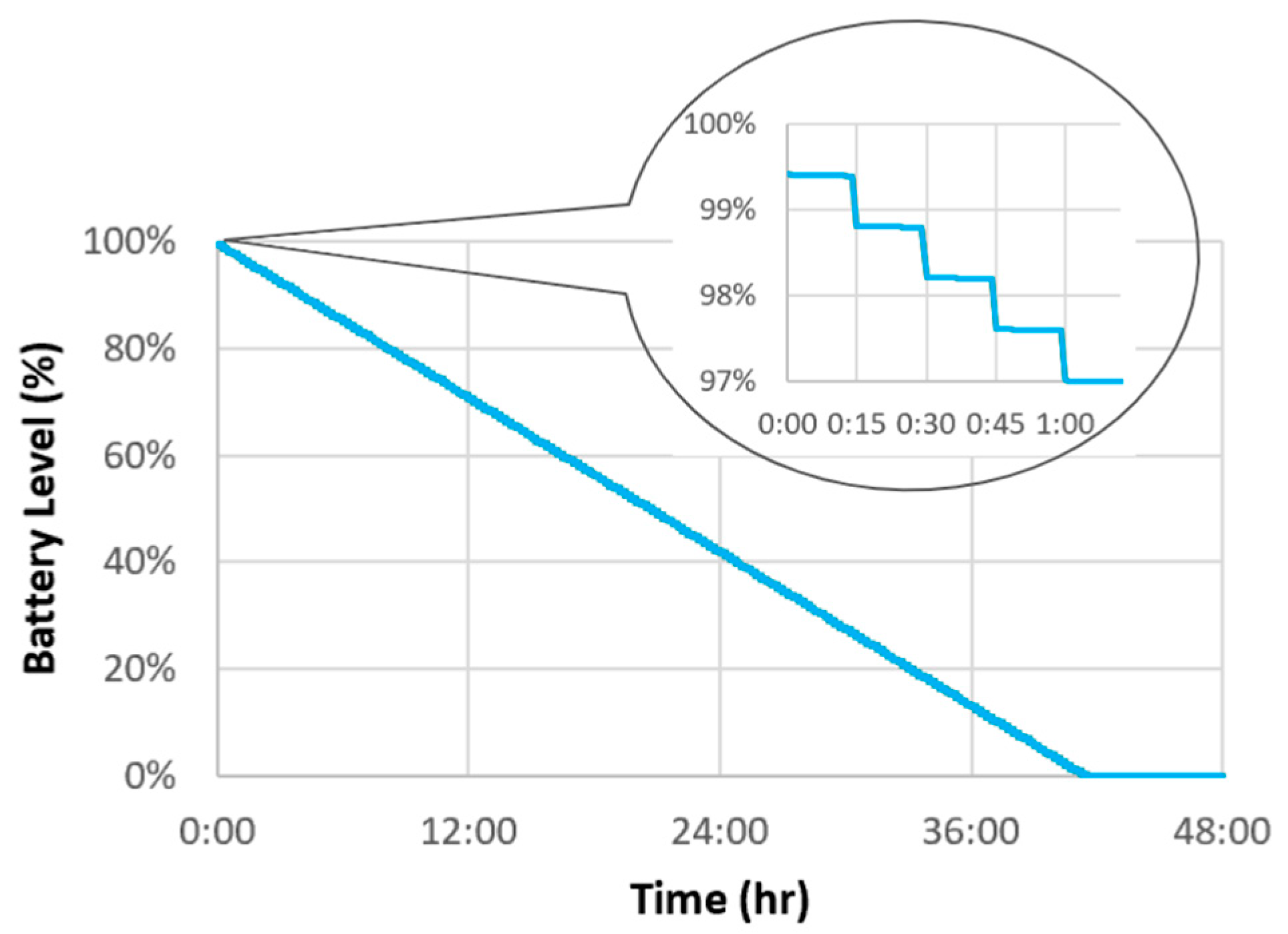

- Battery: The battery is the primary power source for the microcontroller component. It is a 3.7 V lithium-ion 2.6 Ah rechargeable battery that is wired to solar panels that act as an environmentally powered charging station in the event that the battery’s power levels become too low to run the microcontroller alone. This battery was chosen for its robust chemistry and its relatively high temperature tolerance. A battery charging circuit was added to the electronics assembly to simplify the charging of the sensor node battery and to power the rest of the electronic system. The battery charger takes 5 volts from the voltage regulator connected to the solar panels to power itself. It has two separate pins for output voltage and ground. One pair of pins is specifically for battery charging. The other two can be used for powering other components or left alone. The electronics assembly uses these pins to power the microcontroller and, by extension, the sensor node system;

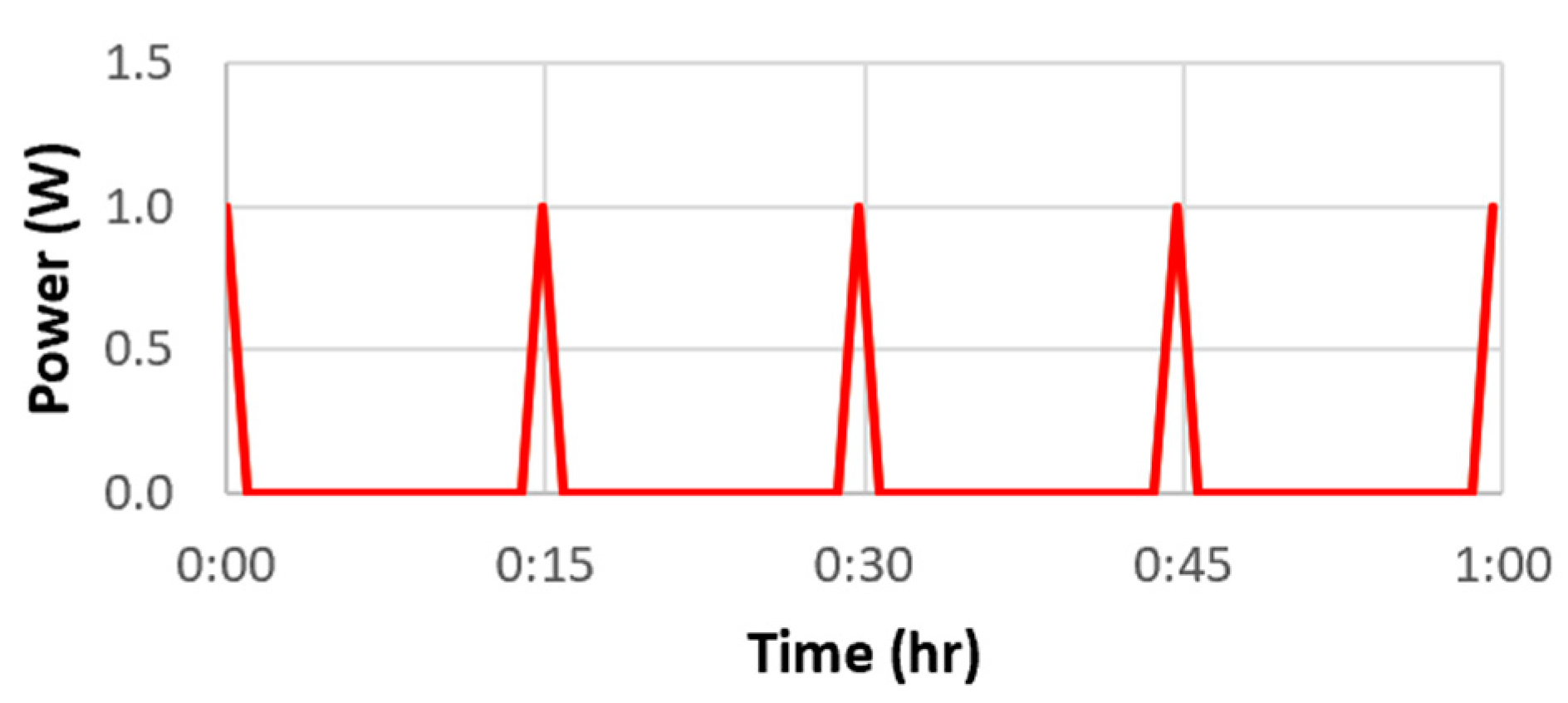

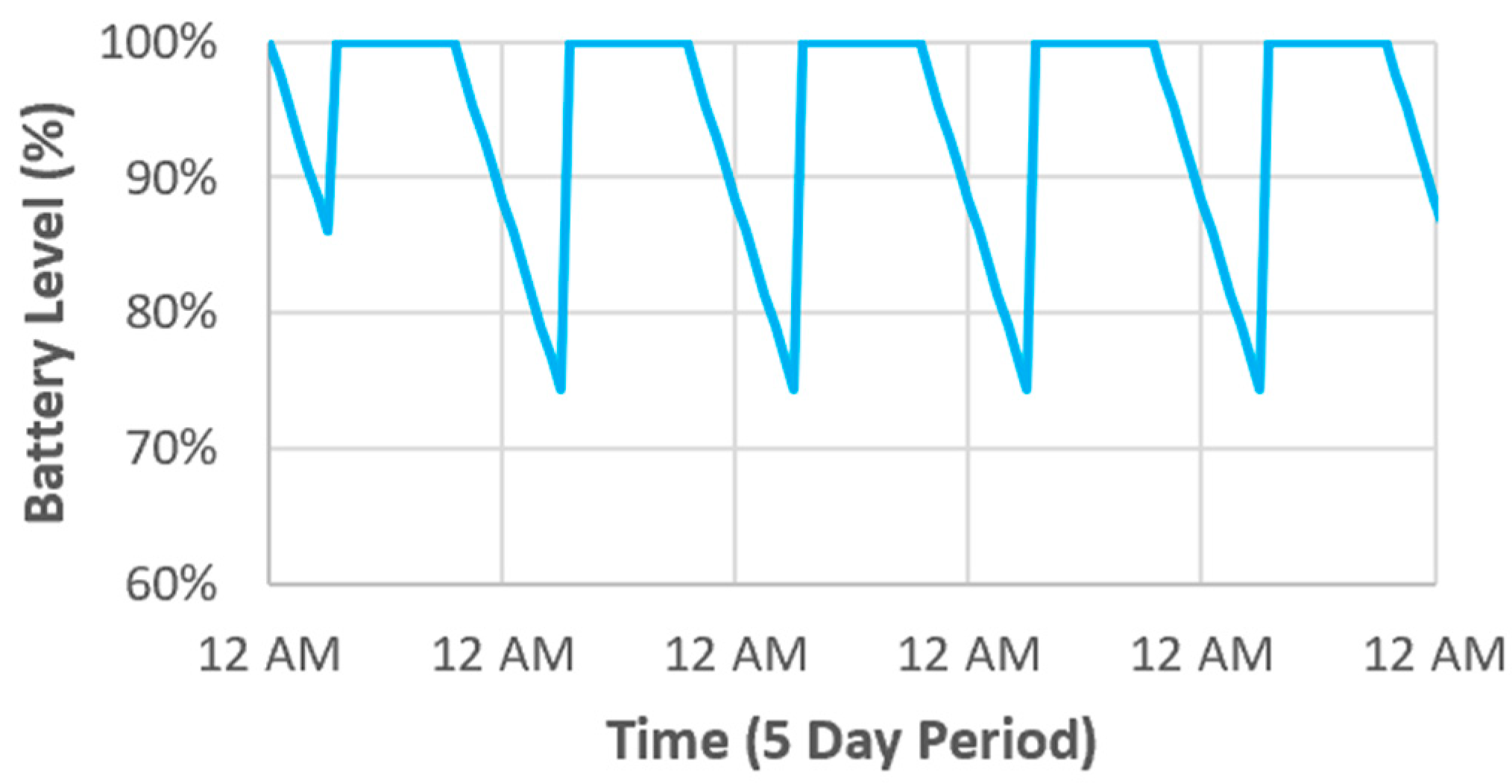

- Solar panels: Solar panels were included in the design as a way to recharge the battery and extend the lifespan of the system. It was decided to use two monocrystalline solar-cell panels connected in parallel to increase the overall amperage output, thus supplying the necessary current to charge the battery. Doing so increased the value by a factor of four in comparison to a singular solar panel. Together, the two panels generate 12 V at up to 0.1 amps, providing a total of 1.2 watts. This allows a charge to be supplied to the battery, while the battery acts as a buffer to the power requirements. A voltage regulator is used to take the voltage generated by the two solar panels and drop it down to half so that the power can be safely carried to the battery charger. However, the voltage regulator by itself cannot produce the necessary voltage downstream. Therefore, a DC/DC step-up converter is also used to guarantee the necessary voltage is delivered to downstream components. This addition proved to be an excellent decision as the lithium ions have better capacity in relation to weight but less current-producing ability. This results in more battery storage for the sensor node to utilize;

- Datalogger: This contains a coin cell battery for its power requirements and an SD card for automatic data storage. The datalogger collects data from all sensors in the sensor cable and stores them until the data are ready to be transmitted to the drone. The inner clock of the datalogger is powered by a lithium cell battery;

- External antenna: The external antenna is directly connected to the circuit board of the microcontroller. This component is used to increase the range of the datalogger so that the data can be transferred to the drone over longer distances. The antenna has excellent performance records for dual-band and omni-direction broadcasting and receiving. The component is capable of being tilted or swiveled for enhanced signal connections;

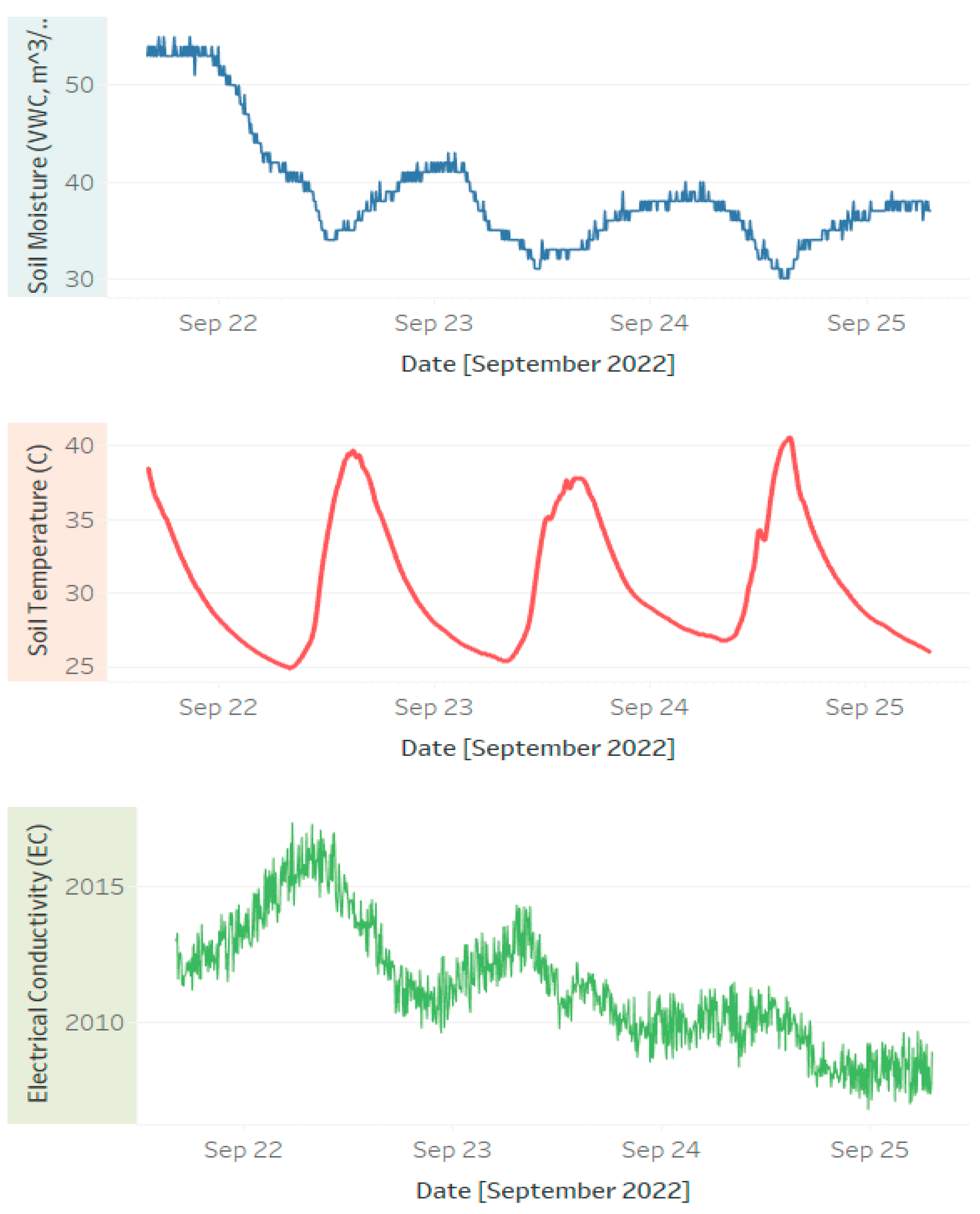

- TEROS 12 sensor: This sensor is capable of taking measurements of the soil’s moisture level, temperature, dielectric measurement frequency, and electrical conductivity. The TEROS 12 sensor has a large volume of influence for its sensor size and is less susceptible to soil variability errors compared to other sensors on the market. Its volume of influence is rated at one liter, while the sensor is only 9.4 cm long. It is designed to be rugged, dustproof, corrosion-resistant, and waterproof. The TEROS 12′s sensor prongs allow it to be easily deployed in the field. Its low power consumption, high data resolution, and factory-guarantee calibration provide increased quality and precision of data over a longer period. The sensor components of the sensor node V4 are wired directly to the datalogger. The sensor cable is programmed to wait for the system queue to start transferring data to the system’s storage component (the datalogger).

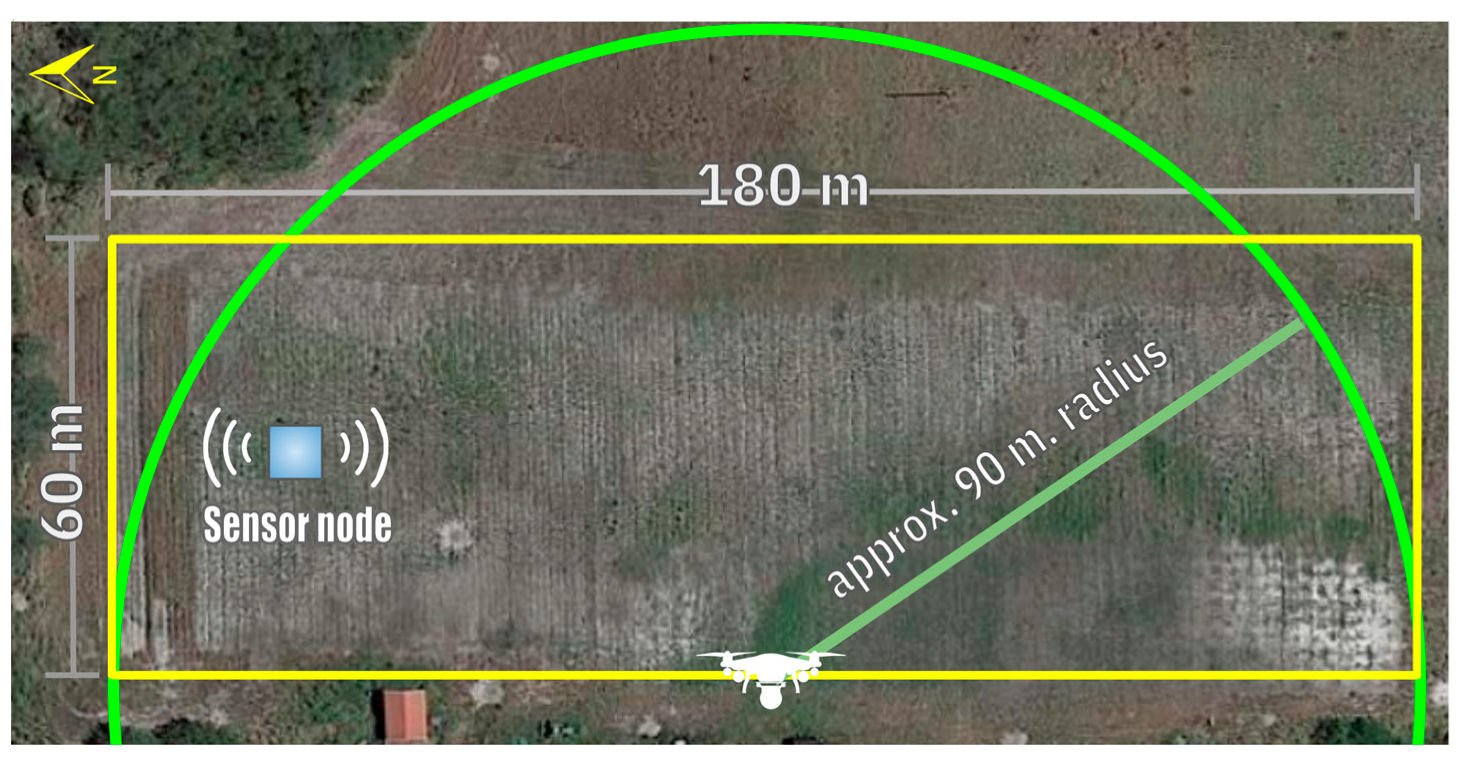

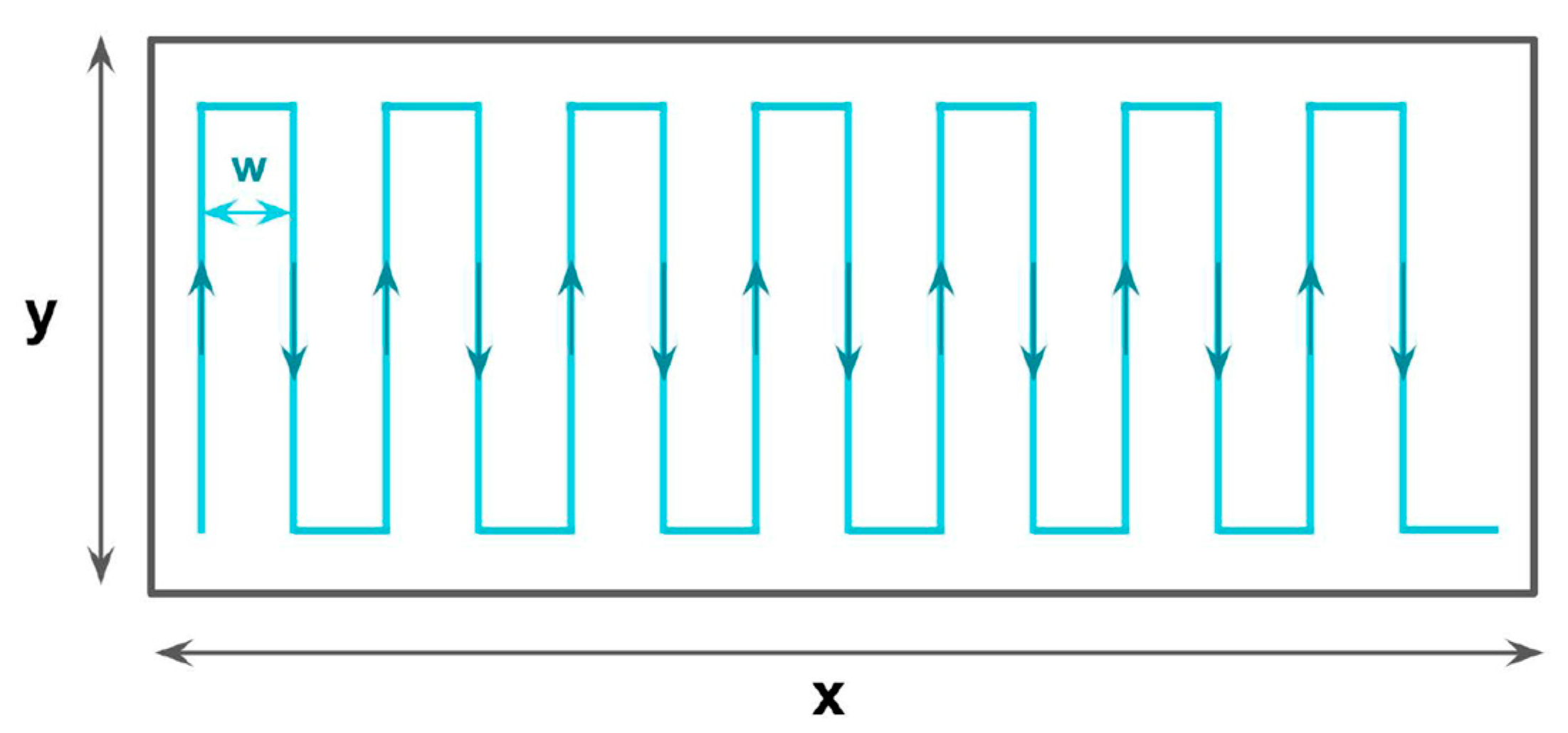

2.5. Field Operations

3. Results

3.1. Power Consumption

3.2. Communication Testing

3.3. Data Collection

4. Discussion

4.1. System Performance

4.2. Comparison with Existing Methods

| OptRx: D = (180/10) × 60 + 180 + 60 D = 1320 m | Ximes: D = (180/18) × 60 + 180 + 60 D = 840 m |

| OptRx: 1320 m/(5 m/s) = 264 s = 4.4 min | Ximes: 840 m/(5 m/s) = 168 s = 2.8 min |

5. Conclusions

5.1. Limitations and Future Work

- -

- Long-range (LoRa) modulation offers advantages over frequency-hopping spread spectrum (DSSS) protocols in terms of range;

- -

- Receiver sensitivity: LoRa receivers are highly sensitive and capable of detecting and decoding weak signals, improving range capabilities;

- -

- Power efficiency: LoRa devices operate at lower power levels, allowing for extended battery life and making them suitable for low-power, long-range communication;

- -

- Signal penetration: LoRa signals have excellent penetration capabilities, passing through obstacles such as buildings and vegetation, maintaining connectivity over greater distances.

5.2. Final Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Population Reference Bureau. 2020 World Population Data Sheet. Available online: https://www.prb.org/wp-content/uploads/2020/07/letter-booklet-2020-world-population.pdf (accessed on 1 January 2023).

- USDA. Irrigation and Water Use: Background. Online Report Based on 2007 US Agricultural Census Data. 2013. Available online: https://www.ers.usda.gov/topics/farm-practices-management/irrigation-water-use/ (accessed on 6 March 2023).

- Ford, A. Modeling the Environment, 1st ed.; Island Press: Washington, DC, USA, 1999. [Google Scholar]

- Huang, J.; Gómez-Dans, J.L.; Huang, H.; Ma, H.; Wu, Q.; Lewis, P.E.; Liang, S.; Chen, Z.; Xue, J.-H.; Wu, Y.; et al. Assimilation of remote sensing into crop growth models: Current status and perspectives. Agric. For. Meteorol. 2019, 276–277, 107609. [Google Scholar] [CrossRef]

- United States Department of Agriculture—National Agricultural Statistics Service. (August, 2021). Farm Computer Usage and Ownership. Available online: https://www.nass.usda.gov/Publications/Methodology_and_Data_Quality/Computer_Usage/index.php (accessed on 3 March 2023).

- Huang, Y.; Chen, Z.X.; Tao, Y.U.; Huang, X.Z.; Gu, X.F. Agricultural remote sensing big data: Management and applications. J. Integr. Agric. 2018, 17, 1915–1931. [Google Scholar] [CrossRef]

- Elijah, O.; Rahman, T.A.; Orikumhi, I.; Leow, C.Y.; Hindia, M.N. An Overview of Internet of Things (IoT) and Data Analytics in Agriculture: Benefits and Challenges. IEEE Internet Things J. 2018, 5, 3758–3773. [Google Scholar] [CrossRef]

- Wan, B.-F.; Zhou, Z.-W.; Xu, Y.; Zhang, H.-F. A Theoretical Proposal for a Refractive Index and Angle Sensor Based on One-Dimensional Photonic Crystals. IEEE Sens. J. 2021, 21, 331–338. [Google Scholar] [CrossRef]

- Citroni, R.; Di Paolo, F.; Livreri, P. Evaluation of an Optical Energy Harvester for SHM Applications. AEU—Int. J. Electron. Commun. 2019, 111, 152918. [Google Scholar] [CrossRef]

- Boursianis, A.D.; Papadopoulou, M.S.; Diamantoulakis, P.; Liopa-Tsakalidi, A.; Barouchas, P.; Salahas, G.; Karagiannidis, G.; Wan, S.; Goudos, S.K. Internet of Things (IoT) and Agricultural Unmanned Aerial Vehicles (UAVs) in smart farming: A comprehensive review. Internet Things 2022, 18, 100187. [Google Scholar] [CrossRef]

- Negash, L.; Kim, H.-Y.; Choi, H.-L. Emerging UAV Applications in Agriculture. In Proceedings of the 2019 7th International Conference on Robot Intelligence Technology and Applications (RiTA), Daejeon, Republic of Korea, 1–3 November 2019; pp. 254–257. [Google Scholar] [CrossRef]

- Motlagh, N.H.; Taleb, T.; Arouk, O. Low-Altitude Unmanned Aerial Vehicles-Based Internet of Things Services: Comprehensive Survey and Future Perspectives. IEEE Internet Things J. 2016, 3, 899–922. [Google Scholar] [CrossRef]

- Puri, V.; Nayyar, A. Agriculture drones: A modern breakthrough in precision agriculture. J. Stat. Manag. Syst. 2017, 20, 507–518. [Google Scholar] [CrossRef]

- Ayed, R.B.; Hanana, M. Artificial Intelligence to Improve the Food and Agriculture Sector. J. Food Qual. 2021, 2021, 5584754. [Google Scholar] [CrossRef]

- Qayyum, T.; Trabelsi, Z.; Malik, A.; Hayawi, K. Trajectory Design for UAV-Based Data Collection Using Clustering Model in Smart Farming. Sensors 2022, 22, 37. [Google Scholar] [CrossRef] [PubMed]

- Liang, H.; Gao, W.; Nguyen, J.H.; Orpilla, M.F.; Yu, W. Internet of Things Data Collection Using Unmanned Aerial Vehicles in Infrastructure Free Environments. IEEE Access 2020, 8, 3932–3944. [Google Scholar] [CrossRef]

- Tsouros, D.C.; Bibi, S.; Sarigiannidis, P.G. A Review on UAV-Based Applications for Precision Agriculture. Information 2019, 10, 349. [Google Scholar] [CrossRef]

- Rejeb, A.; Abdollahi, A.; Rejeb, K.; Treiblmaier, H. Drones in agriculture: A review and bibliometric analysis. Comput. Electron. Agric. 2022, 198, 107017. [Google Scholar] [CrossRef]

- van der Merwe, D.; Burchfield, D.R.; Witt, T.D.; Price, K.P.; Sharda, A. Chapter One—Drones in agriculture. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: Cambridge, MA, USA, 2020; Volume 162, pp. 1–30. ISSN 0065-2113. ISBN 9780128207673. [Google Scholar] [CrossRef]

- Su, J.; Zhu, X.; Li, S.; Chen, W.-H. AI meets UAVs: A survey on AI empowered UAV perception systems for precision agriculture. Neurocomputing 2023, 518, 242–270. [Google Scholar] [CrossRef]

- Singh, P.K.; Sharma, A. An intelligent WSN-UAV-based IoT framework for precision agriculture application. Comput. Electr. Eng. 2022, 100, 107912. [Google Scholar] [CrossRef]

- Ximea. (n.d.). Hyperspectral Cameras with USB3. XIMEA. Available online: https://www.ximea.com/en/usb3-vision-camera/hyperspectral-usb3-cameras-mini (accessed on 13 May 2023).

- Ristorto, G.; Mazzetto, F.; Guglieri, G.; Quagliotti, F. Monitoring performances and cost estimation of multirotor Unmanned Aerial Systems in precision farming. In Proceedings of the 2015 International Conference on Unmanned Aircraft Systems, Denver, CO, USA, 9–12 June 2015; pp. 502–509. [Google Scholar] [CrossRef]

- CREST Center for Sustainable Water Use (CREST-SWU). Award Abstract # 1914745. Available online: https://www.nsf.gov/awardsearch/showAward?AWD_ID=1914745 (accessed on 1 January 2023).

| Proposed System | OptRx | Ximea | |

|---|---|---|---|

| Dist. traveled | 190 m | 1320 m | 840 m |

| Flight speed | 15 m/s | 5.0 m/s | 5.0 m/s |

| Time elapsed | 12.7 s | 4.4 min | 2.8 min |

| Consumption | ~1.0 W | <1.0 W | 1.0 W–1.8 W |

| Power usage | ~1.22 Wh | ~25.34 Wh | ~16.13 Wh |

| Proposed System | OptRx | Ximea | HOBOnet | |

|---|---|---|---|---|

| Unique advantages |

|

|

|

|

| Limitations |

|

|

|

|

| Ground sensors | Yes | No | No | Yes |

| Solar-powered | Yes | No | No | Yes |

| Data collection | Fast | Slow | Slow | Fast |

| Data resolution | Low | High | High | Low |

| Data accuracy | High | Indirect | Indirect | High |

| Data latency | Medium | High | High | Low |

| Energy efficiency | High | Low | Low | High |

| Cost * | USD 55 receiver +(USD 100–430)/node | ~USD 2500 | ~USD 11,000 | ~USD 870.00/logger + USD 480/sensor |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bernier-Vega, A.; Barton, K.; Olson, I.; Rodriguez, J.; Cantu, G.; Ozcelik, S. Remote Data Acquisition Using UAVs and Custom Sensor Node Technology. Drones 2023, 7, 340. https://doi.org/10.3390/drones7060340

Bernier-Vega A, Barton K, Olson I, Rodriguez J, Cantu G, Ozcelik S. Remote Data Acquisition Using UAVs and Custom Sensor Node Technology. Drones. 2023; 7(6):340. https://doi.org/10.3390/drones7060340

Chicago/Turabian StyleBernier-Vega, Agustin, Kyle Barton, Isaac Olson, Juan Rodriguez, Genesis Cantu, and Selahattin Ozcelik. 2023. "Remote Data Acquisition Using UAVs and Custom Sensor Node Technology" Drones 7, no. 6: 340. https://doi.org/10.3390/drones7060340

APA StyleBernier-Vega, A., Barton, K., Olson, I., Rodriguez, J., Cantu, G., & Ozcelik, S. (2023). Remote Data Acquisition Using UAVs and Custom Sensor Node Technology. Drones, 7(6), 340. https://doi.org/10.3390/drones7060340