Design of Non-Conventional Flight Control Systems for Bioinspired Micro Air Vehicles

Abstract

:1. Introduction

2. Theoretical Background

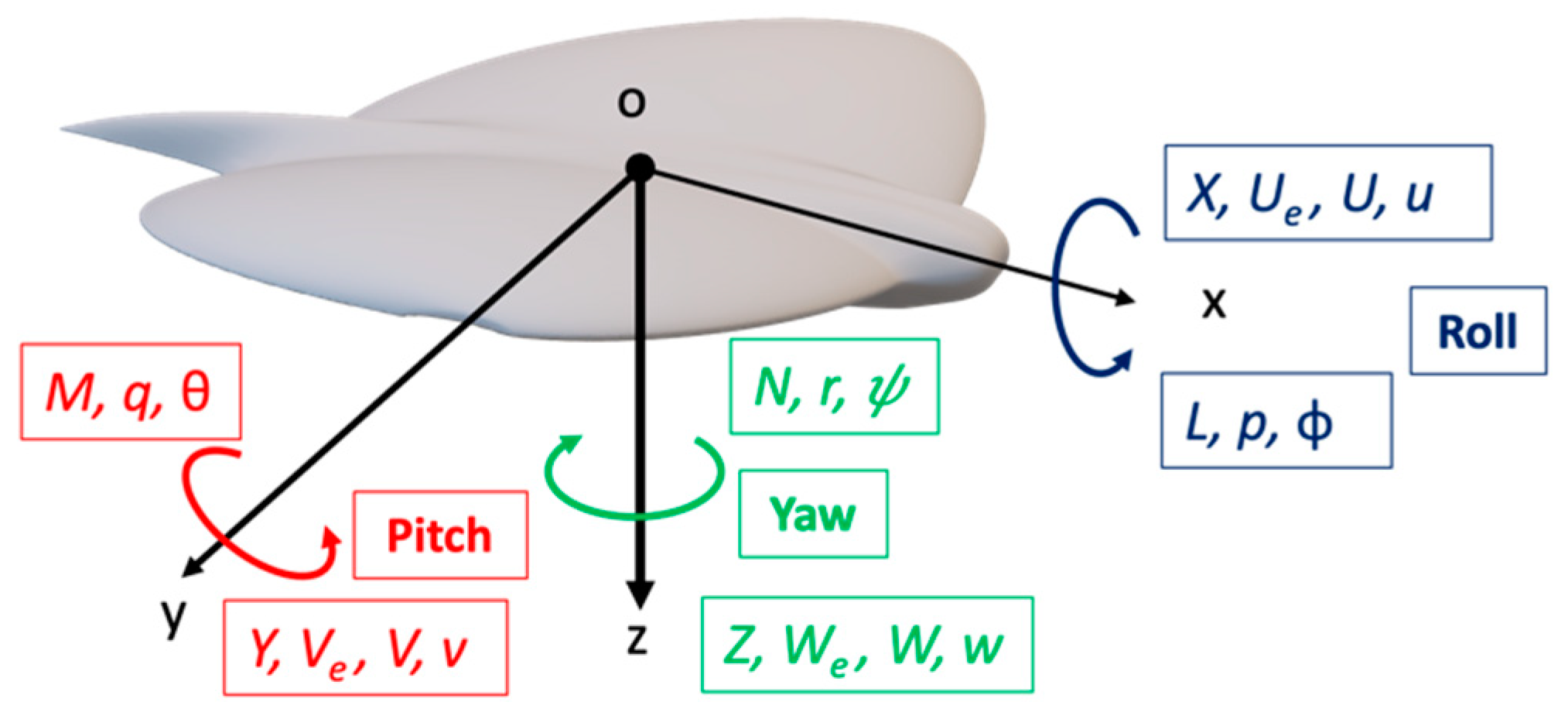

2.1. Stability and Control Properties of the Vehicles

- In both cases, the flight regime must be considered, since the low values of characteristic length (c) and speed lead to a Reynolds number much lower than that of conventional flight regimes. Drones develop Re values close to 105 under their typical flight conditions (U < 20 m/s) [11], compared to a value of Re = 1.1 × 108 for a typical commercial aircraft.

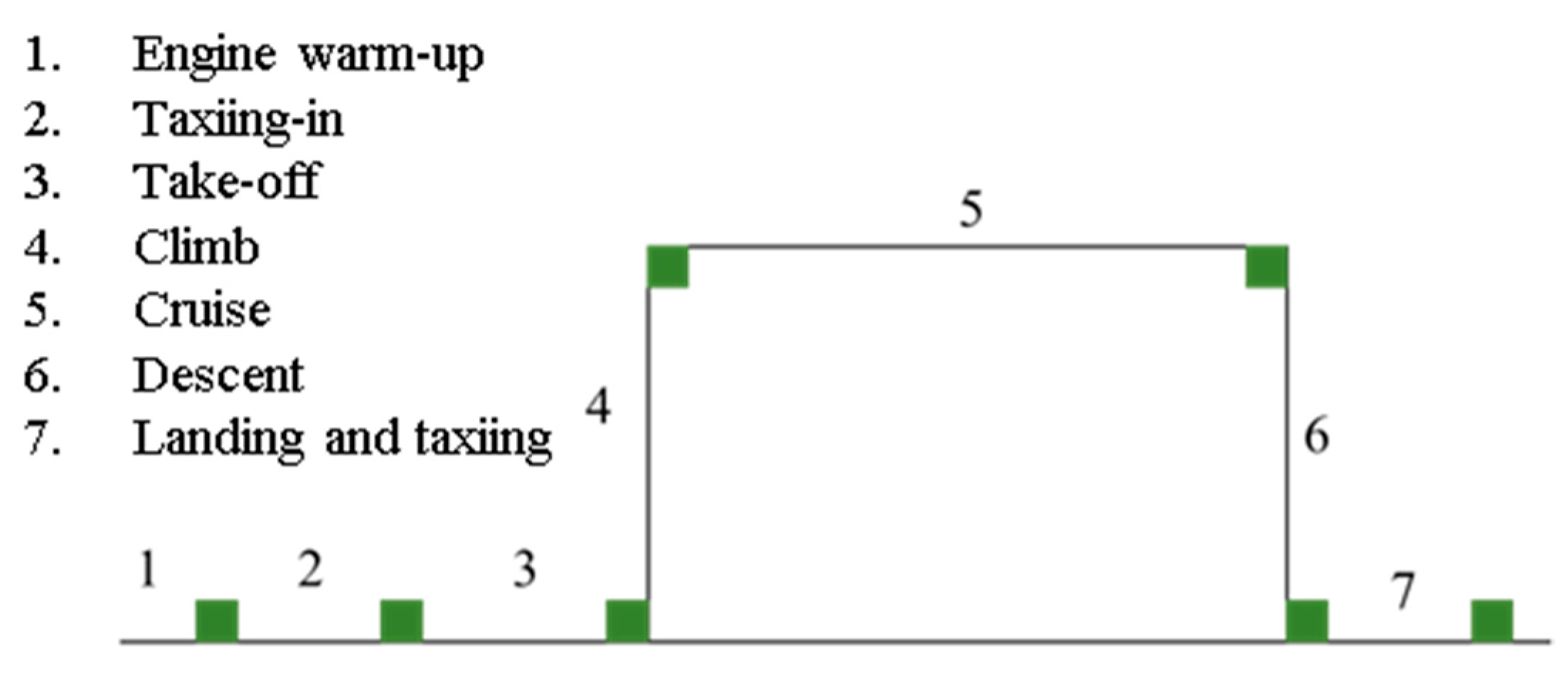

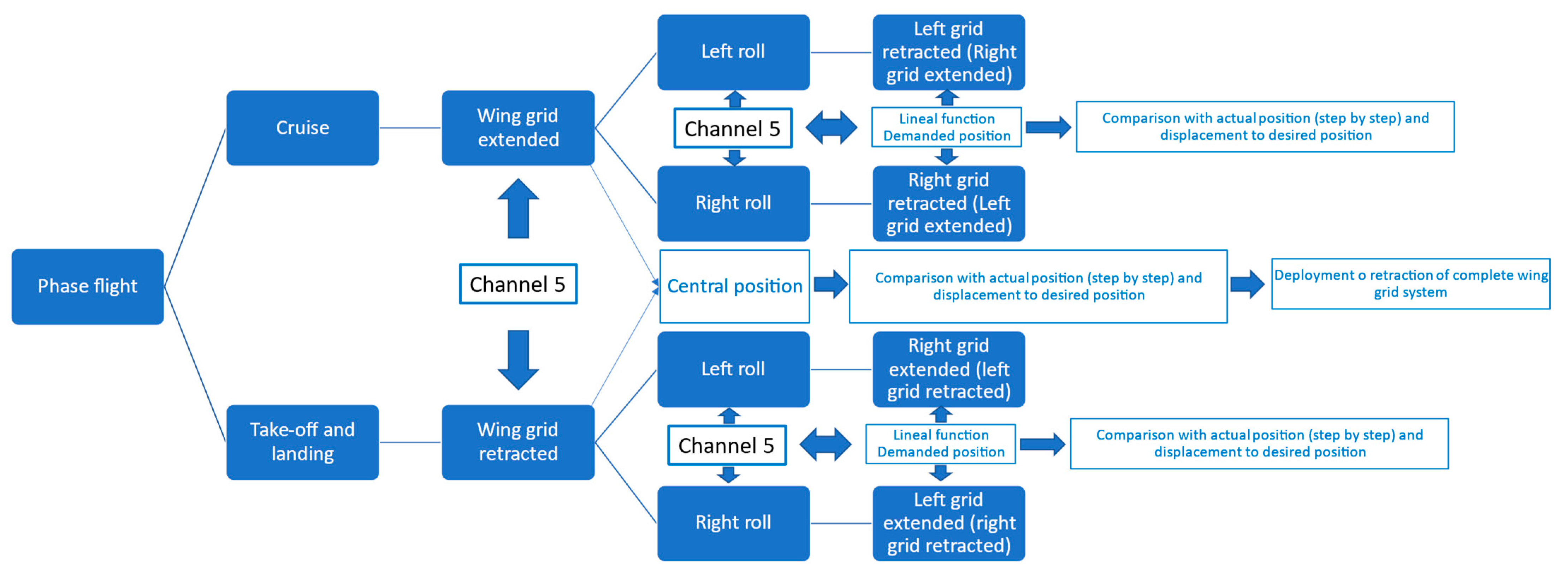

- In both cases, the possibility of modifying the wing planform may serve as a flight attitude control of the MAV. The flight can be considered in several phases (Figure 1), depending on the flight profile. Thus, optimal control will introduce different control strategies depending on the flight phase flown. In this case, the flight problem becomes a continuous reconfiguration of the flight taking the law of detection, actuation, and control of the flight, by means of the variables already explained above.

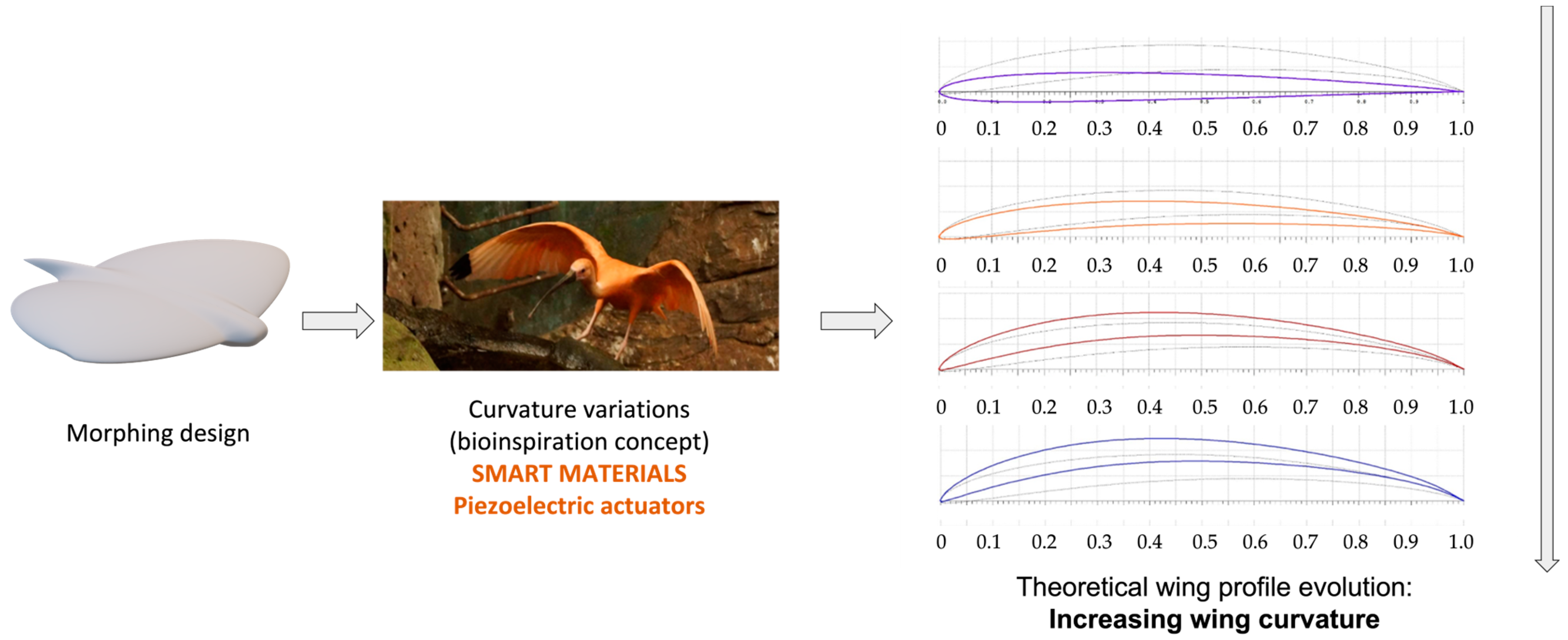

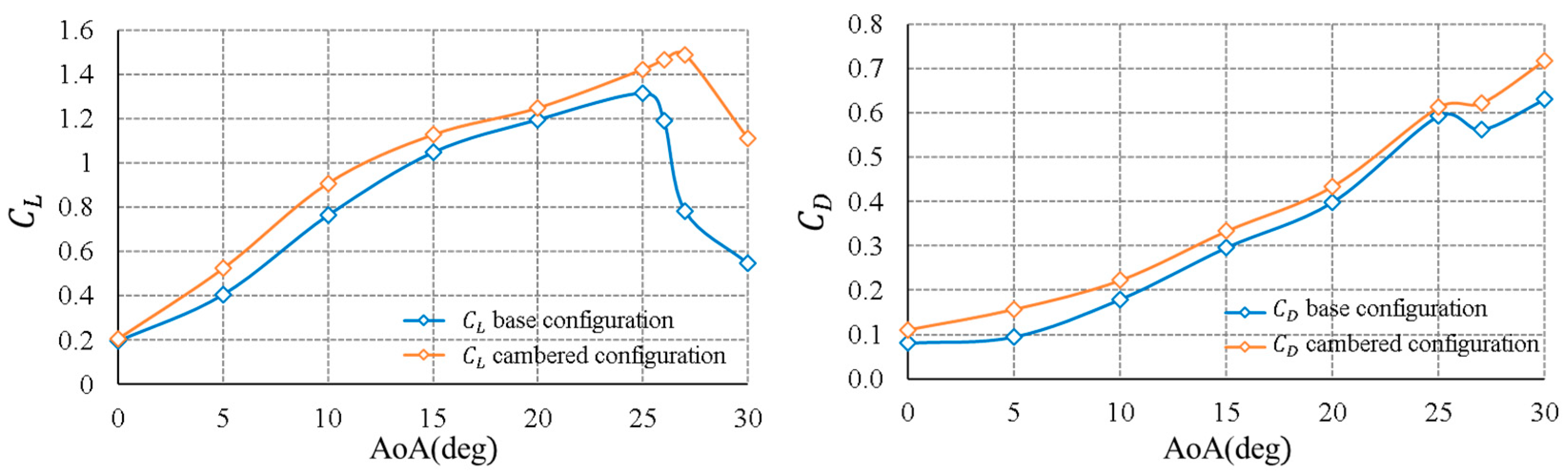

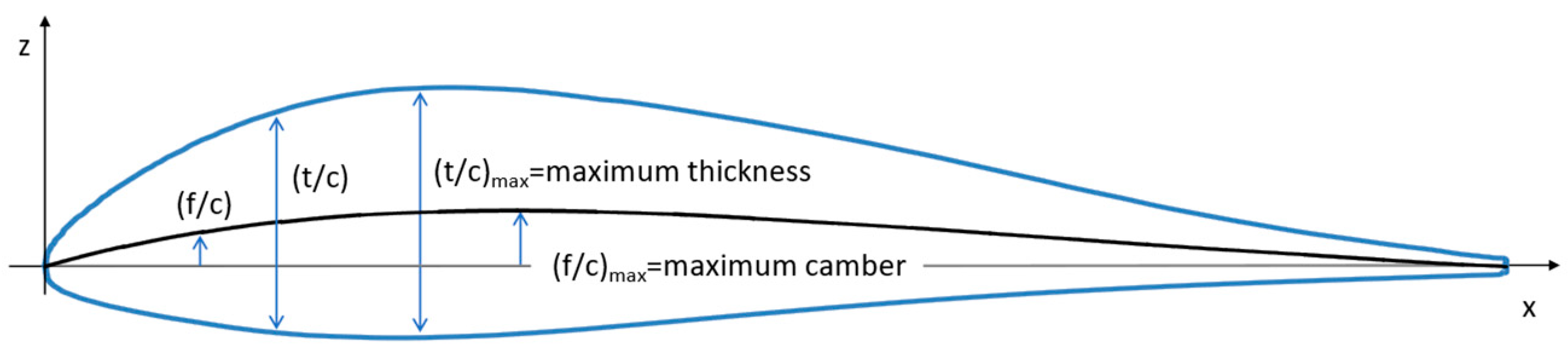

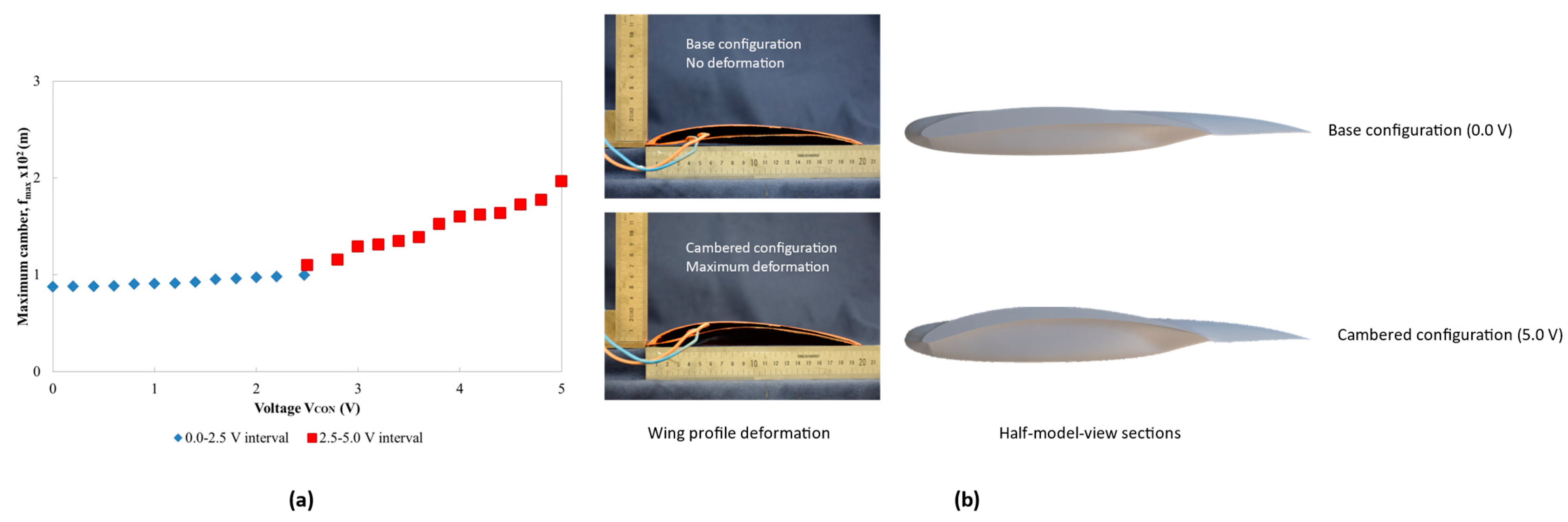

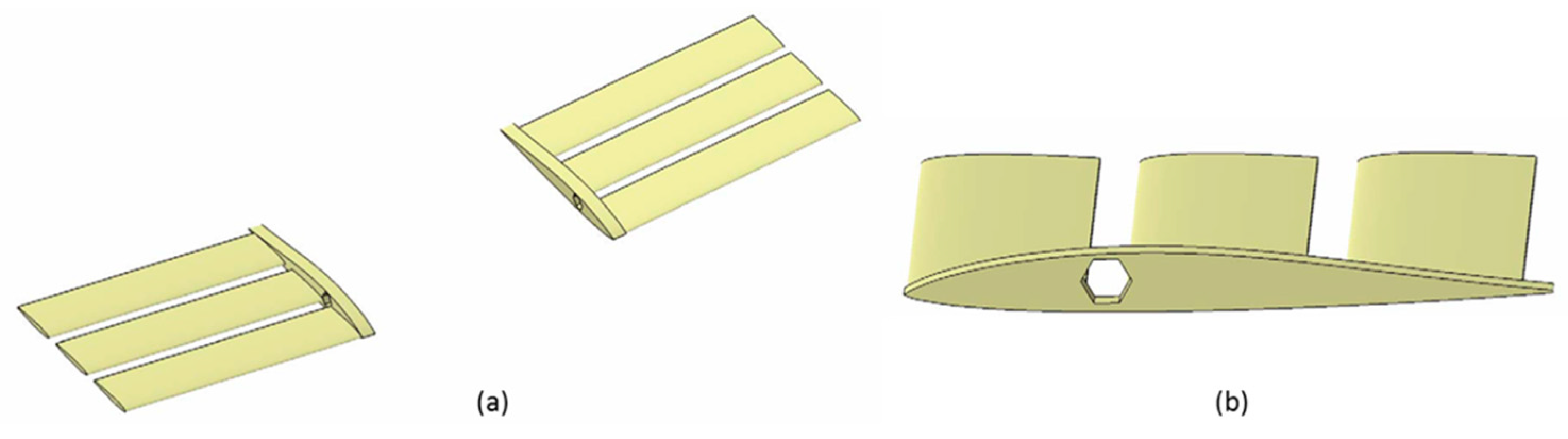

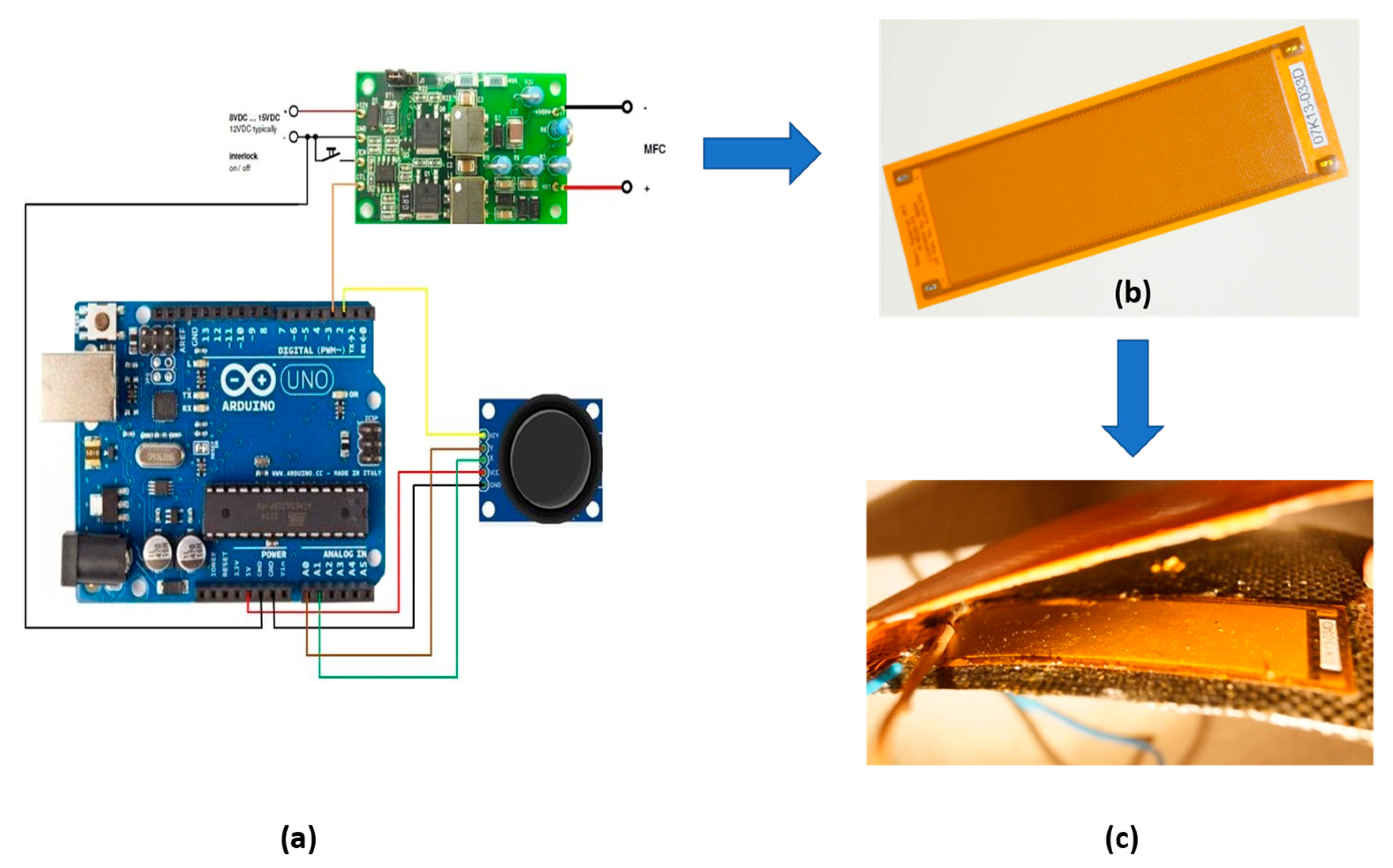

- In the morphing prototype (MM), the absence of conventional control surfaces must be considered. In this case, these surfaces have been substituted by modification of the wing curvature. This modification leads to a change in the lift coefficient (CL), drag coefficient (CD), and pitch moment coefficient (Cm) from the cruise configuration to maneuver. According to this, it is necessary to know the substitution of the usual control parameters by the relationship between the applied voltage (V) and the curvature (y/c), analyzing the capability of the corresponding geometry change to achieve adequate control of the vehicle.

- For the morphing prototype (MM), it is interesting to state the absence of horizontal and vertical stabilizers, which greatly affects the stability of the vehicle.

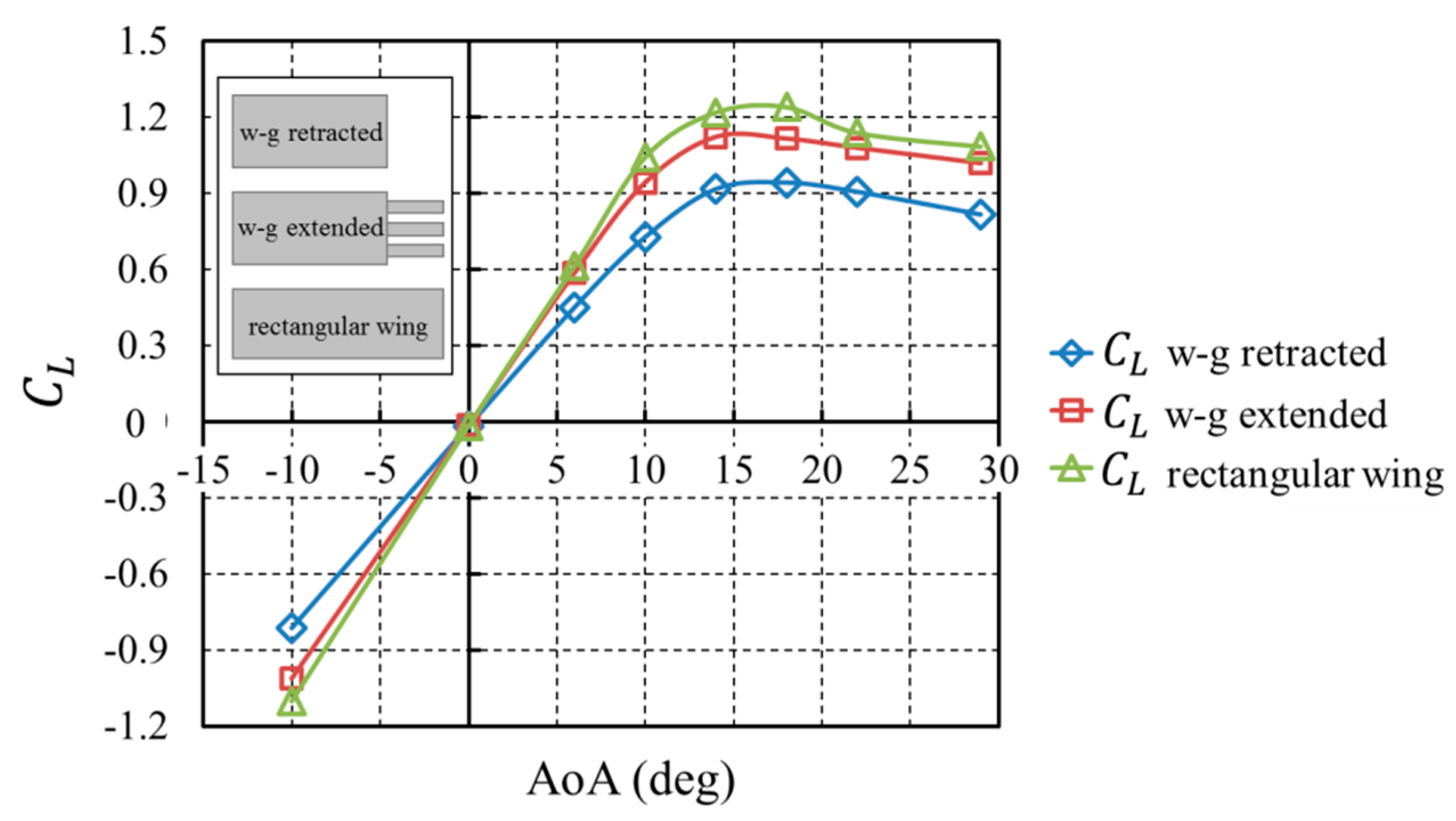

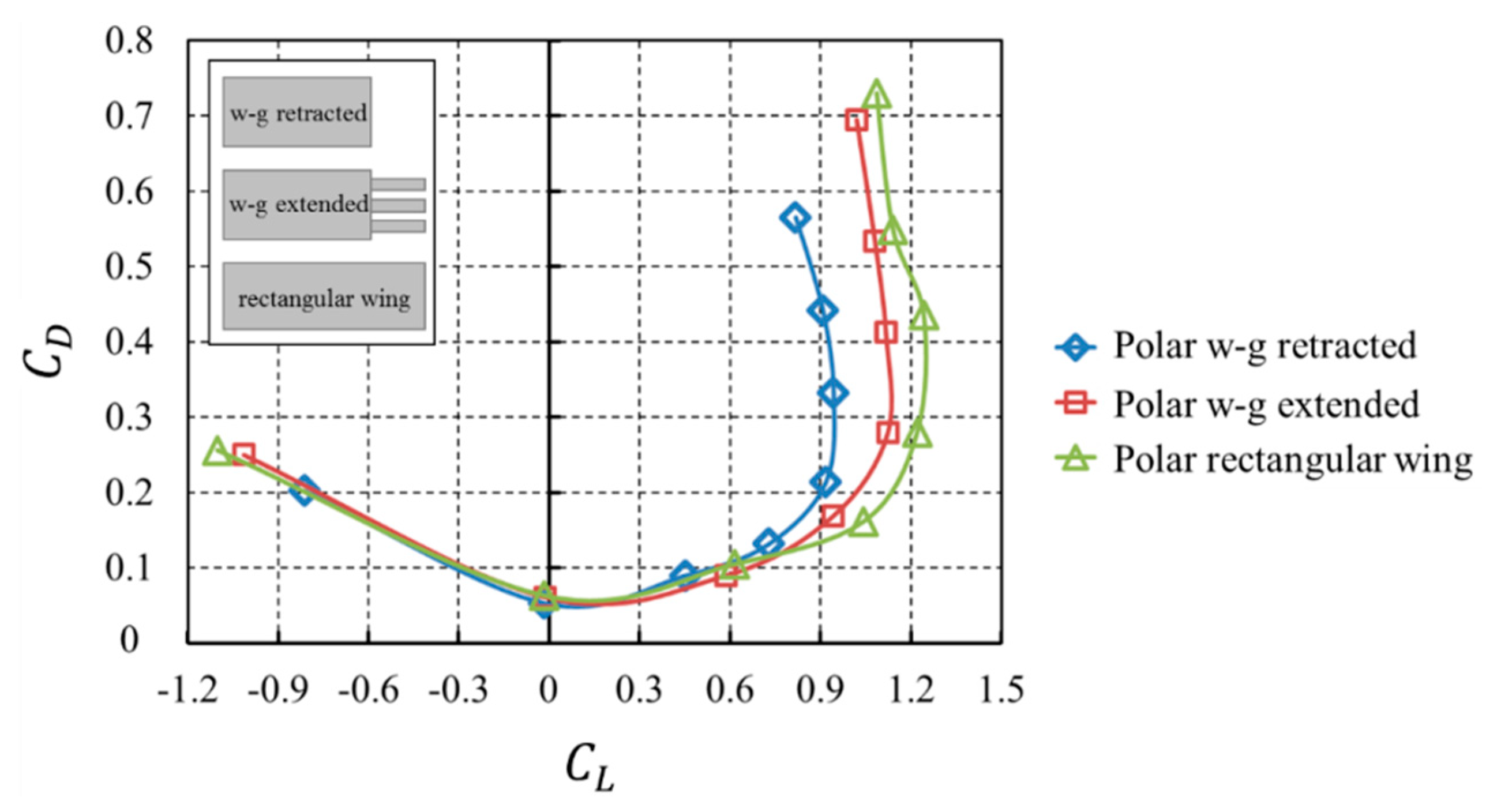

- For the wing grid prototype (WGM), in addition to the reduction in induced drag (CDi), and the increase in lift due (CL) to extension of the wing grid device, this paper focuses on the use of this wing grid to modify the lateral stability or control of the MAV with the asymmetrical deployment of the device.

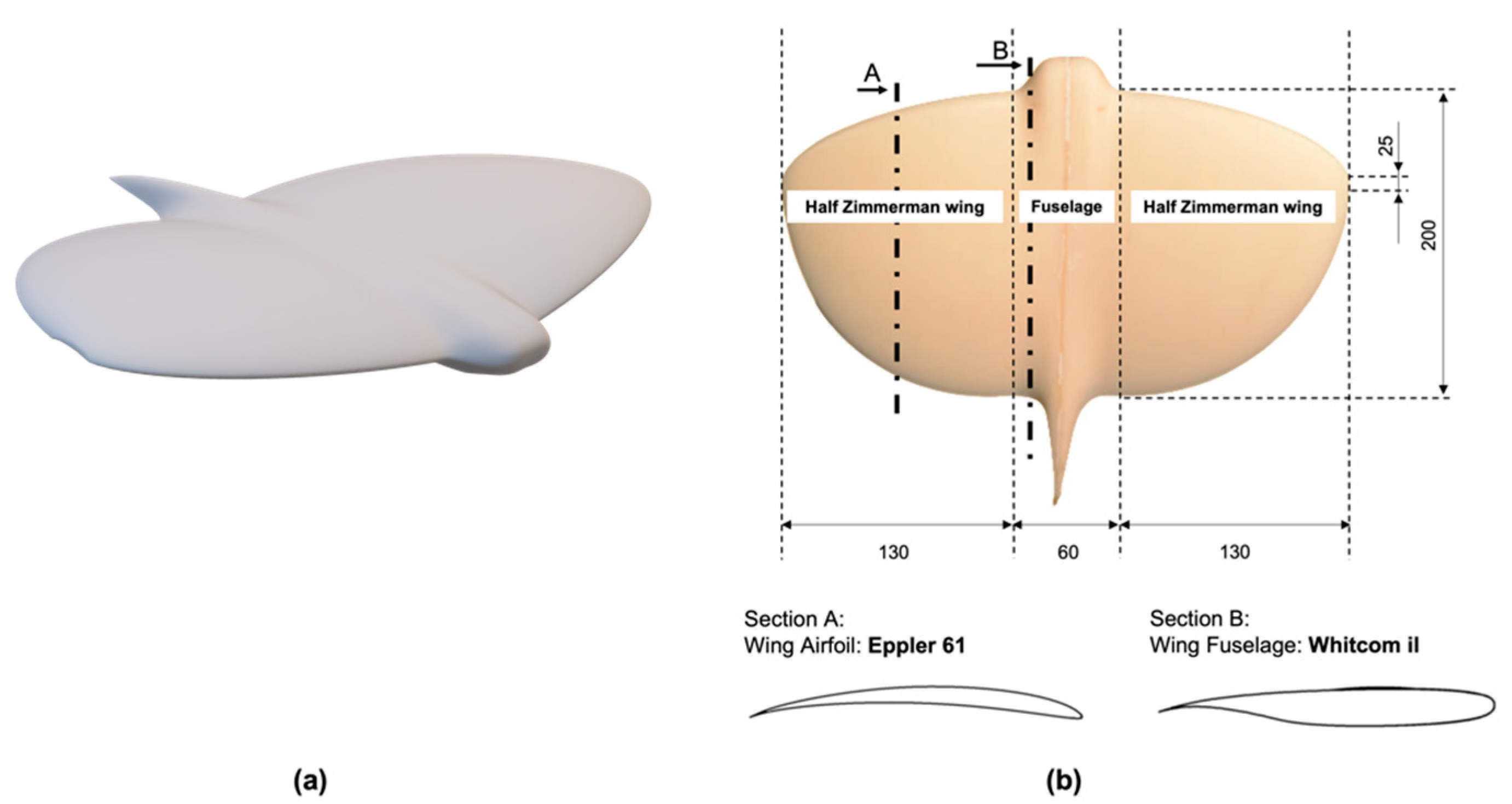

2.2. Morphing MAV (MM) Concept

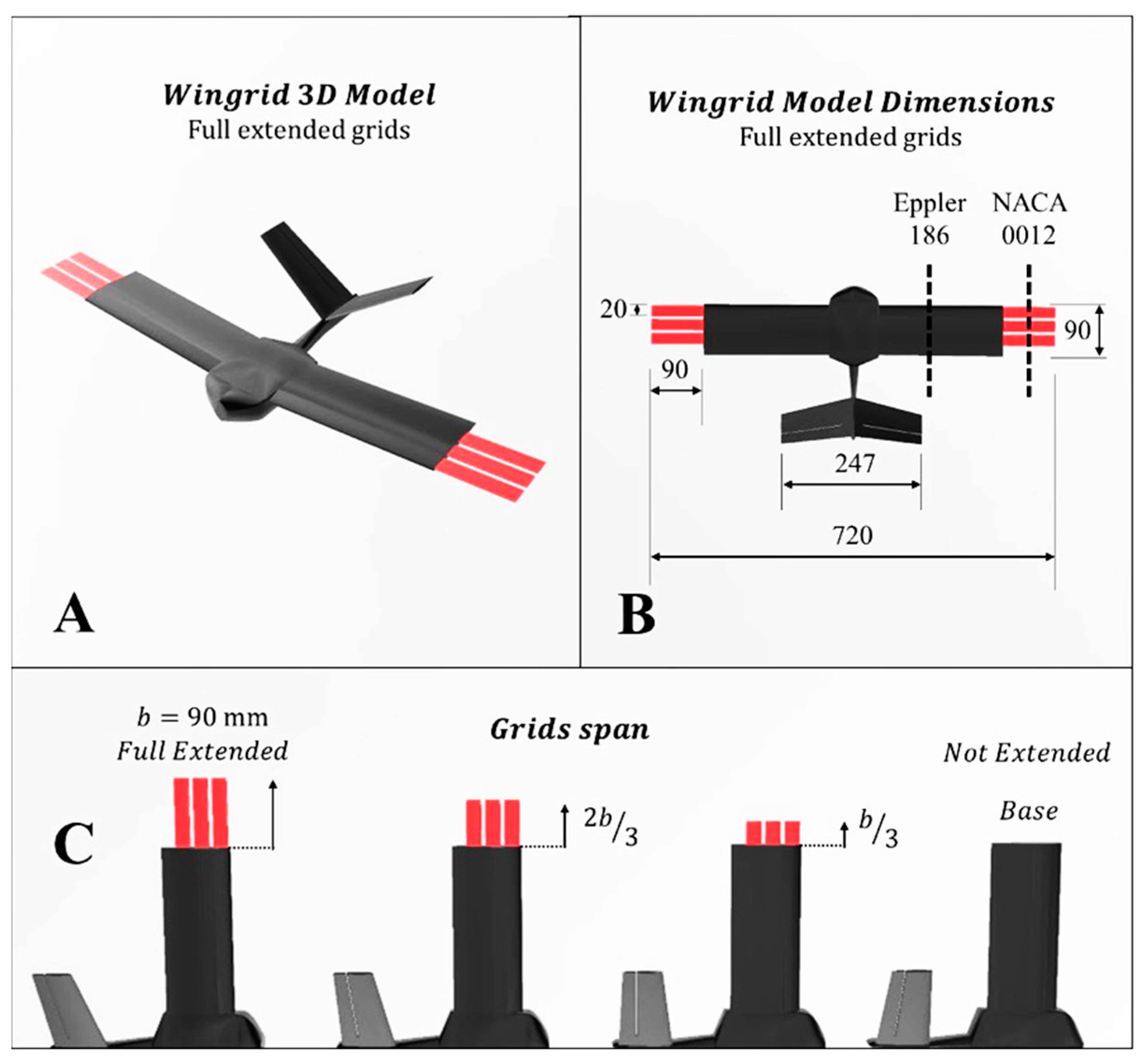

2.3. Wing Grid (WGM) Concept

3. Aerodynamic Data of Both MAVs (MM, WGM)

3.1. Wing Grid Vehicle (WGM)

3.2. Morphing-Based Vehicle

3.3. Aerodynamic Stability Properties

4. Command-and-Control Concept

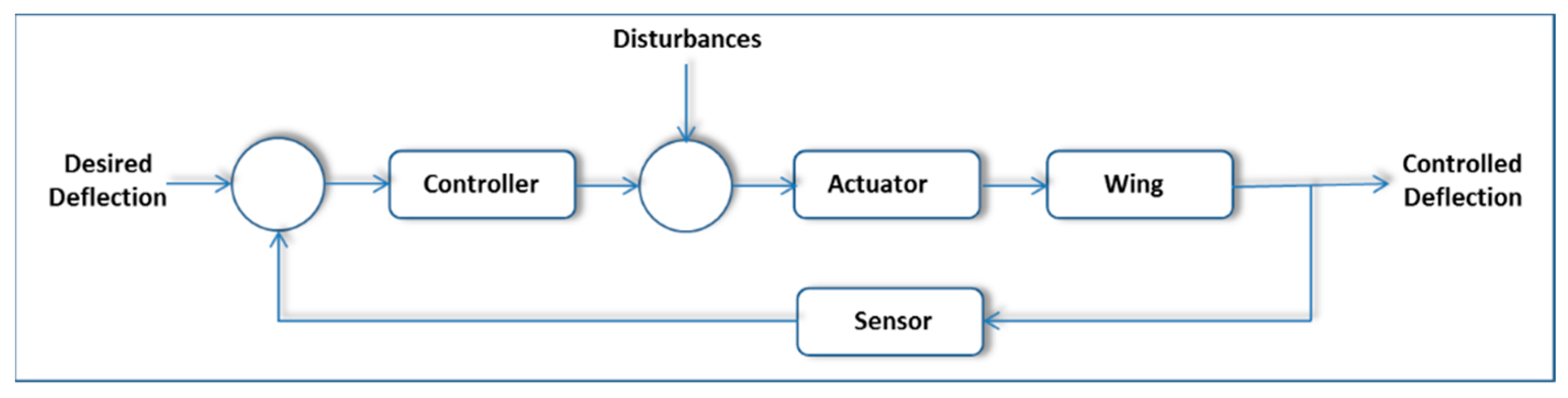

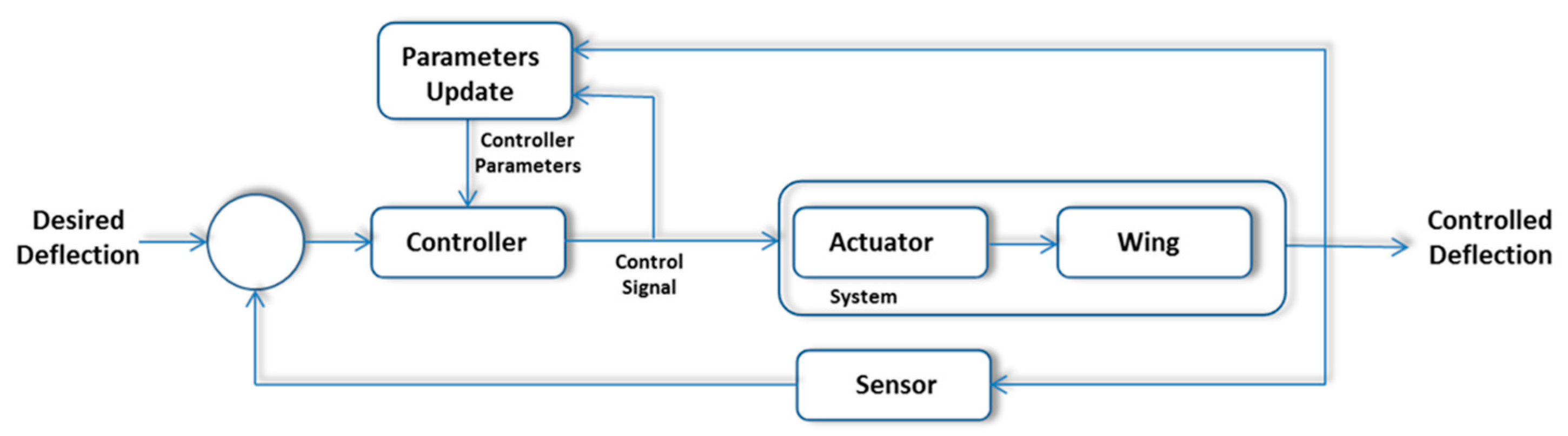

4.1. Control Methods

4.2. Control Law for Geometry Morphing

4.3. Feedback System for Morphing MAV (MM)

5. Practical Aspects

5.1. Configuration and Dimensions of Each Prototype

5.1.1. Wing Grid Prototype (WGM)

- Base configuration: The wing grid system was fully retracted. In the aerodynamic study, this was the base configuration or the reference configuration. In a flight with this configuration, the balance control would be exclusively with the tail surfaces.

- Cruise configuration: The fully deployed wing grid system. Bennet [6] proved in a wind tunnel that the use of the deployed configuration at low angles of attack is more appropriate than at high angles of attack, where the aerodynamic efficiency is halved. They may be more suitable for cruise conditions. The deployment of the symmetrical wing grid increases the wingspan, with a consequent increase in the coefficient of lift () as well as a reduction in the coefficient of induced drag (), with all other flight conditions being equal.

- Rolling configuration: When a wing grid system is deployed antisymmetrically, one half-wing is retracted, and the other half-wing is deployed. An asymmetric lift distribution is generated and the vehicle rolls right or left. This provides the MAV (WGM) with the roll control that would normally be given by the ailerons.

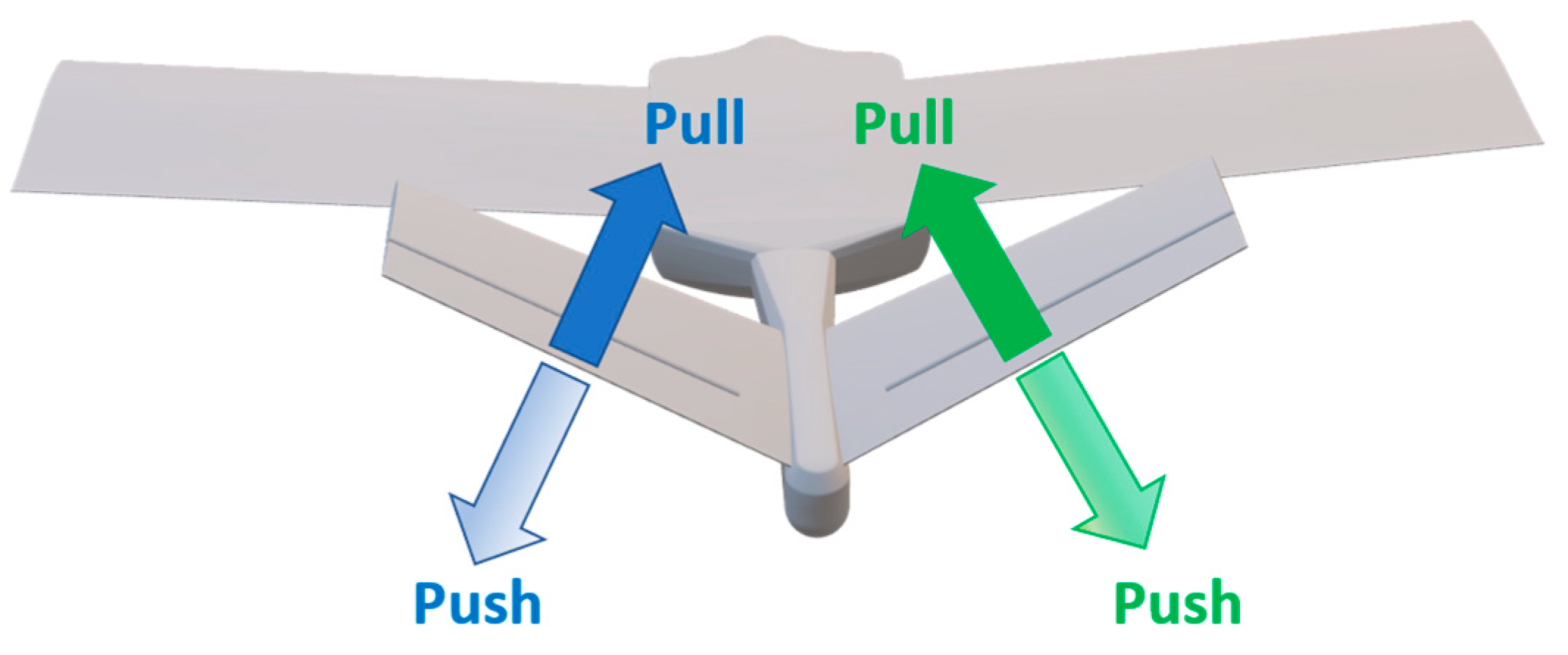

- Yawing/pitching configuration: A V-tail was chosen to control yaw and pitch instead of using the conventional configuration of horizontal and vertical stabilizers. The main dimensions and characteristics of the MAV are shown in Table 2 [3]. Figure 15 includes a description of the control surfaces in the V-tail, and the effects on the MAV attitude are described in Table 3.

5.1.2. Morphing Prototype (MM)

- Base configuration: The morphing system is without any curvature deformation (0.0 V). In the aerodynamic study, this was the base configuration or the cruise configuration.

- Pitching configuration: Morphing properties (curvature) were controlled asymmetrically in each half-wing, generating the same effect (pitch angle, ) such as a conventional elevator. If necessary, a pitch rate also appears.

5.2. Testbed Configuration

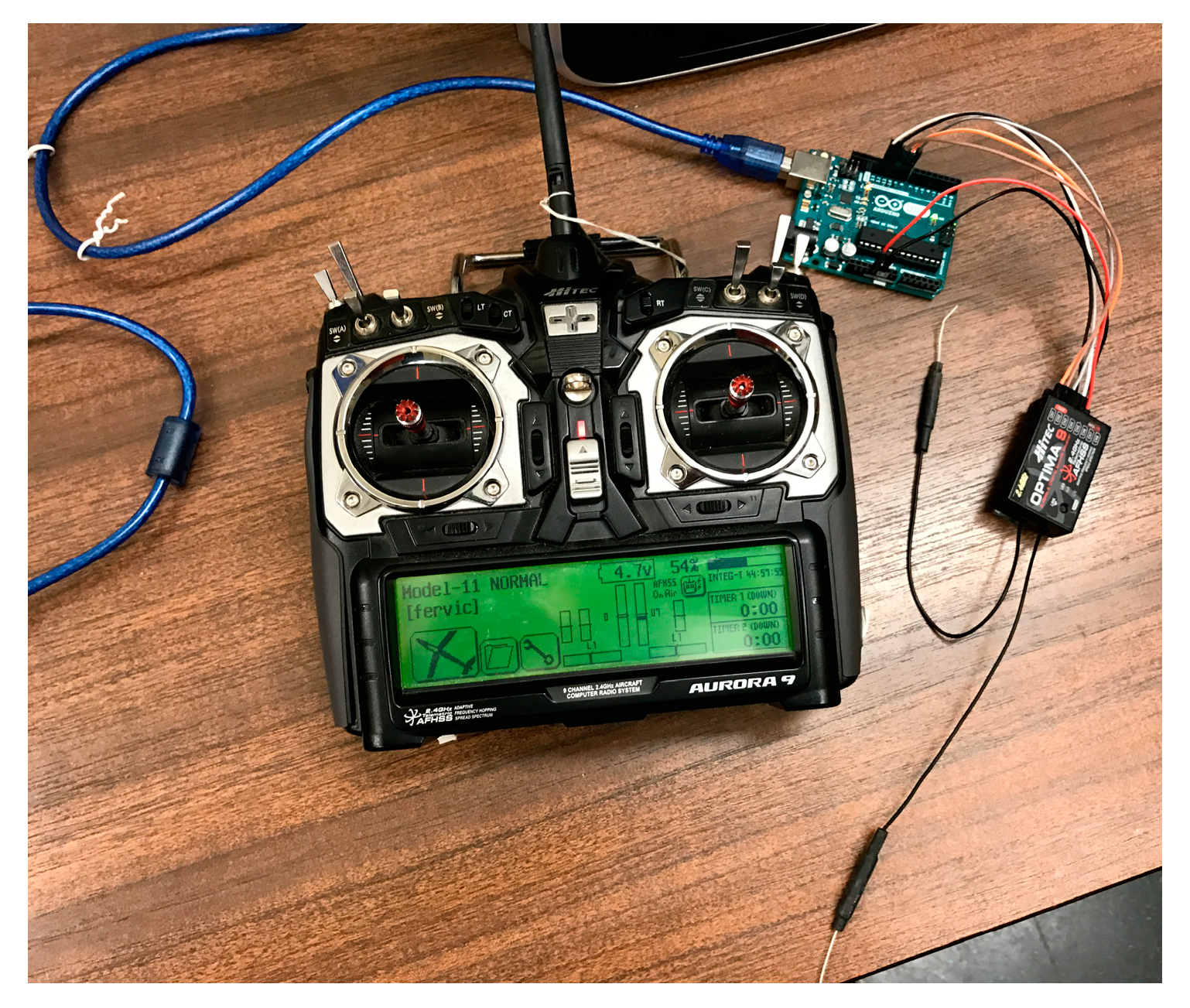

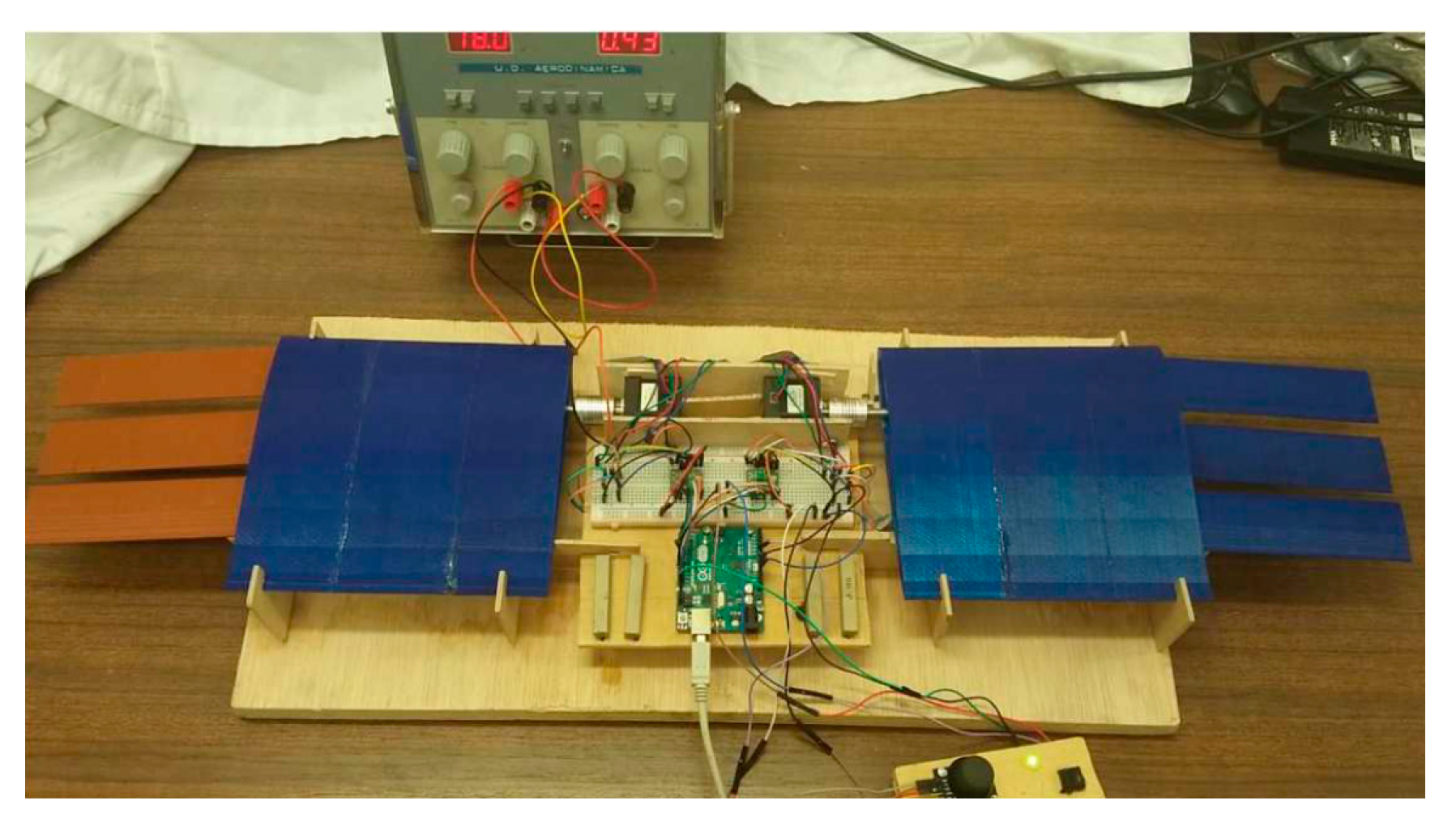

5.2.1. WGM Hardware Testbed

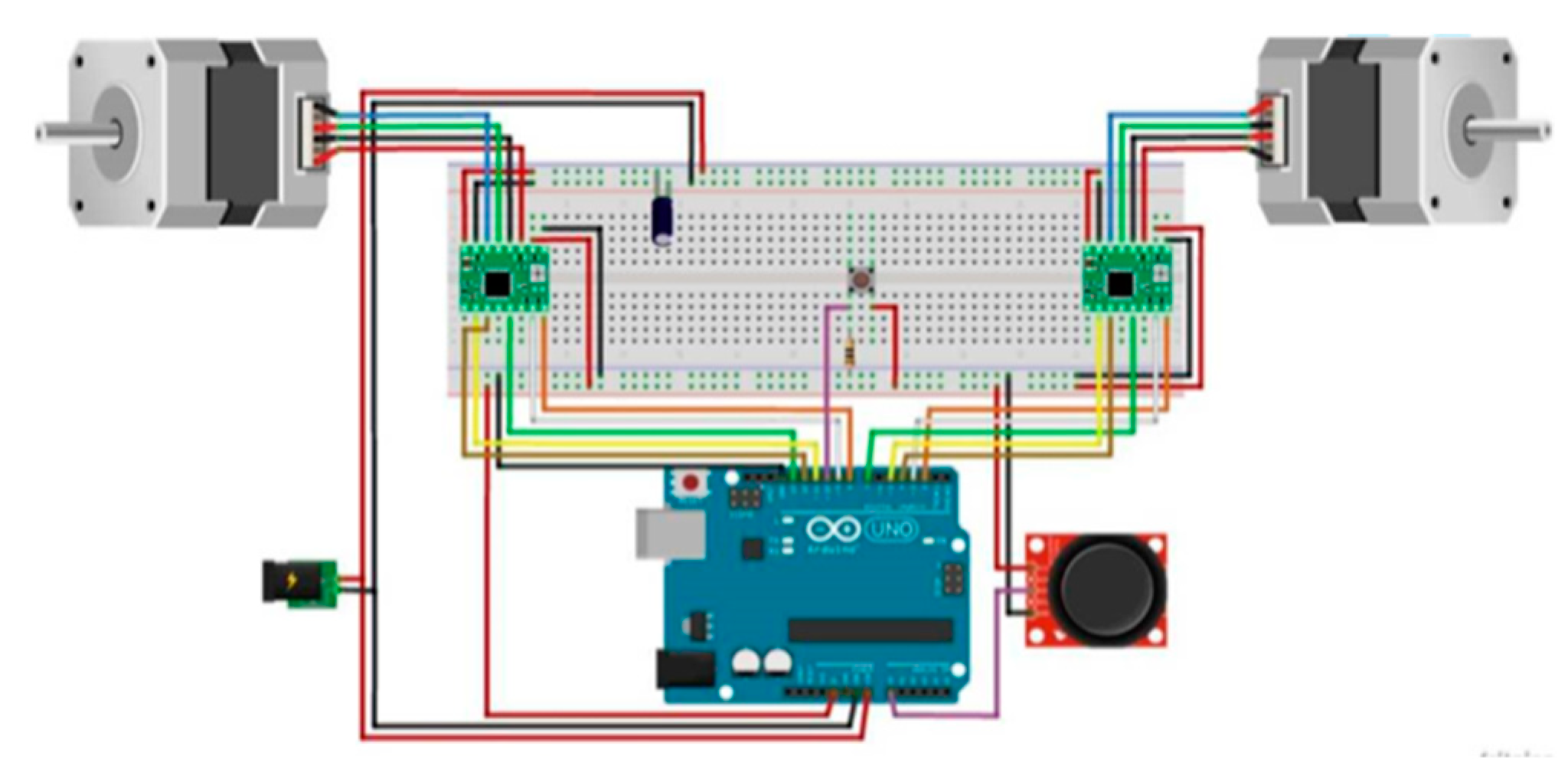

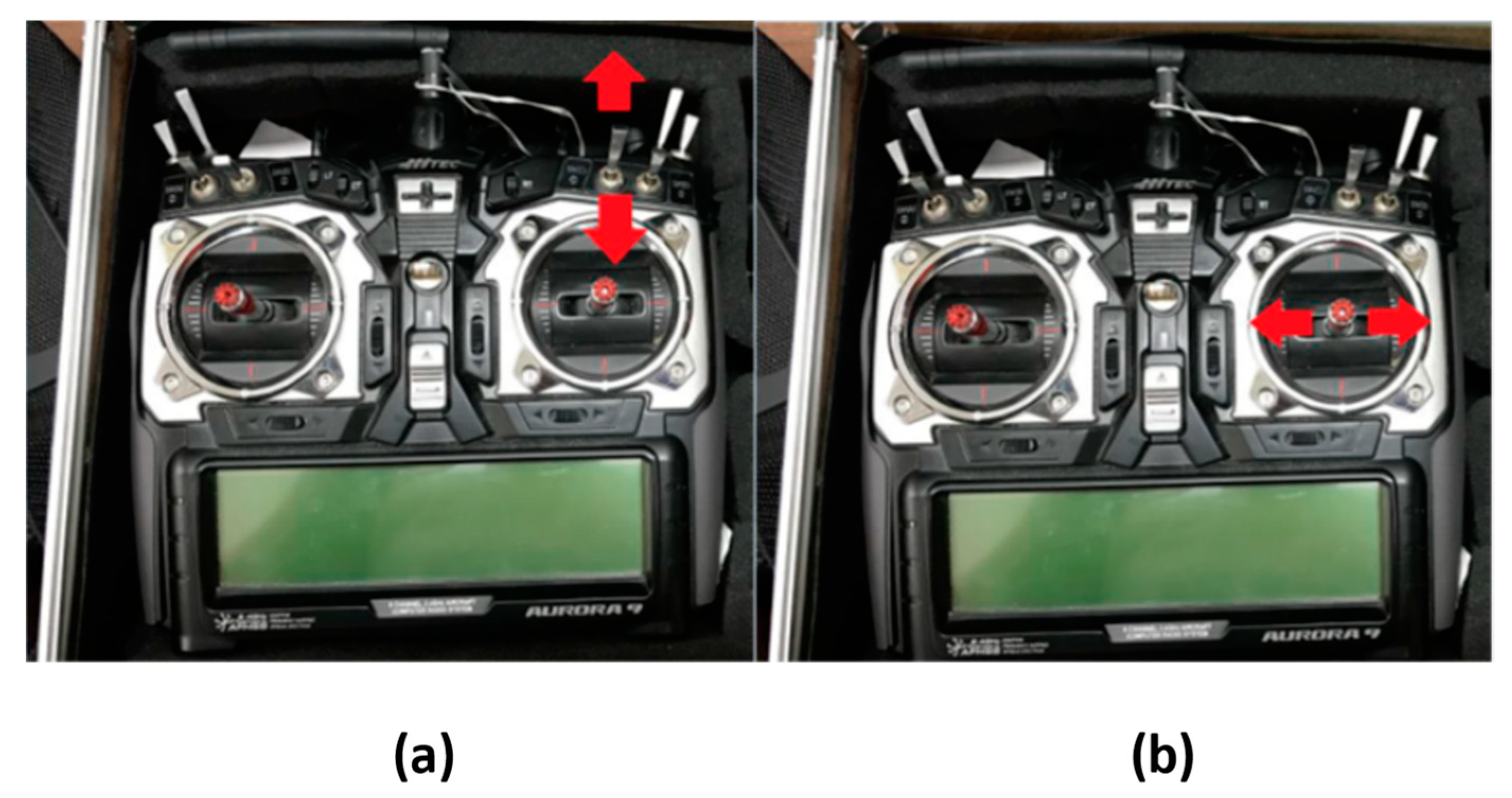

5.2.2. Transmission Mechanism

5.2.3. Connection Details

5.2.4. Software Algorithm

5.2.5. Model Assembly

5.3. Morphing Testbed

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sofla, A.Y.; Meguid, S.A.; Tan, K.T.; Yeo, W.K. Shape morphing of aircraft wing: Status and challenges. Mater. Des. 2010, 31, 1284–1292. [Google Scholar] [CrossRef]

- Li, D.; Zhao, S.; da Ronch, A.; Xiang, J. A review of modelling and analysis of morphing wings. Prog. Aerosp. Sci. 2018, 100, 46–62. [Google Scholar] [CrossRef]

- Rodríguez-Sevillano, Á.A.; Barcala Montejano, M.A.; Bardera Mora, R.; León-Calero, M.; García-Ramírez, J.; de Nova-Trigueros, J. Biomimetic micro air vehicle controlled by wing-grids. In Proceedings of the 8th Conference on Smart Structures and Materials, SMART 2017 and 6th International Conference on Smart Materials and Nanotechnology in Engineering, SMN, Madrid, Spain, 5–8 June 2017; Volume 2017, pp. 413–423. [Google Scholar]

- La Roche, U.; La Roche, H.L. Induced drag reduction using multiple winglets, looking beyond the Prandtl-Munk linear model. In Proceedings of the 2nd AIAA Flow Control Conference, Portland, OR, USA, 28 June–1 July 2004. [Google Scholar]

- Bennett, D. The Wing-Grid: A New Approach to Reducing Induced Drag; Massachusetts Institute of Technology: Cambridge, MA, USA, 2001. [Google Scholar]

- Tucker, V.A. Gliding birds: Reduction of induced drag by wing tip slots between the primary feathers. J. Exp. Biol. 1993, 180, 285–310. [Google Scholar] [CrossRef]

- Mohamed, A.; Watkins, S.; Clothier, R.; Abdulrahim, M.; Massey, K.; Sabatini, R. Fixed-wing MAV attitude stability in atmospheric turbulence—Part 2: Investigating biologically-inspired sensors. Prog. Aerosp. Sci. 2014, 71, 1–13. [Google Scholar] [CrossRef]

- Valasek, J. Morphing Aerospace Vehicles and Structures; John Wiley and Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Cook, M.V. Flight Dynamics Principles: A Linear Systems Approach to Aircraft Stability and Control; Butterworth-Heinemann: Waltham, MA, USA, 2012. [Google Scholar]

- Nelson, R.C. Flight Stability and Automatic Control; WCB/McGraw Hill: New York, NY, USA, 1998; Volume 2. [Google Scholar]

- Barcala-Montejano, M.A.; Rodríguez-Sevillano, Á.A.; Crespo-Moreno, J.; Bardera-Mora, R.; Silva-González, A.J. Optimized performance of a morphing micro air vehicle. In Proceedings of the 2015 International Conference on Unmanned Aircraft Systems (ICUAS), Denver, CO, USA, 9–12 June 2015; pp. 794–800. [Google Scholar]

- Kroo, I. Drag due to lift: Concepts for prediction and reduction. Annu. Rev. Fluid Mech. 2001, 33, 587. [Google Scholar] [CrossRef]

- Pratt, R.W. Flight Control Systems, Practical Issues in Design and Implementation; The Institute of Electrical Engineers: Stevenage, UK, 2000; pp. 119–167. [Google Scholar]

- Bardera, R.; Crespo, J.; Rodríguez-Sevillano, Á.A.; Muñoz-Campillejo, J.; Barderas, E.B.; Cobo-González, Á. Design of a flight control system for a bioinspired drone. In Proceedings of the AIAA AVIATION 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022; p. 3389. [Google Scholar]

- Gomez, J.C.; Garcia, E. Morphing unmanned aerial vehicles. Smart Mater. Struct. 2011, 20, 103001. [Google Scholar] [CrossRef]

- Barcala-Montejano, M.A.; Rodríguez-Sevillano, Á.A.; Bardera-Mora, R.; García-Ramírez, J.; de Nova-Trigueros, J.; Urcelay-Oca, I.; Morillas-Castellano, I. Smart materials applied in a micro remotely piloted aircraft system with morphing wing. J. Intell. Mater. Syst. Struct. 2018, 29, 3317–3332. [Google Scholar] [CrossRef]

- Available online: https://www.arduino.cc (accessed on 30 July 2022).

- Riba Pololu Robotics & Electronics. Stepper Motor: Bipolar, 200 Steps/Rev, 35 × 36 mm, 2.7V, 1 A/Phase. Available online: https://www.pololu.com/product/1209/specs (accessed on 30 July 2022).

| MAV Model | Version | Stability Derivative Coefficient | Value (rad−1) | Flight Condition (Speed m/s) |

|---|---|---|---|---|

| MM | Baseline | 2.196 0.728 0.040 | 10.3 | |

| MM | Maximum deformation | 2.054 0.737 0.068 | 9.1 | |

| WGM | WG retracted | 4.801 −0.151 −0.069 NP | 15.4 | |

| MM | WG extended | 6.311 −0.276 −0.070 −0.002 | 15.4 |

| Magnitude | Wing | Wing Grid (One Element) | Wing + Wing Grid | V-Tail |

|---|---|---|---|---|

| Span (mm) | 540 | 180 | 720 | 250 |

| (mm) | 90 | 20 | 90 | 60 |

| ) | 48,600 | 3600 | 64,800 | 15,000 |

| AR | 6 | 9 | 8 | 3 |

| Λ1/4 (°) | 0 | 0 | 0 | 6 |

| Change in MAV | Left Ruddervator | Right Ruddervator |

|---|---|---|

| Tail right Nose left | Pull | Push |

| Tail left Nose right | Push | Pull |

| Tail up Nose down | Pull | Pull |

| Tail down Nose up | Push | Push |

| Parameter | Value |

|---|---|

| Taper ratio, λ | 0.124 |

| 2.500 | |

| Mean aerodynamic chord | |

| Dihedral angle | |

| Fuselage length, l | |

| Fuselage width, d |

| Variable | Data |

|---|---|

| n (rotational speed of the motor) | 150 rev/20 s = 450 rpm |

| A (feed) = p·e | 1 mm |

| Va (feed rate) = A·n | 7.5 mm/s |

| t (time) = L/Va | 20 s |

| Turn Direction | Deployment | Function |

|---|---|---|

| Left | Retracted | |

| Right | Retracted | |

| Left | Extended | |

| Right | Extended |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barroso-Barderas, E.; Rodríguez-Sevillano, Á.A.; Bardera-Mora, R.; Crespo-Moreno, J.; Matías-García, J.C. Design of Non-Conventional Flight Control Systems for Bioinspired Micro Air Vehicles. Drones 2022, 6, 248. https://doi.org/10.3390/drones6090248

Barroso-Barderas E, Rodríguez-Sevillano ÁA, Bardera-Mora R, Crespo-Moreno J, Matías-García JC. Design of Non-Conventional Flight Control Systems for Bioinspired Micro Air Vehicles. Drones. 2022; 6(9):248. https://doi.org/10.3390/drones6090248

Chicago/Turabian StyleBarroso-Barderas, Estela, Ángel Antonio Rodríguez-Sevillano, Rafael Bardera-Mora, Javier Crespo-Moreno, and Juan Carlos Matías-García. 2022. "Design of Non-Conventional Flight Control Systems for Bioinspired Micro Air Vehicles" Drones 6, no. 9: 248. https://doi.org/10.3390/drones6090248

APA StyleBarroso-Barderas, E., Rodríguez-Sevillano, Á. A., Bardera-Mora, R., Crespo-Moreno, J., & Matías-García, J. C. (2022). Design of Non-Conventional Flight Control Systems for Bioinspired Micro Air Vehicles. Drones, 6(9), 248. https://doi.org/10.3390/drones6090248