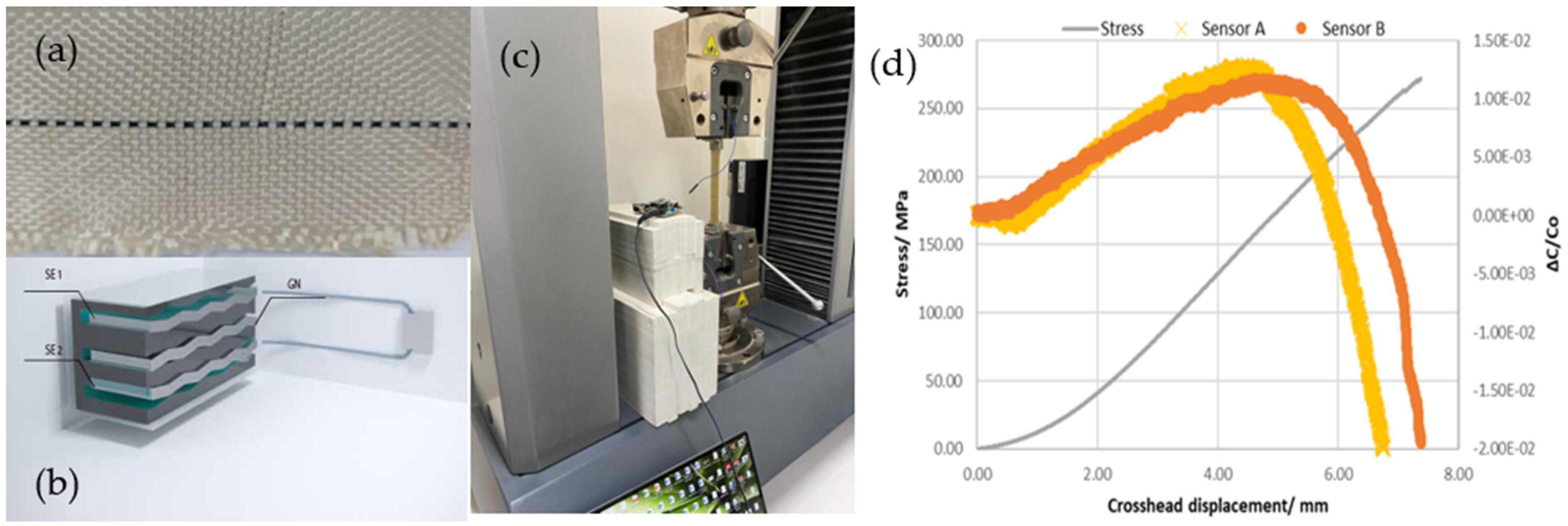

Develop a Smart Material Based on Carbon-Aramid Hybrid Composite for Health Monitoring Structure †

Abstract

1. Introduction

2. Materials and Methods

3. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Clyne, T.W.; Hull, D. An Introduction to Composite Materials; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Alblalaihid, K.; Alghamdi, S.A.; Alburayt, A.; Almutairi, S.H.; Alwahid, A.; Abuobaid, M.; Alkhibari, S.; Almutairi, K.S.; Alarifi, I.M. Interlayer Defect Detection in Intra-Ply Hybrid Composite Material (GF/CF) Using a Capacitance-Based Sensor. Sensors 2022, 22, 2966. [Google Scholar] [CrossRef]

- Alblalaihid, K.; Alghamdi, S.A.; Alburayt, A.; Alwahid, A.; Abuobaid, M.; Alshaikh, A.; Alkhibari, S.; Alarifi, I.M. Self-Sensing Hybrid Fibre-Reinforced Polymer for Structural Health Monitoring (SHM). Key Eng. Mater. 2022, 922, 87–93. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alblalaihid, K.; Aldoihi, S.; Alharbi, A.; Abuobaid, M.; Alkhaibari, S.; Khormi, K.; Alsaleh, S.; Almutairi, K.S.; Albahkali, M.A. Develop a Smart Material Based on Carbon-Aramid Hybrid Composite for Health Monitoring Structure. Proceedings 2024, 97, 28. https://doi.org/10.3390/proceedings2024097028

Alblalaihid K, Aldoihi S, Alharbi A, Abuobaid M, Alkhaibari S, Khormi K, Alsaleh S, Almutairi KS, Albahkali MA. Develop a Smart Material Based on Carbon-Aramid Hybrid Composite for Health Monitoring Structure. Proceedings. 2024; 97(1):28. https://doi.org/10.3390/proceedings2024097028

Chicago/Turabian StyleAlblalaihid, Khalid, Saad Aldoihi, Abdulaziz Alharbi, Meshal Abuobaid, Sabri Alkhaibari, Khalid Khormi, Sami Alsaleh, Khaled S. Almutairi, and Majid A. Albahkali. 2024. "Develop a Smart Material Based on Carbon-Aramid Hybrid Composite for Health Monitoring Structure" Proceedings 97, no. 1: 28. https://doi.org/10.3390/proceedings2024097028

APA StyleAlblalaihid, K., Aldoihi, S., Alharbi, A., Abuobaid, M., Alkhaibari, S., Khormi, K., Alsaleh, S., Almutairi, K. S., & Albahkali, M. A. (2024). Develop a Smart Material Based on Carbon-Aramid Hybrid Composite for Health Monitoring Structure. Proceedings, 97(1), 28. https://doi.org/10.3390/proceedings2024097028