1. Introduction

A low vibration level is, nowadays, an important feature for all hand-held power tools to comply with customer requirements and working environment regulations. In particular, vibration levels generated by percussive tools may cause not only discomfort but also health issues collectively designated as Hand-Arm Vibration Syndrome (HAVS) [

1,

2]. It is, therefore, crucial for operators performing repetitive tasks to use efficient tools emitting as low levels of vibration as possible [

3]. For example, power tool suppliers are required within the European Union to provide information on vibration emissions that reach or exceed a level of 2.5 m/s

2 measured and reported in accordance with several specific standards [

4,

5]. Whereas the current methods for vibration declaration take into account solely frequencies below 1250 Hz, it has been suggested in various studies that vibrations in a frequency range above 1250 Hz may cause nerve damage to power tool users [

6,

7,

8]. As a result, there might be new requirements emerging from authorities and companies concerning the evaluation of and the reduction in high-frequency vibrations.

The current article presents an experimental study of high-frequency vibrations measured on a chipping hammer. In the study, the signals recorded on the chipping hammer are used to assess the damping effects of a soft rubber layer on high-frequency vibrations.

2. Background and Procedure

Percussive tools for chipping and scaling are widely used for material removal tasks in foundries, metal workshops and shipyards. In those industries that require high productivity in rough working environments, chipping hammers shall offer robustness, sufficient percussive power and appropriate ergonomic features to protect the user from health issues, especially due to hand-arm vibrations. In fact, the oscillating forces that drive the piston in the percussive mechanism of a chipping hammer may generate high vibration levels in the tool handle. Therefore, certain models of chipping hammer have a damping system to reduce the vibrations transmitted to the handle. The vibration reduction can be achieved, for example, by using a soft spring that isolates the handle from the percussive mechanism. The chipping hammers with this type of damping system have relatively low vibration levels according to ISO 28927-10. However, the impacts produced in the percussive mechanism may still imply significant accelerations at high frequencies in the handle. Therefore, to investigate high-frequency vibrations and a potential damping method, measurements were performed on a damped chipping hammer manufactured by Atlas Copco and designated as RRF31.

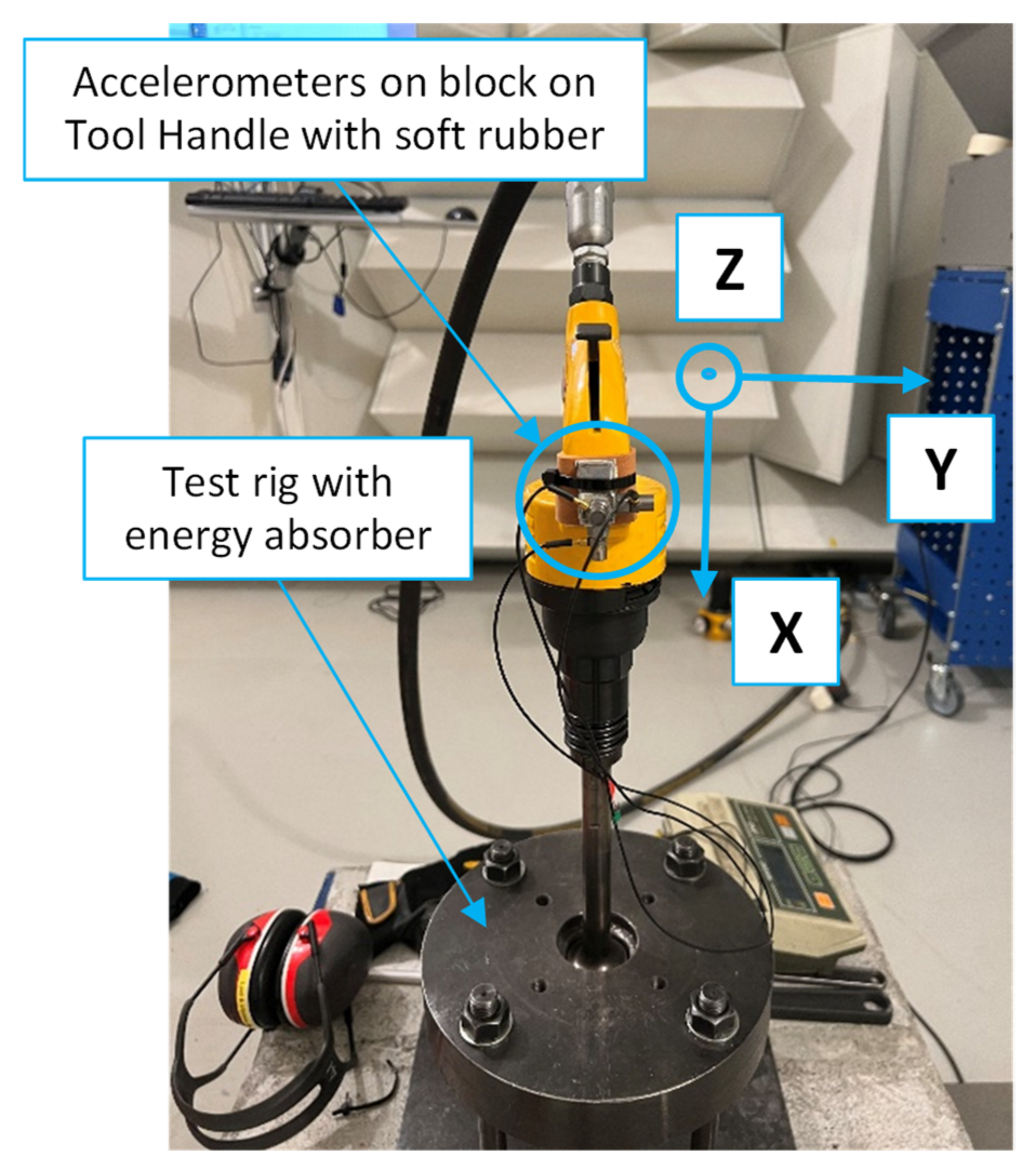

The measurement procedure was conducted according to the general guidelines described in ISO 28927-10. However, the procedure was simplified by using one machine run by only two operators. In addition, the vibration signals were obtained from three accelerometers mounted with mechanical filters on a block attached to the tool handle by using double-sided tape and a cable tie. The time signals were acquired with a sampling frequency of 65,536 Hz. The recorded data were then analysed by applying a low-pass filter at 20 kHz. Moreover, the mechanical filters used to protect the accelerometers from potential overloads provided an additional low-pas filter at 10 kHz. For the measurements, the chipping hammer was operated in a steel ball energy absorber designated as Dynaload, as shown in

Figure 1. Each of the two operators performed five runs of 10 s initially on the chipping hammer with the regular handle (new tool from factory) and then on the same machine with the handle partly covered with a 2 mm layer of soft rubber. The regular handle is made of aluminium with a painted surface.

The data provided by the three accelerometers were used to evaluate the declared vibration emission value

ahw for the chipping hammer. In addition, the Vibration Peak Magnitude (VPM) was calculated by using the relationship

where the parameter

k was set to 2.

According to a report on signal processing [

9], the value produced by the VPM calculation can be used to quantify the high-frequency content of the vibrations generated, for example, by repeated shocks. In the present study, the VPM value is mainly used to characterize the effect of vibration damping at high frequencies.

3. Measurement Results

In

Figure 2, the time signals of the accelerations recorded by the three accelerometers are shown in the X-, Y- and Z-directions for two runs, where one run was performed on the regular handle and the other run on the damped handle. The signal amplitudes can vary significantly during a triggering sequence. Nevertheless, the signal amplitudes are clearly reduced by using the soft layer of damping material in the X-, Y- and Z-directions. The acceleration spectra obtained by averaging the vibration data from the 10 runs are presented for both tool configurations in 1/24th octave bands in X-, Y- and Z-directions, as shown in

Figure 3. A large reduction in the acceleration amplitudes can be observed at high frequencies above 1 kHz, and there are no significant variations in the acceleration levels below 1 kHz.

In

Table 1, the VPM and

ahw values obtained for both tool configurations are given in the X-, Y- and Z-directions and for the resulting vector norm. The soft rubber layer used on the damped handle provides a substantial decrease in the VPM value and, on the contrary, it has no effect on the vibration declaration value

ahw.

4. Discussion and Conclusions

The damping effects of a thin layer of soft rubber on high-frequency vibrations are demonstrated by using time signals, acceleration spectra and VPM values. The soft rubber has no impact on the declared vibration emission value measured at 5.3 m/s

2. The official declaration value for the tool is 5 m/s

2 with an uncertainty K = 1.6 m/s

2. Furthermore, the damping effects at high frequencies, as shown in

Figure 2 and

Figure 3, are clearly indicated by the decrease in the VPM values. This tends to prove that the VPM value can be used as a suitable parameter to quantify high-frequency vibrations. The use of a thin layer of soft rubber on a chipping hammer handle gives a substantial damping effect on high-frequency vibrations and provides extra insulation against the cold surfaces generated by the pneumatic tool. For further development, a suitable damped handle has to be designed and the material durability has to be investigated in industrial applications.

Author Contributions

R.H. and O.L. contributed equally to this article. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Atlas Copco Industrial Technique AB.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are available on request if authorized by company policy.

Conflicts of Interest

There is a potential competing interest as the authors are employed by the tool manufacturer Atlas Copco Industrial Technique AB.

References

- Griffin, M.J. Handbook of Human Vibration; Academic Press: London, UK, 1990. [Google Scholar]

- ISO 5349-1; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 2001.

- Directive 2002-44-EC; The European Parliament and of the Council of 25 June 2002 on the Minimum Health and Safety Requirements Regarding the Exposure of Workers to the Risks Arising from Physical Agents (Vibration). The European Parliament and of the Council: Brussels, Belgium, 2002.

- Directive 2006-42-EC; The European Parliament and of the Council of 17 May 2006 on Machinery. The European Parliament and of the Council: Brussels, Belgium, 2006.

- ISO 28927-10; Hand-Held Portable Power Tools—Test Methods for Evaluation of Vibration Emission. International Organization for Standardization: Geneva, Switzerland, 2011.

- Hand-Arm Vibration: Exposure to Isolated and Repeated Shock Vibrations—Review of the International Expert Workshop 2015 in Beijing; IFA Report; Deutsche Gesetzliche Unfallversicherung (DGUV): Berlin, Germany, 2017.

- Lundström, R. Shock Vibration Caused by Percussive Hand Tools is an Underestimated Contributor to the Development of Vibration Injury. In Proceedings of the American Conference on Human Vibration (7th ACHV), Seattle, WA, USA, 13–15 June 2018. [Google Scholar]

- Lindell, H.; Gerhardsson, L. Risk for VWF is underestimated in assembly industry using impact tools. In Proceedings of the Hand-Arm Vibration 14th International Conference, Bonn, Germany, 21–24 May 2019. [Google Scholar]

- Johannisson, P.; Lindell, H. Definition and Quantification of Shock-Impact-Transient Vibrations; Technical Report; RISE: Mölndal, Sweden, 2022. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).