Effect of Spray Drying on the Microencapsulation of Blueberry Natural Antioxidants †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Obtaining the Phenolic Extract from Blueberries

2.3. Spray Drying of the Blueberry Phenolic Extracts

2.4. Drying Yield or Powder Production Yield

2.5. Moisture Content

2.6. Water Solubility

2.7. Estimation of Phenolic Compounds in Powders

2.7.1. Phenolic Compounds Extraction

2.7.2. Determination of Total Phenolic Content (TPC), Surface Phenolic Content (SPC), and Encapsulation Efficiency of Phenolic Compounds (EE)

2.8. Statistical Analysis

3. Results and Discussion

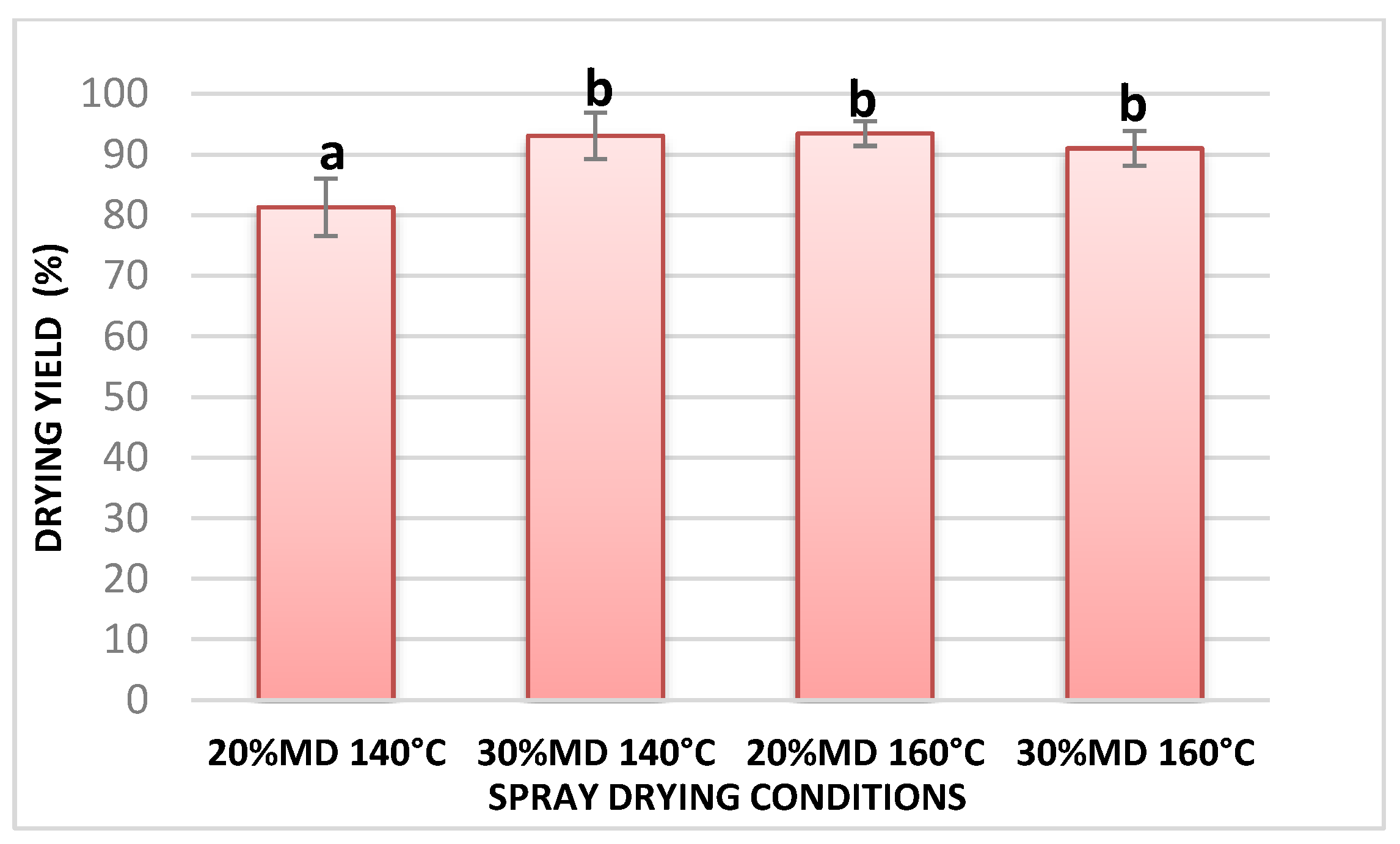

3.1. Drying Yield or Powder Production Yield

3.2. Moisture Content and Water Solubility of Powders

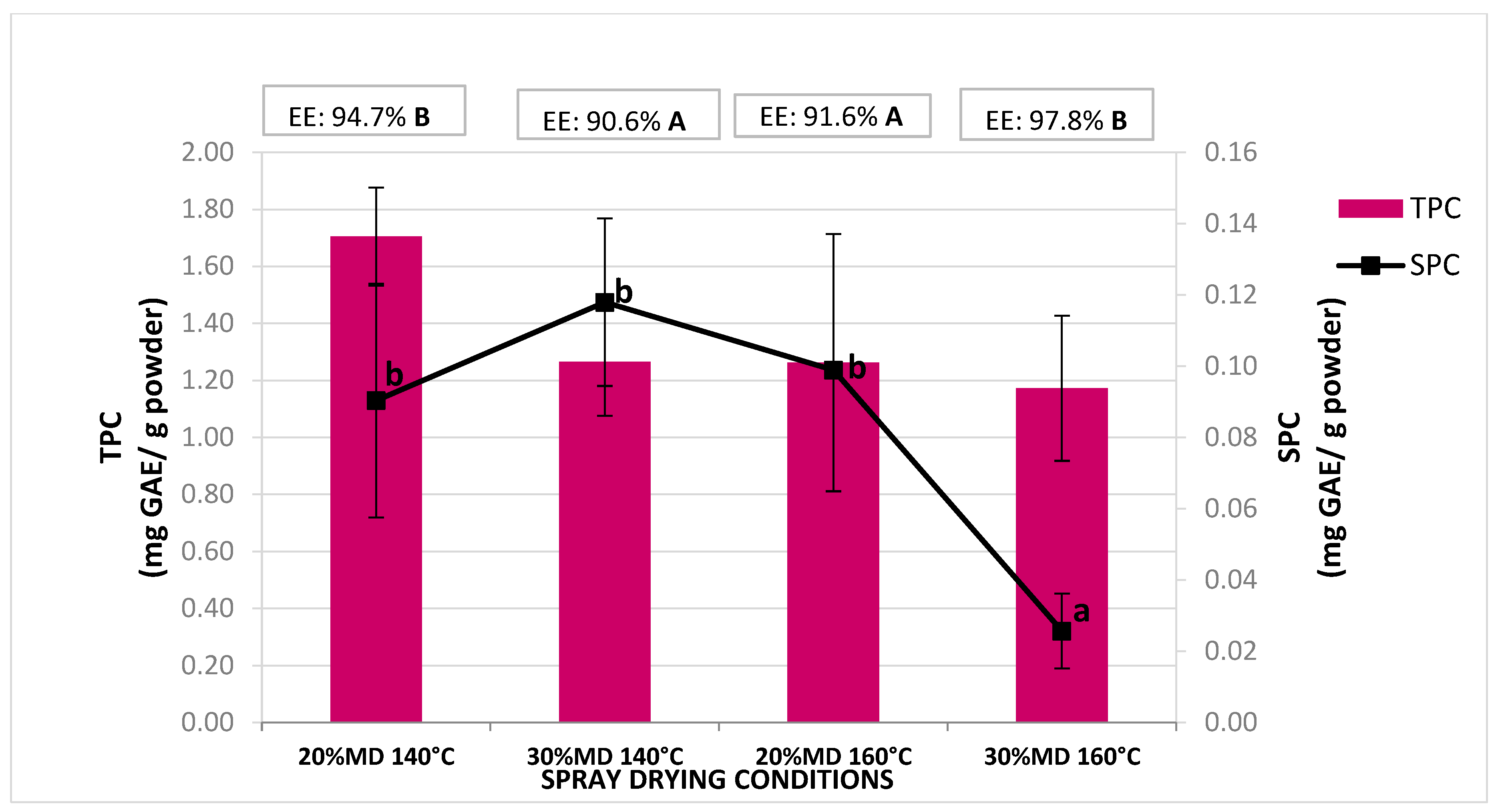

3.3. Total Phenolic Content (TPC), Surface Phenolic Content (SPC), and Encapsulation Efficiency of Phenolic Compounds (EE)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, J.; Wrolstad, R.E. Extraction of anthocyanins and polyphenolics from blueberry processing waste. J. Food Sci. 2004, 69, C564–C573. [Google Scholar] [CrossRef]

- Prior, R.L.; Wilkes, S.E.; Rogers, T.R.; Khanal, R.C.; Wu, X.; Howard, L.R. Purified blueberry anthocyanins and blueberry juice alter development of obesity in mice fed an obesogenic high-fat diet. J. Agric. Food Chem. 2010, 58, 3970–3976. [Google Scholar] [CrossRef] [PubMed]

- Prior, R.L.; Wu, X.L.; Gu, L.W.; Hager, T.J.; Hager, A.; Howard, L.R. Whole berries versus berry anthocyanins: Interactions with dietary fat levels in the C57BL/6J mouse model of obesity. J. Agric. Food Chem. 2008, 56, 647–653. [Google Scholar] [CrossRef] [PubMed]

- Prior, R.L.; Wu, X.L.; Gu, L.W.; Hager, T.; Hager, A.; Wilkes, S.; Howard, L. Purified berry anthocyanins but not whole berries normalize lipid parameters in mice fed an obesogenic high fat diet. Mol. Nut. Food Res. 2009, 53, 1406–1418. [Google Scholar] [CrossRef] [PubMed]

- Betz, M.; Kulozik, U. Whey protein gels for the entrapment of bioactive anthocyanins from bilberry extract. Int. Dairy J. 2011, 21, 703–710. [Google Scholar] [CrossRef]

- Berg, S.; Bretz, M.; Hubbermann, E.M.; Schwarz, K. Influence of different pectins on powder characteristics of microencapsulated anthocyanin and their impact on drug retention of shellac coated granulate. J. Food Eng. 2012, 108, 158–165. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Anthocyanin stability and antioxidant activity of spray-dried açai (Euterpe oleracea Mart.) juice produced with different carrier agents. Food Res. Int. 2010, 43, 907–914. [Google Scholar] [CrossRef]

- Rocha, G.A.; Trindade, M.A.; Netto, F.M.; Favaro-Trindade, C.S. Microcapsules of a casein hydrolysate: Production, characterization, and application in protein bars. Food Sci. Technol. Int. 2009, 15, 407–413. [Google Scholar] [CrossRef]

- Paini, M.; Aliakbarian, B.; Casazza, A.A.; Lagazzo, A.; Botter, R.; Perego, P. Microencapsulation of phenolic compounds from olive pomace using spray drying: A study of operative parameters. LWT-Food Sci. Technol. 2015, 62, 177–186. [Google Scholar]

- Tolun, A.; Altintas, Z.; Artik, N. Microencapsulation of grape polyphenols using maltodextrin and gum arabic as two alternative coating materials: Development and characterization. J. Biotechnol. 2016, 239, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Di Rienzo, J.A.; Casanoves, F.; Balzarini, M.G.; González, L.; Tablada, M.; Robledo, C.W. InfoStat, Versión 2008; Grupo InfoStat, FCA, Universidad Nacional de Córdoba: Córdoba, Argentina, 2008. [Google Scholar]

- Di Rienzo, J.A.; Guzmán, A.W.; Casanoves, F. A Multiple-Comparisons Method Based on the Distribution of the Root Node Distance of a Binary Tree. J. Agric. Biol. Environ. 2002, 7, 129–142. [Google Scholar] [CrossRef]

- Selvamuthukumaran, M. Handbook on Spray Drying Applications for Food Industries; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- de Souza, V.B.; Thomazini, M.; de Carvalho Balieiro, J.C.; Fávaro-Trindade, C.S. Effect of spray drying on the physicochemical properties and color stability of the powdered pigment obtained from vinification byproducts of the Bordo grape (Vitis labrusca). Food Bioprod. Process 2015, 93, 39–50. [Google Scholar] [CrossRef]

- Fang, Z.; Bhandari, B. Effect of spray drying and storage on the stability of bayberry polyphenols. Food Chem. 2011, 129, 1139–1147. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lingua, M.S.; Salomón, V.; Baroni, M.V.; Blajman, J.E.; Maldonado, L.M.; Páez, R. Effect of Spray Drying on the Microencapsulation of Blueberry Natural Antioxidants. Proceedings 2021, 70, 26. https://doi.org/10.3390/foods_2020-07683

Lingua MS, Salomón V, Baroni MV, Blajman JE, Maldonado LM, Páez R. Effect of Spray Drying on the Microencapsulation of Blueberry Natural Antioxidants. Proceedings. 2021; 70(1):26. https://doi.org/10.3390/foods_2020-07683

Chicago/Turabian StyleLingua, Mariana S., Virginia Salomón, María V. Baroni, Jesica E. Blajman, Luis María Maldonado, and Roxana Páez. 2021. "Effect of Spray Drying on the Microencapsulation of Blueberry Natural Antioxidants" Proceedings 70, no. 1: 26. https://doi.org/10.3390/foods_2020-07683

APA StyleLingua, M. S., Salomón, V., Baroni, M. V., Blajman, J. E., Maldonado, L. M., & Páez, R. (2021). Effect of Spray Drying on the Microencapsulation of Blueberry Natural Antioxidants. Proceedings, 70(1), 26. https://doi.org/10.3390/foods_2020-07683