Non-Destructive Evaluation of Internal Sulphate Attack in Cement-Based Materials Applying Non-Linear Ultrasonic Techniques †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Experimental Tecniques

3. Results and Discussion

4. Conclusions

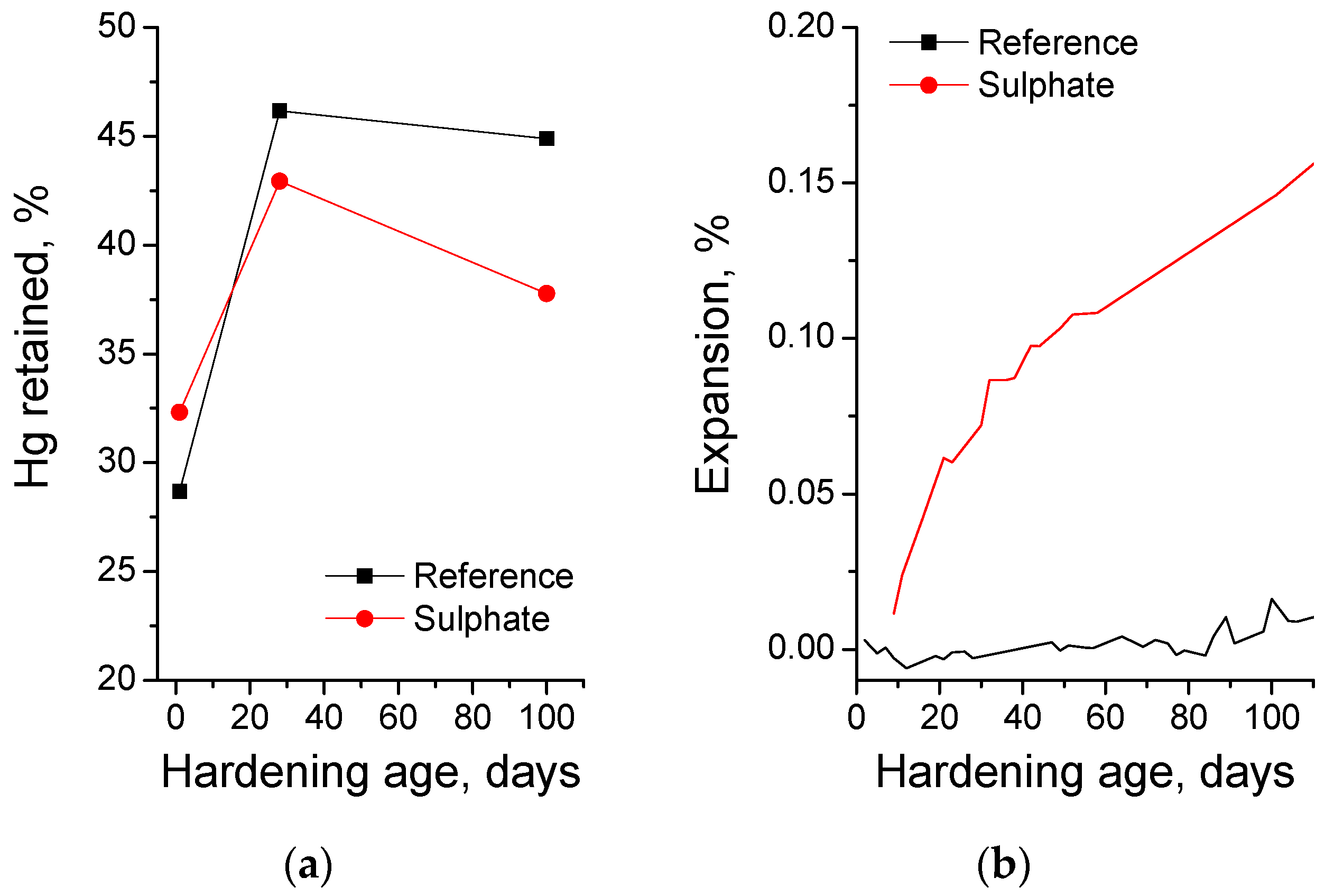

- The reference pastes showed an important pore refinement at 28 hardening days. This could be due to the microstructure development due to the hydration of clinker, which would progressively close the finer pores, reducing the porosity and the relative volume of pores of the smaller diameter ranges.

- The pore size distribution of cements pastes exposed to internal sulphate attack gradually became more refined with time, but this refinement was lower compared to reference pastes. This would suggest that simultaneously to the silting of part of the pores due to clinker hydration and formation of initial products of sulphate attack, it would have pores already filled in which this attack would be starting to produce microcracking of microstructure. Despite that, the deleterious effects of internal sulphate attack were not generalized yet, so a pore refinement during the studied time period has been globally reported. Therefore, it would be expected that at later hardening ages, in further stages of the attack, the loss of pore refinement was more notable, at least for being detected with mercury intrusion porosimetry.

- A continuous expansion has been observed for pastes subject to internal sulphate attack. This would confirm the possible presence of pores already silted in which a possible formation of microcracks due to expansion could be produced.

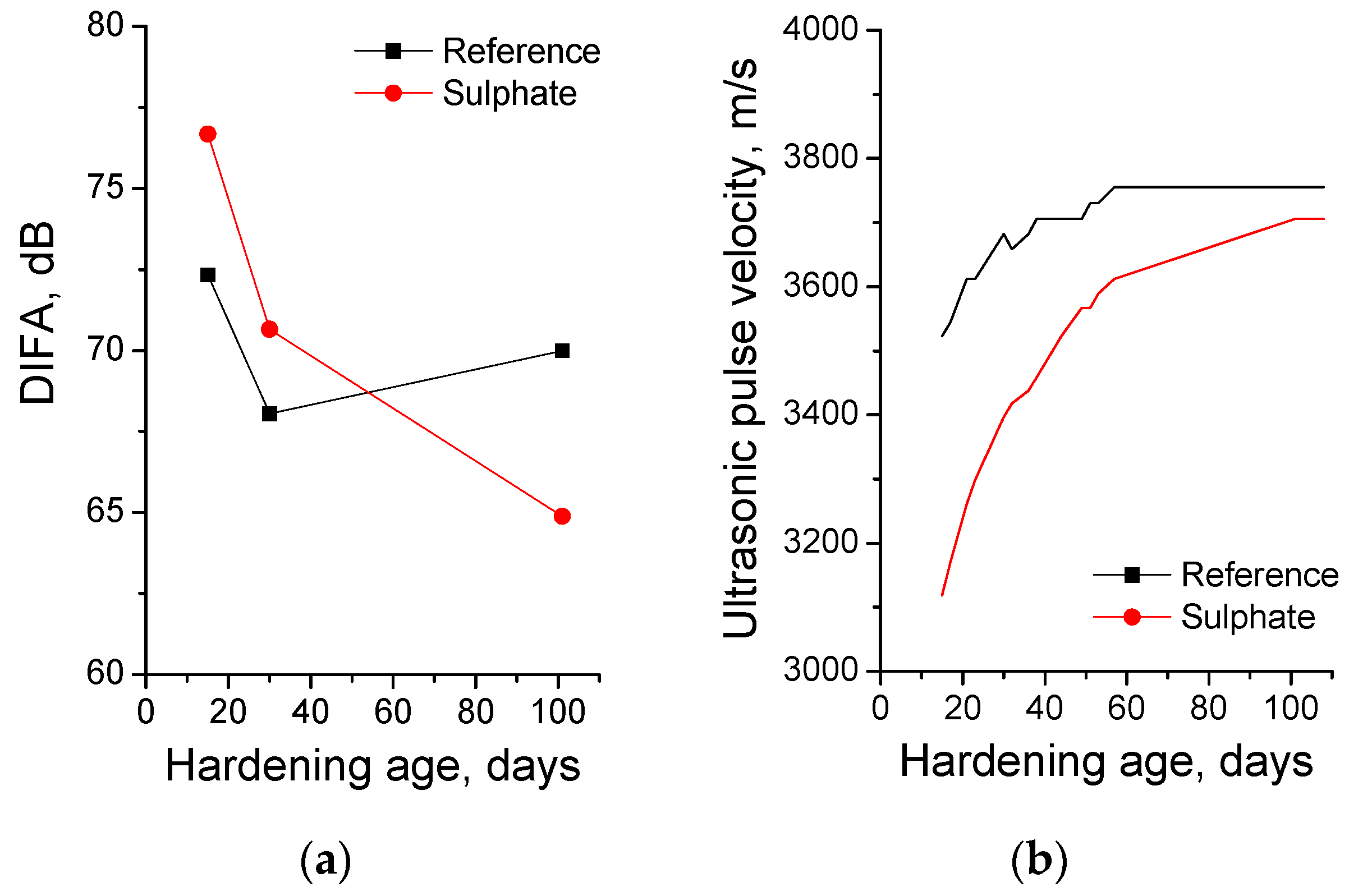

- The tendencies observed for the NLU parameter DIFA were overall in keeping with the results of the length change due to expansion.

- Regarding linear ultrasonic pulse velocity, their results suggest a progressive reduction of voids with age in the studied samples, and effects of sulphate attack in this parameter have not been observed.

- In view of these preliminary results, it seems that NLU technique could be useful for providing information about the deleterious processes due to internal sulphate attack in cement-based materials. Although more research would be needed for confirming this.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, J.; Jiang, M.; Zhu, J. Damage evolution in cement mortar due to erosion of sulphate. Corros. Sci. 2008, 50, 2478–2483. [Google Scholar] [CrossRef]

- Santhanam, M.; Cohen, M.D.; Olek, J. Mechanism of sulfate attack: A fresh look. Part 1: Summary of experimental results. Cem. Concr. Res. 2002, 32, 915–921. [Google Scholar] [CrossRef]

- Ortega, J.M.; Esteban, M.D.; Rodríguez, R.R.; Pastor, J.L.; Ibanco, F.J.; Sánchez, I.; Climent, M. Long-term behaviour of fly ash and slag cement grouts for micropiles exposed to a sulphate aggressive medium. Materials (Basel) 2017, 10. [Google Scholar] [CrossRef] [PubMed]

- Climent, M.Á.; Miró, M.; Carbajo, J.; Poveda, P.; de Vera, G.; Ramis, J. Use of non-linear ultrasonic techniques to detect cracks due to steel corrosion in reinforced concrete structures. Materials (Basel) 2019, 12. [Google Scholar] [CrossRef] [PubMed]

- Climent-Llorca, M.Á.; Miró-Oca, M.; Poveda-Martínez, P.; Ramis-Soriano, J. Use of Higher-Harmonic and Intermodulation Generation of Ultrasonic Waves to Detecting Cracks due to Steel Corrosion in Reinforced Cement Mortar. Int. J. Concr. Struct. Mater. 2020, 14. [Google Scholar] [CrossRef]

- ASTM. ASTM C 452-02 Standard Test Method for Potential Expansion of Portland-Cement Mortars Exposed to Sulfahte; American Society for Testing and Materials: West Conshohocken, PA, USA, 2002; Volume 2. [Google Scholar]

- Escalante-García, J.I.; Sharp, J.H. Effect of temperature on the hydration of the main clinker phasesin Portland cements: Part II, blended cements. Cement Concrete Res. 1998, 28, 1259–1274. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Impedance spectroscopy study of the effect of environmental conditions in the microstructure development of OPC and slag cement mortars. Arch. Civ. Mech. Eng. 2015, 15, 569–583. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega, J.M.; Miró, M.; Poveda, P.; Tenza-Abril, A.J.; Ramis, J.; Climent, M.Á. Non-Destructive Evaluation of Internal Sulphate Attack in Cement-Based Materials Applying Non-Linear Ultrasonic Techniques. Proceedings 2020, 67, 19. https://doi.org/10.3390/ASEC2020-07514

Ortega JM, Miró M, Poveda P, Tenza-Abril AJ, Ramis J, Climent MÁ. Non-Destructive Evaluation of Internal Sulphate Attack in Cement-Based Materials Applying Non-Linear Ultrasonic Techniques. Proceedings. 2020; 67(1):19. https://doi.org/10.3390/ASEC2020-07514

Chicago/Turabian StyleOrtega, José Marcos, Marina Miró, Pedro Poveda, Antonio José Tenza-Abril, Jaime Ramis, and Miguel Ángel Climent. 2020. "Non-Destructive Evaluation of Internal Sulphate Attack in Cement-Based Materials Applying Non-Linear Ultrasonic Techniques" Proceedings 67, no. 1: 19. https://doi.org/10.3390/ASEC2020-07514

APA StyleOrtega, J. M., Miró, M., Poveda, P., Tenza-Abril, A. J., Ramis, J., & Climent, M. Á. (2020). Non-Destructive Evaluation of Internal Sulphate Attack in Cement-Based Materials Applying Non-Linear Ultrasonic Techniques. Proceedings, 67(1), 19. https://doi.org/10.3390/ASEC2020-07514