In addition to friction forces F

Friction and inertia forces F

Inertia, the actuator also needs to overcome the spring forces F

Spring and the flow forces F

Flow, which normally act in closing direction [

6,

8]. The spring forces must be high enough, so that the valve is able to close at any given operation condition [

6,

8]. A preload on the spring prevents the spool from overshooting [

6,

8]. The flow force mostly represents the most significant resistance of these forces [

9]. In addition, an additional inherent force F

Pressure is caused by the fluid in the passive pilot chamber, as is the case of a pilot operated valve. Fluid is displaced by the movement of spool. A pressure rise in the passive pilot chamber can occur depending on the hydraulic resistance of the drain line.

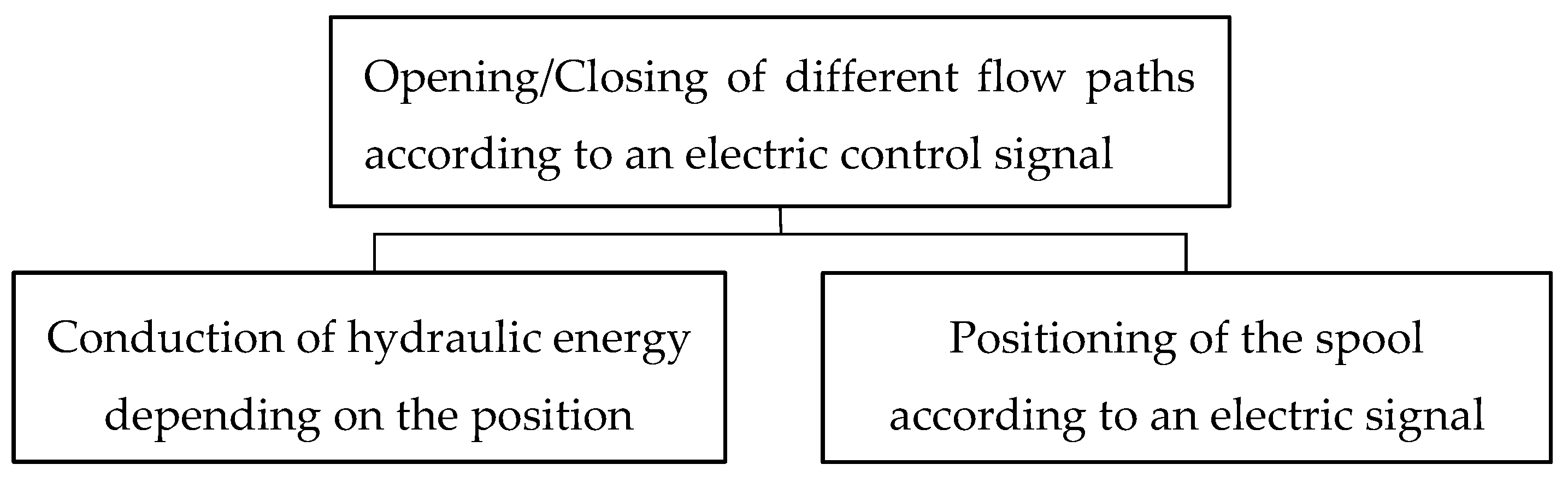

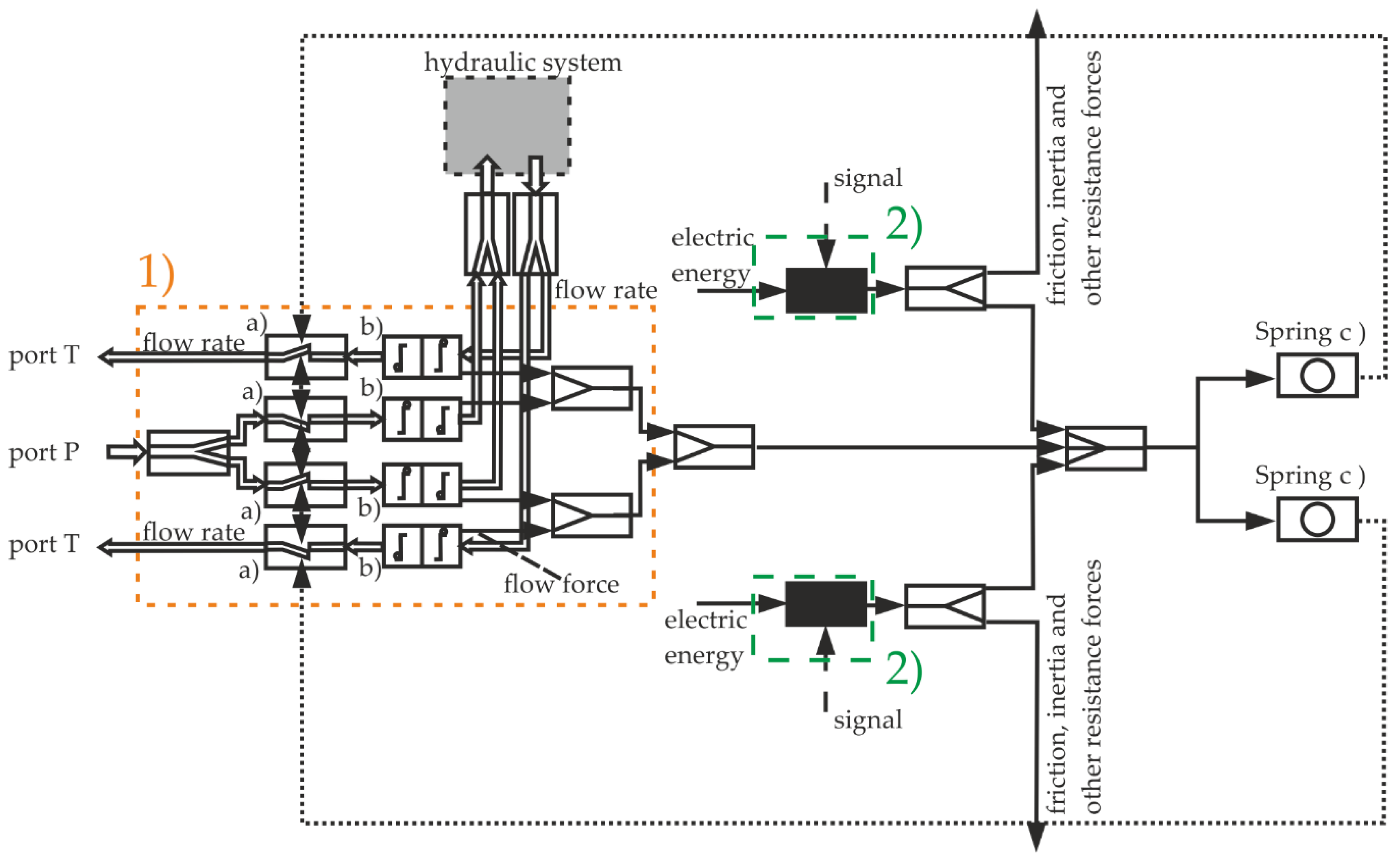

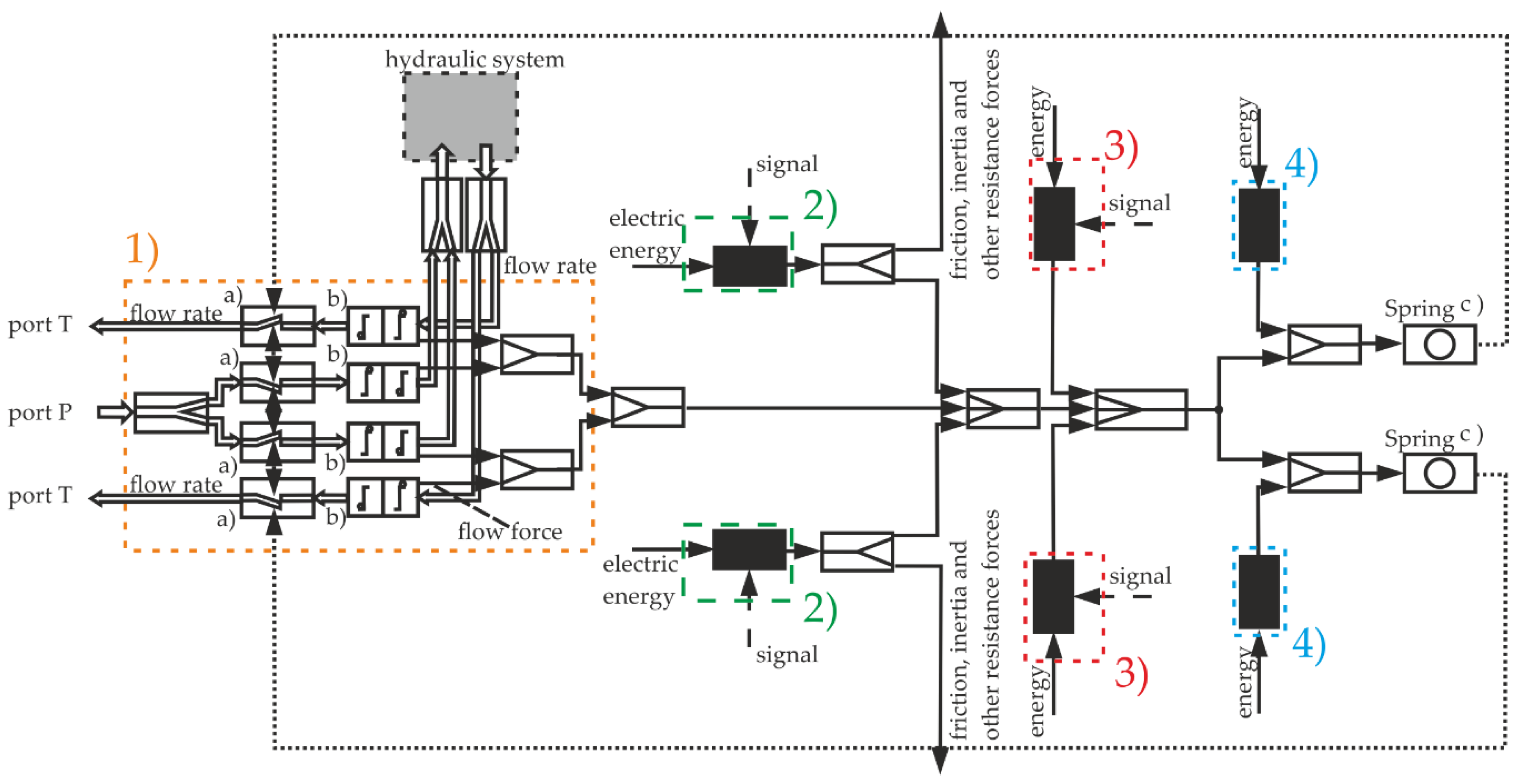

3.1. Functional Structure of a Pilot Operated Large Sized Valve

A functional structure of a 4/3 directional control valve has been derived in

Figure 3 based on the two main functions of a directional control valve according to

Figure 1. The notation of elementary functions according to

Table 1 is used in following figure.

The functional structure can be divided into different subsystems. Subsystem 1) represents the functions attributed to the spool geometry. The flow rate which is entering the system through port P is conducted by the metering edges a) to the working ports of the valve. During the flow conduction a part of the energy is transformed into mechanical energy b), which acts as flow force on the spool. This force normally tends to close the valve. Leaving the subsystem 1), the fluid enters a not further specified hydraulic system. Fluid flows back into the tank resulting in additional flow forces.

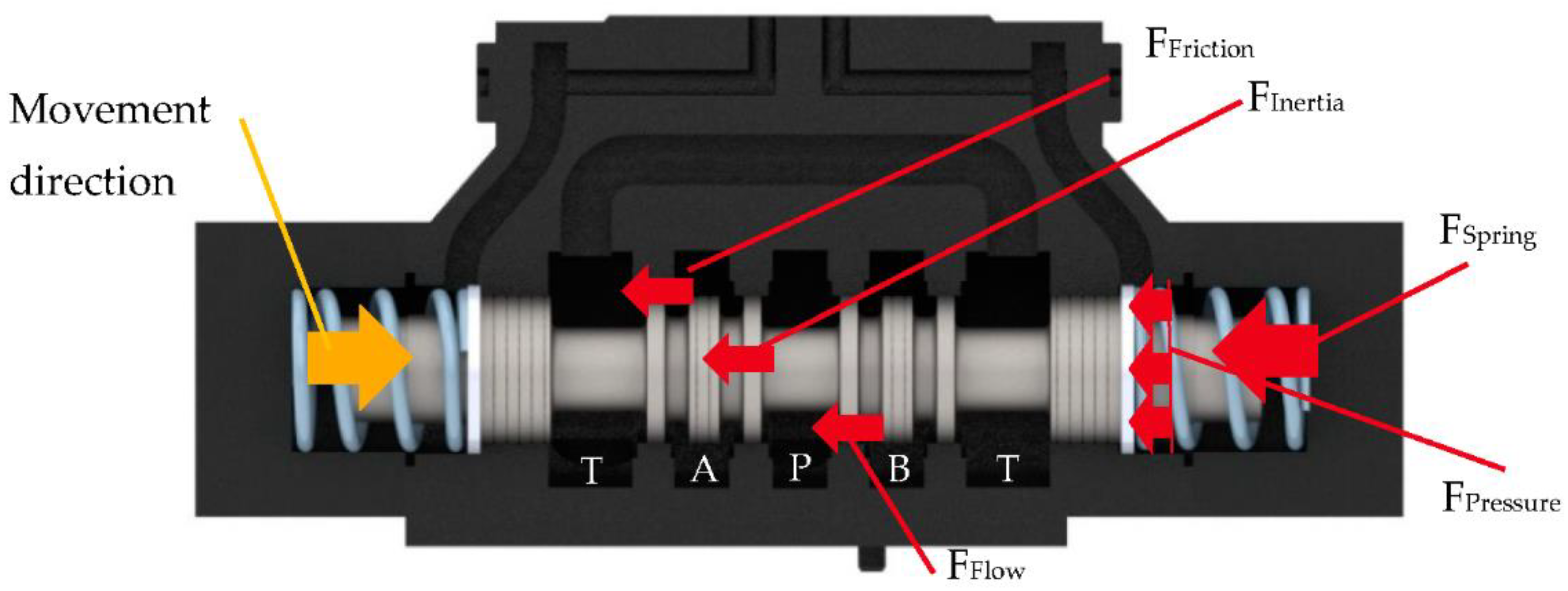

During the positioning of the spool, the actuation unit needs to apply a force larger than all resistance forces acting on the spool. As shown in

Figure 2, these consist of flow forces F

Flow, friction forces F

Friction, inertia forces F

Inerta, spring forces F

Spring, and forces resulting of the hydraulic resistance of the drain line of the passive pilot chamber F

Pressure. Most of these forces are shown leaving the functional structure, since they represent dissipation (friction, inertia and further resistance forces). Flow forces are applied in the valve and are acting on the spool, therefore being displayed on the functional structure as generated forces, which are subtracted from the actuation system force. The remaining force acts against the centering spring, while the spool is deflected into its working position.

The mechanical energy is stored in the spring c), as long as the actuation system provides sufficient force. If the actuation force is reduced, the stored energy is released, thus centering the spool. The stored energy is, according to the spring stiffness, a function of the stroke, which is why an information flow is drawn from the spring c) to the metering edges a).

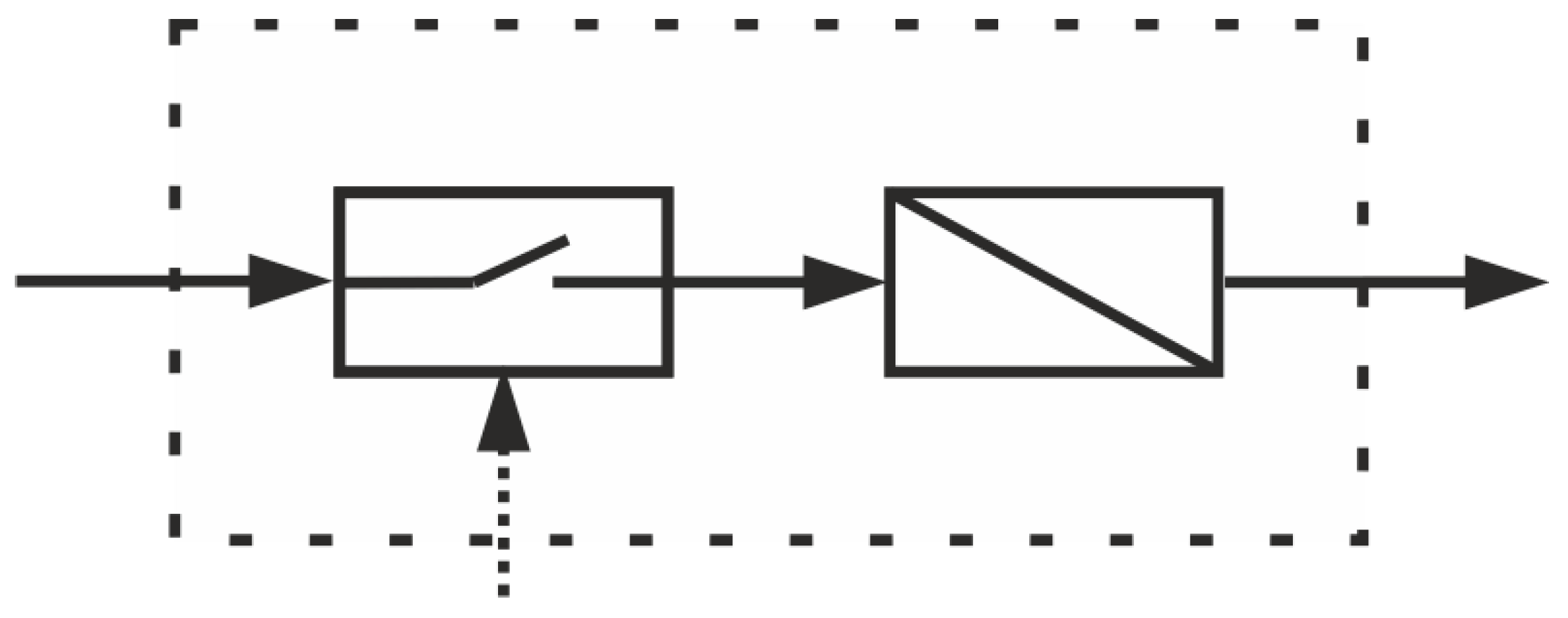

The subsystem 2) needs to be analyzed in detail to design a direct electromechanical valve actuation system. This subsystem consists at least out of two essential functions, as shown in

Figure 4 [

10].

Every actuator consists at least of a switch and an energy converter [

10]. This can be a pilot operation circuit where the pilot valve is the switch and the energy conversion is realized in the pilot chamber. Focusing on the design of an electromechanical valve actuation system, the energy converter is electromechanical, such as solenoids or electrical motor. An evaluation on electromechanical converters was carried out to analyze their suitability for the given application. As a result, an electrical motor, followed by a mechanical component to convert rotary into translatory movement, was the optimal concept.

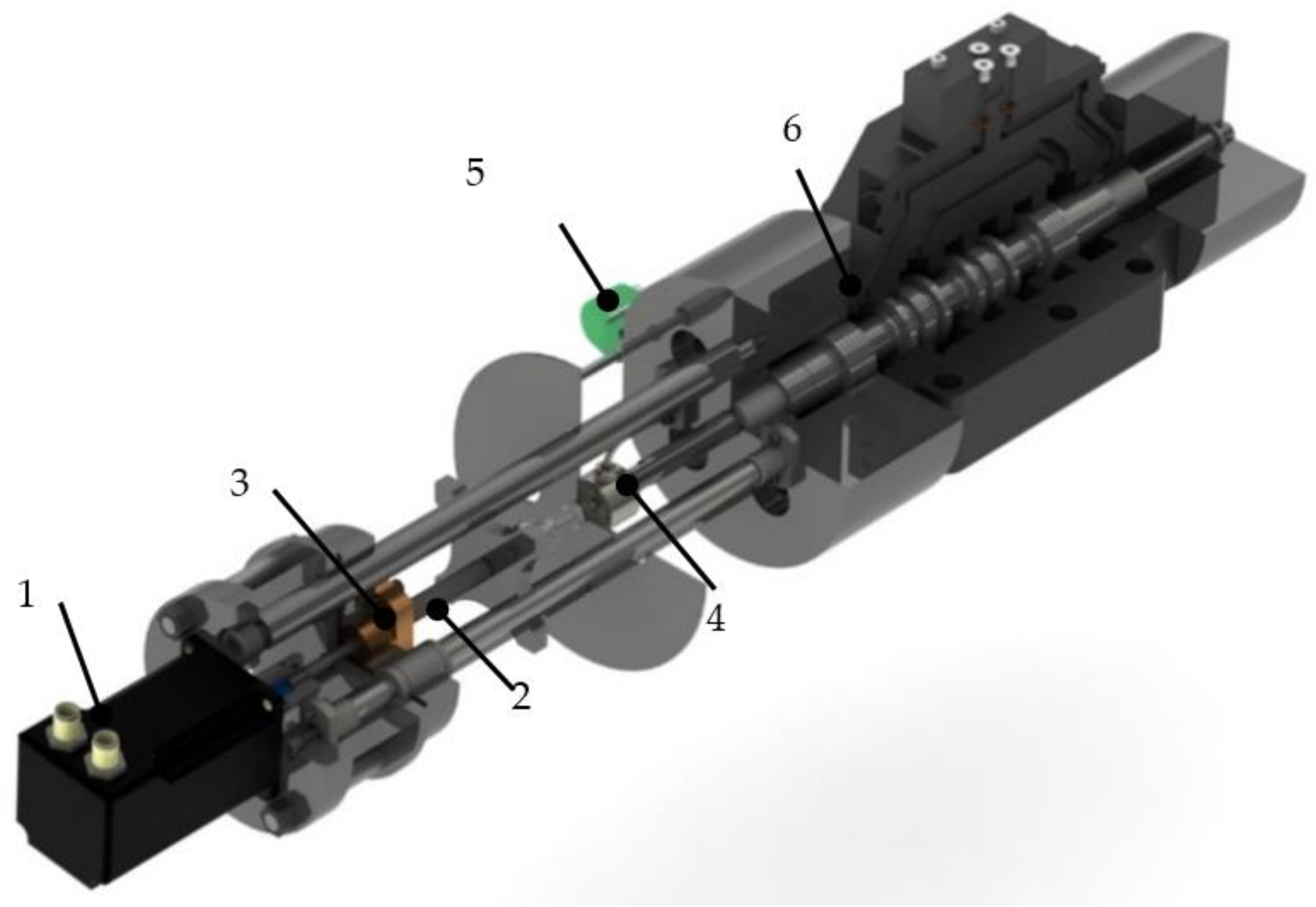

3.3. Design Features of the Electromechanical Valve Actuation System

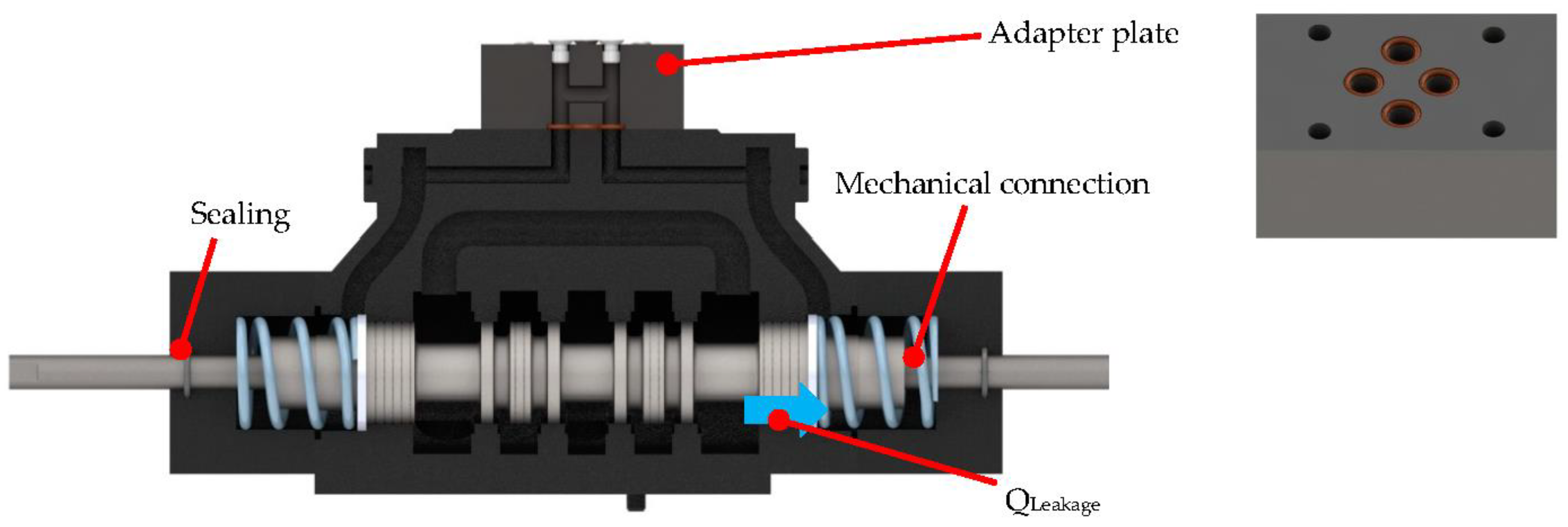

Certain design features must be taken into account if the valve actuator is designed independently from the valve. These result from the design of the valve and can cause additional unwanted forces if they are not considered properly. To highlight these features, a sectional view of a regular pilot operated valve is shown in

Figure 6. The spool of the valve is extended at both ends by a rod, creating a mechanical connection to the outside of the valve. These connections are required as the valve is switched electromechanically.

In the case of externally attached actuators, mechanical connectors are necessary to transmit tensile and compressive forces required for the actuation of the valve. Actuators, which are able to induce both forces, are therefore attached only on one side of the valve. In this configuration, the spool has to be balanced, taking into account the pressure forces at the front sides. To ensure that the pressure in both sides is identical, the pilot chambers needs to be short circuited. Since the actuator design is externally attached, an internal connection between both pilot chambers of the valve is not possible. Therefore, an adapter plate is mounted on the top of the valve instead of the pilot valve. As, the mechanical connection reduces the pressurized area, it should be implemented on both sides.

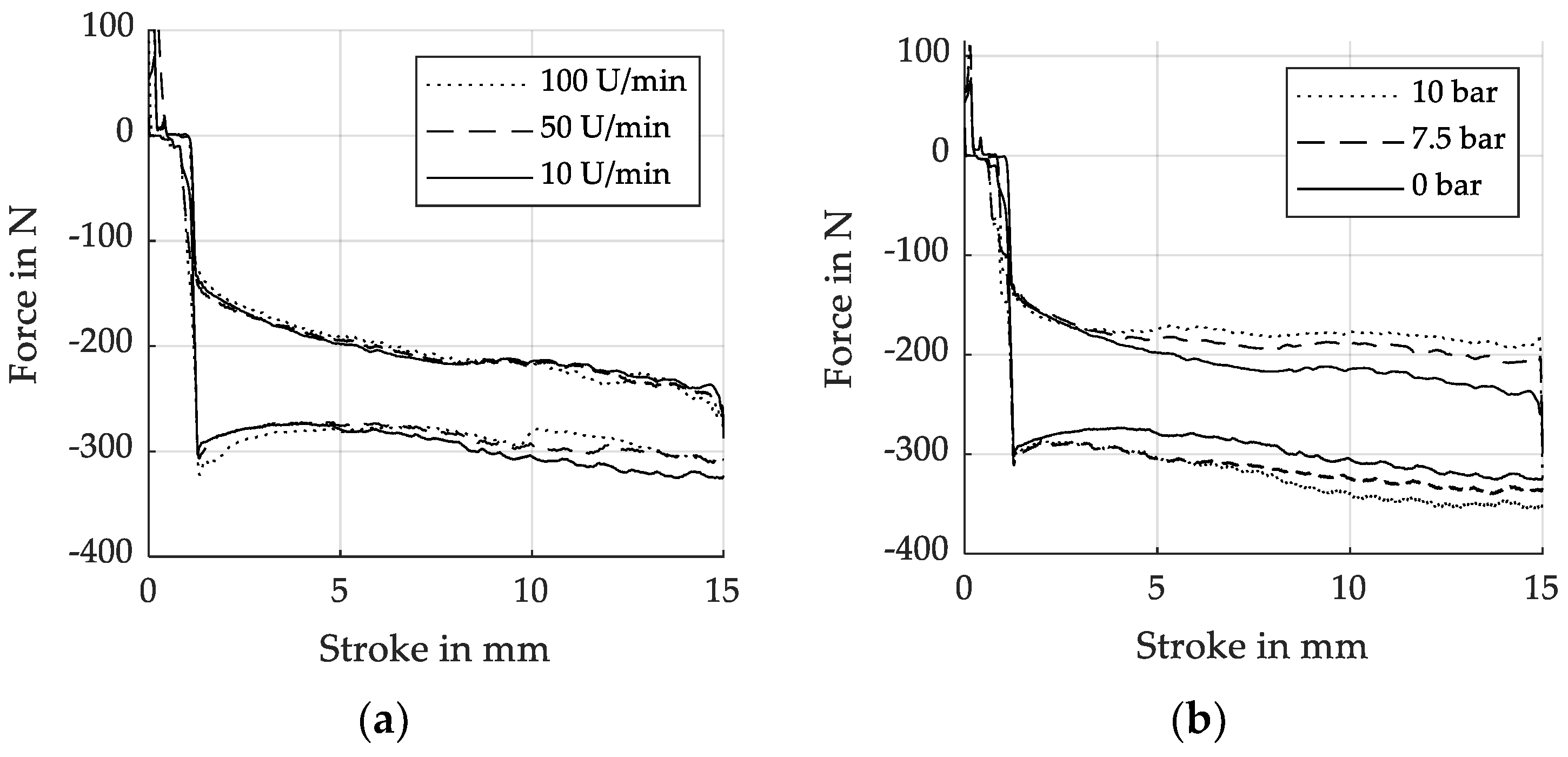

Short-circuiting both pilot chambers with each other has an additional effect. During the movement of the spool, one chamber is expanded, whereas the other is contracted. Therefore, fluid must be able to enter or exit the chambers. This action would require a compensation volume, but using the adapter plate, the displaced volume in one chamber is compensated in the other, thus maintaining a constant volume. No additional volume is necessary. Enabling the fluid to oscillate between the chambers, it needs to overcome the inherent resistance. Therefore, a small pressure difference between the two chambers arises. This needs to be considered in the design of the electromechanical actuator. To investigate this effect, the actuator was driven with different speeds, and the required force was measured. The results are shown in

Figure 7a. The necessary force to move the spool at even tenfold the actuator speed does not increase significantly. It can, therefore, be concluded that this influence is extremely small considering the other factors.

Additional sealings on the caps are necessary to avoid external leakage, leading to further friction forces to be overcome by the actuator. These forces strongly depend on the pressure in the pilot chambers. Further measurements have been conducted to investigate this effect. The force requirements by different pressure levels in the pilot chamber is illustrated in

Figure 7b.

As can be seen in the figure, this effect is not negligible. Even a chamber pressure of 10 bar leads to a significant increase of the required actuator force. Therefore, the pressure in the pilot chambers have to be reduced as much as possible. The pressure in the pilot chamber is adjusted to the pressure at the T port of the valve since there is a leakage flow over the spool. Therefore, the maximum pressure at the tank line of the valve must be considered during the design of outside attached actuators. In case of systems where the pressure at the valve T port can reach high values, an additional drain line in the adapter plate will ensure low pressure in the pilot chamber. The aforementioned design features are only valid for outside attached actuators, which are normally designed independently from the valve geometry. The additional sealing, and therefore the draining line, becomes redundant with the development of an actuation system, which can be pressurized. The adapter plate becomes unnecessary if a direct connection between both chambers is provided.

3.4. Innovative Electromechanical Valve Actuation System

The previously presented actuator is one possible solution while focusing on the functional structure of an actuator. A holistic view of the functional structure of a “valve and its actuation system” leads to further innovative solutions. In the following,

Figure 8, the functional structure of the “valve and its actuation system” was extended by two additional subsystems, 3) and 4).

Other than the additional subsystems, the functional structure is kept the same. Subsystem 1) represents the valve and subsystem 2) the main actuator. New valve actuation systems can be derived based on this functional structure because the requirements of the individual actuators change by combining various subsystems.

Solutions proposed by the subsystem 3) cover all actuation systems, which are extended by an additional actuator 3) to keep the spool in position when it has reached the desired stroke. Therefore, the main actuator (subsystem 2)) does not need to constantly apply the necessary force. The actuator only needs to surpass the opposing forces for a short time. After that, the spool is held in position by the actuator 3). It is conceivable for a design that the actuator 3) holds the spool in position by means of clamping forces. In this case, the actuator 3) only needs to realize relatively small strokes. Due the clamping movement can be realized orthogonal to the spool movement. One example where the clamping idea is realized is a piezoelectric inchworm motor

Solutions resulting of subsystem 4) seem more promising. The general function of the springs is to move the spool into a defined position. In the case of the here analyzed 4/3 directional control valve, it is the centered position. In the functional structure in

Figure 8, the springs are displayed as accumulators c). A closer look to the general function of the springs shows that there are two relevant operations. On the one hand, the springs need to center the spool according to the operation cycle, while, one the other hand, they need to center the spool in case of failure, as in a power outage. Therefore, the general function can be divided into two different functions, according to

Figure 9.

In common pilot operated valves, providing energy for the switching process and compressing the springs takes place simultaneously, while moving the spool into the end position a part of the actuator’s energy is used to compress the springs. This energy is stored in the springs and is required for the reset process. The time dependency can be solved by the separation and redistribution of the spring functions into further components. The first function can be covered by the main actuator using a proportional actuator, like the one present before. Therefore, the springs only must center the spool in case of power outage. Thus, the energy stored in the springs only comes to effect in case of an error. They remain compressed most of the time by the additional force of subsystem 4). The requirements for the applied force of the switching actuator decrease as the high spring forces can be temporarily removed during normal operation.

Two principal solutions turned out to be the most suitable. In one alternative, the springs are preloaded by the main actuator while being held compressed by magnets. Since magnets are optimal for applying high forces at zero gap, they comply perfectly the requirements for this function. During an initial start of the system, the main actuator moves the spool in each end position to compress the springs. This can be done with low velocity. Therefore, the necessary power is reduced. Reaching the end position, the magnets are activated and ensure the holding of the compressed springs. Subsequently, the spool can be moved by the main actuator without applied spring forces. In case of power failure, the magnets are deactivated, causing the springs to decompress and thus centering the spool. This concept is ideal for an actuator, based on a stepper motor, since it can provide large torque during a slow rotation speed. During further operation, the actuator does not need to work against the spring forces anymore. Therefore, the necessary power is reduced drastically.

In another alternative solution an extra chamber containing the spring is designed to preload these by application of hydraulic energy. Hydraulic fluid can be diverted from the main system during high pressure phases, since the time dependency is solved, thus avoiding an additional pilot circuit. Hydraulic pressure controlled by two valves regulate the energy stored in the springs. The first valve is placed to separate the spring chamber from the hydraulic main system, ensuring the preload to remain even in phases of low pressure. The second valve ensures the pressure relief of the spring chamber to the tank in case of a power outage. The missing hydraulic energy in the spring chamber releases the stored energy in the springs, forcing them to expand and thereby centering the spool. Since the springs are preloaded by another actuator during normal operation, the force requirement in the electromechanical actuation system is reduced.