1. Introduction

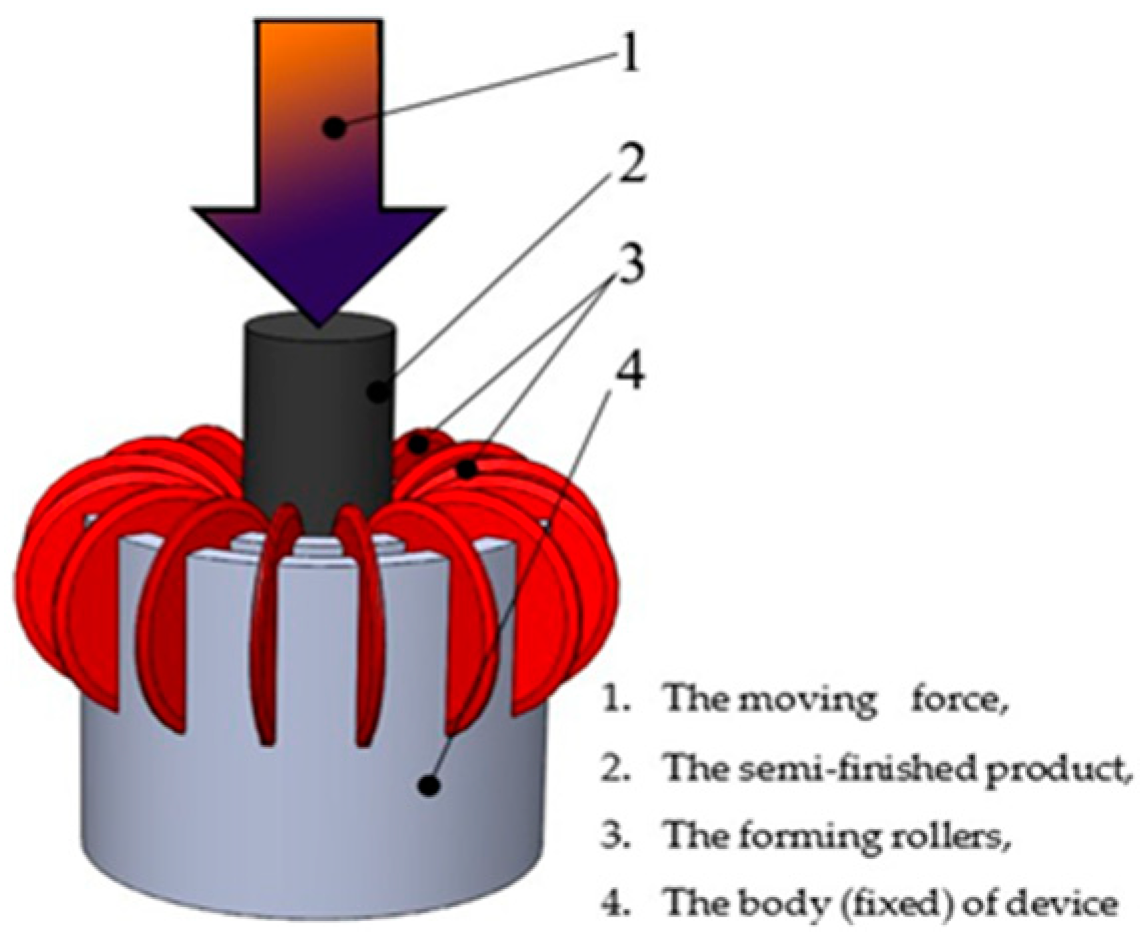

From the start of this research problem, it should be noted that the semi-finished product was obtained through a plastic forming process (pressing) by an equipment with 23 forming rollers [

1]. The symmetry axis of the set is collinear to the symmetry axis of the final toothed gear, so we subjected a slice which is the 46th part from 360°, namely 7.8°, in the simulations. Additionally, we tried to quantify the implications of operating the press punch on the designed and assembled toothed gear wheel.

A mesh network was built for each slice, and the corresponding plastic deformation equations were applied in each of them. Through this research methodology, we noticed how each simulated slice of 7.8° was affected overall, so we reached the necessary conclusions that led us to make the necessary changes in the whole assembly, and finally we saw how the whole set behaved.

The technical parameters of this plastic deformation process were deduced. It was proven that the technical feasibility for the manufacture of toothed gear wheels through this method is clearly superior to the classical method which involves milling, especially due to the significantly higher productivity of the proposed process and the material saving, in addition to the advantage of toothed gear wheels obtained with continuous fiber, who are much more resistant from a mechanical point of view.

2. The Pressing

We started from the idea of making a toothed gear by pressing a cylindrical semi-finished product, made by drawing [

2,

3], through a roller device. In a specific case, we decided that the device should consist of 23 deformation rollers and a body (fixed) on which these rollers are assembled. The design was created using a CAD software: SolidWorks (see

Figure 1). It must be noted that the device was made only for research, being intended for the realization of a gear with straight teeth having a certain number of teeth (23) and a certain circular pitch, respectively.

For practical, concrete cases, such a device can be built for each desired value of the number of teeth and the circular pitch “p” of the final toothed gear.

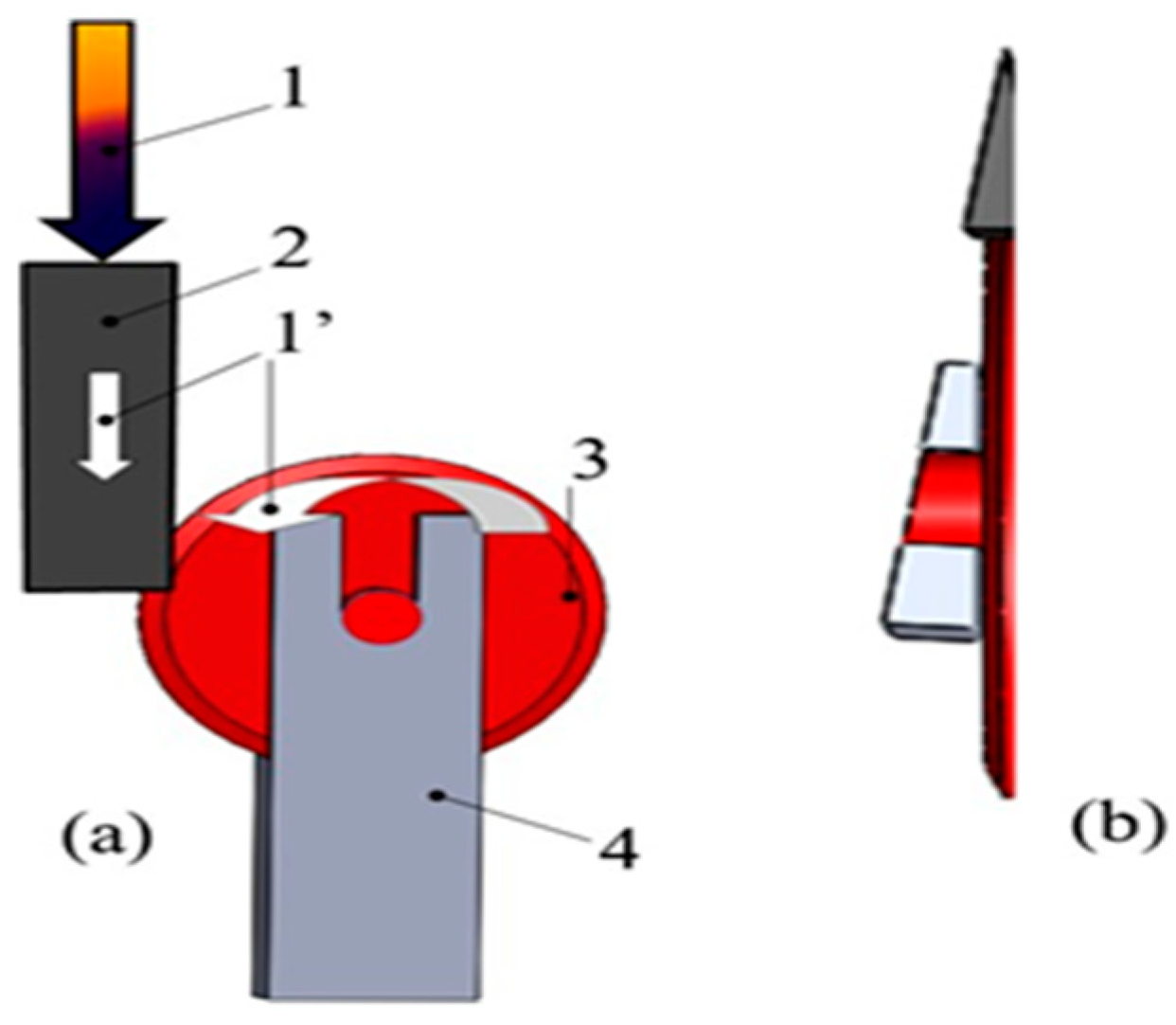

The toothed gear achieved device, built, has 23 deforming rollers, for simulation using the 46th part of a virtual circle, which has in the center the longitudinal axis of symmetry of the semi-finished product, thus being similar to a slice with peak angle of 7.8° as is shown in

Figure 2.

This simplification was used to speed up the analysis time of the simulation process. We want to mention that the simulation of the deformation process was simplified to a “slice” because the process is axisymmetric.

3. The Device Description

The previously proposed device was actually made to confirm the simulation results and its design and real assembly is shown in

Figure 3.

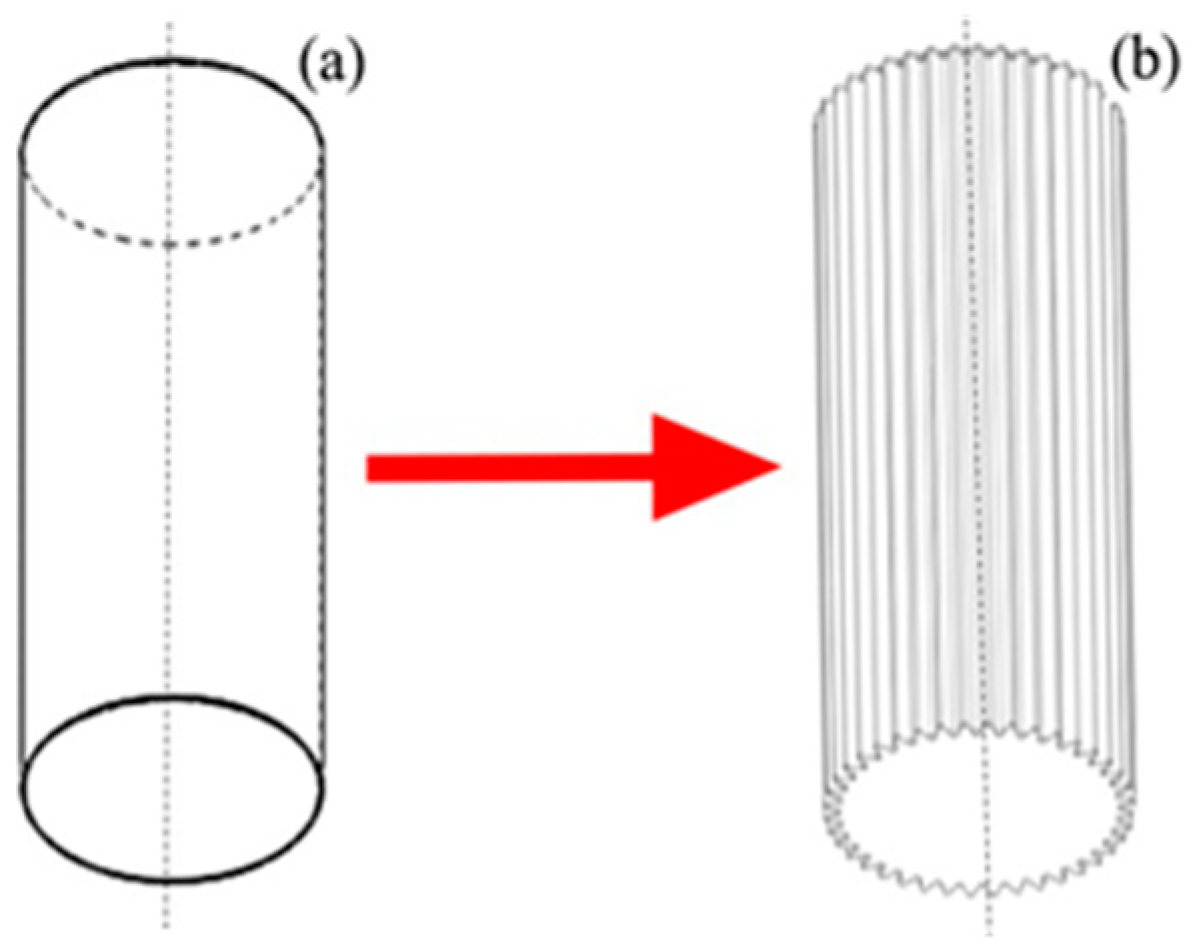

Starting from a cylindrical semi-finished product (see

Figure 4a), the device manages to make toothed gears by hot forming, similar to that shown in

Figure 4b.

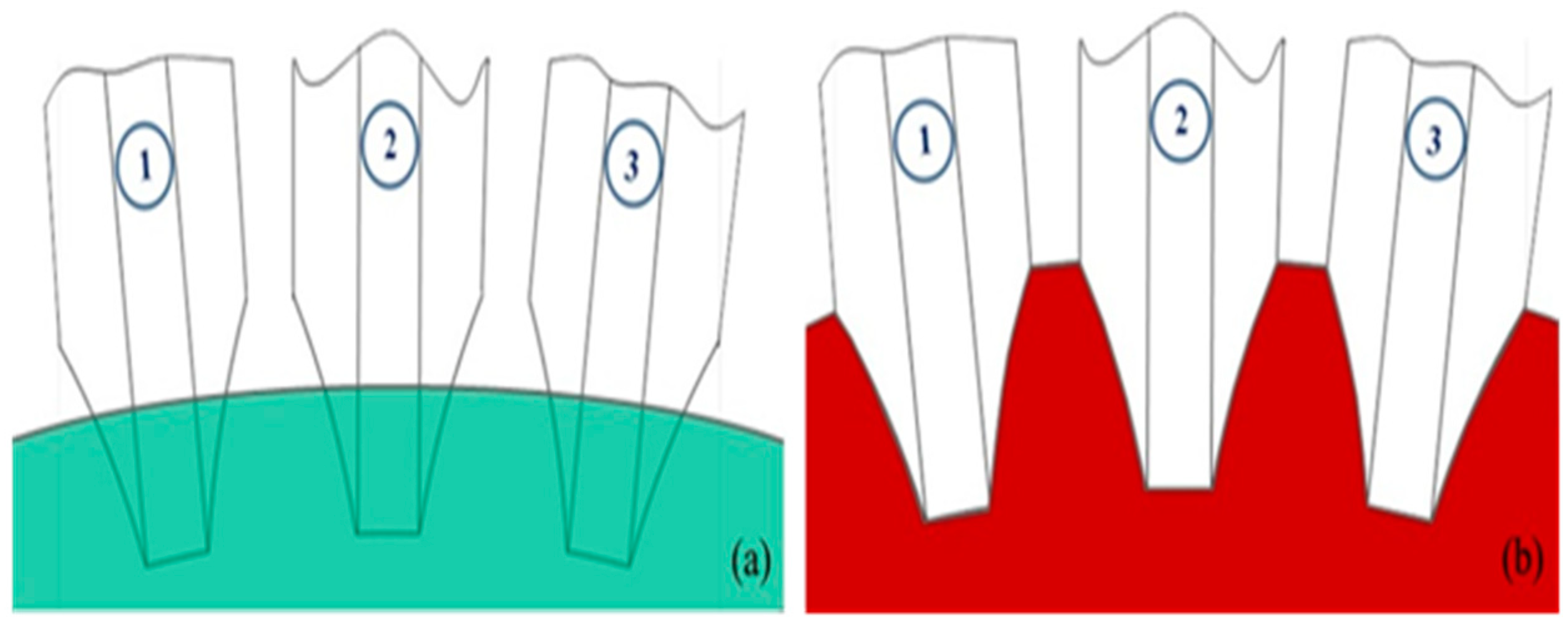

In fact, the intermediate technical stages (viewed in cross section) are detailed in

Figure 5.

4. Simulation

The simulations were performed by finite element analysis (FEA), using FORGE software.

4.1. The Dimension Assessment of the Initial Semi-Finished Product

Basically, the diameter D

s of the semi-finished product and its height H

s were determined. The mathematical calculation of the diameter D

s of the semi-finished product implies that the sum of the transverse areas of the portions displaced by the action of the forming rollers must be equal to the sum of the transverse areas of the tooth tips formed by the flow of the material [

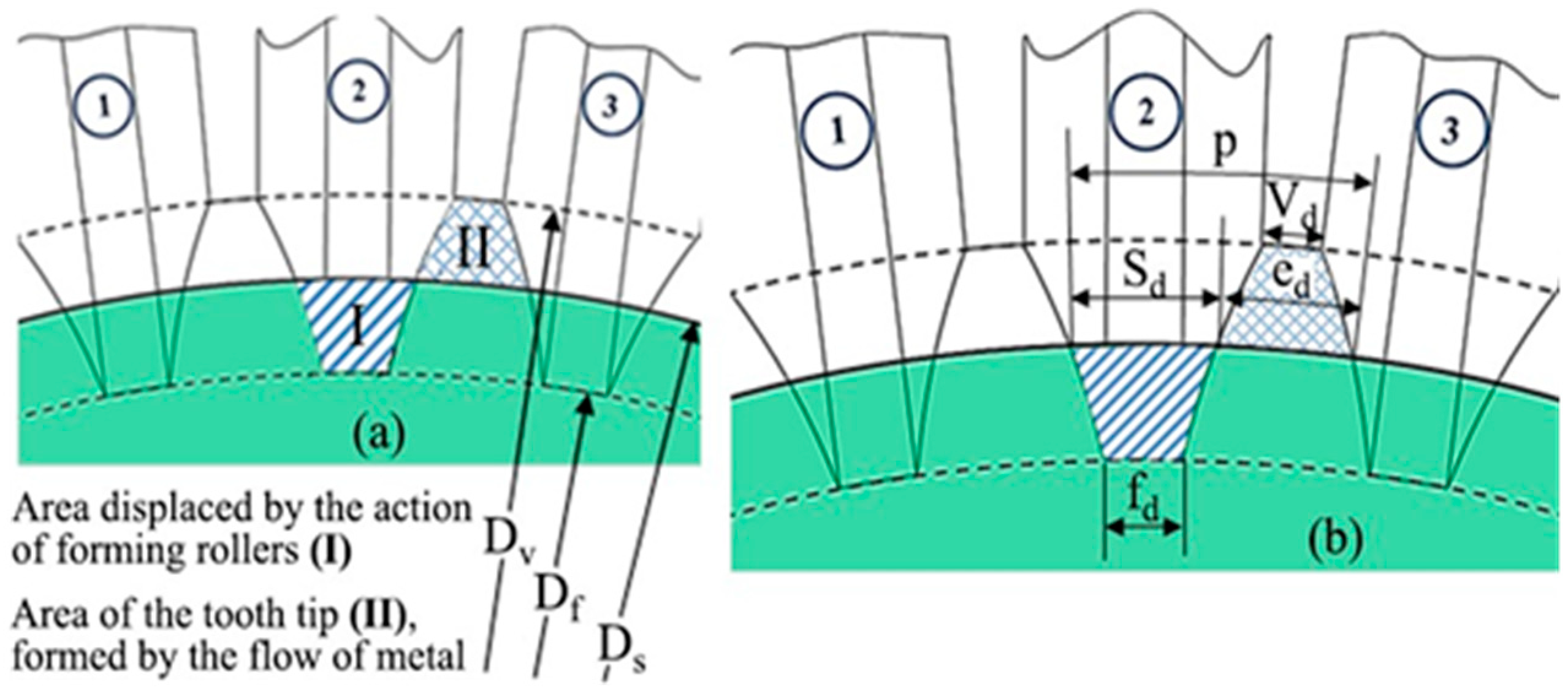

4] (see

Figure 6).

We estimated the area affected by the forming rollers, corresponding to the area displaced by their action (I) and the area of the tooth tip, formed by the flow of the material (II), respectively, with two trapezoids [

5] whose surfaces are:

The approximation of

and

results in:

- SI

the area displaced by the action of the deforming rollers [mm2]

- SII

the area of the tooth tip, formed by the flow of material [mm2]

- Ds

the diameter of the initial semi-finished product [mm]

- Df

the diameter of the dedendum circle [mm]

- Dv

the diameter of the addendum circle [mm]

- sd

tooth thickness [mm]

- ed

tooth space [mm]

- p

circular pitch [mm]

- fd

tooth space peak thickness [mm]

- vd

tooth peak thickness [mm]

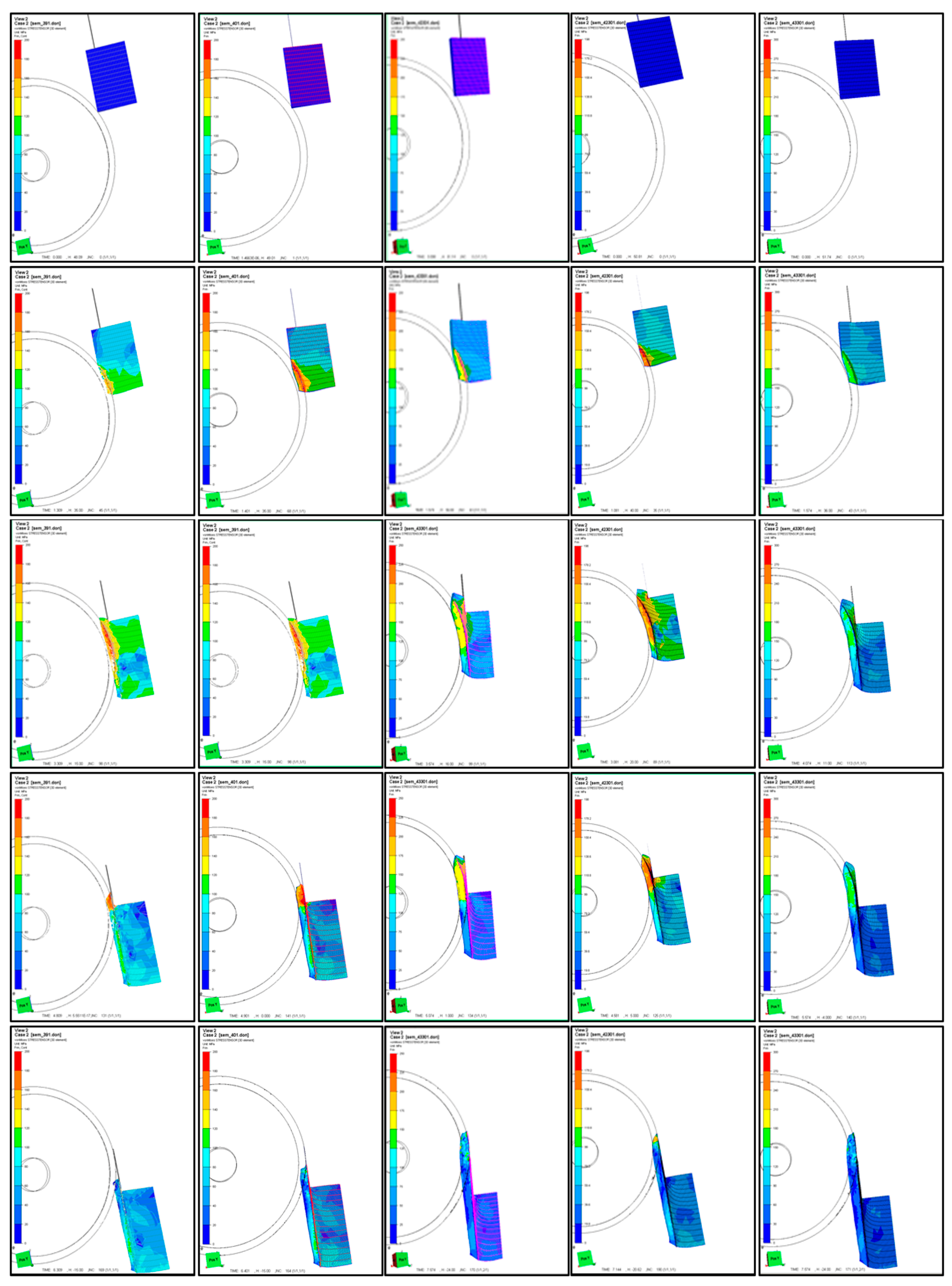

To correct the approximations from these calculations, FEA simulations were performed determining the von Mises stress and deducing the optimum dimensions of the initial semi-finished product: diameter, D

s (

Figure 7), and height, H

s (

Figure 8). The dimensions D

s and H

s are not specified as a value and are only relevant in correspondence with the dimensions of the device object of study. These dimensions were established so as to achieve the maximum degree of filling of the toothed gear by the flow of the material and a certain behavior in the process of its deformation.

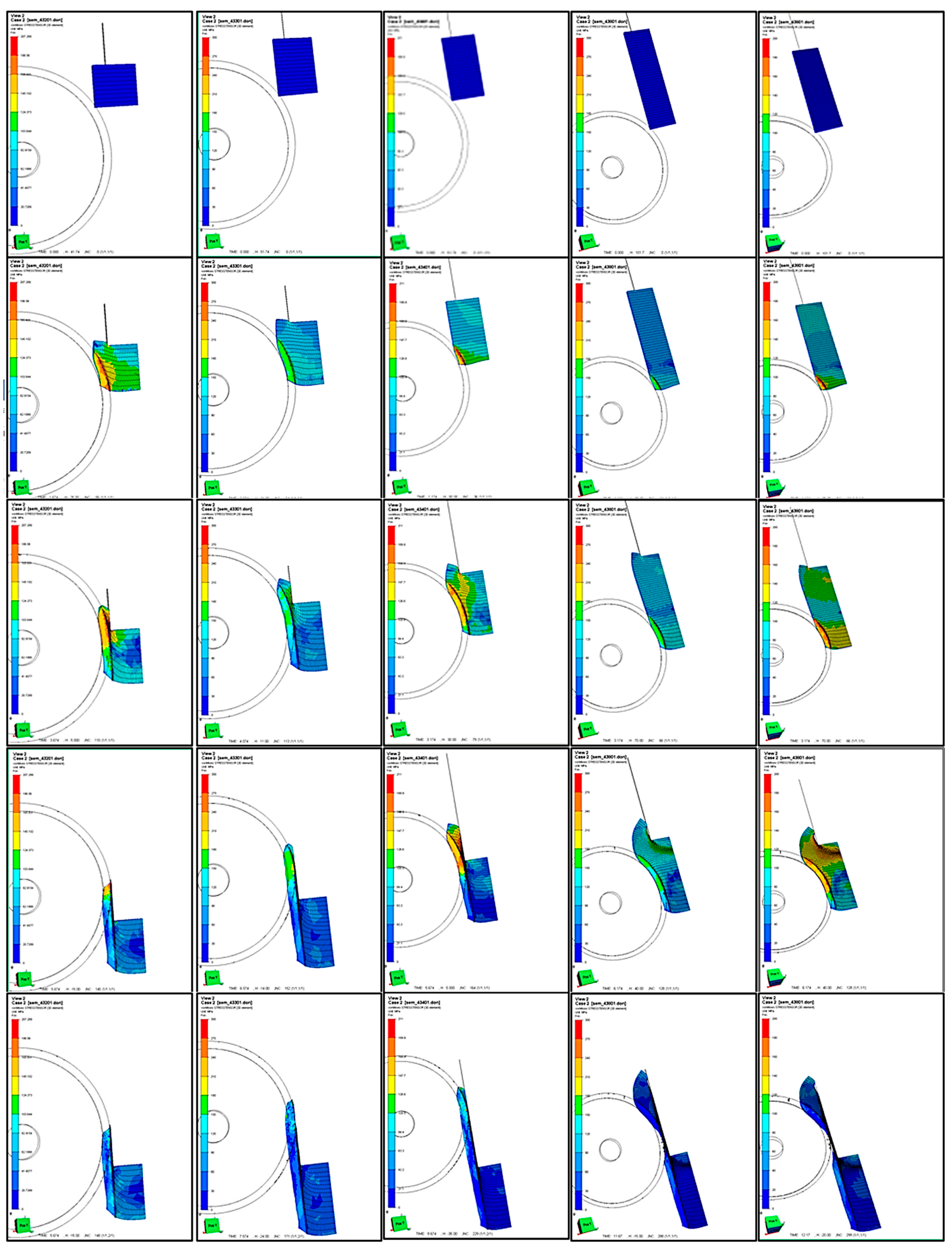

4.2. The Von Mises Stress Determination

In the second phase, with these correct dimensions, a mesh network was applied both for the semi-finished product and for the analyzed device. Thus, the final values of von Mises stress were deduced. Because both the semi-finished product and the analyzed device were involved in the simulation at this moment, a view was achieved in its longitudinal section, focused on the von Mises stress that appeared at the deformation of the semi-finished product [

6].

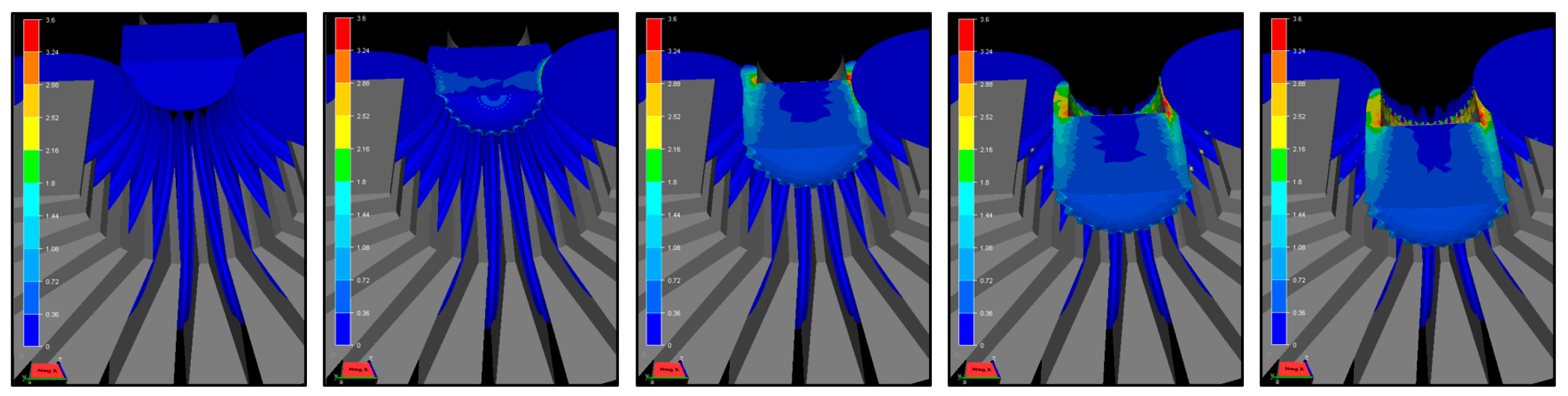

Figure 9 shows 5 figures made at various deformation moments: (

a) corresponds to the deformation start time t = 0 (initial deformation moment), (

b) corresponds to the moment t/5, (

c) moment (2/5)·t, (

d) moment (3/5)·t, (

d) moment (4/5)·t and (

e) the final moment (t = t).

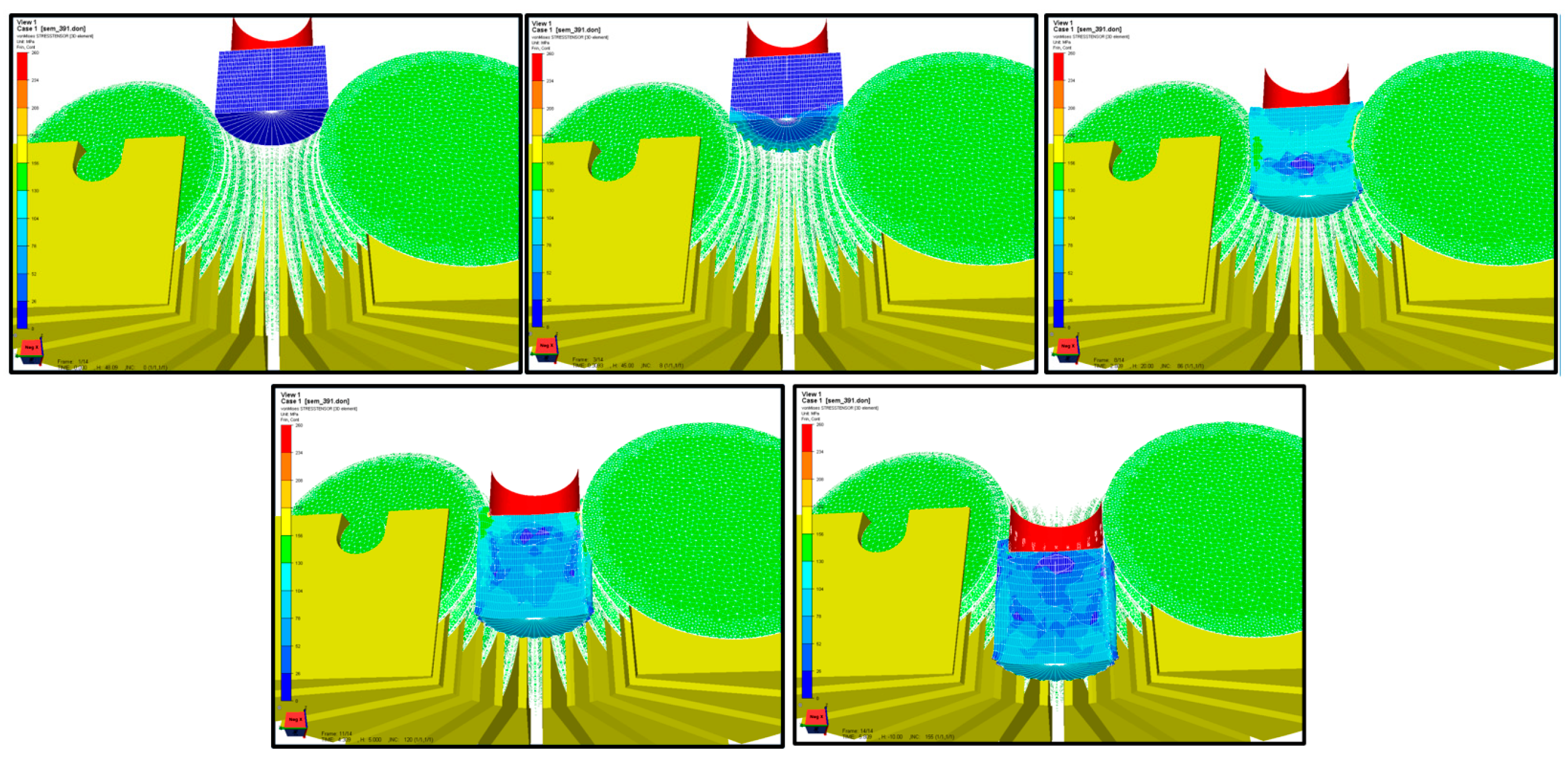

4.3. The Semi-Finished Product Deformations

This simulation is similar as aspect to the previous one, practically focusing on the amplitude of the deformations of the semi-finished product along the entire time interval (t) of its deformation, as shown in

Figure 10.

4.4. The Flow of the Semi-Finished Material

Mesh network was no longer viewed. The whole system device-part was cut from the entire longitudinal section with the aim of analyzing only the evolution of the flow of the part material, as shown in

Figure 11.

5. Conclusions

In this research, it was proven that toothed gears with a certain circular pitch and number of teeth can be achieved by this method [

7] of plastic deformation, and as with any process of plastic deformation, the fibrous structure being continuous, it results in a more resistant final product, able to respond more efficiently to various mechanical stresses [

8]. During the practical hours of simulation, it was also observed that the flow of the material in the tooth formation imposes a certain regime of deformation speed. It was also observed that in the case of obtaining steel toothed gears, the respective deformation process will be performed hot, requiring only the heating of the cylindrical surface of the initial semi-finished product.