Mechanical Behavior of Gypsum Composites Reinforced with Retama monosperma Fibers †

Abstract

1. Introduction

2. Materials and Methods

2.1. Fibers

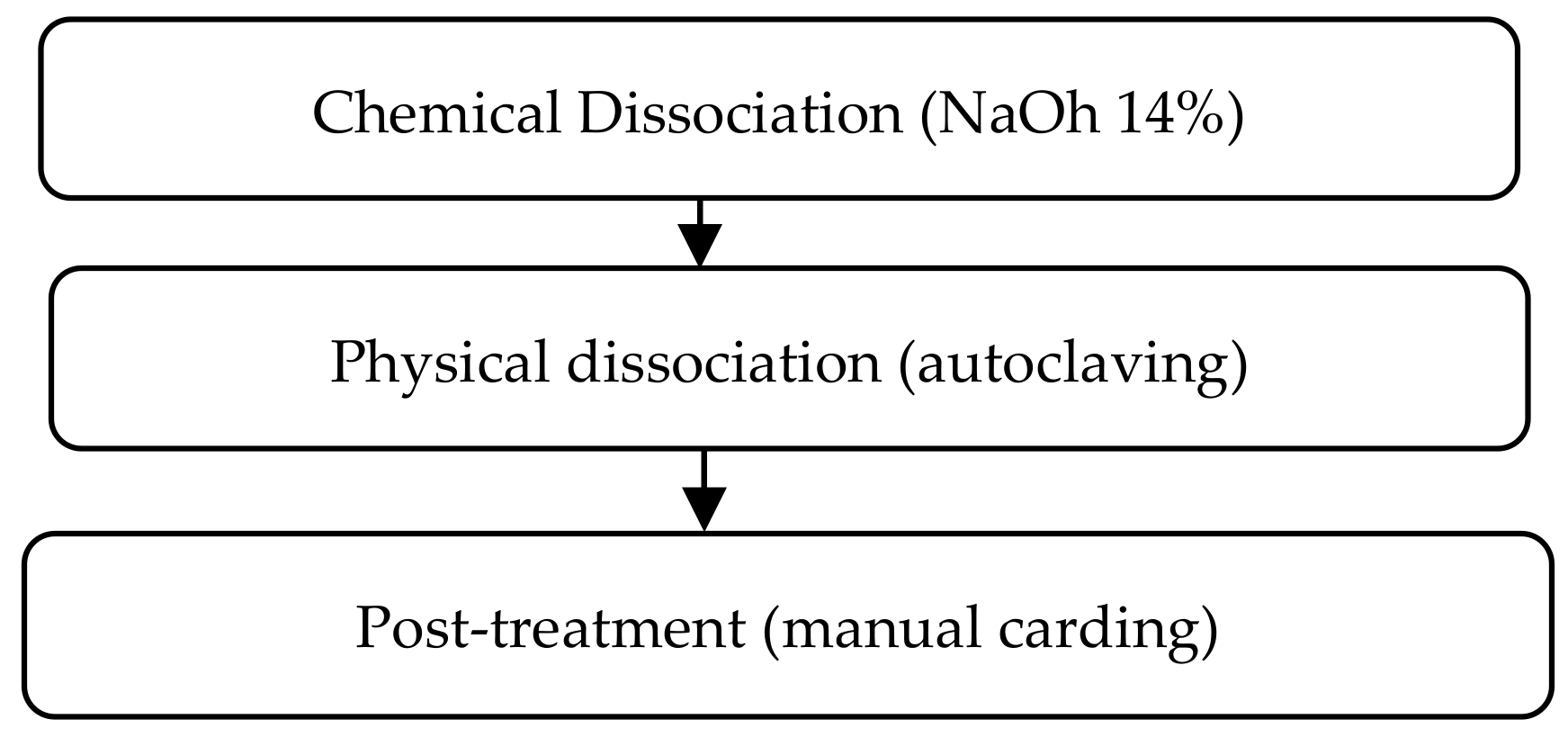

2.1.1. Fiber Extraction

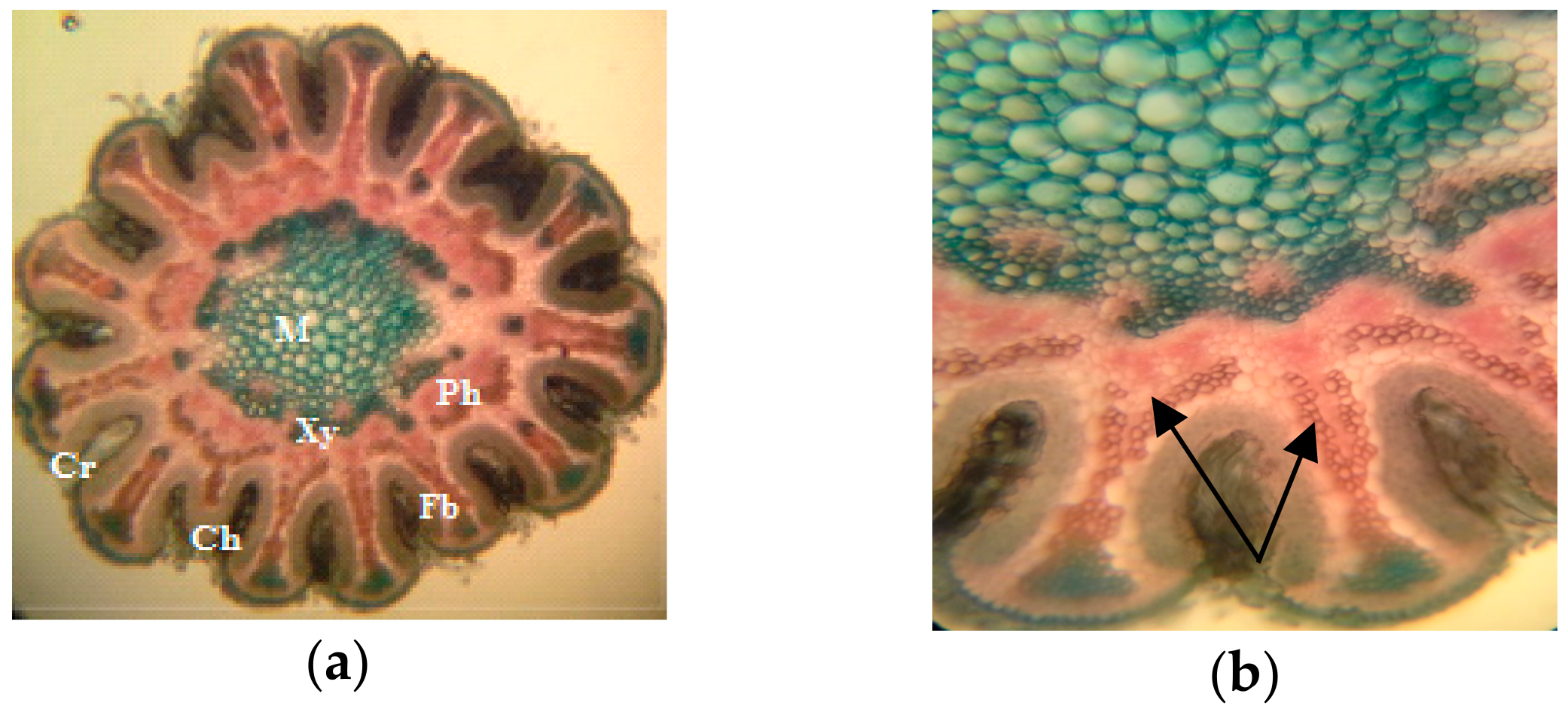

2.1.2. Location of Fibers within the Stem of Retama monosperma

2.1.3. Biometric Study of Fibers

2.1.4. Mechanical Characterization of Fibers

2.1.5. Density

2.1.6. Thermogravimetric Analyses (TGA)

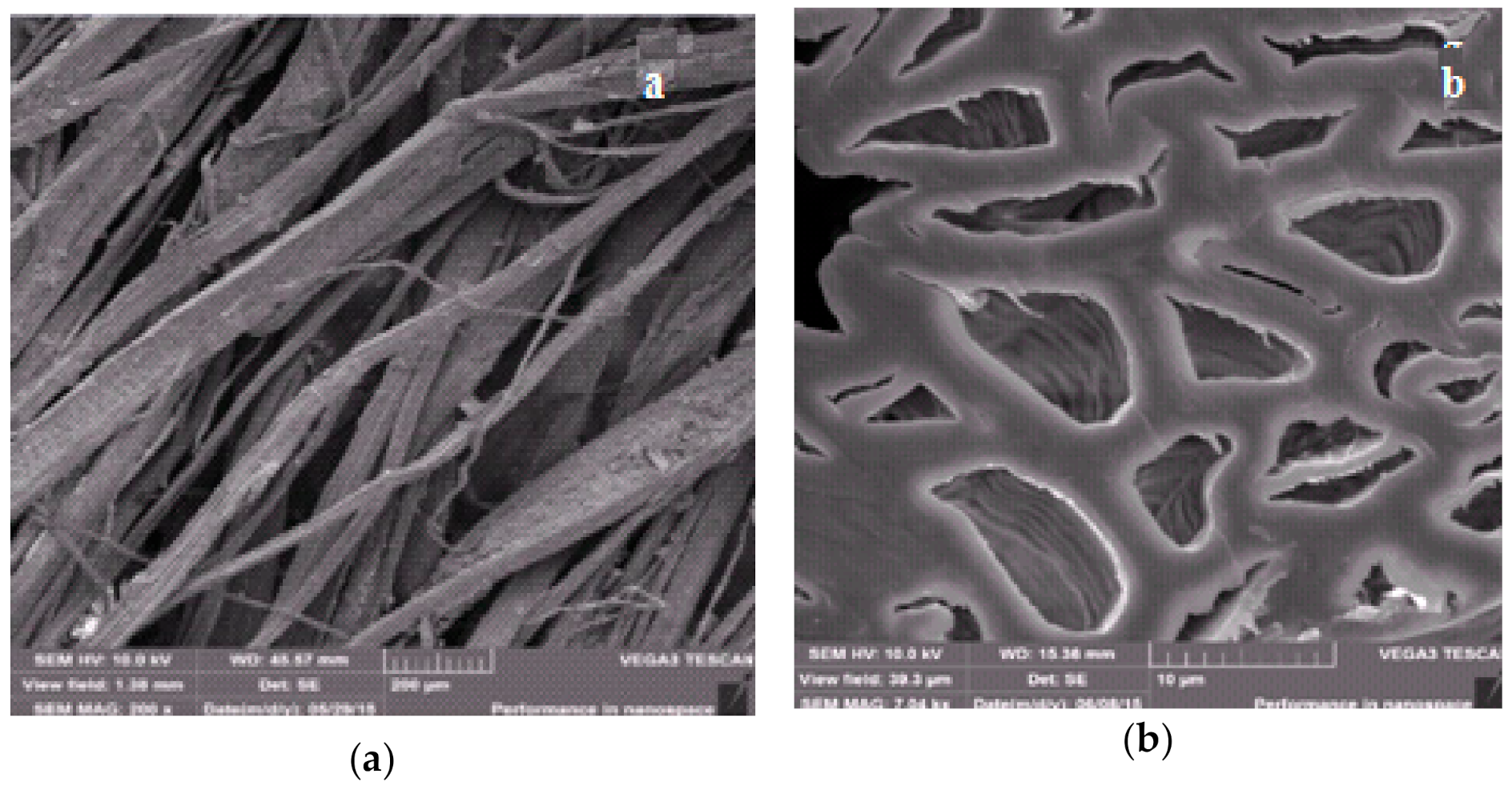

2.1.7. Scanning Microscopy

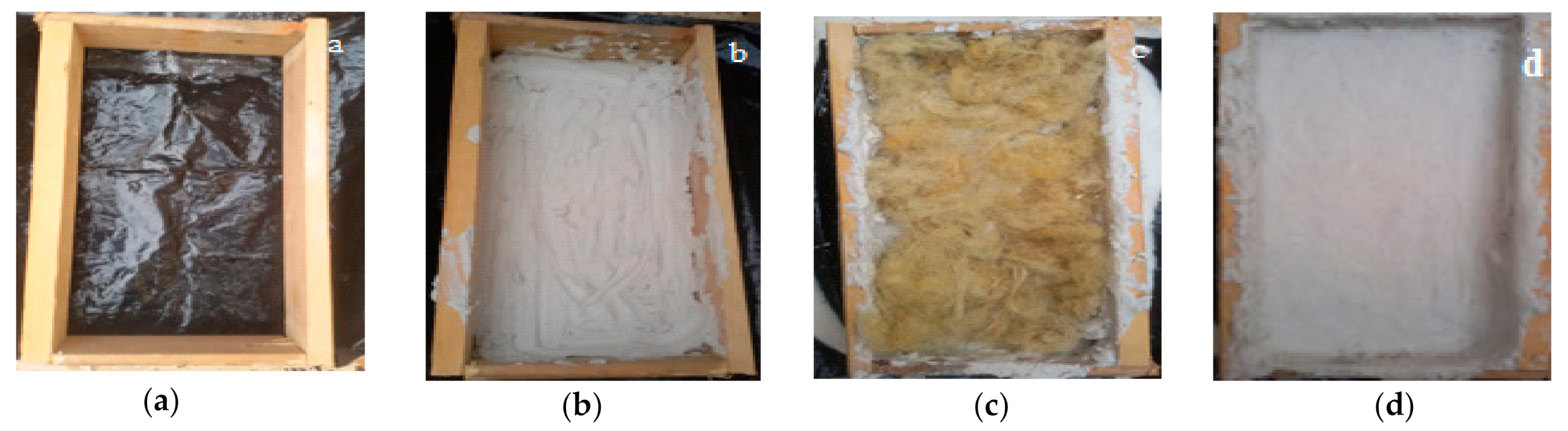

2.2. Plaster Concrete

- The powdered gypsum was mixed with water until a slurry was obtained, which was then spread out in a mold.

- Production of the composite by the gypsum fiber blend; the proportion of fibers in the composite was 1%.

- Finally, the surface of each plaster brick was smoothed to have a regular brick surface of 30 cm length and 15 cm width.

- Mechanical properties relate to flexural strength as well as compressive strength; the results were obtained on MPa.

3. Results and Discussion

3.1. Fiber

3.1.1. Location of the Fibers at the Stems

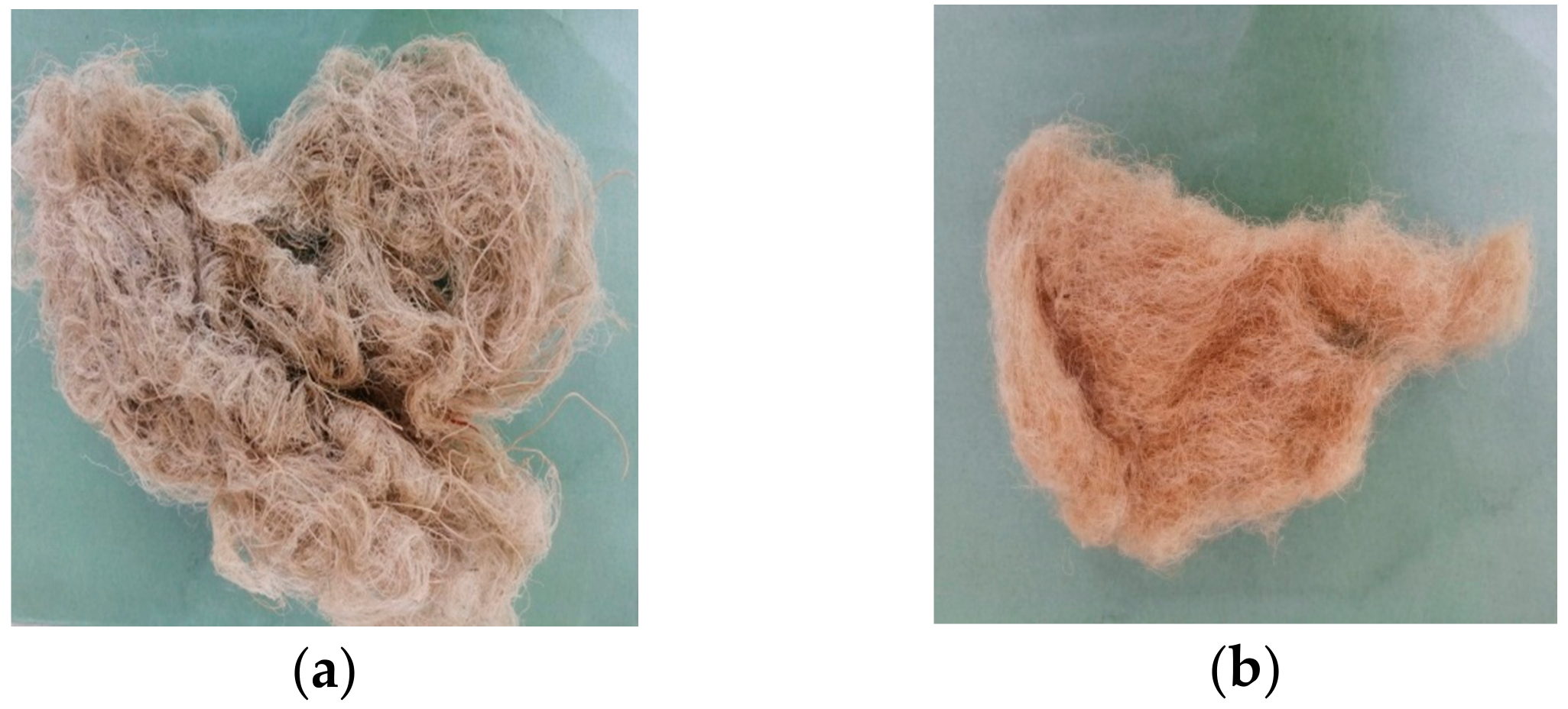

3.1.2. Fibers Extraction

3.1.3. Physical and Mechanical Properties of Retama monosperma Fibers

3.1.4. Geometric Features Including Fiber Length and Width

3.1.5. Thermal Stability

3.2. Plaster Biocomposites Reinforced with Retama Monosperma Fibers

- (1)

- the length of the fibers;

- (2)

- fiber architecture;

- (3)

- the orientation of the fibers;

- (4)

- the fiber–matrix interface.

4. Conclusions

Conflicts of Interest

References

- Eve, S.; Gominaa, M.; Gmouhb, A.; Samdib, A.; Moussab, R.; Orangec, G. Microstructural and mechanical behaviour of polyamide fibre-reinforced plaster composites. J. Eur. Ceram. Soc. 2002, 22, 2269–2275. [Google Scholar] [CrossRef]

- Wu, Y.F. The structural behaviour and design methodology for a new building system consisting of glass fibre reinforced gypsum panels. J. Constr. Build. Mater. 2009, 23, 2905–2913. [Google Scholar] [CrossRef]

- Çolak, A. Physical and mechanical properties of polymer-plaster composites. J. Mater. Lett. 2006, 60, 1977–1982. [Google Scholar] [CrossRef]

- Dalmay, P.; Smith, A.; Chotard, T.; Sahay-Turner, P.; Gloaguen, V.; Krausz, P. Properties of cellulosic fibre reinforced plaster: Influence of hemp or flax fibres on the properties of set gypsum. J. Mater. Sci. 2010, 45, 793–803. [Google Scholar] [CrossRef]

- Le Troëdec, M.; Dalmay, P.; Patapy, C.; Peyratout, C.; Smith, A.; Chotard, T. Mechanical properties of hemp-lime reinforced mortars: Influence of the chemical treatment of fibres. J. Compos. Mater. 2011, 45, 2235–2347. [Google Scholar] [CrossRef]

- Bos, H.L. The Potential of Flax Fibres as Reinforcement for Composite Materials. Ph.D. Thesis, Eindhoven University of Technology, University Press Facilities, Eindhoven, Germany, 2004. [Google Scholar]

- Selami, N. Etude des Associations Symbiotiques de Retama monosperma: Approches Morphologique, Anatomique et Ultrastructurale, Caractérisation Moléculaire des Isolats. Ph.D. Thesis, Université Mouhamed Boudiaf, Oran, Algiers, 2014. [Google Scholar]

- Benmiloud-Mahieddine, R.; Abirached-Darmency, M.; Brown, S.C.; Kaid-Harche, M.; Siljak-Yakovlev, S. Genome size and cytogenetic characterization of three Algerian Retama species. Tree Genet. Genom. 2011, 7, 987–998. [Google Scholar] [CrossRef]

- Muñoz Vallés, S.; Gallego Fernández, J.B.; Cambrollé, J. The Biological Flora of Coastal Dunes and Wetlands: Retama monosperma (L.) Boiss. J. Coast. Res. 2013, 29, 1101–1110. [Google Scholar] [CrossRef]

- Aizi, D.E.; Kaid Harche, M. Extraction and characterization of Retama monosperma fibers. Afr. J. Biotechnol. 2015, 14, 2644–2651. [Google Scholar] [CrossRef]

- Harche, M. Contribution à l’étude sur l’alfa (Stipa tenacissima L.): Germination croissance des feuilles différenciation des fibres. Ph.D. Thesis, 3eme Cycle Univ. Sciences et Techniques, Lille, France, 1978. [Google Scholar]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibers. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Sandy, M.; Bacon, L. Tensile testing of Raffia. J. Mater. Sci. Lett. 2001, 20, 529–530. [Google Scholar] [CrossRef]

- Béakou, A.; Ntenga, R.; Lepetit, J.; Téba, J.A.A.; Ayina, L.O. Physico- chemical and microstructural characterization of Rhectophyllum. Compos. Part A 2008, 39, 67–74. [Google Scholar] [CrossRef]

- Elenga, R.G.; Dirras, G.F.; Goma Maniongui, J.; Djema, P.; Biget, M.P. On the microstructure and physical properties of untreated raffia texilis fiber. Compos. Part A 2009, 40, 418–422. [Google Scholar] [CrossRef]

- Komuraiah, A.; Shyam Kumar, N.; Durga Prasad, B. Chemical composition of natural fibers and its influence of their mechanical properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T.; Selke, S.E.; Harte, R.B.; Hinrichsen, G. Natural fibers, biopolymers, and biocomposites: An introduction. In Natural Fibers, Biopolymers, Biocomposites; Mohanty, A.K., Misra, M., Drzal, T., Eds.; CRC Press: New York, NY, USA, 2005; Chapter 1. [Google Scholar]

- Djafari Petroudy, S.R. Physical and mechanical properties of natural fibers. In Advanced High Strength Natural Fibre Composites in Construction; Woodhead Publishing: Sawston, UK, 2017; pp. 59–83. [Google Scholar]

- Ramaswamy, G.N.; Ruff, C.G.; Boyd, C.R. Effect of bacterial and chemical retting on kenaf fiber quality. Text. Res. J. 1994, 64, 305–308. [Google Scholar] [CrossRef]

- Ramaswamy, G.N.; Craft, S. Uniformity and softness of kenaf fibers for textile products. Text. Res. J. 1995, 65, 765–770. [Google Scholar] [CrossRef]

- Rowell, R.M.; Young, R.A.; Rowell, J.K. Paper and Composites from Agro-Based Resources; Lewis Publishers: New York, NY, USA, 1997. [Google Scholar]

- Batra, S.K. Other long vegetable fibers. In Handbook of Fiber Science and Technology, Fiber Chemistry; Lewin, M., Pearce, E.M., Eds.; Marcel Dekker, Inc.: New York, NY, USA, 1998; Volume 4, pp. 505–571. [Google Scholar]

- Reddy, N.; Yang, Y. New long natural cellulosic fibers from cornhusks: Structure and properties. AATCC Rev. 2005, 5, 24–27. [Google Scholar]

- Deepa, B.; Eldho, A.; Bibin, M.C.; Bismarck, A.; Blaker, J.J.; Pothan, A.L.; Leao, A.L.; Souza, S.F.; Kottaisamy, M. Structure, morphology and thermal characteristics of banana nano fibers obtained by steam explosion. Bioresour. Technol. 2011, 102, 1988–1997. [Google Scholar] [CrossRef]

- Thi Thu Loan, D. Investigation on Jute Fibers and Their Composites Based on Polypropylene and Epoxy Matrices. Ph.D. Thesis, Dresden University, Dresden, Germany, 2006. [Google Scholar]

- Yang, H.; Yan, R.; Chen, H.; Ho Lee, D.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Albano, C.; Gonzalez, J.; Ichazo, M.; Kaiser, D. Thermal stability of blends of polyolefins and sisal fiber. Polym. Degrad. Stab. 1999, 66, 179–190. [Google Scholar] [CrossRef]

- Gram, H.E. Durability of Natural Fibres in Concrete; Swedish Research and Concrete Research Institute: Stockholm, Sweden, 1983. [Google Scholar]

- Swamy, R.N. Natural Fibre Reinforced Cement and Concrete. Concrete Technology and Design; Blackle: London, UK, 1988; Volume 1. [Google Scholar]

- Mathur, V.K. Composite materials from local resources. Constr. Build. Mater. 2005, 20, 470–477. [Google Scholar] [CrossRef]

- Djoudi, A.; Khenfer, M.M.; Bali, A.; Kadri, E.H.; Debicki, G. Performance of date palm fibres reinforced plaster concrete. Int. J. Phys. Sci. 2012, 7, 2845–2853. [Google Scholar] [CrossRef]

| Fibers | Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (GPa) | Density (g/cm3) |

|---|---|---|---|---|

| Retama monosperma | 110 | 4.6–4.7 | 13.3 | 1.3 |

| Flax | 345–1035 | 1.3–3.3 | 27.6 | 1.5 |

| Sisal | 600 | 3 | 12 | 1.5 |

| Jute | 396–773 | 1.5–1.8 | 26.5 | 1.3 |

| Hemp | 690 | 1.6 | 30–60 | 1.15 |

| Cotton | 287–597 | 7–8 | 5.5–12.6 | 1.5–1.6 |

| Raphia textilis | 148–660 | 2 | 28–36 | 0.75 |

| Raphia vinifera | 500 | 4 | 12.3 | - |

| Kenaf | 700 | 3 | 55 | - |

| Single Fiber | Retama monosperma | Cotton | Hemp | Kenaf |

|---|---|---|---|---|

| Length, mm | 0.7 | 15–56 | 40–250 | 1.5–11 |

| Width, µm | 20 | 12–25 | 16–126 | 12–36 |

| Temperature | Energy Released | Weight Loss (%) |

|---|---|---|

| 66.57 | 1.55 J | 6.859% |

| 312.40 | 38.64 J | 53.195% |

| 451 | 35.18 J | 32.988% |

| 568.21 | 6.29 J | 2.404% |

| Length (cm) | Test | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|

| 0 | control | 0.7 | 7.51 |

| 0.5 | 1.33 | 8.75 | |

| 10 | 1 | 1.02 | 7.88 |

| 1.5 | 1.04 | 7.91 | |

| 0.5 | 1.09 | 10.49 | |

| 15 | 1 | 1.12 | 11.68 |

| 1.5 | 1.01 | 9.21 | |

| 0.5 | 0.51 | 6.54 | |

| 20 | 1 | 0.66 | 6.37 |

| 1.5 | 0.47 | 5.98 |

Publisher’s note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aizi, D.-E.; Kaid-Harche, M. Mechanical Behavior of Gypsum Composites Reinforced with Retama monosperma Fibers. Proceedings 2020, 63, 40. https://doi.org/10.3390/proceedings2020063040

Aizi D-E, Kaid-Harche M. Mechanical Behavior of Gypsum Composites Reinforced with Retama monosperma Fibers. Proceedings. 2020; 63(1):40. https://doi.org/10.3390/proceedings2020063040

Chicago/Turabian StyleAizi, Djamel-Eddine, and Meriem Kaid-Harche. 2020. "Mechanical Behavior of Gypsum Composites Reinforced with Retama monosperma Fibers" Proceedings 63, no. 1: 40. https://doi.org/10.3390/proceedings2020063040

APA StyleAizi, D.-E., & Kaid-Harche, M. (2020). Mechanical Behavior of Gypsum Composites Reinforced with Retama monosperma Fibers. Proceedings, 63(1), 40. https://doi.org/10.3390/proceedings2020063040