Innovation of Pull and Torque Testing Device for Cable Cords †

Abstract

1. Introduction

2. Innovation Need

- Stumbling on the cord cable when the socket is positioned at the bottom of the wall. For example, the cord is attached to a vacuum cleaner and the user moves the appliance, creating a tension of the cable through which it no longer sits on the floor but will be taut above the floor.

- Pulling the product from its cable, in cases where the user tries to unplug the appliance by pulling directly on the appliance or pulling on the cable, instead of unplugging it by the plug.

- Transporting or lifting the product by its cable. If the appliance is small, this includes appliances weighing 1 kg or less, such as hair dryers or curlers.

- Attempting to move a product that is still electrically connected in cases where an appliance such as a vacuum cleaner is pulled from the cable.

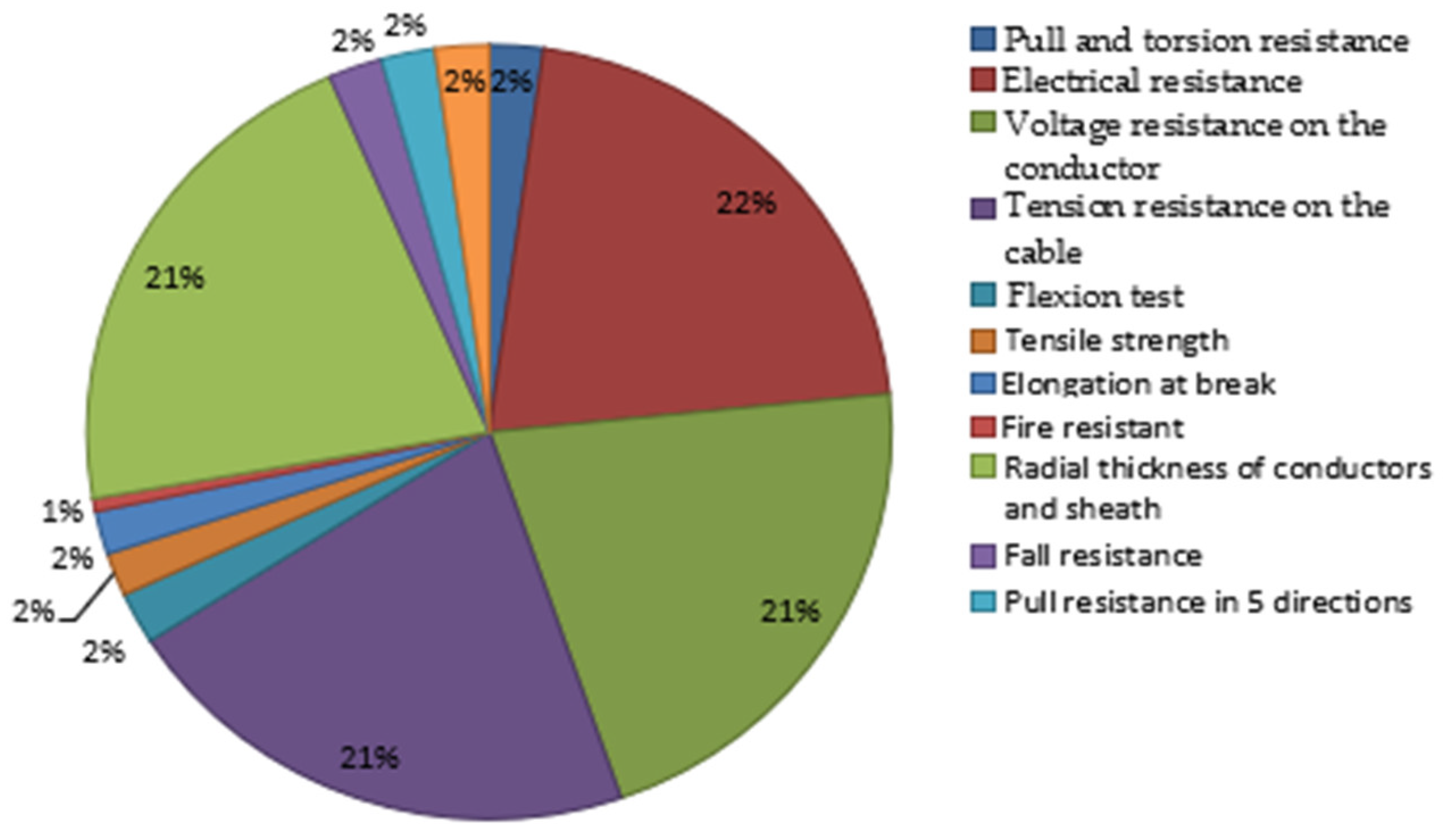

2.1. Frequency of The Test

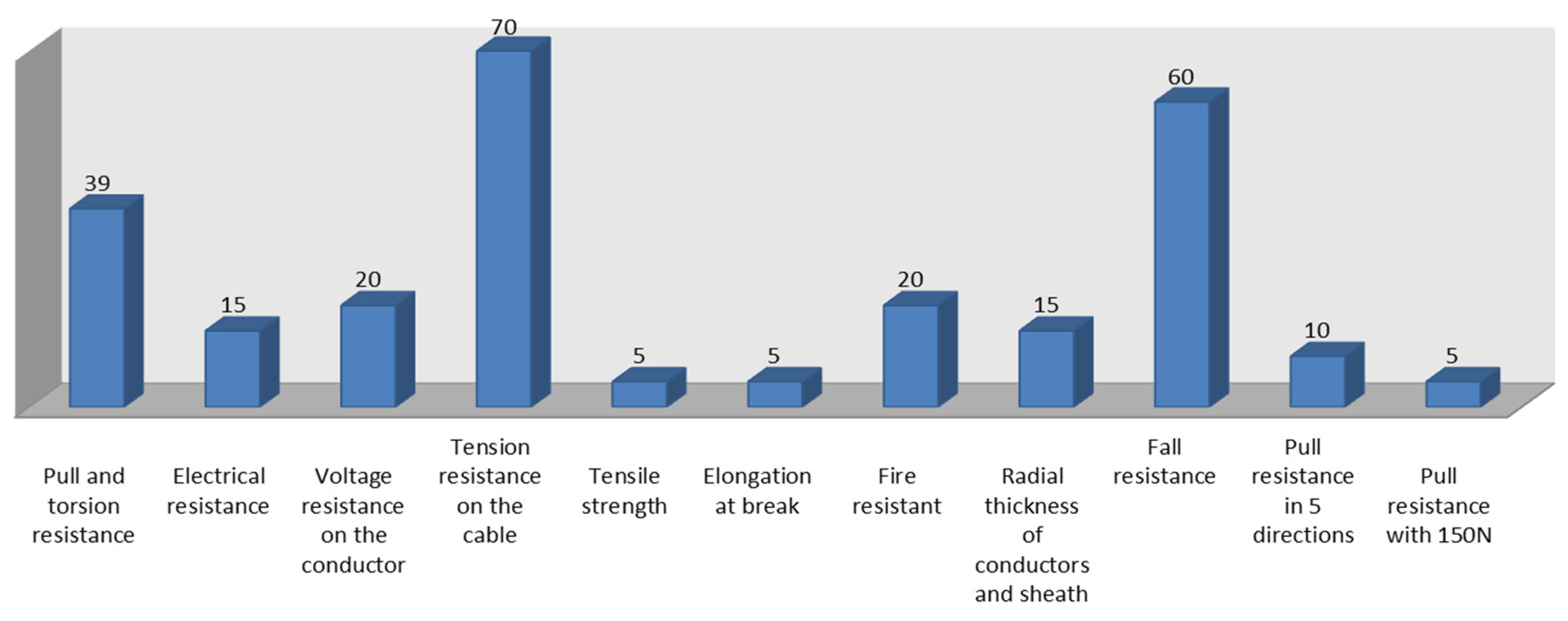

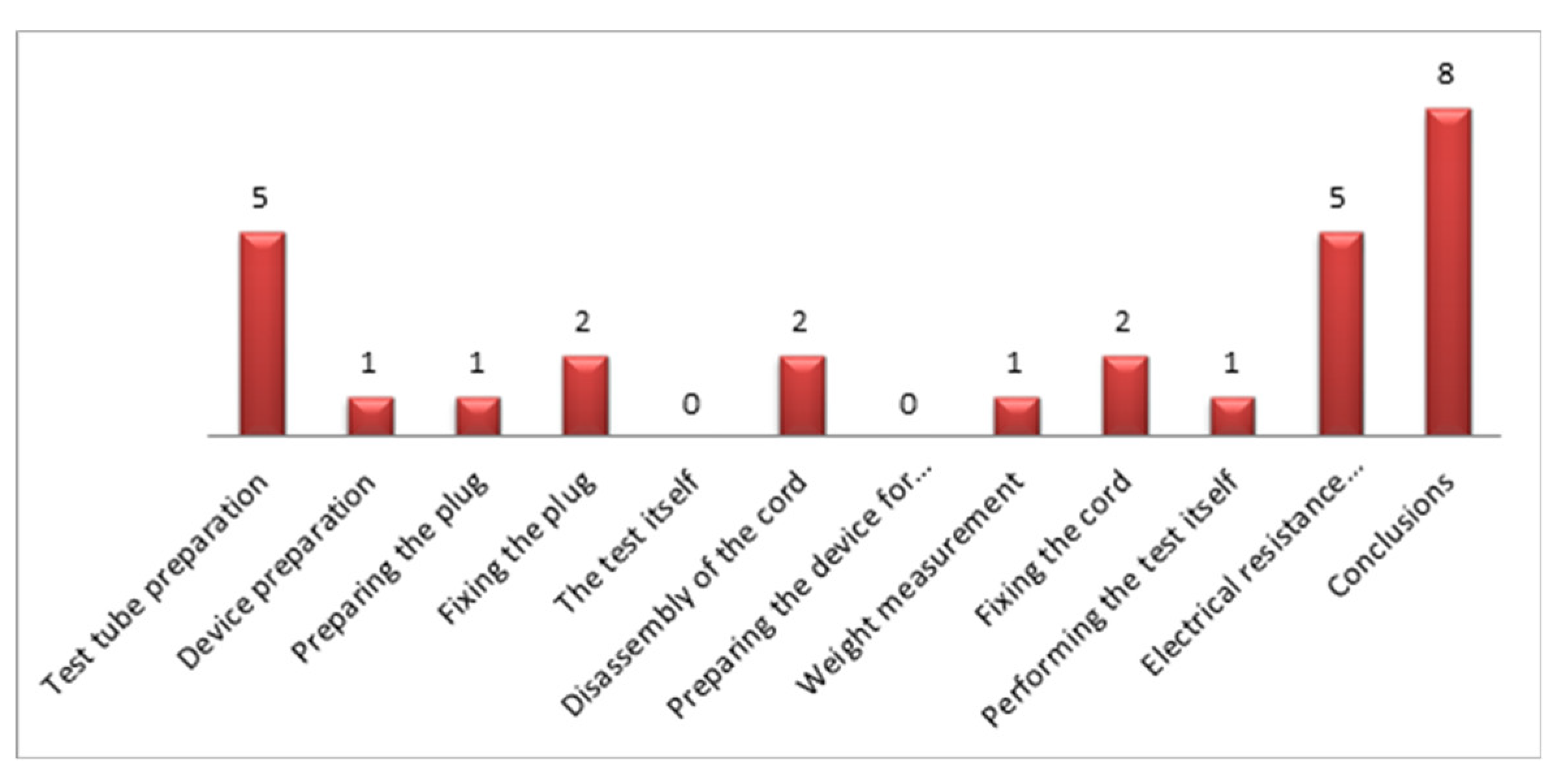

2.2. Time Spent on Each Test

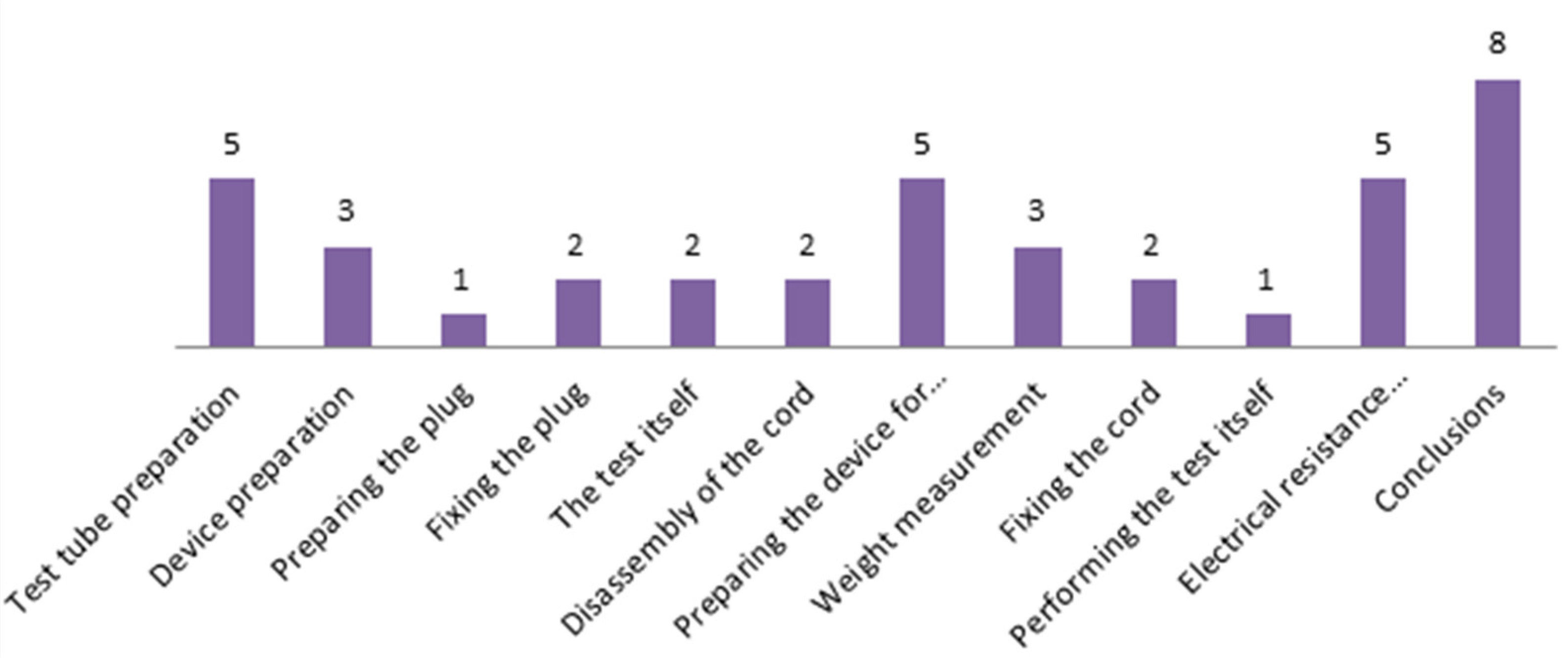

2.3. Average Time Provided for the Method

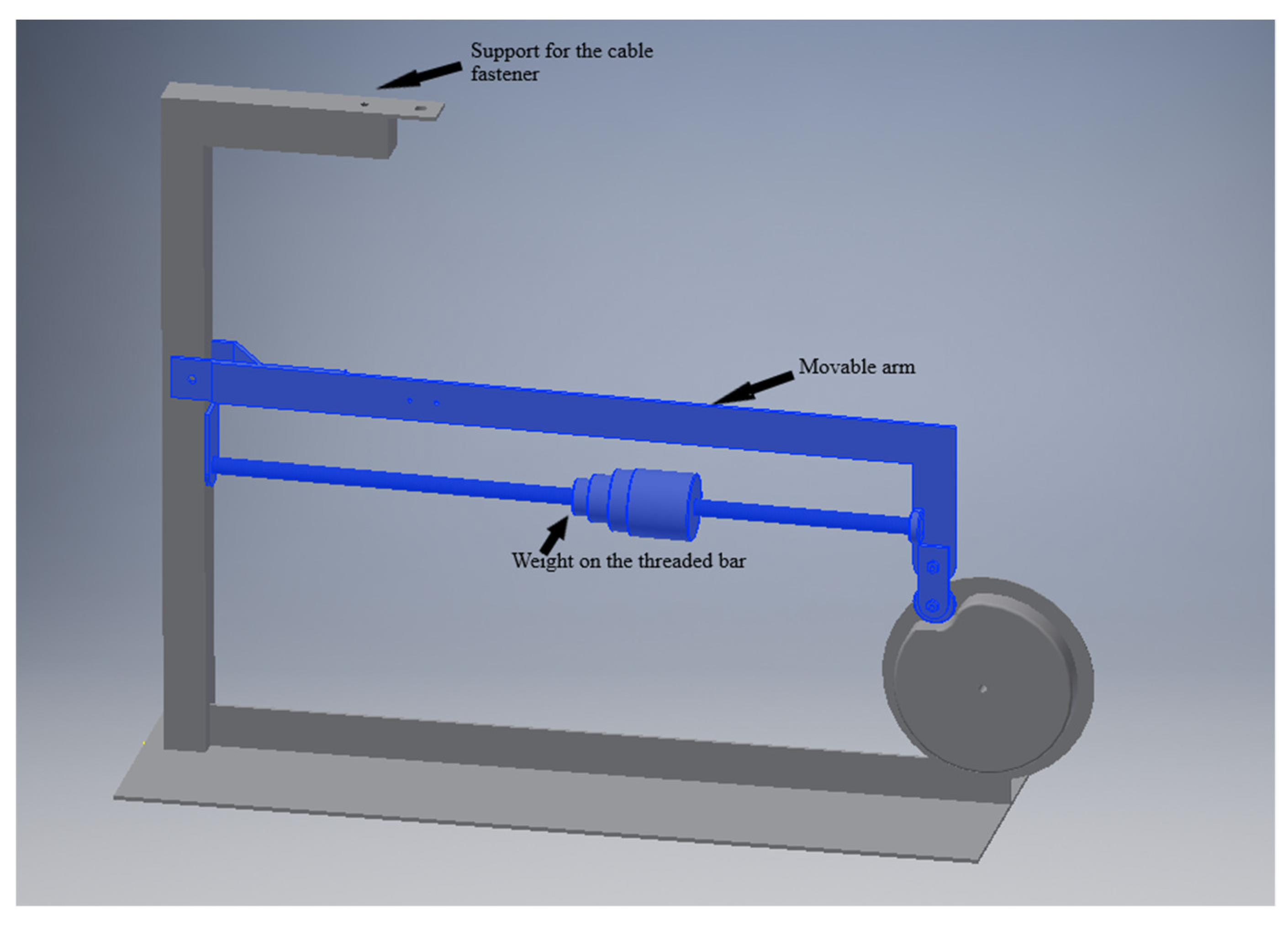

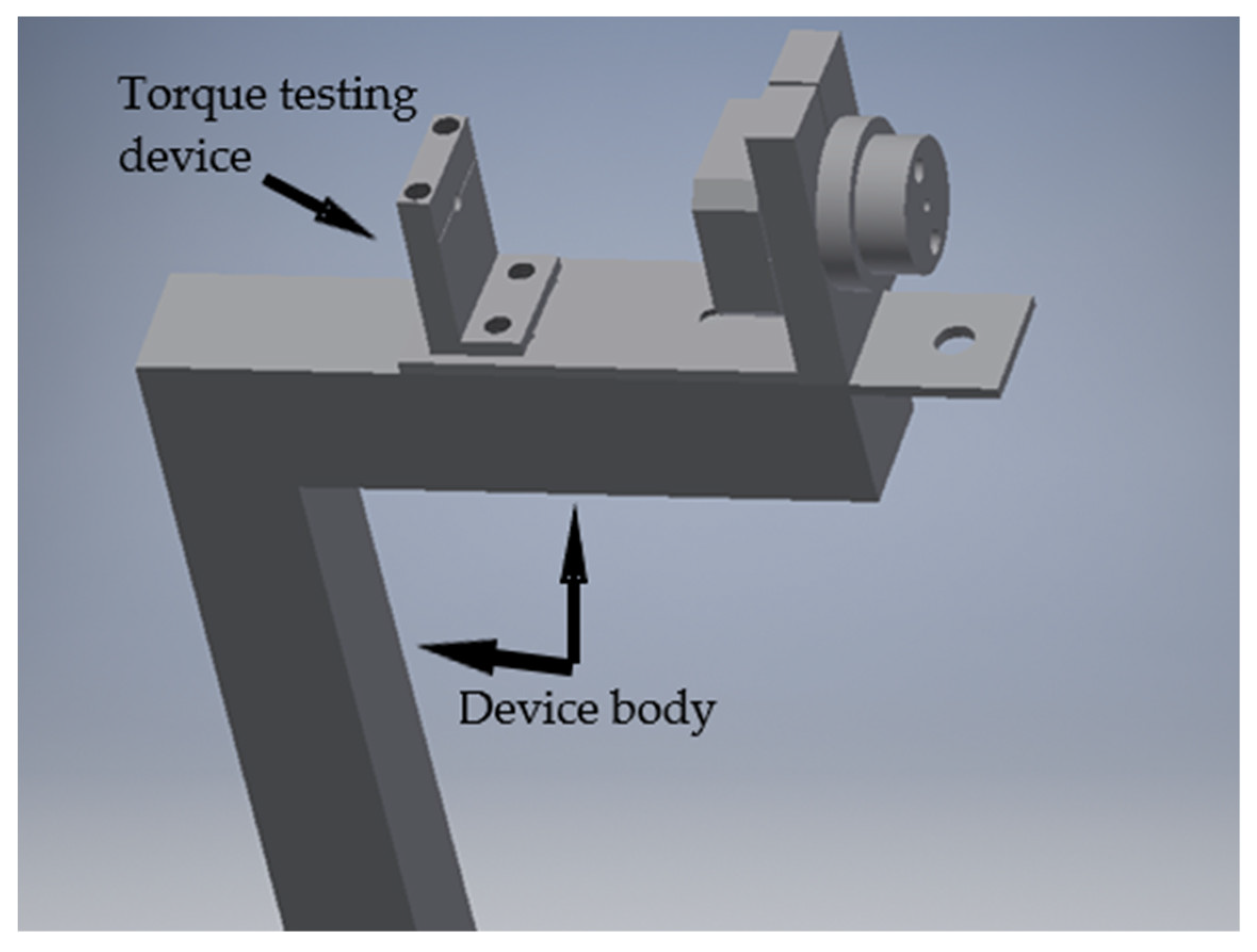

3. Optimization of the Device in Inventor Professional 2018

3.1. Innovation of the Device

3.2. Tests on the Device

4. Comparison between Test Results before Optimization and after Optimization

5. Conclusions

Conflicts of Interest

References

- Moldovan, L. Managementul Calitatii (Quality Management); University “Petru Maior”: Targu-Mures, Romania, 2011; pp. 17–23. [Google Scholar]

- Moldovan, L. Certificarea Coformitatii (Certification of Conformity); University “Petru Maior”: Targu-Mures, Romania, 2011; pp. 3–5. [Google Scholar]

- Andersson, P.; Rossell, L.; Simonson, M. Small and Large Scale Fire Experiments with Electric Cables under Well-ventilated and Vitiated Conditions. Fire Technol. 2004, 40, 247–262. [Google Scholar] [CrossRef]

- Zhang, B.S.; Zhang, J.Q.; Li, Q.; Wang, L.F.; Xie, H.; Fan, M.H. Effects of Insulating Material Ageing on Ignition Time and Heat Release Rate of the Flame Retardant Cables. Procedia Eng. 2018, 211, 972–978. [Google Scholar] [CrossRef]

- Šaršounová, Z. The Inconveniences Related to Accelerated Thermal Ageing of Cables. Transp. Res. Procedia 2019, 40, 90–95. [Google Scholar] [CrossRef]

- Xie, H.; Zang, J.-Q.; Liu, Y.; Zhang, B.; Wang, L.; Fan, M. Study on Insulation Failure Time and Failure Temperature of the Aged Cables under External Heating. Procedia Eng. 2018, 211, 1012–1017. [Google Scholar] [CrossRef]

- Moldovan, L. QFD employment for a new product design in a mineral water company. Proc. Technol. 2014, 12, 462–468. [Google Scholar] [CrossRef]

- IEC 60335-1. Household and Similar Electrical Appliances—Safety—Part 1, 5th ed.; The International Electrotechnical Comission: Geneva, Switzerland, May 2010. [Google Scholar]

- Huanyu Microcomputer Plug and Pull Force Tester. Available online: https://www.amazon.com/Huanyu-Microcomputer-Force-Tester-Machine/dp/B01M6UYROH (accessed on 15 July 2020).

- Plug Socket Pull—Out Testing Machine. Available online: http://www.bndtestequipment.com/plug–socket-and-switch-test-equipment/plug-socket-pull-out-testing-machine.html (accessed on 15 July 2020).

- Cord Grip Test Apparatus. Available online: https://www.indiamart.com/proddetail/cord–grip-test-apparatus-5699994791.html (accessed on 15 July 2020).

- Horizontal Plug Insertion Force Tester Pull Off Tester. Available online: https://www.labtestchamber.com/sale-10859663-horizontal-plug-insertion-force-tester-pull-off-tester.html (accessed on 15 July 2020).

- Pîrvulescu, L.D. Fundamente de Inginerie Mecanică (Fundamentals of Mechanical Engineering); Editura: Timisoara, Romania, 2018; pp. 2–5. [Google Scholar]

| Couple | Section mm² |

|---|---|

| 0.10 Nm | 2 × 0.5 |

| 0.15 Nm | 2 × 0.75 |

| 3 × 0.5 | |

| 0.25 Nm | 3 × 0.75 |

| F = 12.5 N | 2 × 1.00 |

| Bf = 2 cm | 3 × 1.00 |

| 0.5 Nm | 2 × 1.5 |

| F = 25 N | 3 × 1.5 |

| Bf = 2 cm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Havadtöi, C. Innovation of Pull and Torque Testing Device for Cable Cords. Proceedings 2020, 63, 28. https://doi.org/10.3390/proceedings2020063028

Havadtöi C. Innovation of Pull and Torque Testing Device for Cable Cords. Proceedings. 2020; 63(1):28. https://doi.org/10.3390/proceedings2020063028

Chicago/Turabian StyleHavadtöi, Cristina. 2020. "Innovation of Pull and Torque Testing Device for Cable Cords" Proceedings 63, no. 1: 28. https://doi.org/10.3390/proceedings2020063028

APA StyleHavadtöi, C. (2020). Innovation of Pull and Torque Testing Device for Cable Cords. Proceedings, 63(1), 28. https://doi.org/10.3390/proceedings2020063028