Abstract

In this paper, metals’ (Cu, Ag, Au)/Al2O3/Bi2Te3 heterostructures have been fabricated to synergistically optimize their carrier concentration and mobility, thereby enhancing their thermoelectric power factor. Metal can be alloyed with Bi2Te3 to reduce the electron concentration. The introduction of the oxide layer further reduces the electron concentration and leads to an increase in mobility. By adjusting the metal and oxide layer, it is possible to realize the simultaneous optimization of electric conductivity and the Seebeck coefficient. This work will enable the optimal and novel design of heterstructures for thermoelectric materials with further improved performance.

1. Introduction

Thermoelectric technology can convert heat to electricity freely. The thermoelectric efficiency is normally expressed by the dimensionless figure of merit ZT = S2σT/κ, where S, σ, κ and T are the Seebeck coefficient, electrical conductivity, thermal conductivity, and absolute temperature, respectively. One strategy to improve the thermoelectric performance is fabricating nanostructures such as pores or nanograins, which could strongly scatter phonons and thereby reduce the lattice thermal conductivity. However, little room remains for further reducing κ. On the one hand, the contribution of electrons to thermal conductivity is unavoidable due to the Wiedemann–Franz law. On the other hand, the lattice thermal conductivity cannot be lower than the amorphous state. For the Bi2Te3 system, the lattice thermal conductivity has approached values as low as ~0.3 W‧m−1‧K−1, which is the limit value predicted by the Cahill model.[1] Further improvements in the ZT could rely on decoupling S and σ to improve the power factor (PF = S2σ). In this paper, metals’(Cu, Ag, Au) and Al2O3 interfaces were introduced in Bi2Te3 film to explore methods to improve the power factor.

2. Materials and Methods

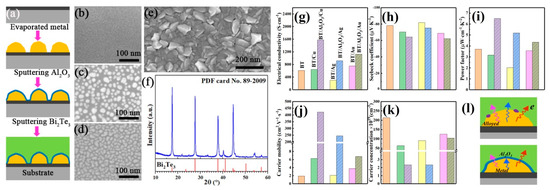

Metals’ (Cu, Ag, Au) with a thickness of 6~7 nm were pre-deposited on a SiO2/Si substrate by an e-beam evaporation system. Using alloy targets, the Al2O3 layer, with a thickness of ~3 nm, is first selectively sputtered on the metal, followed by a Bi2Te3 film with a thickness of 300 nm. The Al2O3 deposited at 100 W and Bi2Te3 deposited at 50 W were both in a radio frequency (RF) mode. The purity of all source materials is 99.99%. The sample preparation is shown in Figure 1a.

Figure 1.

Preparation, characterization and thermoelectric performance of Bi2Te3-based films. (a) Preparation of Bi2Te3-based films in the order of depositing metal, Al2O3 and Bi2Te3; (b), (c) and (d) are the top view of Cu, Ag and Au, respectively; (e) the surface morphology of Bi2Te3; (f) the XRD pattern of Bi2Te3 film; (g) electrical conductivity; (h) Seebeck coefficient; (i) power factor; (j) carrier mobility; (k) carrier concentration; (l) crossing and scattering of electrons at the interface. BT represents Bi2Te3.

3. Results and Discussions

The pre-deposited metal presents as discontinuous particles, as shown in Figure 1b–d. Regardless of whether metal/oxide is deposited, there is no obvious difference in the surface morphology of the Bi2Te3 film, the surface of which is selected as shown in the Figure 1e. The XRD pattern shown in Figure 1f shows that the obtained Bi2Te3 is with good crystallinity. Thermoelectric properties of Bi2Te3-based heterostructures are shown in Figure 1g–k. The metal will alloy with Bi2Te3 (such as Ag2Te or Cu2Te, et al.), thereby reducing the electron carrier concentration [2], which is confirmed in Figure 1k. The doping and alloying effects of metals with different activity are different. The introduction of the oxide layer prevents this alloying process, and scatters part of the carrier, as shown in Figure 1l. Some carriers may tunnel through the thin oxide layer from the metal into Bi2Te3. On the other hand, due to the existence of pores in the local region of the thin oxide layer, it is inevitable that some metal atoms could pass through the oxide layer and be doped into the Bi2Te3. The combined effect of the above factors can optimize the carrier concentration and mobility, thereby enhancing the power factor (S2σ) according to Mott’s expression:

where n(E) and µ(E) are the carrier concentration and carrier mobility depending on energy, respectively. EF is the Fermi energy. kB is the Boltzmann constant, and q is electron charge.

4. Conclusions

In summary, metals’ (Cu, Ag, Au)/Al2O3/Bi2Te3 heterostructures have been fabricated to improve their thermoelectric properties. The introduction of metals and oxide interface synergistically adjust their carrier concentration and mobility, thereby optimizing their thermoelectric power factor. The power factor of the Cu/Al2O3/Bi2Te3 heterostructure film is 6.5 μW‧cm−1‧K−2, which is 1.75 times that of a single Bi2Te3 film.

Author Contributions

Methodology, formal analysis, writing—original draft preparation, Z.W.; Supervision and funding acquisition, Z.H. Both authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China, grant number 51776126.

Acknowledgments

The authors would like to thank the AEMD of Shanghai Jiao Tong University and Instrumental Analysis Center, and the startup fund of Shanghai Jiao Tong University.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, Y.; Bahk, J.-K.; Lee, J.; Birkel, C.S.; Snedaker, M.L.; Liu, D.; Zeng, H.; Moskovits, M.; Shakouri, A.; Stucky, G.D. Hot carrier filtering in solution processed heterostructures: A paradigm for improving thermoelectric efficiency. Adv. Mater. 2014, 26, 2755–2761. [Google Scholar] [CrossRef] [PubMed]

- Hao, F.; Qiu, P.; Tang, Y.; Bai, S.; Xing, T.; Chu, H.S.; Zhang, Q.; Lu, P.; Zhang, T.; Ren, D.; et al. High efficiency Bi2Te3-based materials and devices for thermoelectric power generation between 100 and 300 °C. Energy Environ. Sci. 2016, 9, 3120–3127. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).