Dynamic Monitoring of Multi-Concentrated Silica Nanoparticles Colloidal Environment with Optical Fiber Sensor †

Abstract

:1. Introduction

2. Materials and Methods

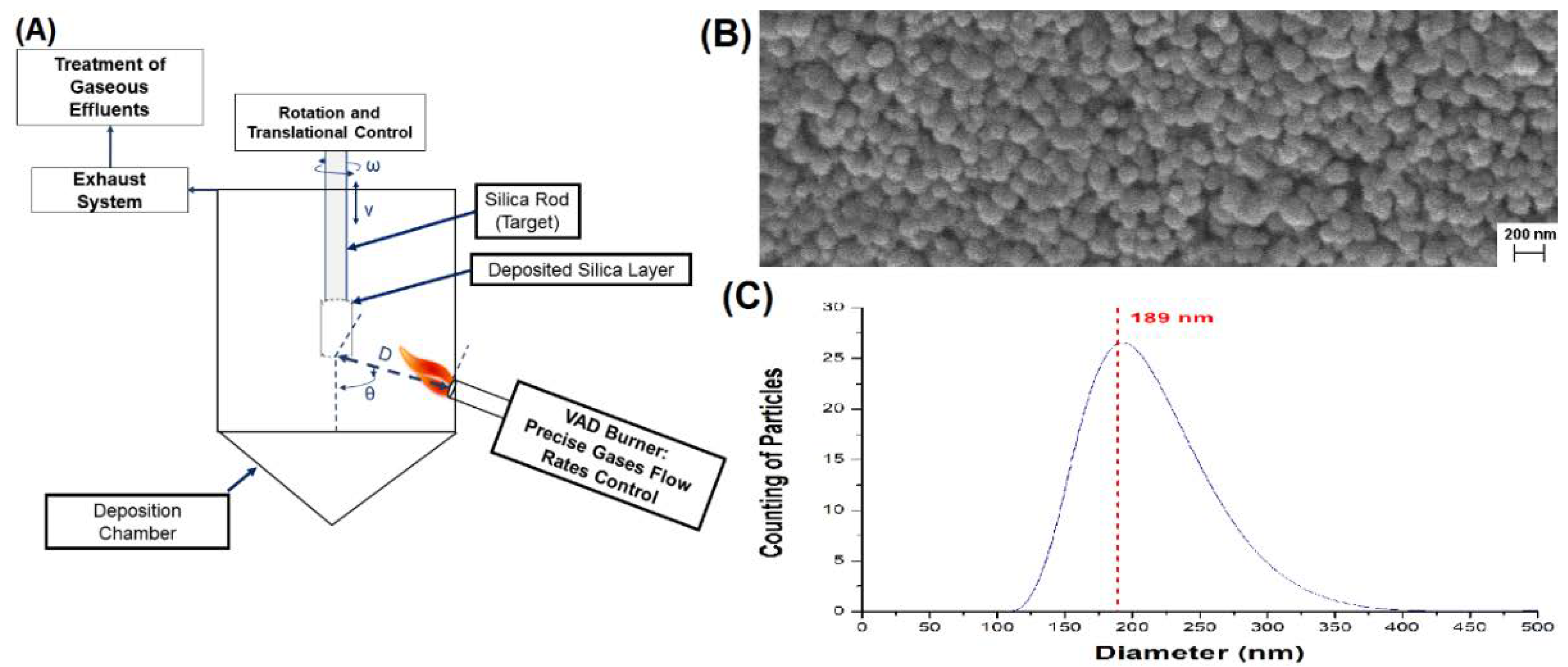

2.1. Preparation of the Colloidal Silica

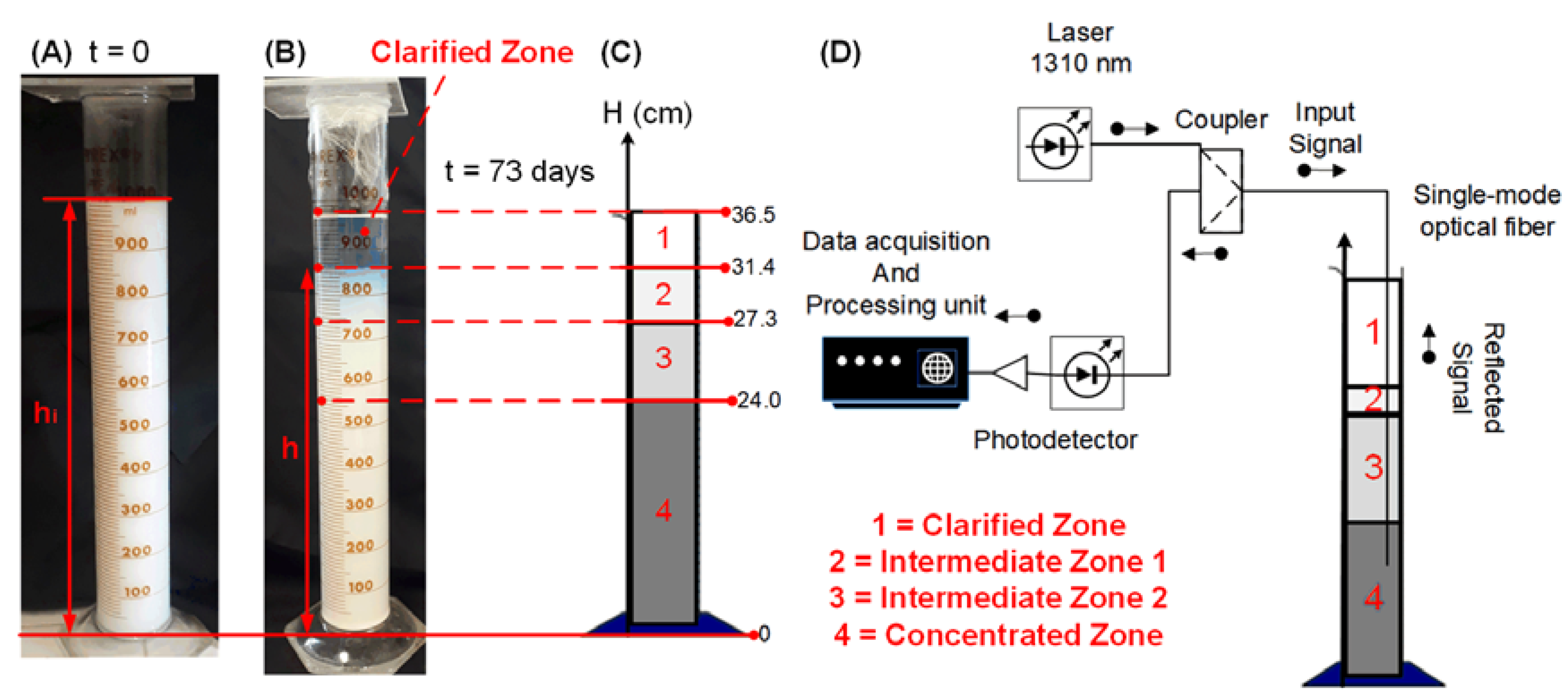

2.2. Optical Fiber Sensor

2.3. Assessment of Colloidal Concentration

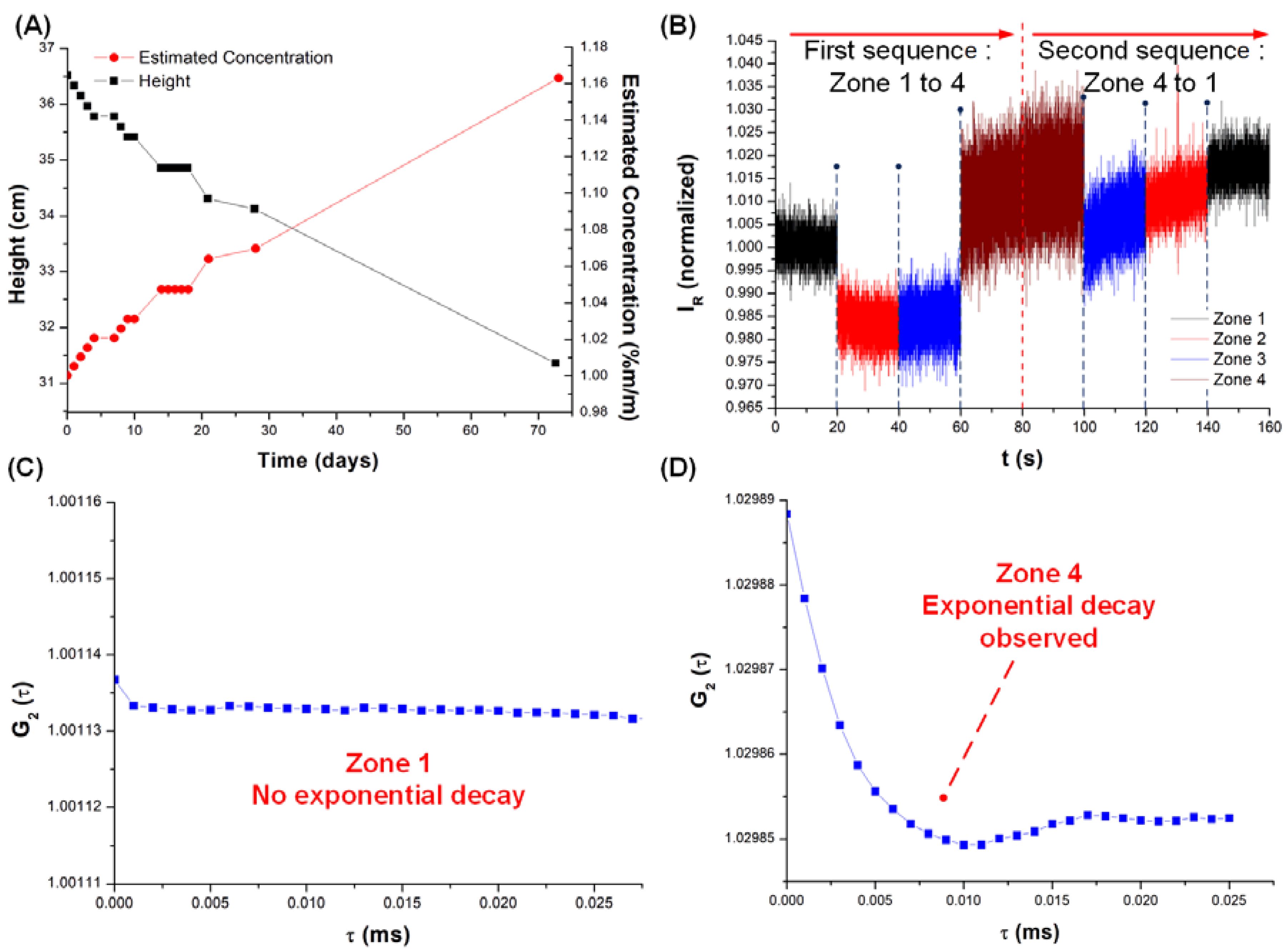

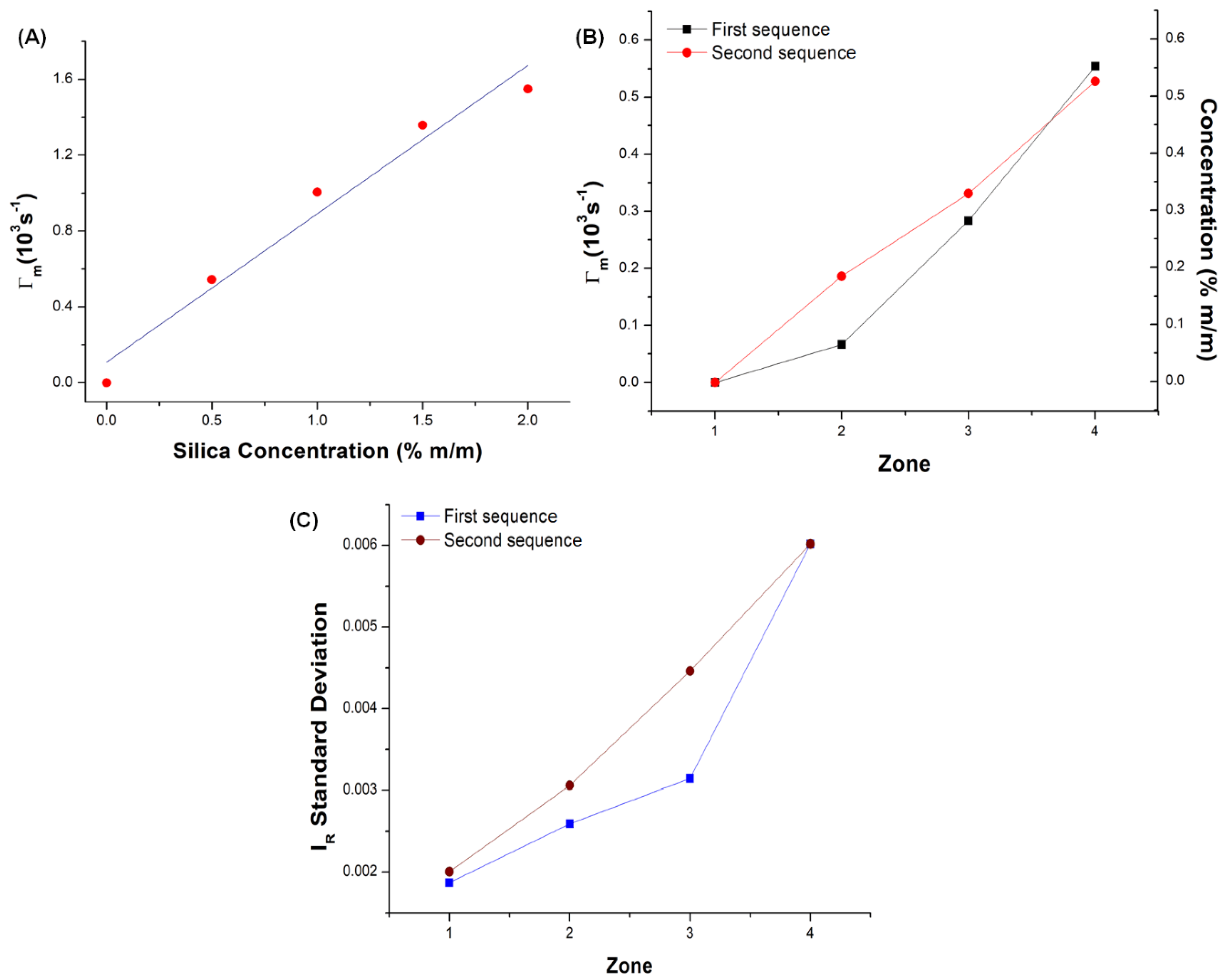

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hunter, R.J. Foundations of Colloid Science, 2nd ed.; Oxford University Press: Oxford, UK, 2004. [Google Scholar]

- Hall, J.B.; Dobrovolskaia, M.A.; Patri, A.K.; McNeil, S.E. Characterization of nanoparticles for therapeutics. Nanomedicine 2007, 2, 789. [Google Scholar] [CrossRef] [PubMed]

- Buhr, E.; Senftleben, N.; Klein, T.; Bergmann, D.; Gnieser, D.; Frase, C.G.; Bosse, H. Characterization of nanoparticles by scanning electron microscopy in transmission mode. Meas. Sci. Technol. 2009, 20, 084025. [Google Scholar] [CrossRef]

- Heurlin, M.; Anttu, N.; Camus, C.; Samuelson, L.; Borgström, M.T. In situ characterization of nanowire dimensions and growth dynamics by optical reflectance. Nano Lett. 2015, 15, 3597–3602. [Google Scholar] [CrossRef] [PubMed]

- Udd, E. Overview of Fiber Optic Sensors. In Fiber Optic Sensors; Yu, F.T.S., Yin, S., Eds.; Marcel Dekker (Taylor and Francis): Abingdon, UK, 2002. [Google Scholar]

- Soares, M.C.P.; Vit, F.F.; Suzuki, C.K.; de la Torre, L.G.; Fujiwara, E. Perfusion Microfermentor Integrated into a Fiber Optic Quasi-Elastic Light Scattering Sensor for Fast Screening of Microbial Growth Parameters. Sensors 2019, 19, 2493. [Google Scholar] [CrossRef] [PubMed]

- McCabe, W.L.; Smith, J.C.; Harriott, P. Unit Operations of Chemical Engineering, 5th ed.; McGraw-Hill: New York, NY, USA, 1993. [Google Scholar]

- Fujiwara, E.; Gomes, M.K.; Soares, M.C.P.; Rodrigues, M.S.; Schenkel, E.A.; Suzuki, C.K. Characterization of Colloidal Silica by Optical Fiber Sensor. In Proceedings of the 2018 SBFoton International Optics and Photonics Conference (SBFoton IOPC), Campinas, Brazil, 8–10 October 2018. [Google Scholar] [CrossRef]

- Finsy, R. Particle sizing by quasi-elastic light scattering. Adv. Coll. Interf. Sci. 1994, 52, 79–143. [Google Scholar] [CrossRef]

- Welty, J.R.; Wicks, C.E.; Wilson, R.E.; Rorrer, G.L. Fundamentals of Momentum, Heat and Mass Transfer, 5th ed.; John Wiley and Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soares, M.C.P.; Rodrigues, M.S.; Schenkel, E.A.; Silva, W.H.A.; Perli, G.; Gomes, M.K.; Fujiwara, E.; Suzuki, C.K. Dynamic Monitoring of Multi-Concentrated Silica Nanoparticles Colloidal Environment with Optical Fiber Sensor. Proceedings 2020, 42, 6. https://doi.org/10.3390/ecsa-6-06546

Soares MCP, Rodrigues MS, Schenkel EA, Silva WHA, Perli G, Gomes MK, Fujiwara E, Suzuki CK. Dynamic Monitoring of Multi-Concentrated Silica Nanoparticles Colloidal Environment with Optical Fiber Sensor. Proceedings. 2020; 42(1):6. https://doi.org/10.3390/ecsa-6-06546

Chicago/Turabian StyleSoares, Marco César Prado, Matheus Santos Rodrigues, Egont Alexandre Schenkel, Willian Hideak Arita Silva, Gabriel Perli, Matheus Kauê Gomes, Eric Fujiwara, and Carlos Kenichi Suzuki. 2020. "Dynamic Monitoring of Multi-Concentrated Silica Nanoparticles Colloidal Environment with Optical Fiber Sensor" Proceedings 42, no. 1: 6. https://doi.org/10.3390/ecsa-6-06546

APA StyleSoares, M. C. P., Rodrigues, M. S., Schenkel, E. A., Silva, W. H. A., Perli, G., Gomes, M. K., Fujiwara, E., & Suzuki, C. K. (2020). Dynamic Monitoring of Multi-Concentrated Silica Nanoparticles Colloidal Environment with Optical Fiber Sensor. Proceedings, 42(1), 6. https://doi.org/10.3390/ecsa-6-06546