Development of a Low-Cost Instrumentation System Applied to an Electrolytic Cell †

Abstract

:1. Introduction

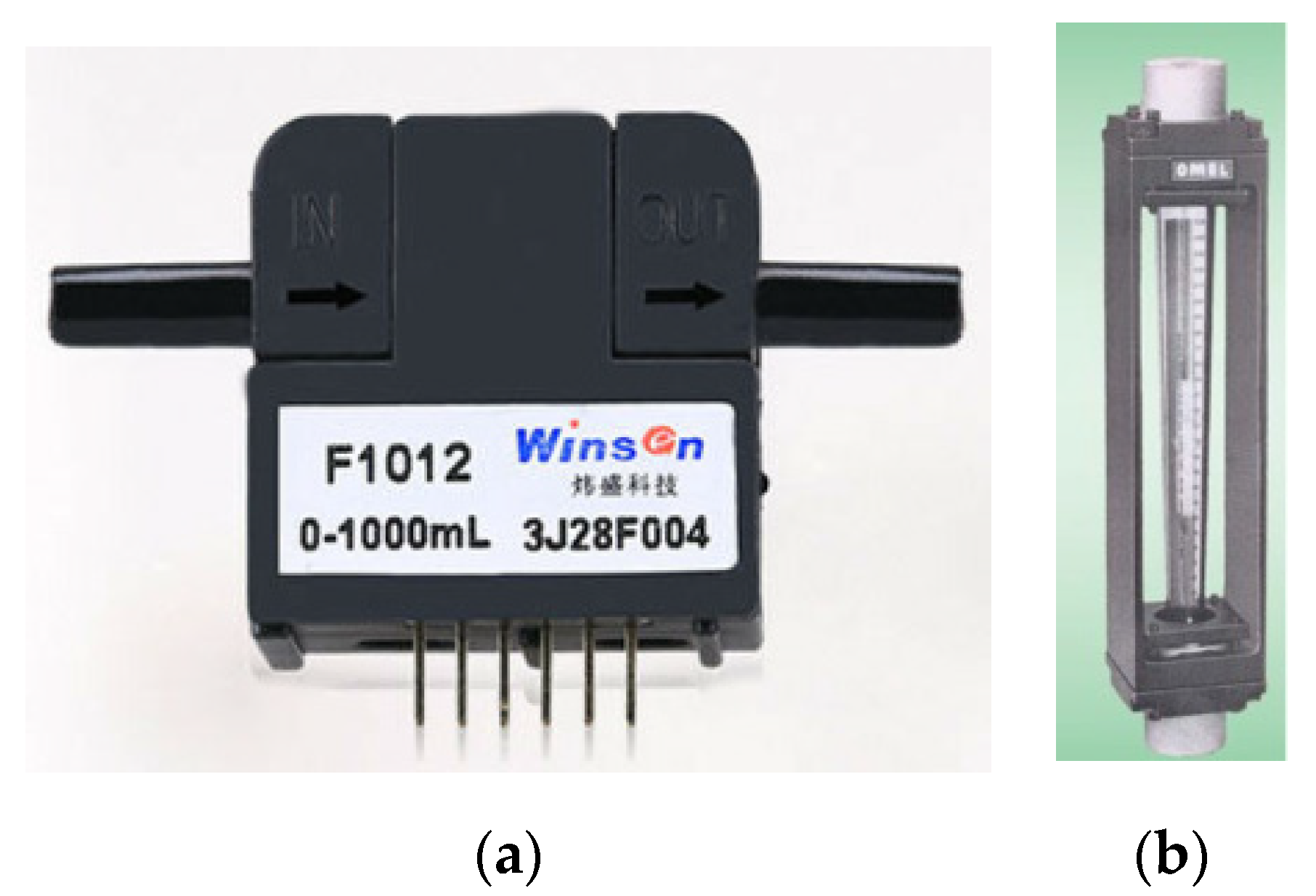

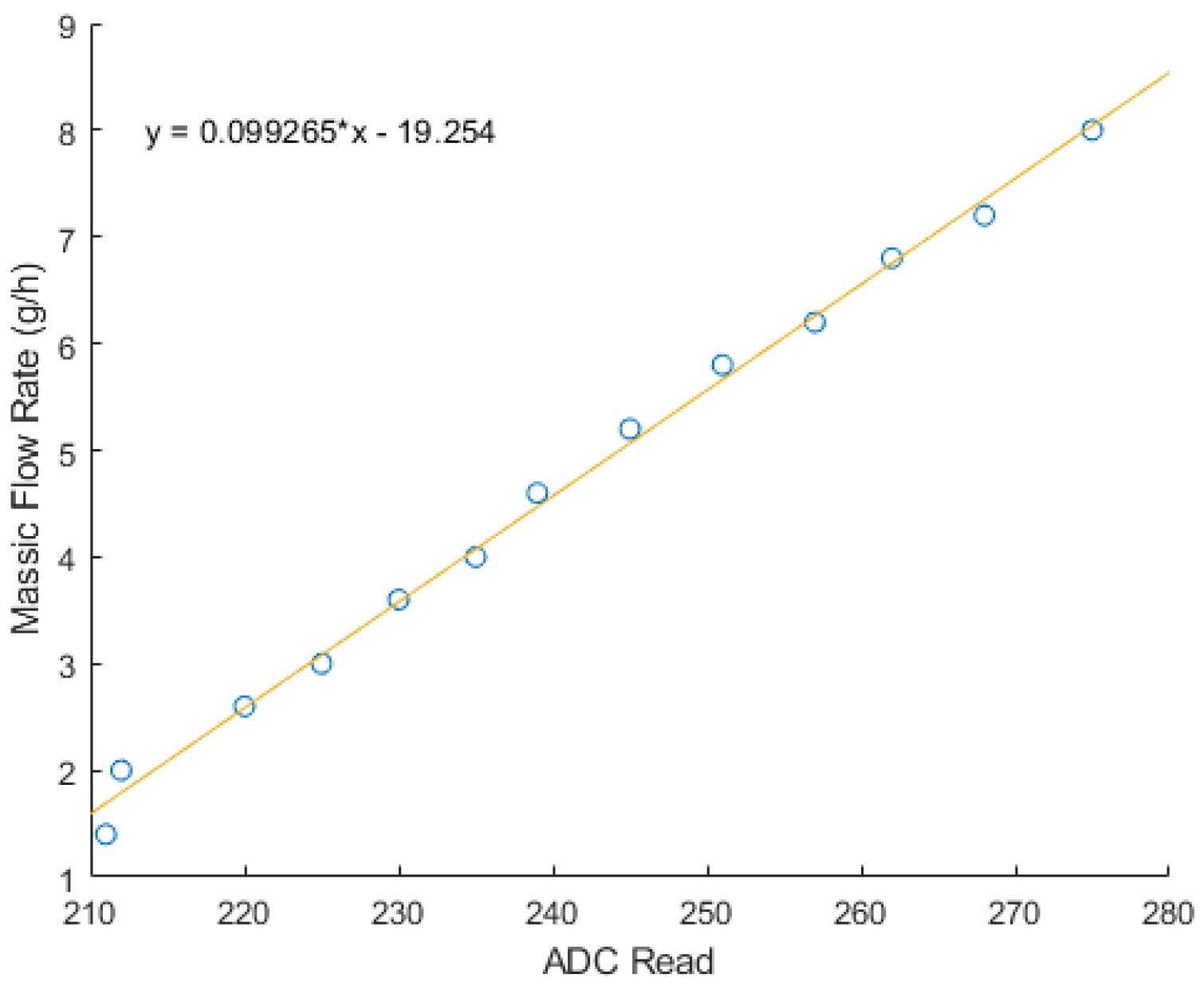

2. Materials and Methods

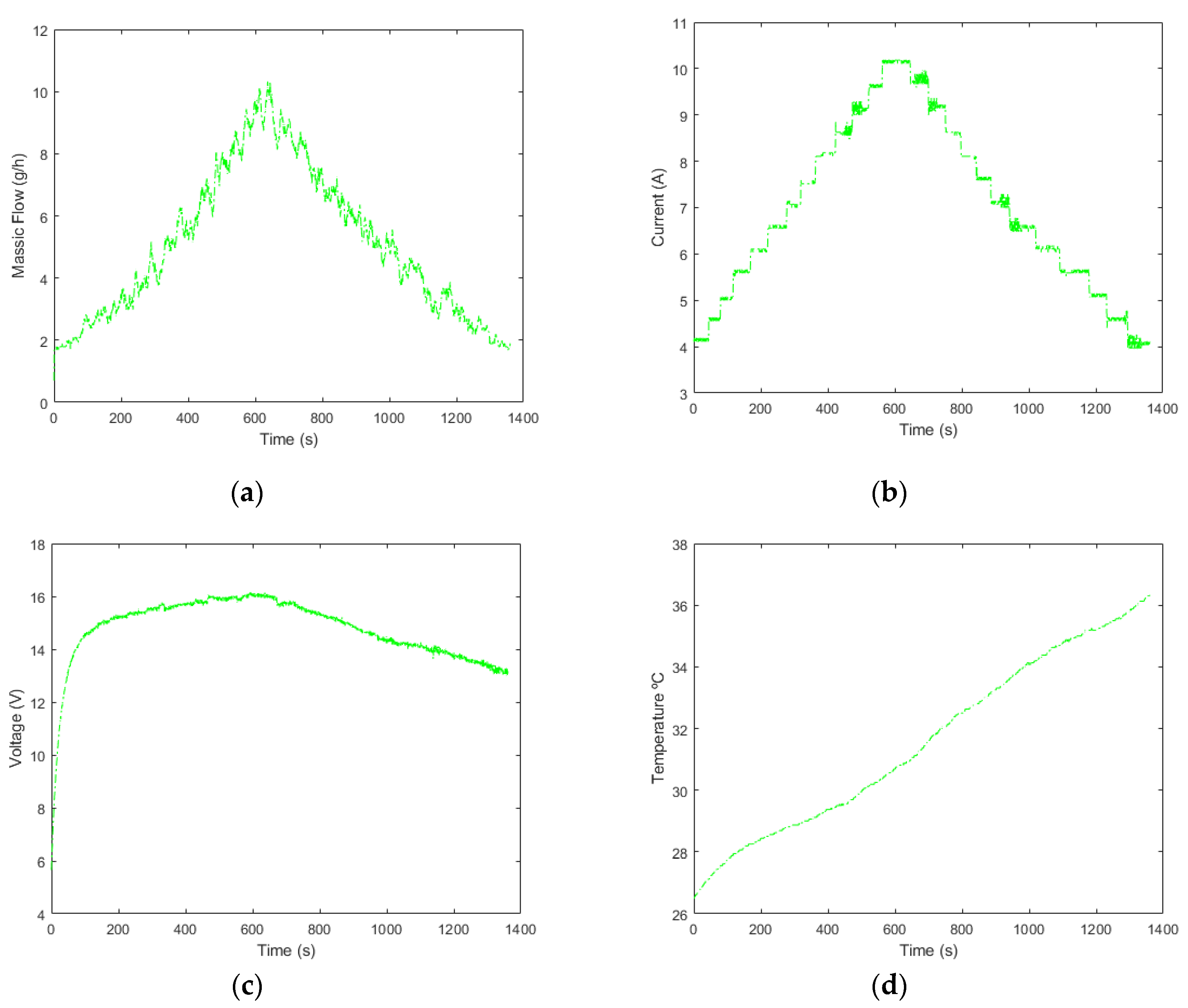

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Seger, B. Global Energy Consumption: The Numbers for Now and in the Future; DTU Orbit, Kgs.: Lyngby, Denmark, 2016. [Google Scholar]

- EIA. Today in energy. U. S. Energy Information Administration. 2017. Available online: https://www.eia.gov/todayinenergy/detail.php?id=32912 (accessed on 20 October 2019).

- Benemann, J. Hidrogênio: Combustível do Futuro Hydrogen: Future Fuel. Ensaios Cienc. Cienc. Biol. Agrar. Saúde 2016, 20, 122–126. [Google Scholar]

- Braga, A.; Pereira, L.; Böhm, G.; Saldiva, P. Poluição atmosférica e saúde humana. Rev. USP 2001, 51, 58–71. [Google Scholar] [CrossRef]

- Saravanan, N.; Nagarajan, G.; Dhanasekaran, C.; Kalaiselvan, K. Experimental investigation of hydrogen port fuel injection in DI diesel engine. Int. J. Hydrogen Energy 2007, 32, 4071–4080. [Google Scholar] [CrossRef]

- CGEE. Hidrogênio energético no Brasil: Subsídios para políticas de competitividade, 2010–2015; Tecnologias críticas e sensíveis em setores prioritários: Brasília, Brazil, 2010. [Google Scholar]

- Knob, D. Geração de hidrogênio por eletrólise da água utilizando energia solar fotovoltaica; 125 f. Dissertação (Mestrado em Ciências na Área de Tecnologia Nuclear - Materiais); Instituto de Pesquisas Energéticas e Nucleares, Autarquia associada à Universidade de São Paulo: São Paulo, Brazil, 2013. [Google Scholar]

- Leroy, R.L.; Janjua, M.B.I.; Renaud, R.L.U. Analysis of time-variation effects in water electrolyzers. J. Electrochem. Soc. 2012, 2, 126–674. [Google Scholar] [CrossRef]

- Bari, S.; Esmaeil, M.M. Effect of H2/O2 addition in increasing the thermal efficiency of a diesel engine. Fuel 2010, 89, 378–383. [Google Scholar] [CrossRef]

- Figueiredo, R.L. Desenvolvimento de um sistema de monitoramento aplicado a um motogerador a diesel com injeção de gás de eletrólise visando redução de consumo de combustível; Dissertação (Mestrado Profissional em Instrumentação, Controle e Automação de Processos de Mineração), Universidade Federal de Ouro Preto e Instituto Tecnológico Vale: Ouro Preto, Brazil, 2018; 82p. (In Portuguese) [Google Scholar]

- Cervantes, M.; Jiménez, R.F.E.; Aguilar, J.F.G.; Morales, J.G.; Peregrino, V.O. Experimental Study on the Performance of Controllers for the Hydrogen Gas Production Demanded by an Internal Combustion Engine. Energies 2018, 11, 2157. [Google Scholar] [CrossRef]

- Yilmaz, A.C.; Uludamar, E.; Aydin, K. Effect of hydroxy (HHO) gas addition on performance and exhaust emissions in compression ignition engines. Int. J. Hydrogen Energy 2010, 35, 11366–11372. [Google Scholar] [CrossRef]

- Tecnotronics. Available online: https://www.tecnotronics.com.br/modulo-medidor-de-corrente-acs712-30a-arduino.html?gclid=CjwKCAjw_uDsBRAMEiwAaFiHa5Flpkuz712k_ePpQDnuNEO2rRw6PCTekdfNbV11Nm9X4KAeDENHIRoCzPoQAvD_BwE (accessed on 8 October 2019).

- Byteflop. Sensores. Módulo Sensor de Tensão 0-25V DC. 2019. Available online: https://www.byteflop.com.br/modulo-sensor-de-tensao-0-25v-dc (accessed on 3 June 2019).

- Robótica Store. Sensor de Temperatura DS18B20 à prova d’água. 2019. Available online: https://robotica.store/produto/sensor-temperatura-ds18b20-waterproof/?v=19d3326f3137 (accessed on 3 July 2019).

- Winsen. Micro Flow Sensor Manual. Available online: https://www.winsen-sensor.com/d/files/PDF/Micro%20Flow%20Sensor/F1012%20Flow%20sensor%20-%20Manual%20V2.1.pdf (accessed on 23 April 2019).

- Omel. Boletim técnico. Rotâmetros modelo “N”. 2014. Available online: http://www.omel.com.br/cms-lang/wp-content/uploads/2014/07/Catalogo_rotametro_4N.pdf (accessed on 2 April 2019).

- Júnior, A.G.; De Sousa, A.R. Fundamentals of Scientific and Industrial Metrology; Manole: Barueri, Brazil, 2008. (In Portuguese) [Google Scholar]

- Santilli, R.M. A new gaseous and combustible form of water. Int. J. Hydrogen Energy 2006, 31, 1113–1128. [Google Scholar] [CrossRef]

- Ivy, J. Summary of Electrolytic Hydrogen Production: Milestone Completion Report; No. NREL/MP-560-36734; National Renewable Energy Lab.: Golden, CO, USA, 2004. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, G.d.P.d.; Matos, S.N.; Segundo, A.K.R.; Leal, E.M.; Figueiredo, R.L. Development of a Low-Cost Instrumentation System Applied to an Electrolytic Cell. Proceedings 2020, 42, 35. https://doi.org/10.3390/ecsa-6-06586

Reis GdPd, Matos SN, Segundo AKR, Leal EM, Figueiredo RL. Development of a Low-Cost Instrumentation System Applied to an Electrolytic Cell. Proceedings. 2020; 42(1):35. https://doi.org/10.3390/ecsa-6-06586

Chicago/Turabian StyleReis, Gemírson de Paula dos, Saulo Neves Matos, Alan Kardek Rêgo Segundo, Elisângela Martins Leal, and Robson Lage Figueiredo. 2020. "Development of a Low-Cost Instrumentation System Applied to an Electrolytic Cell" Proceedings 42, no. 1: 35. https://doi.org/10.3390/ecsa-6-06586

APA StyleReis, G. d. P. d., Matos, S. N., Segundo, A. K. R., Leal, E. M., & Figueiredo, R. L. (2020). Development of a Low-Cost Instrumentation System Applied to an Electrolytic Cell. Proceedings, 42(1), 35. https://doi.org/10.3390/ecsa-6-06586