Investigation of the Interstitial Pore Pressure of Saturated Concrete under High Confinement †

Abstract

:1. Introduction

2. Experimental Procedure

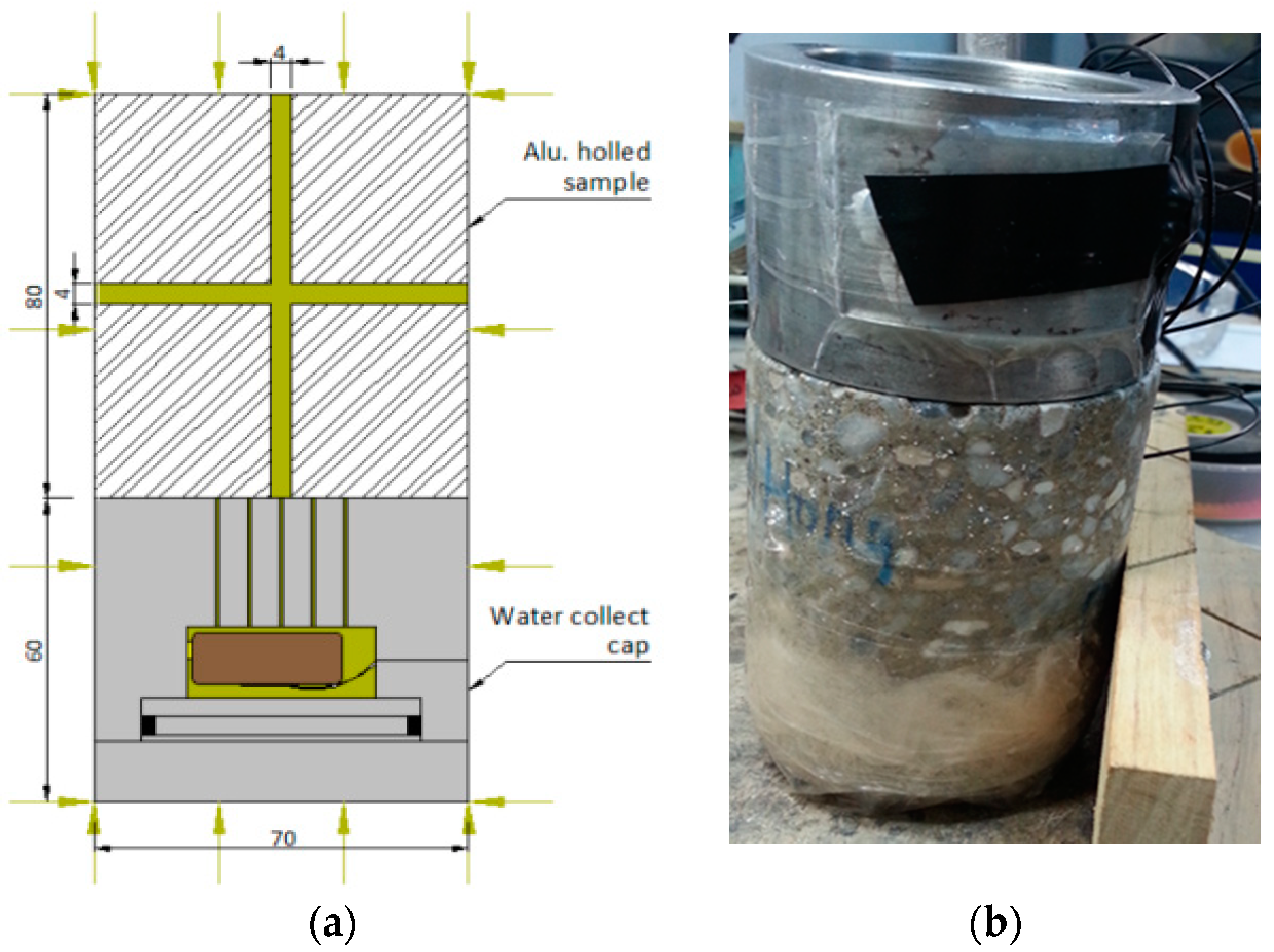

2.1. Experimental Device and Concrete Samples

2.2. Water Collecting Cap and Sensor Design

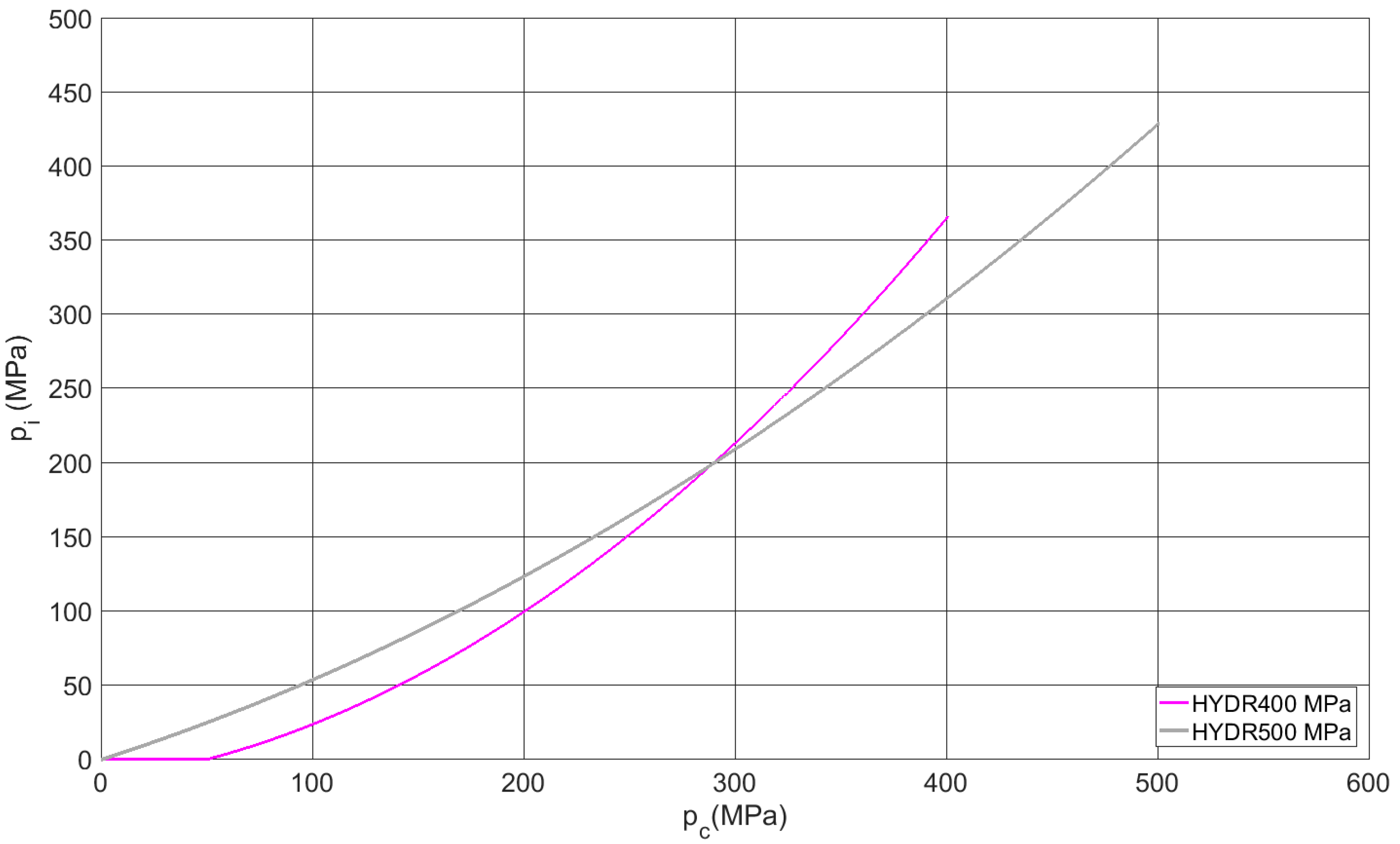

3. Interstitial Pore Pressure Tests

4. Conclusions

References

- Zukas, J.A.; Nicholas, T.; Greszczuk, L.B.; Swift, H.F.; Curran, D.R. Penetration and perforation of solids. In Impact Dynamics; Krieger Publishing Company: New York, NY, USA, 1992. [Google Scholar]

- Daudeville, L.; Malecot, Y. Concrete structures under impact. Eur. J. Environ. Civil Eng. 2011, 15, 101–140. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V.; Mainguy, M.; Lassabatere, T.; Coussy, O. Characterization and identification of equilibrium and transfer moisture properties for ordinary and high performance cementitious materials. Cem. Concr. Res. 1999, 29, 1225–1238. [Google Scholar] [CrossRef]

- Vu, X.H.; Malecot, Y.; Daudeville, L.; Buzaud, E. Experimental analysis of concrete behavior under high confinement: Effect of the saturation ratio. Int. J. Solids Struct. 2007, 46, 1105–1120. [Google Scholar] [CrossRef]

- Forquin, P.; Safa, K.; Gray, G. Influence of free water on the quasi-static and dynamic Strength of concrete in confined compression tests. Cem. Concr. Res. 2010, 40, 321–333. [Google Scholar] [CrossRef]

- Piotrowska, E.; Malecot, Y.; Ke, Y. Experimental investigation of the effect of coarse aggregate shape and composition on concrete triaxial behavior. Mech. Mater. 2014, 79, 45–57. [Google Scholar] [CrossRef]

- Piotrowska, E.; Forquin, P.; Malecot, Y. Experimental study of static and dynamic behavior of concrete under high confinement: Effect of coarse aggregate strength. Mech. Mater. 2016, 92, 164–174. [Google Scholar] [CrossRef]

- Malecot, Y.; Daudeville, L.; Dupray, F.; Buzaud, E.; Poinard, C. Strength and damage of concrete under high triaxial loading. Eur. J. Environ. Civil Eng. 2010, 14, 777–803. [Google Scholar] [CrossRef]

- Thiot-Ingénierie. La Croix Blanche 46130 Saint Michel Loubejou; Thiot-Ingénierie: Paris, France, 2004. [Google Scholar]

- Gabet, T.; Malecot, Y.; Daudeville, L. Triaxial behavior of concrete under high stresses: Influence of the loading path on compaction and limit states. Cem. Concr. Res. 2008, 38, 403–412. [Google Scholar] [CrossRef]

- Gabet, T.; Vu, X.V.; Malecot, Y.; Daudeville, L. A new experimental technique for the analysis of concrete under high triaxial loading. J. Phys. IV 2006, 134, 635–640. [Google Scholar] [CrossRef]

- Vu, X.H.; Malecot, Y.; Daudeville, L.; Buzaud, E. Effect of the water/cement ratio on concrete behavior under extreme loading. Int. J. Numer. Anal. Methods Geomech. 2009, 33, 1867–1888. [Google Scholar] [CrossRef]

| Concrete Mix Properties | Kg/m3 | Mechanical Properties | Values |

|---|---|---|---|

| Cement CEM I 52.5 N | 263 | Compressive strength (MPa) | 30 |

| Sand ‘D’ 1.8 mm | 838 | Porosity accessible to water (%) | 12 |

| Gravel ‘D’ 0.5–8 mm | 1007 | Slump (cm) | 7 |

| Water | 169 | W/C | 0.64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Accary, A.; Daudeville, L.; Malecot, Y. Investigation of the Interstitial Pore Pressure of Saturated Concrete under High Confinement. Proceedings 2018, 2, 524. https://doi.org/10.3390/ICEM18-05397

Accary A, Daudeville L, Malecot Y. Investigation of the Interstitial Pore Pressure of Saturated Concrete under High Confinement. Proceedings. 2018; 2(8):524. https://doi.org/10.3390/ICEM18-05397

Chicago/Turabian StyleAccary, Abdallah, Laurent Daudeville, and Yann Malecot. 2018. "Investigation of the Interstitial Pore Pressure of Saturated Concrete under High Confinement" Proceedings 2, no. 8: 524. https://doi.org/10.3390/ICEM18-05397

APA StyleAccary, A., Daudeville, L., & Malecot, Y. (2018). Investigation of the Interstitial Pore Pressure of Saturated Concrete under High Confinement. Proceedings, 2(8), 524. https://doi.org/10.3390/ICEM18-05397